Page 1

Installation guide

Danfoss17-5027.10

Danfoss

60.9003

Danfoss

60.9030

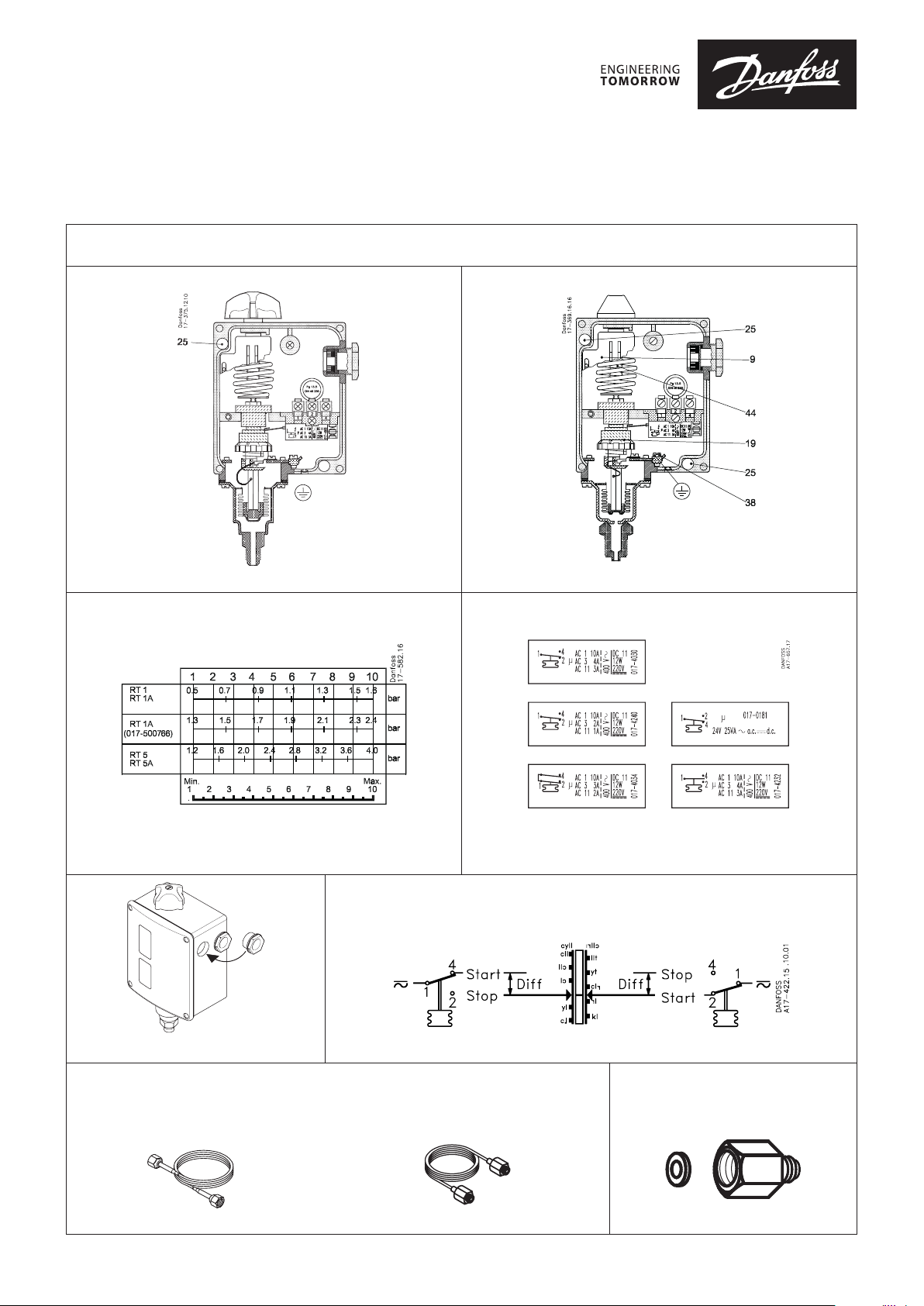

Pressure switch

RT 1, RT 1A, RT 5, RT 5A

Refrigerants:

