Relief Valves Technical Information

1

2

1

2

1

2

1

2

Quick Reference

Thermal Relief Model No. Cavity Description Flow Pressure Page

CP208-4 SDC08-2 Relief Valve,

Thermal Relief,

Poppet Type

Direct Acting Model No. Cavity Description Flow Pressure Page

CP208-3 SDC08-2 Relief Valve,

Direct Acting,

CP200-3 SDC10-2 40 l/min

Poppet Type

1.1 l/min

[0.3 US gal/min]

30 l/min

[8 US gal/min]

[11 US gal/min]

415 bar

[6000 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

RV - 6

RV - 7

RV - 8

Direct Acting Model No. Cavity Description Flow Pressure Page

Quick Reference

Dierential Area Model No. Cavity Description Flow Pressure Page

RV08-DR SDC08-2 Relief Valve,

Direct Acting,

VEN 06 NCS06/2 40 l/min

VME 06 VME06 40 l/min

VME 07 VME07 50 l/min

VME 08 VME08 80 l/min

CP200-2 SDC10-2 Relief Valve,

CP208-1 SDC08-2 40 l/min

CP200-1 SDC10-2 75 l/min

CP201-1 CP12-2 150 l/min

Dampening,

Poppet Type

Dierential Area,

Poppet Type,

30 l/min

[8 US gal/min]

[11 US gal/min]

[11 US gal/min]

[13 US gal/min]

[21 US gal/min]

40 l/min

[11 US gal/min]

[11 US gal/min]

[20 US gal/min]

[40 US gal/min]

250 bar

[3600 psi]

250 bar

[3600 psi]

315 bar

[4500 psi]

315 bar

[4500 psi]

315 bar

[4500 psi]

350 bar

[5075 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

RV - 9

RV - 10

RV - 11

RV - 12

RV - 13

RV - 14

RV - 15

RV - 16

RV - 17

BC332375370104en-000101 • February 2020

RV - 1

Relief Valves Technical Information

1

2

1

2

1

2

Quick Reference

Direct Acting Model No. Cavity Description Flow Pressure Page

CP210-1 SDC10-2 Relief Valve,

Direct Acting,

CP211-1 CP12-2 75 l/min

Pilot Operated Model No. Cavity Description Flow Pressure Page

CP210-2 SDC10-2 Relief Valve,

CP211-2 CP12-2 190 l/min

Spool Type,

Pilot Operated,

Spool Type

45 l/min

[12 US gal/min]

[20 US gal/min]

115 l/min

[30 US gal/min]

[50 US gal/min]

210 bar

[3000 psi]

40 bar

[600 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

RV - 18

RV - 19

RV - 20

RV - 21

Pilot Operated Model No. Cavity Description Flow Pressure Page

RV10-POP SDC10-2 Relief Valve,

Pilot Operated,

Poppet Type, with Free

Reverse Flow

Bi-Directional Model No. Cavity Description Flow Pressure Page

CP200-7 SDC10-2 Relief Valve,

Bi-directional

120 l/min

[32 US gal/min]

40 l/min

[11 US gal/min]

250 bar

[3625 psi]

250 bar

[3600 psi]

RV - 22

RV - 23

Quick Reference

BC332375370104en-000101 • February 2020

RV - 2

Relief Valves Technical Information

1

2

ATM.

V1

C1

V2

C2

Quick Reference

Dierential Area Model No. Cavity Description Flow Pressure Page

VSB 06-EN NCS06/2 Relief Valve,

Dierential Area,

VSB 12-EN NCS12/2 140 l/min

Poppet Type with Reverse

Free Flow Check

Dierential Area Model No. Cavity Description Flow Pressure Page

VSB 06-CN NCS06/2 Relief Valve,

Dierential Area,

VSB 12-CN NCS12/2 140 l/min

Poppet Type with Reverse

Free Flow Check,

Atmospheric Venting

80 l/min

[21 US gal/min]

[37 US gal/min]

80 l/min

[21 US gal/min]

[37 US gal/min]

350 bar

[5075 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

350 bar

[5075 psi]

RV - 24

RV - 25

RV - 26

RV - 27

Quick Reference

Cross-Over Model No. Cavity Description Flow Pressure Page

VA-E 06 none Relief Valve,

Cross-Over, Catalog HIC

CP220-1 none 75 l/min

CP221-1 none 150 l/min

40 l/min

[11 US gal/min]

[20 US gal/min]

[40 US gal/min]

210 bar

[3045 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

RV - 28

RV - 29

RV - 30

BC332375370104en-000101 • February 2020

RV - 3

Relief Valves Technical Information

1

1

Application Notes

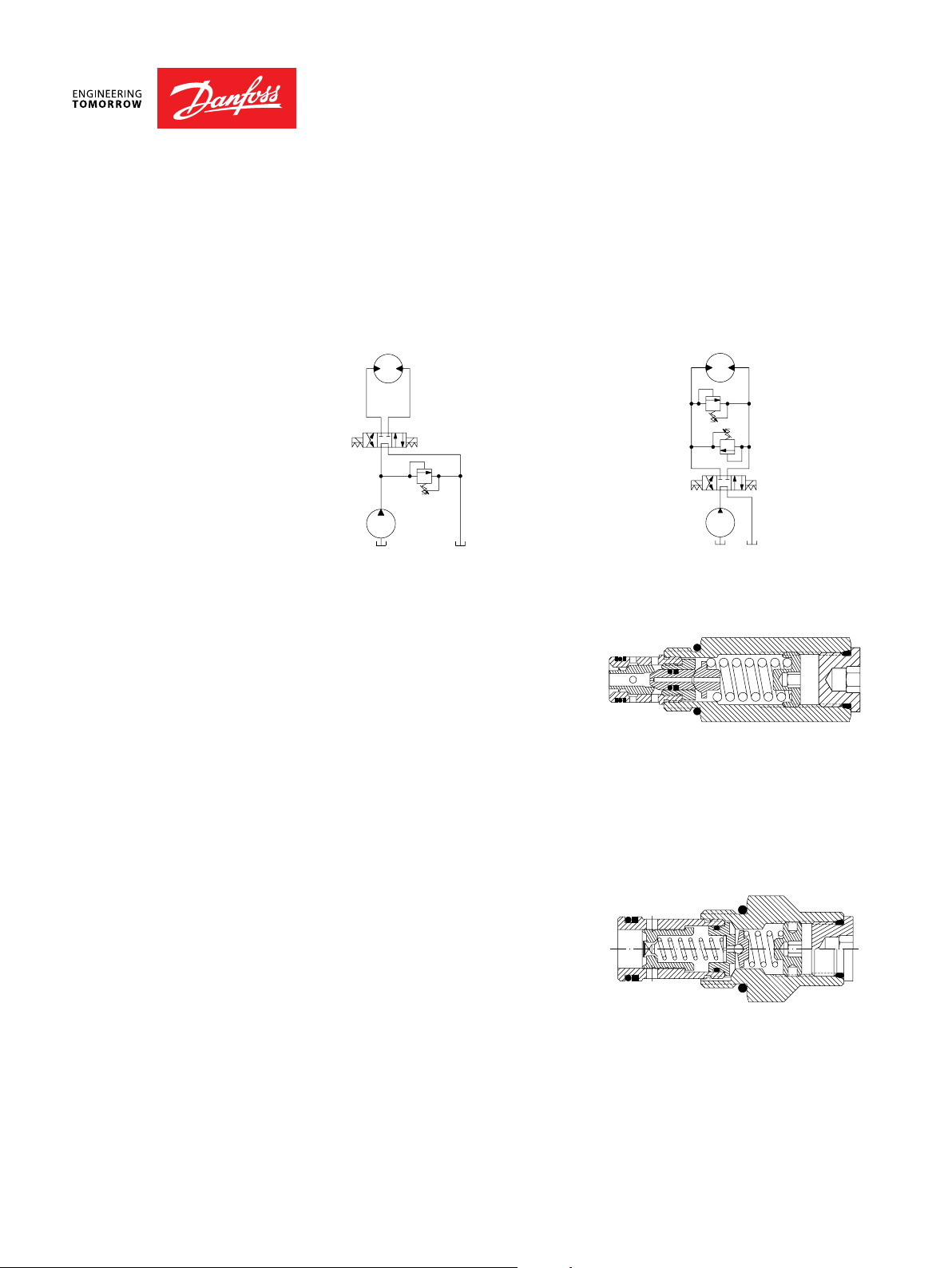

APPLICATIONS

Relief valves are used as pressure limiting devices to protect hydraulic systems and

components. They are available in direct-acting poppet, dierential area poppet,

bi-directional poppet, and pilot-operated spool types.

