Page 1

Data sheet

Check & stop valve, SCA-X

Check valve, CHV-X

SCA-X are check valves with a built-in shut-off valve

function. SCA-X valves are avilable in angleway

versions.

CHV-X are check valves only. CHV-X are available in

both angleway and straightway versions.

The valves are designed to open at very low

differential pressures, allow favourable flow

conditions and are easy to disassemble for

inspection and service.

The SCA-X is equipped with vented cap and has

internal backseating enabling the spindle seal to be

replaced whilst the valve still under pressure.

Laser cut V-ports provide excellent opening

characteristics (SCA-X/CHV-X 50-125).

The valve cone has a built-in flexibility to ensure a

precise and tight closing towards the valve seat.

Features • Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications with

replaced O-ring.

• Modular Concept:

– Each valve housing is available with several

different connection types and sizes.

– Possible to convert SCA-X or CHV-X to any

other product in the FlexlineTM SVL family

(Hand operated regulating valve, shut-off

valve or strainer) just by replacing the

complete top part.

• Fast and easy valve overhaul service. It is easy to

replace the top part and no welding is needed.

• Designed to open at a very low differential pressure of 0.04 bar /0.58 psig.

• Designed with a built-in damping chamber preventing valve flutter in case of low

refrigerant velocity and/or low density.

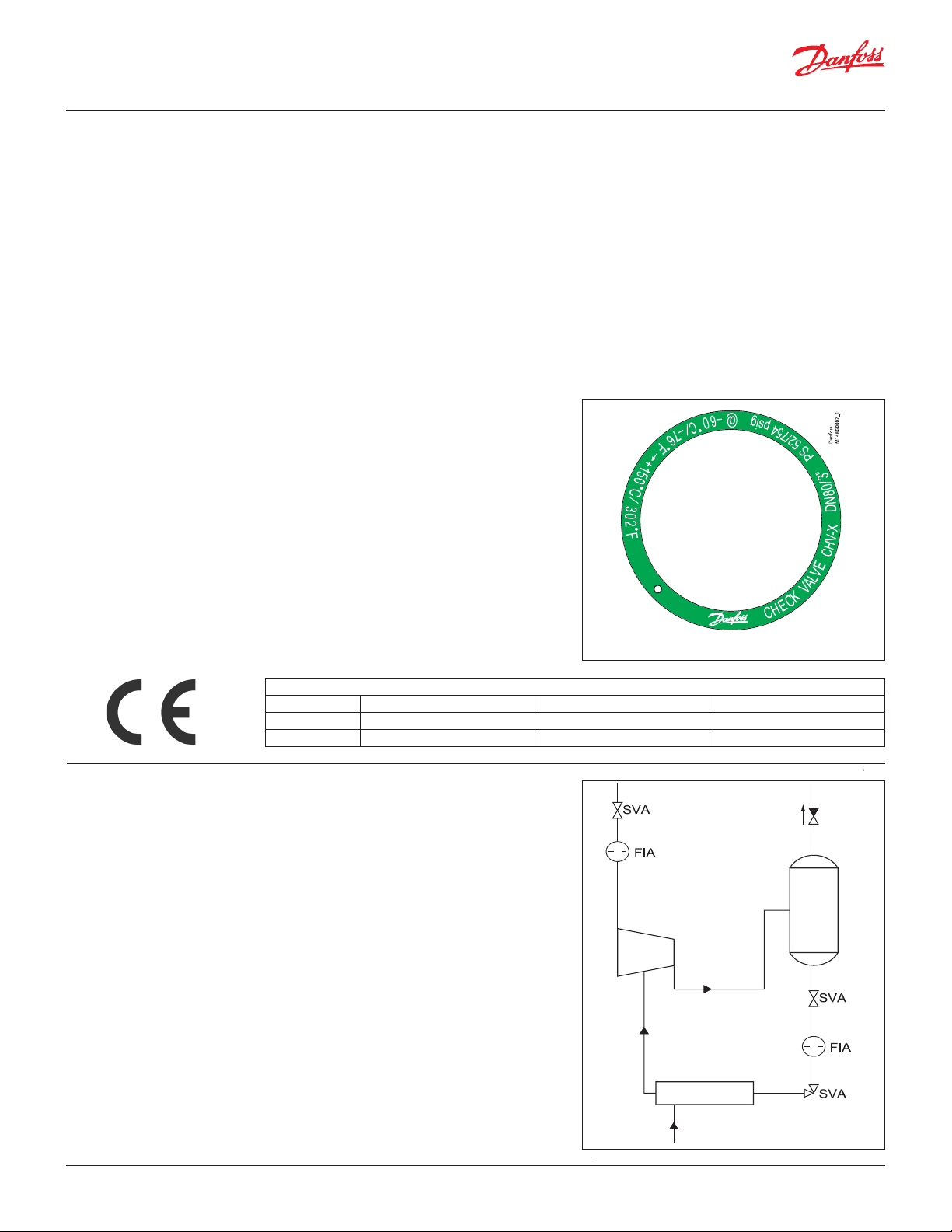

• Each valve is clearly marked with type, size and

performance range.

Additional ID ring to be installed when preparing

for Ammonia Heat Pump or Propylene

application.

A well balanced dampening effect between the

piston and the cylinder gives an optimal protection

during low loads and against pulsations.

• Easy to disassemble for inspection and service.

• Internal backseating enables replacement of the

spindle seal whilst the valve is active, i.e. under

pressure.

• Optimal flow characteristics ensuring quick opening to the fully open position.

• Protection against pulsation by built-in

damping facility.

• Housing and bonnet material is low

temperature steel according to requirements of

the Pressure Equipment Directive and other international classification authorities.

• Equipped with Stainless steel bolts.

• Max. working pressure:

52 bar g / 754 psi g

• Temperature range:

-60 – 150 °C / -76 – 302 °F

• Classification: DNV, CRN, BV, EAC etc.

To get an updated list of certification on the

products please contact your local Danfoss Sales

Company.

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 1

Page 2

SCA-X

Danfoss

M148G0005_1

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Design

Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

DN 15 - 125 (½ - 5 in.)

• Butt-weld ANSI (B 36.10 Schedule 80),

DN 15 - 40 (½ - 1½ in.)

• Butt-weld ANSI (B 36.10 Schedule 40),

DN 50 - 125 (2 - 5 in.)

• Butt-weld GOST, (8734-75 and 8732-78)

DN 15 - 125 (½ - 5 in.)