R717 1), HCFC and non-amable HFC

RT 1 RT 5A

017R9507

Fig. 1 Fig. 2

017R9507

ø6.5 / ø10 mm

Fig. 3 Fig. 4

RT 1, RT 1A (LP) RT 5, RT 5A (HP)

Fig. 5 Fig. 6

RT 1, RT 5:

1m, ¼ in are

060-007166

Fig. 7 Fig. 8

© Danfoss | DCS (jmn) | 2015.11

RT 1A, RT 5A:

1m, G⁄ x M10 x 0.75

060-008266

⁄ in x ⁄ in are

017-420566

Danfoss

17.9051

DKRCC.PI.CE0.C3.72 | 520H10128 | 1

Page 2

ENGLISH DANSK

Pressure switches

1)

Only types with letter A are suitable for

R717

Technical data

Range

)

(P

Typ e Reset

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

auto

min.

auto

max.

e

[bar]

-0.8 – 5

4 – 17

Adjustable

xed appr ox. 0.5

xed appr ox. 1.2

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Max. working pressure, PS / MWP:

22 bar / 315 psig

Max. test pressure, p': 25 bar

Maximum permissible bellows temperature:

70 °C

Enclosure: IP66 according to IEC 529

Contact load

See switch cover or g. 4.

The marking, e.g.10 (4) A, 400 V ~ means

that max. connection current is 10 A

ohmic or 4 A inductive at 400 V ~. The max.

starting current on motor cutin (L.R.) may

be up to seven times the inductive load –

but max. 28 A.

The RT pressure controls comply with

conditions specied in VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

Fitting

A set of Pg13.5 cable gland is attached to

the RT in a separate bag. To ensure IP66

(units with automatic reset) or IP54 (units

with external reset) grade of RT enclosure

it is necessary to assemble this gland as

shown in the g. 5. If this gland is not used

with a cable, a metal blinding should be

also assembled.

The pressure switch is designed for tting

on the valve panel or the compressor. Use

the mounting holes pos. 25, g. 1. If the

control is subjected to vibration, it should

be mounted on a soft intermediate base.

If pressure pulsations occur in the system,

such pulsations should be eectively damped,

e.g. by connecting the pressure switch to the

system through a capillary tube.

See g. 7.

Mains connection

See g. 6.

START = make. STOP = break

DIFF = dierential

Cable diameter: 6 – 14 mm

dierential

∆p

[bar]

0.5 – 1.6

1.2 – 4

*1)

The earth terminal 38 should be connected

to earth.

Refit protective cap.

Adjustment

See gs. 2, 3 and 6.

Set the pressure switch for minimum

actuating pressure (range setting).

NOTE: RT 5 and RT 5A with max. reset

should be set for maximum actuating

pressure (range setting). Setting is done

by rotating the main spindle 44, at the

*2)

same time reading the main scale 9. The

dierential is set by rotating the dierential

adjusting nut 19 according to the diagram

in g. 3. Maximum actuating pressure is

the sum of the setting pressure and the

dierential.

Example

A setting on “5” g. 3. will give a dierential

of approx. 1.8 bar on type RT 1A (code no.

017-500766), while the same setting on

type

RT 5A will give a dierential of approx.

2.3 bar.

In general, turning the main spindle

automatically moves both the maximum

and minimum actuating pressures (break

and make pressures) up or down because

of the xed dierential.

On the other hand turning the dierential

adjusting nut only alters the maximum

actuating pressures.

The scale of all RT types without reset

and RT types with min. reset is calibrated

in such a way that the scale setting

corresponds to contact change-over at

minimum actuating pressure (normal

setting).

In RT switches with min. reset, the pressure

in the bellow system must increase by a

value corresponding to the dierential,

before manual reset can be eected.