Relief valves

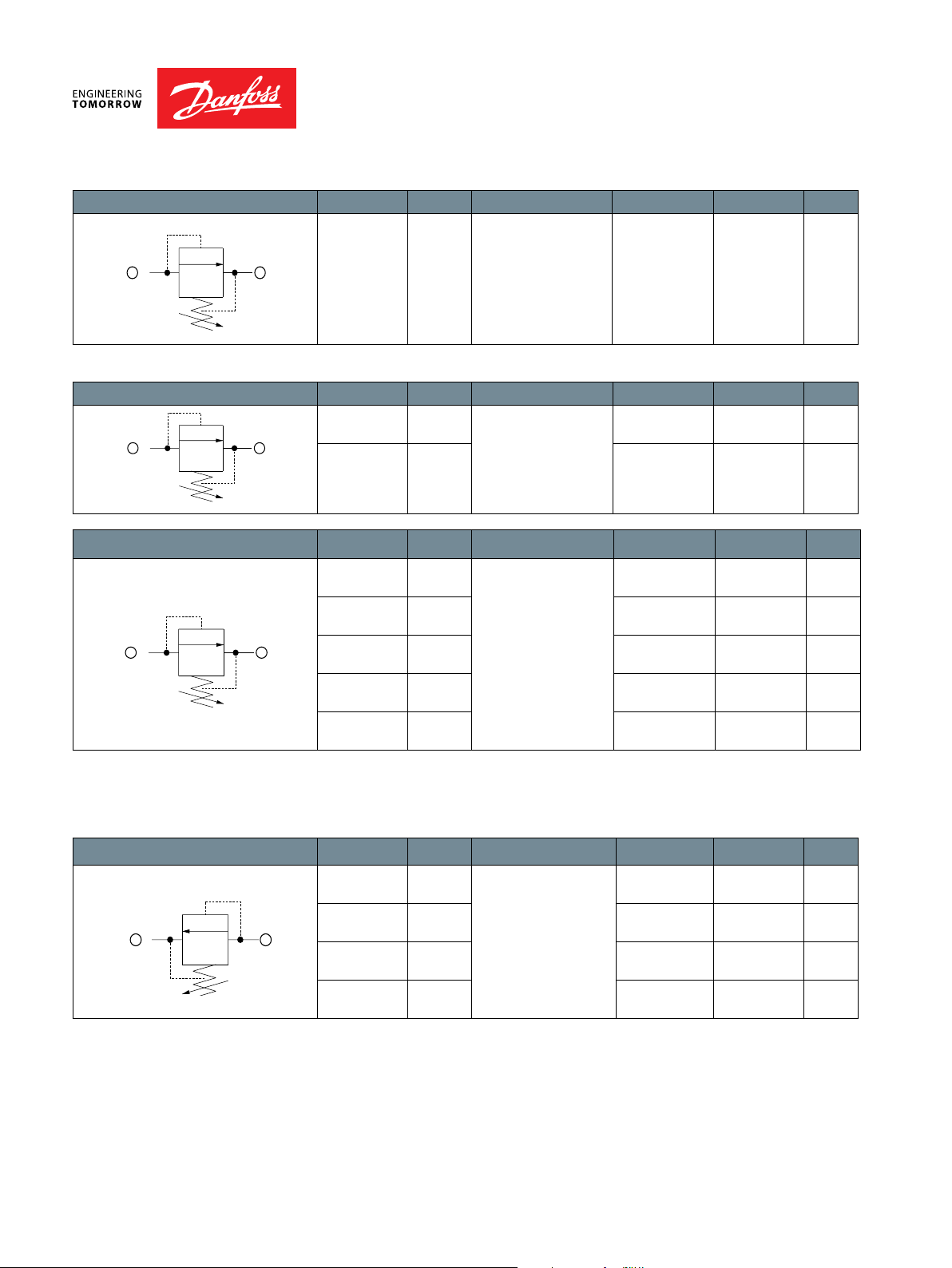

OPERATION Direct-acting poppet

The direct-acting poppet blocks ow

from 1 to 2 until sucient pressure is

present at 1 to force the spring-opposed

poppet from it’s seat. This pressure is

commonly known as the crack pressure.

The valve will remain open until the

pressure drops to a level allowing the

spring to close the valve. This pressure is known as the re-seat pressure and is typically

70-80% of the crack pressure. The dierence between crack and re-seat pressure is

commonly referred to as hysteresis.

Dierential-area poppet

The dierential area poppet operates in the same manner except ow is blocked from 2

to 1 until sucient pressure is present at 2 to force the spring-opposed poppet from it’s

seat.

Advantages of direct-acting poppet and

dierential area poppet relief valves are:

· Fast response

· Contamination tolerant

· Low leakage

· Low cost

Direct acting poppet relief valve

2

Dierential area poppet relief valve

2

Applications Notes

BC332375370104en-000101 • February 2020

RV - 4

Relief Valves Technical Information

1

1

Application Notes

Applications Notes

OPERATION

(continued)

Because of these features some common applications for direct-acting and dierential

area poppet relief valves are:

· Main system relief valve if ow is relatively constant, or as a safety relief valve for

“spike clipping” to protect components from overpressure

· Work port cross-over relief to protect a cylinder or motor from overpressure

System Relief Valve Work Port Cross-Relief Valves

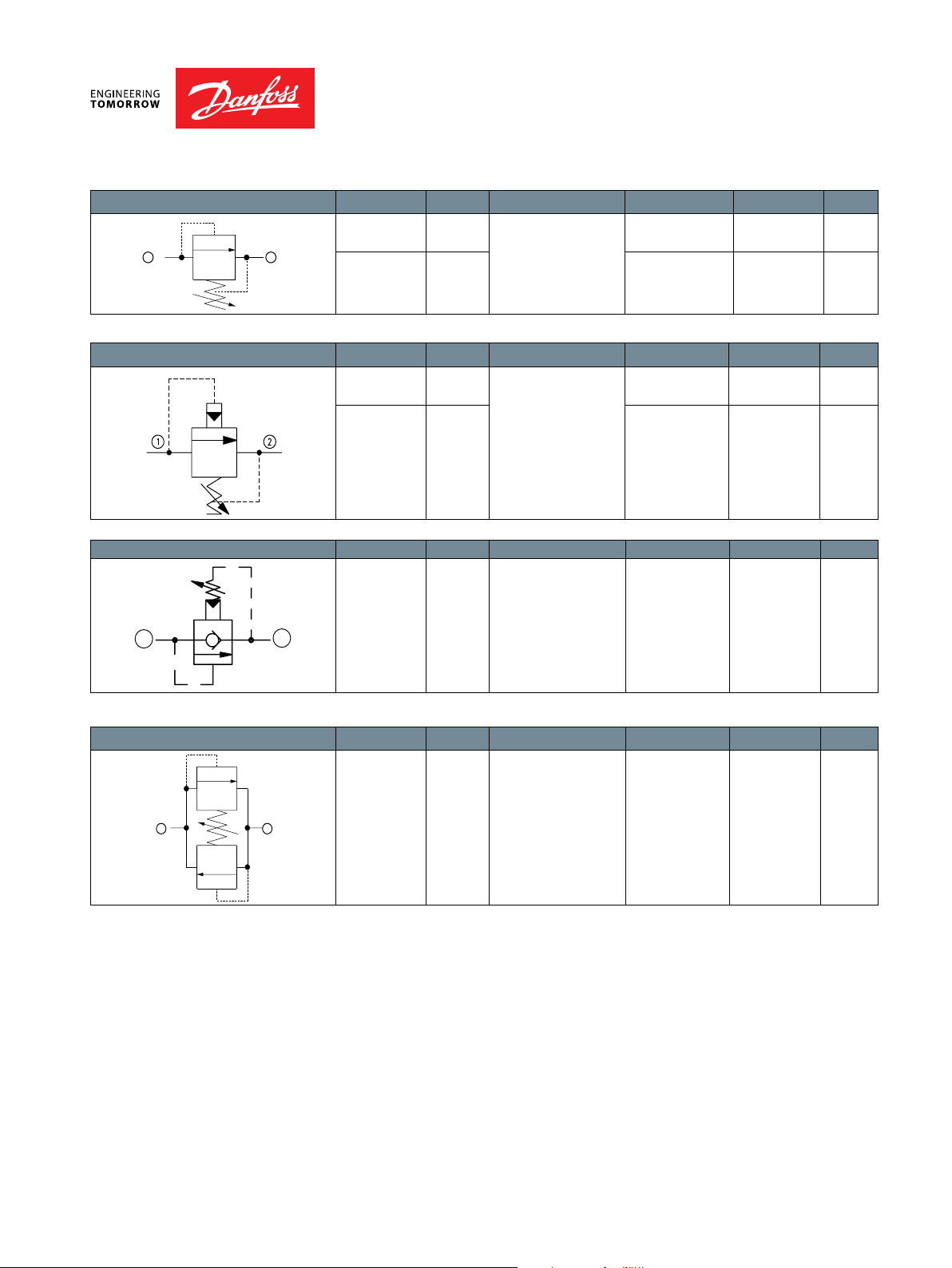

Bi-directional poppet

The bi-directional poppet is a dual

cross-over relief in a single cartridge.

Bi-directional poppet relief valve

When pressure at 1 exceeds the nominal

setting, the lower poppet acts as a

direct-acting relief valve and opens ow

from 1 to 2. When pressure at 2 exceeds

the nominal setting, the upper poppet

acts as a dierential area relief valve and

2

opens ow from 2 to 1 . Note that the

valve is designed so that the crack pressure is the same in either direction

A common application for a bi-directional relief valve is as a work port cross-over relief

where one bi-directional valve can replace two direct-acting valves.

Pilot operated spool

The pilot operated spool blocks ow

Pilot operated spool relief valve

from 1 to 2 until sucient pressure is

present at 1 to force the pilot poppet

o it’s seat. This creates a pressure

dierential across the spool that causes

the spool to shift and open ow from 1

to 2.

2

Advantages of pilot-operated relief valves are:

· Smooth, stable response

· High ow and high pressure capability

· Precise pressure control with varying ow rates. Low pressure rise

· Low hysteresis

A common application for pilot-operated relief valves is as a main system relief where

high pressure or ow capability and/or extremely precise pressure control is required.

