Installation guide

Regulating valves in stainless steel/HL Packing Gland

REG-SA SS, REG-SB SS DN15-40

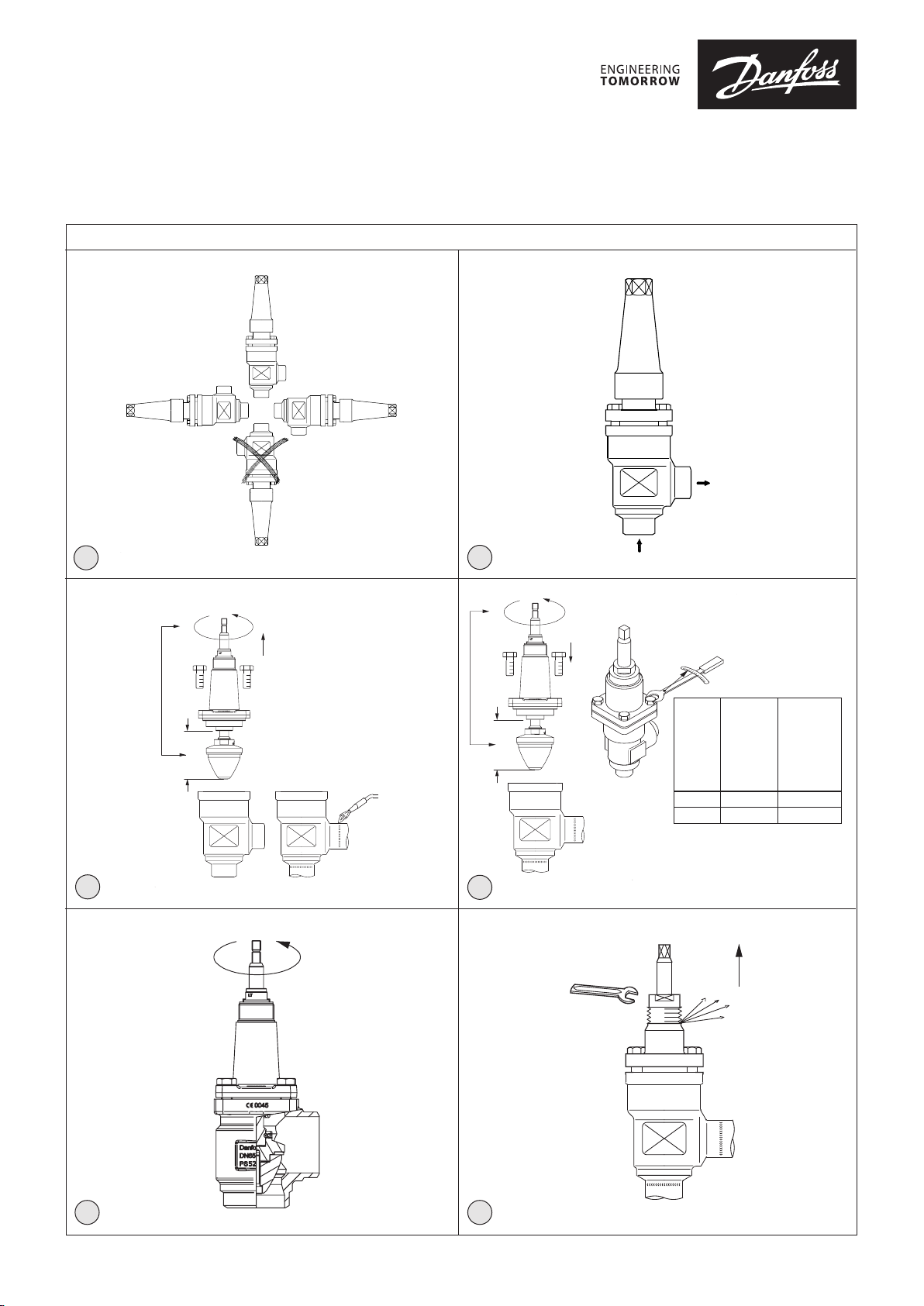

Installation

148R9652

1

2

Max. Nm

Nm máx.

最大Nm

Maks. (Nm)

Макс.

момент

затяжки, Нм

DN 15-20 21 15

DN 25-40 44 32

Max. LB-feet

lb-ft máx.