RT switches with max. reset have a scale

which is calibrated in such a way that

the scale setting corresponds to contact

changeover at maximum actuating

pressure.

(NOTE: contrary to normal setting).

The pressure in the bellows system must

decrease by a value which corresponds to

the dierential, before manual reset can be

eected.

Accessories See figs. 7 and 8.

Pressostater

1)

Kun typer med bogstavet A må kun

anvendes til R717.

Tekniske data

Regulerings-

Typ e Reset

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

auto

min. fast ca. 0.5

auto

max. fast ca.1.2

område

)

(P

e

[bar]

-0.8 – 5

4 – 17

Indstillelig

dierens

∆p

[bar]

0.5 – 1.6

1.2 – 4

*1)

*2)

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Tilladeligt driftstryk, PS / MWP: 22 bar / 315 psig

Maks. prøvetryk, p': 25 bar

Maks. till. temp. i bælg: 70 °C

Tæthedsgrad: IP66 iht. IEC 529

Kontaktbelastning:

Se kontaktdækslet eller g. 4.

Mærkningen, f.eks.10(4) A, 400 V ~, angiver,

at der maks. må tilsluttes 10 A ohmsk eller

4 A induktiv belastning ved 400 V ~. Den

maksimale startstrøm ved indkobling af

motor (L.R.) må være op til syv gange den

induktive belastning – dog maks. 28 A.

RT pressostaterne opfylder betingelserne

i VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

Montering

Et sæt Pg13,5 kabelforskruning er vedlagt

produktet i en separat pose. For at sikre

kapslingsgrad IP66 (enheder med

automatisk reset) eller IP54 (enheder med

ekstern DANSK RESET) er det nødvendigt

at montere denne kabelforskruning som

vist i g. 5. Hvis denne kabelforskruning

ikke bruges sammen med et kabel, bør der

monteres en blindprop (metal skive).

Pressostaten monteres på ventiltavlen eller

på selve kompressoren. Benyt

monteringshullerne pos. 25, g.1. Hvis

apparatet kan blive udsat for vibrationer,

bør det monteres på et blødt underlag.

Forekommer der trykpulsationer i anlægget,

skal disse dæmpes eektivt, f.eks. ved at

tilslutte pressostaten til anlægget ved hjælp

af et kapillarrør.

See g. 7.

El-tilslutning

See g. 6.

START = slutte. STOP = bryde

DIFF = dierens

Kabeldiameter: 6 – 14 mm

Jordforbindelse tilsluttes jordskruen 38.

Beskyttelsesdækslet monteres.

© Danfoss | DCS (jmn) | 2015.11

DKRCC.PI.CE0.C3.72 | 520H10128 | 2

Page 3

Indstilling

See gs. 2, 3 og 6.

Pressostaten indstilles på laveste

aktiveringstryk (områdeindstilling).

NB: RT 5 og RT 5A med maks. reset

indstilles på højeste aktiveringstryk

(områdeindstilling).

med områdespindelen 44

Indstillingen udføres

under samtidig

aæsning af hovedskalaen 9.

Dierensen indstilles med dierensrullen

19 efter diagrammet g. 3.

Højeste aktiveringstryk er lig summen af

indstillingstryk og dierens.

Eksempel

En indstilling på »5« g. 3. vil på type RT 1A

(best.nr.

017-500766

) give en dierens på

ca. 1.8 bar, medens samme indstilling på type

RT 5A vil give en dierens på ca. 2.3 bar.

Generelt gælder, at en drejning af

områdespindelen automatisk ytter

både højeste og laveste aktiveringstryk

(bryde og slutte) op eller ned på grund af

den uændrede dierens. En drejning på

dierensrullen vil derimod kun ændre

det højeste aktiveringstryk.

Alle RT-typer uden reset samt RT-typer med

min. reset har skalaen kalibreret således at

den på skalaen indstillede værdi svarer til

kontaktskifte ved laveste aktiveringstryk

(normal indstilling).

