Page 1

Data Sheet

Thermostatic expansion valves

for ammonia Type TEA

Regulate and monitor ammonia and uorinated refrigerants

in industrial refrigeration systems

Thermostatic expansion valves regulate the

injection of refrigerant liquid into evaporators.

Injection is controlled by the refrigerant

superheat.

Therefore the valves are especially suitable for

liquid injection in „dry“ evaporators where the

superheat at the evaporator outlet follows the

evaporator load proportionally.

Features:

• Large temperature range: -50 °C – +30 °C Can

be used in both freezing and refrigeration

systems

• Interchangeable orice assemblies

• Interchangeable thermostatic element

• Rated capacities from 3.5 – 295 kW, 1 – 85

tons (TR)

• External superheat setting Can be matched to

all evaporators to give optimum evaporator

utilization

• Patented double contact bulb Fast and easy

to install. Good temperature transfer from

tube to bulb

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company

AI172886422449en-000401

Page 2

Thermostatic expansion valves for ammonia, Type TEA

Functions

TEA is equipped with interchangeable orice assembly and thermostatic element. TEA is built up of three

interchangeable main components:

• Thermostatic element (1)

• Orice assembly (2)

• Valve body (3), with ange connections

The valve has external equalization. A separate outlet orice assembly (10) is for use with TEA 20-1 (3.5 kW) only.

The double contact bulb gives fast and precise reaction to temperature changes in the evaporator suction line, even

with much reduced evaporator load. It also makes tting the bulb quick and easy. The valves are able to withstand

the eects that normally occur with hot gas defrosting.

The movement of the setting spindle is transferred by a gearwheel mechanism that ensures smooth superheat

setting. The throttling section of the orice assembly has a long operating life, the valve cone and seat being made

of a special alloy steel with particularly good wear qualities.

NOTE:

The TEA is not able to close completely tight. Consequently a solenoid valve is needed to shut o liquid supply

when systems stops.

Media

Refrigerants

Refrigerant R717 - NH3(Ammonia)

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 2

Page 3

Evaporating temperature range

D: -50 °C – 0 °C

P: -20 °C – 30 °C

Capillary tube length:

5 m

Max. bulb temperature

100 °C

Max. working pressure

PS/MWP = 19 bar

Max. test pressure

28.5 bar

Element label

MADE IN DENMARK

PB 19 bar/MWP 276 psig

BE0410B

TEA 20/85

068G3053

R717

-20/+30 °C / -5/+85 °F

Thermostatic expansion valves for ammonia, Type TEA

Product specications

Pressure and temperature

Table 1: Pressure and temperature

NOTE:

Connection for external pressure equalization 1⁄4 in. or ∅ 6.5 / ∅ 10 mm weld nipple. An 8 mm self-cutting union

can also be used.