Max. Lb-piedi

最大LB-英尺

Maks. (lbf x ft)

Макс.момент

затяжки,

фунт/фут

148R9652

3

5 6

© Danfoss | DCS (ms) | 2021.04

4

AN376339413133en-000101 | 1

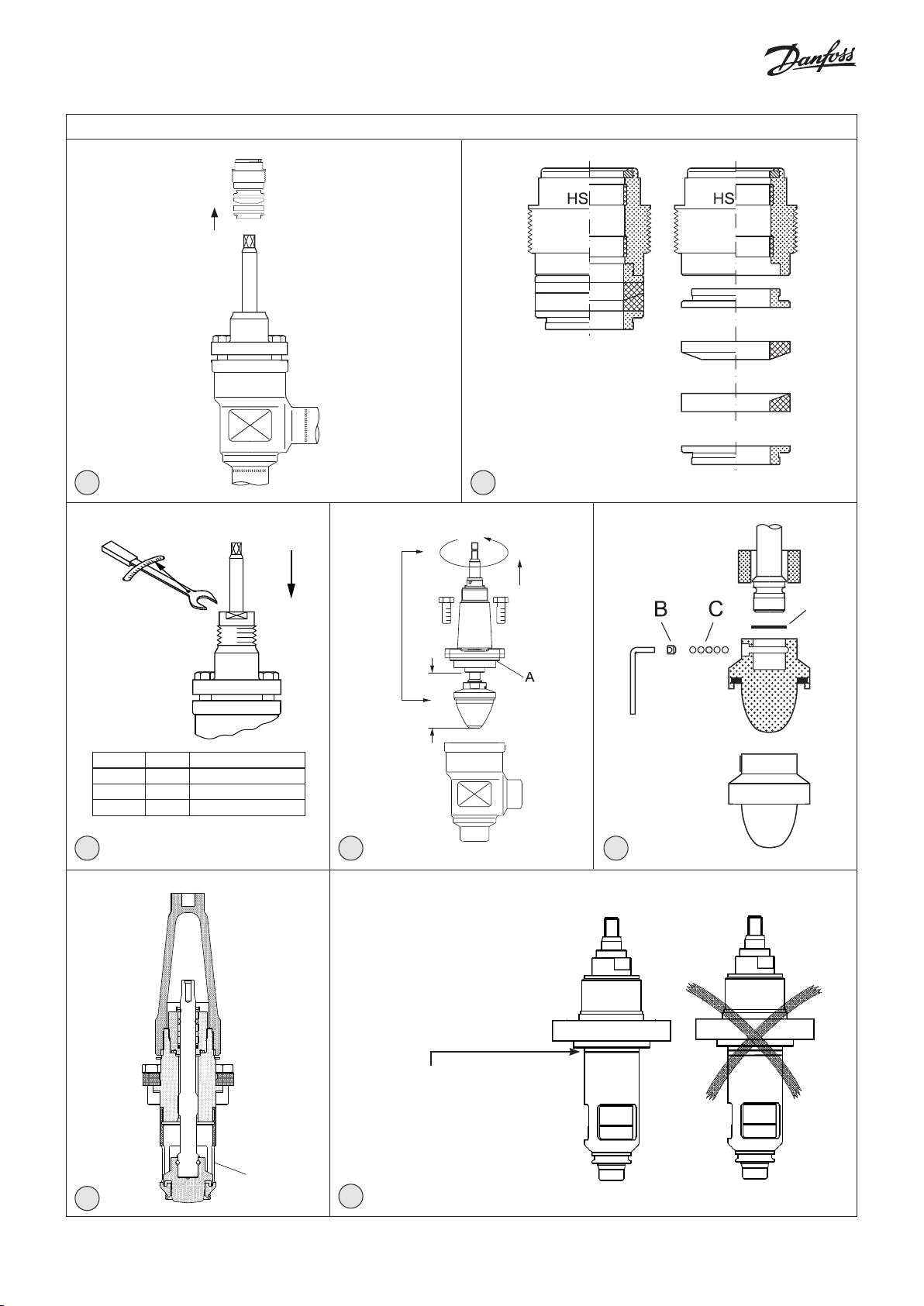

Maintenance

D

Danfoss

M148B0031_1

7 8

Nm LB-feet

DN 10 30 22

DN 15-20 50 37

DN 25-40 75 55

9 10 11

Danfoss

M148B0026_1

Ensure tight screw connection

A

12

13

Danfoss

M148G0018_1

© Danfoss | DCS (ms) | 2021.04

AN376339413133en-000101 | 2

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia),

R744 (CO2), Propane, Butane, Iso-Butane

and Ethane.

The valve is only recommended for use

in closed circuits. For further information

please contact Danfoss.

Temperature range

-60 °C/+150 °C (-76 °F/+302 °F)

Max. working pressure

The valves are designed for a max. working

pressure of 52 bar (754 psig).

Installation

The valve must be installed with the

spindle vertically upwards or in horizontal

position (fig. 1). Valves should be opened

by hand. The valve is designed to withstand

a high internal pressure. However, the

piping system should be designed to avoid

liquid traps and reduce the risk of hydraulic

pressure caused by thermal expansion.

Please ensure that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Recommended flow direction

Direct the flow towards the cone as

indicated by the arrow placed on the valve

housing (fig. 2). The force used to open and

close the valve must not exceed the force

of an ordinary handwheel.

Welding

Remove the bonnet before welding (fig. 3)

to prevent damage to the O-rings in the

packing gland and between the valve body

and bonnet, as well as the teflon gasket in

the valve seat. Be careful not to damage

the teflon cone ring and make sure the

complete bonnet is protected from dirt

and water while removed.

