Data Sheet

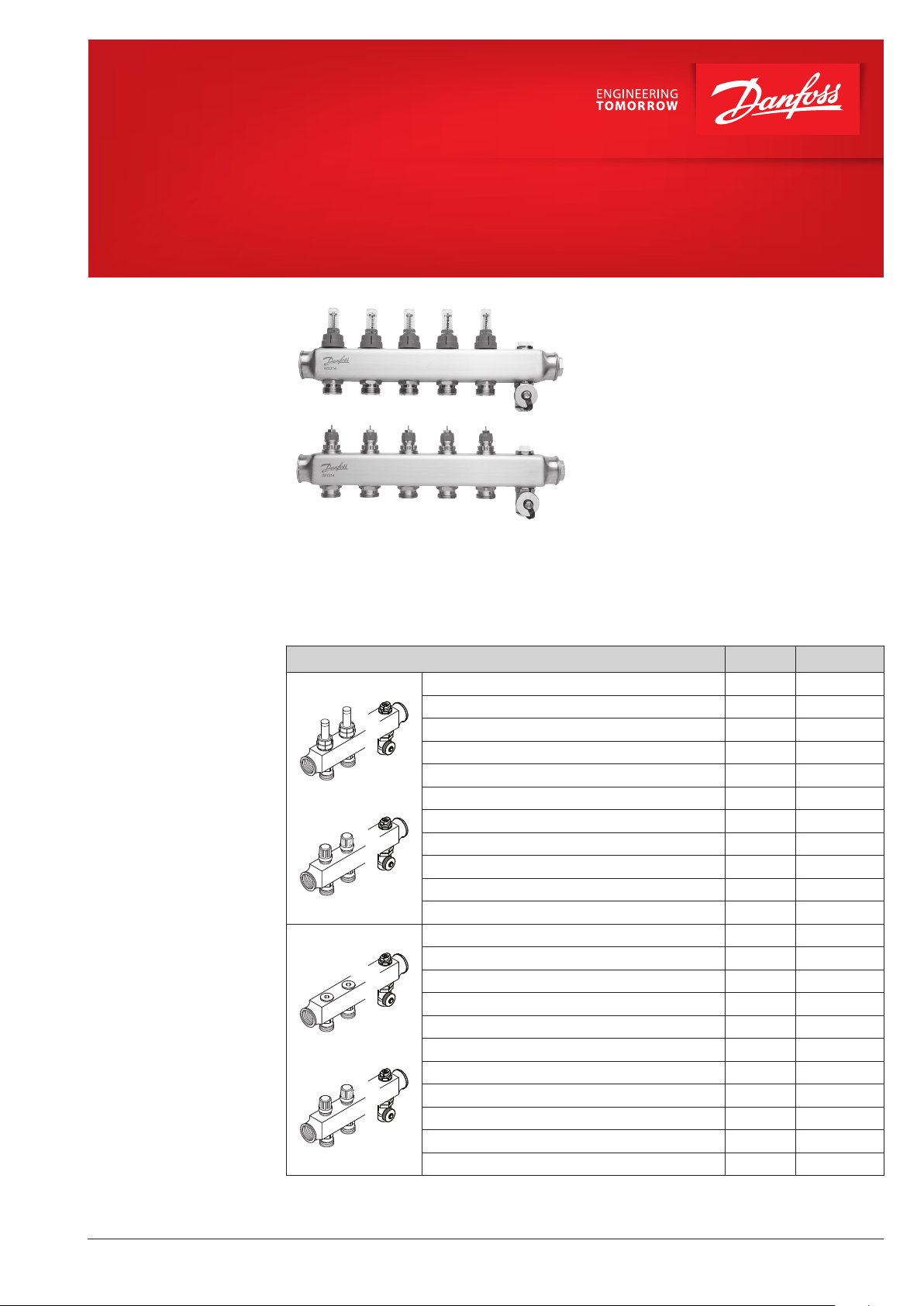

SSM Floor Heating Manifold

Application

Ordering

The manifold consists of a supply and return manifold. The supply manifold includes possibility for

individual shut-off of each circuit on flowmeter

or shut-off valve. The return manifold is equipped

with integrated Danfoss presetting valves securing optimal hydraulic balance in the system.

