Installation Guide

Shut-off valves

STC 15 - 150 (½ - 6 in.)

Installation - 安装

148R9623

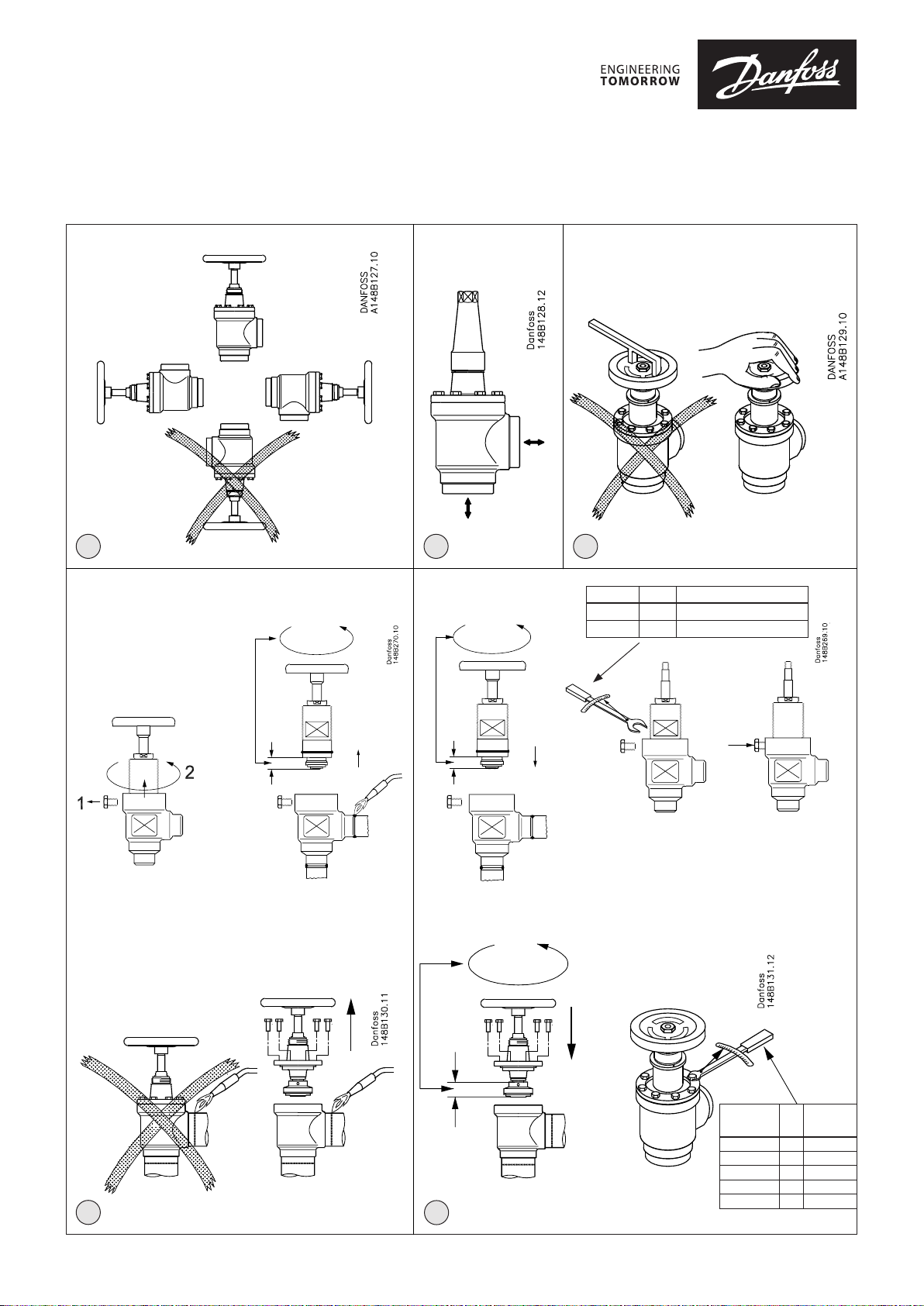

1 2 3

STC 15-40 STC 15-40

148R9623

Nm LB-feet (磅英尺)