• Socket-weld ANSI (B 16.11),

DN 50 (2 in.)

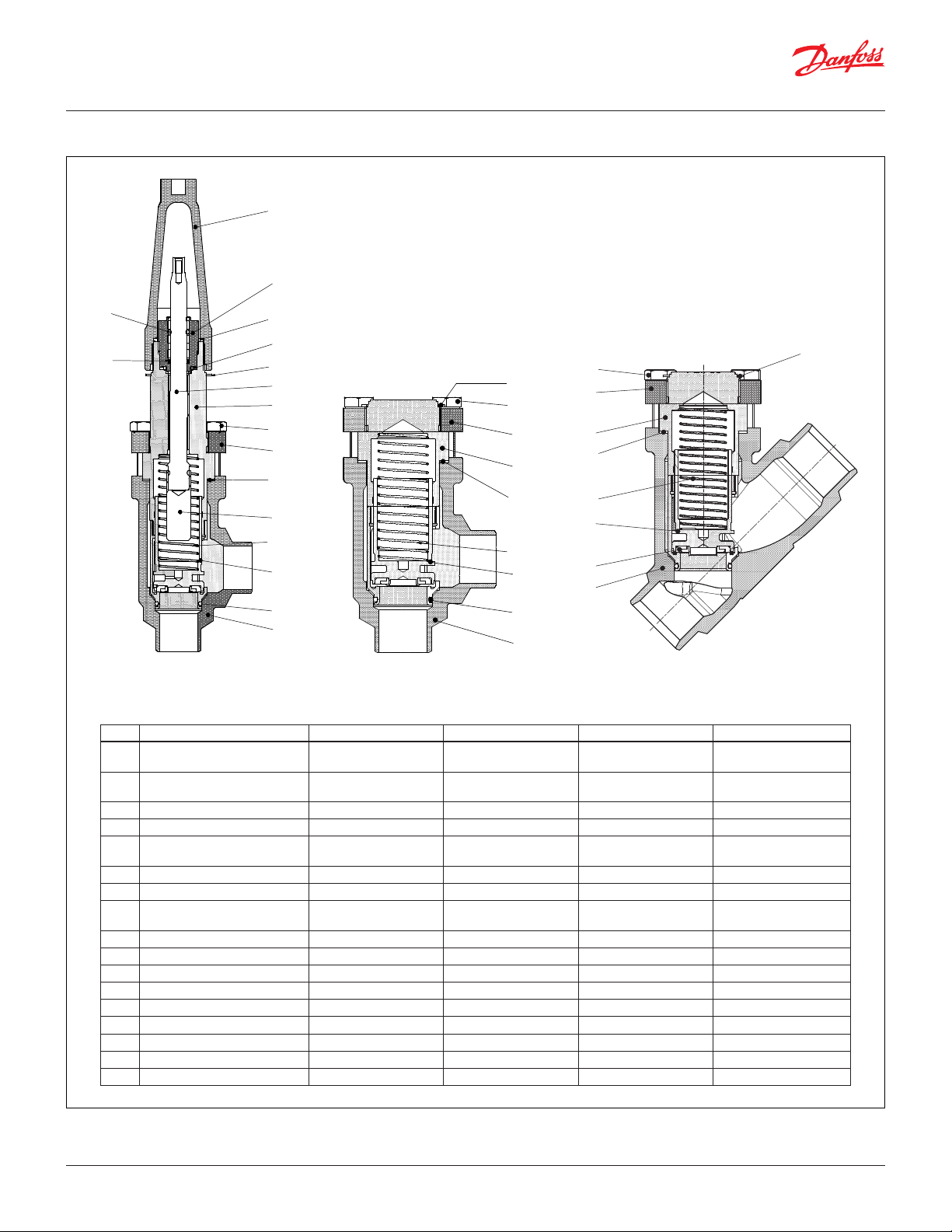

Housing

The housing is made from special, cold resistant steel.

Valve cone

Valve cone with built in metallic stop - prevents

damage to teflon ring in case of overtightening.

Damping chamber

The chamber is filled with refrigerants (gas or liquid),

which provides a damping effect when the valve

opens and closes.

Spindle (SCA-X)

Made of polished stainless steel, which is ideal for

O-ring sealing.

Packing Gland (SCA-X)

The “full temperature range” packing gland is the

standard for the entire SVL platform.

This ensures perfect tightness throughout the whole

temperature range:

-60 – 150 °C / -76 – 302 °F.

Pressure Equipment Directive (PED)

The SCA-X/CHV-X valves are approved according

to the European standard specified in the Pressure

Equipment Directive and are CE marked.

For further details / restrictions - see the product

instruction.

Installation

The valve must be mounted vertically with the cone

downwards.

The valve is designed to resist very high internal

pressure. However, the piping system in general should

be designed to avoid liquid traps and reduce the risk of

hydraulic pressure caused by thermal expansion.

For further information refer to installation instructions

for SCA-X/CHV-X.

If cold refrigeration oil having low viscosity enters

and settles in the damping chamber, problems with

the check valve may arise. Consequently, it may be

necessary to modify the valve for more viscous liquids

by enlarging the hole to the damping chamber.

Example of marking ring, CHV-X

Nominal bore DN = < 25 mm (1 in.) DN32-80 mm (1¼ - 3 in.) DN100 - 125 mm (4 - 5 in.)

Classified for Fluid group I

Category Article 3, paragraph 3 II III

Application Figure 3 shows the check & stop valve SCA-X in

the discharge line of a screw compressor unit.

The SCA-X valve in the discharge line prevents

“back condensation” in the oil separator as well as

pressure equalising through the compressor.

Compared to an ordinary shut-off and check

valve arrangement the combined check & stop

valve solution, as shown, is easier to install and

has lower flow resistance.

Installation of the SCA-X/CHV-X in the

economizer line is not recommended.

For horizontal installation of the function module;

please contact Danfoss.

SCA-X/CHV-X valves

Compressor

Oil cooler

Oil separator

Fig. 3

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 2

Page 3

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Technical data

• Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia), R744

(CO2), Propane, Butane, Iso-Butane and Ethane.

R717 Heat Pump and Propylene applications with

replaced O-ring.

