Page 1

Data Sheet

Thermostatic expansion valve

Type T 2 and TE 2

Thermostatic expansion valves maintain a constant

superheat level at the evaporator outlet

Thermostatic expansion valves regulate the

injection of refrigerant liquid into evaporators.

Injection is controlled by the refrigerant

superheat.

Therefore the valves are especially suitable for

liquid injection in ”dry“ evaporators where the

superheat at the evaporator outlet is

proportional to the evaporator load.

AI241486443133en-001401

Page 2

Thermostatic expansion valve, type T 2 and TE 2

Features

• Large temperature range

◦ Equally applicable to freezing, refrigeration and air conditioning applications.

• Interchangeable orice assembly

◦ easy storage

◦ easy capacity matching

◦ better service.

◦ easy cleaning and replacement of lter

• Rated capacities from 1 to 20.5 kW / 0.3 to 5.8 TR for R407C

• Can be supplied with MOP (Max. Operating Pressure).

◦ Protects the compressor motor against excessive evaporating pressure during normal operation

• Stainless steel bulb and Danfoss patented bulb strap

◦ Fast and easy to install

◦ Good temperature transfer from pipe to bulb

• Valves for special temperature ranges can be supplied

• Design protected

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 2

Page 3

4

3

1

2

Danfoss

68Z05.14.20

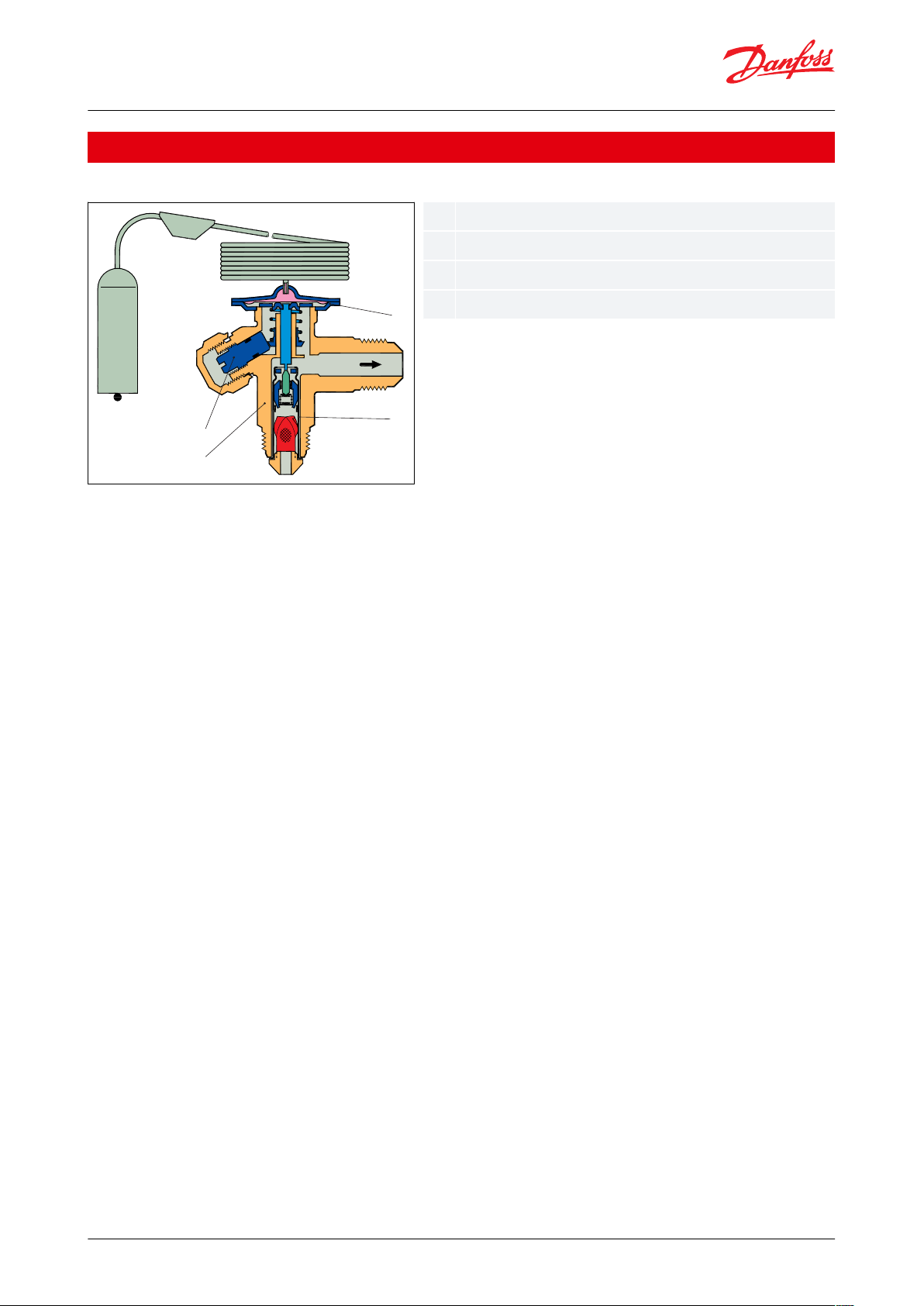

1234Thermostatic element (diaphragm)

Interchangeable orice assembly

Valve body

Superheat setting spindle (see instructions)

Thermostatic expansion valve, type T 2 and TE 2

