Page 1

Data sheet

TDU.5 floor distribution unit

General description

and application

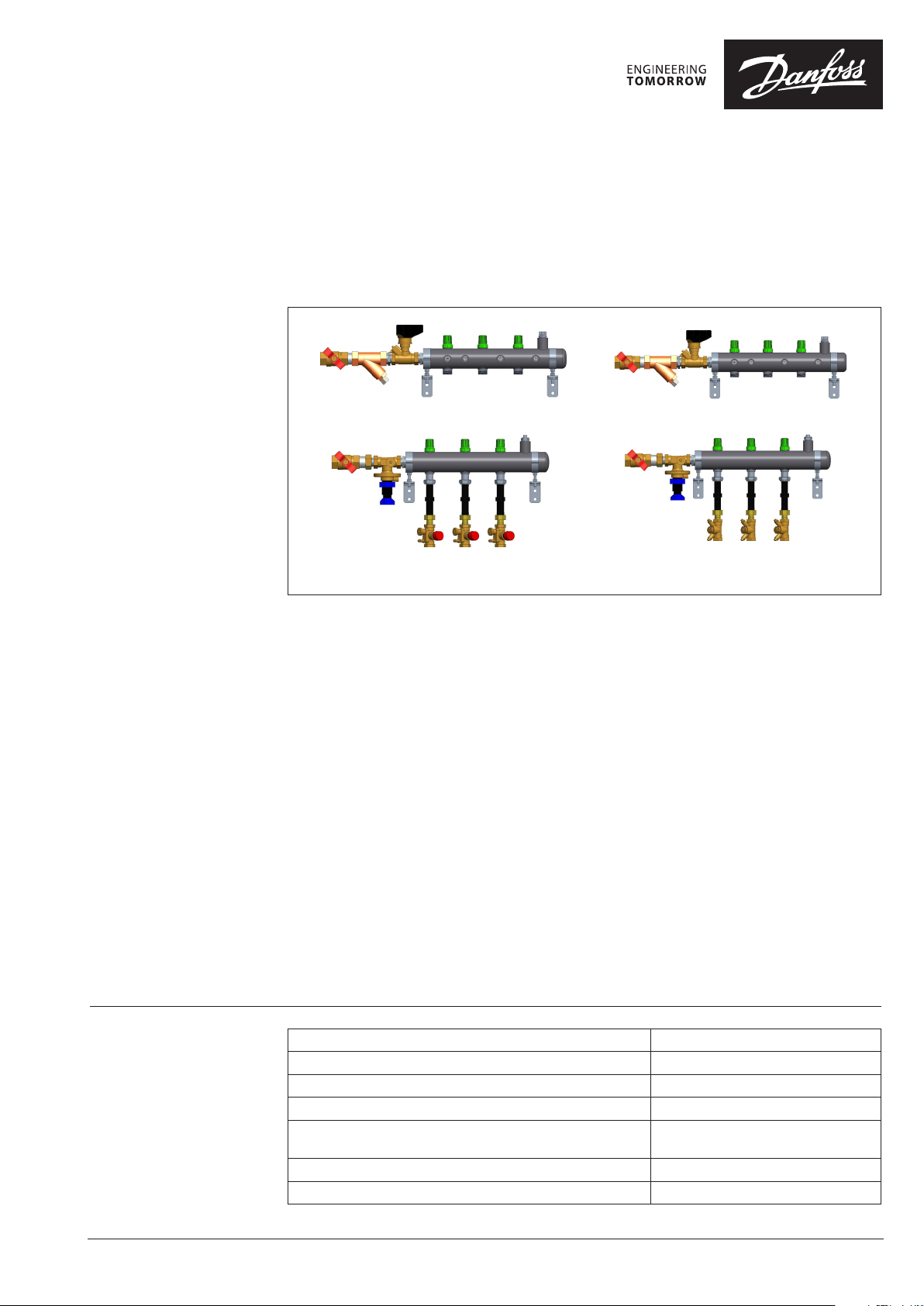

Typ e 1 Typ e 2

General operating

parameters

The TDU.5 floor distribution unit is intended

for two pipe horizontal heating systems and

includes connecting, measuring, regulating and

distribution functions.

