Data Sheet

RA-N / RA-U PURE radiator valves with

presetting

Application

Ordering and

Technical Data

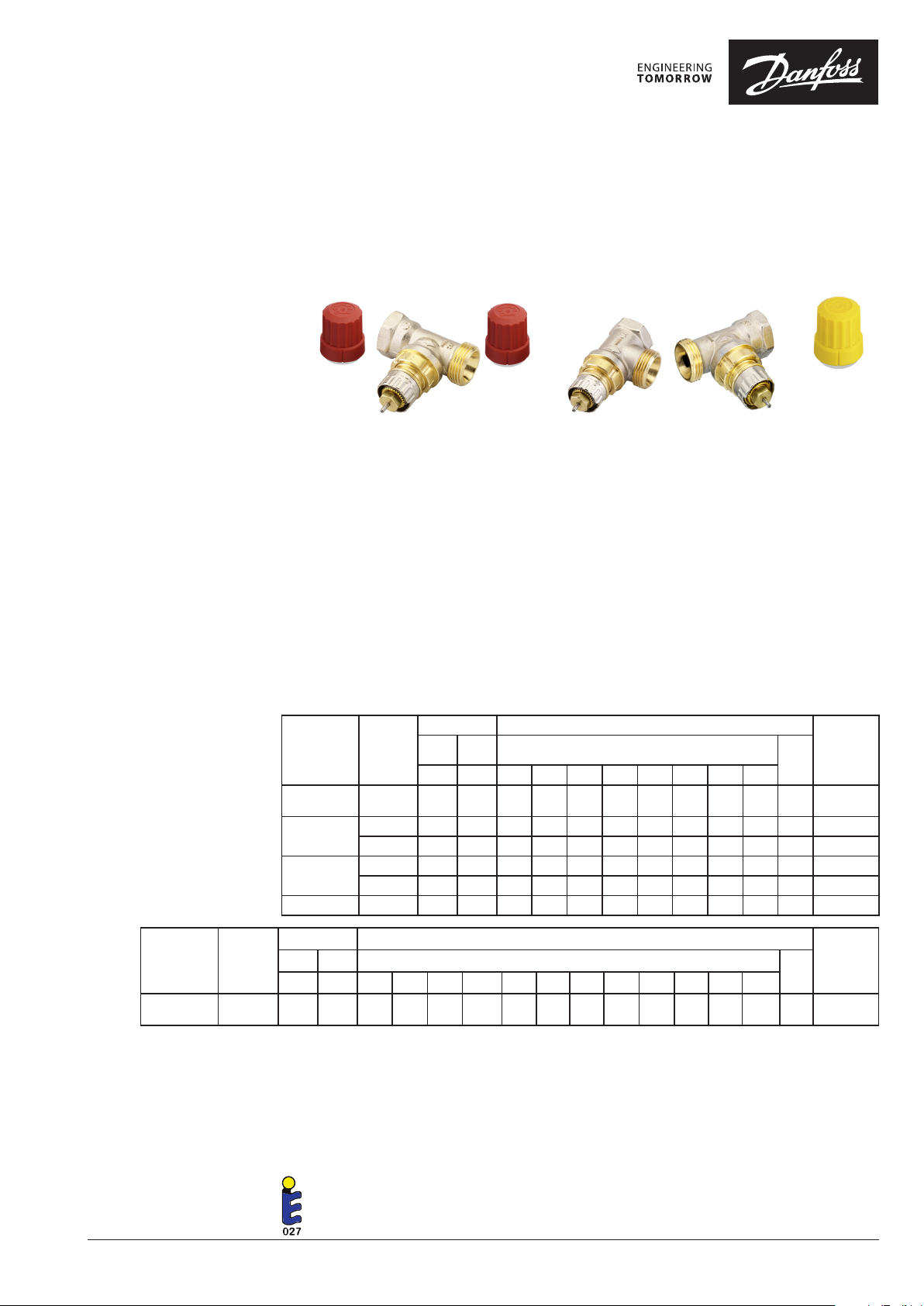

RA-N PURE straight RA-N PURE Angle

All RA-N/ RA-U PURE valve bodies can be used

off device is available as an accessory.