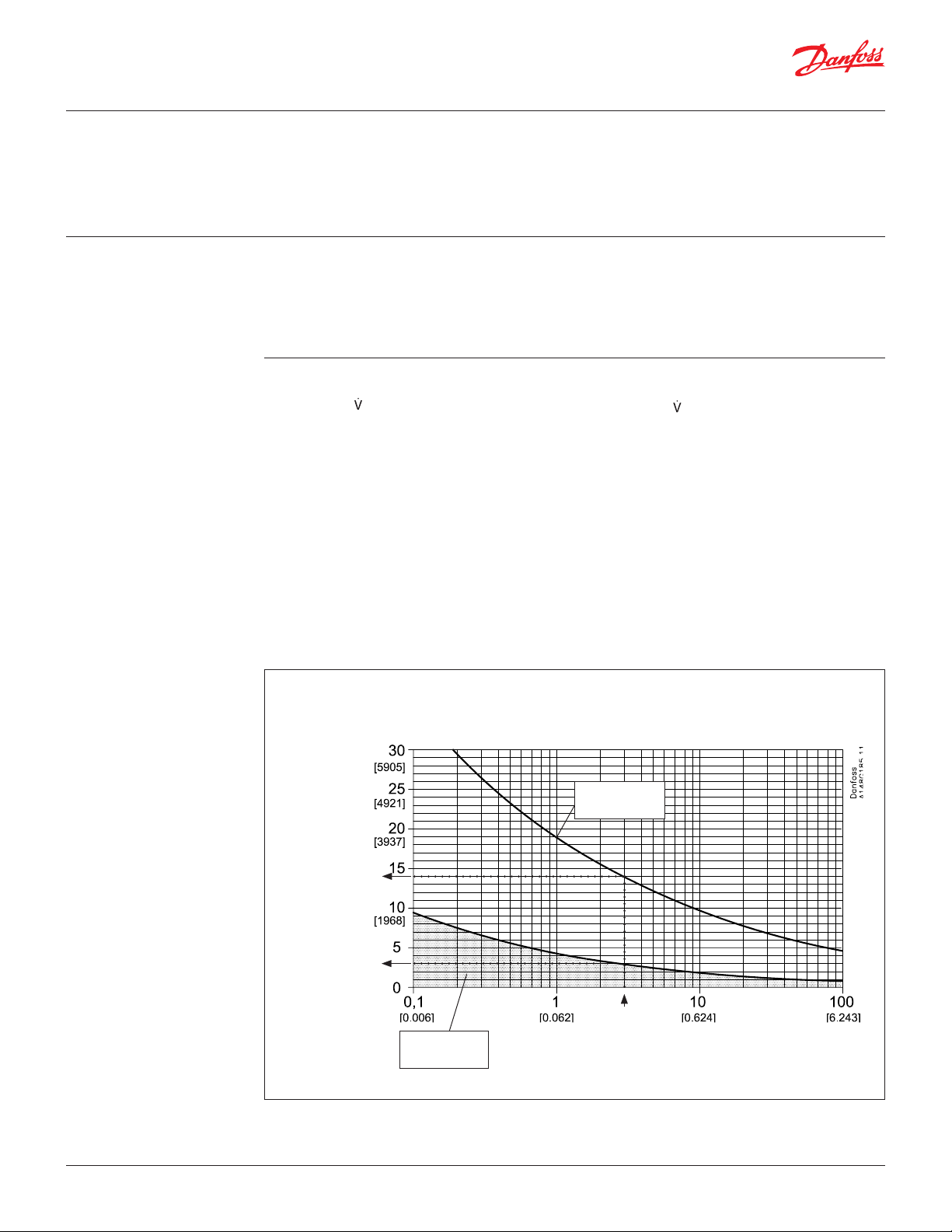

Computation and selection Introduction

When dimensioning SCA-X/CHV-X, it is important

to select a valve that is best suited to all operating

conditions. Therefore, it is necessary to consider

both the nominal and part load working conditions.

Example

SI-Units

Assumed working conditions:

Maximum flow = 1000 m3/h

Density ρ = 3.0 kg/m

Minimum part load = 33%

Used expressions:

Recommended velocity - C

Minimum recommended velocity - C

Maximum velocity - C

Part load velocity - C

We know the density ρ ≈ 3.0 kg/m3, consequently

C

as well as C

rec

below (standard valve).

3

[m/s]

rec

[m/s]

max

[m/s]

part

can be found in the figure

min, rec

min, rec

[m/s]

• Temperature range

-60 – 150 °C / -76 – 302 °F.

• Max. working pressure

52 bar g / 754 psig.

The SCA-X/CHV-X valve can be calculated in two

ways:

– Using the tables below.

– Using Coolselector®2

US-Units

Assumed working conditions:

Maximum flow = 1160 gpm

Density ρ = 0.187 lb/feet

3

Minimum part load = 33%

Used expressions:

Recommended velocity - C

Minimum recommended velocity - C

Maximum velocity - C

Part load velocity - C

part

[ft/min]

max

[ft/min]

[ft/min]

rec

min, rec

[ft/min]

We know the density ρ ≈ 0.187 lb/feet3,

consequently C

as well as C

rec

can be found in

min, rec

the figure (standard valve).

C

≈14 m/s

rec

C

min, rec

Fig. 1

≈ 3 m/s

C

= 14 m/s

rec

C

= 2756 ft/min

rec

C

= 3 m/s

min, rec

C

= 591 ft/min

min, rec

Velocity

m/s

[ft/min]

Not

recommended

C

≈ 2756 ft/min

rec

C

≈ 591 ft/min

min, rec

Recommended

velocity

ρ = 3.0 kg/m

ρ = 0.187 lb/feet

3

3

Density

kg/m

3

[lb/feet3]

© Danfoss | DCS (MWA) | 2018.11

Selection example continued on following page.