Functions

Figure 1: Functions

T2 and TE2 valves have an interchangeable orice assembly.

The orice assembly is suitable for all versions of valve body and refrigerants and in all evaporating temperature

ranges.

The charge in the thermostatic element depends on the refrigerant and evaporating temperature range.

The valves are available with internal (T2) or external (TE2) pressure equalization.

External pressure equalization should always be used on systems with liquid distributors. The bulb gives fast and

precise reaction to temperature changes in the evaporator. The bulb is xed with a Danfoss patented bulb strap for

quick, easy and reliable connection. The valves are able to withstand the eects that normally occur with hot gas

defrosting.

To ensure long operating life, the valve cone and seat are made of a special alloy with particularly good wear

qualities.

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 3

Page 4

Refrigerant

Range N

-40 °C – 10 °C

Range NM

-40 °C – -5 °C

Range NL

-40 °C – -15 °C

Range B

-60 °C – -25 °C

MOP-point in evaporating temperature te and evaporating pressure p

e

(1)

15 °C / 60 °F

0 °C / 32 °F

-10 °C / 15 °F

-20 °C / -4 °F

R22

100 psig / 6.9 bar (abs)

60 psig / 4.0 bar (abs)

35 psig / 2.4 bar (abs)

20 psig / 1.4 bar (abs)

R407C

95 psig / 6.6 bar (abs)

–––

R134a

55 psig / 3.8 bar (abs)

30 psig / 2.0 bar (abs)

15 psig / 1.0 bar (abs)

–

R404A/R507

120 psig / 8.3 bar (abs)

75 psig / 5.2 bar (abs)

50 psig / 3.4 bar (abs)

30 psig / 2.1 bar (abs)