BC332375370104en-000101 • February 2020

RV - 5

Relief Valves Technical Information

1

2

=[

CP208-4-B-4S-E-C-300

K = Knob

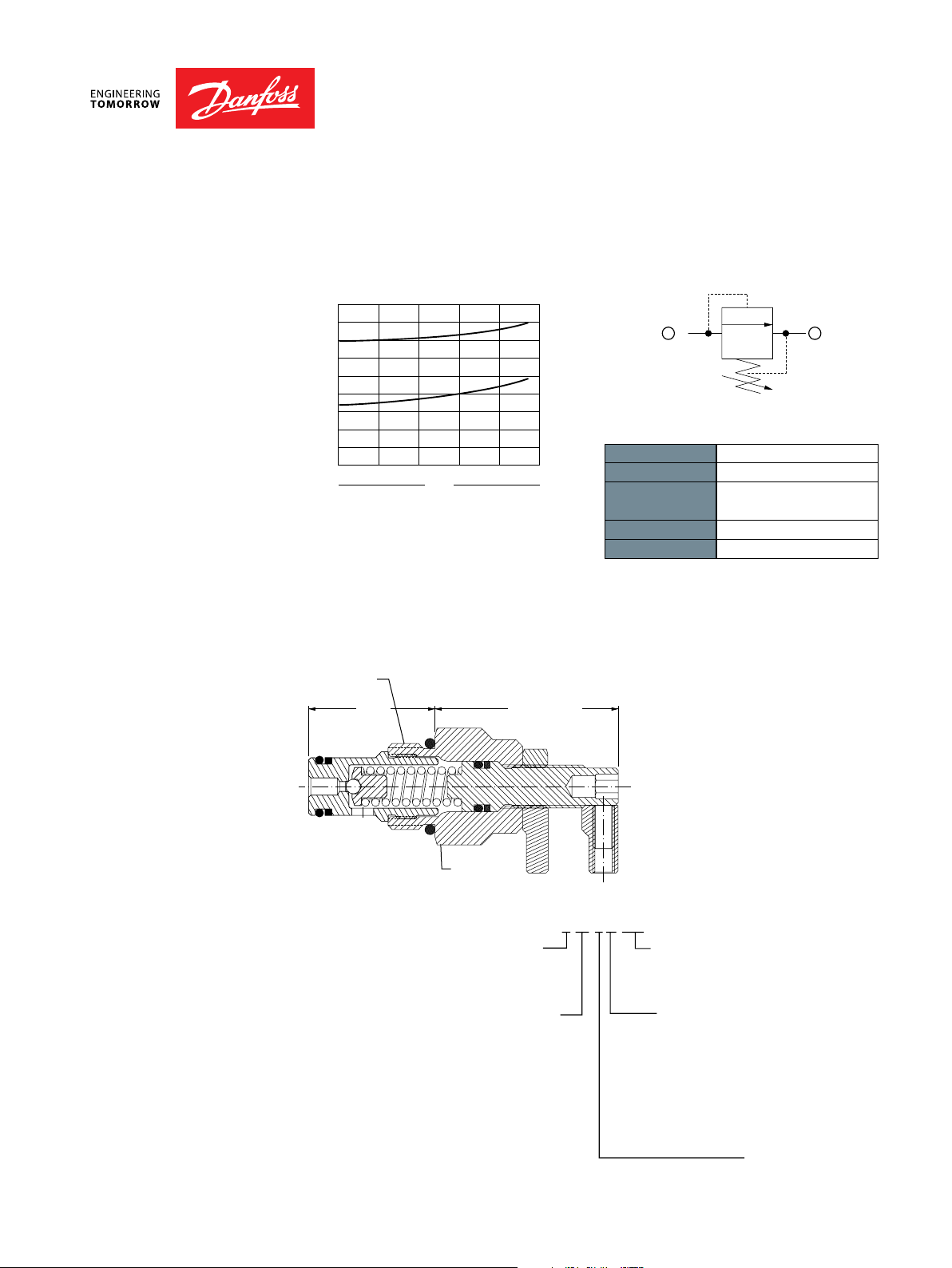

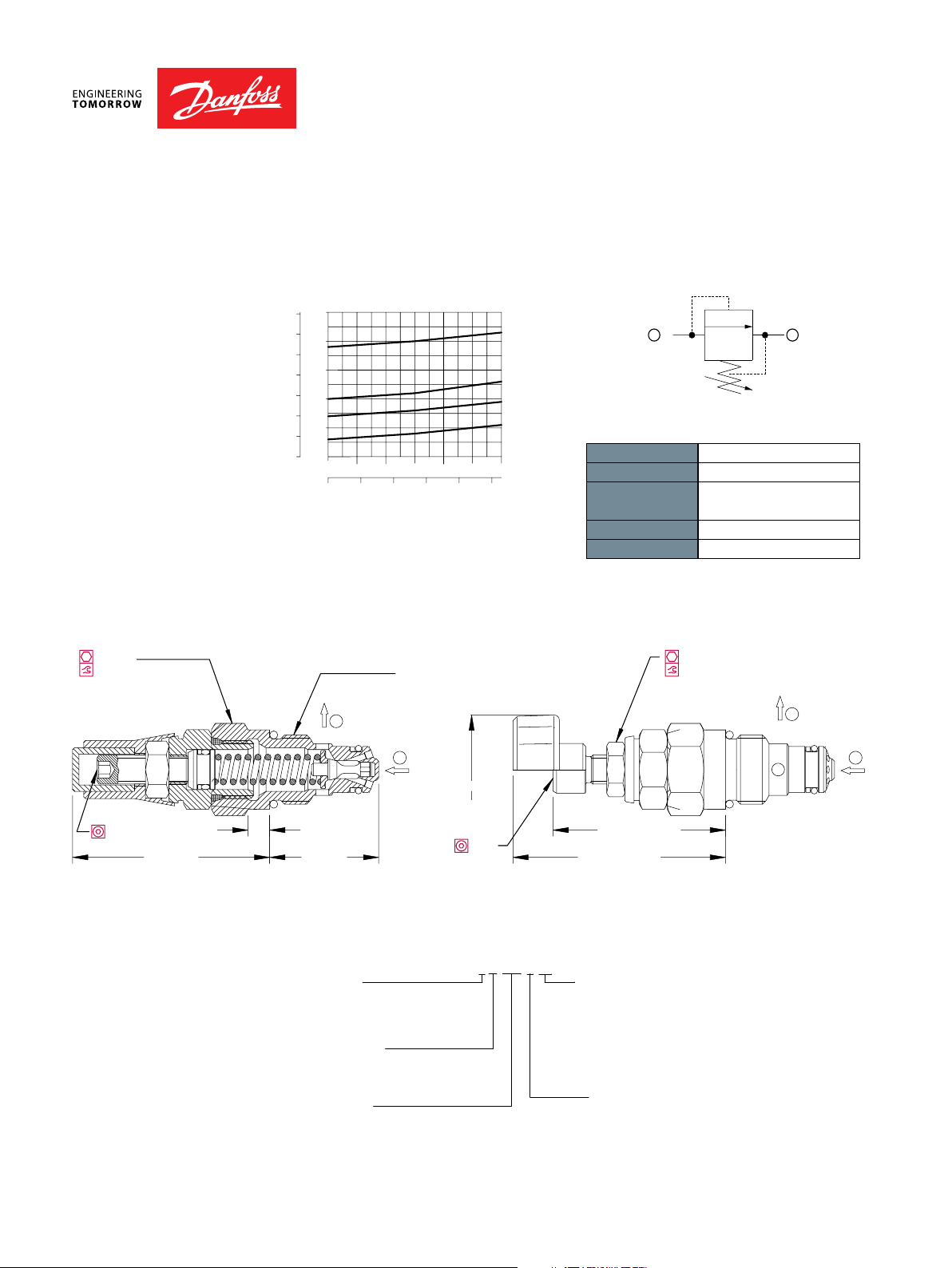

Thermal Relief

CP208-4

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting poppet type thermal relief valve that relieves from 1 to 2.

Theoretical performance Schematic

psi bar

6527

5802

5076

4351

3626

2901

2176

1450

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

450

400

350

300

250

200

150

100

50725

0

US gal/min

L/min

0.4

0.1

0.8 1.21.6 2

Flow

0.2 0.3 0.4 0.5

Specications

Rated pressure 415 bar [6000 psi]

Rated ow 1.1 l/min [0.3 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.23 kg [0.50 lb]

Cavity SDC08-2

Cross-sectional view

3/4-16 UNF

1

ORDERING

INFORMATION

Housing and portsHousing P/N

0=No Housing No Housing

DG2B =Al, 1/4 BSP SDC08-2-DG-2B

DG3B =Al, 3/8 BSP SDC08-2-DG-3B

4S =Al,#4 SAE CP08-2-4S

6S =Al,#6 SAE CP08-2-6S

Other housings available

BC332375370104en-000101 • February 2020

1.10

[27.8]

1.59

[40.3]

2

ht0.875 in

27-34 N•m

[20-25 lbf•ft]

Seals Seal kits

B = Buna-N 120221

V =Viton 120222

max.

Type E

adjustment

Type K

adjustment

Crack pressure

Code x 10 = psi

Example: 300 = 3000 psi

Adjustment ranges

bar psi

A = 2-103 [30-1500]

Standard 207 [1000]

B

7-207

Standard 103 [1500]

C =69-414 [1000-6000]

Standard 207 [3000]

Adjustment options

100-3000]

E = External

RV - 6

Relief Valves Technical Information

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

1 450

2 176

2 901

3 626

6

1

2

Adjustment option

[100-1000]

[200-2000]

[500-3600]

Seals

Housing and po

DG2

DG3

O

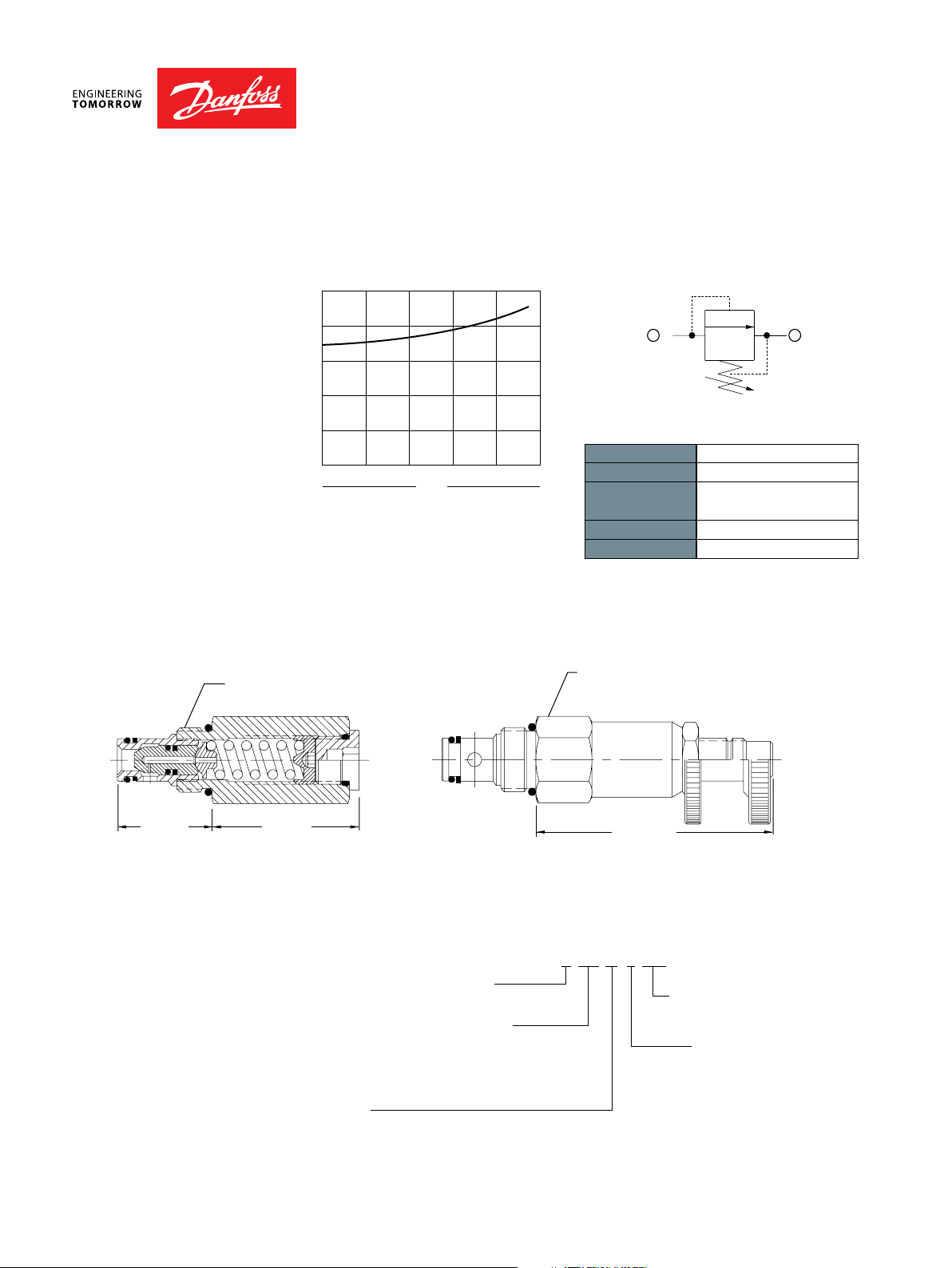

Direct Acting

CP208-3

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting poppet type relief valve that relieves from 1 to 2.