RA-U PURE

together with all types of thermostatic elements

in the RA 2000 series and with TWA-A thermal

actuators.

RA-N/ RA-U PURE valve bodies are manufactured

from Eco brass contains less than 0.1% lead with

nickel plating.

RA-N/ RA-U PURE valves are used in two-pipe

heating systems and comes in series S.

The pressure pin of the gland seal is of low lead

metal and works in a lifetime lubricated O-ring.

RA-N/ RA-U PURE valves are fitted with a kv limiting

device for pre-setting of max. water flow and

The complete gland seal assembly can be

replaced without draining down the system.

are available with the setting ranges: in the table

below.

In order to avoid deposition and corrosion the

composition of the hot water must be in accordance

Each valve body is supplied with a protective cap,

which can be used for manual regulation during

the construction phase. This cap must not be used

with the VDI 2035 guideline (Verein Deutscher

Ingenieure). It is recommended that formulations

containing mineral oil are avoided.

as a manual shut off device. A special manual shut

Connections Pre-setting

Type Design

RA-N PURE 10

with lock

RA-N PURE 10

RA-N PURE 15

RA-N PURE 20 Straight 3/4 3/4 0.10 0.15 0.17 0.26 0.35 0.46 0.73 1.04 1.40 015G0076

Straight 3/8 3/8 0.04 0.08 0.12 0.19 0.25 0.33 0.38 0.56 0.65 015G4022

Angle 3/8 3/8 0.04 0.08 0.12 0.19 0.25 0.33 0.38 0.56 0.65 015G0071

Straight 3/8 3/8 0.04 0.08 0.12 0.19 0.25 0.33 0.38 0.56 0.65 015G0072

Angle 1/2 1/2 0.04 0.08 0.12 0.20 0.30 0.40 0.51 0.73 0.90 015G0073

Straight 1/2 1/2 0.04 0.08 0.12 0.20 0.30 0.40 0.51 0.73 0.90 015G0074

Out-

let

Rp R 1 2 3 4 5 6 7 N

kv-max.1) (m3/h at Δp = 1 bar)

Code noInlet

k

vs

Quality

Type Design

RA-U PURE 10

with lock

Straight 3/8 3/8

Connection Pre-setting

Code noInlet Outlet kv-max.1) (m3/h at Δp = 1 bar)

k

Rp R 1 2 3 4 5 6 7 8 9 10 11 N

0.016 0.025 0.035 0.05 0.06 0.08 0.10 0.12 0.16 0.21 0.26 0.28 0.30

1)

The kv-value indicates the water flow (Q) in m3/h at a pressure drop (∆p) across the valve of 1 bar; kv = Q: √ ∆p. At setting N the

kv-value is stated according to EN 215, at XP = 2K i.e. the valve is closed at 2°C higher room temperature. At lower settings the XP

value is reduced to 0.5K of the setting value 1.

The kvs-value states the flow Q at a maximum lift, i.e. at fully open valve at setting N.

2)

Working pressure = static + differential pressure. The maximum differential pressure specified is the maximum pressure at

which the valves give satisfactory regulation. As with any device which imposes a pressure drop in the system, noise may occur

under certain flow/pressure conditions. To ensure quiet operation, maximum pressure drop should not exceed 30 to 35 kPa. The

differential pressure can be reduced by the use of the Danfoss differential pressure regulators types AB-PM , ASV-P or ASV-PV.

vs

015G3022

RA-N/ RA-U PURE valves are certified according to the European standard EN 215.

Danfoss radiator thermostats are manufactured in factories, assessed and certified by BVC

(Bureau Veritas Certification) against ISO 9001 and ISO 14001.