Removing the bonnet can be omitted

provided that: The temperature in the

area between the valve body and bonnet

during welding does not exceed

+150 °C/+302 °F. This temperature depends

on the welding method as well as on

any cooling of the valve body during the

welding itself. (Cooling can be ensured

by, for example, wrapping a wet cloth

around the valve body.) Make sure that no

dirt, welding debris etc. get into the valve

during the welding procedure.

Only materials and welding methods,

compatible with the valve housing

material, must be applied to the valve

housing. The valve housing must be

free from stresses (external loads) after

installation.

Clean the valve internally to remove

welding debris at completion of welding

and before the valve is reassembled. Avoid

welding debris and dirt in the threads of

the housing and the bonnet.

Do NOT remove or service the dark colored

grease between the spindle thread and

the bonnet. In case the grease has been

contaminated with dirt, debris, particles

or water the complete top part must be

replaced.

Do not mount REG valves in systems where

the outlet side of the valve is open to

atmosphere. The outlet side of the valve

must always be connected to the system

or properly capped off, for example with a

welded-on end plate.

Assembly

Remove welding debris and any dirt from

pipes and valve body before assembly.

Check that the cone has been fully screwed

back towards the bonnet before it is

repositioned in the valve body

(REG-SA/SB SS DN 15-40) (fig. 4).

Tightening

Tighten the bonnet with a torque wrench,

to the values listed in the table (fig. 4).

Colours and identification

The REG-SA/SB SS valves are painted

with a red primer in the factory. Precise

identification of the valve is made via the

yellow ID ring at the top of the bonnet, as

well as by the stamping on the valve body.

The external surface of the valve housing

must be protected against corrosion

with a suitable protective coating after

installation and assembly.

Protection of the ID ring when repainting

the valve is recommended.

Maintenance

Packing gland

When performing service and

maintenance, replace the complete

packing gland only, which is available as a

spare part. As a general rule, the packing

gland must not be removed if there is

internal pressure in the valve. However, if

the following precautionary measures are

taken, the packing gland can be removed

with the valve still under pressure:

Backseating (fig. 5)

To backseat the valve, turn the spindle

counter-clockwise until the valve is fully

open.

Pressure equalization (fig. 6)

In some cases, pressure forms behind the

packing gland. Hence a handwheel or

similar should be fastened on top of the

spindle while the pressure is equalized.

The pressure can be equalized by slowly

screwing out the gland.

Removal of packing gland (fig. 7)

The packing gland can now be removed.

Fitting a replacement packing gland

(Fig. 8)

Great care should be taken when fitting a

new packing gland and damage to Teflon

gaskets must be avoided.

During fitting, the individual components

in the packing gland should be placed in

order and positioned as shown (Fig. 8).

Dismantling the valve

Do not remove the bonnet while the valve

is still under pressure.

- Check that the O-ring (fig. 10, pos. A) has

not been damaged.

- Check that the spindle is free of scratches

and impact marks.

- If the teflon cone ring has been

damaged, the whole cone assembly

must be replaced.

- DN 15-40: Unscrew the adapter (fig. 12,

pos. A) to be able to change the cone.

Replacement of the cone (fig. 11)

Unscrew the cone screw (pos. B) with an

Allen key. (An Allen key is included in the

Danfoss Industrial Refrigeration gasket set).

REG-SA/SB SS 15-40 ...................... 2.0 mm A/F

Remove the balls (pos. C).

Number of balls in fig. 11, pos. C:

REG-SA/SB SS 15-20 ................................ 10 pcs.

REG-SA/SB SS 25-40 ................................ 14 pcs.

The cone can now be removed. Place the

new cone on the spindle and remember to

place the disk spring (pos. D) between the

spindle and the cone. Compress the disk

spring and replace the balls (pos. C).

Refit the cone screw in again using Loctite

No. 648. to ensure that the screw is

properly fastened.

Do NOT remove or service the dark colored

grease between the spindle thread and

the bonnet. In case the grease has been

contaminated with dirt, debris, particles

or water the complete top part must be

replaced.

Assembly

Remove any dirt from the body before the

valve is assembled. Check that the cone

has been screwed back towards the bonnet

before it is replaced in the valve body (fig. 4).

Note:

For REG-SA/SB SS sizes DN 15-40 it is

important to ensure that the lower

and upper part of the insert is tightly

screwed together (fig. 13) and that this

screw connection is kept tight during

repositioning of the cone in the housing.

Tightening

Tighten the bonnet with a torque wrench,

to the values indicated in the table (fig. 4).

Tighten the packing gland with a torque

wrench, to the values indicated in the table

(fig. 9).

Use only original Danfoss parts, including

packing glands, O-rings and gaskets for

replacement. Materials of new parts are

certified for the relevant refrigerant.

In cases of doubt, please contact your local

Danfoss sales office.

© Danfoss | DCS (ms) | 2021.04

AN376339413133en-000101 | 3

Danf

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order pro

All trademarks in this material are property of the respec

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DCS (ms) | 2021.04

AN376339413133en-000101 | 4

Loading...

Loading...