Page 1

Data Sheet

Desuperheating valve

Type TEAT

Used to inject refrigerant into the suction line of the refrigeration system

Refrigerant injection into the suction line

TEAT valves are used to inject refrigerant into

the suction line of the refrigeration system to

reduce the high discharge temperatures that

can occur when the system operates with

highly superheated suction vapour.

This applies when, for example:

• A compressor runs either with low suction

pressure or with high condensing

temperature

• A compressor runs with both low suction

pressure and high condensing temperature.

This applies especially to systems with R 22

• A compressor receives highly superheated

suction vapour

• A compressor runs with capacity regulation

by hot gas bypass

Two-stage refrigeration plant

TEAT valves are also used in two-stage

refrigeration plant to control liquid injection

into the intercooler. The bulb is installed on the

discharge line from the highpressure

compressor. The theoretically obtainable

discharge temperature for given operating

conditions can be found in the h, log p diagram

for the refrigerant concerned.

Temperature regulation of the medium

TEAT valves have a further application: the

temperature regulation of the medium, e.g. the

temperature of the oil in a screw compressor.

AI172886419299en-000501

Page 2

Desuperheating valve, Type TEAT

Features

• Refrigerants Applicable to HCFC, non ammable HFC and R717 (Ammonia)

• Regulation ranges: See ordering table

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 2

Page 3

Desuperheating valve, Type TEAT

Functions

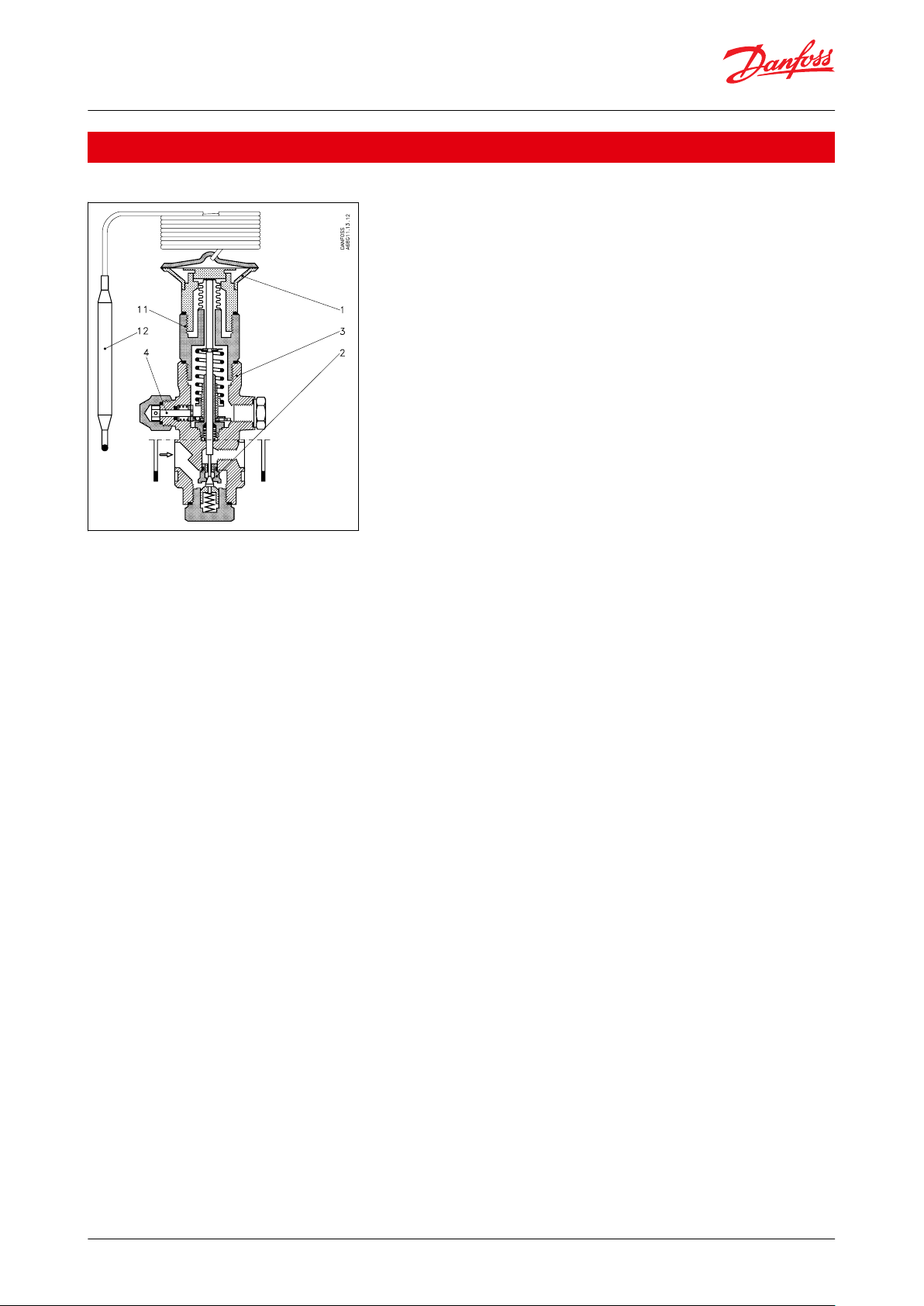

Figure 1: TEAT

Temperature variations in the discharge pipe where the bulb is placed act on the thermal charge in the bulb (12).

