Page 1

MAKING MODERN LIVING POSSIBLE

User Manual

Danfoss Telematics Solutions

Logging Data

powersolutions.danfoss.com

Page 2

User Manual Danfoss Telematics Solution Logging Data

Revision history Table of revisions

Date Changed Rev

October 2015 Danfoss layout 0100

July 2015 Review 0001

February 2015 First edition 0000

2 BC00000348 en-US • Rev 0100 • October 2015

Page 3

User Manual

Danfoss Telematics Solution Logging Data

Contents

About this Manual

General.................................................................................................................................................................................................5

Creating object dictionary groups and objects

Rename entry.....................................................................................................................................................................................7

Modifying the logging configuration....................................................................................................................................... 7

Configuring the device for Data Logging................................................................................................................................7

Logging CAN messages and sending them to DTS portal................................................................................................ 8

Receiving the J1939 message......................................................................................................................................................9

Creating a PGN 61444................................................................................................................................................................9

Receive Message Communication Parameters..............................................................................................................10

Timeout and Conditions........................................................................................................................................................ 11

Logging of all data bytes every 60 seconds....................................................................................................................11

Logging...................................................................................................................................................................................11

Log specific bytes under certain conditions or every 10 minutes.......................................................................... 13

Variables................................................................................................................................................................................. 13

Logging...................................................................................................................................................................................14

Mapping.......................................................................................................................................................................................15

Active Conditions................................................................................................................................................................15

Data Link.................................................................................................................................................................................16

Jobs................................................................................................................................................................................................17

Job 1.........................................................................................................................................................................................17

Job 2.........................................................................................................................................................................................19

Saving CAN messages to microSD memory cards.............................................................................................................20

Logging GNSS positions..............................................................................................................................................................20

Logging internal variables..........................................................................................................................................................21

Configure Logged Data View

Data view.......................................................................................................................................................................................... 24

Adapt the configuration to the web portal..........................................................................................................................24

Elements of the xml file............................................................................................................................................................... 25

XML Header......................................................................................................................................................................................25

Message definition........................................................................................................................................................................ 25

Global dictionary............................................................................................................................................................................26

Transformer......................................................................................................................................................................................26

Units....................................................................................................................................................................................................26

Value definitions.............................................................................................................................................................................27

Parsing definition ..........................................................................................................................................................................28

View definition ...............................................................................................................................................................................29

Appendix

CLF file................................................................................................................................................................................................32

File header...................................................................................................................................................................................32

File payload.................................................................................................................................................................................32

Message Payload Definitions............................................................................................................................................... 33

Timestamp Value Definitions...............................................................................................................................................35

Message tail......................................................................................................................................................................................35

Bitmask.............................................................................................................................................................................................. 36

Examples........................................................................................................................................................................................... 36

Example 1.................................................................................................................................................................................... 36

Section 1, “File Header” [3]....................................................................................................................................................36

Section 2, “File Payload” [3]...................................................................................................................................................36

Message Type 0 - 11 bit CAN Message - Node 1........................................................................................................... 36

Message Type 1 - 29 bit CAN Message - Node 1........................................................................................................... 36

Message Type 2 - 11 bit CAN Message - Node 2........................................................................................................... 37

Message Type 3 - 29 bit CAN Message - Node 2........................................................................................................... 37

Message Type 16 - GPS Location Data (J1939 Format)...............................................................................................37

Message Type 17 - GPS Movement Data (J1939 Format).......................................................................................... 37

Timestamp Type 00 = No Time Stamp..............................................................................................................................37

Timestamp Type 01 = UNIX Time Stamp......................................................................................................................... 37

Section 3, “Message Tail” [11]...............................................................................................................................................37

BC00000348 en-US • Rev 0100 • October 2015 3

Page 4

User Manual Danfoss Telematics Solution Logging Data

Contents

Example 2.................................................................................................................................................................................... 37

4 BC00000348 en-US • Rev 0100 • October 2015

Page 5

User Manual Danfoss Telematics Solution Logging Data

About this Manual

General

This document is part of the Danfoss Telematics Solutions portal and provides important information on

the intended use, and operation of the portal described below.

The device is delivered with a basic configuration. Customize the configuration to your purposes by

defining the CAN messages to be logged and by using the WS Configurator tool to update the device

configuration (via CAN bus or remotely).

BC00000348 en-US • Rev 0100 • October 2015 5

Page 6

User Manual

Danfoss Telematics Solution Logging Data

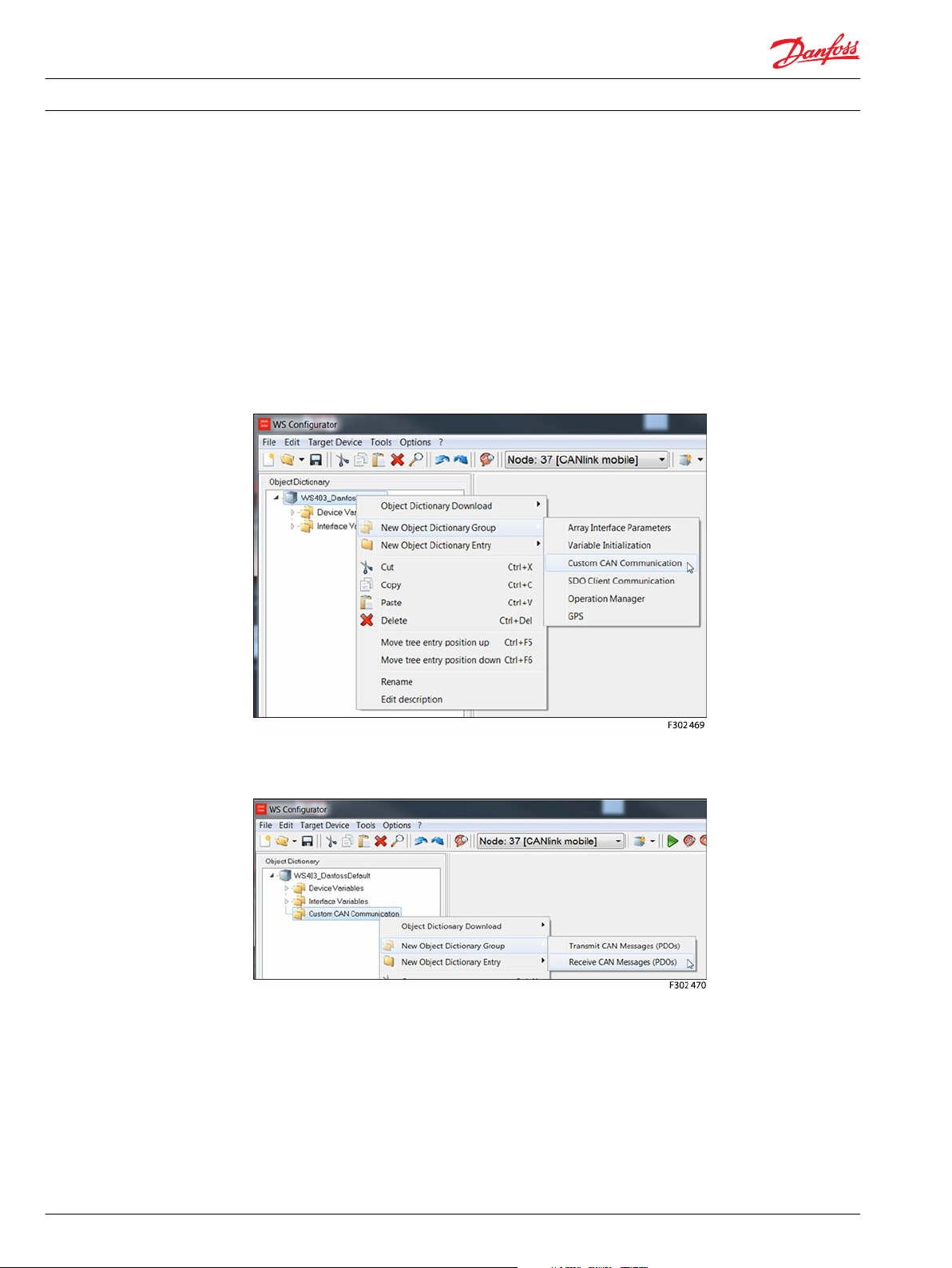

Creating object dictionary groups and objects

Configure the device with WS Configurator. You can find the basic instructions for this in WS 403 Remote

Solution Installation Guide - L1419125.

You can create, rename, or remove object dictionary groups or objects in the tree structure.

Below is an explanation of how to create object dictionary groups and objects. In the example, the object

RECEIVE MESSAGE PDO is created.

In order to create the object Receive Message PDO, you need the object dictionary group CUSTOM CAN

COMMUNICATION and then the object dictionary group Receive CAN Messages (PDOs).

1. Open the WSxxx_DanfossDefault.DOD configuration file

2. Right-click on the top entry in the tree structure to open the context menu.

3. In the context menu, click on New Object Dictionary Group > Custom CAN Communication.

This creates the object dictionary group Custom CAN Communication.

4. Right-click on the object dictionary group Custom CAN Communication.

5. In the context menu, click on New Object Dictionary Group > Recieve CAN Messages (PDOs).

This creates the object dictionary group Receive CAN Messages (PDOs).