AI250986497520en-US1001 | 3

Page 4

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

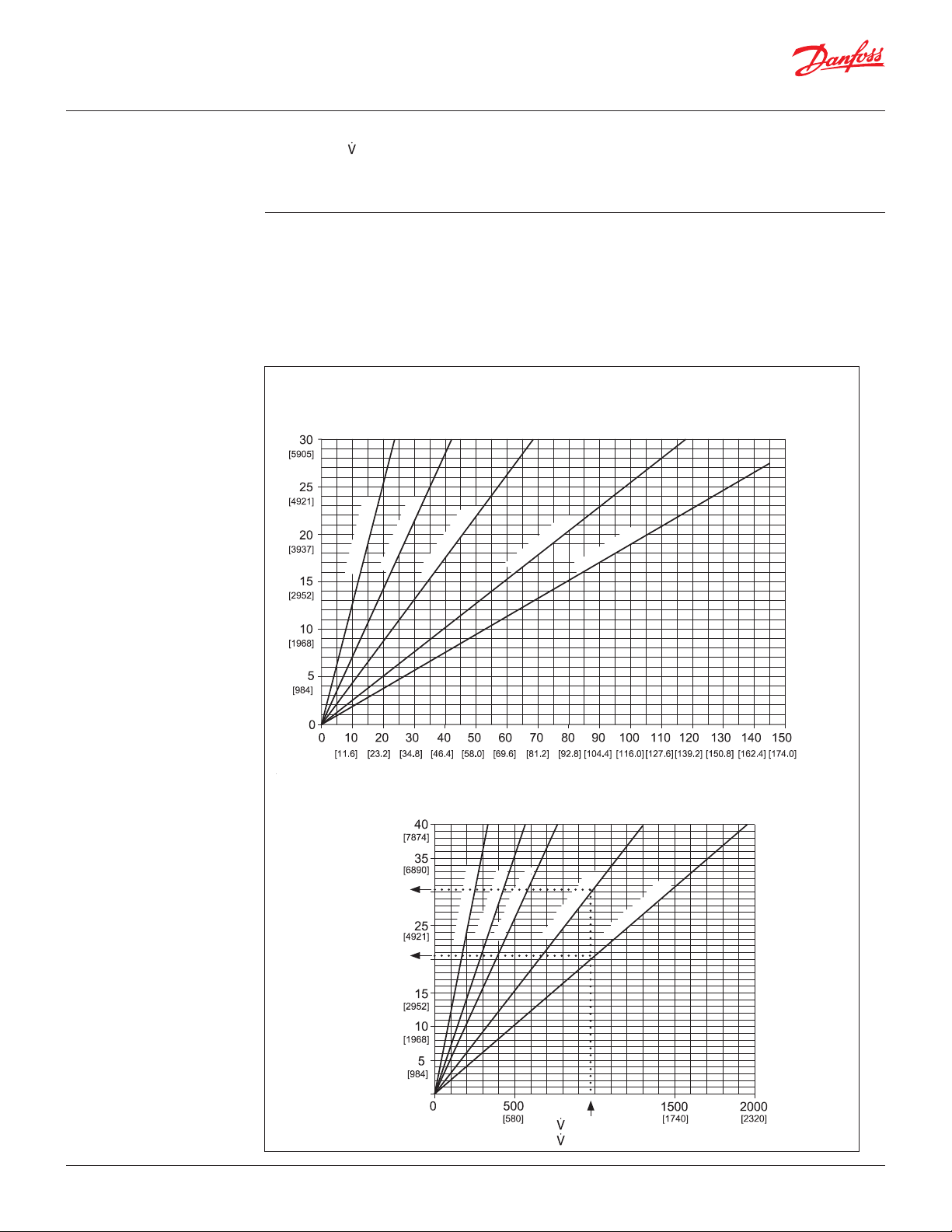

Computation and selection

(continued)

Knowing that = 1000 m3/h (1160 gpm) fig. 2 gives the following choices:

For SCA-X/CHV-X in size DN 100 the maximum velocity C

For SCA-X/CHV-X in size DN 125 the maximum velocity C

In conclusion SCA-X in size DN 125 is selected

because C

to the recommended velocity C

≈ 20 m/s (3900 ft/min) comes nearest

max

≈ 14 m/s (2756 ft/

rec

min) and at the same time part load conditions fulfil

the requirements, as described:

≈ 31 m/s (6100 ft/min)

max

≈ 20 m/s (3900 ft/min)

max

(3.0 m/s)

and the sele cted SCA-X model DN125 is

the perfect choice.

lf the valve in question (for instance under part load

conditions) provides a velocity less than

C

the valve might start hammering and

min, rec

become noisy. As a result the valve may wear

We know that C

minimum part load is 33%. lt fol lows that

m/s (1290 ft/min). Thus, C

DN 15 - 40

m/s

[ft/min]

≈ 20 m/s (3900 ft/min) and that

max

SCA

(6.5 m/s) > C

part

15

20

V-X

/CHV-X

X

-

-X/CH

CA

S

SC

X/CHV-X

-

A

2

5

C

part

min, rec

SCA-X/CHV-X 32

≈ 6.5

prematurely.

CA-X/CHV-X 40

S

Danfoss

M148G0003_1

© Danfoss | DCS (MWA) | 2018.11

SCA-X/CHV-X 100

SCA-X/CHV-X 125

Fig. 2

DN 50 - 125

m/s

[ft/min]

[m/s]

m3/h

[gpm]

Danfoss

M148G0004_1

0

5

-X

V

H

X/CHV-X 65

-

-X/C

A

CA

C

SCA-X/CHV-X 80

S

S

SCA-X/CHV-X 100

SCA-X

125

/CHV-X

m3/h

= 1000 m3/h

[gpm]

= 1160 gpm

AI250986497520en-US1001 | 4

Page 5

Danfoss

M148G0009_1

1

2

3

5

14

13

12

6

15

17

8

9

4

3

12

13

7

14

5

1

16

15

2

6

11

10

Danfoss

M148G0008_1

Danfoss

148G237_02-2017

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Material specification

12

2

3

13

14

5

6

1

SCA-X 15 - 40

No. Part Material DIN/EN ISO ASTM

1 Housing Steel P285QH

2 Bonnet, Flange Steel P275NL1

3 Bonnet, Insert Steel

4 Spindle Stainless steel X 10CrNiS18-9 Type 17, 17440 AISI 303, 683/13

5 Cone Steel

6

7 Spindle extension Steel

8 Packing gland

9 Packing washer Aluminium

10 Spring loaded seal Teflon (PTFE)

11 O-ring Cloroprene (Neoprene)

12 Bolts Stainless steel A2-70 A2-70 Type 308

13 Gasket Fiber, non-asbestos

14 Spring Steel

15 Identification ring Stainless steel

16 Seal cap gasket Nylon

17 Spindle seal cap Aluminium

O-ring Cloroprene (Neoprene)

Teflon (PTFE)

O-rings

Steel

Cloroprene (Neoprene)