The valves can be controlled electronically by thermal actuators or act as self-acting units by means

of remote temperature adjusters.

The manifold is supplied in modules of up to

12 outlets. Ball valves are available as an option for

The SSM manifold is used for controlling water

flow in under floor heating systems. Each tube of

the floor heating system is connected to the manifold, thus making it possible to control water flow

or heat supply to each room in the building individually.

Description Type Code no.

Manifold set 2+2, with flowmeter SSM-2F 088U0752

Manifold set 3+3, with flowmeter SSM-3F 088U0753

Manifold set 4+4, with flowmeter SSM-4F 088U0754

Manifold set 5+5, with flowmeter SSM-5F 088U0755

Manifold set 6+6, with flowmeter SSM-6F 088U0756

Manifold set 7+7, with flowmeter SSM-7F 088U0757

Manifold set 8+8, with flowmeter SSM-8F 088U0758

Manifold set 9+9, with flowmeter SSM-9F 088U0759

Manifold set 10+10, with flowmeter SSM-10F 088U0760

Manifold set 11+11, with flowmeter SSM-11F 088U0761

Manifold set 12+12, with flowmeter SSM-12F 088U0762

Manifold set 2+2 SSM-2 088U0802

Manifold set 3+3 SSM-3 088U0803

Manifold set 4+4 SSM-4 088U0804

Manifold set 5+5 SSM-5 088U0805

Manifold set 6+6 SSM-6 088U0806

Manifold set 7+7 SSM-7 088U0807

Manifold set 8+8 SSM-8 088U0808

Manifold set 9+9 SSM-9 088U0809

Manifold set 10+10 SSM-10 088U0810

Manifold set 11+11 SSM-11 088U0811

Manifold set 12+12 SSM-12 088U0812

positive shut-off between manifold and system.

The SSM manifold is supplied with a manual air-

vent and a purge valve.