Theoretical performance Schematic

psi bar

250

200

150

100

50

725

Specications

Rated pressure 250 bar [3600 psi]

0

8L/min

16 24 32 40

2.1US gal/min

Flow

4.2 6.3 8.5 10.

Rated ow 30 l/min [8 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.15 kg [0.32 lb]

Cavity SDC08-2

Cross-sectional view

ORDERING

INFORMATION

BC332375370104en-000101 • February 2020

1

2

27.7

[1.09]

3/4-16 UNF

43.4

[1.71]

ther housings available

Type A

adjustment

Type F

adjustment

B=Buna-N 120221

V=Viton 120222

0=No Housing No Housing

B=Al,1/4 BSP SDC08-2-DG-2B

B=Al,3/8 BSP SDC08-2-DG-3B

4S =Al, #4 SAE CP08-2-4S

6S =Al, #6 SAE CP08-2-6S

A= Internal

E= External

F= Tamper resistant

K= Knob

rtsHousing P/N

Seal Kit

ht0.875 in

27-34 N.m

[20-25 lbf.ft]

68.3

max.

[2.69]

CP208-3-B-6S-A-C - 150

Type E

adjustment

Type K

adjustment

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-69

Standard 28 [400]

B= 14-138

Standard 69 [1000]

C= 35-248

Standard 103 [1500]

bar [psi]

RV - 7

Relief Valves Technical Information

1 450

2 176

2 901

3 626

9

1

2

A

]

]

]

Seals

Housing and po

DG3

DG4

O

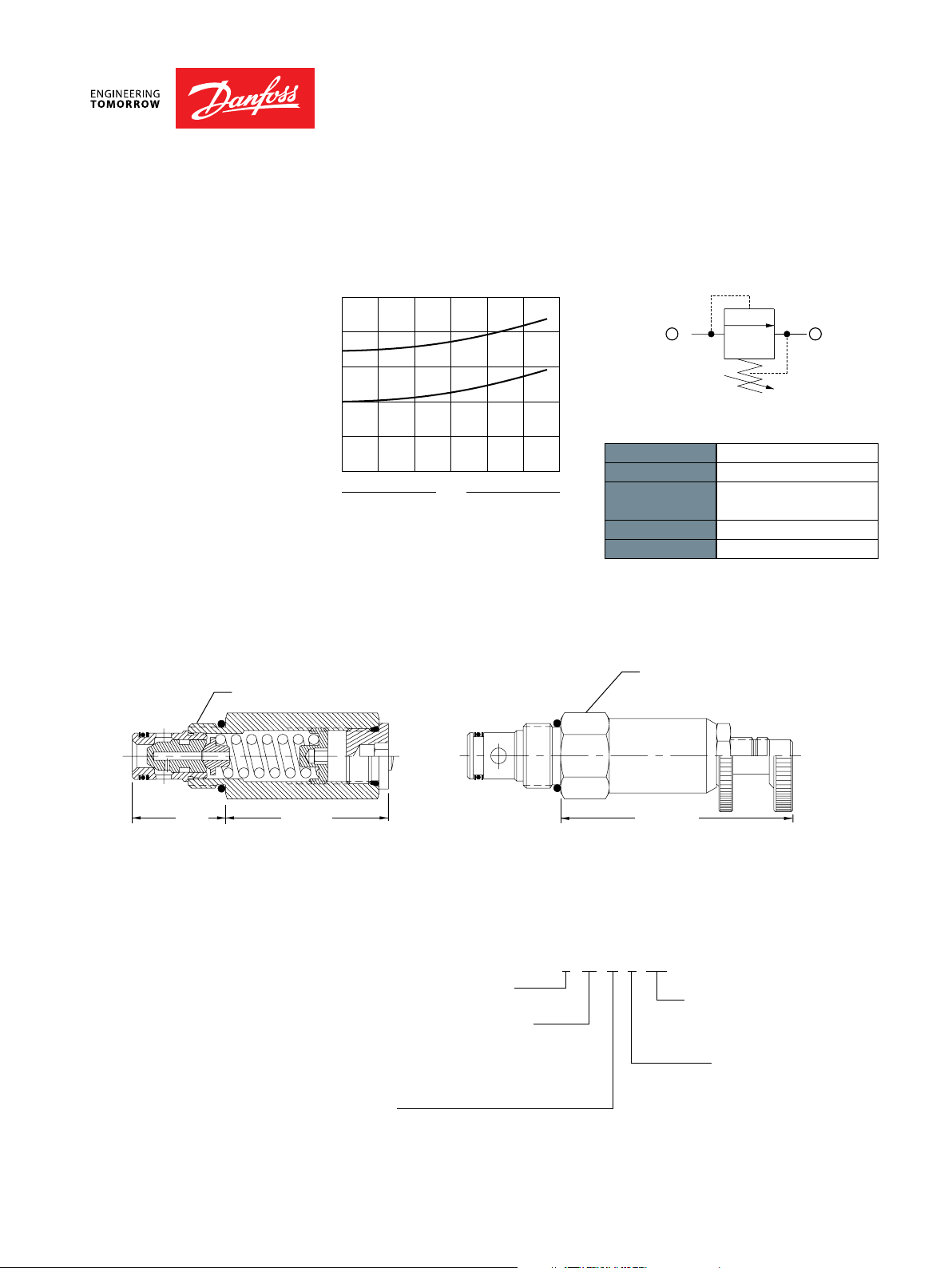

Direct Acting

CP200-3

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting poppet type relief valve that relieves from 1 to 2.

Theoretical performance Schematic

psi bar

US gal/min

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

100

50725

0

10

L/min

20 30 40 50 60

2.6

5.3 7.9 10.6 13.2 15.

Flow

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 40 l/min [11 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.21 kg [0.47 lb]

Cavity SDC10-2

Cross-sectional view

7/8-14 UNF

1

2

31.8

[1.25]

55.9

[2.20]

ORDERING

INFORMATION

B=Buna-N 120073

V=Viton120074

0=No Housing No Housing

B=Al,3/8 BSP SDC10-2-DG-3B

B=Al,½ BSP SDC10-2-DG-4B

6S =Al, #6 SAE CP10-2-6S

8S =Al, #8 SAE CP10-2-8S

ther housings available

djustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

BC332375370104en-000101 • February 2020

Type A

adjustment

Type F

adjustment

CP200-3-B-6S-A-C - 150

Seal kit

rt s Housing P/N

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

Type E

adjustment

Type K

adjustment

80.0

max.

[3.15]

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-69 [100-1000

Standard 28 [400]

B= 17-172 [250-2500

Standard 69 [1000]

C= 41-248 [600-3600

Standard 103 [1500]

bar [psi]

RV - 8

Relief Valves Technical Information

1500

1000

3000

2000

2500

3500

n

1

2

Direct Acting

RV08-DR

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

22mm

35-40 Nm [26-30 lbf*ft]

Type F

Adjustment

This is a direct-acting, poppet-type relief valve that relieves from 1 to 2. It features a

highly damped poppet for smooth and stable response.

Theoretical performance Schematic

psi

bar

26 cSt[121 SUS]hyd.oil@50°C[122°F]

250

200

150

100

50

500

0

0

0

0

5

1.5

10

15

20

25

3

4.5

6

30

US gal/mi

7.5

l/min

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 30 l/min [8 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.10 kg [0.22 lb]

Cavity SDC08-2

Cross-sectional view

3/4-16 UNF 2A

Type K

Adjustment

2

13mm

7-9Nm [5-6 lbf*ft]

2

4mm

6 [0.24]

30 [1.18]54.3 [2.14]

ORDERING

INFORMATION

Pressure range

1 = 20-80 Bar [290-1150 psi]

2 = 35-160 Bar [500-2300 psi]

3 = 60-250 Bar [870-3600 psi]

Adjustment option

E = External

F =Tamper resistant

K = Knob

Crack pressure

Code = Setting in Bar

XXX = No specific setting

BC332375370104en-000101 • February 2020

1

Ø30.0 [1.18]

6mm

RV08-DR-1-E-XXX-B-4S

Type E

Adjustment

47.5 [1.87] MAX.

58.5 [2.30] MAX.

Housing and portsHousing P/N

00 =No Housing No Housing

DG2B= Al,1/4 BSPSDC08-2-DG-2B

DG3B= Al,3/8 BSPSDC08-2-DG-3B

4S =Al, #4 SAE CP08-2-4S

6S =Al, #6 SAE CP08-2-6S

Other housings available

Seals Seal Kit

B = Buna-N 354000119

V =Viton 354000219

1

RV - 9

Relief Valves Technical Information

P103 393E

1000

2000

3000

4000

5000

04

81

1

2

61.8

[2.43]

27 mm

44-50 N•m

[32-37 lbf•ft]

33.2

[1.31]

2

1

M 22 x 1.5

1

Direct Acting

VEN 06

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, poppet-type relief valve that relieves from 1 to 2. It features a

highly damped poppet for smooth and stable response.