DN 15-25 80 60

DN 32-40 120 88.5

STC 50-150 STC 50-150

4

© Danfoss | DCS (mwa) | 2019.01

5

LB-feet

Nm

(磅英尺)

DN 50 36 26

DN 65 62 45

DN 80 36 26

DN 100 62 45

DN 125-150 130 95

AN14898641672401zh-410402 | DKRCI.PI.KK0.D3.2P | 1

Maintenance - 维护

148B8125_06-2014

Danfoss

148B8126_06-2014

STC 15-40 STC 50-150 STC 15-40 STC 50-150

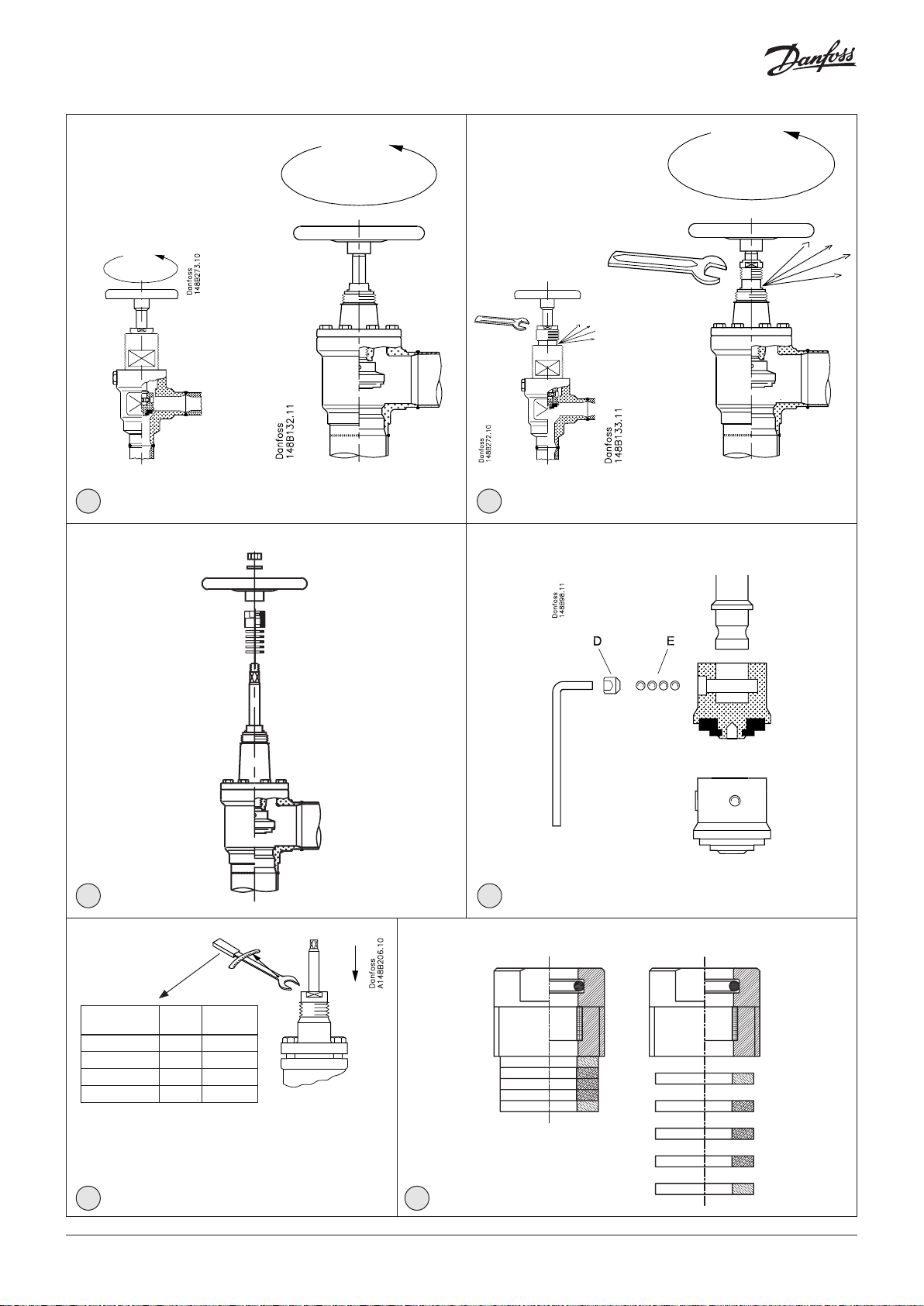

6 7

Danfoss

8 9

Nm LB-feet

(磅英尺)