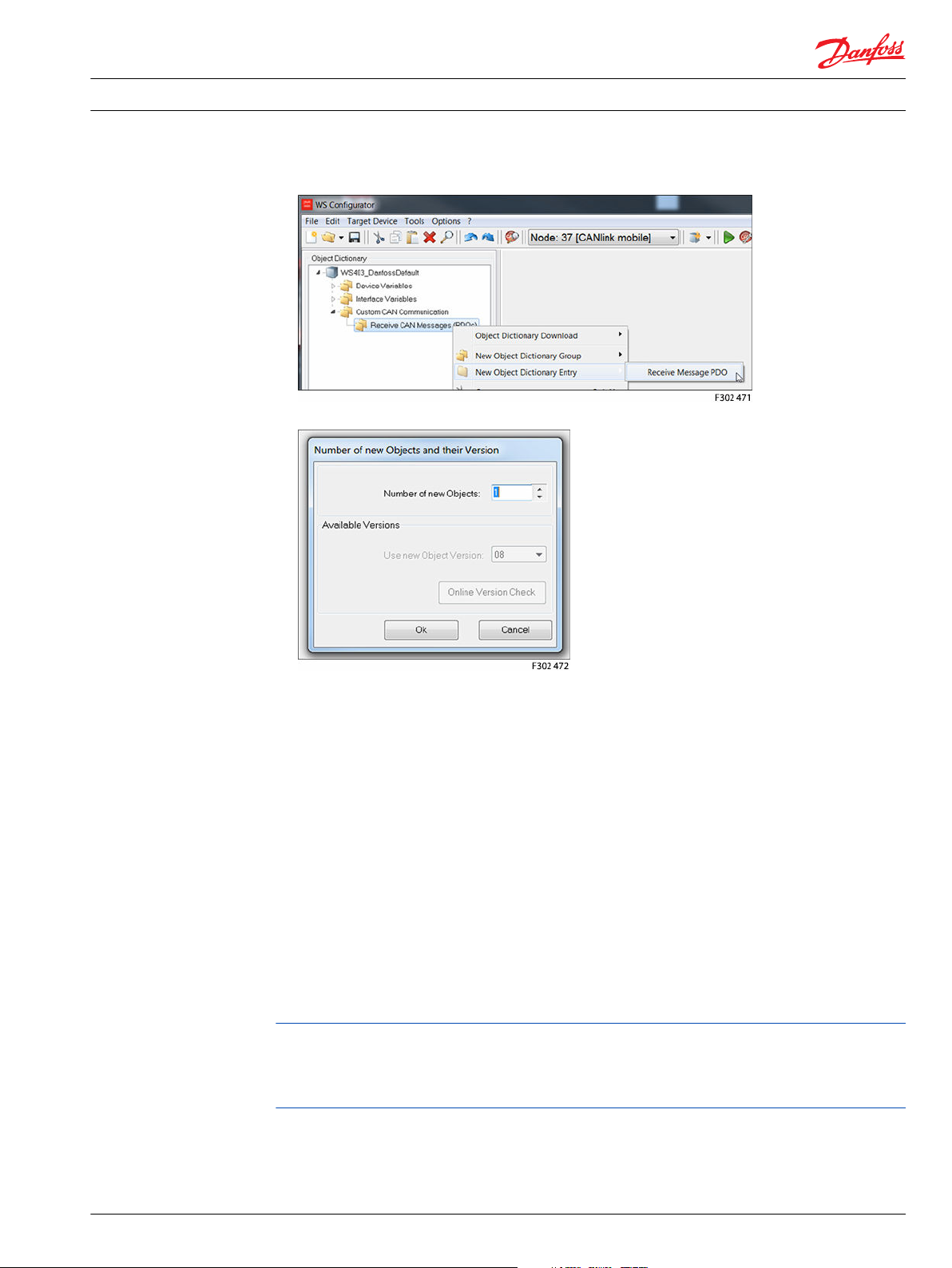

6. Right-click on the object dictionary group Recieve CAN Messages (PDOs).

6 BC00000348 en-US • Rev 0100 • October 2015

Page 7

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

7. In the context menu, click on New Object Dictionary Entry > Recieve Message PDO.

This opens the window Number of new Objects and their Version.

8. Under Number of new Objects, enter the number of objects (received messages) you want to create.

In this example: 1.

9. Click on the OK button.

The object Receive Message PDO is created.

Rename entry

Rename an entry in the tree structure;

1. Click on the corresponding entry to select it.

2. Click on the entry again to rename it.

Modifying the logging configuration

In logging mode, the device logs CAN messages, GNSS data, and internal variables. All logged data is

saved to an internal, nonvolatile memory and sent to the DTS portal.

Alternatively, you can also save the data to an inserted microSD memory card. You can read off the data

saved on the microSD memory card using the USB interface.

The internal nonvolatile memory has a capacity of 32 MB and can save a maximum of 5000 files.

When the memory is full, each new file saved is overwritten over the oldest file. Here you will find an

explanation of how to configure the device, using some concrete examples.

You must define basic variables in order to correctly link up the device with an existing CAN network.

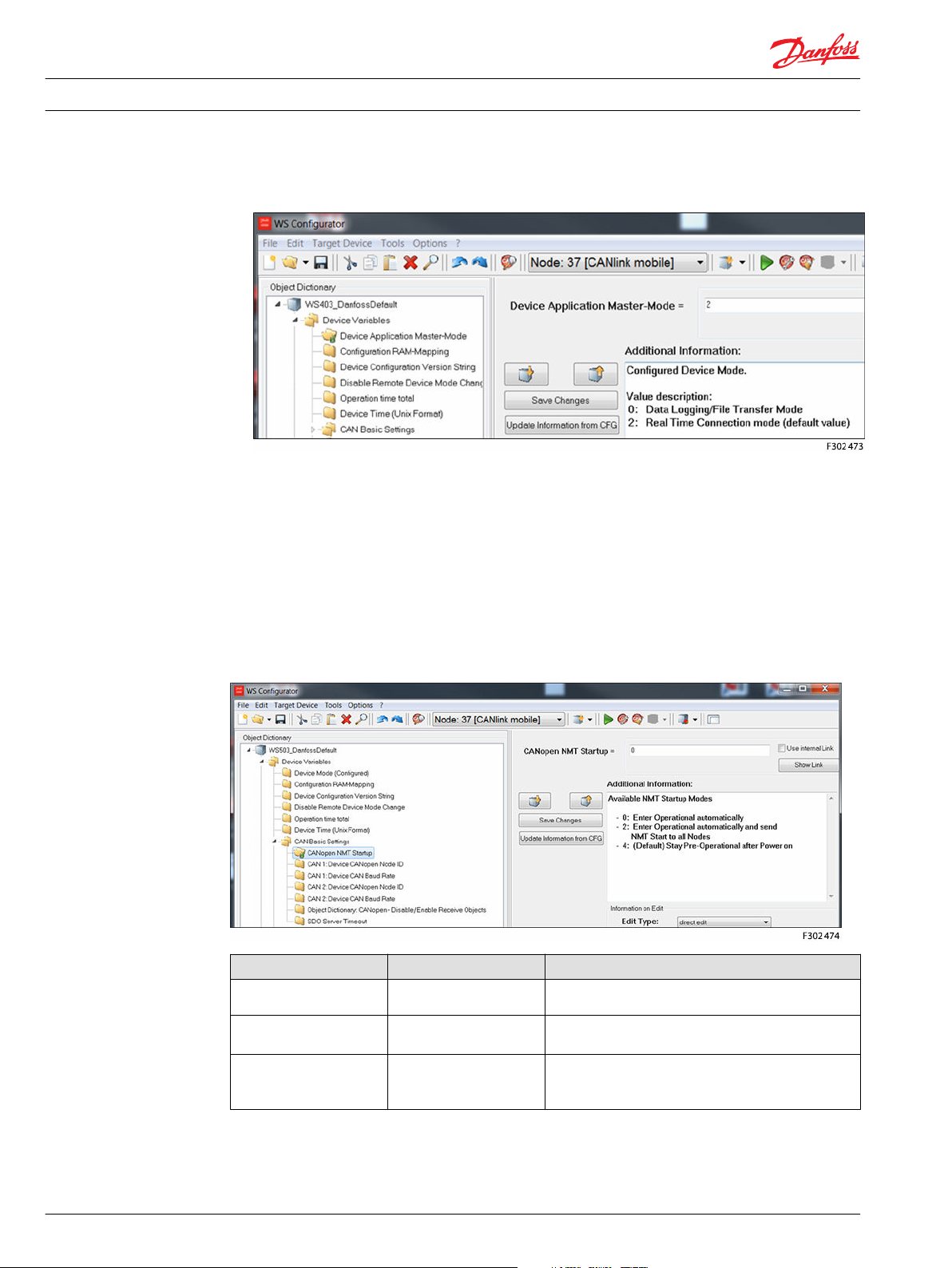

Configuring the device for Data Logging

BC00000348 en-US • Rev 0100 • October 2015 7

Page 8

User Manual Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

1. In the object dictionary group Device Variables, click on the variable Device Application MasterMode.

2. Enter the value 0 to enable Data Logging/File Transfer Mode.

Logging CAN messages and sending them to DTS portal

You must configure at least the following variables to enable CAN communication (the variables belong

to the object dictionary group Device Variables > CAN Basic Settings):

•

CANopen NMT Startup

•

CAN1 Device CANopen Node ID

•

CAN1 Device Baud Rate

•

CAN2 Device CANopen Node ID

•

CAN2 Device Baud Rate

Variable Value Function

CANopen NMT Startup 0 Automatically sets the device to CANopen mode

CAN1: Device CANopen

Node ID

CAN1: Device Baud Rate

8 BC00000348 en-US • Rev 0100 • October 2015

1 … 127 (default 37)

min. 50 kbit/s

max. 1 Mbit/s

(default: 250 kBit/s)

Operational.