In RT controls with min. reset, the pressure

in the bellow system must increase by a

value corresponding to the dierential,

before manual reset can be eected.

I RT-apparater med min. reset skal trykket

i bælgsystemet stige med en værdi

svarende til dierensen, før manual reset

kan ske.

RT-apparater med maks. reset har skalaen

kalibreret således, at den på skalaen

indstillede værdi svarer til kontaktskifte ved

højeste aktiveringstryk (NB: modsat normal

indstilling).

Trykket i bælgsystemet skal falde med en

værdi svarende til dierensen, før manual

reset kan ske.

TiIbehør See figs. 7 og 8.

DEUTSCH

Pressostate

1)

Nur Typen mit dem Zusatz „A“ sind geeignet

für R717

Technische Daten

Regelbereich

(P

Typ Reset

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

auto

min. fest ca. 0. 5

auto

max. fest ca.1.2

e

[bar]

-0.8 – 5

4 – 17

Einstellbare

)

0.5 – 1.6

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Zul. Betriebsüberdruck, PS / MWP: 22 bar / 315 psig

Max. Prüfdruck, p': 25 bar

Max. zul. Temp. im Wellrohr: 70 °C

Schutzart: IP66 nach IEC 529

Schaltleistung

Die Kennzeichnung, z.B.10(4) A, 400 V ~,

gibt an, daß bei 400 V ~ maximal eine

Belastung von 10 A ohmsch oder 44 A

induktiv angeschlossen werden darf.

Der maximale Einschaltstrom beim

Einschalten eines Motors (L.R.) darf bis zum

siebenfachen der induktiven Belastung

betragen – jedoch max. 28 A.

Die RT Pressostate genügen den

Bedingungen nach VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

Montage

Die Kabelverschraubungen PG13,5 sind in

einem separaten Beutel verpackt. Zum

erreichen des IP66 Schutzgrades (Geräte

mit automatischen Reset) oder IP54 (Geräte

mit externen Reset) ist eine Montage dieser

Verschraubung notwendig, (siehe Abb.

5.). Wenn diese Kabelverschraubung nicht

benötigt wird ist ein Metall Blindstopfen zu

verwenden.

Der Pressostat kann an der Ventiltafel oder

am Kompressor selbst montiert werden.

Montagelöcher pos. 25, g. 1 benutzen.

Falls das Gerät Vibrationen ausgesetzt

ist sollte es auf einer weichen Unterlage

montiert werden.

Kommen Druckpulsationen in der Anlage vor,

müssen diese wirksam gedämpft werden, z.B.

durch Anschluß des Pressostats an die Anlage

über ein Kapillarrohr, siehe Fig.7.

Elektrischer Anschluß

Siehe Fig. 6.

START = Einschalten. STOP = Ausschalten

DIFF = Dierenz

Kabeldurchmesser: 6 – 14 mm

Die Erdleitung ist an die Erdungsschraube

dierenz

∆p

[bar]

1.2 – 4

*1)

*2)

38 anzuschliessen.

Schutzkappe wieder montieren.

Einstellung

Siehe Fig. 2, 3 und 6.

Der Pressostat ist auf den unteren Ansprechdruck

einzustellen (BereichseinstelIung).

Anm.: RT 5 und RT 5A mit max. Reset

sind auf den oberen Ansprechdruck

einzustellen (Bereichseinstellung).

Die Einstellung wird mit der Bereichsspindel

44 unter gleichzeitigem Ablesen der

Hauptskala 9 vorgenommen.

Die Dierenz wird nach dem Diagramm in

Fig. 3 mit der Dierenzrolle 19 eingestellt.

Der obere Ansprechdruck ist gleich der

Summe von Einstelldruck und Dierenz.

Beispiel

Eine Einstellung auf »5« Fig. 3. wird beim

Typ RT 1A (Bestell-Nr. 017-500766) eine

Dierenz von etwa 1.8 bar, ergeben,

während die gleiche Einstellung beim Typ

RT 5A eine Dierenz von etwa 2.3 bar

ergeben wird.