Theoretical performance Schematic

psi bar

26 mm °C [° F]²/sec (cSt) [124 SUS] @ 50 122

400

300

200

100

Specications

0

US gal/min

0

010203

02 46

Minimum setting value

l/min

0

0

Rated pressure 315 bar [4500 psi]

Rated ow 40 l/min [11 US gal/min]

Weight 0.20 kg [0.44 lb]

Cavity NCS06/2

Cross-sectional view

ORDERING

INFORMATION

Ty pe of adjustmen t

EN = External screw

M = Handwheel

Setting r ange

1 = 20 - 80 bar [290 - 1160 psi]

2 = 35 - 160 bar 508 2321[- psi]

3 = 70 - 315 bar 1015 4569[- psi]

To order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

VEN 06 - M - 1 - DG3/8 -V - XXX

Housing and po rt sHousing P/N

0=No Housing No Housing

DG3/8 =AL, 3/8 BSP NCS06/2-DG-3/8

DG1/2 =AL,1/2 BSP NCS06/2-DG-1/2

DG6S=AL,#6 SAE NCS06/2-DG-6S

DG8S=AL,#8 SAE NCS06/2-DG-8S

Other housings available

Seals

V =Viton seals

Omit = Buna-N

Seal kit

230000380

230000060

RV - 10

Relief Valves Technical Information

P103 396E

1000

2000

3000

4000

5000

1

2

A

S

VME06-DG-3/8

Direct Acting

VME 06

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, poppet-type relief valve that relieves from 1 to 2. It features a

highly damped poppet for smooth and stable response.

Theoretical performance Schematic

psi bar

26 mm °C [° F]

400

300

200

100

0

²/sec (cSt) [124 SUS] @ 50 122

i

1

4

m

US gal/min

0

0

0

Flow

n

2

m

i

l/min

u

12

8

3

16

4

Specications

Rated pressure 315 bar [4500 psi]

Rated ow 40 l/min [11 US gal/min]

e

u

l

a

v

g

n

i

t

t

e

s

m

Weight 0.13 kg [0.29 lb]

Cavity VME06

Cross-sectional view

ORDERING

INFORMATION

djustment

EN = External screw

M = Handwheel

MG = Handwheel (panel mounted)

etting r ange

1 = 25 - 70 bar [363-1015 psi]

2 = 35 - 170 bar 508 2466[- psi]

3 = 70 - 315 bar 1015 4569[- psi]

To order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

I

VM E 06 -EN-2- DG3/8 -V - XXX

Seals

V =Viton seals

Omit = Buna-N

Housing and po rtsHousing P/N

00 =No Housing No Housing

DG3/8 =Al, 3/8 BSP

DG6S= Al,#6 SAE VME06-DG-6S

Other housings available

RV - 11

Relief Valves Technical Information

1000

2000

3000

4000

5000

1

2

55

[2.17]

32

[1.26]

Hex 27

54-60 N m

[40-44 lbf ft]

M 24 X 1.5

1

2

A

S

VME07-DG-1/2

1 = 25 - 80 bar [363-1160 psi

2 = 35 - 180 bar

3 = 70 - 315 bar

Direct Acting

VME 07

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, poppet-type relief valve that relieves from 1 to 2. It features a

highly damped poppet for smooth and stable response.

Theoretical performance Schematic

P

psi bar

0

26 mm °C [° F]

400

300

200

100

0

²/sec (cSt) [124 SUS] @ 50 122

u

m

i

n

i

m

12.5

0

0

3

25

l/min

6

US g/min

ti

t

e

s

m

9

n

37.5

e

u

l

a

v

g

50

Specications

Rated pressure 315 bar [4500 psi]

Rated ow 50 l/min [13 US gal/min]

12

Weight 0.20 kg [0.44 lb]

Cavity VME07

Cross-sectional view

ORDERING

INFORMATION

BC332375370104en-000101 • February 2020

VM E07 - E- 2- DG1/2 -V - XXX

djustment

E =Internal screw

M = Handwheel

etting r ange

]

508 2611[- psi]

1015 4569[- psi]

Omit = Buna-N

Housing and po rtsHousing P/N

00 =No Housing No Housing

DG1/2 =Al, 1/2 BSP

DG8S= Al,#8 SAE VME07-DG-8S

Seals

V =Viton

Other housings available

To order this valve with a specic factory setting,contact your Danfoss ICS representative.

Seal kit

Consult factory

Consult factory

RV - 12

Relief Valves Technical Information

psi bar

80

[° F]

2

20

Flow

1

2

S

VME08-DG-12S

Direct Acting

VME 08

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, poppet-type relief valve that relieves from 1 to 2. It features a

highly damped poppet for smooth and stable response.

Theoretical performance Schematic

26 mm °C

²/sec (cSt) [124 SUS] @ 50 12

m

i

n

i

m

20

0

0

4

40

l/min

8

US gal/min

ue

l

a

v

g

n

ti

t

e

s

m

u

60

12

16

Specications

Rated pressure 315 bar [4500 psi]

Rated ow 80 l/min [21 US gal/min]

Weight 0.35 kg [0.77 lb]

Cavity VME08

5000

4000

3000

2000

1000

400

300

200

100

0

0

Cross-sectional view

Hex 32

54-60 N•m

[40-44 lbf•ft]

M 30 X 1.5

2

1

46.5

[1.83]

ORDERING

INFORMATION

Adjustment

E =Internal screw

M = Handwheel

etting r ange

1 = 25 - 80 bar [363-1160 psi]

2 = 35 - 160 bar 508 2321[- psi]

3 = 70 - 315 bar 1015 4569[- psi]

To order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

64.0

[2.52]

VM E08 - E- 2- DG3/4 -V -XXX

Housing and po rt sHousing P/N

00 =No Housing No Housing

DG3/4 =Al,3/4 BSP VME08-DG-3/4

DG12S =Al,#12 SAE

Other housings available

Seals

V =Viton

Omit = Buna-N

Seal kit

Consult factory

Consult factory

RV - 13

Relief Valves Technical Information

1,45

2,17

2,90

3,62

4,35

2

1

2

Seal

B = Buna-N

V

]

Dierential Area

CP200-2

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting dierential area poppet type relief valve that relieves from 2 to 1.

Theoretical performance Schematic

psi bar

1

6

1

6

0

US gal/min

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

300

250

200

150

Press ure drop

100

50725

0

L/min

10

2.6

20 30 40 50

Flow

5.3 7.9 10.6 13.

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 40 l/min [11 US gal/min]

Leakage 10 drops/min @ 80%

of crack pressure

Weight 0.21 kg [0.46 lb]

Cavity SDC10-2

Cross-sectional view

ORDERING

INFORMATION

s

=Viton 120016

Housing and portsHousing P/N

0=No Housing No Housing

DG3B=Al,3/8 BSP SDC10-2-DG-3B

DG4B=Al,1/2 BSP SDC10-2-DG-4B

6S =Al, #6 SAE CP10-2-6S

8S =Al, #8 SAE CP10-2-8S

Other housings available

BC332375370104en-000101 • February 2020

Seal kits

120015

CP200-2- B - 6S - E - D - 150

Adjustment options

A = Internal

F =Tamper resistant

E = External

K = Knob

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Adjustment ranges

D = 69-345 [1000-5000

Standard 103 [1500]

bar psi

RV - 14

Relief Valves Technical Information

US gal/min

1

2

A

]

]

]

Seals

Housing and po

DG2

DG3

O

Dierential Area

CP208-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting dierential area poppet type relief valve that relieves from 2 to 1.

Theoretical performance Schematic

psi bar

6

1

6

0

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

100

Press ure drop

50

0

20L/min

5.3

Flow

10.6

Specications

Rated pressure 250 bar [3600 psi]

40

60

15.9

Rated ow 40 l/min [11 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.15 kg [0.32 lb]

Cavity SDC08-2

Cross-sectional view

3/4-16 UNF

1

2

43.4

[1.71]

ORDERING

INFORMATION

B=Buna-N 120221

V=Viton120222

0=No Housing No Housing

B=Al, 1/4 BSP SDC08-2-DG-2B

B=Al, 3/8 BSP SDC08-2-DG-3B

4S =Al, #4 SAE CP08-2-4S

6S =Al, #6 SAE CP08-2-6S

ther housings available

djustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

BC332375370104en-000101 • February 2020

type A

adjustment

type F

adjustment

CP20 8-1-B-6S-A-C - 150

Seal Ki t

rtsHousing P/N

h 0.875 in

27-34 N.m

t

[20-25 lbf.ft]

68.3

[2.69]

type E

adjustment

type K

adjustment

max.

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-69 [100-1000

Standard 28 [400]

B= 14-138 [200-2000

Standard 69 [1000]

C= 35-248 [500-3600

Standard 103 [1500]

bar [psi]

RV - 15

Relief Valves Technical Information

5.3US gal/min

1,45

2,17

2,90

3,62

100

10.6 15.9 21.1 26.4

1

2

[250-2000]

[600-3600]

Seals

Dierential Area

CP200-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting dierential area poppet type relief valve that relieves from 2 to 1.

Theoretical performance Schematic

psi bar

6

1

6

0

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

100

Press ure drop

50

0

20L/min

40 60 80

Flow

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 75 l/min [20 US gal/min]

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.21 kg [0.46 lb]

Cavity SDC10-2

Cross-sectional view

7/8-14 UNF

1

2

31.8

[1.25]

55.9

[2.20]

ORDERING

INFORMATION

B=Buna-N 120015

V=Viton 120016

Housing and portsHousing P/N

0=No Housing No Housing

DG3B=Al,3/8 BSP SDC10-2-DG-3B

DG4B=Al,1/2 BSP SDC10-2-DG-4B

6S =Al, #6 SAESDC10-2-6S

8S =Al, #8 SAESDC10-2-8S

Other housings available

Adjustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

BC332375370104en-000101 • February 2020

Type A

adjustment

Type F

adjustment

CP200-1-B-8S-A-C-150

Seal kit

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

80.0

max.

[3.15]

Type K

adjustment

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-55 [100-800]

Standard 28 [400]

B= 17-138

Standard 69 [1000]

C= 41-248

Standard 103 [1500]

bar [psi]

Type E

adjustment

RV - 16

Relief Valves Technical Information

1,16

1,45

1,74

2,03

1

2

Ad

[100-1000]

[250-2500]

[500-3600]

Seal

Housing and po

O

Dierential Area

CP201-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting dierential area poppet type relief valve that relieves from 2 to 1.