© Danfoss | FEC | 2021.04

AI195986472412en-000501 | 1

Data Sheet SSM Floor Heating Manifold

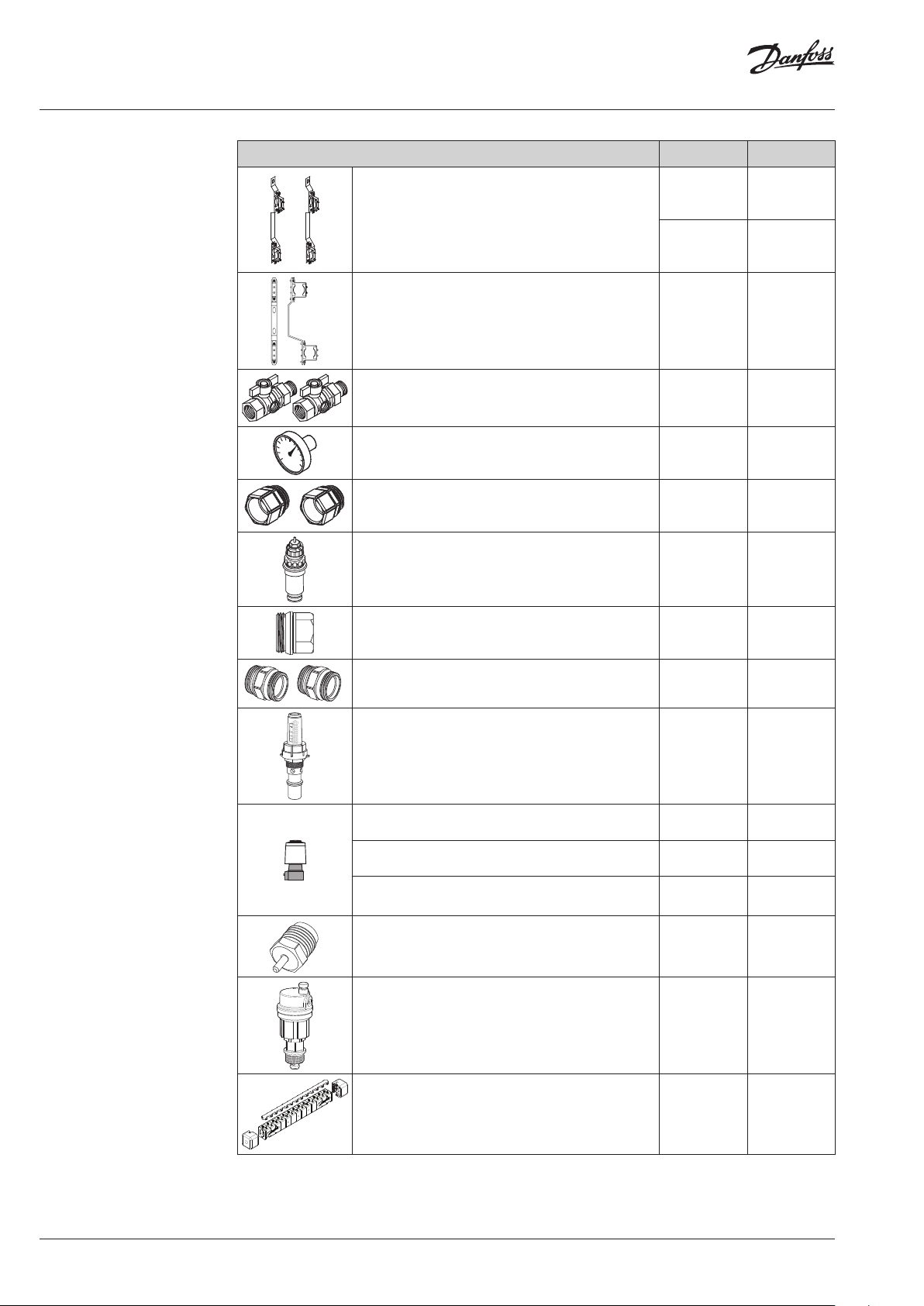

Accessories

Description Type Code no.

FHF-MB 088U0585

Mounting brackets — set (offset)