The TDU.5 is easily installed on the wall surface

and connected to the riser of heating system.

The apartment horizontal heating systems are

connected to the branches of the unit. Design of

the TDU.5 provides convenient access to all the

elements thus simplifies system adjustment.

The TDU.5 floor distribution units are

manufactured with 2–6 circuits

(left-hand / right-hand versions).

All manifolds are factory insulated with 13 mm

elastomeric insulation.

Design temperature °C 95

Design pressure bar 10

Test pressure, bar 16

Maximum differential pressure in the risers bar 1,5

Setting of differential pressure in the apartment

heating system kPa

Connection to the risers (3 variants) Rp ¾; Rp 1; Rp 1¼

Connection to heating system of apartments Rp ½ – return line

Standard TDU.5 consists of:

On main manifolds DN50

• Automatic balancing valve – differential

pressure controller ASV-PV

• Partner valve with flow limitation

function ASV-BD

• Strainer

• Shut-off valves

• Drain

• Deairing

On branches DN15:

• Heat meter inserts for each apartment

• Type 1: Manual balancing valves USV-I

• Type 2: Control balancing valves RA-HC

The TDU.5 floor distribution units are

manufactured with 2–6 circuits

(left-hand / right-hand versions).

Accessories:

• Cabinets

• TWA actuators for RA-HC

• Room thermostats

• Energy meters

5 – 25

© Danfoss | 2021.09

AI378433154991en-010103 | 1

Page 2

Data sheet TDU.5 floor distribution unit

Designation

Code numbers

Typ e 1

Code Designation

152F0275 TD U.5 2L-20-AS VBD15-A SVPV15-USV I15 2 left RP ¾” 15 USV-I

152F0276 TDU.5 3L-25-ASVBD20-ASVPV20-USVI15 3 left RP 1” 20 USV-I

152F0277 TDU.5 4L-25-ASVBD20-ASVPV20-USVI15 4 left RP1” 20 USV-I

152F0278 TDU.5 4L-32-ASVBD25-ASVPV25-USVI15 4 left R P 1¼” 25 USV-I

152F0279 TDU.5 5L-32-ASVBD25-ASVPV25-USVI15 5 left R P 1¼” 25 USV-I

152F0280 TDU.5 6L-32-ASVBD25-ASVPV25-USVI15 6 left RP 1¼” 25 USV-I

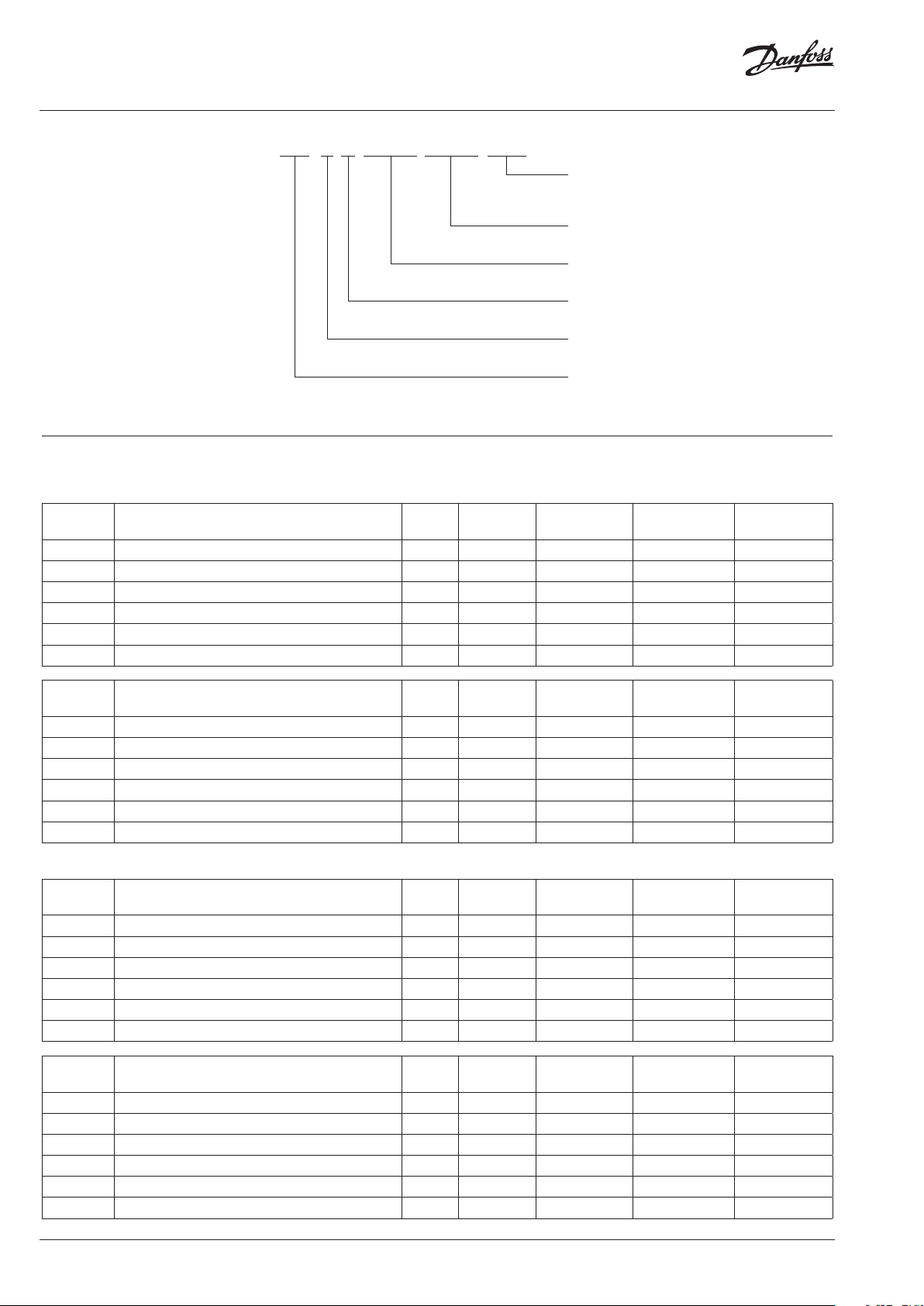

TDU.5 - 4L - 25 - ASVBD20 - ASVPV 20 - USVI15

Circuits

Execution

Balancing in each circuit

USVI15 – manual balancing valve

RAHC15 – control balancing valve

Automatic balancing valve

ASPV15; ASPV20; ASPV25

Partner valve

ASVBD15; ASVBD20; ASVBD25

Connection to risers

(20 – RP ¾; 25 – RP 1; 32 – RP 1¼)

Execution (L – left-hand / R – right-hand)

Number of circuits (from 2 to 6)*

Floor distribution units generation (TDU.5)