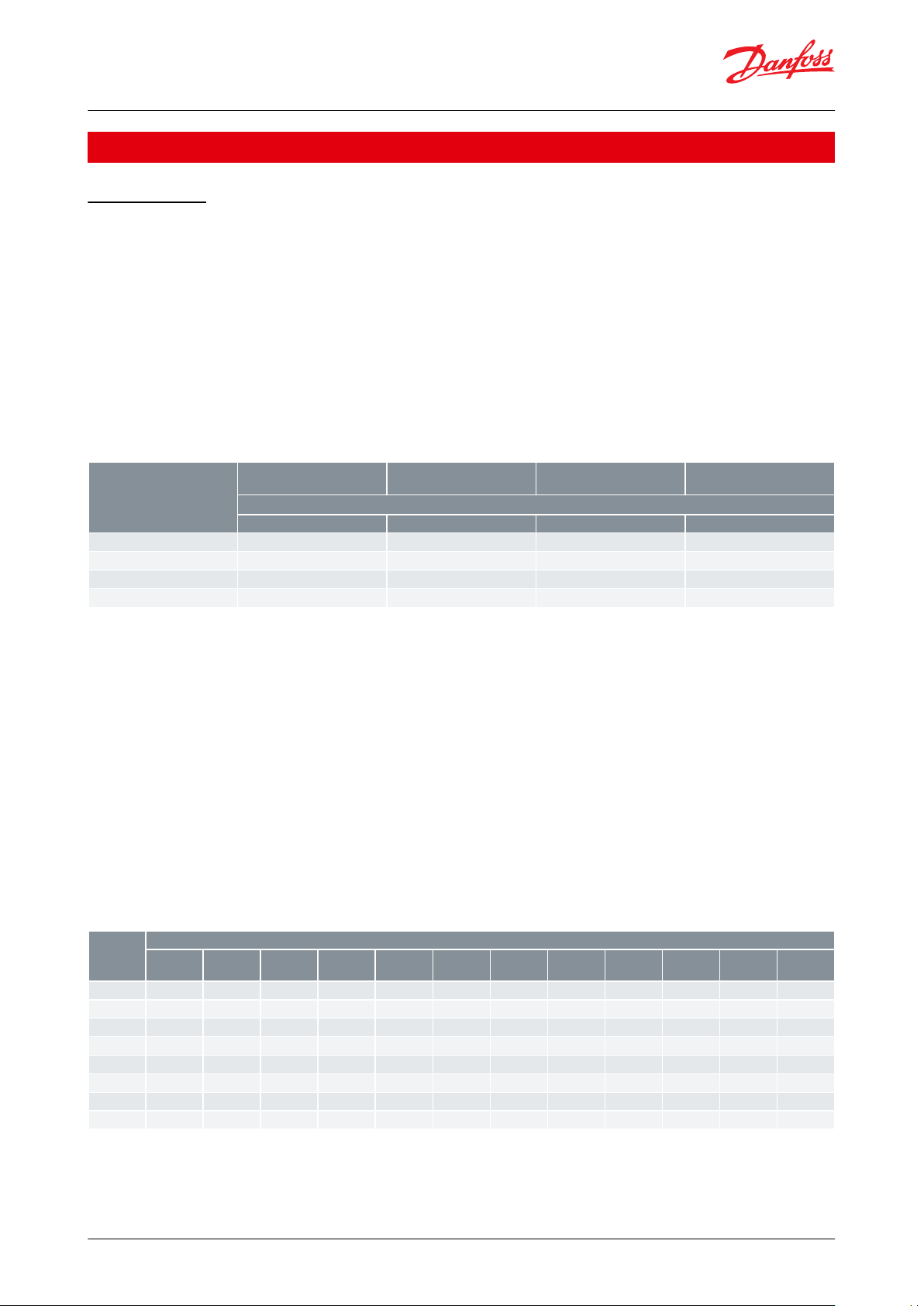

Orice no.

Rated capacity in tons (TR)

R22

R407C

R134a

R513A

R404A

R507

R407A

R407F

R448A

R449A

R454C

R455A

R1234yf

0X

0.25

0.26

0.19

0.16

0.18

0.25

0.28

0.26

0.25

0.22

0.24

0.1400.51

0.51

0.34

0.29

0.37

0.49

0.56

0.51

0.49

0.42

0.47

0.251110.59

0.51

0.7511.110.97

0.79

0.93

0.4321.3

1.4

0.73

0.6211.3

1.5

1.4

1.311.3

0.5332.3

2.3

1.211.8

2.3

2.6

2.3

2.3

1.8

2.2

0.8843.4

3.5

1.8

1.5

2.8

3.5

4.1

3.6

3.5

2.6

3.3

1.354.8

4.7

2.423.7

4.6

5.4

4.6

4.5

3.4

4.2

1.765.6

5.6

2.9

2.5

4.4

5.6

6.5

5.7

5.5

4.2

5.2

2.1

Thermostatic expansion valve, type T 2 and TE 2

Product specication

Technical data

Max. temperature

Bulb, when valve is installed: 100 °C

Bulb, element not mounted: 60 °C

Min. temperature

T2 – TE2: -60 °C

Max. test pressure

PT = 38 bar

Max. working pressure

PS/MWP = 34 bar

Table 1: Technical data

(1)

(1)

Pe in bar gauge

Pe in bar gauge

Superheat

SS = static superheat

OS = opening superheat

SH = SS + OS = total superheat

Q

= rated capacity

nom

Q

= maximum capacity

max

Static superheat SS can be adjusted with setting spindle.

Standard superheat setting SS is 4K for all standard valves.

The opening superheat OS is 6 K from when opening begins to where the valve gives its rated capacity Q

Example

Static superheat SS = 5 K

Opening superheat OS = 6 K

Total superheat SH = 5 + 6 = 11 K

Table 2: Range N: -40 to 50 °F

nom

.