Design

Materials

Valve housing made of GGG40.3

Gaskets are non asbestos

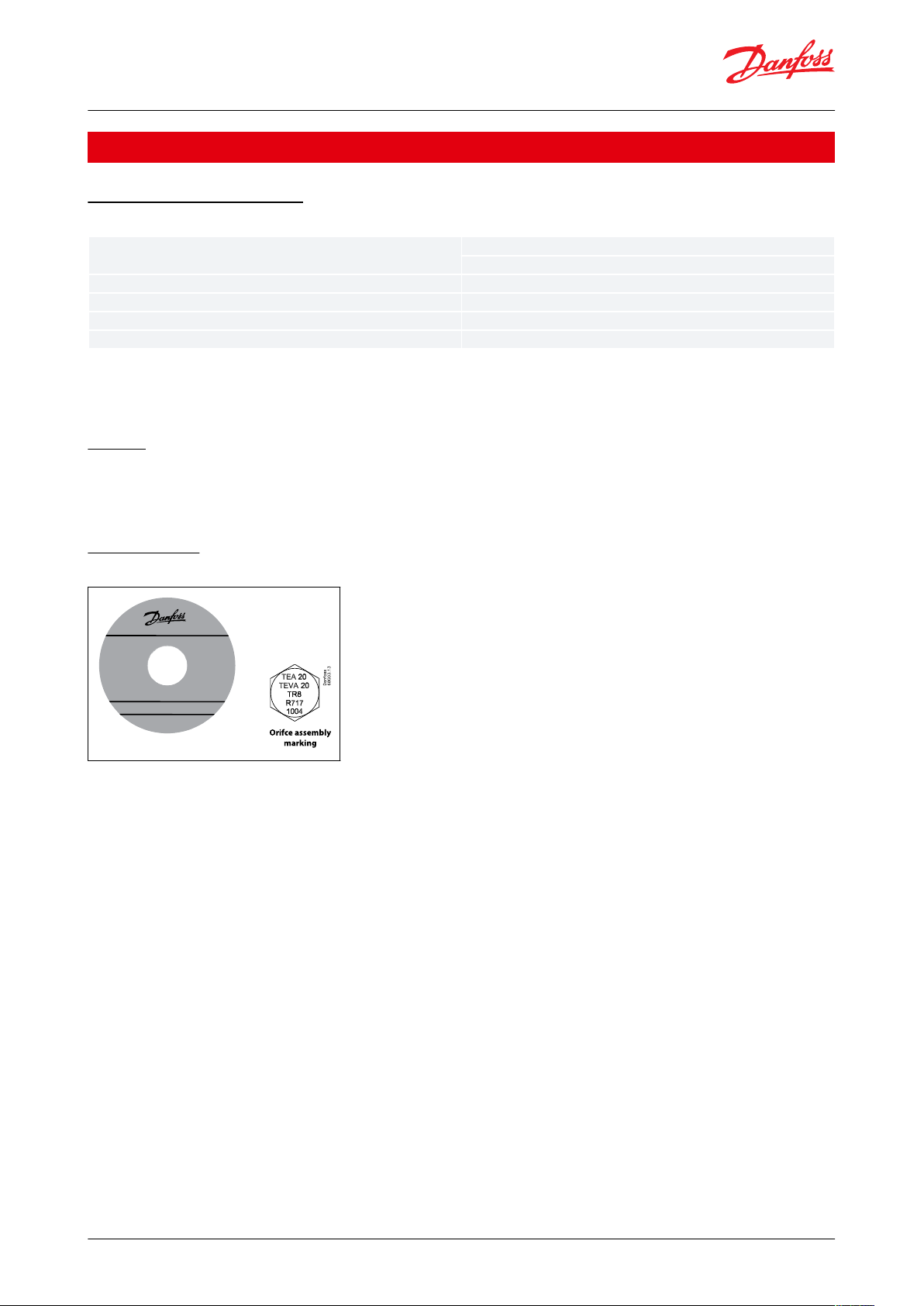

Identication

Figure 1: Element label

The thermostatic element

Has a white label attached to its top. The colour refers to the refrigerant for which the valve is designed: R 717

(Ammonia).

The orice assembly

is marked with

− valve type (TEA 20)

− rated capacity (8 TR = 28 kW)

− refrigerant R717 (NH3)

− date stamp

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 3

Page 4

12345

10

Danfoss

68G68

TEA 20 / TEA 85

Thermostatic element (diaphragm)

Orice assembly

Valve body

Superheat setting spindle (see „Instructions“)

Ext. pressure equalizing connection

Separate outlet orice (for TEA 20-1 only)

Danfoss

68G69

Type

H1H2H3H

4

LBWeight

Excl. strainer

Incl. strainer

Excl. strainer

Incl. strainer

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

[kg]

TEA 20

94382596110

164802.1

3

TEA 85

1043735

106

125

199953

4.5

Thermostatic expansion valves for ammonia, Type TEA

Material specication

Figure 2: TEA

Dimensions and weights

Figure 3: Dimensions and weights

Table 2: Dimensions and weights

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 4

Page 5

Danfoss

68G67

Type and rated

capacity in tons

Rated capacity

(1)

Connection weld anges

Code no.

(TR)

[kW]

Inlet

Outlet

Assembled valve

Separate strain‐

er

(2)

Separate orice

assembly

Separate thermo‐

static element

[in]

[in]

