Page 1

Design guide

DATA COMMUNICATION MODBUS RS 485 RTU

For product type - EKD / EIM controllers

This User guide document provides general

information on the setup of Modbus RS-485

networks and explains how to congure the

communication between EKD/EIM and a system

controller, using the Modbus RTU.

Features • Simplicity

• Standard Ethernet

• Open protocol

• Availability on many devices

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 1

Page 2

Design guide | Data Communication Modbus RS485 RTU

Part 1 - Hardware network specication

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Denitions and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RS-485 specic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cable connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Conductors in a daisy chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ground connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Part 2 - Software specication and conguration

Introduction of RS-485 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Modbus RTU message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Modbus RTU message structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to access parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RS485 bus function codes overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EKD examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EIM examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix 1 EIM Modbus conversion table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix 2 EKD Modbus table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix 3 Modbus exception code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix 4 Modbus tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 2

Page 3

Design guide | Data Communication Modbus RS485 RTU

Introduction

References

Denitions and

abbreviations

Making a network means to connect devices together with a communication bus. But to make

reliable and high performance networks strict rules must be followed.

Modbus specications, Modbus.org

EIA-485 RS-485 eldbus specication

RTU Remote Terminal Unit

SW Software

HW Hardware

AWG American Wire Gauge

EKE / EIM / EKD Superheat Controller/driver

Parameter The parameter number indicates the number of a given parameter.

Value Indicates the factory settings.

Typ e Group. Group (number) indicates the group the relevant parameter

belongs to. The group number is only of importance for presentation

in AKM PC software.

PNU Short for Parameter NUmber. In Modbus terminology it corresponds to the

register number which is also often referred to as the oset. The PNU numbers

can have values in the range from 1 to 65535. The corresponding Modbus

address is found by subtracting 1 from the PNU number. For instance PNU

number 117 would correspond to Modbus address 116.”

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 3

Page 4

84N404.10

Design guide | Data Communication Modbus RS485 RTU

Wiring

Wiring characteristics

Wiring types

Recommendations

(Source Modbus.org)

The wires should have the following characteristics:

• Characteristic impedance: 120 Ohm +/- 10%;

• Specic resistance depending on network length.

• Cable must be with Screen if the bus cable exceeds 3m.

• The cable is connected from controller to controller and no branches are allowed on the cable

• Each shield must be grounded at one side only.

Two types of wires can be used based on required ruggedness:

1. Twisted pair with ground: short leads, no power lines in proximity.

2. Twisted pair + ground and shield: long leads, disturbed environment.

When choosing a transmission line for RS-485, it is necessary to examine the required distance of the

cable and the data rate of the system.