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

1

Datasheet

RA-N / RA-U PURE radiator valves with presetting

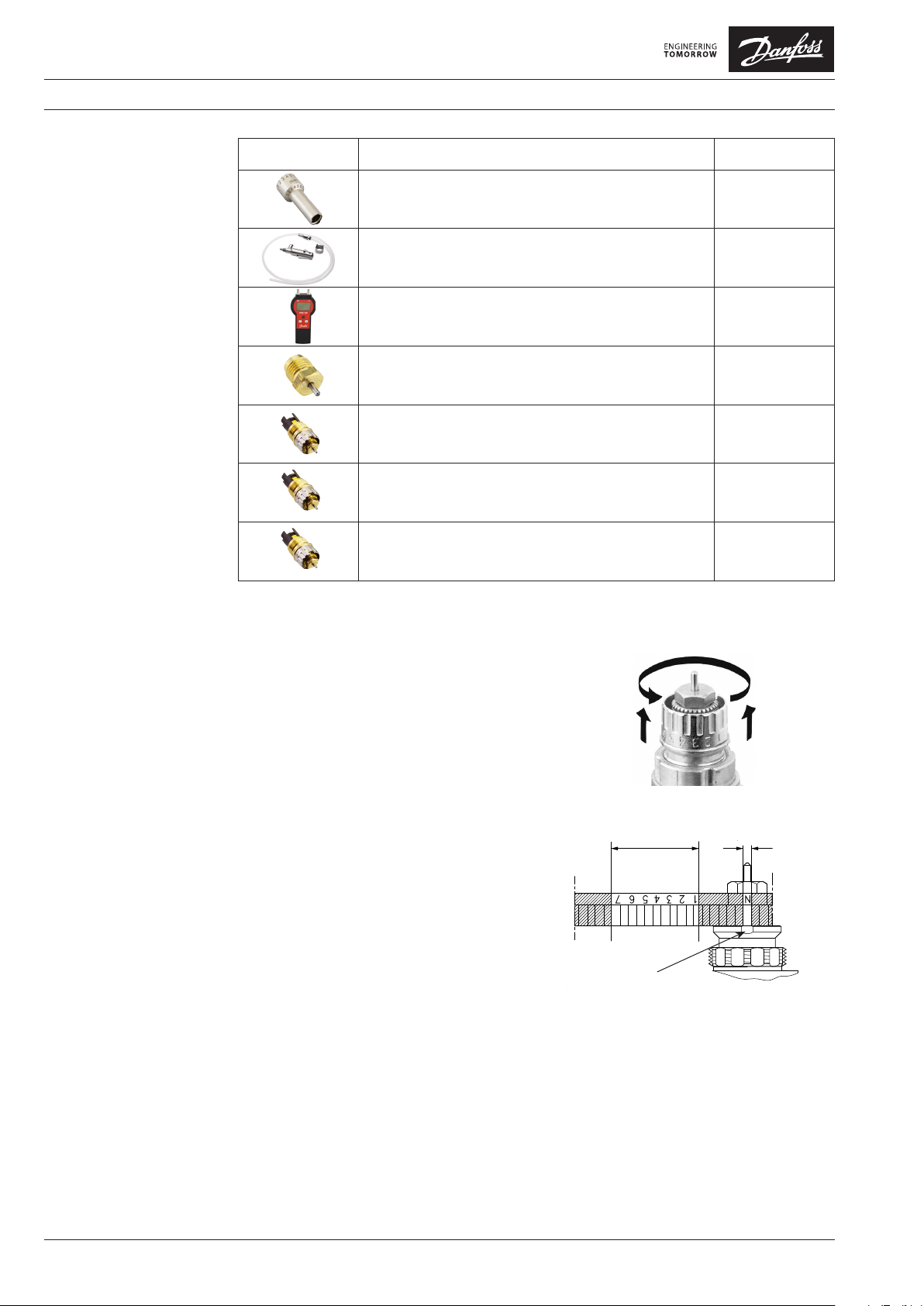

Accessories

Typ e Code Number

Presetting key for RA-U valves & also RA-N with lock 013G3028

p tool for pump optimization 013G7861

PFM100 measuring instrument 003L8260

PURE gland-seal 015G 0290

Service insert, Lock, RA-N 10, PURE 015G3018

Service insert, RA-N 10, PURE 015G3063

Service insert, RA-N 15, PURE 015G3073

Presetting

The presetting values of RA-N/ RA-U PURE valves

can be adjusted easily and accurately without the

use of tools (factory setting = N):