The CANopen node address / device ID number (can be

left at standard value).

The bit rate at which the CAN bus operates

Page 9

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Variable Value Function

CAN2: Device CANopen

Node ID

CAN2: Device Baud Rate

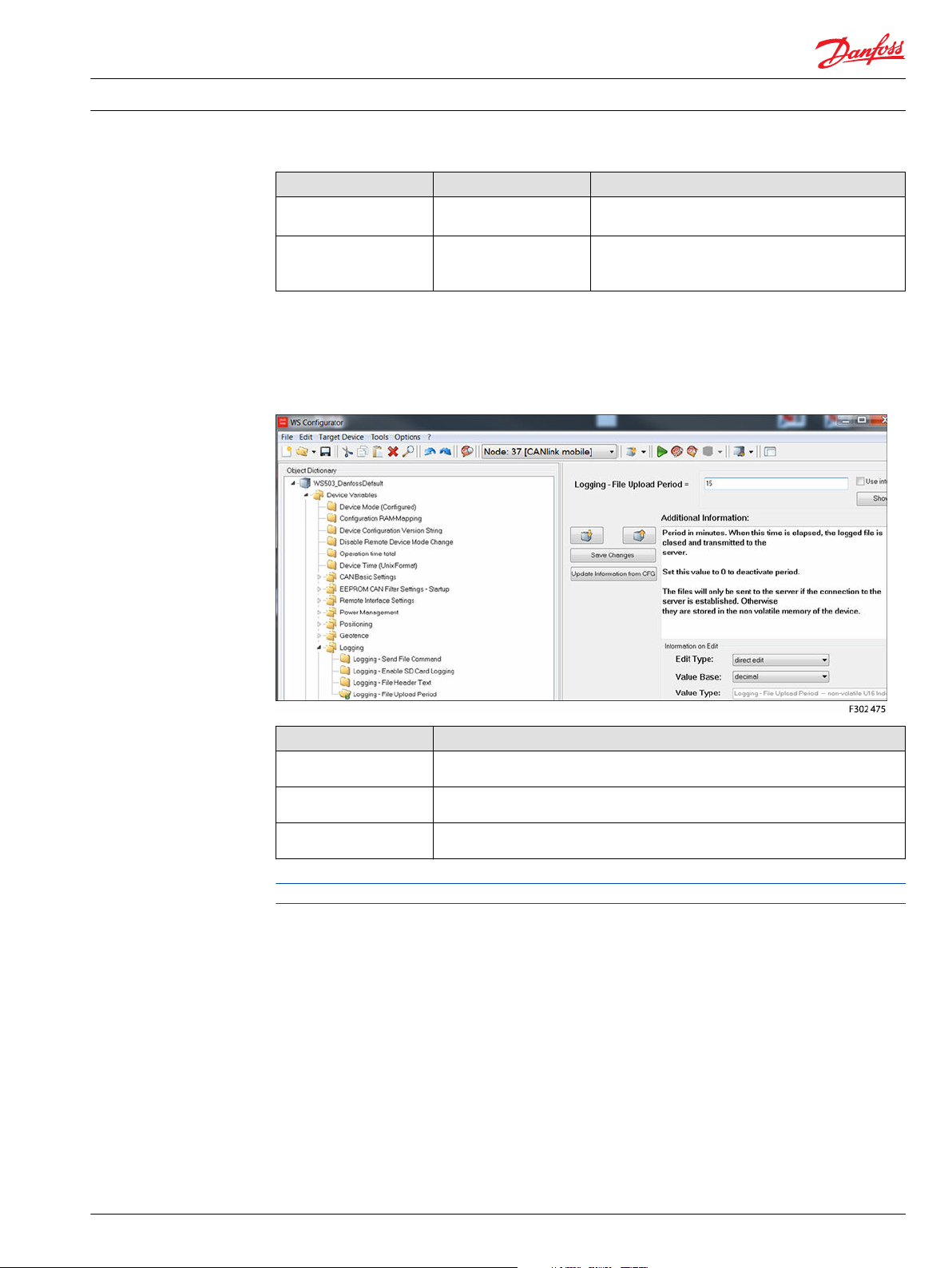

For the logfiles, you must configure further variables (These variables belong to the object dictionary

group Device Variables > Logging):

•

Logging – File Upload Period

•

Logging – File Header Text

•

Logging – Send File Command

1 … 127 (default 37)

min. 50 kbit/s

max. 1 Mbit/s

(default: 250 kBit/s)

The CANopen node address / device ID number (can be

left at standard value).

The bit rate at which the CAN bus operates

Receiving the J1939 message

Variable Function

Logging – File Upload

Period

Logging – File Header

Text

Logging – Send File

Command

Period in which the logfile is completed and sent to the DTS Portal. 0 = data is sent

when the size of the logfile reaches 1 kB.

Information text in the head of each logfile. Can contain for instance version

information (max. 32 characters).

Assign any value to the variable during operation in order to close and send the

existing logfile.

The logfile is sent to the DTS Portal when its size reaches 1 kB, irrespective of the time set.

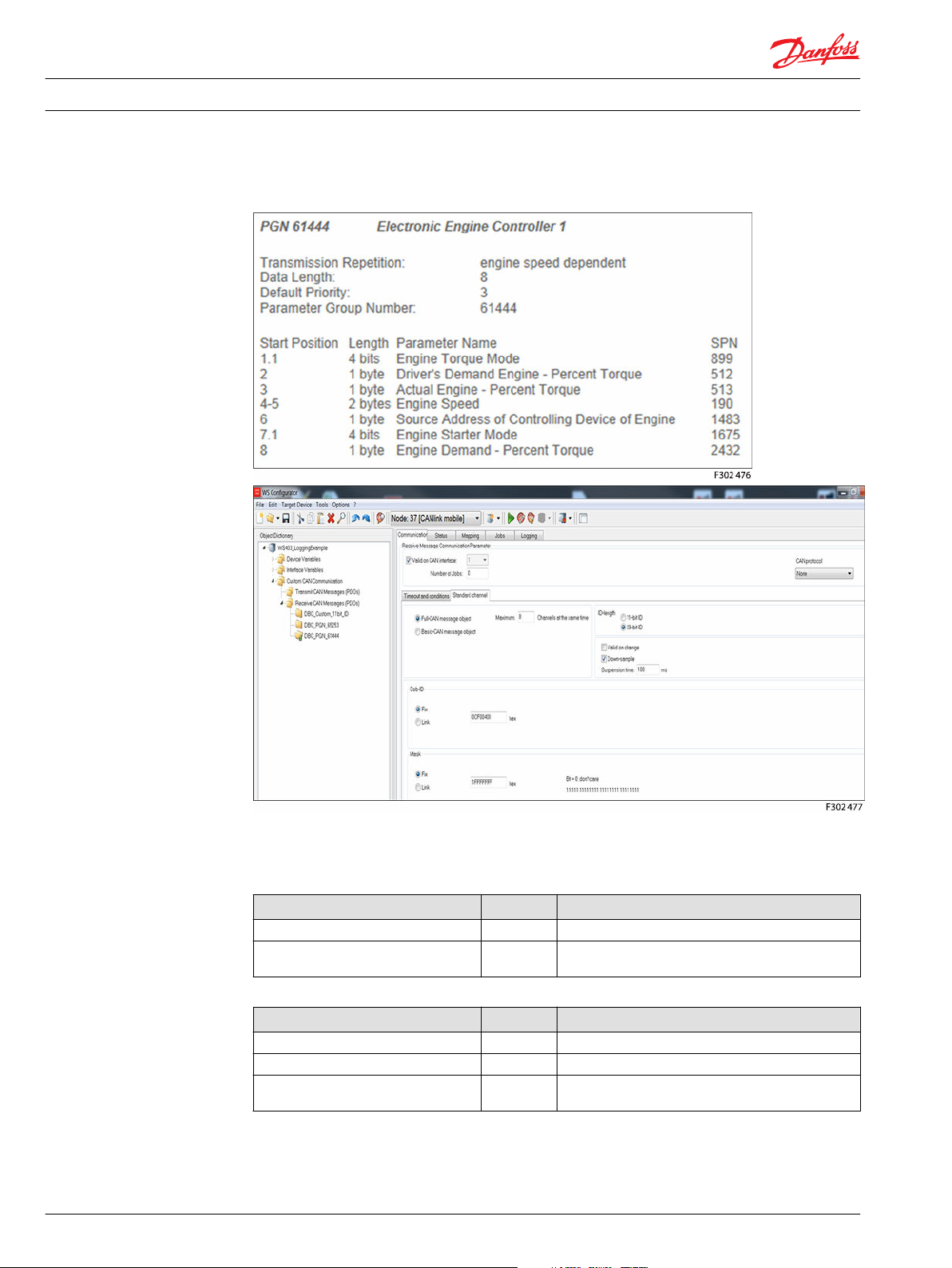

Using the example of the receipt of the J1939 message (with PGN 61444 Electronic Engine Controller 1),

we will explain the general procedure for configuring CAN messages received. The procedure can also be

applied to other CAN messages from other CAN protocols.

