Page 1

Data Sheet

Electro-hydraulic actuator type

PVHC

The PVHC is an electrical actuator module for main

spool control in PVG 32 and PVG 100. The actuator

uses two current controlled proportional pressurereducing valves. PVHC does not use the known PVE

internal closed loop control technology, and

therefore does not offer any kind of fault monitoring

system, neither active nor passive.

Function

With electrical proportional actuation, the main spool

position is adjusted so that its position corresponds to

an electrical control signal.

The control signal is converted into a hydraulic

pressure signal that moves the main spool in the PVG.

This is done by means of two proportional pressurereducing valves. The electrical actuator can be

controlled either by a current amplifier card, or

directly from a programmable micro-controller.

(see drawing fig. 1 page 2).

Features

•

PVM current control signals

•

AMP JPT and DEUTSCH DT connector

options

•

12 V or 24 V supply options

•

Only to be used with 25 bar pilot

pressure and hydraulic spring

•

Only standard mounting on PVG 32 and

PVG 100.

Comprehensive technical literature is

online at powersolutions.danfoss.com

©

Danfoss | January 2018 11006692 | AI00000005en-US0303 | 1

Page 2

Fig 1.

157-764.10

+

-

Setpoint

Driver A

Current

Feedback A

Driver B

Current

Feedback B

+

---

W

Hydraulic Actuation

It is necessary only to use the PVHC in combination with 25 bar [362.6 psi] pilot pressure, 157B5190 (OC) and -5191 (CC), and standard FC

spools fitted for hydraulic actuation. See PVG 32 Technical Information DKMH.PK.570.C4.02. Because of the 25 bar pilot pressure, it is not

possible to combine PVHC with PVE on a PVG32 or PVG 100.

Warning

All marks and all types of directional control valves – including proportional valves – can fail and cause serious damage. It is therefore

important to analyze all aspects of the application. Because the proportional valves are used in many different operation conditions and

applications, the manufacturer of the application is alone responsible for making the final selection of the products – and assuring that

all performance, safety and warning requirements of the application are met. The process of choosing the control system – and safety

level – could e.g. be governed by EN 954-1 (Safety related parts of control system).

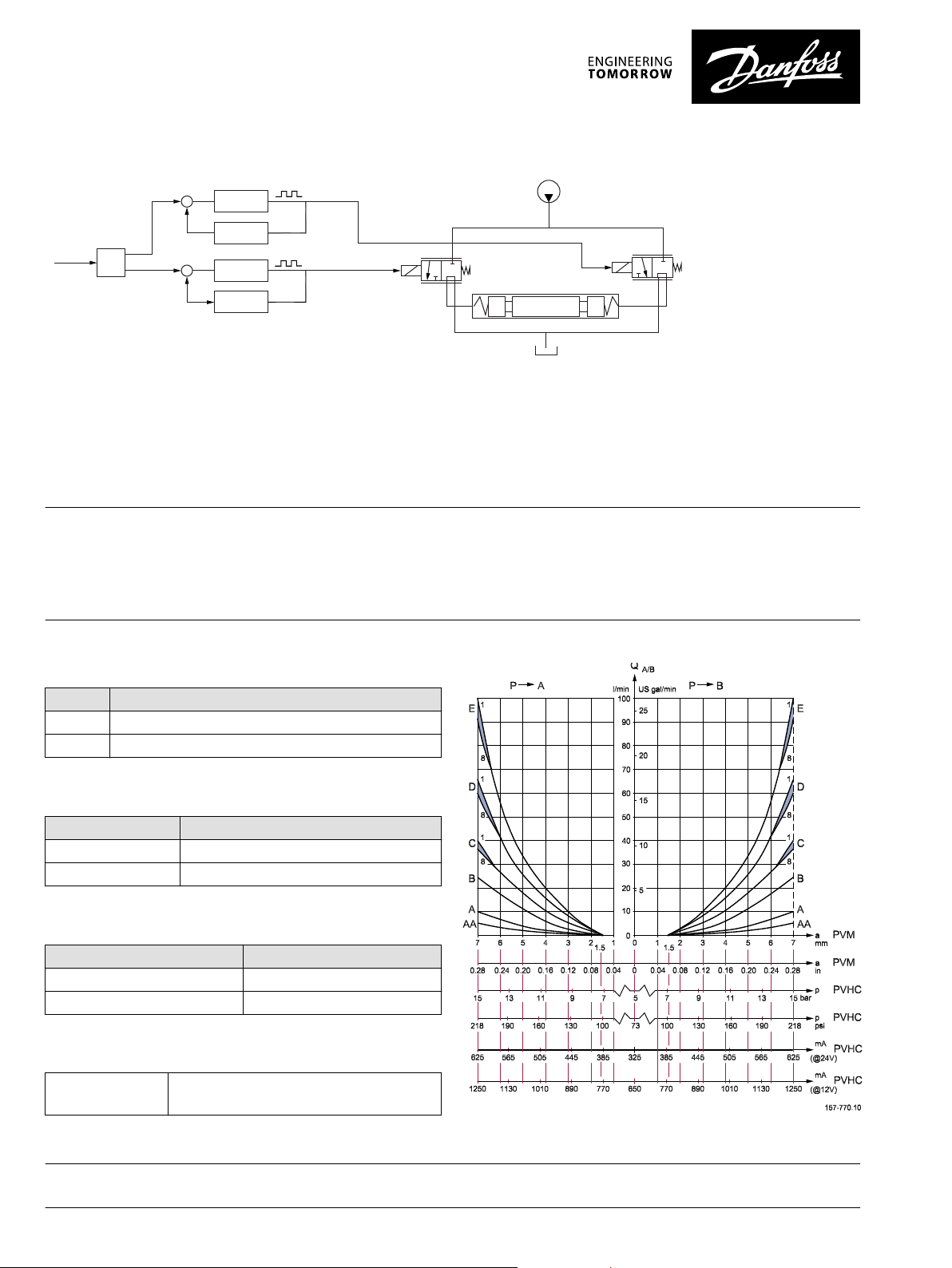

Technical data: Input-Output relation

Fig 2.

Temperature

Temperature range

Ambient -30°C to 80°C [-22 °F to 176°F]

Medium -20°C to 80°C [-4 °F to 176°F]

Input control

Parameter Control range: 12 V; 24 V

Current 0 - 1500 mA; 0 - 750 mA

Pressure control range 5 to 15 bar [72.5 to 217.5 psi]

Enclosure

Connector type Protection class

DEUTSCH DT IP 65

AMP JPT 12/24 V IP 65

Filtering

Filtering in the

hydraulic system

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Max. permissible degree of contamination (ISO

4406, 1999 version): 23/19/16

2 | © Danfoss | January 2018 11006692 | AI00000005en-US0303

Loading...

Loading...