TEA 20, range: -50 °C – 0 °C

TEA 20-1

3.5

1⁄21

⁄2

068G6000

006-0042

068G2050

068G3250

TEA 20-2

7

1⁄21

⁄2

068G6001

068G2051

TEA 20-3

10.5

1⁄21

⁄2

068G6002

068G2052

TEA 20-5

17.5

1⁄21

⁄2

068G6003

068G2053

TEA 20-8

28

1⁄21

⁄2

068G6004

068G2054

TEA 20-12

42

1⁄21

⁄2

068G6005

068G2055

TEA 20-20

70

1⁄21

⁄2

068G6006

068G2056

TEA 20, range : -20 °C – 30 °C

TEA 20-1

3.5

1⁄21

⁄2

068G6137

006-0042

068G2050

068G3252

TEA 20-2

7

1⁄21

⁄2

068G6133

068G2051

TEA 20-3

10.5

1⁄21

⁄2

068G6134

068G2052

TEA 20-5

17.5

1⁄21

⁄2

068G6138

068G2053

TEA 20-8

28

1⁄21

⁄2

068G6139

068G2054

TEA 20-12

42

1⁄21

⁄2

068G6140

068G2055

TEA 20-20

70

1⁄21

⁄2

068G6135

068G2056

TEA 85, range: -50 °C – 0 °C

TEA85-33

115

3⁄43

⁄4

068G6007

006-0048

068G2057

068G3250

TEA 85-55

190

3⁄43

⁄4

068G6008

068G2058

TEA 85-85

295

3⁄43

⁄4

068G6009

068G2059

TEA 85, range: -20 °C – 30 °C

TEA85-33

115

3⁄43

⁄4

068G6141

006-0048

068G2057

068G3252

TEA 85-55

190

3⁄43

⁄4

068G6142

068G2058

TEA 85-85

295

3⁄43

⁄4

068G6143

068G2059

Capacity in kW, range -50 °C – 0 °C

Type and rated

capacity in tons

(TR)

Pressure drop across valve Δp bar

Pressure drop across valve Δp bar

2468101214162468101214

16

Evaporating temperature 0 °C

Evaporating temperature -10 °C

TEA 20-1

2.1

2.9

3.3

3.7

4.1

4.3

4.5

4.8

2.733.3

3.644.2

4.4

TEA 20-2

4.1

5.6

6.5

7.4

8.1

8.699.3

5.266.8

7.588.3

8.7

TEA 20-3

5.9

8.3

9.9

11.2

12.11313.5147.8

9.1

10.1

11.21212.6

13

Thermostatic expansion valves for ammonia, Type TEA

Ordering

Figure 4: TEA

Table 3: Ordering

(1)

(1)

The rated capacity is the valve capacity at -15 °C evaporating temperature and +32 °C condensing temperature. The capacities are based on

The rated capacity is the valve capacity at -15 °C evaporating temperature and +32 °C condensing temperature. The capacities are based on

approx. 4 K subcooling ahead of valve.

approx. 4 K subcooling ahead of valve.

(2)

(2)

The lter is supplied with gaskets, bolts and nuts.

The lter is supplied with gaskets, bolts and nuts.

NOTE:

Subcooling of the liquid in front of the valve is essential for the function of the valve. Lack of subcooling will lead to

malfunction of the valve, and increased wear on the orice.

Table 4: Capacities

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 5

Page 6

Capacity in kW, range -50 °C – 0 °C

Type and rated

capacity in tons

(TR)