* more circuits are available on request

Connection

to risers

DN ASV-PV /

ASV-BD

Branch

Code Designation

152F0281 TDU.5 2R -20 -ASV BD15-AS VPV15 - USVI15 2 right RP ¾” 15 USV-I

152F0282 TDU.5 3R-25-ASVBD20-ASVPV20-USVI15 3 right RP 1” 20 USV-I

152F0283 TDU.5 4R-25-ASVBD20-ASVPV20-USVI15 4 right RP1” 20 USV-I

152F0284 TDU.5 4R-32-ASVBD25-ASVPV25-USVI15 4 right RP 1¼” 25 USV-I

152F0285 TDU.5 5R-32-ASVBD25-ASVPV25-USVI15 5 right R P 1¼ ” 25 USV-I

152F0286 TDU.5 6R-32-ASVBD25-ASVPV25-USVI15 6 right R P 1¼” 25 USV-I

Typ e 2

Code Designation

152F0287 TD U.5 2L-20-AS VBD15-A SVPV15-RAHC15 2 left R P ¾” 15 RA-HC

152F0288 TDU.5 3L-25-ASVBD20-ASVPV20-RAHC15 3 left RP 1” 20 RA-HC

152F0289 TDU.5 4L-25-ASVBD20-ASVPV20-RAHC15 4 left RP1” 20 RA-HC

152F0290 TDU.5 4L-32-ASVBD25-ASVPV25-RAHC15 4 left R P 1¼” 25 RA-HC

152F0291 TDU.5 5L-32-ASVBD25-ASVPV25-RAHC15 5 left RP 1¼” 25 RA-HC

152F0292 TDU.5 6L-32-ASVBD25-ASVPV25-RAHC15 6 left RP 1¼” 25 RA-HC

Code Designation

152F0293 TDU.5 2R-20-ASV BD15 -ASV PV15-RAHC15 2 right RP ¾” 15 RA-HC

152F0294 TDU.5 3R-25-ASVBD20-ASVPV20-RAHC15 3 right RP 1” 20 RA-HC

152F0295 TDU.5 4R-25-ASVBD20-ASVPV20-RAHC15 4 right RP1” 20 RA-HC

152F0296 TDU.5 4R-32-ASVBD25-ASVPV25-RAHC15 4 right RP 1¼” 25 RA-HC

152F0297 TDU.5 5R-32-ASVBD25-ASVPV25-RAHC15 5 right R P 1¼ ” 25 RA-HC

152F0298 TDU.5 6R-32-ASVBD25-ASVPV25-RAHC15 6 right R P 1¼” 25 RA-HC

Circuits

Circuits

Circuits

Execution

Execution

Execution

Connection

to risers

Connection

to risers

Connection

to risers

DN ASV-PV /

ASV-BD

DN ASV-PV /

ASV-BD

DN ASV-PV /

ASV-BD

Branch

Branch

Branch

2 | © Danfoss | 2021.09

AI378433154991en-010103

Page 3

Data sheet TDU.5 floor distribution unit

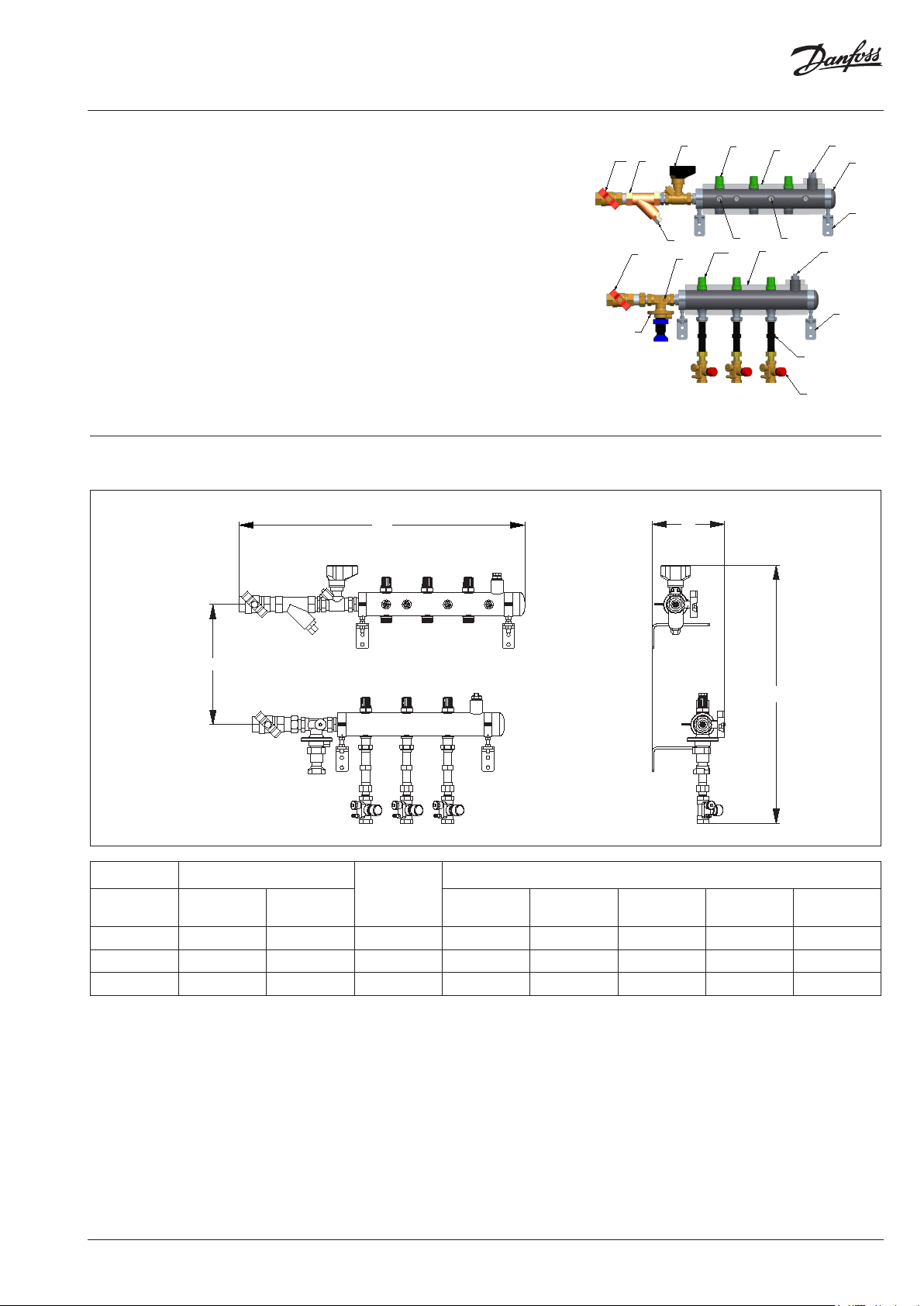

Construction Ball valve with fitting.

1. Shut-off valve

2. Strainer

3. Partner valve ASV-BD

4. Manifold

5. Shut-off valve

6. Automatic balancing valve ASV-PV.

7. Drain valve

8. Clamp

9. Insert for heat meter DN15, L=110 mm.

10. Balancing valve (USV-I/RA-HC)

11. Manual air vent

12. Drain valve

13. Fitting for impulse tube connection. (In case

there is no partner valve)

14. Fitting for temperature sensor connection

15. Insulation

Dimensions

W

1

1

6

3

2

7

12

5

15

13

5

14

15