SSM-MB 088U0595

Mounting brackets — set (straight) SSM-MB 088U0596

2 × ball valve 1” — for connection to manifold and

for blocking of floor heating system

1 × thermometer (0 °C to 60 °C) Ø 35 mm —

for flow/return temperature measurement

Union, 1” — 088U0820

Replacement valve for manifold — 013G7376

FHF-BV 088U0822

FHD-T 088U0029

Reducing Bush FHF-R 088U0584

Connection piece FHF-C 088U0583

Flowmeter — 088U0819

Thermal actuator, 24V, NC,

Danfoss RA connection to valve

Thermal actuator, 230V, NC,

Danfoss RA connection to valve

Thermal actuator, 24V, NC, with end switch,

Danfoss RA connection to valve

Stuffing box for manifolds DZR 013G0554

Automatic air ventilation valve SSM-AV 088U0945

TWA-A 088H3110

TWA-A 088H3112

TWA-A 088H3114

2 | © Danfoss | FEC | 2021.04

Insulation capsule for SSM manifold SSM-I 088U0824

AI195986472412en-000501

Data Sheet SSM Floor Heating Manifold

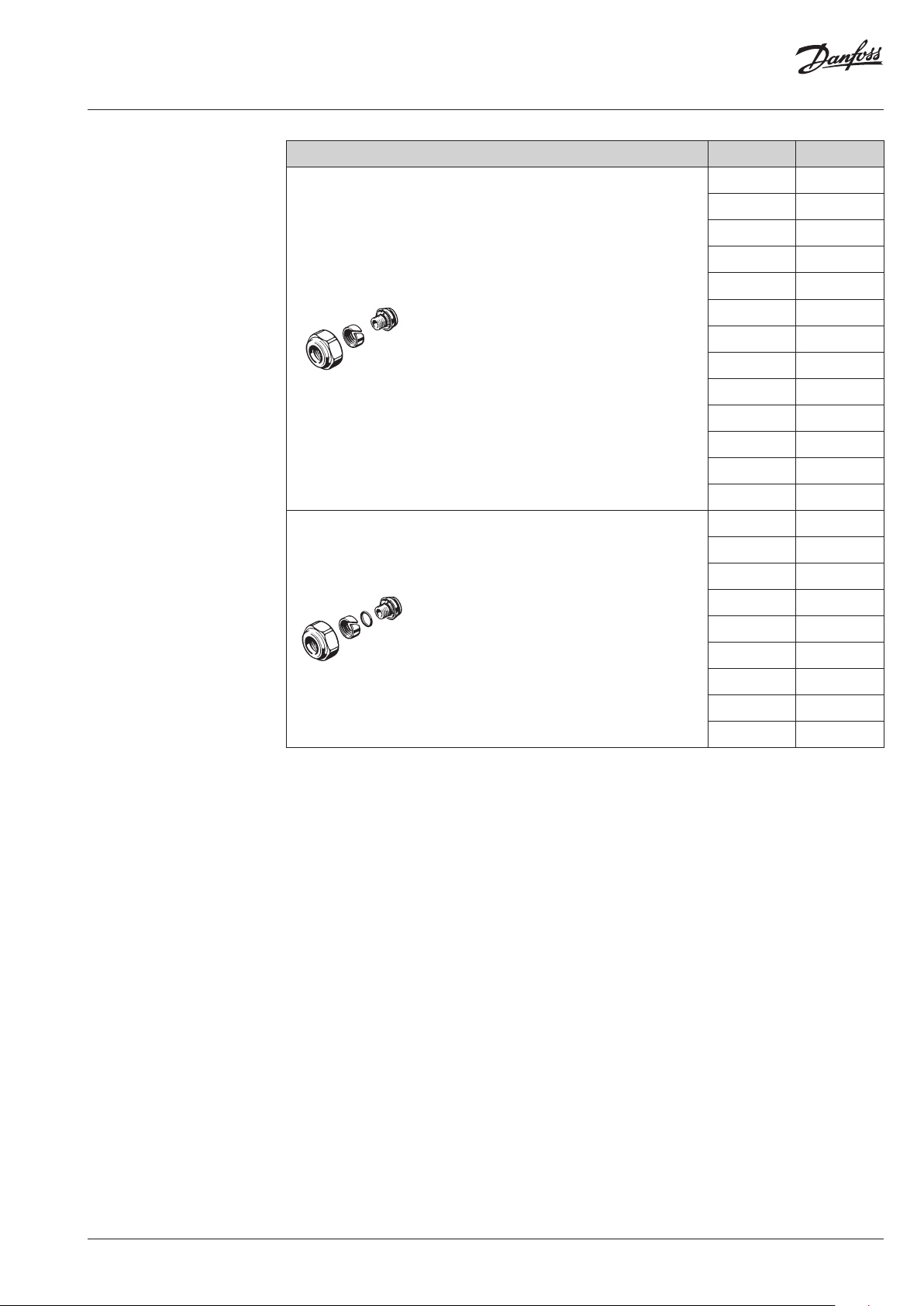

Compression fittings

Description Type, mm Code no.

12 × 2 013G4152

13 × 2 013G4153

14 × 2 013G4154

Compression fittings for PEX tubing in

accordance with ISO 15875.

Max working pressure: 6 bar

Test pressure: 10 bar

Max. flow temperature: 95 °C

G ¾” internal thread

Max. flow temperature given by the tube

manufacturer must not be exceeded.

15 × 2,5 013G4155

16 × 1,5 013G4157

16 × 2 013G4156

16 × 2,2 013G4163

17 × 2 013G4162

18 × 2 013G4158

18 × 2,5 013G4159

20 × 2 013G4160

20 × 2,25 013G4093

20 × 2,5 013G4161

12 × 2 013G4182

Compression fittings for ALUPEX tubing.

