Page 1

Data Sheet

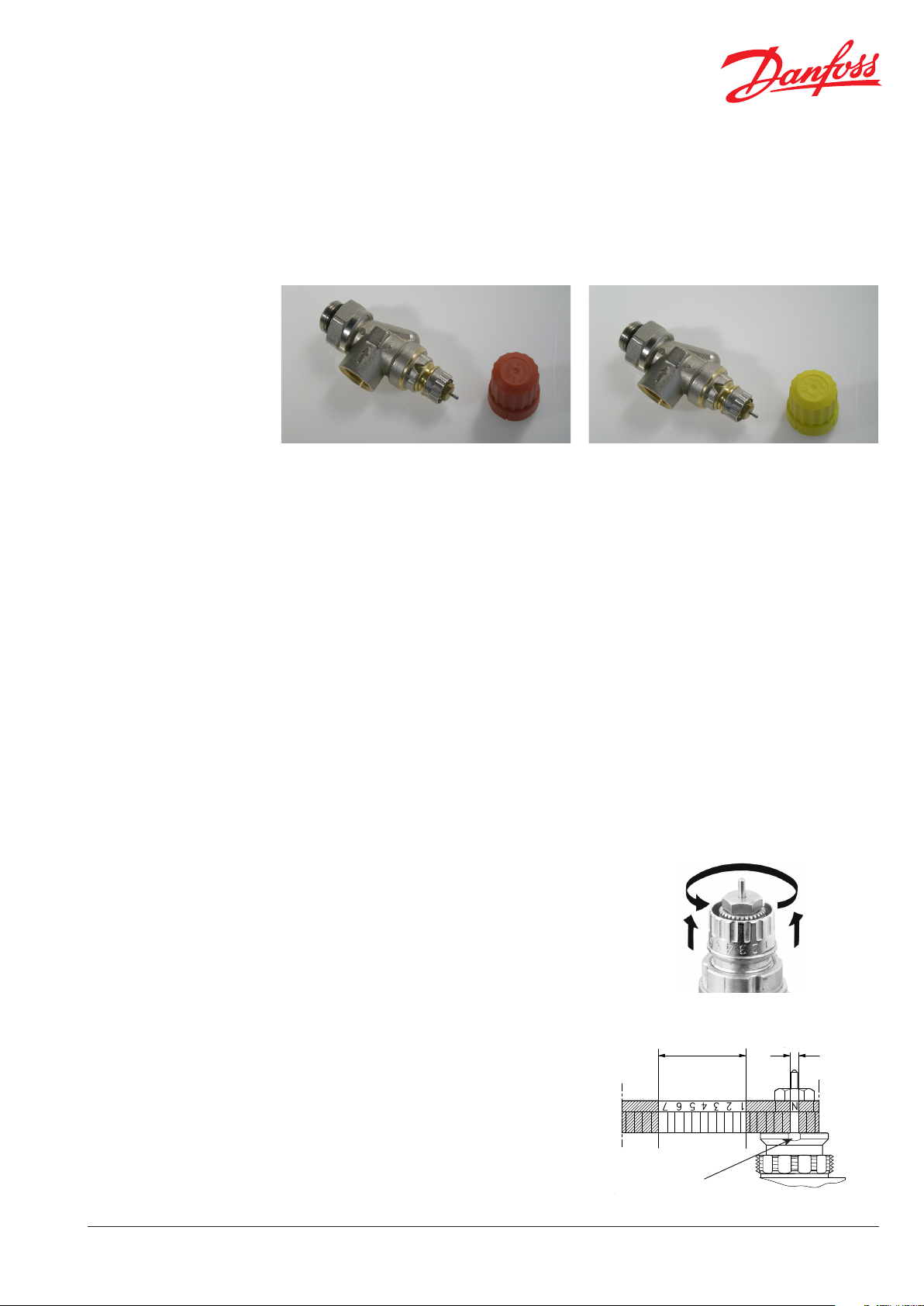

Radiator Valves with Integrated Presetting, Types

RA-N, 013G3301* and RA-U, 013G3302

Application

Quality, approvals

Presetting

RA-N and RA-U valve bodies are used with all types of thermostatic sensors with RA 2000 connection and with TWA-A thermal actuators.

Both valves are designed for two-pipe heating

systems.

The valves features an integrated pre-setting of

maximum water ow.

The setting range is:

RA-N, 013G3301: kv = 0.16 - 1.02 m3/h

RA-U, 013G3302: kv = 0.03 - 0.73 m3/h

The protective valve cap (red or yellow) may be

used for manual regulation during the building

period, until the sensor is tted.