Allgemein gilt, daß eine Verstellung an

der Bereichsspindel automatisch sowohl

den oberen als auch den unteren Ansprechdruck (Aus-schalten und Einschalten) nach

oben oder unten versetzen wird, weil die

Dierenz unverändert ist.

Eine Verstellung an der Dierenzrolle wird

dagegen nur den oberen Ansprechdruck

ändern.

Bei allen RT-Typen ohne Reset sowie

bei den RT- Typen mit min. Reset ist die

Skala so kalibriert, daß der an der Skala

eingestelIte Wert einem Kontaktwechsel

beim unteren Ansprechdruck entspricht

(die normale Ein-stellung).

Bei RT-Geräten mit min. Reset muss der

Druck im Wellrohrsystem um einen der

Dierenz entsprechenden Wert ansteigen,

bevor eine Rückstellung von Hand

vorgenommen werden kann.

Bei RT-Geräten mit max. Reset ist die

Skala so kalibriert, daß der an der Skala

eingestellte Wert einem Kont a k twechsel

beim oberen Ansprechdruck entspricht

(also im Gegensatz zur normalen

Einstellung).

Der Druck im Wellrohrsystem muß um

einen der Dierenz entsprechenden Wert

abfallen bevor eine Rückstellung von Hand

vorgenommen werden kann.

Zubehör Siehe fig. 7 und 8.

© Danfoss | DCS (jmn) | 2015.11

DKRCC.PI.CE0.C3.72 | 520H10128 | 3

Page 4

FRANÇAIS

Pressostats

1)

Seuls les appareils avec la lettre A sont

adaptés au R717

Caractéristiques techniques

Plage de

Typ e

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

Réarme-

ment

auto

min. xe env. 0.5

auto

max. xe env.

réglage

)

(P

e

[bar]

-0.8 – 5

4 – 17

Diérentiel

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Pression de service max., PS / MWP:

22 bar / 315 psig

Pression d’aissai max., p': 25 bar

Pression max. admis. dans le souet: 70 °C

Capsulage: IP66 selon IEC 529

Charge des contacts

Voir le couvercle de contact ou la g. 4.

Le marquage de, par exemple, 10(4) A, 400 V ~

indique qu’au maximum, il est admis de

raccorder une charge ohmique de 10 A ou

charge inductive de 4 A sous 400 V ~.

Le courant de démarrage maximal à

l’enclenchement du moteur (L.R.) est admis

à sept fois la charge inductive – avec un

maximum de 28 A.

Les pressostats RT sont conformes aux

normes VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

(Association des Ingénieurs Électriciens Allemands)

Montage

Un ensemble presse étoupe Pg13.5 est

joint au RT dans un sac séparé. Pour

assurer l’indice IP66 du RT (pressostat avec

réarmement automatique) ou IP54

(pressostat avec réarmement manuel), il

faut assembler le presse étoupe comme

indiqué sur la g. 5. Si le presse étoupe n’est

pas utilisé avec un câble, il faut le boucher

avec une pièce métallique.

Monter le pressostat sur le tableau général

ou sur le compresseur proprement dit.

Utiliser les trous de montage repére pos.

25, g. 1. Si l’appareil risque d’être soumis

à des vibrations, il doit être xé sur un

support souple.

En cas de pulsations au niveau de la prise

de pression il faut les amortir d’une façon

ecace, p. ex. en raccordant le pressostat à

l’installation au moyen d’un capillaire.

Voir g. 7.

réglable

∆p

[bar]

0.5 – 1.6

1.2 – 4

1.2

*1)

*2)

Raccordement électrique

Voir g. 6.

START = enclencher. STOP = déclencher

DIFF = diérentiel

Diamètre du câble: 6 – 14 mm

Raccorder la terre à la vis 38

Remonter la capuchon protecteur.