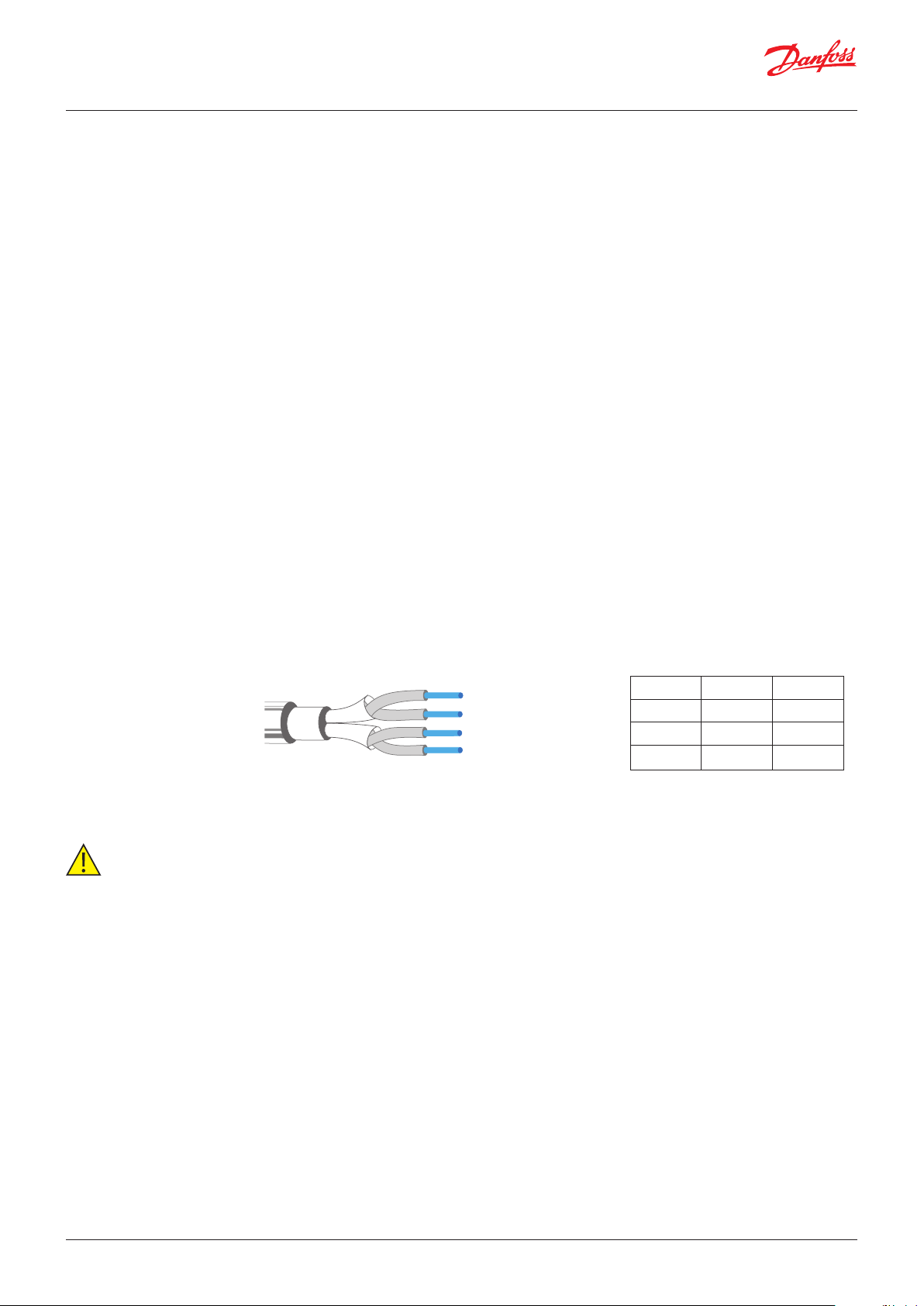

An RS485-Modbus must use a balanced pair (for D+-D-) and a third wire (for the Common/Gnd).

For RS485-Modbus, Wire Gauge must be chosen suciently wide to permit the maximum length

(1000 m ). AWG 22 is always sucient for the Modbus Data.

Category 5 cables may operate for RS485-Modbus, to a maximum length of 600m.

For the balanced pairs used in an RS485-system, a Characteristic Impedance with a value higher than

100 Ohms may be preferred, especially for 19200 and higher baud rates.

Use one twisted pair of conductors for connecting the dierential signals and use another conductor

(for example a second twisted pair) for connecting the ground.

Note!

Modbus

D+ (A+)

D– (B–)

Modbus connections

EKE EKD EIM

D+ A+ TxD+

D- B- TxD-

Danfoss

Fig. 1 Connection example

GND

Gnd Gnd

1

) Gnd has been omitted from EIM.

Connection of a twisted cable in a 2-wire Modbus system may cause damages.

1

)

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 4

Page 5

Danfoss

84B3210.10

Repeater

Design guide | Data Communication Modbus RS485 RTU

RS-485 specic

RS-485: Controllers

Repeater

The RS-485 consists of three wires:

• RS-485-A (D+);

• RS-485-B (D-);

• GND.

The two wires RS-485-A (D+) and RS-485-B (D-) propagate a dierential communication signal.

In addition there is the ground wire for the common mode voltage reference.

