Page 1

Data Sheet

Integrated preset valve type RA-N 013G8370,

for normal ow

Application

Ordering and

Technical Data

The integrated valve type RA-N (013G8370) with

built-in presetting is designed for incorporation

into valve radiators and convectors from dierent

radiator and convector manufacturers.

The integrated valves can be used in single and

two pipe installations with circulating pump.

Typ e Connection

1 2 3 4 5 6 7 N N

RA-N G½A 0.14 0.21 0.26 0.32 0.46 0.59 0.73 0.87 1.05 013G 8370

Technical Data

Max. water temperature ..................120 °C Test pressure............................ 16 bar

Rec. dierential pressure. ...........0.05-0.2 bar Working pressure ....................... 10 bar

Tech. dierential pressure 2)..............0.6 bar

1)

kv-values indicate the ow volume (Q) in m3/h at a pressure loss (Δp) across the valve of 1 bar. kv = Q :√∆p. At setting N,

the kv-value in accordance with EN 215 can be stated as Xp = 2 K. At lower preset values, Xp will be reduced until

approximately Xp 0.5 at presetting 1. The table shows the average measured values for integrated valves with radiator.

The kvs-values indicate the valve capacity, when the valve is fully open. When using a liquid lled radiator thermostat

e.g. RAW, RAS-D or remote setting element t ype RA 5060 Xp will be increased by factor 1.6 (at setting “N”, ref. EN 215).

2)

The technical dierential pressure indicates the upper limit for a proper valve function. In most t wo-pipe systems the

recommended dierential pressure is sucient. In order to achieve a noiseless function we recommend in smaller

systems to apply automatic bypass valves or automatic balancing valves. If pump dierential pressure exceeds the

recommended max. valve dierential pressure it is recommended that an automatic balancing valve type ASV-P/PV is

added to the system.

The integrated valves have a reinforced stung

box to avoid damage on the valve at low

temperatures.

To avoid calcication and corrosion, it is important for the composition of the circulating water

to comply with the VDI 2035 guidelines.

All thermostatic sensors in the RA series can be

combined with RA-N 013G8370.

Presetting

1)

k

Code no.kv-value

vs

Accessories and

Spare Parts

Product Code no.

Gland seal, 10 pcs.

Green protection cap 013G 8469

1)

The gland seal of the valve can be replaced under pressure, i.e. while the installation is in operation.

VDTV Y202 © Danfoss 02/2011

1)