Réglage

Voir g. 2, 3 and 6.

Régler le pressostat sur la pression d’actionnement la plus basse (réglage de la plage).

NB: régler le RT 5 et RT 5A à réarmement

max. sur la préssion d’actionnement la plus

élevée (réglage de la plage).

Faire le réglage à l’aide de la tige de plage

44, en lisant simultanément l’échelle

principale 9.

Régler le diérentiel au moyen du rouleau

19 d’après le diagramme g. 3.

La pression d’actionnement la plus élevée

est égale à la somme de la pression de

réglage et du diérentiel.

Exemple

Le réglage sur »5« g. 3. donnera, pour

type RT 1A (no de code 017-500766) un

diérentiel d’env. 1.8 bar, tandis qu’il donnera,

pour le type RT 5A, un diérentiel d’env. 2.3

bar.

En général, en tournant la tige de la

plage, on déplace automatiquement vers

le haut ou vers le bas tant la pression

d’actionnement la plus élevée que celle la

plus basse (de coupure et de fermeture) car

la valeur de diérentiel reste inchangée.

La modication du diérentiel ne fait varier

par contre, que la pression d’actionnement

là plus élevée.

Pour tous les types RT sans réarmement

ainsi que pour les types RT à réarmement

min., I’échelle est étalonnée de sorte que

sa valeur de réglage corresponde à une

inversion du contact pour la pression

d’actionnement la plus basse (réglage

normal).

Pour les appareils RT à réarmement min.,

la pression dans le système de souet doit

augmenter d’une valeur correspondant

au diérentiel, avant que le réarmement

manuel ne puisse avoir lieu.

En ce qui concerne les appareils RT à

réarmement max. I’échelle est étalonnée de

sorte que sa valeur de réglage corresponde

à une inversion du contact pour la pression

d’actionnement la plus élevée (NB: contraire

au réglage normal).

La pression dans le système de souet

doit baisser d’une valeur correspondant

au diérentiel, avant que le réarmement

manuel ne puisse avoir lieu.

Accessories Voir fig. 7 et 8.

ESPAÑOL

Presostatos

1)

Sólo modelos con la letra A son válidos para

R717

Características técnicas

Campo

)

(P

Tipo

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

Rearme

manual

auto

min.

auto

max.

e

[bar]

-0.8 – 5

4 – 17

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Presión de funcionamiento max., PS / MWP:

22 bar / 315 psig

Presión de prueba max., p': 25 bar

Temperatura máxima permisible en el fuelle:

70 °C

Caja: IP66 según normas IEC 529

Carga de los contactos

Véase tapa del termostato o gura 4

La inscripción, par ejemplo 10(4) A, 400

V ~ signica que la corriente de conexión

máxima es de 10 A con cargo ohmica o de

4 A con cargo inductiva, a 400 V ~.

La corriente de arranque máxima en el

momento de la conexión del motor (L.R.)

puede ser de haste 7 veces la corriente con

cargo inductiva (máx. 28 A).

Los presostatos RT satisface las condiciones

estipuladas en VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

Montaje

En una bolsa separada, se incluye, junto

con el RT, un conjunto de prensaestopas

Pg13.5.Es necesario instalar el

prensaestopas como se muestra en la g. 5.,

para garantizar el grado de protección del

RT, IP66 (unidades con rearme automático)

o IP54 (unidades con rearme manual).Si no

se utiliza el prensaestopas con un cable,

debería montarse un cegamiento metálico.

El presostato está destinado a ser montado

en el panel de control o en el mismo compresor. Utilice los oricios de montaje pos.

25, g. 1. Si el presostato esta expuesto a

vibraciones ha de ser montado en una base

intermedia blanda.

Si se producen pulsaciones de presión en

el sistema, estas pulsaciones han de ser

ecazmente amortiguadas, por ejemplo

conectando el presostato a la instalación por

medio de un tubo capilar.

Véase g. 7.

