Page 1

Data sheet X-tra™ Collection Valves for Jaga

Application

The new X-tra Collection is a TRV specially designed for towel rails and designer radiators. Its new

and innovative self-sealing ½" valve to radiator

connection makes for a seemless, elegant and

easy installation.

The towel rails valve set includes a matching lockshield valve with drain-off function. The valves

and sensors are available in Chrome and Inox.

The valve set provides the perfect finishing touch

for towel rails. The aesthetically pleasing and

compact design allows the sensor to be mounted

underneath the towel rail, parallel with the wall,

avoiding the risk of accidentally knocking the

sensor.

Small to medium-sized convectors with valves

matching in colour or in contrast colours, is also

an interesting application for this series of valves.

DKCD VD.VJ.B1.02 © Danfoss 01/2007 1

Page 2

Data sheet X-tra™ Collection Valves for Jaga

Ordering, Set Packs

Type

Description Chrome Inox

Technical data

RAX sensor, valve and lockshield valve

Set, Right mounted

Set, Left mounted

Connection kv -values [m3/h] with RAX sensor at setting¹⁾

Type Design

RA-URX

Type Design

RLV-X

Max. working pressure: 10 bar, Max. differential pressure²⁾: 0,6 bar, Test pressure 16 bar, Max. flow temperature: 120 °C

¹⁾ The kv-value indicates the water flow (Q) in m³/h at a pressure

drop (Δp) across the valve of 1 bar; kv = Q: √Δp.

At setting N the kv-value is stated according to EN 215, at XP = 2K

i.e. the valve is closed at 2˚C higher room temperature.

At lower settings the XP value is reduced to 0.5K of the setting value 1.

The kvs-value states the flow Q at a maximum lift, i.e. at fully open

valve at setting N.

Left mounted angle valve

Right mounted angle valve

Left mounted lockshield valve

Right mounted lockshield valve

Radiator System 1 2 3 4 5 6 7 N

R ½ M24 0.03 0.06 0.13 0.17 0.23 0.27 0.29 0.34 0.44

Connection kv -values [m3/h] at number of turns

Radiator System 0.25 0.50 0.75 1 1.5 2 k

R ½ M24 0.18 0.36 0.47 0.52 0.58 0.58 0.60

²⁾ The maximum differential pressure specified is the maximum

pressure at which the valves give satisfactory regulation.

As with any device which imposes a pressure drop in the system,

noise may occur under certain flow/pressure conditions.

The differential pressure can be reduced by the use of the Danfoss

differential pressure regulators.

013G4227

013G4323

013G4228

013G4324

N

(kvs)

vs

2 VD.VJ.B1.02 © Danfoss 01/2007 DKCD

Page 3

;MWG=

Data sheet X-tra™ Collection valves for Jaga

Pre-setting

Capacities

Danfoss pre-settable valve bodies incorporate easy

setting adjustment rings with clearly engraved

setting markers scaled from 1 - 7 and N. Setting

values can be set quickly and precisely, without

the need for tools, as follows:

· Remove protective cap or sensor element

· Lift setting ring

· Turn anti-clockwise to the desired engraved

setting value

· Allow setting ring to spring back into position

The preset level can be selected in 0.5 increments

between 1 and 7 (see chart on page 3 for flow

rates).

At setting N the valve is fully open (flushing

option).

Capacity with RA-URX, RLV-X and RAX sensor at a P-band between 0.5 K and 2 K.

Sizing example Alternatively the setting can be read directly in

Required heat: 0.45 kW

Cooling across radiator: 20 ˚C.

the table “Ordering and technical data”:

Flow through radiator:

0.45

Q = = 0.019 m3/h = 0.005 l/s.

20 x 1.16

Pressure drop across valve: ∆p = 1 mwg.

kv =

Q (m3/h)

√∆p (bar)

Valve setting: "2"

Valve presetting when using

RTX sensor. The sensor must be

ordered separately.

Due to the function of the RTX sensor its influence on the hydraulic balance of the heating

system is very limited. Consequently it is seldom

required to adjust the kv-setting of the valve from

the factory setting ”N”.

The table shows the reduced flow in m3/h when

applying different kv-settings:

Valve pre-setting 2K 5K

1 0,03 0,03

2 0,07 0,07

3 0,12 0,13

4 0,16 0,18

5 0,19 0,24

6 0,21 0,27

7 0,22 0,29

N 0,23 0,33

CD-ST VD.VJ.B1.02 © Danfoss 01/2007 3

Page 4

Data sheet X-tra™ Collection Valves for Jaga

Construction

RA-URX - Gland seal for RAX

1. Protective cap

2. Gland seal

3. Pressure pin

4. Return spring

5. Setting cylinder

6. Valve body

7. Allen screw

8. Self-sealing gland

RLV-X

1. Self-sealing gland

2. Allen screw

3. Valve body

4. Shut-off facility

5. Cylindric guide

6. Cover cap

The valve assembly features valve body and a

self-sealing gland pre-mounted with 2 O-rings

- one for sealing against the radiator and one for

sealing in the valve housing.

The Allen-screw features an O-ring seal to ensure

a tight seal against the valve body.

In situations where radiator in- and outlets are

not suitable for O-ring seal, conventional sealing

material is used.