DN 15-25 30 22

DN 32-40 40 29.5

DN 50-65 50 37

DN 80-150 120 88.5

DN 15-150

10

© Danfoss | DCS (mwa) | 2019.01

11

AN14898641672401zh-410402 | DKRCI.PI.KK0.D3.2P | 2

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC and R717

(Ammonia).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use in closed circuits. For

further information please contact Danfoss.

Temperature range

STC: –50/+150°C (–58/+302°F)

Pressure range

The valves are designed for a max. working

pressure of 25 bar g (363 psi g).

Installation

The valve must be installed with the spindle

vertically upwards or in horizontal position

(fig. 1). Valves should be opened by hand

without the use of tools or other devices (fig.

3). The valve is designed to withstand a high

internal pressure. However, the piping system

should be designed to avoid liquid traps and

reduce the risk of hydraulic pressure caused

by thermal expansion. It must be ensured

that the valve is protected from pressure

transients like “liquid hammer” in the system.

Attention!

STC are shut off valves and must always be

either fully closed or fully open. Half open

positions are not allowed.

Recommended flow direction

To achieve optimum flow conditions, the

valve should be installed with the flow

towards the valve cone as indicated by the

arrow on the side of the valve body

(fig. 2). Flow in the opposite direction is also

acceptable (fig. 2), but slightly reduces the

- / Cv value.

k

v

Welding

The bonnet should be removed before

welding (fig. 4) to prevent damage to the

O-rings in the packing gland and between

the valve body and bonnet, as well as the

teflon gasket in the valve seat. Only materials

and welding methods, compa-tible with the

valve housing material, must be welded to

the valve housing. The valve should be

cleaned internally to remove welding debris

on completion of welding and before the

valve is reassembled.

Avoid welding debris and dirt in the threads

of the housing and the bonnet.

Removing the bonnet can be omitted

provided that:

The temperature in the area between the

valve body and bonnet during welding does

not exceed +150°C/+302°F. This

temperature depends on the welding

method as well as on any cooling of the valve

body during the welding itself.

(Cooling can be ensured by, for example,

wrapping a wet cloth around the valve body.)

Make sure that no dirt, welding

debris etc. get into the valve during the

welding procedure.

Be careful not to damage the teflon cone ring.

Stop valves must not be mounted in

sy-stems where the outlet side of the valve is

open to atmosphere. The outlet side of the

valve must always be connected to the

system or properly capped off, for example

with a welded-on end plate.

Assembly

Remove welding debris and any dirt from

pipes and valve body before

assembly. Check that the cone has been fully

screwed back towards the bonnet

before it is re-placed in the valve body.

Tightening

Tighten the bonnet with a torque wrench, to

the values indicated in the table

(fig. 5).

Colours and identification

The STC valves are painted with a gray oxide

primer in the factory. The external surface of

the valve housing must be guarded against

corrosion with a suitable protective coating

after installation and

assembly.

Maintenance

Packing gland

When performing service and mainte-nance,

replace the complete packing gland only,

which is available as a spare part. As a general

rule, the packing gland must not be removed

if there is internal pressure in the valve.

However, if the following

pre-cautionary measures are taken, the

packing gland can be removed with the valve

still under pressure:

Backseating (fig. 6)

To backseat the valve, turn the spindle

counter-clockwise until the valve is fully open.

Pressure equalization (fig. 7)

In some cases, pressure forms behind the

packing gland. Hence a handwheel or

similar should be fastened on top of the

spindle while the pressure is equalized. The

pressure can be equalized by slowly screwing

out the gland.

Removal of packing gland (fig. 8)

Handwheel and packing gland can now be

removed.