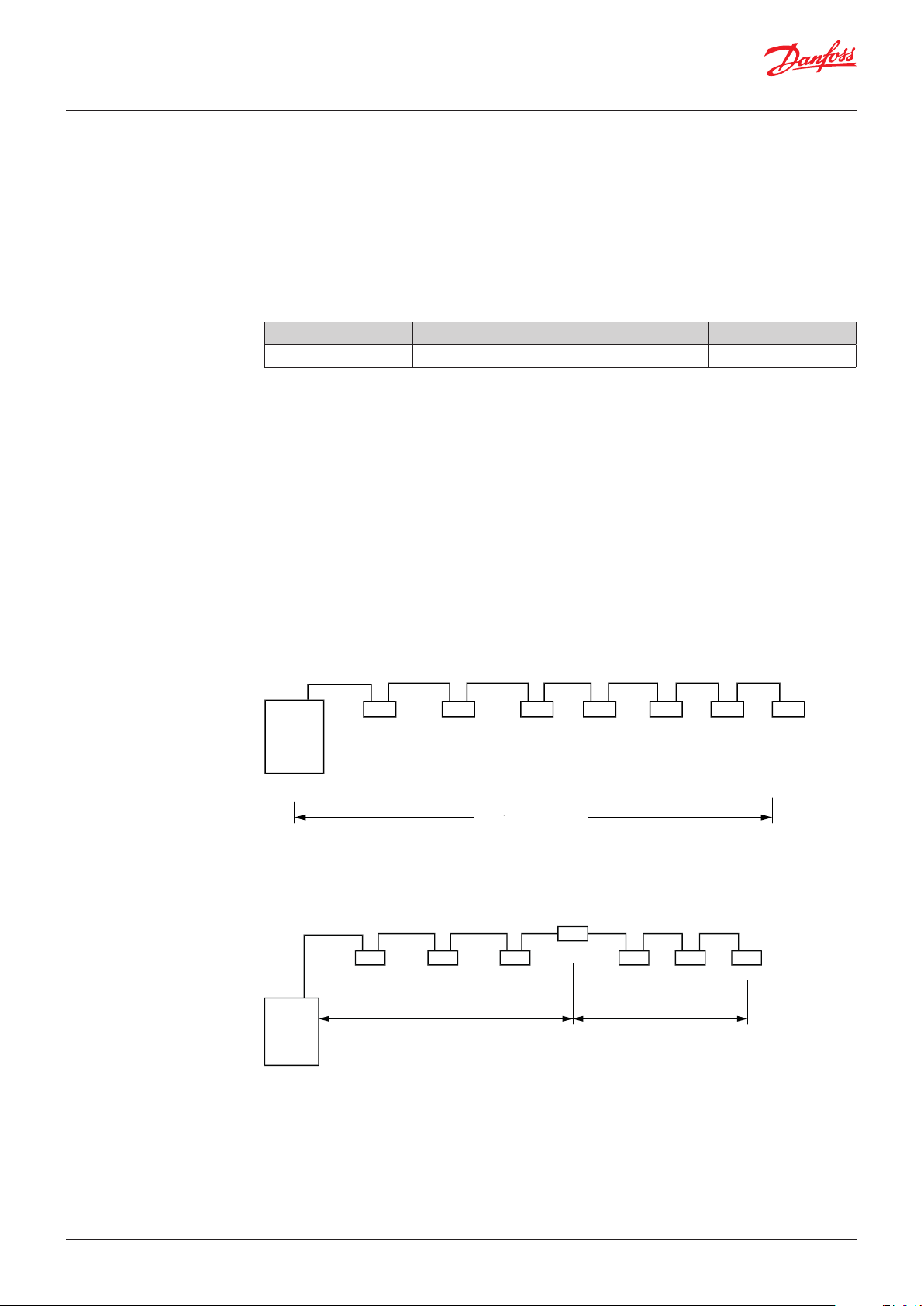

The recommended maximum Modbus cable length between the EKE(/EKD/EIM) and the system

controller should not exceed 1000 meters (3300 feet).

Wire length

Length (m) Max. baudrate Min. Wire size Suggested types

1000 125 K AWG22 Belden 3106A / 3107A

The maximum number of controllers that can be connected to a Modbus line is 120.

One repearter must be added for every 32 controllers. If the data communication cable runs through

an electrically noisy environment which impairs the data signal, one or more repeaters must be

added to stabilize the signal.

A repeater has no address.

A repeater from the company "Phoenix" can be used:

Danfoss code no. = 084B2240 (type AKA 222).

Master

Modbus

Master

Modbus

Slaves

max. 1000 m

Slaves Slaves

Danfoss

84B3210.10

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 5

Page 6

Min 10-15 cm

Danfoss

84B3206.10

Field BUSField BUS

Danfoss

84B3205.10

Field BUS

Stub

Danfoss

84B3203.10

Design guide | Data Communication Modbus RS485 RTU

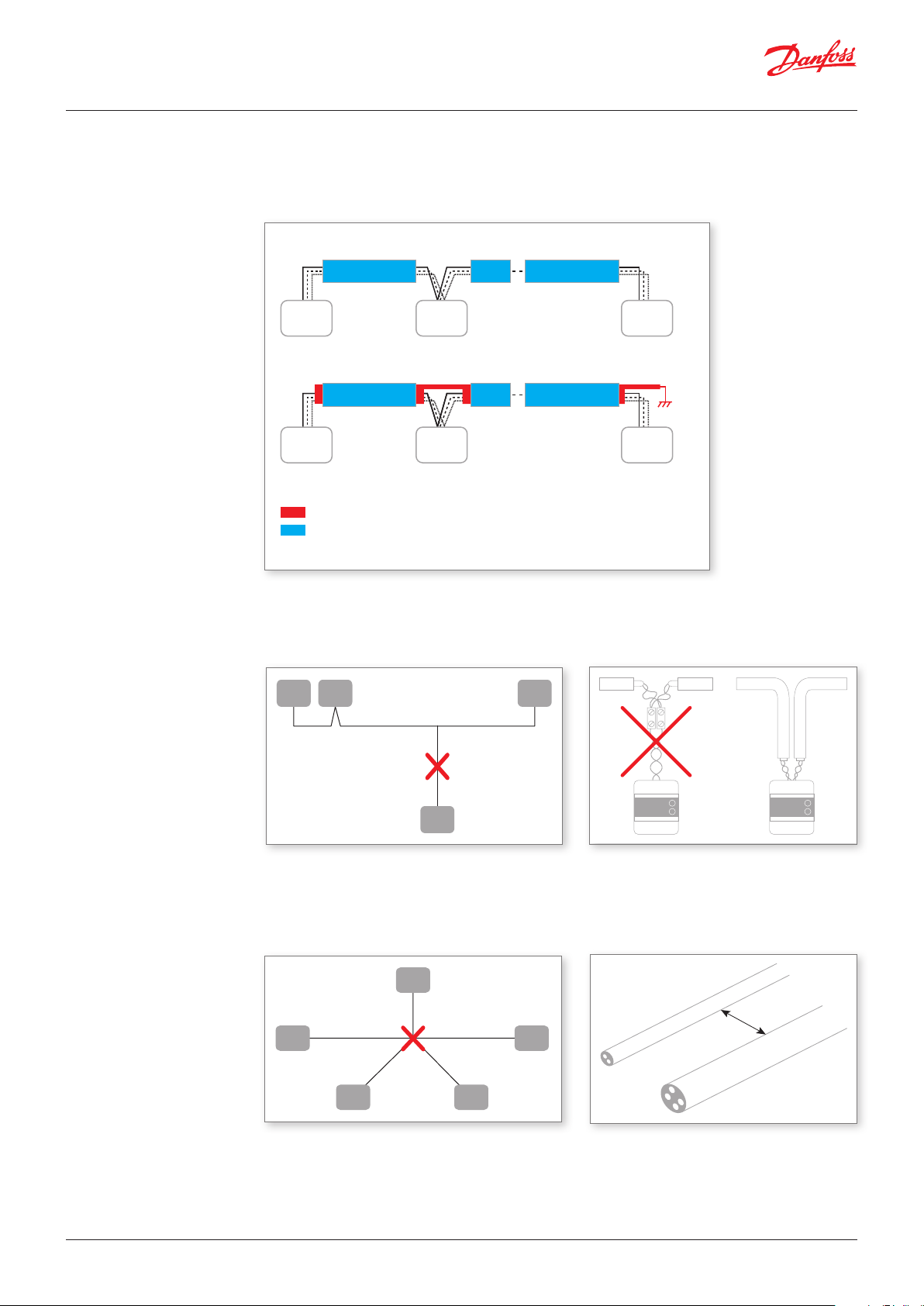

Topology

Standard topology

Recommendations

The controller should be connected according to the bus topology. That means that the communication cable is wired from one controller to the next without branches.