Pressure drop across valve Δp bar

Pressure drop across valve Δp bar

2468101214162468101214

16

TEA 20-5

10.5

14.1

16.7

18.6

20.2

21.5

22.4

23.3

12.9

15.1

17.1

18.72020.8

21.5

TEA 20-8

15.7

22.1

26.2

29.73234.3

36.1

37.2

20.9

24.4

27.9

30.2

31.7

33.1

34.3

TEA 20-12

24.4

33.1

39.5

44.5

48.3

51.8

54.7

56.4

31.4

36.6

41.94547.75052.3

TEA 20-20

40.75566.3

74.4

80.9

86.1

90.2

93.7

51.8

60.5

68.6

75.1

79.1

83.3

85.6

TEA 85-33

69.3

92.8

110

122

134

145

151

157

85.6

101

113

122

134

140

145

TEA 85-55

114

151

180

204

221

238

250

256

145

169

186

204

221

233

244

TEA 85-85

180

238

285

320

343

366

384

395

221

256

291

314

337

355

372

Evaporating temperature -20 °C

Evaporating temperature -30 °C

TEA 20-1

2.2

2.6

2.9

3.1

3.3

3.5

3.722.2

2.4

2.6

2.8

2.9

TEA 20-2

4.3

4.9

5.6

6.2

6.6

6.9

7.1

4.1

4.5

4.9

5.2

5.5

5.6

TEA 20-3

6.5

7.4

8.5

9.41010.4

10.6

6.2

6.9

7.4

7.9

8.3

8.5

TEA 20-5

11

12.9

14.4

15.6

16.5

17.2

17.7

10.1

11.3

12.3

13.1

13.7

14.3

TEA 20-8

17.4

20.4

22.72526.2

27.3

27.9

16.31819.8

20.9

22.1

22.7

TEA 20-12

25.6

30.8

34.9

37.2

39.5

41.94325

27.9

30.2

31.4

32.6

33.7

TEA 20-20

44.2

51.2

57.6

61.6

65.7

68.6

72.1

40.7

45.4

49.4

52.3

54.7

57

TEA 85-33

72.1

84.9

94.9

103

109

114

116

68.67580.9

85.6

90.2

94.2

TEA 85-55

116

145

163

174

180

186

192

114

128

140

145

151

157

TEA 85-85

180

221

244

267

279

291

302

174

192

209

221

233

244

Evaporating temperature -40 °C

Evaporating temperature -50 °C

TEA 20-1

1.3

1.7

1.922.2

2.3

1.2

1.3

1.4

1.5

1.6

1.7

TEA 20-2

3.1

3.5

3.844.2

4.4

2.4

2.7

2.833.1

3.3

TEA 20-3

4.8

5.2

5.766.4

6.6

3.7

4.1

4.3

4.5

4.8

5

TEA 20-5

8

8.7

9.4

10.1

10.6116

6.6

7.1

7.6

7.9

8.3

TEA 20-8

12.81415.1

16.3

16.9

17.4

9.3

10.51111.6

12.2

12.8

TEA 20-12

19.2

20.9

22.7

24.4

26.2

27.3

14.5

15.7

16.91819.2

20.4

TEA 20-20

32

35.5

38.4

40.74344.8

24.4

26.2

27.9

29.7

31.4

32.6

TEA 85-33

52.3

58.2

61.6

65.1

68.6

72.1

39.5

43.6

46.5

49.4

51.8

54.1

TEA 85-55

86.8

96.5

104

110

116

122

66.3

72.1

77.8

81.9

86.1

89.6

TEA 85-85

134

151

163

174

180

186

104

113

122

128

134

140

Capacity in kW, range -20 °C – +30 °C

Type and rated

capacity in tons

(TR)

Pressure drop across valve Δp bar

Pressure drop across valve Δp bar

2468101214162468101214

16

Evaporating temperature +30 °C

Evaporating temperature +20 °C

TEA 20-1

2.6

3.4

3.9

4.3

4.6

4.855.2

2.7

3.4

3.9

4.2

4.5

4.8

4.9

5.1

TEA 20-2

4.7

6.5

7.5

8.1

8.7

9.2

9.6

9.9

4.9

6.6

7.5

8.1

8.7

9.1

9.5

9.9

TEA 20-3

5.6

7.8

9.3

10.4

11.4

12.2

12.9

13.5

5.989.6

10.8

11.7

12.5

13.2

13.9

TEA 20-5

11.61619

20.9

22.2

23.4

24.5

25.4

12.1

16.5

19.3

20.9

22.2

23.4

24.4

25.4

TEA 20-8

19.9

27.3

31.3

34.4

36.6

38.6

40.3

41.8

20.7

28.1

31.5

34.2

36.5

38.4

40.1

41.6

TEA 20-12

29.1

39.6

45.3

49.2

52.2

55.2

57.7

59.8

30.2

40.24548.85254.8

57.2

59.3

TEA 20-20

42.9

66.2

74.6

81.1

86.4

90.9

94.8

98.3

50.7

65.9

73.88085.2

89.7

93.7

97.2

TEA 85-33

83

106

122

133

143

150

158

16485106

120

132

141

149

156

163

TEA 85-55

134

179

205

222

236

248

259

268

137

181

202

219

233

245

256

265

TEA 85-85

196

257

297

328

353

374

392

408

200

258

296

326

351

372

390

406

Evaporating temperature +10 °C

Evaporating temperature 0 °C

TEA 20-1

2.6

3.3

3.8

4.2

4.4

4.7

4.952.6

3.2

3.7

4.1

4.3

4.6

4.8

5

TEA 20-2

5.1

6.6

7.488.699.5

9.9

5.2

6.4

7.2

7.9

8.4

8.9

9.4

9.7

TEA 20-3

6.1

8.3

9.81112

12.8

13.5

14.1

6.3

8.51011.2

12.1

12.9

13.6

14.2

TEA 20-5

12.51719.1

20.72223.2

24.3

25.2

12.9

16.8

18.7

20.3

21.7

22.9

23.9

24.9

TEA 20-8

21.3

27.8

31.1

33.73637.9

39.6

41.2

21.8

27.1

30.33335.2

37.23940.5

TEA 20-12

30.9

39.5

44.2

47.9

51.1

53.9

56.3

58.5

31.4

38.4

42.9

46.7

49.9

52.7

55.2

57.4

Thermostatic expansion valves for ammonia, Type TEA

NOTE:

Subcooling ∆t = 4K ahead of the valve.