11

4

8

11

8

9

10

D

*200 mm.

DN Height H, mm *

insret

group

Left

connection

connection

Right

Maximum

depth D,

mm *

Maximum width W, mm * (depending on number if circuits)

2 3 4 5 6 **

20 533 533 177 568 668 768 868 968

25 536 536 177 597 697 797 897 997

32 539 539 188 640 740 840 940 1040

* Overall dimensions in width, depth and height depend on the installation position.

It is allowed to mount the unit without a casing with the collectors displaced vertically and

horizontally within the length of the ASV-PV impulse tube, while maintaining the possibility

of its mounting and dismounting (impulse tube length is 1.5m). The minimum recommended

vertical distance between manifolds is 200 mm.

** More circuits are available on request

H

AI378433154991en-010103

© Danfoss | 2021.09 | 3

Page 4

Data sheet TDU.5 floor distribution unit

Accessories

Cabinets for TDU5

990

DN of

ASV-PV

W

Maximum

height H,

mm

Maximum

depth D,

mm

Maximum width W, mm (depending on number if circuits)

2 3 4 5 6 **

200

15 990 200 750 750 750 850 1000

20 990 200 750 750 850 1000 1000

25 990 200 750 750 850 1000 130 0

Code Execution

Dimensions

H × W × D mm

152F0335 On-wall 990 × 750 × 200

152F0336 On-wall 990 × 850 × 200

152F0337 On-wall 990 × 1000 × 200

152F0339 On-wall 990 × 1300 × 200

** More circuits are available on request

4 | © Danfoss | 2021.09

AI378433154991en-010103

Page 5

Data sheet TDU.5 floor distribution unit

Automatic balancing valves ASV

Design

1. Spring guide

2. Shut-off handle

3. Spring

4. Differential pressure setting

spindle

5. Setting scale

6. O-ring

7. Locking ring

8. Impulse tube connection

9. Diaphragm element

10. Control diaphragm

11. Internal connection

12. Valve body

13. Pressure-relieved valve cone

14. Seat

ASV handling video

Typ e DN

15 1,6 Rp ½

ASV-PV is a compact differential pressure

controller designed to guarantee

high quality of automatic balancing. Innovative

construction and ease of use are incorporated

into the valve with the following features:

• integrated membrane part into valve body

(12) ,

• easy setting with locking function (7),

• flushing function,

• shutt-off function, separated from presetting

• membrane adapted to valve size.