Three conductors

T

001

002

T

n

Three conductors + shiels

T

001

Legend

Shield

Communication cable, 120 Ω impedance

T

120 Ω termination

002

T

n

Danfoss

84B3202.10

Avoid making stubs on the line.

If stubs are present in the network they should be kept as short as possible

(<0.3 m at 1 Mbit; <3 m at 50 kbit).

Fig Fieldbus with ‘’STUB” 01

Fig Star topology

Do not use a ‘STAR topology’

- 0.0.0. - 0.0.0.

Fig Fieldbus with ‘’STUB” 02

Fig Fieldbus wire

Do not route the eldbus wires close to power

lines or wires leading to heavy loads

Danfoss

84B3204.10

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 6

Page 7

Danfoss

80G168.10

Danfoss84B3208.1

Design guide | Data Communication Modbus RS485 RTU

Cabinet mounting

Note!

Route the wires close to the devices separating the twisted wires only for the shortest possible distance needed for inserting

them into the screw terminals.

When controllers are installed in a cabinet,

internal cable ducting must also comply with

the relevant requirements. Use this cable

ducting when one or more controllers are

installed in a cabinet. The short connections

between controllers must also be of the correct cable types.

On running/bundling the communication wires very close to high power wires or

other sources of electrical noise (frequency

converters etc.) could cause electromagnetic

interference. Therefore, try to separate the

wires from such sources if possible.

Max. 5 cm

Danfoss

84B3207.10

Fig Wires close

• Do not use dierent wire types on a network, even

for short distances.

• Do not route through terminal blocks

- 0.0.0. - 0.0.0. - 0.0.0.

Danfoss

84B3209.10

Cable connection and

termination Modbus

Keep a distance to relays, their cables and other things

emitting electric noises

Connect the RS-485 cable to the dedicated terminals of the EKD controller:

• Negative (B-) polarity wire to terminal 9

• Positive (A+) polarity wire to terminal 10

• Cable screen to terminal 11.

For EIM , connect it as shown in the gure to terminal COM

EIM

-

TxD

TxD+

D

PWR

COM

0

Modbus to master

controller

POS4S2

ADR

EEV

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 7

Page 8

80G169.10

Design guide | Data Communication Modbus RS485 RTU

Termination

Conductors in a

daisy chain

There must be always two terminations on the network, one at each bus end.

The termination can be installed by connecting a 120 Ohm ± 10 % resistor between D+ and Dfor RS-485.

Here is shown a picture of how a Modbus network is typically terminated. The resistors are in this

picture called LT (Line Termination) and are typically 120 Ohm.

The pull up and pull down are usually built into the master on the Modbus. They are not built in

Danfoss controllers i.e EIM 336, EKD 316.

LT

D

Slave 1Slave 2

Danfoss

Ballanced Pair

R

Master

D

R

D+

D–

Common

R

D

Figure. Two wire bus trophology

5V

Pull up

LT

Pull down

The wires are looped from device to device

D+ is connected to D+

D- is connected to DIn other words, Start Node (with termination resistor) from Node x to Node Y …. to End Node (with

Termination Resistor)in such a way that the polarity of the wires matches with the polarity of the

controller terminals.

Conducters

Note!

Ground connections

Modbus

D+ D- D+ D- D+ D-

Shield (drain) should only be connected in one end, not both ends.

In case of EIM, this is how it is done. The communication line in PWR and COM are internally connected.

RS485 +

Master controller

Danfoss

80G165.10

RS485 -

PWR

EIM slave 1

If two EIMs are connected remember to remove the addressing jumper on one of the EIMs.

There must be a clean ground connection between all devices connected in the network.

In unisolated controller like EKD and EIM, if grounding is required , it should strick followed the

guideline as explained on section 3.1

RS485 +

COM

RS485 -

Danfoss

PWR

EIM slave 2

84B3212.10

COM

R = 120 Ohm

Min. 0.25 Watt

Note!

Be careful when connecting the bus to devises that have non isolated communication interfaces. If

the units are tied to dierent ground potentials, this may lead to communication problems or even to

damage to the units!

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 8

Page 9

Design guide | Data Communication Modbus RS485 RTU

Part 2 Software specication and conguration

Introduction This Chapter explains how to congure the communication between a EKE(/EKD/EIM) and a system

controller, using the Modbus RTU (Remote Terminal Unit) protocol. For detailed information about

Modbus communication, refer to Modbus Application Protocol Specications V1.1b from

www.modbus.org

RS-485 Communication The Electronics Industry Association (EIA) established the RS-485 standard as a guide for developing a

multi-drop, bi-directional communication network.