All Danfoss radiator thermostats are manufactured in factories, assessed and certied by BSI

(British Standards Institution) against ISO 9000

and ISO14001.

The presetting values of RA-N and RA-U valves

can be adjusted easily and accurately without the

use of tools (factory setting = N):

RA-N valve bodies are manufactured from brass

with nickel plating.

The pressure pin of the gland seal is of chromium

steel and works in a lifetime lubricated O-ring. The

complete gland seal assembly can be replaced

without draining down the system.

In order to avoid deposition and corrosion the

composition of the hot water must be in accordance

with the VDI 2035 guideline (Verein Deutscher

Ingenieure).

It is recommended that formulations containing

mineral oil are avoided.

* RA-N, code 013G3301, is Keymarked certied

according to EN215.

Danfoss Heating Solutions

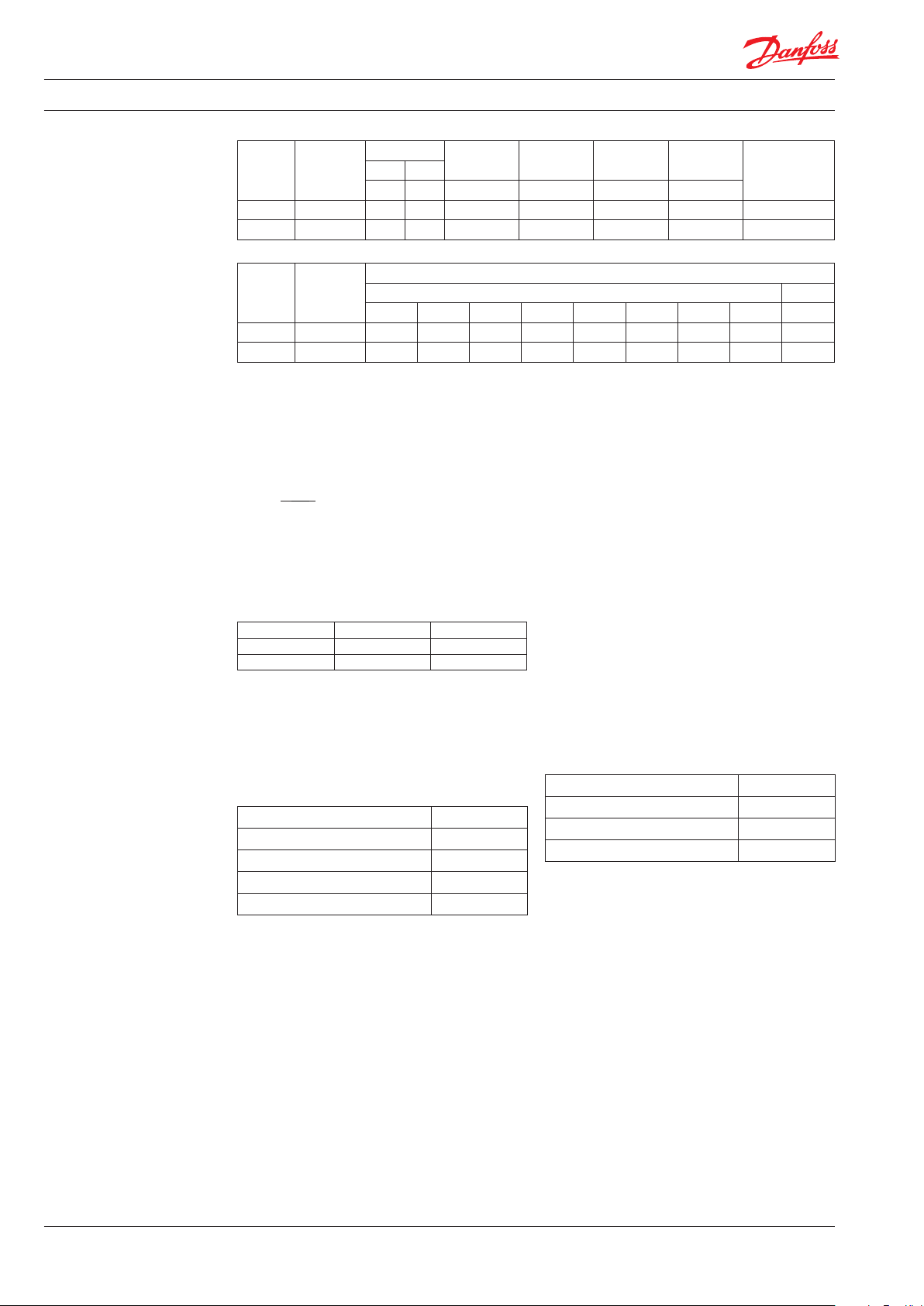

• Remove protective cap / thermostatic sensor

• Find reference mark

• Lift and turn setting ring until the required

setting aligns with the reference mark.