Via an internal connection and together with

the reference spring (3), pressure in the return

pipe acts on the lower side of the control

diaphragm (10) while via an impulse tube (8),

pressure in the flow pipe acts on the top of

the diaphragm. In this way the balancing valve

maintains adjusted differential pressure.

The valves factory set to 30 kPa. They can be

easily adjusted to another setting using setting

scale (5). Turning the setting ring clockwise

increases the setting; turning it counter clockwise

reduces the setting.

k

[m3/h]

vs

Connection

p setting

range [kPa]

Code no.

003Z5501

20 2,5 Rp ¾ 003Z5502

25 4,0 Rp 1 003Z5503

ASV-BD shut-off valve, multifunctional partner

valve (shut-off, rotating measuring station)

Typ e DN

k

[m3/h]

vs

Connection Code No.

15 3,0

20 6,0 Rp ¾ 003Z4042

internal

thread

25 9,5 Rp 1 003Z4043

Manual balancing

valve USV-I

003Z 2131

Design USV-I

USV valves are designed for manual hydronic

balancing of heating and cooling systems. USV-I

(red knob) is used to limit the flow in heating or

cooling installation or can work separately as

1. Shut-off knob

2. Shut-off spindle

3. Setting spindle

4. Scale disc

5. O-ring

6. Valve cone

7. Valve body

5 – 25

Rp ½ 0 03Z40 41

manual balancing valves for flow limitation. If

certain pipe sectors do not require a control of

differential pressure, USV-I can be used as shutoff- and measuring valve.

AI378433154991en-010103

For USV-I adjustment please consult product data sheet.

© Danfoss | 2021.09 | 5

Page 6

Data sheet TDU.5 floor distribution unit

Control valve RAHC

Description

Accesories:

TWA actuators for RAHC

The RA-HC is a control valve applied together

with Danfoss electronic controls.

Combined with Danfoss thermo actuators (TWA)

the RA-HC valves provide On / Off control, control

the flow over the terminal unit and maintain

optimum temperatures based on room load

requirements.

RA-HC valves have eight presettings, thus the

correct quantity of water flow is ensured for each

circuit.

Typ e

DN 15 G ½ no 16 1,8 −10 ... 100 003Z3932

* The max. differential pressure specified is the maximum pressutre at which the valves give

satisfactory regulation. As with any device which imposes a pressure drop on the system, noise

may occur under certain flow / pressure conditions.

For RA-HC adjustment please consult product data sheet.

manual shut off knob – 013G330 0

Connection

(*)

Typ e

TWA-A NC

TWA-A NO 08 8 H3111

TWA-A NC

TWA-A NO 088 H 3113

Test plugs

Connection

type

RA

RA-HC matches high flow capacities and with its

compact design only little installation space is

required.

The RA-HC with TWA

• Balancing and control function

• High flow capacity

• Compact design, requires

small installation space

• Easy presetting, no tools required

• Shut-off (for isolation during system

maintenance) using manual shut off knob.

Max.

working

pressure

Supply

voltage

24V

AC / DC

230V

AC

Max. diff.

Pressure

with TWA-A

Code No.

08 8 H3110

08 8 H3112

Medium

temp.

(°C)

Code No.

6 | © Danfoss | 2021.09

AI378433154991en-010103

Page 7

Data sheet TDU.5 floor distribution unit

Accesories:

Room thermostats

RET1000

Smart Room

Thermostat

087N6450

RET1000 Smart Room Thermostats combine

sleek modern design with high performing

energy saving control. Chrono-proportional

control significantly improves comfort and

generally improves boiler efficiency by

optimising water temperature.