RS-485 systems can be implemented using two-wires or four-wires modes. Danfoss uses the two-

wires system with shield. With the two-wires system, communication is half-duplex (cannot transmit

and receive at the same time).

The Modbus line uses one twisted–pair line – two wires twisted around themselves. This is known as

balanced data transmission. The signal on one wire is ideally the exact opposite of the signal on the

second wire. In other words, if one wire is transmitting a high, the other wire will be transmitting the

low, and vice versa. Since RS-485 is a multipoint communication system, all devices are connected to

the single twisted-pair cable.

The RS-485 system uses master/slave architecture, where each slave device (EKE/EKD/EIM) ) has its

unique address and responds only to requests packets addressed to this device. The requests packets

are generated by the master (system controller), which periodically polls all connected slave devices.

Data travels over the single line in both directions.

A basic RS-485 system requires an I/O driver with dierential outputs and an I/O receiver with differential inputs. Since the signal is transferred via a twisted pair of wires, if noise or interference is

introduced into the line, the voltage dierence (between twisted pair wires) of this interference

is almost zero. Because the input to the receiver is dierential, this interference is eliminated. Dierential inputs also ignore dierent earth potentials of the transmitter and the receiver.

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 9

Page 10

Design guide | Data Communication Modbus RS485 RTU

Modbus RTU message

The controllers are set up to communicate on the Modbus network using RTU (Remote Terminal Unit)

mode, with each byte in a message containing consisting of 11 bit. The format for each byte is shown

below.

Start bit Date byte Stop Parity Stop

Cooling system 8-bit binary, hexadecimal 0–9, A–F. Two hexadecimal characters contained

in each 8-bit eld of the message

Bits Per Byte 1 start bit

8 data bits, least signicant bit send rst

1 bit for even/odd parity; no bit for no parity

1 stop bit if parity is used; 2 bit if no parity

Error check eld Cylindric Redundance Check (CRC)

Danfoss controller follows the standard modbus communication with the following defaults :19200

Baudrate, Even parity and one stop bit.

In EIM/EKD, communication frequency (baudrate) can be one of the following: 9600 baud, 19200

baud and 38400 baud.

The only available xed communication setting in EKD is 8 data bit, EVEN parity and 1 stop bit.

The default unit address is 240 which, can be changed using parameter “03 unit address”. Whereas a

wide range of selection bits are available in EIM modbus , check the product manual for detail.

Modbus RTU message

structure

How to access parameters

A typical message frame is shown below.

Start Address Sunction Data CRC check End

Start 8 bits 8 bits N x 8 bits 16 bits end

Example

Slave

Address

Function

Code

H1 Byte

Address

Lo byte

Adress

NumRegs

Hi Lo

CRC

A5 03 00 10 00 02 DC EA

The PNU (Parameter Number) is translated from the register address contained in the Modbus read

or write message. For detail check the section ‘Example’

When addressing holding registers on Modbus, the range of valid addresses is 0-65535 (0x0000 to

0xFFFF). In the documentation they are however often described in two dierent ways.

The rst is using register numbers instead of addresses. By this convention the range of valid register

numbers is 1-65536, and the register address 0 is refered to as register number 1. Danfoss follows this

convention so when reading the PNU (Parameter Number) 117, the actual request asks for data from

address 116. So address = PNU – 1.

The second convention denes seperate ranges for dierent types of registers (coils, discrete inputs,

input register and holding registers). The number of available registers were originally limited to

10000 for each type, and in order to easily distinguish between the register types, in manuals etc.,

each type was assigned a part of the numbering range. In this way holding registers were numbered

from 40001 to 50000. The address range is however the same as before so the rst holding register

with register number 40001 still is addressed on Modbus as address 0. So address = register number –

40001. This convention was introduced by the company Modicon and is therefore often referred to as

the Modicon convention.

Note!

Modicon conventionway of addressing is available in EIM 336/316 controller only.

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 10

Page 11

Design guide | Data Communication Modbus RS485 RTU

RS485 bus function

codes overview

Example The following examples illustrate various Modbus RTU commands in EKD

Note!

Action Description

Setup Switching the Main switch OFF/ON.

1 = Set “r12 Main switch ” PNU 117 to 0 (using address 240).

2 = Set “r12 Main switch ” PNU 117 to 1 (using address 240).

Result Verify that the EKD respond the Modbus master with an accept message.

Conclusion Writing r12 (PNU 117) to 0

[F0][06][00][74][00][00][DC][F1]

[F0][06][00][74][00][00][DC][F1] – Slave acknowledges

Writing r12 (PNU 117) to 1

[F0][06][00][74][00][01][1D][31]

[F0][06][00][74][00][01][1D][31] – Slave acknowledges

EKD/EIM RS485 Function code Comment

Read PNU 0x03 Read holding registers

Write PNU 0x06 Write Single PNU/holding register only

1. Requests are shown in blue and the hexadecimal representation of the data on the Modbus .

2. Responses are shown in green. The text in green is an interpretation of the response.

Action Description

Setup Setting up the Superheat maximum parameter n09

1 = Write “r12 Main switch ” PNU 117; Set it to 0.

2 = Write “n09 Max. SH “ PNU 3015; Set to 60.

3 = Read “n09 Max. SH ” PNU 3015; veryfying step 2.

Result Reading n09 max. SH i.e. PNU 3015 must be 60.