Presetting can be selected in steps from 1 to 7.

At setting N the valve is fully open. This setting is

used when ushing or draining the system.

Settings other than the recommended range

should be avoided.

When the thermostatic sensor has been installed,

the presetting is protected against unintended

regulation.

VDSXJ202 © Danfoss 03/2011

Presetting

Reference mark

range

Factory setting and

one-pipe system

1

Page 2

Data Sheet Radiator Valves with Integrated Presetting, Types RA-N, 013G3301* and RA-U, 013G3302

Data and ordering

Max. di.

press.

2)

Test

Max. work.

temp.

Code noInlet Outlet

Type Design

Connections

Max. work.

press.

Rp R bar bar bar ˚C

RA-N 15 Horiz. angle 1/2 1/2 10 0.6 16 120 013G3301

RA-U 15 Horiz. angle 1/2 1/2 10 0.6 16 120 013G3302

Pre-setting

Type Design

kv-max.1) (m3/h at Δp = 1 bar) k

vs

1 2 3 4 5 6 7 N N

RA-N 15 Horiz. angle 0.16 0.20 0.25 0.35 0.47 0.59 0.74 0.81 1.00

RA-U 15 Horiz. angle 0.03 0.06 0.10 0.19 0.27 0.39 0.44 0.62 0.73

1)

Working pressure = static + dierential pressure. The maximum dierential pressure specied is the maximum pressure at which

the valves give satisfactory regulation. As with any device which imposes a pressure drop in the system, noise may occur under

certain ow/pressure conditions. To ensure quiet operation, maximum pressure drop should not exceed 30 to 35 kPa. The dierential pressure can be reduced by the use of the Danfoss dierential pressure regulators types AVD, AVDL, AVDS, IVD or ASV-P.

2)

The kv-value indicates the water ow (Q) in m3/h at a pressure drop (∆p) across the valve of 1 bar;

kv =

Q

√∆p

At setting N the kv-value is stated according to EN 215, at XP = 2K i.e. the valve is closed at 2°C

higher room temperature. At lower settings the XP value is reduced to 0.5K of the setting value 1. The kvs-value states the ow Q

at a maximum lift, i.e. at fully open valve at setting N. When using remote setting adjusters or RAE sensors kv values are reduced

for identical P-band

Technical data

Kv (Xp=2) kvs

RA-N 0.62 1.00

RA-U 0.44 0.73

Parts in contact with water

Valve body and other metal parts Ms 58, brass

Kv-limiter PPS

O-ring EPDM

Valve cone NBR

Pressure pin and valve spring Chrome steel

The valve bodies are nickel-plated.

Max. ambient temperature 60 ˚C

Max. medium temperature 120 ˚C

Max. working pressure 10 bar

Test pressure 16 bar

2

VDSXJ202 © Danfoss 03/2011

Danfoss Heating Solutions

Page 3

Data Sheet Radiator Valves with Integrated Presetting, Types RA-N, 013G3301* and RA-U, 013G3302

Dimensions

The valve tailpiece features an o-ring seal to ensure easy and safe mounting. The mating part of the radiator must be

chamfered 45˚ in order to prevent damage of the seal. See illustration.

RA-N, 013G3301Capacities

Danfoss Heating Solutions

VDSXJ202 © Danfoss 03/2011

3

Page 4

Data Sheet Radiator Valves with Integrated Presetting, Types RA-N, 013G3301* and RA-U, 013G3302

RA-U, 013G3302

Danfoss A/S

Residential Heating

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Sizing example:

Required heat: 1.5 kW

Cooling across radiator: 20° C

Flow through

radiator:

Pressure drop across valve: ∆p = 1 mwg

Valve setting: RA-N, 013G3301 2

1.5

Q =

= 0.064 m3/h= 0.018 l/s

20 x 1.16

RA-U, 013G3302 5

Alternatively the setting can be read directly in the table

"Data and Ordering".

Q (m3/h)

kv =

√∆p (bar)

4

VDSXJ202 © Danfoss 03/2011

Danfoss Heating Solutions

Loading...

Loading...