The rated capacity is based on:

Evaporating temperature te = 40 °F

Condensing temperature tc = 100 °F

Refrigerant temperature ahead of valve tl = 98 °F

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 4

Page 5

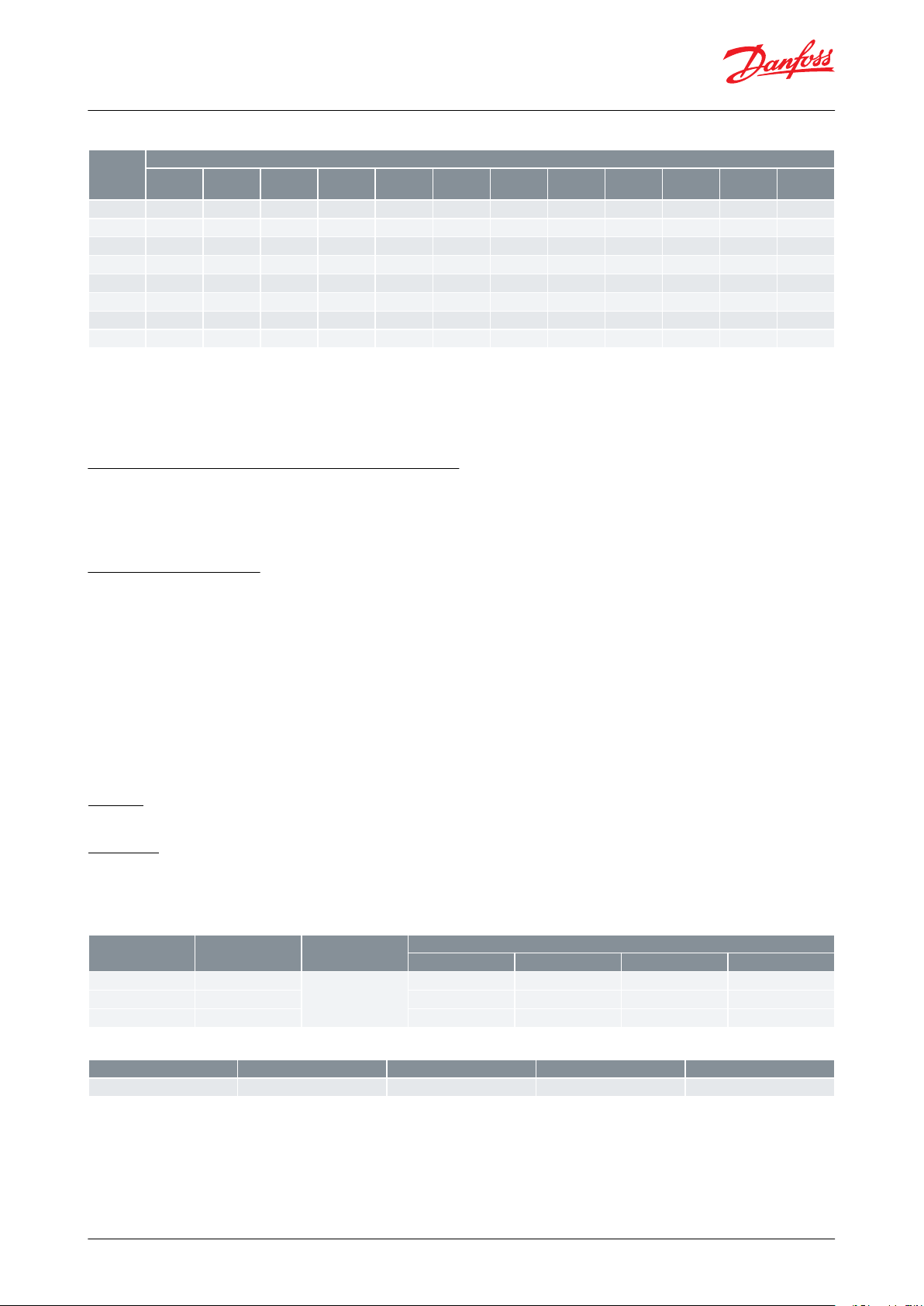

Orice no.

Rated capacity in kW

R22

R407C

R134a

R513A

R404A

R507

R407A

R407F

R448A

R449A

R454C

R455A

R1234yf

0X

0.9

0.92

0.68

0.58

0.64

0.8810.9

0.88

0.77

0.86

0.4901.8

1.8

1.211.3

1.721.8

1.7

1.5

1.7

0.8713.5

3.5

2.1

1.8

2.6

3.4

3.9

3.5

3.4

2.8

3.3

1.524.7

4.8

2.6

2.2

3.7

4.7

5.4

4.8

4.6

3.6

4.4

1.838

8.1

4.3

3.7

6.389.2

8.1

7.9

6.2

7.6

3.1412.1

12.4

6.4

5.4

9.9

12.4

14.3

12.6

12.1

9.3

11.5

4.6516.7

16.5

8.4

6.91316.31916.3

15.7

11.8

14.7

5.9619.7

19.7

10.1

8.6

15.5

19.6

22.9

19.8

19.1

14.8

18.3

7.3

Valve type

Orice

no.