14 × 2 013G4184

15 × 2,5 013G4185

Max working pressure: 6 bar

Test pressure: 10 bar

Max flow temperature: 95 °C

G ¾” Internal thread

Max flow temperature given by the tube

manufacturer must not be exceeded.

16 × 2 013G4186

16 × 2,25 013G4187

18 × 2 013G4188

20 × 2 013G4190

20 × 2,25 013G4093

1)

1)

2)

2)

20 × 2,5 013G4191

1)

Compression fittings also suitable for PERT tubing in accordance with ISO 15875.

2)

Compression fittings also suitable for PERT/ALU/PERT tubing.

© Danfoss | FEC | 2021.04

AI195986472412en-000501 | 3

Data Sheet SSM Floor Heating Manifold

Capacity/commissioning

The pre-setting of the manifold valves determines

the flow in the floor heating tubes and is therefore

an important factor for obtaining optimal hydraulic balance in the system.

A correct hydraulic balance is important if optimal

comfort shall be achieved with a minimum of energy consumption and is easily carried out following the example shown below.

Example

Room 1: 1. Determine longest tube/largest room 25 m

2. Desired cooling (Δt) 5 °C (typical)

3. Determine heat requirement for the room 50 W/m

4. Conversion factor 1,16

5. Calculation of flow for the room

Q (l/h) =

50 W/m2 × 25 m

5 °C × 1,16

2

= 216 l/h

Room 2: 6. Determine area for the next room 15 m2

7. Calculation of flow for the room (Δt and heat

requirement is assumed identical for the rooms

in this case)

Q (l/h) =

50 W/m2 × 15 m

5 °C × 1,16

2

= 129 l/h

Manifold,

with flowmeter

Pre-setting:

Room 1 N

Room 2 5

2

2

4 | © Danfoss | FEC | 2021.04

Manifold,

without flowmeter

Pre-setting:

Room 1 N

Room 2 6

AI195986472412en-000501

Data Sheet SSM Floor Heating Manifold

Presetting the manifold

valves

Operation conditions

The diagram shows the capacities for each heating circuit at different presettings of the manifold

valves.

Supply manifold

with flowmeter

Based on the above calculations and capacity diagram each manifold valve is preset by rotating the

red ring until the correct value on the ring is in-line

with the sight mark on the valve.

Supply manifold

without flowmeter

System layout

Max differential pressure 0,6 bar 0,6 bar

Max working pressure 6 bar 10 bar

Max test pressure 10 bar 16 bar

Max flow temperature 90 °C 90 °C

© Danfoss | FEC | 2021.04

AI195986472412en-000501 | 5

Data Sheet SSM Floor Heating Manifold

L1

55

78

L1

55

78

Dimensions

G1 ISO228/1

213

G1 ISO228/1

G1 ISO228/1

213

50

G1 ISO228/1

359

G1 ISO228/1

50

G1 ISO228/1

359

G1 ISO228/1

G1 ISO228/1

with 088U0585 brackets set

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 190 240 290 340 390 440 490 540 590 640 690

6 | © Danfoss | FEC | 2021.04

AI195986472412en-000501

Data Sheet SSM Floor Heating Manifold

L1

42

65

L1

42

65

Dimensions

G1 ISO228/1

213

G1 ISO228/1

G1 ISO228/1

213

50

G1 ISO228/1

359

G1 ISO228/1

50

G1 ISO228/1

359

G1 ISO228/1

G1 ISO228/1

with 088U0595 brackets set

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 190 240 290 340 390 440 490 540 590 640 690

© Danfoss | FEC | 2021.04

AI195986472412en-000501 | 7

L1

36,5

L1

36,5

71,5

Dimensions

71,5

G1 ISO228/1

208

G1 ISO228/1

G1 ISO228/1

208

50

G1 ISO228/1

344

G1 ISO228/1

50

G1 ISO228/1

344

G1 ISO228/1

8 | © Danfoss | FEC | 2021.04

G1 ISO228/1

with 088U0596 brackets set

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 190 240 290 340 390 440 490 540 590 640 690

AI195986472412en-000501

Loading...

Loading...