CHV-X 15 - 40

EN10222-4

EN10028-3

CHV-X 15 - 40

LF2A350

15

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 5

Page 6

Danf

148G243_01-2018

17

12

11

10

18

Danf

148G244_01-2018

17

12

11

4

10

18

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Material specification

8

5

7

6

3

2

1

8

4

3

7

2

5

9

1

6

9

SCA-X 50 - 125

CHV-X 50 - 125

oss A/S

CHV-X 50 - 125

oss A/S

No. Part Material DIN/EN ISO ASTM

1 Housing DN 50-65 Steel P285 QH

LF2A350

EN 10222-4

Housing DN 80-125 Steel G20Mn5 QT

LCC, A352

SEW 685

2 Gasket Fiber, Non-asbestos

SCA-X: Valve bonnet

3

CHV-X: End cover

Steel

P285 QH

EN 10222-4

LF2A350

4 Bolts Stainless steel A2-70 A2-70 A-276

5 Tube Steel

6 Seat Steel

7 Valve plate Steel

8 Guide sleeve Steel

9 Spring ring Steel

10 Spring Steel

11 O-ring Cloroprene (Neoprene)

12 Teflon ring Teflon (PTFE)

13 Soft back seal Teflon (PTFE)

14 Spindle DN 50-65 Stainless steel X8CrNiS18-9

Spindle DN 80-125 Stainless steel X5CrNi1810

17440

17440

R 683/13

Type 11

683/13

Type 17

AISI 303

AISI 304

A-276

15 Packing gland Steel 9Mn28, 1651 Type 2, R 683/9 1213, SAE J403

16 Spindle seal cap and gasket Aluminium

17 Marking label Stainless steel

18 Eye bolt DIN 580 Steel

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 6

Page 7

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Connections

ANSI

SOC

Size

Size

mm

in.ODmmTmmODin.Tin.

k

v

Angleway

m3/h

C

v

Angleway

USgal/min

K

v

Straightway

m3/h

Butt-weld ANSI (B 36.10 Schedule 80)

15 ½ 21.3 3.7 0.839 0.146 8 9.3 4 4.6

20 ¾ 26.9 4.0 1.059 0.158 10 11.6 7 8.1

25 1 33.7 4.6 1.327 0.181 24 27.8 16 18.6

32 1¼ 42.4 4.9 1.669 0.193 30 34.8 21 24.4

40 1½ 48.3 5.1

1.902

0.201 30 34.8 21 24.4

Butt-weld ANSI (B 36.10 Schedule 40)

50 2 60.3 3.9 2.37 0.15 45 53 28 34

65 2½ 73.0 5.2 2.87 0.20 72 85 41 48

80 3 88.9 5.5 3.50 0.22 103 129 81 94

100 4 114.3 6.0 4.50 0.24 196 232 157 182

125 5 141.3 6.6 5.56 0.26 301 356 250 290

Size

Size

mm

in.IDmmTmmIDin.Tin.LmmLin.

Socket welding ANSI (B 16.11)

1520½¾21.8

25

32

40

50 2 61.2 6.2 2.41 0.24 16 0.63

1

1¼

1½

27.264.6

33.9

42.7

48.8

7.2

6.1

6.6

0.858

1.071

1.335

1.743

1.921

0.235

0.1811013

0.284

0.240

0.260

0.39

0.51

13

0.51

13

0.51

13

0.51

C

v

Straightway

USgal/min

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 7

Page 8

DANFOSS148G238_02-2017

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

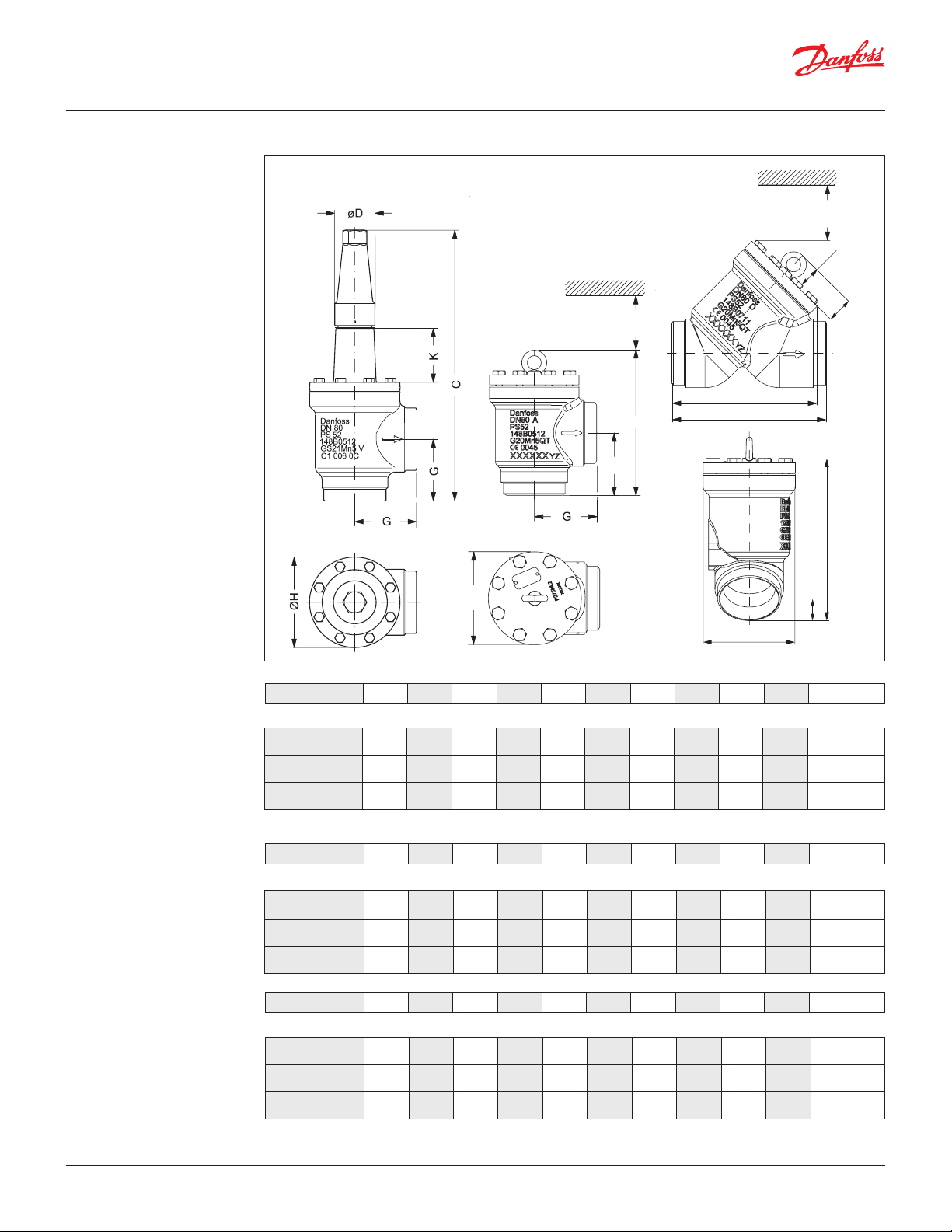

Dimensions and weights

SCA-X /CHV-X 15 - 40 (½- 1½ in.)