Conclusion Write r12 (PNU 117) to 0

[F0][06][00][74][00][00][DC][F1]

[F0][06][00][74][00][00][DC][F1] – Slave acknowledges

Reading PNU 3015

[F0][03][0B][C6][00][01][73][32]

[F0][03][02][00][64][C4][7A] – Slave responds 100

Writing PNU 3015 to 60

[F0][06][0B][C6][00][3C][7E][E3]

[F0][06][0B][C6][00][3C][7E][E3] – Slave acknowledges

Reading PNU 3015 again

[F0][03][0B][C6][00][01][73][32]

[F0][03][02][00][3C][C5][80] – Slave responds 60

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 11

Page 12

Design guide | Data Communication Modbus RS485 RTU

Example The following examples illustrate various Modbus RTU commands in EKD

Note!

Action Description

Setup Changing the device address

1 = Read “o03 Unit addr. ” PNU 2008 using address: 240.

2 = Set “o03 Unit addr. “ PNU 2008 to 239

Result 1 = Verify that it’s possible to use address 240.

2 = Verify that it’s possible to use address 239.

Conclusion Reading PNU 2008 from ID 240

[F0][03][07][D7][00][01][20][67]

[F0][03][02][00][F0][C5][D5] – Slave responds 240

Setting PNU 2008 to 239 on ID 240

[F0][06][07][D7][00][EF][6C][2B]

[F0][06][07][D7][00][EF][6C][2B] – Slave acknowledges

Reading PNU 2008 from ID 240

[F0][03][07][D7][00][01][20][67]

No response since the address is changed

Reading PNU 2008 from ID 239

[EF][03][07][D7][00][01][22][08]

[EF][03][02][00][EF][11][DF] – Slave responds 239

1. Requests are shown in blue and the hexadecimal representation of the data on the Modbus .

2. Responses are shown in green. The text in green is an interpretation of the response.

Action Description

Setup Reading Evaporator Pressure

1 = Read “u25 EvapPress Pe ” PNU 2543 using Modbus function code 0x03.

2 = Read “u25 EvapPress Pe ” PNU 2543 using Modbus function code 0x04.

Result Note: Read 0x04 function is only available in some selective danfoss controllers.

1 & 2 = Both Modbus commands responds with the same answer.

Conclusion Reading PNU 2543 with function code 03

[F0][03][09][EE][00][01][F2][82]

[F0][03][02][00][87][85][F3] – Slave responds 135

Reading PNU 2543 with function code 04

[F0][04][09][EE][00][01][47][42]

[F0][04][02][00][87][84][87] – Slave responds 135

Action Description

Setup Setting the controller in Manual mode

Set “o45 Manual OD%” PNU 2064 to 45.

Result Verify that the message and responds are:

Message: 0xA5 0x06 0x08 0x0F 0x00 0x2D 0x62 0x90

Responds: 0xA5 0x06 0x08 0x0F 0x00 0x2D 0x62 0x90

Conclusion Setting PNU 2064 to 45

[A5][06][08][0F][00][2D][62][90]

[A5][06][08][0F][00][2D][62][90] – Slave acknowledges

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 12

Page 13

Design guide | Data Communication Modbus RS485 RTU

Example The following examples illustrate various Modbus RTU commands in EKD

Note!

Action Description

Setup Examples explaining some illegal addressing and request with 0x03 (Read function) and 0x06 (Write).

Result The device must respond with illegal address or no response.

Conclusion Read 2 register starting from PNU 2008 from slave 240

[F0][03][07][D7][00][02][60][66]

[F0][83][02][91][02] - slave responds illegal address because 2009 is not dened

Read o03 unit address (PNU 2008) from slave 240 with wrong CRC

[F0][03][07][D7][00][01][20][68]

no response

Read PNU 2009 (undened) from slave 240

[F0][03][07][D8][00][01][10][64]

[F0][83][02][91][02] - slave responds illegal address because 2009 is not dened

Write 2 to r12 main switch (PNU 117) on slave 240

[F0][06][00][74][00][02][5D][30]

[F0][86][03][53][92] - slave responds illegal data

Write 1 to PNU 118 (undened) on slave 240

[F0][06][00][75][00][01][4C][F1]

[F0][86][02][92][52] - slave responds illegal address

1. Requests are shown in blue and the hexadecimal representation of the data on the Modbus .

2. Responses are shown in green. The text in green is an interpretation of the response.

Write 1 to r12 main switch (PNU 117) on slave 240 with wrong CRC

[F0][06][00][74][00][01][1D][31]

no response

Use function code 5 (undened)

[F0][05][00][74][00][01][59][31]

[F0][85][01][D2][A3] - slave responds illegal function

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 13

Page 14

Design guide | Data Communication Modbus RS485 RTU

Example The following examples illustrate various Modbus RTU commands in EIM

Note!

Action Description

Setup

Conclusion

Action Description

Setup

Conclusion

1. Requests are shown in blue and the hexadecimal representation of the data on the Modbus .

2. Responses are shown in green. The text in green is an interpretation of the response.

Switching the Main switch OFF/ON (using address 165).