Dismantling the valve

Do not remove the bonnet while the valve is

still under pressure.

Check that the O-ring has not been

damaged.

Check that the spindle is free of scratches

and impact marks.

If the teflon cone ring has been damaged,

the whole cone assembly must be

replaced.

Note! For all sizes DN15~150 Teflon

gaskets should not be re-used after

removing the spindle seal.

Fitting a replacement spindle seal for DN

15-40 (fig. 11)

Great care should be taken when fitting a new

spindle seal and damage to

Teflon gaskets must be avoided.

During fitting, the individual components in

the spindle seal should be placed in order and

positioned as shown (fig. 11).

Replacement of the cone (fig. 9)

Unscrew the cone screw (pos. D) with an Allen

key.

STC 15-40 .................................................2.0 mm A/F

STC 50-65 .................................................2.5 mm A/F

STC 80-100 ................................................. 4 mm A/F

STC 125-150 .............................................. 5 mm A/F

(An Allen key is included in the Danfoss

Industrial Refrigeration gasket set).

Remove the balls (pos. E).

Number of balls in pos. E:

STC 15-25 ..........................................................10 pcs.

STC 32-65 ..........................................................14 pcs.

STC 80-150 ......................................................13 pcs.

The cone can then be removed. Place the new

cone on the spindle and replace the balls.

Refit the cone screw in again using Loctite

No. 648. to ensure that the screw is properly

fastened.

Assembly

Remove any dirt from the body before the

valve is assembled. Check that the cone has

been screwed back towards the

bonnet before it is replaced in the valve body

(fig. 5).

Tightening

Tighten the bonnet with a torque wrench, to

the values indicated in the table (fig. 5b).

Tighten the packing gland with a torque

wrench, to the values indicated in the table

(fig. 10).

For all sizes DN15~150: If the packing gland is

leaking, it is possible to carefully tighten it

with a wrench. Make sure not to apply very

high force. Danfoss recommend turning the

packing gland in steps and to check the

leaking between each step.

Use only original Danfoss parts, including

packing glands, O-rings and gaskets for

replacement. Materials of new parts are

certified for the relevant refrigerant.

In cases of doubt, please contact

Danfoss.

The valve housing must be free from stresses

(external loads) after installation.

© Danfoss | DCS (mwa) | 2019.01

AN14898641672401zh-410402 | DKRCI.PI.KK0.D3.2P | 3

简体中文

安装

制冷剂

适用于 HCFC、非可燃性 HFC 和 R717

(氨)。

不推荐使用易燃的碳氢化合物。

STC只推荐用于封闭管路系统中。

有关更多信息,请联系 Danfoss。

温度范围

STC: –50/+150°C (–58/+302°F)

压力范围

阀门的最大设计工作压力为 25 bar g

(363 psi g)。

安装

‘安装阀门时,阀杆必须垂直向上或处于

水平位置(图 1)。

应手动操作打开阀门,不可使用工具或其

他装置(图 3)。

虽然阀门在设计上可承受高压,但是,

设计管道系统时应避免出现急弯(如U型

或S型管路),以减少由于热力膨胀引起

的压力冲击风险。

必须防止阀门受系统中瞬时压力冲击

(如:液击)的影响。

注意!