SCA-X 15 - 40

Valve size C G ∅D F

CHV-X 15 - 40

SCA-X 15 - 40

SCA-X 15 (½ in.)

SCA-X 20 (¾ in.)

SCA-X 25 (1 in.)

SCA-X 32 (1¼ in.)

SCA-X 40 (1½ in.)

mm 212 45 38 60 60

in. 8.35 1.77 1.50 2.36 2.36

mm 212 45 38 60 60

in. 8.35 1.77 1.50 2.36 2.36

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

mm 295 55 50 85 70

in. 11.61 2.17 1.97 3.35 2.76

CHV-X 15 - 40 Angleway

CHV-X 15 (½ in.)

CHV-X 20 (¾ in.)

CHV-X 25 (1 in.)

CHV-X 32 (1¼ in.)

CHV-X 40 (1½ in.)

mm 103

in.

mm 103 45 60 60

in. 4.06 1.77 2.36 2.36

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

mm 143 55 85 70

in. 5.63 2.17 3.35 2.76

4.06

45

1.77

60

2.36

G

B

C

E

H

min

H

60

2.36

Weight

1.6 kg

3.53 lb

1.6 kg

3.53 lb

3.2 kg

7.05 lb

3.2 kg

7.05 lb

3.2 kg

7.05 lb

1.2 kg

2.65 lb

1.2 kg

2.65 lb

2.3 kg

5.07 lb

2.3 kg

5.07 lb

2.3 kg

5.07 lb

Specified weights are approximate

values only.

© Danfoss | DCS (MWA) | 2018.11

Valve size C B E G F

CHV-X 15 - 40 Straightway

CHV-X 15 (½ in.)

CHV-X 20 (¾ in.)

CHV-X 25 (1 in.)

CHV-X 32 (1¼ in.)

CHV-X 40 (1½ in.)

mm 99 114 19 120 60 60 1.3kg

in. 3.90 4.49 0.75 4.72 2.36 2.36 2.87lb

mm 99 114 19 120 60 60 1.3kg

in. 3.90 4.49 0.75 4.72 2.36 2.36 2.87lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

mm 141 157 26 155 85 70 2.6kg

in. 5.55 6.18 1.02 6.10 3.35 2.76 5.73lb

CHV-X 32-40 Straightway, Socket weld

CHV-X 32-40 (1¼ - 1½ in.)

mm 132 156 26 155 85 70 2.8kg

in. 5.20 6.14 1.02 6.10 3.35 2.76 6.11lb

min

H

Weight

AI250986497520en-US1001 | 8

Page 9

Danfoss

148G240_03-2017

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Dimensions and weights

SCA-X/CHV-X 50 - 65 (2 - 2½ in.)

B

G

C

E

H

Valve size K C G ∅D

H

Weight

SCA-X

SCA-X 50 mm 70 315 60 50 77 3.8 kg

SCA-X (2) in. 2.76 12.40 2.36 1.97 3.03 8.40 lb

SCA-X 65 mm 70 335 70 50 90 5.5 kg

SCA-X (2½) in. 2.76 13.19 2.76 1.97 3.54 12.16 lb

Valve size C G F

H

min.

Weight

CHV-X Angleway

CHV-X 50 mm 132 60 92 77 3.2 kg

CHV-X (2) in. 5.20 2.36 3.62 3.03 7.10 lb

CHV-X 65 mm 152 70 107 90 4.5 kg

CHV-X (2½) in. 5.98 2.76 4.21 3.54 9.95 lb

Valve size C B E G F

H

min.

Weight

CHV-X Straightway

CHV-X 50 mm 139 140 32 148 92 77 3 kg

CHV-X (2) in. 5.47 5.51 1.26 5.83 3.62 3.03 6.72 lb

CHV-X 65 mm 163 164 40 176 107 90 4.3 kg

CHV-X (2½) in. 6,4 6,4 1,6 6,9 4.21 3.54 9.44 lb

CHV-X Straightway, Socket weld

CHV-X 50 mm 142 147 37 162 92 77 3.8 kg

CHV-X (2) in. 5.59 5.79 1.46 6.38 3.62 3.03 8.33 lb

Specified weights are approximate values only.

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 9

Page 10

Danfoss

M148G0006_1

Danfoss A/S

ØH

8

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Dimensions and weights SCA-X/CHV-X 80 - 125 (3 - 5 in.)

148G245_01-2018

Danfoss A/S

148G246_01-201

min.

F

29.6

36

min.

F

B

C

G

G

C

E

ØH

Valve size K C G ∅D ∅H Weight

SCA-X

SCA-X 80 mm 76 388 90 58 129 9.7 kg

SCA-X (3) in. 3.00 15.28 3.54 2.28 5.08 21.4 lb

SCA-X 100 mm 90 437 106 58 156 15.3 kg

SCA-X (4) in. 3.54 17.20 4.17 2.28 6.14 33.7 lb

SCA-X 125 mm 90 533 128 74 193 28.1 kg

SCA-X (5) in. 3.54 20.98 5.04 2.91 7.60 61.9 lb

Valve size C G F

min.

∅H Weight

CHV-X Angleway

CHV-X 80 mm 218.6 90 103.4 129 8.7 kg

CHV-X (3) in. 8.61 3.54 4.07 5.08 19.23 lb

CHV-X 100 mm 252.6 106 133.4 156 14.3 kg

CHV-X (4) in. 9.94 4.17 5.25 6.14 31.60 lb

CHV-X 125 mm 297.6 128 160.4 193 25.6 kg

CHV-X (5) in. 11.72 5.04 6.31 7.60 56.58 lb

Valve size C B E G F

min.

∅H Weight

CHV-X Straightway

CHV-X 80 mm 206 204 48 216 133 129 9.3 kg

CHV-X (3) in. 8.11 8.03 1.89 8.50 5.24 5.08 20.4 lb

CHV-X 100 mm 256 248 62 264 163 156 14.6 kg

CHV-X (4) in. 10.08 9.76 2.44 10.39 6.43 6.14 32.29 lb

CHV-X 125 mm 314 302 74 322 190 193 32.5 kg

CHV-X (5) in. 12.36 11.89 2.91 12.68 7.48 7.60 71.65 lb

Specified weights are approximate values only.