Theoretical performance Schematic

psi bar

1

0

0

0

870

580

US gal/min

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

140

120

100

80

60

Press ure drop

40

20290

0

25

L/min

50 100 125 150 175

13.2

6.6

75

19.8

Flow

26.4

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 150 l/min [40 US gal/min]

46.2

39.6

33

Leakage 10 drops/min @ 80%

of pressure setting

Weight 0.42 kg [0.92 lb]

Cavity CP12-2

Cross-sectional view

1-1/16-12 UN

1

2

44.5

[1.75]

61.2

[2.41]

ORDERING

INFORMATION

s Seal kit

B=Buna-N 120017

V=Viton 120018

0=No Housing No Housing

4B =Al, 1/2 BSP CP12-2-4B

6B =Al, 3/4 BSP CP12-2-6B

10S=Al, #10 SAE CP12-2-10S

12S=Al,#12 SAE CP12-2-12S

ther housings available

justment option

A= Internal

E= External

F= Tamper resistant

K= Knob

rtsHousing P/N

BC332375370104en-000101 • February 2020

Type A

adjustment

Type F

adjustment

h 1.25 in

t

CP201-1-B-12S-A-C - 150

68-75 N.m

[50-55 lbf.ft]

81.3

max

[3.20]

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-69

Standard 28 [400]

B= 17-172

Standard 69 [1000]

C= 35-248

Standard 103 [1500]

Type E

adjustment

Type K

adjustment

bar [psi]

RV - 17

Relief Valves Technical Information

2.6

US gal/min

5.3 7.9 10.6 13.2 15.9

1

2

[100-1400]

[500-2400]

Seals

Direct Acting

CP210-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting spool-type relief valve that relieves from 1 to 2.

Theoretical performance Schematic

psi bar

2,031

1,740

1,450

1,160

870

580

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

140

120

100

80

60

Press ure drop

40

20290

0

L/min

20 30 40 50 60

10

Specications

Rated pressure 210 bar [3000 psi]

Rated ow 45 l/min [12 US gal/min]

Flow

Leakage 82 cm³/min [5 in³/min] @ 80%

of pressure setting

Weight 0.22 kg [0.48 lb]

Cavity SDC10-2

Cross-sectional view

7/8-14 UNF

1

2

31.8

[1.25]

55.9

[2.20]

ORDERING

INFORMATION

B=Buna-N 120015

V=Viton 120016

Housing and portsHousing P/N

0=No Housing No Housing

DG3B=Al, 3/8 BSP SDC10-2-DG-3B

DG4B=Al, 1/2 BSP SDC10-2-DG-4B

6S =Al, #6 SAE CP10-2-6S

8S =Al, #8 SAE CP10-2-8S

Other housings available

Adjustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

BC332375370104en-000101 • February 2020

Type A

adjustment

Type F

adjustment

Seal kit

ht1.00 in

80.0

[3.15]

CP210-1-B-6S-A-C - 075

41-47 N.m

[30-35 lbf.ft]

max.

Crack pressure

Code x 10 = psi

Example: 075 = 750 psi

Pressure range

A= 3.4-28 [50-400]

Standard 17 [250]

B= 5.5-55 [80-800]

Standard 28 [400]

C= 6.9-97

Standard 52 [750]

D= 34-166

Standard 103 [1500]

bar [psi]

Type E

adjustment

Type K

adjustment

RV - 18

Relief Valves Technical Information

20

5

US gal/min

40

80

10

15

20

133

35

1

2

Direct Acting

CP211-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct acting spool-type relief valve that relieves from 1 to 2.

Theoretical performance Schematic

psi bar

1000

0

600

0

0

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

69

56

42

28

Press ure drop

14

0

19

L/min

38 57

Flow

76 95

Specications

Rated pressure 40 bar [600 psi]

114

30

25

Rated ow 75 l/min [20 US gal/min]

Leakage 82 cm³/min [5 in³/min] @ 80%

of pressure setting

Weight 0.41 kg [0.90 lb]

Cavity CP12-2

Cross-sectional view

ht1.25 in

1 1/16-12UN

68-75 N•m

[50-55 lbf•ft]

Type A

1

adjustment

Type F

adjustment

Type E

adjustment

Type K

adjustment

2

44.5

[1.75]

ORDERING

INFORMATION

BC332375370104en-000101 • February 2020

62.2

[2.45]

CP211-1-B-10S-A-C-040

44.5

[1.75]

Pressure range

A = 0-10 bar [0-150 psi]

B = 3.4-34 bar [50-400 psi]

C = 5.2-41 bar [80-600 psi]

Housing and portsHousing P/N

0=No Housing No Housing

4B =Al, 1/2 BSP CP12-2-4B

6B =Al, 3/4 BSP CP12-2-6B

10S=Al, #10 SAE CP12-2-10S

12S=Al,#12 SAE CP12-2-12S

Other housings available

81.3

max

[3.20]

Crack pressure

Adjustment option

A = Internal

E = External

F =Tamper resistant

K = Knob

SealsSeal kit

B = Buna-N 120017

V =Viton 120018

Code x 10 = psi

Example: 040 = 400 psi

RV - 19

Relief Valves Technical Information

1,45

2,17

2,90

3,62

120

7

Seals

[200-1500]

[400-3000]

[400-5000]

Pilot Operated

CP210-2

OPERATION

SPECIFICATIONS

DIMENSIONS

7/8-14 UNF

This is a pilot operated spool type relief valve that relieves pressure from 1 to 2.

Theoretical performance Schematic

psi bar

6

1

6

0

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

100

Press ure drop

50

0

20L/min

40 60 80 100

10.6 15.9 21.1 26.4 31.

5.3US gal/min

Flow

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 115 l/min [30 US gal/min]

Leakage 82 cm³/min [5 in³/min] @

207 bar [3000 psi]

Weight 0.18 kg [0.40 lb]

Cavity SDC10-2

Cross-sectional view

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

1

2

31.8

[1.25]

41.7

[1.64]

ORDERING

INFORMATION

B=Buna-N 120015

V=Viton 120016

Housing and portsHousing P/N

0=No Housing No Housing

DG3B=Al,3/8 BSP SDC10-2-DG-3B

DG4B=Al,½ BSP SDC10-2-DG-4B

6S =Al, #6 SAE CP10-2-6S

8S =Al, #8 SAE CP10-2-8S

Other housings available

Adjustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

BC332375370104en-000101 • February 2020

Type A

adjustment

Type F

adjustment

Seal kit

CP210-2-B-6S-A-C - 150

62.2

[2.45]

Type E

adjustment

Type K

adjustment

max.

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 14-69 [200-800]

Standard 28 [400]

B= 14-103

Standard 69 [1000]

C= 28-207

Standard 103 [1500]

D= 28-345

Standard 103 [1500]

bar [psi]

RV - 20

Relief Valves Technical Information

10.6US gal/min

21.1 31.7 42.3 52.8

Ad

[300-1500]

[400-3000]

[400-5000]

Housing and po

O

Pilot Operated

CP211-2

OPERATION

SPECIFICATIONS

DIMENSIONS

1-1/16-12 UN

1

2

45.7

[1.80]

This valve relieves from 1 to 2 and is a pilot operated spool type relief.

Theoretical performance Schematic

psi bar

4,351

3,626

2,901

2,176

1,450

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

300

250

200

150

Press ure drop

100

Specications

50

725

0

40L/min

80 120 160 200

Flow

Rated pressure 350 bar [5075 psi]

Rated ow 190 l/min [50 US gal/min]

Leakage 82 cm³/min [5 in³/min] @

207 bar [3000 psi]

Weight 0.17 kg [0.37 lb]

Cavity CP12-2

Cross-sectional view

h 1.25 in

t

Type A

adjustment

Type F

adjustment

37.1

[1.46]

57.9

[2.28]

68-75 N.m

[50-55 lbf.ft]

Type E

adjustment

Type K

adjustment

max.

ORDERING

INFORMATION

Seals Seal kit

B=Buna-N 120017

V=Viton 120018

0=No Housing No Housing

4B =Al, 1/2 BSP CP12-2-4B

6B =Al, 3/4 BSP CP12-2-6B

10S=Al, #10 SAE CP12-2-10S

12S=Al, #12 SAE CP12-2-12S

ther housings available

justment option

A= Internal

E= External

F= Tamper resistant

K= Knob

rtsHousing P/N

BC332375370104en-000101 • February 2020

CP211-2-B-12S-A-C - 150

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 14-69 [200-800]

Standard 28 [400]

B= 14-103

Standard 69 [1000]

C= 28-207

Standard 103 [1500]

D= 28-345

Standard 103 [1500]

bar [psi]

RV - 21

OPERATION

3200

US gal/min

2000

1600

1200

2400

2800

1

2

[10

.

4]

100 = 100 Bar [1500 psi]

E = Ex

F

K = Knob adjustmen

RV10 -POP -3-E-XXX-B-00

Pr

3=

e

SPECIFICATIONS

DIMENSIONS

Relief Valves Technical Information

Pilot Operated

RV10-POP

This is a pilot-operated poppet type relief valve that relieves pressure from 1 to 2, with an

integral free-ow check from 2 to 1.

Theoretical performance Schematic

psi

bar

300

240

180

120

800

60

400

0

0

P104 901

Cross-sectional view

Operating Envelope

26 cSt [121 SUS] hyd.oil@50°C [122°F]

0

4020

80

60

1680

100

24

120

32

l/min

Specications

Rated pressure 250 bar [3625 psi]

Rated ow 120 l/min [32 US gal/min]

Leakage 6 drops/min @ 80%

of pressure setting

Weight 0.22 kg [0.49 lb]

Cavity SDC10-2

24mm

35-40 Nm [26-30 lbf*ft]

Type F

adjustment

4mm

ORDERING

INFORMATION

65.6

[2.58]

4.54

[0.18]

32.9

[12.95]

essure Range

25-250 Bar[3 60-3600 psi]

Adjustment option

ternal adjustment

=Tamper resistant

t

Cracking pressure

Code = Std. setting in bar:

XXX = No specific setting

7/8 UNF 2A

6mm

60.3 max

[2.37 max]

13mm

7-9 Nm [5-6 lbf*ft]

Body and Ports

Omit = Cartridge only

6S = Al,#6 SAE

8S = Al,#8 SAE

DG3B = Al, 3/8 BSP

DG4B = Al, 1/2 BSP

Other housing available

Seals Seal Kit

B = Buna-N seals 354004019

V =Viton seals 354003419

2

Body Nomenclatur

No Body

CP10-2-6S

CP10-2-8S

SDC10-2-DG3B

SDC10-2-DG4B

26.5

1

Type K

adjustment

Ø30

[1. 18]

Type E

adjustment

71.3 max

[2.81 max]

BC332375370104en-000101 • February 2020

RV - 22

Relief Valves Technical Information

1,45

2,17

2,90

3,62

6

1

2

Seal

Ad

[250-2000]

[600-3600]

Housing and po

DG3

DG4

O

Bi-Directional

CP200-7

OPERATION

SPECIFICATIONS

DIMENSIONS

This is a bi-directional relief valve that relieves pressure from 1 to 2 and from 2 to 1.