Conexión a la red de alimentación

Véase g. 6.

Diferencial

ajustable

[bar]

0.5 – 1.6

jado aprox. 0.5

1.2 – 4

jado apr ox. 1.2

∆p

*1)

*2)

© Danfoss | DCS (jmn) | 2015.11

DKRCC.PI.CE0.C3.72 | 520H10128 | 4

Page 5

START = cierre. STOP = abertura

DIFF = diferencial

Diámetro del cable: 6 – 14 mm

El terminal de tierra 38 ha de ser conectado

a tierra.

Volver a colocar caperuza protectora.

Reglaje

Véanse guras 2, 3 y 6.

Ajustar el presostato a la presión de accionamiento mínima (ajuste de gama).

NOTA: Los aparatos RT 5 y RT 5A con

reposición máx. han de ser ajustados para

la presión de accionamiento máxima

(ajuste de gama).

Ej ajuste se hace hacienda girar el eje

principal 44 observando al mismo tiempo

la escala principal 9. La diferencial se

regula haciendo girar la tuerca de ajuste de

diferencial 19 de acuerdo con el diagrama

de la g. 3.

La presión de accionamiento máxima es

la suma de la presión de ajuste y de la

diferencial.

Ejemplo

Un reglaje sobre »5« g. 3. dará una diferencial

de aproximadamente 1.8 bar el aparato

tipo RT 1A (no de código 017-500766),

mientras

que el mismo ajuste en el

aparato tipo RT 5A dará una diferencial de

aproximada-mente 2.3 bar.

En general haciendo girar el eje principal,

las presiones de accionamiento máxima y

mínima (presiones de abertura de cierre) se

desplazan ambas automáticamente hacia

arriba o hacia abajo debido a la diferencial

ja. Por otra parte, hacienda girar la tuerca

de ajuste de diferencial, solamente cambia

la presión de accionamiento máxima.

La escala de todos los tipos RT sin reposición,

y de todos los tipos RT con reposición min.,

está calibrada de tal manera que el ajuste

de escala corresponda al cambio de

posición del contacto – cuando se supera

la presión de accionamiento mínima

(ajuste normal).

En Los presostatos RT con reposición mínima,

la presión en el sistema de fuelle debe

aumentar en un valor correspondiente a la

diferencial, antes de que pueda realizarse la

reposición manual.

Los equipos de control RT con reposición

máx., tienen una escala calibrada de tal

manera que el ajuste de escala corresponda

al cambio de posición del contacto cuando

se alcanza la presión de accionamiento

máxima, (NOTA: al revés que en el ajuste

normal).

La presión en el sistema de fuelle debe

disminuir en un valor correspondiente

a la diferencial, antes de que pueda

realizarse la reposición manual.

Accesorios Véanse figuras 7 y 8.

ITALIANO

Pressostati

1)

Solo I modelli con la lettera A sono idonei

per utilizzo con R717

Dati tecnici

Campo

(P

Tipo

RT 1

RT 1A

RT 5

RT 5A

*1)

RT 1A 017-500766 - adjustable dierential

1.3 – 2.4 bar

*2)

RT 5 017-528466 - adjustable dierential

Reinser-

zione

auto

min. 0.5 ja

auto

max. 1.2 ja

e

[bar]

-0.8 – 5

4 – 17

0.6 – 3.0 bar

RT 5 017-539566 - adjustable dierential

0.3 – 2.5 bar

Max. pressione di esercizio, PS / MWP:

22 bar / 315 psig

Max. pressione di prova, p': 25 bar

Max. temperatura permessa ai soetti: 70 °C

Sistema di chiusura: IP66 a IEC 529

Carico contatti

Indicato sul coperchio dello stesso contatto

g. 4.

Esempio di marcatura:10(4) A, 400 V~

signica che alla tensione di 400 V ~ il

contatto puo’ sopportare un massimo di 10

A omico o 4 A induttivi.