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 10

Page 11

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Ordering complete valves

How to order

The table below is used to identify the valve

required.

Please note that the type codes only serve to identify the valves, some of wich may not form part of

the standard product range.

Valve type SCA-X

(valve size measured on the

connection diameter)

Connections A

Valve housing ANG Angle flow

CHV-X

Check & stop valve

Check Valve

15 DN 15 x x

20 DN 20 x x

25 DN 25 x x

32 DN 32 x x

40 DN 40 x x

50 DN 50 x x

65 DN 65 x

80 DN 80 x

100 DN 100 x

125 DN 125 x

Welding branches: ANSI B 31.5 schedule 80 DN 15 - 40 (½ - 1½ in.)

Welding branches: ANSI B 31.5 schedule 40 DN 50 - 125 (2 - 5 in.)

SOC

Socket weld: ANSI B 16.11

STR Straight flow

Important!

Where products need to be certified according

to specific certification societies the relevant

information should be included at the time of order.

For further information please contact your local

Danfoss Sales Company.

A SOC

ANG = Angleway

Angleway

SCA-X Butt-weld ANSI (B 36.10 Schedule 80)

Size

mm in.

15 ½ SCA-X 15 A ANG 148B5209

20 ¾ SCA-X 20 A ANG 148B5309

25 1 SCA-X 25 A ANG 148B5409

32 1¼ SCA-X 32 A ANG 148B5509

40 1½ SCA-X 40 A ANG 148B5609

Type Code No.

SCA-X Butt-weld ANSI (B 36.10 Schedule 40)

Size

mm in.

50 2 SCA-X 50 A ANG 148B5703

65 2½ SCA-X 65 A ANG 148B5802

80 3 SCA-X 80 A ANG 148B5903

100 4 SCA-X 100 A ANG 148B6004

125 5 SCA-X 125 A ANG 148B6103

Type Code No.

SCA-X Socket welding ANSI (B 16.11)

Size

mm in.

50 2 SCA-X 50 SOC ANG 148B5704

Type Code No.

Angleway

CHV-X Butt-weld ANSI (B 36.10 Schedule 80)

Size

mm in.

15 ½ CHV-X 15 A ANG 148B5237

20 ¾ CHV-X 20 A ANG 148B5337

25 1 CHV-X 25 A ANG 148B5437

32 1¼ CHV-X 32 A ANG 148B5537

40 1½ CHV-X 40 A ANG 148B5637

Type Code No.

CHV-X Butt-weld ANSI (B 36.10 Schedule 40)

Size

mm in.

50 2 CHV-X 50 A ANG 148B5737

65 2½ CHV-X 65 A ANG 148B5837

80 3 CHV-X 80 A ANG 148B5937

100 4 CHV-X 100 A ANG 148B6037

125 5 CHV-X 125 A ANG 148B6137

Type Code No.

CHV-X Socket welding ANSI (B 16.11)

Size

mm in.

32 1¼ CHV 32 SOC ANG 148B5539

50 2 CHV 50 SOC ANG 148B5740

Type Code No.

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 11

Page 12

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Ordering complete valves

(continued)

STR = Straightway

Straightway

CHV-X Butt-weld ANSI (B 36.10 Schedule 80)

Size

mm in.

15 ½ CHV-X 15 A STR 148B6582

20 ¾ CHV-X 20 A STR 148B6584

25 1 CHV-X 25 A STR 148B6586

32 1¼ CHV-X 32 A STR 148B6588

40 1½ CHV-X 40 A STR 148B6590

Type Code No.

CHV-X Butt-weld ANSI (B 36.10 Schedule 40)

Size

mm in.

50 2 CHV-X 50 A STR 148B6592

65 2½ CHV-X 65 A STR 148B6594

80 3 CHV-X 80 A STR 148B6596

100 4 CHV-X 100 A STR 148B6598

125 5 CHV-X 125 A STR 148B6600

Type Code No.

CHV-X Socket welding ANSI (B 16.11)

Size

mm in.

15 ½ CHV-X 15 SOC STR 148B6601

20 ¾ CHV-X 20 SOC STR 148B6602

25 1 CHV-X 25 SOC STR 148B6603

32 1¼ CHV-X 32 SOC STR 148B6604

40 1½ CHV-X 40 SOC STR 148B6605

50 2 CHV-X 50 SOC STR 148B6606

Type Code No.