Theoretical performance Schematic

psi bar

6

1

6

0

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

1

150

100

Press ure drop

50

0

2

8L/min

2.1US gal/min

1

2

16 24 32 40

Flow

4.2 6.3 8.5 10.

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 40 l/min [11 US gal/min]

Leakage 5 cm³/min [0.3 in³/min] @ 80%

of pressure setting

Weight 0.20 kg [0.43 lb]

Cavity SDC10-2

Cross-sectional view

7/8-14 UNF

1

2

31.8

[1.25]

55.9

[2.20]

ORDERING

INFORMATION

s

B=Buna-N 120073

V=Viton 120074

0=No Housing No Housing

B=Al,3/8 BSP SDC10-2-DG-3B

B=Al,1/2 BSP 4

6S =Al, #6 SAE CP10-2-6S

8S =Al, #8 SAE CP10-2-8S

ther housings available

justment option

A= Internal

E= External

F= Tamper resistant

K= Knob

rtsHousing P/N

BC332375370104en-000101 • February 2020

h 1.00 in

41-47 N.m

t

[30-35 lbf.ft]

Type A

adjustment

Type F

adjustment

Seal kit

SDC10-2-DG- B

80.0

max.

[3.15]

CP200-7-B-8S-A-C - 150

Type E

adjustment

Type K

adjustment

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-41 [100-600]

Standard 28 [400]

B= 17-138

Standard 69 [1000]

C= 41-248

Standard 103 [1500]

bar [psi]

RV - 23

Relief Valves Technical Information

80

2000

3000

4000

5000

8

2

S

Dierential Area

VSB 06-EN

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, dierential area, poppet-type relief valve that relieves from 2 to 1

with an integral free-ow check from 1 to 2.

Theoretical performance Schematic

psi bar

1000

0

26 mm °C [° F]

400

300

200

100

0

l/min

²/sec (cSt) [124 SUS] @ 50 122

nimum setting value

Mi

20 40 60

0510 15 20

Flow

US gal/min

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 80 l/min [21 US gal/min]

Weight 0.22 kg [0.49 lb]

Cavity NCS06/2

Cross-sectional view

27 mm

44-50 N m

[32-37 lbf ft]

M 22 x 1.5

69.0

[2.72]

ORDERING

INFORMATION

etting range

1 = 20 - 80 bar [363 - 2031 psi]

2 = 70 - 210 bar [1015 - 3046 psi]

3 = 105 - 350 bar 1523[- 5076 psi]

To order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

2

31.0

[1.21]

VSB 06-EN - 1 - 00 -V - XXX

Omit = Buna-N

Housing and po rtsHousing P/N

00 =No Housing No Housing

DG3/8=AL,3/8 BSP NCS06/2-DG-3/

DG1/2=AL, 1/2 BSP NCS06/2-DG-1/

DG6S =AL, #6 SAE NCS06/2-DG-6S

DG8S =AL, #8 SAE NCS06/2-DG-8S

Other housings available

Seals

V =Viton

1

Seal Kit

230000380

230000060

RV - 24

Relief Valves Technical Information

1000

2000

3000

4000

5000

5140

90.7

[3.57]

38 mm

64-70 Nm•

[47-52 lbfft]•

41.3

[1.63]

2

1

M 33 x 2

S

Dierential Area

VSB 12-EN

OPERATION

SPECIFICATIONS

DIMENSIONS

This is a direct-acting, dierential area, poppet-type relief valve that relieves from 2 to 1

with an integral free-ow check from 1 to 2.

Theoretical performance Schematic

psi bar

0

26 mm °C [° F]

400

300

200

100

0

l/min

²/sec (cSt) [124 SUS] @ 50 122

Minimum setting

35 70 10

010203035

Flow

US gal/min

v

lue

a

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 140 l/min [37 US gal/min]

Weight 0.60 kg [1.32 lb]

Cavity NCS12/2

Cross-sectional view

ORDERING

INFORMATION

etting range

1 = 25 - 170 bar [363 - 2466 psi]

2 = 70 - 270 bar [1015 - 3916 psi]

3 = 105 - 350 bar 1523[- 5076 psi]

BC332375370104en-000101 • February 2020

VSB 12-EN - 1 - 00 -V - XXX

Omit = Buna-N

Housing and portsHousing P/N

00 =No Housing No Housing

DG1/2=AL,1/2 BSP NCS12/2-DG-1/2

DG3/4=AL,3/4 BSP NCS12/2-DG-3/4

DG8S =AL, #8 SAE NCS12/2-DG-8S

DG12S= AL,#12 SAE NCS12/2-DG-12S

Other housings available

Seals

V =Viton

Seal Kit

230000470

230000120

RV - 25

Relief Valves Technical Information

80

1000

2000

3000

4000

5000

1

2

ATM.

8

2

S

Dierential Area

VSB 06-CN

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, dierential area, atmospherically-vented, poppet-type relief valve

that relieves from 2 to 1 with an integral free-ow check from 1 to 2.

Theoretical performance Schematic

psi bar

0

26 mm °C [° F]

400

300

200

100

0

l/min

²/sec (cSt) [124 SUS] @ 50 122

nimum setting value

Mi

20 40 60

0510 15 20

Flow

US gal/min

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 80 l/min [21 US gal/min]

Weight 0.29 kg [0.64 lb]

Cavity NCS06/2

Cross-sectional view

27 mm

44-50 Nm·

[32-37 lbfft]·

M 22 x 1.5

1

2

87.0

[3.43]

31.0

[1.21]

ORDERING

INFORMATION

etting range

1 = 25 - 140 bar [363 - 2031 psi]

2 = 70 - 210 bar [1015 - 3046 psi]

3 = 105 - 350 bar 1523[- 5076 psi]

BC332375370104en-000101 • February 2020

To order this valve with a specic factory setting,contact your Danfoss ICS representative

VSB 06-CN - 1 - 00 -V - XXX

Omit = Buna-N

Housing and po rt sHousing P/N

00 =No Housing No Housing

DG3B =AL, 3/8 BSP NCS06/2-DG-3/

DG4B =AL, 1/2 BSP NCS06/2-DG-1/

DG6S =AL, #6 SAE NCS06/2-DG-6S

DG8S =AL, #8 SAE NCS06/2-DG-8S

Other housings available

Seals

V =Viton

Seal Ki t

230000380

230000060

RV - 26

Relief Valves Technical Information

1000

2000

3000

4000

5000

5140

S

S

Dierential Area

VSB 12-CN

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a direct-acting, dierential area, atmospherically-vented, poppet-type relief valve

that relieves from 2 to 1 with an integral free-ow check from 1 to 2.

Theoretical performance Schematic

psi bar

0

26 mm °C [° F]

400

300

200

100

0

l/min

²/sec (cSt) [124 SUS] @ 50 122

Minimum setting

35 70 10

010203035

Flow

US gal/min

v

2

ATM.

lue

a

Specications

Rated pressure 350 bar [5075 psi]

Rated ow 140 l/min [37 US gal/min]

Weight 0.75 kg [1.65 lb]

Cavity NCS12/2

Cross-sectional view

38 mm

64-70 Nm•

[47-52 lbfft]•

M 33 x 2

1

127.9

[5.03]

ORDERING

INFORMATION

etting range

1 = 25 - 170 bar [363 - 2466 psi]

2 = 70 - 270 bar [1015 - 3916 psi]

3 = 105 - 350 bar 1523[- 5076 psi]

To order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

VSB 12-CN - 1 - 00 -V - XXX

Omit = Buna-N

Housing and po rt sHousing P/N

00 =No Housing No Housing

DG1/2=AL,1/2 BSP NCS12/2-DG-1/2

DG3/4=AL,3/4 BSP NCS12/2-DG-3/4

DG8S =AL, #8 SAE NCS12/2-DG-8S

DG12S =AL, #12 SAE NCS12/2-DG-12

Other housings available

2

41.1

[1.62]

Seals

V =Viton

1

Seal Kit

230000470

230000120

RV - 27

Relief Valves Technical Information

1000

2000

3000

4000

5000

m

Ad

refer to

fo

T

Cross-Over

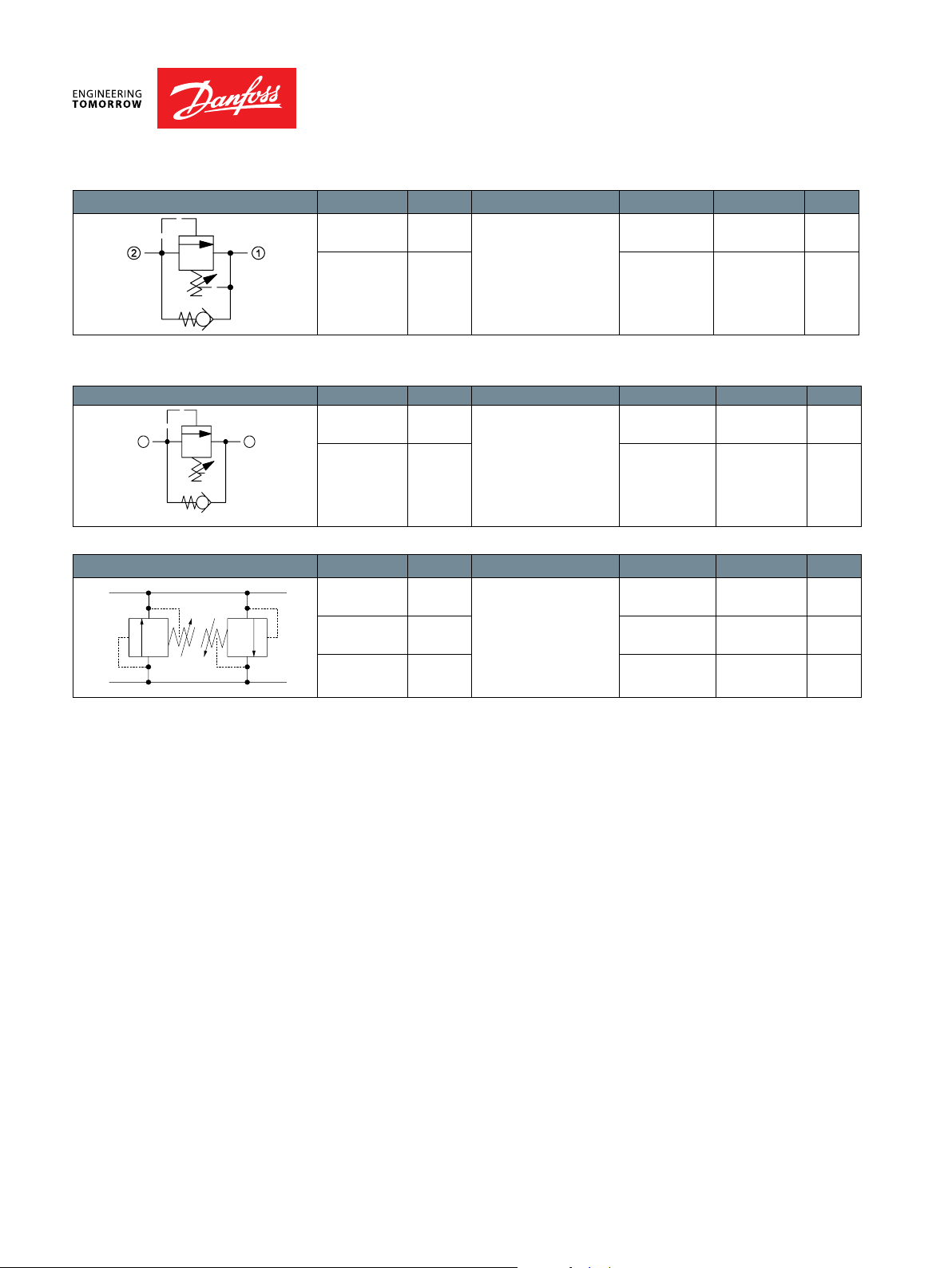

VA-E 06

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

justment option E shown,

VME 06 catalog page

r other options

This valve is an inline cross relief. It uses two VME 06 direct-acting relief valves.