• Selectable Chrono Proportional

or On/Off control

• User Set Upper

and Lower Temperature Limits

• Output On Indication

• Power Indication

TPOneTM Series

Programmable

Room

Thermostat

087N7851

Danfoss Icon™

Programmable

TPOne Programmable Room Thermostat

platform delivers new levels of user friendly

interaction.

Additional TPOne features include:

• Seperate User & Installer Setting Menus

• Holiday Scheduler

• Upper and Lower Temperature Limits

• Capacitive Touch Button Control

• Push Button Lock

• °C or °F Selectable Display

• Audible Button Click (selectable)

• Frost Protect Temperature Setting

• Selectable Domestic Hot Water Channel

(Mains Variant only)

• Clear Text Display (7 Languages)

• External Sensor/Window Switch input

• Boiler Service Timer

Danfoss Icon™ is a range of flush and surface

mounted room thermostats for hydronic

floor

heating applications.

Features

• Accurate PWM-control

• Compatible with 3’rd party wall frames

• Shine through display with mode keys

• 7 pre-defined schedules and forecast

• Range limitation via user menu

• Neutral design and simple user interface

• Frost protection setting

• Can be used with 230V NC or NO

actuators

• Can be optimized for different

heatsources via service menu

• Valve exercise feature

• Can be used in systems with cooling

• Has input for global setback

• Can be used with floor sensor (optional)

• Very high UV-resistance

AI378433154991en-010103

© Danfoss | 2021.09 | 7

Page 8

Data sheet TDU.5 floor distribution unit

T

ar

f

c

a

d

Accesories:

SonoSelect 10 and

SonoSafe 10 Energy Meters

he Danfoss SonoSelect 10 and SonoSafe 10

e ultrasonic compact energy meters intended

or measuring energy consumption in heating,

ooling and combined heating and cooling

pplications for billing purposes. The meters are

The energy meters consist of an ultrasonic flow

sensor, a pair of Pt1000 temperature sensors

and a calculator with integrated circuits for

temperature measurement, flow calculation and

energy calculation.

esigned for remote meter read-out (AMR).

Feature highlights:

• Proven ultrasonic measuring principle designed for long operating life time

• No calming section or inlet/outlet restrictions

• Low pressure drop down to 0.03 bar at q

• Large 85 x 35 mm LCD display with 8 digits (11.5 mm high), guiding menu and info panel

• Compact design

• Extensive change and error log

• Memory: 4 years of data, yearly and monthly values stored (incl. pulse input)

• Upgradable with communication modules in bracket (dual M- Bus, connection with water meter)

• Power supply 3.6V battery (replacable) or 230V mains power

• Communication baud rate 300, 2400, 4800 and 9600 bps

• SonoApp usable for Android (Bluetooth LE via dongle)

Special

features:

Batter y • 16 + 1 years batter y life (from production date) • 10 + 1 years battery life

Flexibility

Safety

SonoApp

SonoSelect 10 SonoSafe 10

• Heating or cooling or combined heating and cooling

• Supply and return can be configured on site

• Energy units can be configured on site

• Slot for communication upgrade

• 1.5m PUR or silicone cable between calculator and flow

sensor allow for flexible installation, e.g. in flat stations

• EN1434 class 2 + flow and energy calculated every 0.5

second

• Tamper monitor sets alarm if meter is opened by

unauthorized personnel

• Diagnostic function to secure confidence in meter data

• IP65 calculator

• Reverse flow indication

• Installer tool (Guides and configure e.g. AMR, Pulse, units,

supply/return)

• Commissioning tool (Link location to s

• Operation tool (walk by + diagonstics)

p

• Heating

erial number)

• Energy units can be configured on site

• Slot for communicatio

• 0.5 m cable PVC between calculator and

flow sensor

• EN1434 class 2 + flow and energy calculated

every 2 seconds

• IP54 calculator

• Installer tool (Guides and configure e.g.

AMR, Pulse, units)

• Operation tool (walk-by)

• Commissioning tool (Link location to serial

number)

n upgrade

8 | © Danfoss | DCS-SGDPT/PL | 2021.09

AI378433154991en-010103

Loading...

Loading...