Creating a PGN 61444 You require an object Receive Message PDO in the object dictionary group Custom CAN

Communication > Receive CAN Messages (PDOs).

1. Create the object dictionary group Custom CAN Communication > Receive CAN Messages

(PDOs) , if it does not already exist.

See Creating object dictionary groups and objects on page 6.

2. Create the object Recieve Message PDO in the object dictionary group Receive CAN Messages

(PDOs).

BC00000348 en-US • Rev 0100 • October 2015 9

Page 10

User Manual Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

3. Rename the object.

In this example in PGN 61444.

Receive Message Communication Parameters

1. Click on the Communication tab and make the following settings:

Description Selection Result

CAN Protocol None The receive CAN message is a single message (Layer 2).

Valid on CAN Interface Set Activates the configuration, sets the reception channel

2. Click on the Standard Channel tab in the Communication tab and make the following settings:

Description Selection Result

Full CAN Message Object Set Assigns the receive message to a controller channel.

ID-Length 29-bit ID ID length of the CAN message to be received.

DOWN-SAMPLE Set (100) Receive message max. every 100 ms (not every 10ms as

10 BC00000348 en-US • Rev 0100 • October 2015

(if several are available).

transmitted)

Page 11

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Description Selection Result

Cob-ID Fix

Mask Fix

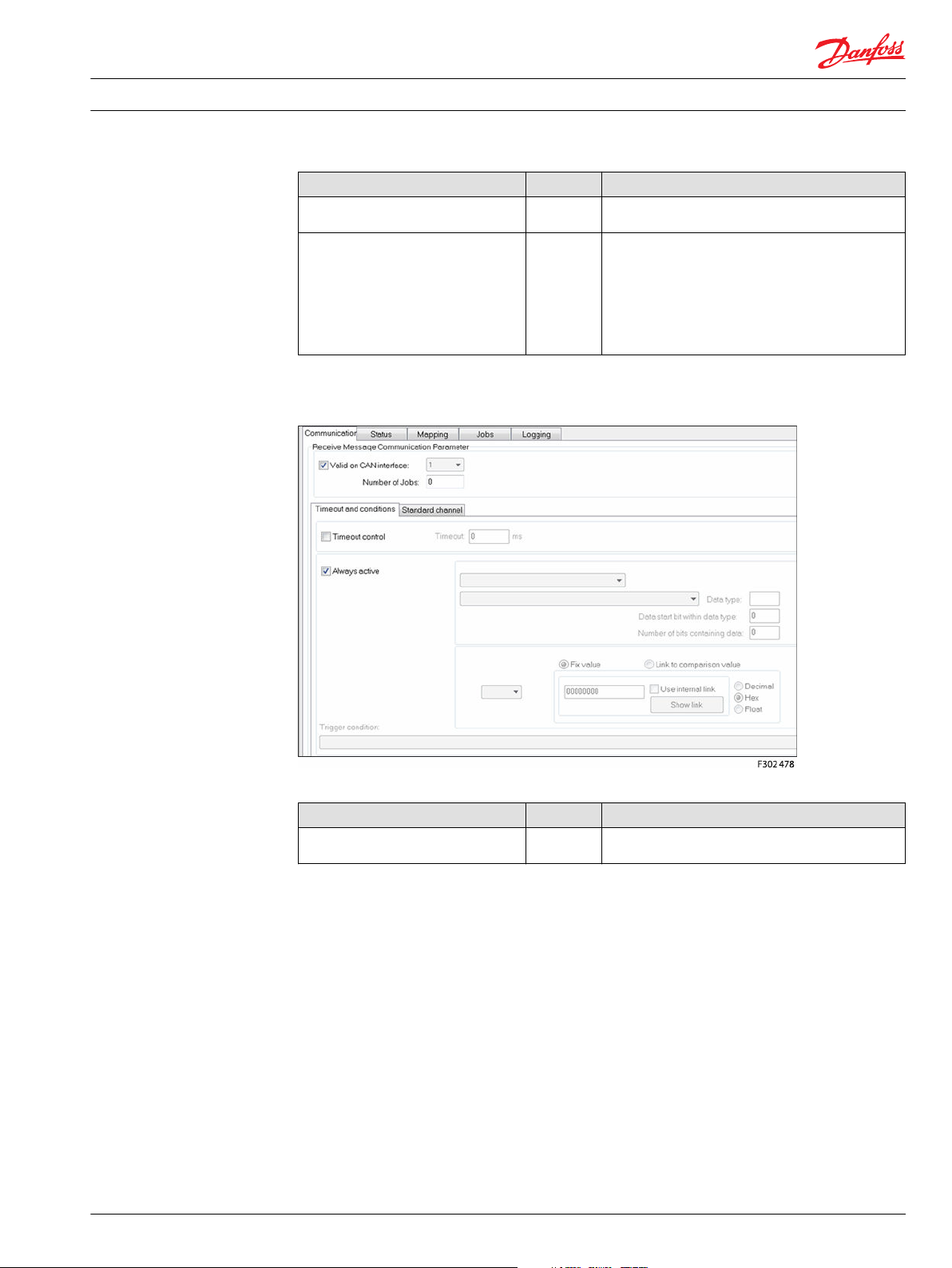

Timeout and Conditions

1. Click on the Timeout and conditions tab in the Communication tab

(00F00400)

(00FFFF00)

Fixed identifier of the receive message (J1939 PGN

61444).

This mask determines that bits 8 … 24 of the identifier

fixed in Cob-ID must not vary in the identifier of the

receive message. In the J1939 protocol, this is the PGN

area. The first bits of the identifier define the priority

and the last bits of the identifier define the source

address. That is why these bits of the identifier in the

J1939 protocol can be different and are not evaluated

on reception in this example.

2. Make the following settings:

Description Selection Result

Always active Set The CAN message is received irrespective of events or

conditions.

Logging of all data bytes every 60 seconds

Example 1

Simple cyclical logging without checking additional conditions.

The example is based on the settings in the chapter Receiving the J1939 message on page 9.

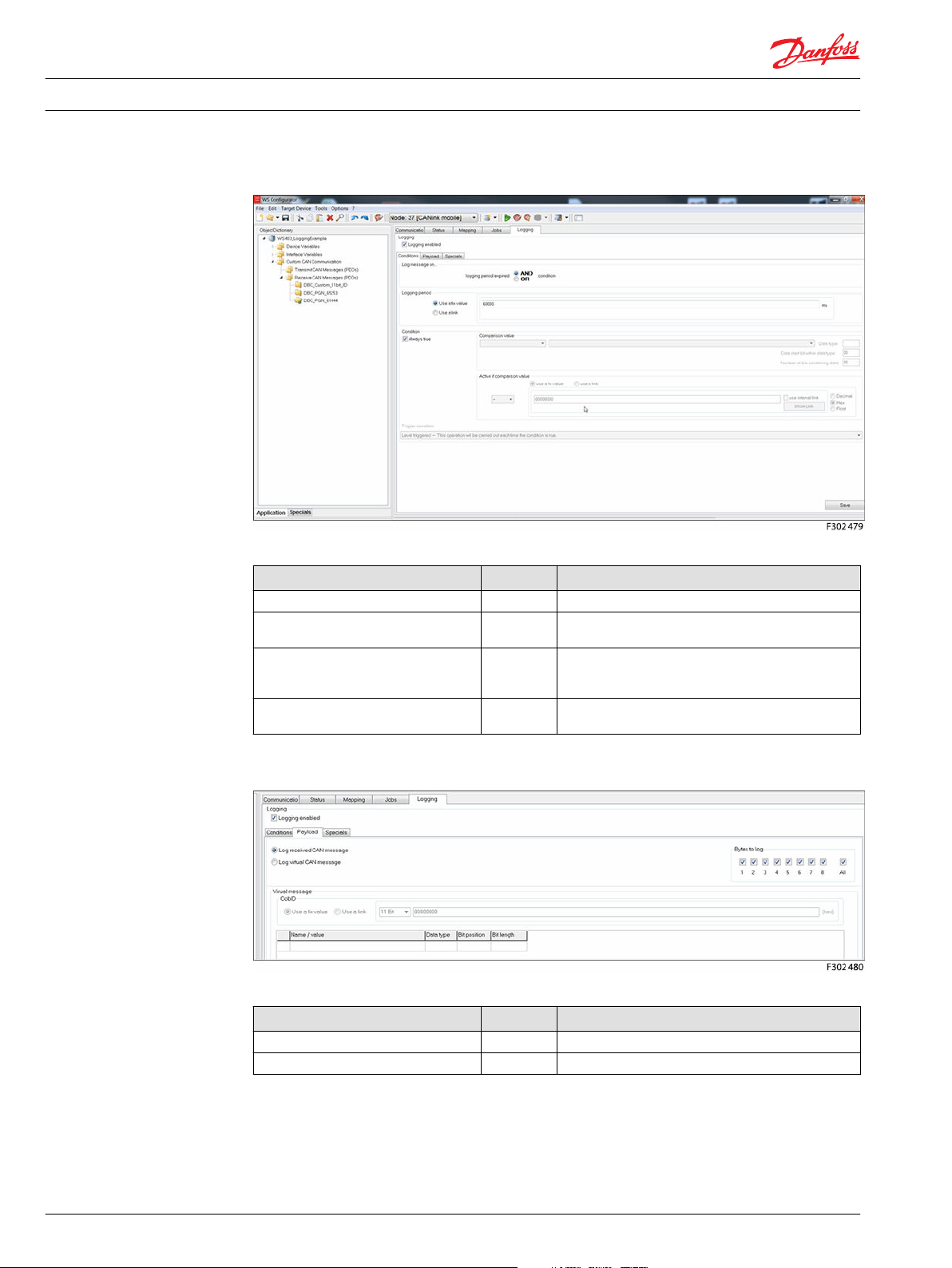

Logging

Conditions

1. Click on the Logging tab.

BC00000348 en-US • Rev 0100 • October 2015 11

Page 12

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

2. In the Logging tab, click on the Conditions tab.

3. Make the following settings

Description Selection Result

Logging enabled Set Logging enabled

Log message on AND The data is only logged when timeout is reached AND

Logging period Use a fix

value

(60000)

Condition / Always true Set Logging takes place without prior checking of

the condition is met.