La corrente di spunto (L.R.) puo’ essere

calcolata per un massimo di sette volte il

carico induttivo (max. 28 A).

Il pressostato RT é omologato secondo

norme VDE* 0660.

*VDE = Verband Deutscher Elektrotechniker

Montaggio

Un set di pressacavo lettato Pg13.5 è

allegto all’RT in una busta a parte. Per

assicurare un grado di protezione per l’RT

di IP66 (unità con reset automatico) o di

IP54 (unità con reset esterno), è necessario

assemblare questo pressacavo come

illustrato in g. 5. Se questo pressacavo

non è usato con un cavo, un connettore in

metallo deve essere assemblato.

Il pressostato è adatto per essere montato

sul pannello delle apparecchiature o direttamente sul compressore stesso. Usare i fori

di ssaggio pos. 25, g. 1.

Se l’automatismo può essere sottoposto

a vibrazioni, dovrà essere montato su una

basetta ammortizzata.

Se si vericano pulsazioni di pressione nel

sistema, tale pulsazioni dovranno essere

eliminate, collegando, per esempio, il

pressostato al sistema per mezzo di un tubo

capillare. Vedere g. 7.

Collegamenti principali

Vedere g. 6.

START = attacco. STOP = stacco

DIFF = dierenziale

Diametro del cavo: 6 – 14 mm

Dierenziale

)

regolabile

[bar]

0.5 – 1.6

1.2 – 4

∆p

Il terminale terra 38 dovrà essere collegato

alla massa.

Rimontare il cappuccio di protezióne.

Regolazione

Vedere g. 2, 3 e 6.

Tarate il pressostato per la minima pressione

di funzionamento (taratura del campo).

NOTA: RT 5 e RT 5A con reinserzione di

massima dovrebbero essere tarati per

una massima pressione di funzionamento

*1)

(taratura del campo).

La taratura è fatta girando l’asta principale

44, leggendo contemporaneamente la

*2)

scala princi-pale 9. Il dierenziale è tarato

girando il dado 19 di regolazione del

dierenziale, secondo il diagramma della

g. 3.

La massima pressione di funzionamento è

la somma della pressione di taratura e del

dierenziale.

Esempio

Una taratura di «5» g. 3. darà un dierenziale di circa 1.8 bar sul tipo RT 1A

017- 500766), mentre la stessa taratura sul

tipo

RT 5A darà un dierenziale di circa

2.3 bar.

In generale, girando l’asta principale

automaticamente muove sia la pressione

massima e minima di funzionamento

(interrompe e attacca) per pressioni piú alte

o piú basse per via del die-renziale sso.

D’altra parte, girando il dado di regolazione

del dierenziale si altera solo la pressione

massima di funzionamento.

La scala di tutti i tipi RT senza reinserzione

e dei tipi RT con reinserzione di minima è

calibrata in modo tale che la taratura della

scala corrisponde all’intervento del contatto

relativo alla pressione minima di funzionamento (taratura normale).

En Los presostatos RT con reposición mínima,

la presión en el sistema de fuelle debe

aumentar en un valor correspondiente a la

diferencial, antes de que pueda realizarse la

reposición manual.

Sulle apparecchiature RT con reinserzione

di minima, la pressione nel sistema dei

soetti deve aumentare di un valore

corrispondente al dierenziale, prima che

la reinserzione manuale si possa eettuare.

Gli apparecchi RT con reinserzione di

massima hanno una scala che é calibrata

in modo che la taratura della scala

corrisponda all’intervento del contatto

relativo alle pressione massima di

funzionamento. (NOTA: contrariamente alla

taratura normale).

La pressione nel sistema dei soetti deve

diminuire di un valore che corrisponde

al dierenziale, prima che la reinserzione

manuale possa essere eettuata.

Accessori Vedere fig. 7 e 8.

(n° codice

© Danfoss | DCS (jmn) | 2015.11

DKRCC.PI.CE0.C3.72 | 520H10128 | 5

Loading...

Loading...