• Remove protective cap / thermostatic sensor

• Find reference mark

• Lift and turn setting ring until the aquired

presetting aligns with the reference mark.

Presetting can be selected in steps from 1 to 7.

(RA-U PURE 10 pre-setting steps from 1 to 11). At

setting N the valve is fully open. This setting can

be used as a flushing position, if the system has to

be flushed out because of dirt problems. In onepipe installations, the setting N must be used.

Settings outside 1 to 7 and N should be avoided.

When the thermostatic sensor has been installed,

the presetting is protected against unintended

regulation.

Presetting

Reference mark

range

Factory setting and

one-pipe system

2

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

Datasheet

Operating principle

RA-N / RA-U PURE radiator valves with presetting

1. Gland seal

2. O-Ring

3. Pressure pin

4. Seal

5. Regulation spring

6. Setting dial

7. Valve body

8. kv-nozzle (Only 015G3022)

Principles

The radiator thermostats consist of the

thermostatic elements of the RA 2000 series and

the valve body RA-N / RA-U PURE. The element

and the valve body are ordered separately.

Valve body and other metal parts Eco Brass CW724R

Setting dial PPS

O-ring EPDM

Valve cone NBR

Pressure pin and valve spring Chrome steel

Nozzle PP

The valve bodies are nickle-plated on the outside.

A clamping band with Allen screw ensures a

simple, firm connection between element and

valve body. The gland seal of the valve can be

changed in operation, i.e. with water and pressure

on the system.

Max. ambient temperature 60 ˚C

Max. medium temperature 120 ˚C

Max. working pressure 10 bar

Test pressure 16 bar

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

3

Datasheet

RA-N / RA-U PURE radiator valves with presetting

Capacities

RA-N PURE 10, Rp 3/8 connection

RA-N PURE 15, Rp 1/2 connection

Sizing example:

Required heat: 0.7 kW

Cooling across radiator: 20° C

Flow through

radiator:

Pressure drop across valve: p = 10 kPa

Valve setting: RA-N PURE 10 2

4

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

0.7

Q = = 0.03 m3/h= 0.0083 l/s

20 x 1.16

RA-N PURE 15 2

RA-N PURE 20 1

Alternatively the setting can be read directly in the table

"Data and Ordering".

Q (m3/h)

kv =

√p (bar)

Datasheet

RA-N / RA-U PURE radiator valves with presetting

RA-N PURE 20, Rp 3/4 connection

RA-U PURE 10, Rp 3/8 connection

5

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

Datasheet

Dimensions

RA-N / RA-U PURE radiator valves with presetting

Straight valve with sensor RA 2990

Angle valve with sensor RA 2992

Type

RA-N PURE 10 10 Rp3/8 R 3/8 50 75 24 49 20 47 96 27 52 22 22 27

RA-N PURE 15 15 Rp1/2 R 1/2 55 82 26 53 23 47 96 30 58 26 27 30

RA-N PURE 20 20 Rp3/4 R 3/4 65 98 30 63 26 52 101 32 37

RA-U PURE 10 Rp3/8 R 3/8 50 75 96 23 27

ISO 7-1

DN D d S1 S2

L1 L2 L3 L4 L5 L6 L7 L8 L9 L10

Arc. flats

6

© Danfoss Climate Solutions | 02/2022 | AI403040432014en-000101

Loading...

Loading...