Duration of the logging interval in milliseconds.

conditions.

Payload

1. In the Logging tab, click on the Payload tab.

2. Make the following settings:

Description Selection Result

Log received CAN message Set Log the data of the receive CAN message.

Bytes to log All Log all data bytes.

3. Save the configuration file and load the configuration to the device as described in Configuring the

device for Data Logging on page 7.

12 BC00000348 en-US • Rev 0100 • October 2015

Page 13

User Manual Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Log specific bytes under certain conditions or every 10 minutes

Example 2

More complex logging based on the following conditions.

The example is based on the settings in the chapter Receiving the J1939 message on page 9.

Log bytes 2 to 5 and 8 of the receive message if the engine speed (byte 4 - 5) has changed by ± 500 rpm,

or every 10 minutes.

Variables

You need various variables for checking values if you want to log data only under certain conditions.

To set the corresponding variables, you need the object dictionary group Interface Variables.

1. Create the object dictionary group Interface Variables if it does not already exist.

See Creating object dictionary groups and objects on page 6.

2. Create 4 interface variables in the object dictionary group Interface Variables.

For each variable, the window List of Interface Variables opens.

3. Click on the variable you require.

4. Click on the OK button.

The selected variable is created.

5. Repeat the process for each variable.

6. Rename the variables in a useful way.

You need the following variables for the value checks.

Description Type Sign Size

volatile U8 Trigger volatile unsigned 8 bits

volatile S32 Engine Speed new volatile signed 32 bits

BC00000348 en-US • Rev 0100 • October 2015 13

Page 14

User Manual Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Description Type Sign Size

volatile S32 Engine Speed old volatile signed 32 bits

non-volatile U16 threshold value non-volatile unsigned 16 bits

Logging

Enter the following settings in the PGN 61444 object dictionary in the Custom CAN Communication

object dictionary group.

Conditions

1. Click on the Logging tab.

2. In the Logging tab, click on the Conditions tab.

3. Make the following settings:

Description Selection Result

Log message on OR The data is logged when timeout is reached OR the

Logging period Fix value

Condition / Always true not set The data is logged irrespective of the result of the

Comparison value volatile U8

Number of bits containing data 8 All 8 bits of the variable are compared with the

14 BC00000348 en-US • Rev 0100 • October 2015

condition is met.

Duration of the logging interval in milliseconds.

(600000)

check.

Logging depends on the volatile U8 Trigger variable.

Trigger

comparison value.

Page 15

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Description Selection Result

Active if comparison value <>0 Data is only logged if the variable volatile U8 Trigger

Trigger condition This

Payload

1. In the Logging tab, click on the Payload tab

operation

will be

carried out

each time

the

condition is

true

is not equal to 0.

Logging is enabled as long as the variable volatile U8

Trigger is not equal to 0.

2. Make the following settings:

Description Selection Result

Log received CAN message Set Log the data of the receive CAN message.

Bytes to log 2..5 and 8 Log selected data bytes.

Mapping

During mapping, data is copied from the CAN message to variables. You can then process the copied

data in the device and perform calculations.

Active Conditions

1. Click on the Mapping tab.

BC00000348 en-US • Rev 0100 • October 2015 15

Page 16

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

2. Click on the Active condition tab in the Mapping tab.

3. Make the following settings:

Description Selection Result

Always active Set Mapping always takes place without conditions.

Data Link

1. Click on the Data link tab in the Mapping tab.

16 BC00000348 en-US • Rev 0100 • October 2015

Page 17

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

2. Make the following settings:

Description Selection Result

Parameter volatile S32 Engine Speed new The data is written to the volatile

Data start bit within receive

message

Number of bits containing data 16 bits The data used has 16 bits (2 bytes).

3. Click on the New button to create the mapping entry.

The mapping entry is adopted in the table.

The data is copied into the internal variable on receipt of the CAN message.

Jobs

Change to the Jobs tab.

Every time a CAN message is received, jobs are performed after mapping and before logging. In the Jobs

tab, configure the calculation operations you need for your job.

For the example configuration, you need two jobs of type Calculate Parameter Value Function. With

this function, you perform calculation operations and overwrite interface variables with calculated values.

S32 Engine Speed new variable.

24 bits The data used starts with bit 24

(from byte 4).

Job 1

With the first job (Job 1), you check whether the current engine speed is above or below the threshold

value. If one of these cases applies, set the variable volatile U8 trigger to 1, which triggers logging of the

message.

1. Click on the Jobs tab.

2. In the list under Current function of selected job, click on Calculate Parameter Value Function.

The jobs already defined are listed in the adjacent field.

3. In the list adjacent to Result, click on volatile U8 trigger.

4. Using the buttons on the tab, enter the calculation operations (A < (B - C)) or (D > (E + F))

If you click on the placeholder (e.g. A), this opens the window Input Operand Information or open a

new "(" Operation. To find out which variables you must assign to the placeholders, see Table

Variables for Job1.

BC00000348 en-US • Rev 0100 • October 2015 17

Page 18

User Manual Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

5. In the list, click on the variable you want to assign to the placeholder

(in the example, for A, the variable volatile S32 Engine Speed New).

6. Click on the button with the placeholder (e.g. A).

7. Click on the New button when you have entered the calculation operations completely.

The buttons for entering the calculation operations have the following functions:

Buttons Description

18 BC00000348 en-US • Rev 0100 • October 2015

C = Clear: Deletes the entire calculation operation

CE = Clear Entry: Only deletes the last symbol entered

Add variables to the calculation operation.

Click on the button to open a window. Assign fixed values, interface variables, or device

variables to the variables. After you have defined a variable, the display on the button

jumps to the next variable.

The selected variables are listed under List of operands, including their values and types.

Basic calculation types (addition, subtraction, multiplication, division)

Page 19

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Buttons Description

The calculation formulas are evaluated from left to right. Mathematical priority rules are not

observed. Define the priority calculations in the formula using brackets.

8. Assign the following variables to the placeholders.

Job 1 variable

Variable Type Name/Value

A S32 volatile S32 Engine Speed new

B S32 volatile S32 Engine Speed old

C U16 non-volatile U16 threshold value

D S32 volatile S32 Engine Speed new

E S32 volatile S32 Engine Speed old

F U16 non-volatile U16 threshold value

and = logical AND link

If all linked operands are true or not equal to zero, the result is Operation 1. Otherwise,

the result is Operation 0.

or = logical OR link

If one of the linked operands is true or not equal to zero, the result is Operation 1.

Otherwise, the result is Operation 0.

If both linked variables are full-number values (integers), the link is made by bits.

Comparison signs (equal to, smaller than, greater than, not equal to, smaller or equal to,

and larger or equal to)

The result is 1 when the comparison is true.

The result is 0 when the comparison is not true.

Brackets

Job 2

With the second job (Job 2), you replace the value of the variable volatile S32 Engine Speed Old with

the value of the variable volatile S32 Engine Speed New as soon as the variable volatile U8 Trigger has

the value 1. This updates the speed from which the deviation should be detected.

1. Click on the Jobs tab.

2. In the list under Current function of selected job, click on Calculate Parameter Value Function.

The jobs already defined are listed in the adjacent field.

3. In the list adjacent to Result, click on volatile S32 Engine Speed Old.

BC00000348 en-US • Rev 0100 • October 2015 19

Page 20

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

4. Using the buttons on the tab, enter the calculation operations ((A <> B) * C) + ((D – E) * F).

If you click on the placeholder (e.g. A), this opens the window Input Operand Information or open a

new "(" Operation. To find out which variables you must assign to the placeholders, see Job 2

variable on page 20.

5. In the list, click on the variable you want to assign to the placeholder

(in the example, for A, the variable volatile U8 Trigger).

6. Click on the button with the placeholder (e.g. A).

7. Click on the New button when you have entered the calculation operations completely.

8. Assign the following variables to the placeholders.

Job 2 variable

Variable Type Name/Value

A U8 volatile U8 Trigger

B fix 0

C S32 volatile S32 Engine Speed new

D U8 volatile U8 Trigger

E fix 0

F S32 volatile S32 Engine Speed old

9. Save the configuration file and load the configuration to the device as described in Configuring the

device for Data Logging on page 7.

Saving CAN messages to microSD memory cards

You can save the data to an inserted microSD memory card. You can read off the data saved on the

microSD memory card using the USB interface.

The data (.cls) is saved in the LOG directory. For this, a microSD memory card must be inserted.

Set the variable Device Variable > Logging > Enable SD Card Logging to 1, to enable data logging

to the microSD memory card.