Cond. temp. [°C]

Evaporating [°C]

-40

-30

-20

-10

T2 / TE2

0X250.76

0.83

0.88

0.9

T2 / TE2000.99

1.21

1.42

1.6

T2 / TE211.41

1.8

2.27

2.77

Subcooling [K]241015

Correction factor

0.98

1

1.07

1.12

Thermostatic expansion valve, type T 2 and TE 2

Table 3: Range N: -40 to 10 °C

The rated capacity is based on:

Evaporating temperature te = 4.4 °C

Condensing temperature tc = 38 °C

Refrigerant temperature ahead of valve tl = 37 °C

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

How to select a valve

Example:

Refrigerant = R407C

Q (capacity) = 1.1kW

Tcond (condensing temperature) = 25 °C

Tevap (evaporator temperature) = -30 °C

Tsub (subcooling temperature) = 2 K

Dpd (distributer pressure drop) = 1 bar

Q (capacity) = 1.1kW

fsub (subcooling correction factor) = 0.98

fp (distribution correction factor) = 0.96

Q

fsub× fp

0.98 × 0.96

The selection will be: TE2 orice 00 (1.21 kW > 1.17 kW)

Table 4: Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K

= selectedcapacity

1.1

= 1.17kW

Table 5: Subcooling correction factor 'fsub'

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 5

Page 6

Pressure drop [bar]

Evaporating [°C]

-40

-35

-30

-25

“Pressure drop [bar]”

0111110.96

0.96

0.96

0.96

1.5

0.94

0.94

0.94

0.9420.92

0.92

0.92

0.92

Outlet

Equalization

WeightAB

[kg / lb]

Flare × are

1/2 ” are

1/4 ” are

0.3 / 0.7

Flare × solder

1/2 ” solder

12 mm solder

1/4 ” solder

6 mm solder

0.3 / 0.7

Solder ODF

Weight

[in]

[mm]

[kg / lb]

1/460.05 / 0.11

3/8100.05 / 0.11

Thermostatic expansion valve, type T 2 and TE 2

Table 6: Distributer correction factor 'fp' *

* Calculated at 32 °C condensing temperature

Dimensions and weights

Figure 2: Flare × are (All dimentions are in mm) Figure 3: Flare × solder (All dimentions are in mm)

Table 7: Dimensions and weights

Figure 4: Solder adaptor

Table 8: Solder adaptor

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 6

Page 7

T2

TE2N4511A

internal equalization

external equalization

Nordborg, Denmark (BE = Wuqing, China)

week

2011

Monday

Thermostatic expansion valve, type T 2 and TE 2

Identication

Figure 5: Identication

Production place and date N4511A

The thermostatic element has laser engraved data on top of the diaphragm. This engraving gives valve type (with

code number), evaporating temperature range, MOP point, refrigerant, and max. working pressure. PS/MWP.

Figure 6: Orice assembly and lter for are x are version for T2 and TE2

Orice assembly for T2 and TE2

The orice assembly is marked with the orice size (e.g. 06) and week stamp + last number in the year (e.g. 174).

The orice assembly number is also given on the lid of its plastic container.

Figure 7: Capillary tube label for T2 and TE2

Capillary tube label for T2 and TE2

The label gives the orice size (04) and consists of the lid of the orice assembly plastic container. It can easily be

fastened around the expansion valve capillary tube to clearly identify the valve size.

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 7

Page 8

Refrigerant

Type

Range

MOP

Pressure equliza‐

tion Flare

Connection are inlet × outlet

Code no. Multi

pack

[°C]

[°C]

[in]

[mm]

R22/R407C

(1)