Reading r12 main switch (PNU 117)

[A5][03][00][74][00][01][DD][34]

[A5][03][02][00][00][C9][9D] – Slave responds 1

Setting r12 main switch (PNU 117) to 1

[A5][06][00][74][00][01][11][34]

[A5][06][00][74][00][01][11][34] - Slave acknowledges

Setting r12 main switch (PNU 117) to 0

[A5][06][00][74][00][00][D0][F4]

[A5][06][00][74][00][00][D0][F4] – Slave responds 0

Setting up the Superheat Max. SH value on address 165

Reading PNU 3015

[A5][03][0B][C6][00][01][7F][37]

[A5][03][02][00][A0][C9][E5] – Slave responds

Setting PNU 3015 to 100

[A5][06][0B][C6][00][64][73][1C]

[A5][06][0B][C6][00][64][73][1C] – Slave acknowledges

Reading PNU 3015 again

[A5][03][0B][C6][00][01][7F][37]

[A5][03][02][00][64][C8][76] – Slave responds 100

Action Description

Setup

Conclusion

Changing EIM addressing from PNU to Modicon addressing

Reading PNU 64200 (Modbus translation table)

[A5][03][FA][C7][00][01][1C][0B]

[A5][03][02][00][00][C9][9D] – Slave responds 0 (use PNU)

Setting PNU 64200 to 1

[A5][06][FA][C7][00][01][D0][0B]

[A5][06][FA][C7][00][01][D0][0B] – Slave acknowledges

Reading PNU 64200 again

[A5][03][FA][C7][00][01][1C][0B]

[A5][03][02][00][01][08][5D] – Slave responds 1

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 14

Page 15

Design guide | Data Communication Modbus RS485 RTU

Example The following examples illustrate various Modbus RTU commands in EIM

Note!

Action Description

Setup

Conclusion

Action Description

1. Requests are shown in blue and the hexadecimal representation of the data on the Modbus .

2. Responses are shown in green. The text in green is an interpretation of the response.

Switching the Main switch OFF/ON with Modicon addressing

Setting Modicon 40011 (r12 main switch) to 0

[A5][06][00][0A][00][00][B0][EC]

[A5][06][00][0A][00][00][B0][EC] – Slave acknowledges

Reading Modicon 40011 (r12 main switch)

[A5][03][00][0A][00][01][BD][2C]

[A5][03][02][00][00][C9][9D] – Slave responds 0

Setting Modicon 40011 (r12 main switch) to 1

[A5][06][00][0A][00][01][71][2C]

[A5][06][00][0A][00][01][71][2C] – Slave acknowledges

Reading Modicon 40011 (r12 main switch) again

[A5][03][00][0A][00][01][BD][2C]

[A5][03][02][00][01][08][5D] – Slave responds 1

Setup

Conclusion

Reading the registers with Modicon addressing.

Reading Modicon 40001 to 4004

[A5][03][00][00][00][04][5D][2D]

[A5][03][08][FC][E0][07][08][05][DC][00][00][4D][7A] – Slave responds -800, 1800, 1500, 0