013L0669

1

Page 2

Data Sheet Integrated preset valve type RA-N 013G8370, for normal ow

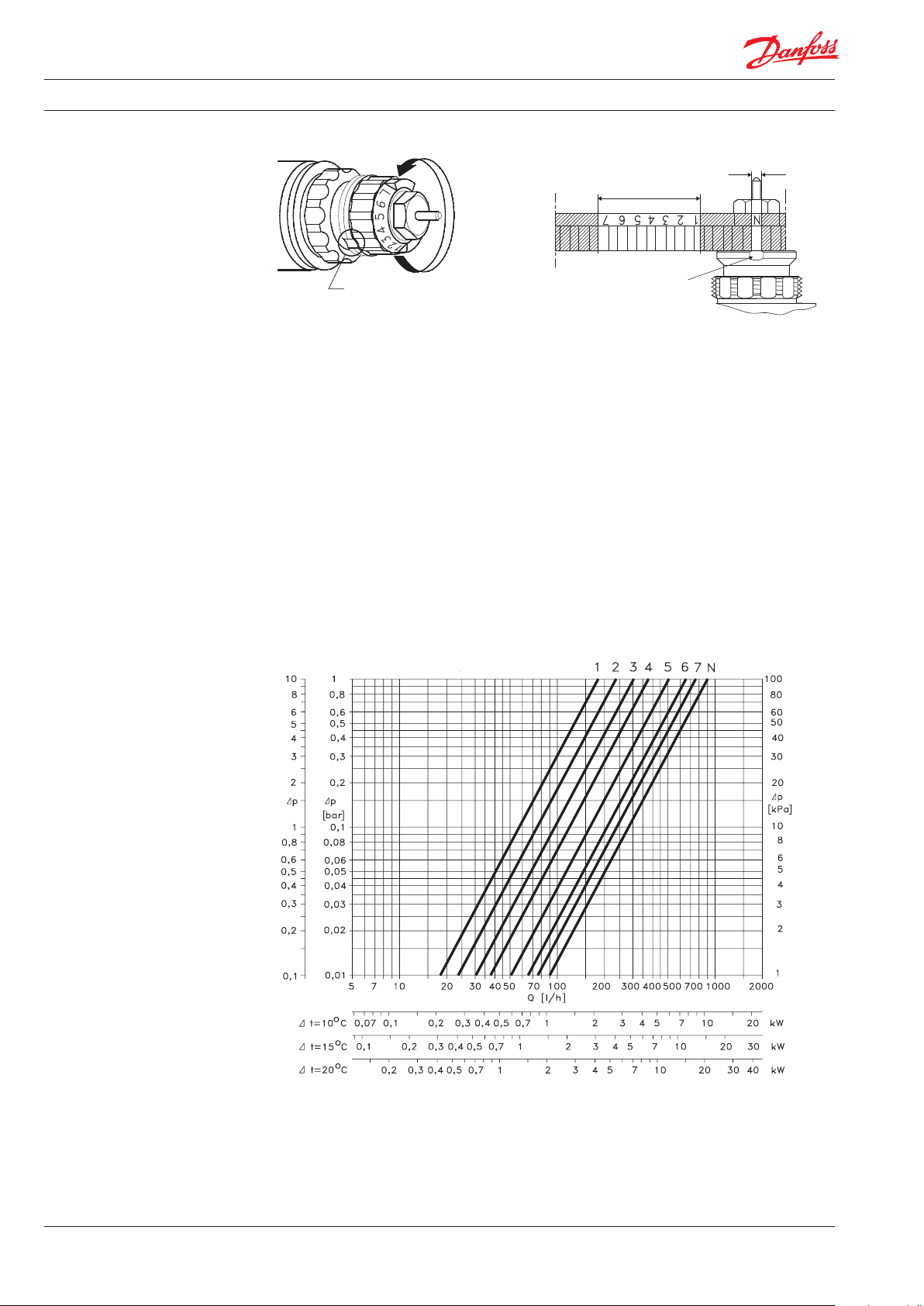

Presetting

Reference mark

The presetting values of the integrated valves

can be adjusted easily and accurately without the

use of tools (factory setting: ‘N’):

• Remove the protective cap or the thermostatic

sensor.

• Find the reference mark.

• Turn the setting ring until the desired presetting aligns with the reference mark.

The presetting is controlled directly without the

use of equipment. After installation in the

radiator, the reference mark of the valves will not

always be positioned in the same place.

Presetting can be selected innitely variably

within and between the setting numbers 1 to 7.

Factory

setting

Presetting range

Reference mark

At setting ‘N’ the valve is fully open. Setting in the

shaded areas of the drawing should be avoided.

In a one-pipe installation, the setting ‘N’ must be

used.

Setting ‘N’ can be used as a ushing position if

the system has to be ushed out because of dirt

problems.

When the radiator thermostat has been installed,

the presetting is protected against unintended

regulation.

For Danfoss elements RA 2000 and RAW, a theft

protection device is available; this also provides

added security against unwanted adjustment of

the preset values.

Capacities

Capacities without radiator and ttings

Capacities at Xp = 2K with Danfoss radiator thermostats RA-N are measured without radiator and connection ttings.

2

VDTV Y202 © Danfoss 02/2011

Page 3

Data Sheet Integrated preset valve type RA-N 013G8370, for normal ow

Design and Dimensions

Materials

Valve body Ms 58 Brass

Valve seat PPS

Throttle nozzle PPS

Setting dial Plastic

O-ring NBR/EPDM

Valve spindle PPS

Valve cone NBR

Pressure pin and valve spring Chrome steel

Standard Fittings

The dimensions stated may vary according to dierent radiator manufacturers (013M5058 E0002 001 047 97.03.25)

VDTV Y202 © Danfoss 02/2011

3

Page 4

Data Sheet Integrated preset valve type RA-N 013G8370, for normal ow

Mounting Instructions

Installation of an integrated valve at radiator

manufacturer’s plant

An integrated valve can only be tted once in a

radiator (because of the load on the deformation

zone).

• Fit the integrated valve in the radiator using a 12-edge

spanner, KW 21.

• Tighten using a torque of 30-35 Nm.

• If required, continue turning until one of the cap thread

beads points upwards (only clockwise).

Tolerance for adjustment: ±5°.

Replacement of the gland seal

While the system is in operation, the gland seal can be

replaced by means of a spanner, KW 10.

Hold the setting ring using a 12-edge ring-spanner, KW 17.

10 mm

KW 17

Press the pressure pin rmly.

4

VDTV Y202 © Danfoss 02/2011

Loading...

Loading...