This changes the pressure in the thermostatic element (1) and thus gives modulating liquid injection.

If leakage in the thermostatic element does occur, it will not result in refrigerant loss.

The thermostatic element is screwed to the intermediate section (11) of the valve. A bellow on the intermediate

section means that the suction pressure cannot inuence the valve setting.

The movement of the setting spindle (4) is transferred through a gearwheel mechanism.

The orice assembly (2) is identical to that of TEA thermostatic expansion valves.

NOTE:

The TEAT is not able to close completely tight, so a solenoid valve is needed to shut o liquid supply, when the

system stops.

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 3

Page 4

Desuperheating valve, Type TEAT

Media

Refrigerants

Applicable to HCFC, non ammable HFC and R717 (Ammonia).

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 4

Page 5

Description

Values

P band

20 °C

Capillary tube length

5 m

Max. bulb temperature

150 °C

Max. working pressure

PS = 20 bar

Max. test pressure

p' = 30 bar

Desuperheating valve, Type TEAT

Product specications

Pressure and temperature data

Table 1: Pressure and temperature data

Design

Materials

• Valve housing made of GGG40.3

• Gaskets are non asbestos

Identication

Figure 2: Element label

The thermostatic element

Has a label giving valve type, temperature range and max. test pressure.

Figure 3: Orice assembly marking

The orice assembly

Is common to TEAT, TEA and TEVA. The rated capacity, e.g. 8 TR (= 28 kW) for the refrigerant ammonia is given on the

orice assembly.

The orice assembly can be used for both ammonia and uorinated refrigerants.

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 5

Page 6

123411

12

Thermostatic element (diaphragm)

Orice assembly

Valve body

Setting spindle

Intermediate section

Bulb

Type and rated

capacity (TR)

Rated capacity in kW

(1)

at Δp = 8 bar

R717 (NH

3

)

R22

R134a

R404A

R12

R502

TEAT 20-1

3.3

0.8

0.7

0.6

0.5

0.6

TEAT 20-2

6.4

1.5

1.2

1.1

0.9

1.1

TEAT 20-3

9.7

2.3

1.7

1.6

1.3

1.6

TEAT 20-5

16

3.632.9

2.3

2.7

TEAT 20-8

25.6

6.2

4.6

4.4

3.5

4.4

TEAT 20-12

38.4

9.2

6.9

6.7

5.3

6.5

TEAT 20-20

64

15.4

13.1

12.61010.8

TEAT 85-33

1062619.5

18.8

14.9

18

TEAT 85-55

173

42.4

31.8

30.6

24.3

27.4

TEAT 85-85

274

66.3

50.3

48.4

38.4

46.5

(1)

Valve size

Pressure drop across valve Δp bar

4681115

20 - 1

2.3

2.8

3.3

3.6

4.7

20 - 2

4.8

5.7

6.4

7.2

7.9

20 - 3

7.2

8.5

9.7

10.8

11.7

20 - 5

12.1

14.21618

19.8

20 - 8

18.6

22.1

25.6

28.5

31.4

20 - 12

29.1

33.7

38.44347.1

20 - 20

47.75764

72.1

79.1

Desuperheating valve, Type TEAT

Material specication

Figure 4: TEAT

Rated capacity in kW

Table 2: Rated capacity in kW

(1)

(1)

Rated capacity is valve capacity at +5 °C evaporating temperature, and 4K subcooling of the liquid in front of the valve.

Rated capacity is valve capacity at +5 °C evaporating temperature, and 4K subcooling of the liquid in front of the valve.

NOTE:

Subcooling of the liquid in front of the valve is essential for the function of the valve. Lack of subcooling will lead to

malfunction of the valve and increased wear on orice.

Extended capacities in kW

Table 3: Extended capacities in kW R717

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 6

Page 7

(1)

Valve size

Pressure drop across valve Δp bar

4681115

85 - 33

80.2

94.2

106.4

118.6

130.3

85 - 55

136.1

157

176.8

197.7

215.2

85 - 85

203.5

239.6

274.5

302.4

334.9

(2)

Valve size

Pressure drop across valve Δp bar

4681115

20 - 1

0.6

0.7

0.8

0.9

1

20 - 2

1.2

1.4

1.5

1.7

1.9

20 - 3

1.722.3

2.6

2.9

20 - 5

2.7

3.1

3.644.8

70 - 8

4.4

5.2

6.2

6.9

7.6

20 - 12

7

8.1

9.2

10.4

11.3

20 - 20

11.5

13.7

15.4

17.2

18.8

85 - 33

19.3

22.4

25.6

28.5

31.4

85 - 55

32.6

37.8

42.4

47.7

52.3

85 - 85

48.8

58.2

66.3

72.1

81.4

120

Type

H1 [mm]