Theoretical performance Schematic

psi bar

400

300

200

100

0

²/sec (cSt) [124 SUS] @ 50 122

26 mm °C [° F]

lu

a

v

g

tin

t

e

s

m

u

m

i

n

i

1

4

m

8

l/min

2

US gal/min

12

3

0

0

0

Flow

e

16

4

V1

V2

Specications

Rated pressure 210 bar [3045 psi]

Rated ow 40 l/min [11 US gal/min]

Weight 1.11 kg [2.45 lb]

Cavity none

Cross-sectional view

166.0[6.54]

70.0 [2.76]

18.0 [0.71] 34.0 [1.34]

Ø6.5 [0.26]

2THRU HOLES

35.0 [1.38]

C1

C2

35.0 [1.38]50.0 [1.97]

7.5[0.30]

7.5[0.30] 55.0 [2.17]

ORDERING

INFORMATION

Adjustment option

EN =External screw

M= Handwheel

Setting range

1 = 25 - 70 bar [360 - 1000 psi]

2 = 35 - 170 bar510 2500[- psi]

3 = 70 - 315 bar 1000 4500[- psi]

o order this valve with a specic factory setting,contact your Danfoss ICS representative

BC332375370104en-000101 • February 2020

13 mm

13-17Nm[9-12 lbf ft]

VA -E 06 - EN - 2 - LG -V - XXX

Seals Seal kit

V=Viton

Omit Consult factory

=Buna-N

Housing and port s

LG = AL,3/8 BSP

Consult factory

4m

RV - 28

Relief Valves Technical Information

1,45

2,17

2,90

3,62

4

31.8

88.9 [3.50]

[250-2000]

[600-3600]

Seal

Housing and po

O

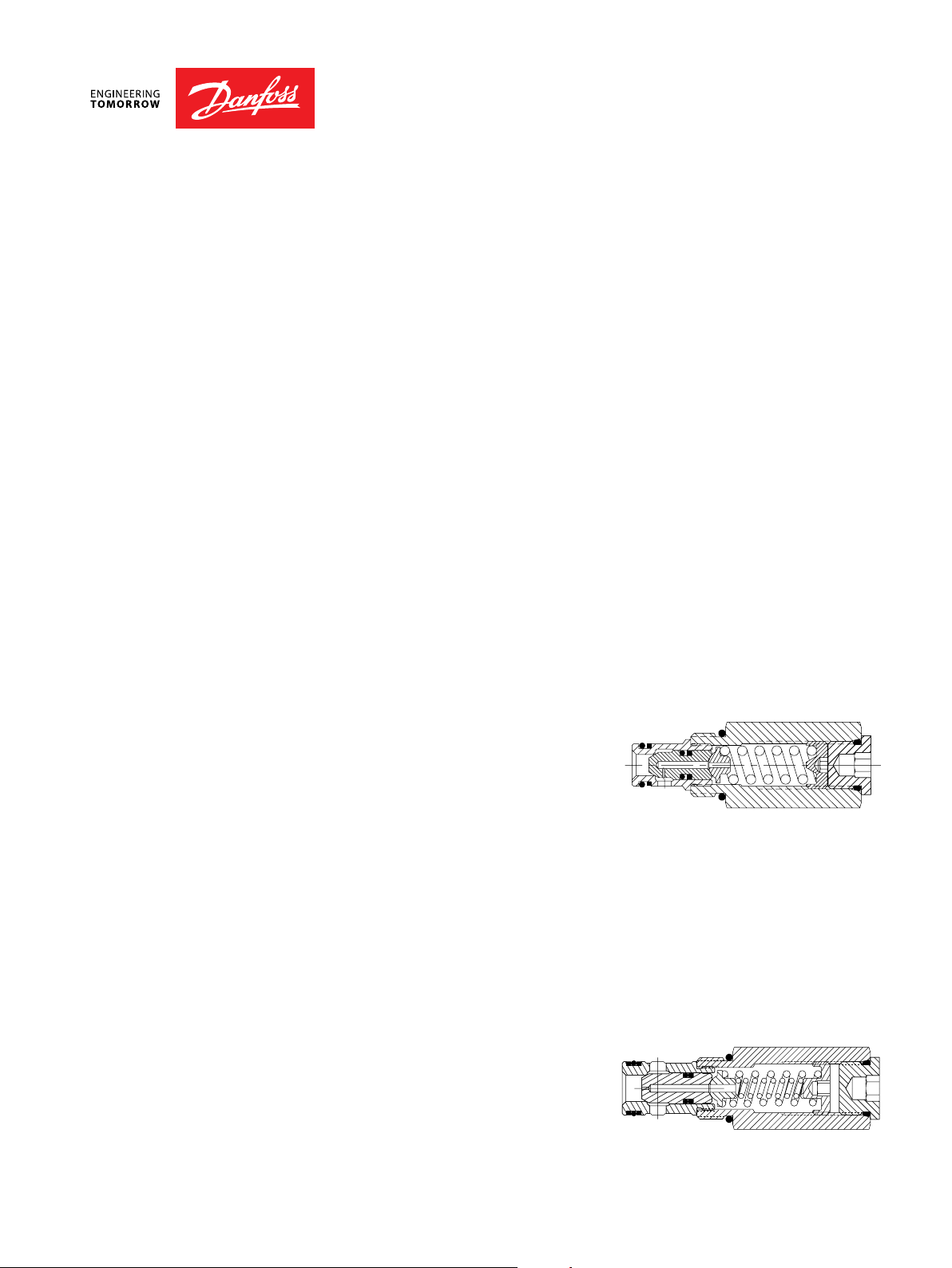

Cross-Over

CP220-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

[1.25]

This valve is an inline cross relief. It uses two CP200-1 dierential area relief valves.

Theoretical performance Schematic

psi bar

6

250

1

200

6

150

100

0

Press ure drop

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

50

0

20L/min

40 60 80 100

5.3US gal/min

10.6 15.9 21.1 26.

Flow

V1

V2

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 75 l/min [20 US gal/min]

Weight 0.82 kg [1.80 lb]

Cavity none

Cross-sectional view

15.9

[0.63]

30.2

[1.19]

6.4

[0.25]

19.1

[0.75]

82.6 [3.25]

C1

C2

V1

57.2

[2.25]

V2 C2

76.2

[3.00]

ORDERING

INFORMATION

3B =Al, 3/8 BSP 221743

4B =Al, 1/2 BSP 221744

6S =Al, #6 SAE 220216

8S =Al, #8 SAE 220217

ther housings available

s

B=Buna-N 120072

V=Viton 120161

Adjustment option

A= Internal

E= External

F= Tamper resistant

K= Knob

rtsHousing P/N

BC332375370104en-000101 • February 2020

38.1

[1.50]

V1

V2

C1

C2

58.7

[2.31]

CP220-1-8S-B-0-A-C-150

Seal kit

8.6

[0.34]

C1

186.9

[7.36]

Crack pressure

Code x 10 = psi

Example: 150 = 1500 psi

Pressure range

A= 7-55 [100-800]

Standard 28 [400]

B= 17-138

Standard 69 [1000]

C= 41-248

Standard 103 [1500]

bar [psi]

RV - 29

Relief Valves Technical Information

1,45

2,17

2,90

3,62

200

8

i

Cross-Over

CP221-1

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

V1

V2

63.5

[2.50]

This valve is an inline cross relief. It uses two CP201-1 dierential area relief valves.

Theoretical performance Schematic

psi bar

6

1

6

0

725

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

250

200

150

100

Press ure drop

50

0

40L/min

21.1 31.7 42.3 52.

10.6US gal/min

80 120 160

Flow

V1

V2

Specications

Rated pressure 250 bar [3600 psi]

Rated ow 150 l/min [40 US gal/min]

Weight 2.25 kg [4.95 lb]

Cavity none

Cross-sectional view

101.6 [4.00]

88.9 [3.50]

44.5

[1.75]

25.4

[1.00]

12.7

[0.50]

25.4

[1.00]

57.2

[2.25]

88.9

[3.50]

114.3

[4.50]

62.7

[2.47]

38.9

[1.53]

V1 C1

V2

C2

11.9

[0.47]

C1

C2

234.7

[9.24]

C1

C2

ORDERING

INFORMATION

Housings & Ports

6B: 3/4 BSP, AL

8B: 1 BSP, AL

12S: #12 SAE, AL

16S: #16 SAE, AL

Seal Option

Code Seal Material Seal kit

B Buna 120017

V Viton 120018

BC332375370104en-000101 • February 2020

Housing P/N

221742

221690

220223

220222

CP221-1 -

16S

- B - 0 -

Adjustment Option

A

Internal

E

External

F

Tamper Resistant

K

Knob

A

- C - 150

Cracking Pressure

Code x 10 = psi

Example: 150 = 1500 ps

Pressure Range

bar [psi]

A = 7-69 [100-1000]

Standard 28 [400]

B = 17-172 [250-2500]

Standard 69 [1000]

C = 41-248 [500-3600]

Standard 103 [1500]

RV - 30

Loading...

Loading...