Do not delete data from the Logging directory. This could cause problems with sending to DTS

server. However, you can delete the entire Logging directory with all the data. If the variable Device

Variable > Logging > Enable SD Card Logging is set to 0 or no microSD memory card is inserted,

the data is saved to the internal nonvolatile memory. The internal nonvolatile memory has a capacity

of 32 MB and can save a maximum of 5000 files. When the memory is full, each new file saved is

overwritten over the oldest file.

Logging GNSS positions

The GNSS position data contains information on longitude and latitude, altitude, direction, and speed

over ground as well as time and date.

Data is only logged when valid position data is received (GNSS LED lights up constantly).

20 BC00000348 en-US • Rev 0100 • October 2015

Page 21

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

Logging internal variables

Make the following settings:

Variable Function

Once per file Each logfile contains position data at least once.

Enabled Enables/ disables the position data logging.

AND / OR

Logging period Time period during which the position data should be logged.

Logging distance Distance between the last position logged and the current position (linear distance).

AND: Position data is logged if both conditions (time and distance) are met.

OR: Position data is logged if one of the conditions (time or distance) is met.

You can log various internal variables. Internal variables can be both device variables and interface

variables.

To log internal variables, you need an object Action - Function - Operation in the object dictionary

group Operation Manager. With the object Action - Function - Operation, up to 8 internal variables

can be logged in one process as a virtual CAN message.

1. Create an Operation Manager object dictionary group if it does not already exist.

See Creating object dictionary groups and objects on page 6.

2. Create an object Action - Function - Operation in the Operation Manager object dictionary group.

BC00000348 en-US • Rev 0100 • October 2015 21

Page 22

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

3. Click on the Basic tab.

4. Select a time period (in ms) during which you want logging to take place.

5. Enable Always active if you want logging to take place irrespective of conditions.

Alternatively, you can define conditions for logging.

6. Click on the Save button.

7. Click on the Jobs tab.

8. Click on the Add button adjacent to the Overview field.

The Create new job window opens.

9. Select Logging in the Create new job window.

10. Click on the OK button.

The job is added to the Overview list.

11. Enter the ID for the virtual CAN message in the Cob-ID field.

The ID must not be used by other CAN messages.

22 BC00000348 en-US • Rev 0100 • October 2015

Page 23

User Manual

Danfoss Telematics Solution Logging Data

Creating object dictionary groups and objects

12. Select the variable type and the variable in the field ADD NEW ROW.

13. Click on the Add button next to the field Add new row.

The selected variable is added to the list.

14. Add more variables to the list as required.

15.

Save the settings.

BC00000348 en-US • Rev 0100 • October 2015 23

Page 24

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

As a Danfoss Telematics Solutions customer using the WS403, on your DTS portal account you have the

possibility to show some of the logging data direct on the portal.

Data view

If the selected machine shows on the right side of the machine overview a highlighted symbol

A mouse click on the symbol will show the configured selection of the logging data.

it is possible to see all or a collection of the latest logging data direct on the portal screen.

Adapt the configuration to the web portal

The display of the logging data needs a configuration via a xml script. This script must be downloaded to

portal via Administration > Machine Configuration.

Select the Add Machine Configuration option to open the file selection menu

The selected xml-file will be tested of consistence after pressing the load button. If any error is detected

inside the xml-file, the system will reject the file with an error message pointing to the first error position.

24 BC00000348 en-US • Rev 0100 • October 2015

Page 25

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

After system accept the configuration it is possible to select a number of machines that are able to use

this configuration.

Please take care the also the dod-file of the selected machines have the same logging configuration to

support the needed logging data.

Don’t forget to press the Save button to activate this script on the portal.

Elements of the xml file

To support the structure of an xml file it much easier to use an editor that support these structures.

One option it to use the freeware https://notepad-plus-plus.org/ plus xml support http://sourceforge.net/

projects/notepad-plus/#add-ons-plugins.

To identify the xml configuration we need a UUID. There are some creators for ID’s available on the

internet like https://www.uuidgenerator.net .

XML Header

Message definition

The header has fixed and variable values. All values are fixed like in the sample below except the uuid,

the customerVersion and the keyPrefix.

For each xml file we need a unique identification ID uuid. To implement a change it is needed to

increment the customerVersion. The keyPrefix shows a short description about this script but is not

used internally. This prefix must be present to fulfill the rules of the scheme.

The next parts of the header are some message definition to generate a message on the portal to make

an identification of the script easier. Both messages will be descripted in all available languages to take

BC00000348 en-US • Rev 0100 • October 2015 25

Page 26

User Manual Danfoss Telematics Solution Logging Data

Configure Logged Data View

care that the correct language will displayed regarding the user preference of the user profile. If only one

language is defined this label will be used independent of the user preference.

Global dictionary

Inside the global directory all used message are defined this section will be used at the definition of the

show value. All needed information on the web portal must defined in this section. This included the

name of the used tab of the views, the signal name and the unit name. Also in this message definition it is

possible to define in all supported languages. The message is identified by the key value.

Transformer

Units

The transformer section will define calculation to change transferred binary information in physical units.

The transformer includes a key value to identify the transformer. The formula identifies the type of the

calculation. Actual only the "LinearFormula" is available as formula. The scale value will be multiplied with

the raw data value and additional the offset will be added to create a physical value from the CAN bus

raw data.

Include-tag loads description of pre-defined units.

<xi:include href="http://xml.proemion.com/ProemionDataConfiguration/

predefinedUnits.xml" parse="xml" xpointer="element(/1)"/>

These units can be converted automatically according to the user‘s Preferences settings in the Portal

(Metric / US).

The following predefined units are available when using the include :

< VELOCITY > predefined.unit.velocity.METERS_PER_SECOND

predefined.unit.velocity.FOOT_PER_SECOND

< FLOW RATE > predefined.unit.flow.LITER_PER_HOUR

predefined.unit.flow.GALLON_LIQUID_US_PER_HOUR

< FORCE > predefined.unit.force.NEWTON

predefined.unit.force.POUND_FORCE

26 BC00000348 en-US • Rev 0100 • October 2015

Page 27

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

< LENGTH > predefined.unit.length.KILOMETER

predefined.unit.length.MILE

predefined.unit.length.METER

predefined.unit.length.FOOT

predefined.unit.length.MILLIMETER

predefined.unit.length.INCH

< MASS > predefined.unit.mass.KILOGRAM

predefined.unit.mass.POUND

< PRESSURE > predefined.unit.pressure.KILOPASCAL

predefined.unit.pressure.PSI

predefined.unit.pressure.BAR

predefined.unit.pressure.opt.PSI

< TEMPERATUR > predefined.unit.temperature.CELSIUS

predefined.unit.temperature.FAHRENHEIT

< SPEED > predefined.unit.speed.KILOMETERS_PER_HOUR

predefined.unit.speed.MILES_PER_HOUR

predefined.unit.speed.METERS_PER_SECOND

predefined.unit.speed.FOOT_PER_SECOND

< VOLUME > predefined.unit.volume.LITER

predefined.unit.volume.GALLON_LIQUID_US

Value definitions

Custom units can be defined inside the section Units.

Symbol identifies the symbol or numeric value of the unit. Description is actual not used but must be

present to fulfill the rules of the scheme.

Available store types:

•

NumericValueStoreType

•

TextValueStoreType

•

BooleanValueStoreType

This entry combines a value label and a value unit to the defined value. This value is in any cases a

floating point value.

BC00000348 en-US • Rev 0100 • October 2015 27

Page 28

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

Parsing definition

This parsing information needs to synchronize the needed data for this portal display with the

configuration of the remote logging data transmit device. Actual only the CAN data are available for the

BinaryStreamDefinition. The message will be defined via the CAN-ID with the corresponding ID-Type and

Mask. The actual version support only the GENERIC protocol is supported.

CAN Message examples Short identifier 11 bit Long identifier 21 bit

canId “0x123” "0x18FF5003"

canIdLength “11” “29”

mask “0x7FF” "0x1FFFFFFF"

For every used value of a CAN message a value section must be defined.

Possible values can be:

•

IntValue

•

FloatValue

•

SimpleCharValue

•

SeparatedCharValue

To separate the value from a CAN stream (8byte = 64 bits) for each value can be defined a start bit and a

length of the value. For values bigger than one byte the correct byte order must be selected options are:

•

endianness =”LITTLE” -> LSB first

•

endianness =”BIG” -> MSB first

For the presentation of the values the system must know if the value shall be showen as signed or

unsigned. The selction here is:

•

signed = “true”

•

signed = “false”

The entry continueOnLastPosition needs to be always false.

The ValueDefinition is reverencing to the previously defined value.

The Transformer is referencing a calculation for the collected value. The Transformer is optional and only

needed if the raw data will not represent the actual numeric value.