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3206

T2

-40 – 1015–

3/8 × 1/2

10×12

068Z3208

T2

-40 – -50–

3/8 × 1/2

10×12

068Z3224

T2

-40 – -15

-10–3/8 × 1/2

10×12

068Z3226

T2

-60 – -25––

3/8 × 1/2

10×12

068Z3207

T2

-60 – -25

-20–3/8 × 1/2

10×12

068Z3228

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3209

TE2

-40 – 10

15

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3211

TE2

-40 – -5

0

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3225

TE2

-40 – -15

-10

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3227

TE2

-60 – -25

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3210

TE2

-60 – -25

-20

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3229

R407C

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3496

T2

-40 – 1015–

3/8 × 1/2

10×12

068Z3516

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3501

TE2

-40 – 10

15

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3517

R134a/R513A

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3346

T2

-40 – 1015–

3/8 × 1/2

10×12

068Z3347

T2

-40 – -50–

3/8 × 1/2

10×12

068Z3393

T2

-40 – -15

-10–3/8 × 1/2

10×12

068Z3369

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3348

TE2

-40 – 10

15

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3349

TE2

-40 – -5

0

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3392

TE2

-40 – -15

-10

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3370

Thermostatic expansion valve, type T 2 and TE 2

Ordering

T2/TE2 Thermostatic element with bulb strap

Flare x are

Figure 8: Flare x are

Capillary tube: 1.5 m

Range N = -40 – 10 °C

Range B = -60 – -25 °C

Range NM = -40 – -5 °C MOP 0 °C

Range NL = -40 – -15 °C MOP -10 °C

Table 9: Flare x are

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 8

Page 9

Refrigerant

Type

Range

MOP

Pressure equliza‐

tion Flare

Connection are inlet × outlet

Code no. Multi

pack

[°C]

[°C]

[in]

[mm]

R404A/R507

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3400

T2

-40 – 1015–

3/8 × 1/2

10×12

068Z3402

T2

-40 – -50–

3/8 × 1/2

10×12

068Z3406

T2

-40 – -15

-10–3/8 × 1/2

10×12

068Z3408

T2

-60 – -25––

3/8 × 1/2

10×12

068Z3401

T2

-60 – -25

-20–3/8 × 1/2

10×12

068Z3410

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3403

TE2

-40 – 10

15

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3405

TE2

-40 – -5

0

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3407

TE2

-40 – -15

-10

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3409

TE2

-60 – -25

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3404

TE2

-60 – -25

-20

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3411

R407F/R407A

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3715

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3714

R448A/R449A

T2

-40 – 10––

3/8 × 1/2

10×12

068Z3727

TE2

-40 – 10

–

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3728

T2

-40 – -15

-10–3/8 × 1/2

10×12

068Z3675

T2

-60 – -25

-20–3/8 × 1/2

10×12

068Z3735

TE2

-60 – -25

-20

¼ in / 6 mm

3/8 × 1/2

10×12

068Z3736

R454C

T2

-40 – 10-–

3/8 × 1/2

10x12

068Z7483

TE2

-40 – 10

-

¼ in / 6 mm

3/8 × 1/2

10x12

068Z7485

R455A

T2

-40 – 10-–

3/8 × 1/2

10x12

068Z7496

TE2

-40 – 10

-

¼ in / 6 mm

3/8 × 1/2

10x12

068Z7499

R1234yf

T2

-40 – 10-–

3/8 × 1/2

10x12

068Z7487

TE2

-40 – 10

-

¼ in / 6 mm

3/8 × 1/2

10x12

068Z7489

Thermostatic expansion valve, type T 2 and TE 2

(1)

(1)

For R407C plants. Please select valves from the dedicated R407C program

For R407C plants. Please select valves from the dedicated R407C program

Flare x solder

Figure 9: Flare x solder

Capillary tube:1.5 m

Range N=-40 – 10 °C

Range NL = -40 – -15 °C

Range B= -60 – -25 °C

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 9

Page 10

Refrigerant

Type

Range

MOP

Pressure equliza‐

tion Flare

Connection are inlet × outlet

Code no. Multi

pack

[°C]

[°C]

[in]

[mm]

R22/R407C

(1)