Table 5: Capacities

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 6

Page 7

Capacity in kW, range -20 °C – +30 °C

Type and rated

capacity in tons

(TR)

Pressure drop across valve Δp bar

Pressure drop across valve Δp bar

2468101214162468101214

16

TEA 20-20

51.6

64.5

72.1

78.2

83.48892

95.6

51.7

62.3

69.87681.3

85.99093.7

TEA 85-33

84

104

118

129

139

147

153

16082101

114

126

135

143

151

157

TEA 85-55

140

178

198

214

228

241

251

261

139

172

192

208

223

235

246

256

TEA 85-85

200

255

292

321

346

367

385

401

196

248

285

314

339

360

378

395

Evaporating temperature -10 °C

Evaporating temperature -20 °C

TEA 20-1

3.1

3.6

3.9

4.2

4.4

4.6

4.8

2.9

3.2

3.5

3.844.2

4.4

TEA 20-2

6.1

6.9

7.5

8.1

8.699.4

5.4

6.2

6.8

7.3

7.8

8.2

8.6

TEA 20-3

8.51011.2

12.1

12.9

13.5

14.1

8.4

9.91111.9

12.51313.4

TEA 20-5

15.6

17.5

19.1

20.4

21.6

22.7

23.6

13.6

15.41718.3

19.4

20.4

21.3

TEA 20-8

24.7

27.8

30.4

32.6

34.6

36.3

37.82124

26.5

28.6

30.43233.4

TEA 20-12

36.9

41.5

45.3

48.6

51.55456.3

32.2

36.7

40.4

43.5

46.3

48.7

50.9

TEA 20-20

59.7

67.3

73.67983.7

87.9

91.7

56.9

64.67176.6

81.4

85.6

89.5

TEA 85-33

97

111

122

131

140

147

15492107

118

128

136

144

150

TEA 85-55

165

185

202

216

229

241

251

158

178

196

211

224

235

245

TEA 85-85

239

276

306

331

352

371

388

230

267

297

323

345

364

381

Description

Values

Evaporator capacity Q

e

265 kW (75.3 TR)

Evaporating temperature t

e

-20 °C (~pe = 1.9 bar)

Condensing temperature t

c

+32 °C (~pc = 12.4 bar)

Subcooling Δt

4K

Thermostatic expansion valves for ammonia, Type TEA

NOTE:

Subcooling ∆t = 4K ahead of the valve.

Example

Table 6: Temperature and cooling data

If the pressure drop Δp1 across pipelines, etc. is calculated, for example, as 0.5 bar, the eective pressure drop across

the thermostatic valve becomes

Δp = pc − pe − p1

Δp = 12.4 − 1.9 − 0.5 = 10 bar.

Now, from the capacity table at an evaporating temperature te = -20 °C and Δp = 10 bar, the capacity is 267 kW.

The column on the far left of this point gives the valve designation: TEA 85-85.

The ordering table gives the code no. for TEA 85-85: 068G6009.

Generally, the maximum capacity of a valve is approx. 20% higher than the value given in the table.

If a dierent capacity is subsequently required, a separate orice assembly with a suitable rated capacity can be

ordered to replace the one tted in the installed valve.

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 7

Page 8

Type

File name

Document type

Document topic

Approval authority

TEA

RU Д- DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

11-1-0310-2012

Explosive - Safety Certicate

GPN

068G9603.00

Manufacturers Declaration

RoHS

Danfoss

UA.TR-089.0993-17

Pressure - Safety Certicate

PED

LLC CDC EURO TYSK

TEA 20

0C14029.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

TEA 85

0C14029.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

Thermostatic expansion valves for ammonia, Type TEA

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 7: Valid approvals

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI172886422449en-000401 | 9

Loading...

Loading...