Extracting bits and multiple of bits from a virtual CAN message

To rebuild status information based on bits and multiple bits below 8 the system needs a mirrored

notation of the bit position in the frame, shifted by the length of the information (See Count in standard

order (orange) and mirrored order (yellow) on page 29)

28 BC00000348 en-US • Rev 0100 • October 2015

Page 29

30 31 16 17 18 19 20 21 22 23 8 9 10 11 12 13 14 15 0 1 2 3 4 5 6 7

X X X X X X X X X X X X X X X X X X X X

25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

… Byte 2 Byte 1 Byte 0

P301 878.A

Position Length Parameter name SPN

0 1 byte Hydraulic temperature 1638

1..0 2 bits Hydraulic oil filter restriction switch 1713

1..2 2 bits Winch oil pressure switch 1857

2 1 byte Hydraulic oil level 2602

P301 879.A

<CanMessage canId="0x18FE6800" canIdLength="29" mask="0x1FFFFFFF" protocolStyle="GENERIC">

<Values>

<IntValue startPos="0" length="8" endianness="LITTLE" signed="false" continueOnLastPosti on="false">

<valueDefinition ref="value.hydraulic.temp" />

</IntValue>

<IntValue startPos="14" length="2" endianness="LITTLE" signed="false" continueOnLastPosti on="false">

<valueDefinition ref="value.hydraulic.oilfilter.restrict.switch" />

</IntValue>

<IntValue startPos="12" length="2" endianness="LITTLE" signed="false" continueOnLastPosti on="false">

<valueDefinition ref="value.hydraulic.oil.press.switch" />

</IntValue>

<IntValue startPos="16" length="8" endianness="LITTLE" signed="false" continueOnLastPosti on="false">

<valueDefinition ref="value.hydraulic.oil.level" />

</IntValue>

</Values>

</CanMessage>

P301 880.A

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

Count in standard order (orange) and mirrored order (yellow)

Example: J1939 Vehicle Fluids PGN 65128 (0x00FE68)

To get this information from a logged CAM message, it needs to be a setup like follow:

View definition

Each ViewDefinition is displayed as one tab on the portal. Actual there are the following types are

available:

•

SimpleTableViewDefinition

•

CustomTableViewDefinition

•

DataHistoryTableViewDefinition

•

ErrorTableViewDefinition

The title is displayed in the tab header.

BC00000348 en-US • Rev 0100 • October 2015 29

Page 30

User Manual

Danfoss Telematics Solution Logging Data

Configure Logged Data View

The ValueView reverence to defined Value Definitions. Additional information in this row are related to

show a unit or not and to format a value in C-type configuration (only f = float are allowed). Also a

conditional analysis of a value is possible.

Simple and custom table are tables to show a bunch of actual data. The error and history view are useful

for event data like error flags. This kind of message can be shown with status flag value and time of

appear.

Inside a Value View the name of the value and the appearance of this entry will be defined. Additional to

the numeric value view a conditional option can show text and hints based on a numerical value. A

condition has one default section and one or more case sections. As selection for the cases the following

options are available:

•

•

•

LessThan

Equals

GreatherThan

Inside a valid case section the following actions can be done:

•

replaceValue

•

setTextFormat

With the text format option several of standard options can be used:

•

bold

•

italic

•

underline

•

color

•

backgroundColor

The color definition is a 24 bit hexadecimal value with a byte for red, green and blue part.

•

#RRGGBB

•

#FF0000 -> color red

•

#00FF00 -> color green

•

#0000FF -> color blue

•

#000000 -> color black

•

#FFFFFF -> color white

In the custom view table it is possible to create a table of values in rows and columns. A headline and a

row description are also possible. The unit is a constituent part of the value and shown direct behind the

value in the same window. If a unit is not needed a empty Unit is to define for the value definition.

30 BC00000348 en-US • Rev 0100 • October 2015

Page 31

User Manual Danfoss Telematics Solution Logging Data

Configure Logged Data View

BC00000348 en-US • Rev 0100 • October 2015 31

Page 32

User Manual Danfoss Telematics Solution Logging Data

Appendix

CLF file

File header

Type Length

Start byte 1 * 0x55 STX (Start of TeXt): Marks the beginning of a

File format version 2 Big

Length Byte 2 Big

Encryption Byte 1 * 00 00 = data is not encrypted

Length of header 1 * 0x00..0x20 Header String Length= 'n'. A value of '00'

Header String Value 1 1 * 0x00..0xFF First character or data byte of Header String

Header String Value 2 1 * 0x00..0xFF

…

Header String Value

‘n’

[bytes]

1 * 0x00..0xFF

Byte

Order

Endian

Endian

Value/Range Comment

datagram

0x0000..0xFFFF Version indicating the file format's version;

Current Version = 13.

0x0000..0xFFFF Length of data to follow (everything after

Encryption Byte, including all messages and

up to, but not including, the Checksum XOR,

Checksum ADD and Stop Bytes)

01 01 = data is encrypted

Other Reserved

indicates there are no Header String values to

follow. Note: valid header length is within

0-32 bytes (was 0-255 in version 12)

(ASCII) for the file. Typically a Vehicle

Identification Number (VIN)

File payload

Typical message definition

Type Length

[bytes]

Message Type 1 * 0 - 7 CAN Data

Timestamp type 1 * 00 No timestamp for this message

Message Length 2 Big

Message Value 1 1 * 0x00..0xFF Message's payload: bytes 1-'n'. Format

Message Value 2 1 * 0x00..0xFF

32 BC00000348 en-US • Rev 0100 • October 2015

Byte

Order

Endian

Value/Range Comment

8 - 15 Statistic Data

16 - 31 GPS Data

32 - 63 I/O Data

64 - 127 RS-232 Data

128 - 192 Customer-Specific

Others Reserved

01 UNIX message timestamp

Others Reserved

0x0000..0xFFFF The sum of bytes to follow for this message,

including Message Values (1-'n') and

Timestamp Values (1-'z').

determined by Message Type and defined in

Section 2, “File Payload” [3].

Page 33

User Manual

Appendix

Danfoss Telematics Solution Logging Data

Type Length

[bytes]

… 1 * 0x00..0xFF

Message Value ‘n’ 1 * 0x00..0xFF Last byte of Message Payload

…

Timestamp Value 1 1 * 0x00..0xFF Timestamp Payload: bytes 1-'z', if Timestamp.

Timestamp Value 2 1 * 0x00..0xFF

…

Timestamp Value ‘z’ 1 * 0x00..0xFF Last byte of Timestamp payload

Byte

Order

Value/Range Comment

Type is nonzero. Format determined by

Timestamp Type as defined in Section 3,

“Message Tail” [11].

Repeat the above sequence for all subsequent messages in file. See Section 2, “File Payload” [3] above

Message Payload Definitions

Message Type 0 = 11-bit CAN Message

Type Length

Message Value 1: Bitmask

Message Header 2 Big

Data Byte Value 1 1 * 0x00..0xFF

Data Byte Value 2 1 * 0x00..0xFF Second byte of up to 8 Data Bytes in the

…

Data Byte Value ‘n’ 1 * 0x00..0xFF

[bytes]

1 * 0x00..0xFF 8 bits, each bit representing, respectively,

Byte

Order

Endian

Value/Range Comment

which of the 8 Data Bytes (1-'n') of the

original 11-bit message are included.

0x000..0x7FF 11-bit CAN message ID

First byte of up to 8 Data Bytes in the original

11-bit message

original 11-bit message

Last byte of up to 8 Data Bytes in the original

11-bit message

Message Type 1 = 29-bit CAN Message

Type Length

Message Value 1: Bitmask

Message Header 4 Big

Data Byte Value 1 1 * 0x00..0xFF

Data Byte Value 2 1 * 0x00..0xFF Second byte of up to 8 Data Bytes in the

…

Data Byte Value ‘n’ 1 * 0x00..0xFF Last byte of up to 8 Data Bytes in the original

[bytes]

1 * 0x00..0xFF 8 bits, each bit representing, respectively,

Byte

Order

Endian

Value/Range Comment

which of the 8 Data Bytes (1-'n') of the original

29-bit message are included. If Bitmask = '00',

the message length can be equal to 0x8 and

up to 0x6F9.

0x0000 0000..

0x7FFF FFFF

11-bit CAN message ID

First byte of up to 8 Data Bytes in the original

29-bit message

original 29-bit message

29-bit message

Message Type 2 = 11-bit CAN Message with source

Version 14+

BC00000348 en-US • Rev 0100 • October 2015 33

Page 34

User Manual Danfoss Telematics Solution Logging Data

Appendix

Type Length

Message Value 1:

Source Bus

Bit-mask 1 * 0x00..0xFF 8 bits, each bit representing, respectively,

Message Header 2 Big

CAN Data Length

Code introduced with

V.15

Data Byte Value 1 1 * 0x00..0xFF First byte of up to 8 Data Bytes in the original

Data Byte Value 2 1 * 0x00..0xFF Second byte of up to 8 Data Bytes in the

…

Data Byte Value ‘n’ 1 * 0x00..0xFF Last byte of up to 8 Data Bytes in the original

[bytes]

1 * 0x01..0xFF Some of our logging hardware has more than

1 * 0x00..0xFF CAN DLC - necessary to work with bitmask

Byte

Order

Endian

Value/Range Comment

one CAN interface. This value represents the

physical CAN bus from which the message

originated.

which of the 8 data bytes (1-'n') of the

original 11-bit message are included.

0x000..0x7FF 11-bit CAN message ID

11-bit message

original 11-bit message

11-bit message

Message Type 3 = 29-bit CAN Message with source

Version 14+

Type Length

Message Value 1:

Source Bus

Bit-mask 1 * 0x00..0xFF 8 bits, each bit representing, respectively,

Message Header 4 Big

CAN Data Length

Code introduced with

V.15

Data Byte Value 1 1 * 0x00..0xFF First byte of up to 8 Data Bytes in the original

Data Byte Value 2 1 * 0x00..0xFF Second byte of up to 8 Data Bytes in the

…

Data Byte Value ‘n’ 1 * 0x00..0xFF Last byte of up to 8 Data Bytes in the original

[bytes]

1 * 0x01..0xFF Some of our logging hardware has more than

1 * 0x00..0xFF CAN DLC - necessary to work with bitmask

Byte

Order

Endian

Value/Range Comment

one CAN interface. This value represents the

physical CAN bus from which the message

originated.

which of the 8 data bytes (1-'n') of the

original 29-bit message are included. If

bitmask = '00', the message length can be

equal to 0x8 and up to 0x6F9.