1

2

3

4

5

1

2

3

4

5

6

Materials in contact with water

Setting cylinder PPS

Spindle

O-rings EPDM

Valve cone NBR

Valve body Ms 58

Ms, resistant against

dezincification

8

7

6

4 VD.VJ.B1.02 © Danfoss 01/2007 DKCD

Page 5

Data sheet X-tra™ Collection Valves for Jaga

Spare parts

and accessories

Fittings

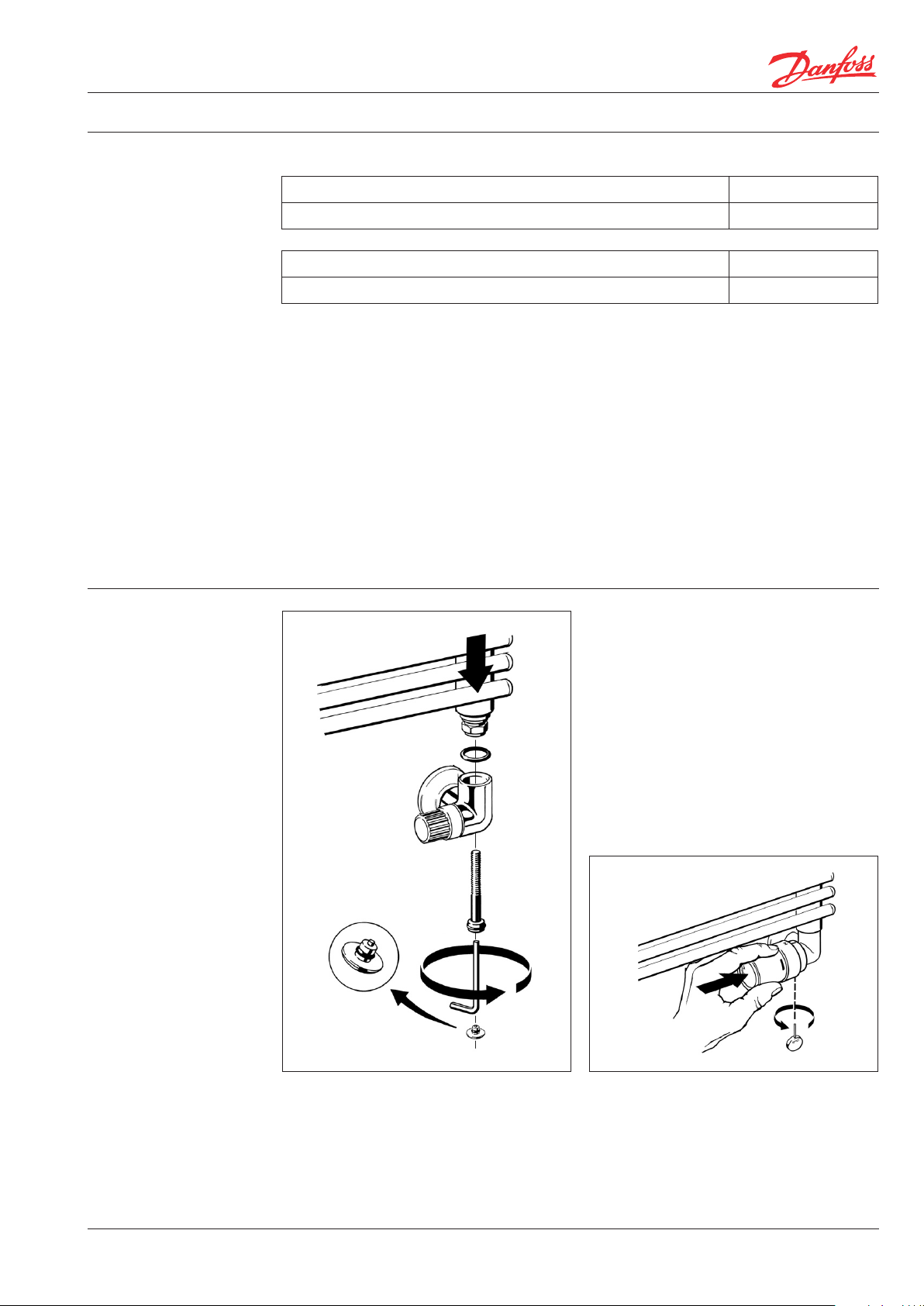

Installation

Spare parts Code no.

Gland seal for RA-URX valve with RAX sensor 013G0290

Accessories Code no.

Drain and fill tap 003L0152

Relevant compression fittings are delivered by

Jaga

The self-sealing gland is mounting in radiator inlet and outlet using a 17 mm hexagonal key.

Valve and lockshield valve has matching design.

The yellow valve cap can temporarily be used to

open and shut the valve. The lockshield valve

features shut-off and draining facility.

All O-rings are of the EPDM-type which means no

mineral oils or grease are to be used.

CD-ST VD.VJ.B1.02 © Danfoss 01/2007 5

Page 6

Data sheet X-tra™ Collection Valves for Jaga

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Shut-off, filling

and draining

Dimensions

RLV-X

lockshield valve

RA-URX

return valve

RAX and RTX

thermostatic sensors

6 VD.VJ.B1.02 © Danfoss 01/2007 DKCD

Loading...

Loading...