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 12

Page 13

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

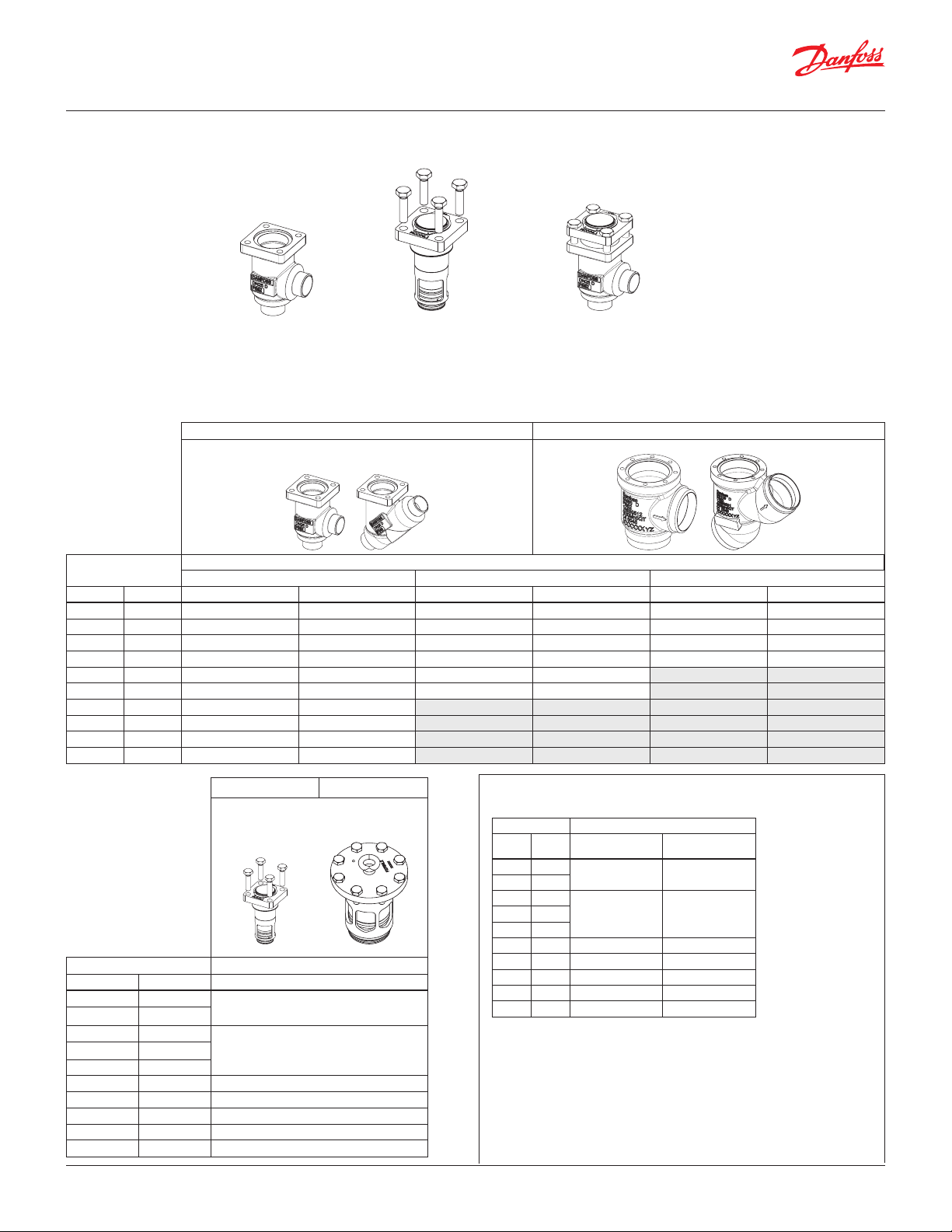

Ordering SCA-X from the parts programme

Example

(select from

table 1 and 2)

+ =

Table 1

SVL valve housings

Valve housing, size 25 (1 in.),

ANSI butt weld, angleway,

148B5454

Table 1

DN 15-65 mm (½ - 2½ in.) DN 80-125 mm (3 - 5 in.)

Top part, SCA-X

size 25 (1 in.)

148B5482

Table 2

w/different

connections

Sizes [DN] Valve Housing SVL

ANSI-Butt weld SOC FPT

mm in. ANG STR ANG STR ANG STR

15 ½ 148B5254 148B5255 148B5256 148B5257 148B5258 148B5259

20 ¾ 148B5354 148B5355 148B5356 148B5357 148B5358 148B5359

25 1 148B5454 148B5455 148B5456 148B5457 148B5458 148B5459

32 1¼ 148B5578 148B5579 148B5580 148B5581 148B5582 148B5583

40 1½ 148B5654 148B5655 148B5656 148B5657

50 2 148B5743 148B5744 148B5745 148B5746

65 2½ 148B5818 148B5819

80 3 148B5914 148B5915

100 4 148B6016 148B6017

125 5 148B6114 148B6115

Table 2

SCA-X complete top part

SCA-X 15-50 SCA-X 80-125

including gaskets and

bolts

Sizes [DN] Complete top part

mm in. SCA-X

15 ½

20 ¾

25 1

40 1½

50 2 148B5735

65 2½ 148B5825

80 3 148B5918

100 4 148B6019

125 5 148B6118

148B5282

148B548232 1¼

Replacement kit (O-ring replacement) for R717 Ammonia Heat

Pump* and Propylene applications (including ID tag)

Size (DN) O-ring kit for

mm in.

15 ½

20 ¾

25 1

40 1½

50 2 148B6072 148B6079

65 2½ 148B6073 148B6080

80 3 148B6074 148B6081

100 4 148B6075 148B6082

125 5 148B6076 148B6083

* Replacement kits for R717 Ammonia Heat Pump is

applicable for continuous operating temperature between

+100°C to 150°C (212°F to 302°F)

R717

Heat pump

148B6070 148B6077

148B6071 148B607832 1¼

R1270

Propylene

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 13

Page 14

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

Ordering CHV-X from the parts programme

Example

(select from

table 1 and 2)

+ =

Table 1

SVL valve housings

Valve housing, size 25 (1 in.),

ANSI butt weld, angleway,

148B5454

Table 1

DN 15-65 mm (½ - 2½ in.) DN 80-125 mm (3 - 5 in.)

Top part, CHV-X

size 25 (1 in.)

148B5483

Table 2

w/different

connections

Sizes [DN] Valve Housing SVL

ANSI-Butt weld SOC FPT

mm in. ANG STR ANG STR ANG STR

15 ½ 148B5254 148B5255 148B5256 148B5257 148B5258 148B5259

20 ¾ 148B5354 148B5355 148B5356 148B5357 148B5358 148B5359

25 1 148B5454 148B5455 148B5456 148B5457 148B5458 148B5459

32 1¼ 148B5578 148B5579 148B5580 148B5581 148B5582 148B5583

40 1½ 148B5654 148B5655 148B5656 148B5657

50 2 148B5743 148B5744 148B5745 148B5746

65 2½ 148B5818 148B5819

80 3 148B5914 148B5915

100 4 148B6016 148B6017

125 5 148B6114 148B6115

Table 2

CHV-X complete top part

CHV-X 15-50 CHV-X 80-125

including gaskets and

bolts

Sizes [DN] Complete top part

mm in. CHV-X

15 ½

20 ¾

25 1

40 1½

50 2 148B5747

65 2½ 148B5827

80 3 148B5919

100 4 148B6022

125 5 148B6119

© Danfoss | DCS (MWA) | 2018.11

148B5283

148B548332 1¼

Replacement kit (O-ring replacement) for R717 Ammonia Heat

Pump* and Propylene applications (including ID tag)

Size (DN) O-ring kit for

mm in.

15 ½

20 ¾

25 1

40 1½

50 2 148B6072 148B6079

65 2½ 148B6073 148B6080

80 3 148B6074 148B6081

100 4 148B6075 148B6082

125 5 148B6076 148B6083

* Replacement kits for R717 Ammonia Heat Pump is

applicable for continuous operating temperature between

+100°C to 150°C (212°F to 302°F)

R717

Heat pump

148B6070 148B6077

148B6071 148B607832 1¼

R1270

Propylene

AI250986497520en-US1001 | 14

Page 15

Data sheet | Check & stop valve, type SCA-X - Check valve, type CHV-X

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 15

Page 16

© Danfoss | DCS (MWA) | 2018.11

AI250986497520en-US1001 | 16

Loading...

Loading...