T2

-40 – 10––

3/8 × 1/2

–

068Z3281

T2

-40 – 10–––10×12

068Z3302

T2

-40 – 1015–

3/8 × 1/2

–

068Z3287

T2

-40 – 1015––10×12

068Z3308

T2

-40 – -15

-10––

10×12

068Z3366

T2

-60 – -25––

3/8 × 1/2

–

068Z3357

T2

-60 – -25–––10×12

068Z3361

T2

-60 – -25

-20–3/8 × 1/2

–

068Z3319

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3284

TE2

-40 – 10–6 mm–10×12

068Z3305

TE2

-40 – 1015¼ in

3/8 × 1/2

–

068Z3290

TE2

-40 – 10156 mm–10×12

068Z3311

TE2

-40 – -15

-10

6 mm–10×12

068Z3367

TE2

-60 – -25–¼ in

3/8 × 1/2

–

068Z3359

TE2

-60 – -25

–

6 mm–10×12

068Z3363

TE2

-60 – -25

-20

¼ in

3/8 × 1/2

–

068Z3320

R407C

T2

-40 – 10–––10×12

068Z3502

T2

-40 – 1015–

3/8 × 1/2

–

068Z3329

T2

-40 – 1015––10×12

068Z3514

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3446

TE2

-40 – 10–6 mm–10×12

068Z3503

TE2

-40 – 1015¼ in

3/8 × 1/2

–

068Z3447

TE2

-40 – 10156 mm–10×12

068Z3515

R134a/R513A

T2

-40 – 10––

3/8 × 1/2

–

068Z3383

T2

-40 – 10–––10×12

068Z3384

T2

-40 – 1015–

3/8 × 1/2

–

068Z3387

T2

-40 – 1015––10×12

068Z3388

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3385

TE2

-40 – 10–6 mm–10×12

068Z3386

TE2

-40 – 1015¼ in

3/8 × 1/2

–

068Z3389

TE2

-40 – 10156 mm–10×12

068Z3390

R404A/R507

T2

-40 – 10––

3/8 × 1/2

–

068Z3414

T2

-40 – 10–––10×12

068Z3435

T2

-40 – 1015–

3/8 × 1/2

–

068Z3416

T2

-40 – 1015––10×12

068Z3423

T2

-40 – -15

-10–3/8 × 1/2

–

068Z3429

T2

-40 – -15

-10––

10×12

068Z3436

T2

-60 – -25––

3/8 × 1/2

–

068Z3418

T2

-60 – -25–––10×12

068Z3425

T2

-60 – -25

-20–3/8 × 1/2

–

068Z3420

T2

-60 – -25

-20––

10×12

068Z3427

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3415

TE2

-40 – 10–6 mm–10×12

068Z3422

TE2

-40 – 10156 mm–10×12

068Z3424

TE2

-40 – 1015¼ in

3/8 × 1/2

–

068Z3417

TE2

-40 – -15

-10

¼ in

3/8 × 1/2

–

068Z3430

TE2

-40 – -15

-10

6 mm–10×12

068Z3437

TE2

-60 – -25–¼ in

3/8 × 1/2

–

068Z3419

TE2

-60 – -25

–

6 mm–10×12

068Z3426

TE2

-60 – -25

-20

¼ in

3/8 × 1/2

–

068Z3421

TE2

-60 – -25

-20

6 mm–10×12

068Z3428

R407F/R407A

T2

-40 – 10––

3/8 × 1/2

–

068Z3716

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3713

Thermostatic expansion valve, type T 2 and TE 2

Table 10: Flare x solder

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 10

Page 11

Refrigerant

Type

Range

MOP

Pressure equliza‐

tion Flare

Connection are inlet × outlet

Code no. Multi

pack

[°C]

[°C]

[in]

[mm]

R448A/R449A

T2

-40 – 10––

3/8 × 1/2

–

068Z3729

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3730

T2

-40 – -15

-10–3/8 × 1/2

–

068Z3664

T2

-60 – -25

-20–3/8 × 1/2

–

068Z3737

TE2

-40 – -15

-10

¼ in

3/8 × 1/2

–

068Z3665

TE2

-60 – -25

-20

¼ in

3/8 × 1/2

–

068Z3738

T2

-40 – -15

-10––

10×12

068Z3674

TE2

-60 – -25

-20

6 mm–10×12

068Z3672

R452A

T2

-40 – 10––

3/8 × 1/2

–

068Z3806

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z3807

T2

-40 – 10–––10×12

068Z3808

TE2

-40 – 10–6 mm–10×12

068Z3809

R454C

T2

-40 – 10––

3/8 × 1/2

–

068Z7490

T2

-40 – 10–––10x12

068Z7484

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z7492

TE2

-40 – 10–6 mm–10x12

068Z7486

R455A

T2

-40 – 10––

3/8 × 1/2

–

068Z7494

T2

-40 – 10–––10x12

068Z7498

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z7501

TE2

-40 – 10–6 mm–10x12

068Z7500

R1234yf

T2

-40 – 10––

3/8 × 1/2

–

068Z7491

T2

-40 – 10–––10x12

068Z7488

TE2

-40 – 10–¼ in

3/8 × 1/2

–

068Z7493

TE2

-40 – 10–6 mm-10x12

068Z7495

Connection for copper tubing with outside diameter

Reducer for copper tubing with outside diameter

Code no.