H2 [mm]

H3 [mm]

H4 [mm]

L

B [mm]

Weight

Excl. strainer

[mm]

Incl. strainer

[mm]

Excl. strainer

[kg]

Incl. strainer

[kg]

TEAT 20

121.5372596110

164802.1

3

TEAT 85

131.53735

106

125

199953

4.5

Desuperheating valve, Type TEAT

(1)

(1)

The rated capacity is valve capacity at +5 °C evaporating temperature, +32 °C condensing temperature and 4K subcooling of the liquid in front

The rated capacity is valve capacity at +5 °C evaporating temperature, +32 °C condensing temperature and 4K subcooling of the liquid in front

of the valve

of the valve

Table 4: Extended capacities in kW R22

(2)

(2)

The rated capacity is valve capacity at +5 °C evaporating temperature, +32 °C condensing temperature and 4K subcooling of the liquid in front

The rated capacity is valve capacity at +5 °C evaporating temperature, +32 °C condensing temperature and 4K subcooling of the liquid in front

of the valve

of the valve

Dimensions and weights

Figure 5: Dimensions and weights

Table 5: Dimensions and weights

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 7

Page 8

Type and rated capacity

(TR)

Regulating range °C

Flange connection

Code no.

Assembled valve

Separate orice

assembly

Separate thermostatic

element

TEAT 20-1

35 - 65

½ × ½

(1)

068G2050

068G3262

55 - 95

½ × ½

(1)

068G2050

068G3260

90 - 130

½ × ½

(1)

068G2050

068G3261

TEAT 20-2

35 - 65

½ × ½

068G6125

068G2051

068G3262

55 - 95

½ × ½

068G6062

068G2051

068G3260

90 - 130

½ × ½

068G6065

068G2051

068G3261

TEAT 20-3

35 - 65

½ × ½

(1)

068G2052

068G3262

55 - 95

½ × ½

(1)

068G2052

068G3260

90 - 130

½ × ½

(1)

068G2052

068G3261

TEAT 20-5

35 - 65

½ × ½

068G6126

068G2053

068G3262

55 - 95

½ × ½

068G6061

068G2053

068G3260

90 - 130

½ × ½

068G6127

068G2053

068G3261

TEAT 20-8

35 - 65

½ × ½

068G6128

068G2054

068G3262

55 - 95

½ × ½

068G6063

068G2054

068G3260

90 - 130

½ × ½

068G6066

068G2054

068G3261

TEAT 20-12

35 - 65

½ × ½

(1)

068G2055

068G3262

55 - 95

½ × ½

(1)

068G2055

068G3260

90 - 130

½ × ½

(1)

068G2055

068G3261

TEAT 20-20

35 - 65

½ × ½

068G6068

068G2056

068G3262

55 - 95

½ × ½

068G6064

068G2056

068G3260

90 - 130

½ × ½

068G6067

068G2056

068G3261

TEAT 85-33

35 - 65

¾ × ¾

068G6129

068G2057

068G3262

55 - 95

¾ × ¾

068G6070

068G2057

068G3260

90 - 130

¾ × ¾

068G6072

068G2057

068G3261

TEAT 85-55

35 - 65

¾ × ¾

068G6130

068G2058

068G3262

55 - 95

¾ × ¾

068G6073

068G2058

068G3260

90 - 130

¾ × ¾

068G6131

068G2058

068G3261

TEAT 85-85

35 - 65

¾ × ¾

068G6069

068G2059

068G3262

55 - 95

¾ × ¾

068G6071

068G2059

068G3260

90 - 130

¾ × ¾

068G6132

068G2059

068G3261

Desuperheating valve, Type TEAT

Ordering

Figure 6: TEAT

Table 6: Ordering

(1)

(1)

This valve size must be ordered as a complete valve + a separate orice assemble in the required size.

This valve size must be ordered as a complete valve + a separate orice assemble in the required size.

Example: TEAT 20-3 must be ordered as 068G6125 + 068G2052.

Example: TEAT 20-3 must be ordered as 068G6125 + 068G2052.

The orice in the complete TEAT 20-2 valve must then be changed with the separate orice assemble.

The orice in the complete TEAT 20-2 valve must then be changed with the separate orice assemble.

Separate lter with gaskets, staybolts and nuts

for TEAT 20, code no. 006-0042 for TEAT 85, code no. 006-0048. Stainless steel bulb pocket, gasket, and union nut,

code no. 993N3615, for screwing into G ½ socket welded to tube or tank.

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 8

NOTE:

Page 9

Type

File name

Document type

Document topic

Approval authority

TEAT

EAC RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC RU

MD 033F0691.AE

Manufacturers Declaration

RoHS

033F0686.AG

Manufacturers Declaration

PED

RMRS 19.10034.262

Marine - Safety Certicate

RMRS

TEAT 20

TSSA CRN.0C14029.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

TEAT 85

TSSA CRN.0C14029.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

Desuperheating valve, Type TEAT

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 7: Valid approvals

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 9

Page 10

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI172886419299en-000501 | 10

Loading...

Loading...