0x0000 0000..0x7FFF

FFFF

29-bit CAN message ID

29-bit message

original 29-bit message

29-bit message

34 BC00000348 en-US • Rev 0100 • October 2015

Page 35

User Manual Danfoss Telematics Solution Logging Data

Appendix

Message Type 16 = GPS Location Data (J1939 format)

Type Length

[bytes]

GPS Latitude 4 Little

GPS Longitude 4 Little

Byte

Order

Endian

Endian

a Reference from J1939-71 SPN 584

b Reference from J1939-71 SPN 585

Message Type 17 = GPS Movement Data

Type Length

[bytes]

Heading 4 Little

Ground Speed (2-D) 4 Little

Byte

Order

Endian

Endian

Value/Range Comment

0x00000000..

0xFAFEE27A

0xFFFFFFFF Invalid Data

0x00000000..

0xFAFEE27A

0xFFFFFFFF Invalid Data

Value/Range Comment

0x00000000..

0xFFFFFFFF

0x00000000..

0xFFFFFFFF

Scalar: 10-7 deg/bit

Offset: -210 deg

Range: -210 deg (SOUTH)a to +211.108122

deg (NORTH)

Scalar: 10-7 deg/bit

Offset: -210 deg

Range: -210 deg (WEST) to +211.108122 deg

(EAST)b

Signed 32-bit Int

Scaling: 1e-5 Degrees

cm/second

Message tail

Timestamp Value Definitions

Timestamp Type 00 = No Timestamp

Type Length

[bits]

No timestamp 0 * Null Zero length.

Byte

Order

Value/Range Comment

Timestamp Type 01 = UNIX Timestamp (seconds)

Type Length

[bits]

UNIX timestamp 4 Big

Type Length

[bits]

Checksum XOR 1 * 0x00..0xFF XOR checksum over encryption byte (offset 5)

Checksum ADD 1 * 0x00..0xFF ADD checksum over encryption byte (offset

Stop Byte 1 * 0xAA ETX (End of Text): Marks the end of the file

Byte

Order

Endian

Byte

Order

Value/Range Comment

0x00000000..

0xFFFFFFFF

Value/Range Comment

Timestamp for each message (32 bit positive

or negative number of seconds since

midnight on January 1, 1970).

and all subsequent bytes.

5) and all subsequent bytes including XOR

checksum bytes. All bytes will be summed up

and the carry over will be discarded.

BC00000348 en-US • Rev 0100 • October 2015 35

Page 36

User Manual

Appendix

Bitmask

Examples

Danfoss Telematics Solution Logging Data

Empty or irrelevant bytes of CAN messages can be omitted by defining a proper bitmask. A set bit marks

a transmitted byte, an unset bit a omitted bytes.

The bits are interpreted in order of their significance (Bitmask: MSB 8 7 6 5 4 3 2 1 LSB, Message Bytes: 01

02 03 04 05 06 07 08 ).

A bitmask of 0x04 defines, that only the 3rd byte of the can message is transferred.

When using bitmasks, the can messages can't be longer than 8 bytes. If all bit are either unset (0x00) or

set (0xFF) the message is transferred completely and, if the message type supports it, can be longer than

8 bytes.

Example 1

The first example explains the order in which file section will occur.

The second example will demonstrate what the data byte will look like in the file format.

Section 1, “File Header” [3]

File Header - The file header will always start the file structure.

This contains Start Byte, File Format Version, Length Bytes, Encryption Byte and the File Header.

Section 2, “File Payload” [3]

Message Header - The section describes the Message Type that is to follow, the Timestamp Type that is to

follow and the Message Length, which is the length of the Message Values and Timestamp Values.

Message Payload - This is unique to each Message Type. The length of this section is defined by Message

Length in the Message Header.

The meaning of the data bytes is detailed in the following sections.

Message Type 0 - 11 bit CAN Message - Node 1

Each 11 bit CAN message consists of a Bitmask, Message Header and up to 8 Data Bytes. The user has the

ability to remove irrelevant or undefined payload bytes from the original 11-bit CAN message using the

Bitmask. The Bitmask allows the message to retain the position of the bytes in the message when

irrelevant bytes are removed from the message. The 11 bit Message Header is the CAN ID of the 11 bit

message.

The meaning of the 11 bit Message Value is user defined.

Message Type 1 - 29 bit CAN Message - Node 1

Each 29 bit CAN message consists of a Bitmask, Message Header and up to 1,785 Data Bytes. The user has

the ability to remove irrelevant or undefined payload bytes from the original 29-bit CAN message using

the Bitmask. The Bitmask allows the message to retain the position of the bytes in the message when

irrelevant bytes are removed from the message. If the Bitmask is 00, then the 29 Bit Message Values can

be greater than or equal to 8 bytes but less than or equal to 1,785. The 29 bit Message Header is the CAN

ID of the 29 bit message.

29 bit Message Values that have a length longer than 8 are often created using J1939 multicast BAM

message.

Please reference J1939-21. The meaning of the 29 bit Message Value is user defined.

36 BC00000348 en-US • Rev 0100 • October 2015

Page 37

User Manual Danfoss Telematics Solution Logging Data

Appendix

Message Type 2 - 11 bit CAN Message - Node 2

Exactly the same as type 0, but the message originates from the second CAN node of the micro controller.

This is a physically separate CAN bus.

Message Type 3 - 29 bit CAN Message - Node 2

Exactly the same as type 1, but the message originates from the second CAN node of the micro controller.

This is a physically separate CAN bus.

Message Type 16 - GPS Location Data (J1939 Format)

The GPS Data message is a fixed length of 8 bytes. The first 4 bytes are GPS Latitude coordinate and the

second 4 bytes are the GPS Longitude coordinate. The binary value is an unsigned 32 bit.

To decode the meaning of this binary value, convert to decimal; apply the scalar of 107 and the offset of

-210 (decimal).

This method of conversion is valid for both GPS Latitude and Longitude.

If the Value is 'FFFFFFFF' then the GPS data is invalid.

Message Type 17 - GPS Movement Data (J1939 Format)

This message contains the heading and speed data of the device. The heading is encoded as a four-byte

signed integer. The scaling is 1e-5 degrees. The speed is a four byte unsigned integer representing

centimeters per second.

Timestamp Type 00 = No Time Stamp

No Time Stamp has a length of zero. Thus, there is no timestamp in this message.

Timestamp Type 01 = UNIX Time Stamp

The UNIX Time Stamp has a length of 4 bytes. The 32 bit signed binary number can be converted.

This is a count of the number of seconds that have passed since January 1st, 1970.

Section 3, “Message Tail” [11]

Checksum XOR - The XOR of all bytes from the encryption byte to all bytes up to but no including the

Checksum XOR byte.

Checksum ADD - The SUM off all bytes from the encryption byte to all bytes up to, but not including, the

Checksum ADD byte.

Stop Byte. - Marks the end of the binary file. (ETX)

Example 2

Let us have a look at the following example:

Line 1: 55 00 0C 00 37 00 05 56 49 4E 20 31

Line 2: 00 00 00 05 0C 02 3A FF AA

Line 3: 41 01 00 0B 01 02 03 04 05 06 07 47 79 F3 00

Line 4: 08 00 00 04 00 19 00 05

Line 5: 21 01 00 08 0A 62 00 64 47 79 F3 01

Line 6: 22 00 00 01 4A

Line 7: 4A 44 AA

BC00000348 en-US • Rev 0100 • October 2015 37

Page 38

User Manual

Appendix

Danfoss Telematics Solution Logging Data

The above binary file contains the following information

•

Line 1 - File Header:

Version: 12

‒

Header: VIN 1

‒

Length: 55

‒

Data is not encrypted

‒

•

Line 2 - 11 bit CAN Message:

CAN Message ID: 570

‒

Message Values: 00 00 00 00 FF AA 00 00

‒

No Timestamp

‒

•

Line 3 - RS232 String:

RS232 Values: 01 02 03 04 05 06 07

‒

Timestamp: January 1st, 2008, 08:00:00

‒

•

Line 4 - Statistics String:

On/Off Counter: 25

‒

GSM Registration Counter: 5

‒

No Timestamp

‒

•

Line 5 - Analog Input:

Value 1: 2658

‒

Value 2: 100

‒

Timestamp: January 1st, 2008, 08:00:01

‒

•

Line 6 - Digital Output:

Value 1: High

‒

Value 2: Low

‒

Other: Not Present

‒

No Timestamp

‒

•

Line 7 - Checksum XOR:

Checksum and Stop Byte

‒

38 BC00000348 en-US • Rev 0100 • October 2015

Page 39

User Manual Danfoss Telematics Solution Logging Data

BC00000348 en-US • Rev 0100 • October 2015 39

Page 40

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

BC00000348 en-US • Rev 0100 • October 2015 www.danfoss.com

Local address:

©

Danfoss A/S, 2015

Loading...

Loading...