STC 是一种截止阀,必须始终保持全关或

全开状态。

使用时不允许处于半开状态。

推荐的流向

为了获得最佳的流动特性,应当根据阀体

上箭头指示的流体流动方向安装阀门

(图 2)。

阀门也可接受与指示方向向反的流向

(图 2),但此种情况下会稍微降低

k

- / Cv 值。

v

焊接

焊接前应当 拆下阀盖(图 4),以防止

损坏填料函内、阀体与阀盖之间的

O 形圈,以及阀芯上的聚四氟乙烯垫圈。

焊接阀体时,只可采用与其兼容的材料和

焊接工艺。

焊接完成时,在重新组装之前应当清除阀

体内焊渣。

阀体和阀盖螺纹上应避免焊渣和灰尘。

在下列情况中,无需拆下阀盖:焊接时,

阀体和阀盖之间区域的温度不超过

+150°C/+302°F。

此温度取决于焊接工艺,以及阀体在焊接

过程中的冷却情况。

(例如可以在阀体上包裹湿布对其进行冷

却。)焊接过程中要避免灰尘、

焊接碎屑等异物进入阀体内。

小心不要损坏聚四氟乙烯阀芯密封垫圈。

组装

组装前,清除管道和阀体中的焊渣和灰

尘。

将阀芯装回阀体之前,检查并确保其处于

最大开度位置。

拧紧

使用扭矩扳手依据表中指定的力矩值将阀

盖拧到阀体上(图 5)。

颜色和识别

STC 在出厂时其表面喷有一层灰色的水

性底漆。

焊接和装配结束后,阀门必须使用适当

的保护涂层,以防止阀体的外表面受到

腐蚀。

维护

填料函

维修保养时,只可整体更换填料函组件,

该组件作为备件出售。 作为常识,

禁止在阀门内部仍承压时拆下填料函。

但是,如果采取下列的预防措施,

即使阀门承压时,也能拆除填料函。

背密封(图 6)

需要使用背密封时,逆时针旋转阀杆至阀

门处于全开位置即可。

压力平衡(图 7)

在某些情况下,填料函下会形成压力。

因此平衡压力时应该将手轮或类似物固定

在阀杆顶部。

慢慢地拧松填料函,即可平衡压力。

拆除主轴密封(图8)

现可拆除手轮及其它轴密封件。

拆除阀门

当阀门承压时,请勿拆除阀盖

确认 O 形环没有受损。

确认阀杆无刮伤和撞击痕迹。

如果聚四氟乙烯阀芯垫已损坏,则必须

更换整个阀芯配件。

注意!对于DN15-150的阀门,拆除主轴

密封后聚四氟乙烯垫片不可重复使用。

安装主轴密封配件 针对DN15-40 阀门(图

11)

安装新的主轴密封时应格外小心并同时避免

损坏聚四氟乙烯垫片。

主轴密封的各个组件安装顺序及位置如图。

(图11)

更换阀芯(图 9)

使用艾伦内六角扳手旋开阀芯螺钉

(位置 D) 。

STC 15-40.................2.0 mm A/F

STC 50-65.................2.5 mm A/F

STC 80-100..................4 mm A/F

STC 125-150 ................5 mm A/F

(Danfoss 工业制冷密封垫套装内含有艾

伦内六角扳手)。

拆除滚珠(位置 E)。

E处滚珠的数目:

STC 15-25 ....................10 个

STC 32-65 .....................14 个

STC 80-150 ....................13 个

此时可以拆除阀芯。

将新阀芯放在阀杆上并更换滚珠。

用Loctite No.648处理阀芯锁紧螺丝后再

次拧紧, 确保锁紧螺丝被适当固定。

组装

‘安装阀门之前,清除阀体上的所有灰

尘。

将阀芯装回阀体之前,请检查阀芯是否已

拧至最大开度位置。

(图 5)。

拧紧

使用扭力扳手将阀盖地拧到阀体上,

力矩如表所示 (图 5b)。

使用扭力扳手将填函拧到阀体上,

力矩如表所示(图 10)。

针对DN15-150的阀门,如果填料函发生泄

漏, 可以用扳手小心的再次拧紧,但是

要确保不能使用过高的扭力。丹佛斯建议

分步地拧紧填料函,这样可以在每拧紧一

步后确认是否还有泄漏而不至于实施过大

扭力。

只可使用原装的 Danfoss 部件

(包括填料函、O 形环和密封垫)

来更换。

新部件的材料经认证适用于相关的制冷

剂。

如有疑问,请与 Danfoss 办事处联系。

安装完成后,阀体必须进行应力卸载

(外部卸载)。

截止阀禁止安装在一端出口直接对空的系

统中。

阀的出口端必须与系统连接或适当的封

闭,如焊接端封闭。

© Danfoss | DCS (mwa) | 2019.01

AN14898641672401zh-410402 | DKRCI.PI.KK0.D3.2P | 4

Loading...

Loading...