[in]

[mm]

[in]

[mm]

1/46––011L1101

3/810––011L1135

1/212––011L1103––

1/46011L1107

Thermostatic expansion valve, type T 2 and TE 2

(1)

(1)

For R407C plants, please select valves from the dedicated R407C program

For R407C plants, please select valves from the dedicated R407C program

Flare connections

Figure 10: Flare connections

Table 11: Flare connections

Example :

A TE2 thermostatic expansion valve consists of two parts + are nuts if required:

• 1 thermostatic element

• 1 orice assembly and are nuts

When ordering one thermostatic expansion valve, TE2 with orice 01, ve code numbers are required:

• 1-o thermostatic element - 068Z3209

• 1-o orice assembly 01 - 068-2010

• 1-o 3⁄8 in are nut - 011L1135

• 1-o 1⁄2 in are nut - 011L1103

• 1-o 1⁄4 in are nut - 011L1101

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 11

Page 12

Danfoss

68Z62.11

Orice no.

Code no.

0X

068-2002

00

068-2003

01

068-2010

02

068-2015

03

068-2006

04

068-2007

05

068-2008

06

068-2009

Danfoss

68z17

Orice

no.

Code no.

0X

068-2089

00

068-2090

01

068-2091

02

068-2092

03

068-2093

04

068-2094

05

068-2095

06

068-2096

Thermostatic expansion valve, type T 2 and TE 2

Orice assembly with lter

Figure 11: Orice assembly with lter

Table 12: Orice assembly with lter

Orice assembly with lter for solder adaptor

Figure 12: Orice assembly with lter for solder adaptor

Table 13: Orice assembly with lter for solder adaptor

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 12

Page 13

Filter type

Code no. Multi pack

For are connection

068-0003

For solder adaptor

068-0015

Danfoss

68-8026

Connection ODF solder

Code no.

1⁄4 in

068-2062

6 mm

068-2063

3⁄8 in

068-2060

10 mm

068-2061

Description

Code no.

Filter excl.

orice assembly

068-0015

Thermostatic expansion valve, type T 2 and TE 2

Filter

Figure 13: Filter

Table 14: Filter

Solder adaptor

Figure 14: Solder adaptor

The adaptor is for use with thermostatic expansion valves T2 and TE2 with are × solder connections. When the

adaptor is tted correctly it meets the sealing requirements of DIN 8964.

The adaptor oers the following advantages:

• The orice assembly can be replaced.

• The lter can be cleaned or replaced.

When using the solder adapter, a special orice assembly is required. Please use the following tables to select both

the appropriate adapter and orice asembly.

Only in this way can the sealing requirements of DIN 8964 be fullled.

Solder adaptor for lter drier (FSA) must not be used in the T2 inlet.

Table 15: Solder adaptor without orice assembly and lter

Table 16: Filter for solder adaptor

Bulb strap (Danfoss patented)

Figure 15: Bulb strap

Each valve is delivered with a Danfoss patented bulb strap. Spares can be ordered.

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 13

Page 14

Description

Pack mode

Quantity / pack

Code no.

Bulb strap 0.4 mm Max. 28 mm tube

I45068U3505

Bulb strap 0.4 mm Max. 50 mm tube

I45068U3506

Bulb strap 0.4 mm Max. 28 mm tube

M25068U3507

Bulb strap 0.4 mm Max. 50 mm tube

M25068U3508

Thermostatic expansion valve, type T 2 and TE 2

Table 17: Bulb strap (Danfoss patented)

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 14

Page 15

File name

Document type

Document topic

Approval_authority

EAC RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

Danfoss 068U9615.06

Manufacturers Declaration

PED/RoHS

Danfoss

Danfoss 068Z9620.00

Manufacturers Declaration

-

Danfoss

Danfoss 068-9601.00

Manufacturers Declaration

-

Danfoss

UA.089.D.00188-17

UA Declaration

PED

LLC CDC EURO TYSK

UA.TR-089.0993-17

Pressure - Safety Certicate

PED

LLC CDC EURO TYSK

Danfoss 068U9616.01

Manufacturers Declaration

China RoHS

Danfoss

Thermostatic expansion valve, type T 2 and TE 2

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 18: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 15

Page 16

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI241486443133en-001401 | 16

Loading...

Loading...