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 15

Page 16

Design guide | Data Communication Modbus RS485 RTU

Appendix.1

EIM Modbus Conversion table

Parameter PNU Modicon

address

u25 EvapPress Pe 2543 40001

u20 S2 temp. 2537 40002

u16 S4 air temp. 2531 40003

u27 Temp. S3 2545 40004

--- Ctrl Status 3100 40005

u26 EvapTemp Te 2544 40006

u22 SuperheatRef 2535 40007

u21 Superheat 2536 40008

u24 Opening % 2542 40009

--- LOC Alarm 50006 40010

r12 Main switch 117 40 011

--- Te Reference 3117 40012

--- Comp Speed 3120 40 013

ext EvapPress P0 2643 4 0 014

ext S2 temp 2644 40015

--- Di MOP 3121 40016

r09 Adjust S2 113 40017

o45 Manual OD% 2064 40018

n09 Max SH 3015 4 0 019

n10 Min SH 3021 40020

n22 SH close 3027 40021

--- Tn SH 3103 40022

n11 MOP 3013 40023

--- SH Low 3105 40024

--- SH High 3106 40025

--- Gain High 3107 40026

--- Gain Low 3108 40027

--- Tau High 3109 40028

--- Tau Low 3110 40029

--- Alpha 3111 40030

--- Kp MOP 3113 40031

--- Tn MOP 3114 40032

--- Kp Te 3115 40033

Parameter PNU Modicon

address

--- Tn Te 3116 40034

n20 Kp T0 3025 40035

o18 Manual ctrl. 2075 40036

--- LOC Trig 50003 40037

--- LOC Reset 50004 40038

--- LOC Timer 50005 40039

--- LOC SH Trig 50007 40040

o03 Unit addr. 2008 40041

--- Unit Addr. 2 2009 40042

--- Modbus Baud 50060 40043

--- ModbusParity 50061 40044

--- ModbusStopB 50062 40045

--- ClosedValveT 3101 40046

--- Def Activate 50 011 40047

--- Def Hold OD 50008 40048

--- Def HoldTi 1 50009 40049

--- Def HoldTi 2 50010 40050

--- Max SH shdw 64301 40051

--- Min SH shdw 64302 40052

--- Tn SH shdw 64303 40053

--- Alpha shdw 64304 40054

--- DefHold shdw 64305 40055

--- SWVer shdw 64306 40056

--- Startup 64307 40057

n15 StartUp time 3017 40058

n17 Start OD % 3012 40059

--- O Min.OD % 64308 40060

--- HwMainSwitch 6 410 0 40061

o20 MinTransPres 2034 40062

o21 MaxTransPres 2033 40063

o30 Refrigerant 2551 40064

--- Rfg.Fac.A1 2548 40065

--- Rfg.Fac.A2 2549 40066

Parameter PNU Modicon

address

--- Rfg.Fac.A3 2550 40067

--- Standby 20000 40068

--- EKC Error 20001 40069

--- S2 Error 20002 40070

--- S4 Error 20004 40071

--- Pe inp.error 20005 40072

--- No Rfg. Sel. 20006 40073

--- Valve error 20007 40074

--- Reset alarm 2046 40075

n37 Max steps 3032 40076

n38 Max StepsSec 3033 40077

n39 Start BckLsh 3034 40078

n40 Backlash 3035 40079

n56 MotorCurrent 3051 40080

--- Factory2User 64060 40081

--- User2Factory 64062 40082

--- ControlState 3099 40083

--- LOC Tmr 3102 40084

--- Avg Opening 50033 40085

--- OpenHighRes 50052 40086

--- InputMeas 1 64050 40087

--- InputMeas 3 64052 40088

--- Sw. version 2003 40089

--- OrderNoLow 2 011 40090

--- OrderNoHigh 2015 40091

--- Avg KT0 Time 50020 40092

--- Avg OD 3hour 50021 40093

--- Avg CompTime 50022 40094

--- AvgFltTime 3118 40095

--- Modbus trans 64200 Not available in BO

address

range

For detail description on the above parameters, please refer to the product user guide

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 16

Page 17

Design guide | Data Communication Modbus RS485 RTU

Appendix 2

EKD modbus table

Parameter PNU

r05 Temp.unit 105

r09 Adjust S2 113

r10 Adjust S3 114

r12 Main switch 117

A34 Battery low 10035

n03 Valve type 3002

n04 Kp factor 3003

n05 Tn seconds 3004

n06 Td seconds 3005

n09 Max SH 3015

n10 Min SH 3021

n11 MOP 3013

n15 Start time 3017

n17 MinOdAtStart 3012

n18 Stability 3014

n19 Kp min. 3024

n20 Kp T0 3025

n21 SH mode 3026

n22 SH close 3027

n32 ETS OD% Max 3023

--- Kp Actual 64090

n37 Max steps 3032

n38 Max StepsSec 3033

n39 Start BckLsh 3034

n40 Backlash 3035

n42 Comp. dir. 3037

n43 Atten.Factor 3038

n44 TnT0 sec. 3039

n45 Min.Lim.Ref 3040

n56 MotorCurrent 3051

--- EKC state 2007

o10 AI type 2027

Parameter PNU

o18 Manual ctrl. 2075

o20 MinTransPres 2034

o21 MaxTransPres 2033

o30 Refrigerant 2551

o45 Manual OD% 2064

o56 Reg. type 2076

o61 Appl.mode 2077

--- Rfg.Fac.A1 2548

--- Rfg.Fac.A2 2549

--- Rfg.Fac.A3 2550

--- Sw. version 2003

--- OrderNoLow 2011

--- Factory2User 64060

--- Open Hyst. 64091

--- Close Hyst. 64092

--- Cal.Interval 64093

--- Alarm relay 2509

--- Reset alarm 2046

u06 Analog input 2504

u10 DI status 2002

u20 S2 Temp 2537

u21 Superheat 2536

u22 SuperheatRef 2535

u24 Opening OD% 2542

u25 EvapPres Pe 2543

u26 EvapTemp Te 2544

u27 Temp S3 2545

P67 Open Hyst. 2181

P68 Close Hyst. 2182

P69 OvD Enable 2183

P70 OvDProtect T 218 4

P71 ForcedCloseT 2185

For detail description on the above parameters, please refer to the product user guide/installation guide.

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 17

Page 18

Appendix 3.

Modbus exception code For a full explanation of the structure of an exception code response, please refer to the Modbus

specication.”

Code Name Meaning

1

2

3

4

Illegal function This function code received in the quer y is not an allowable action for the server (or slave).

This may be because the function code is only applicable to newer devices and was not

implemented in the unit selected. It could also indicate that the server (or slave) is in the

wrong state to process a request of this type, for example because it is not congured and

is being asked to return register values.

Illegal data adress The data address received in the query is not an allowable address for the server (or slave).

More specically, the combination of reference number and transfer length is invalid. For a

controller with 100 registers, a request with oset 96 and length 4 would succeed. a request

with oset 96 and length 5 will will generate exeption 02.

Illegal data value A value contained in the query data eld is not an allowable value for the server (or slave).

This indicates a fault in the structure of the remainder of a complex request, such as that

the implied length is incorrect. It specically does NOT mean that a data item submitted for

storage in the register has a value outside the expec tation of the application program since

the Modbus protocol is unaware of the signicance of any particular value of any particular

reg ister.

Slave device failure An unrecoverable error occurred while the ser ver (or slave) was attemptingto perform the

requested action.

Appendix 4. Following are some of the free modbus tool available on the Internet.

Please note that Danfoss doesn't provide any support on any third party modbus

communication tools.

For your own notes

Some non commercial free programs are:

ModbusMat - http://www.ataytugal.com/ModbusMat.htm

Modbus Request Pro:

http://forums.mrplc.com/index.php?app=downloads&showle=465

Please note that there may be restrictions on the use of above stated modbus tools for commercial

applications

© Danfoss | DCS (sw) | 2015.10

DKRCC.PS.R00.A1.02 | 520H10468 | 18

Loading...

Loading...