Page 1

Instructions

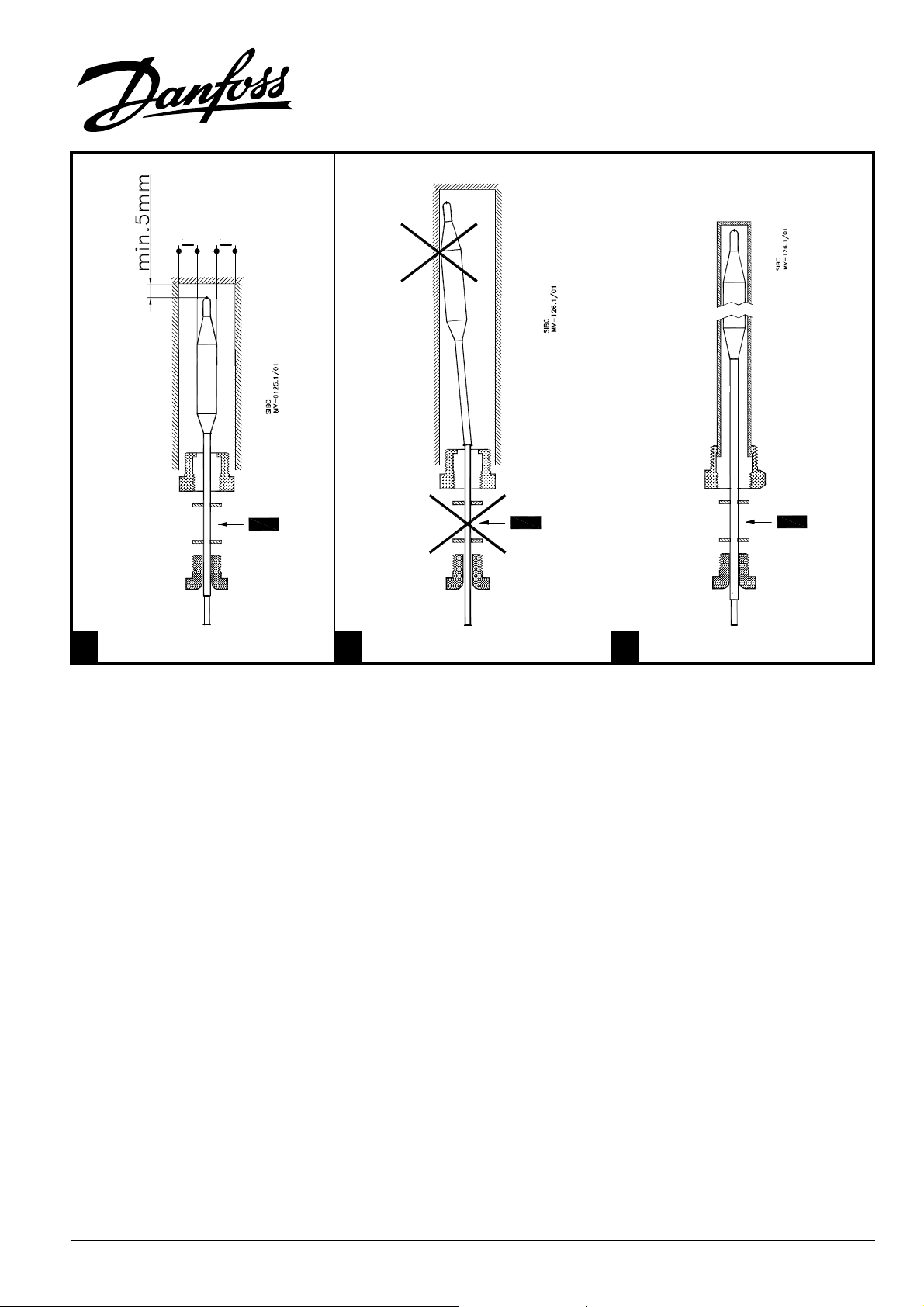

RAV - Installation for sensors

082R9106

082R9106

31 2

The main purpose of these

instructions for RAV group of

products is explaining how to make

and assure the correct installation of

the products in order to avoid

corrosion effect which could later on

cause complete malfunction of the

products.

We have experienced that main

corrosion effect is caused by so

called “galvanic” type of corrosion.

This type of galvanic corrosion is

caused by metal contact between

sensor’s housing and other metal

(e.g. inner wall or plate of heat

exchanger) in the presence of water.

Metal contact between sensor’s

housing and other metal causes

galvanic cell, which is a “perfect

condition” for previously mentioned

corrosion (especially when we have

a contact of two different metals).

Final effect of corrosion is “broken

housing” and lost charge (gas).

When charge is partly or completely

gone, product is not able to provide

its specified performance.

Water flow and resulting vibrations in

the system can result in so called

hammering of the sensor against

adjacent metals, which even

mechanically accelerates the whole

corrosion phenomena.

Please consider the following

recommendation supported by

relevant figures before you make

final installation of RAV products.

! Install sensor part as shown on

figure 1 in order to assure at least

5 mm distance between sensor

housing made of brass and other

metal parts.

! Consider adequate distance over

the whole side length and end part

of the sensor (figure 1).

! Assure that sensor is properly

fixed; larger dimension of capillary

tube has to be fixed with stuffing

box (2 washers with rubber gasket

in between, tightened with screw),

(figure 1).

! By installation shown on figure 1

you also assure the optimal arm

(distance between stuffing box

where sensor is fixed and end part

of the sensors inserted in the

media in heat exchanger or boiler)

which will reduce the risk of

vibrations which could cause a

metal contact.

! Please avoid installation which is

shown on figure 2 (thinner

diameter of capillary tube fits in

stuffing box, longer arm etc.).

! If you can not avoid or at least you

assume the possibility of metal

contact, than you have to use

a protecting pocket (sleeve) made

of stainless steel (figure 3).

By using this standard type of

accessory you will be faced with

longer response time of RAV’s

performance due to slower heat

transition.

7369186-0 SIBC R&D VI.52.B2.02 © Danfoss 8/00

Loading...

Loading...