Page 1

Technical Information

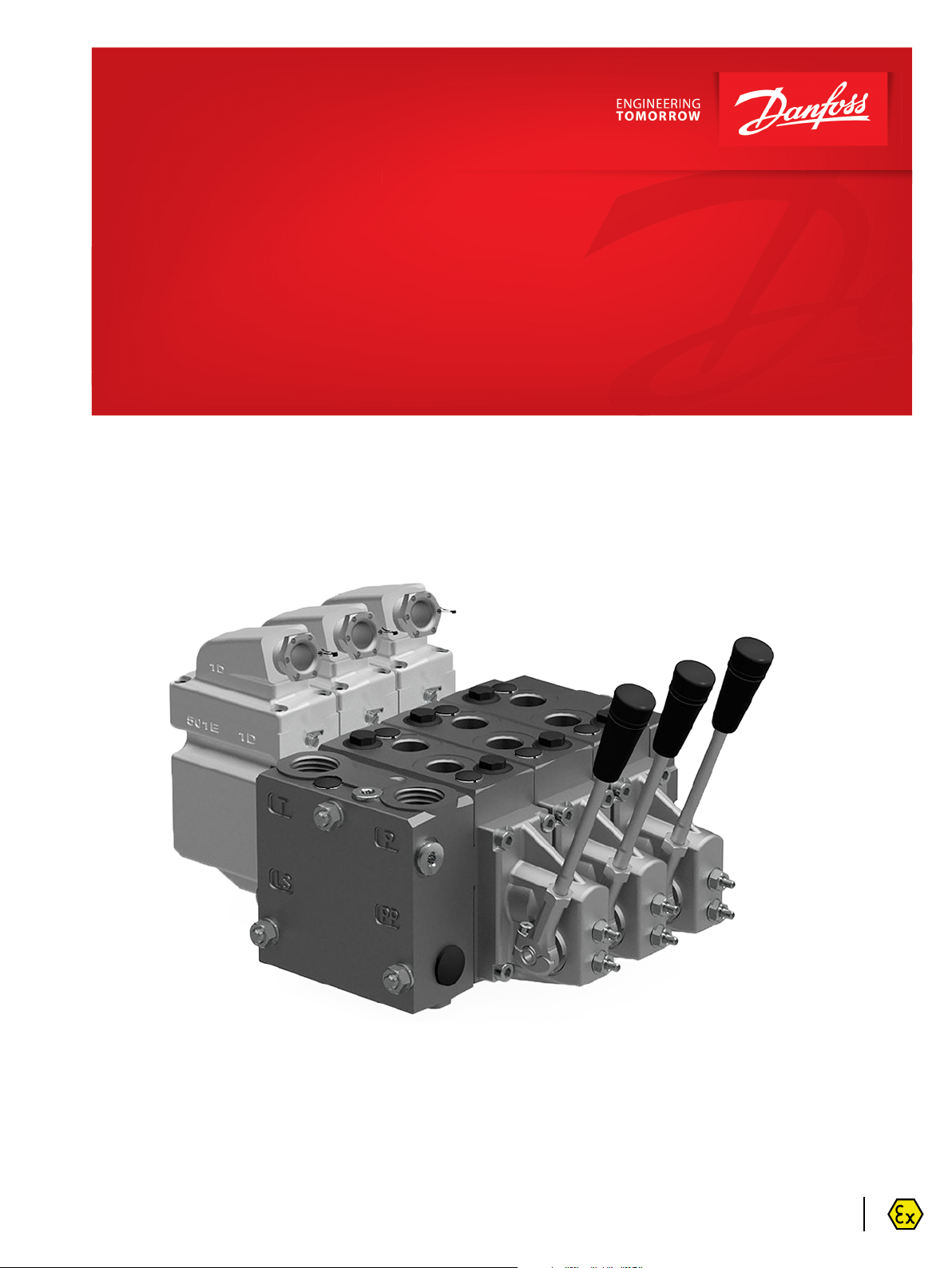

Proportional Valve Group

PVG-EX 32/128/256

www.danfoss.com

Page 2

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

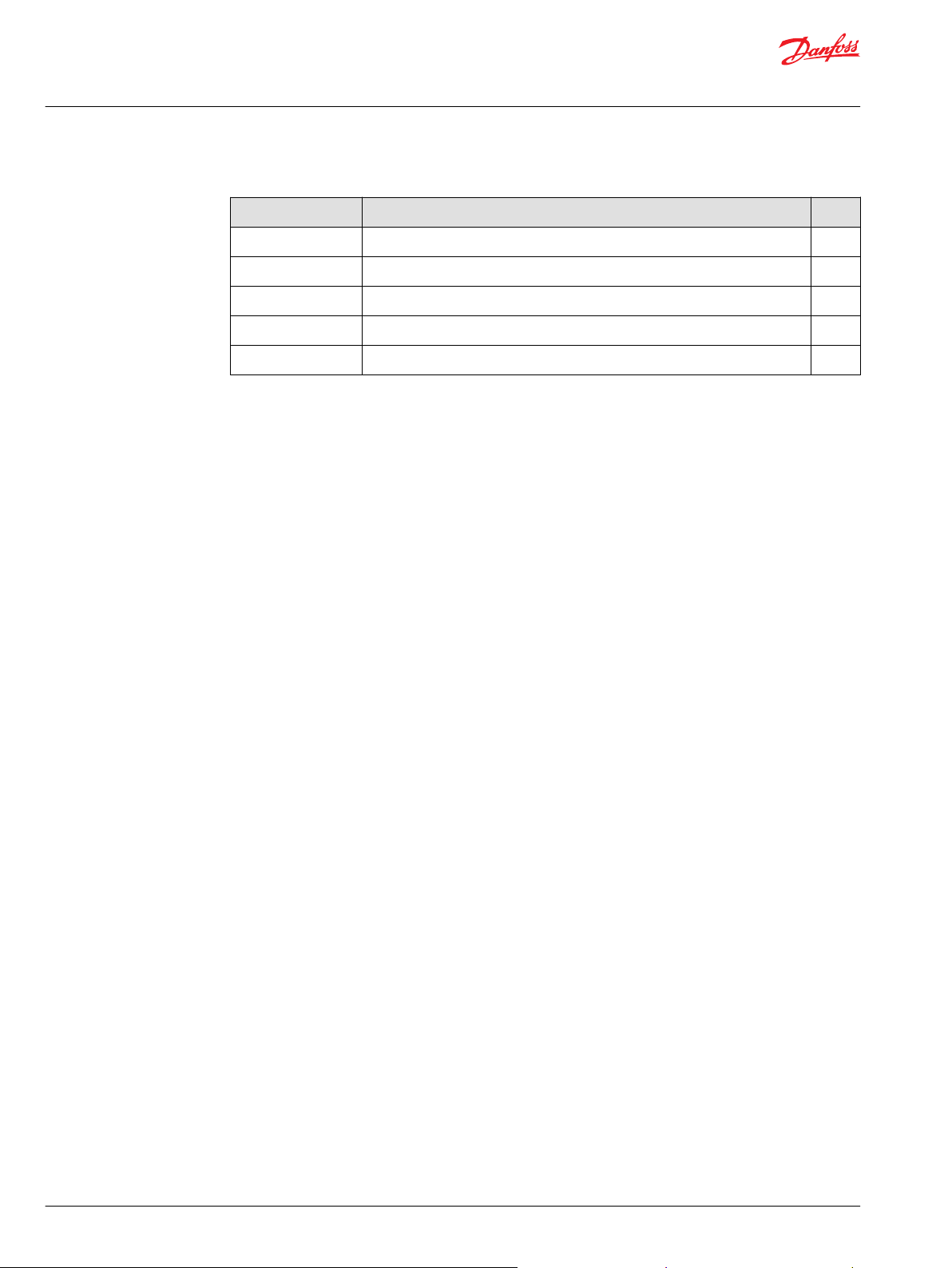

Revision history Table of revisions

Date Changed Rev

January 2022 Updated EU Declaration of Conformity 0301

November 2020 Added PVG 128/256, new EU Declaration of Conformity 0201

June 2019 New EU Declaration of Conformity 0103

May 2019 Updated EU Declaration of Conformity, and minor changes 0102

May 2019 First edition 0101

2 | © Danfoss | January 2022 BC290860493426en-000301

Page 3

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

Contents

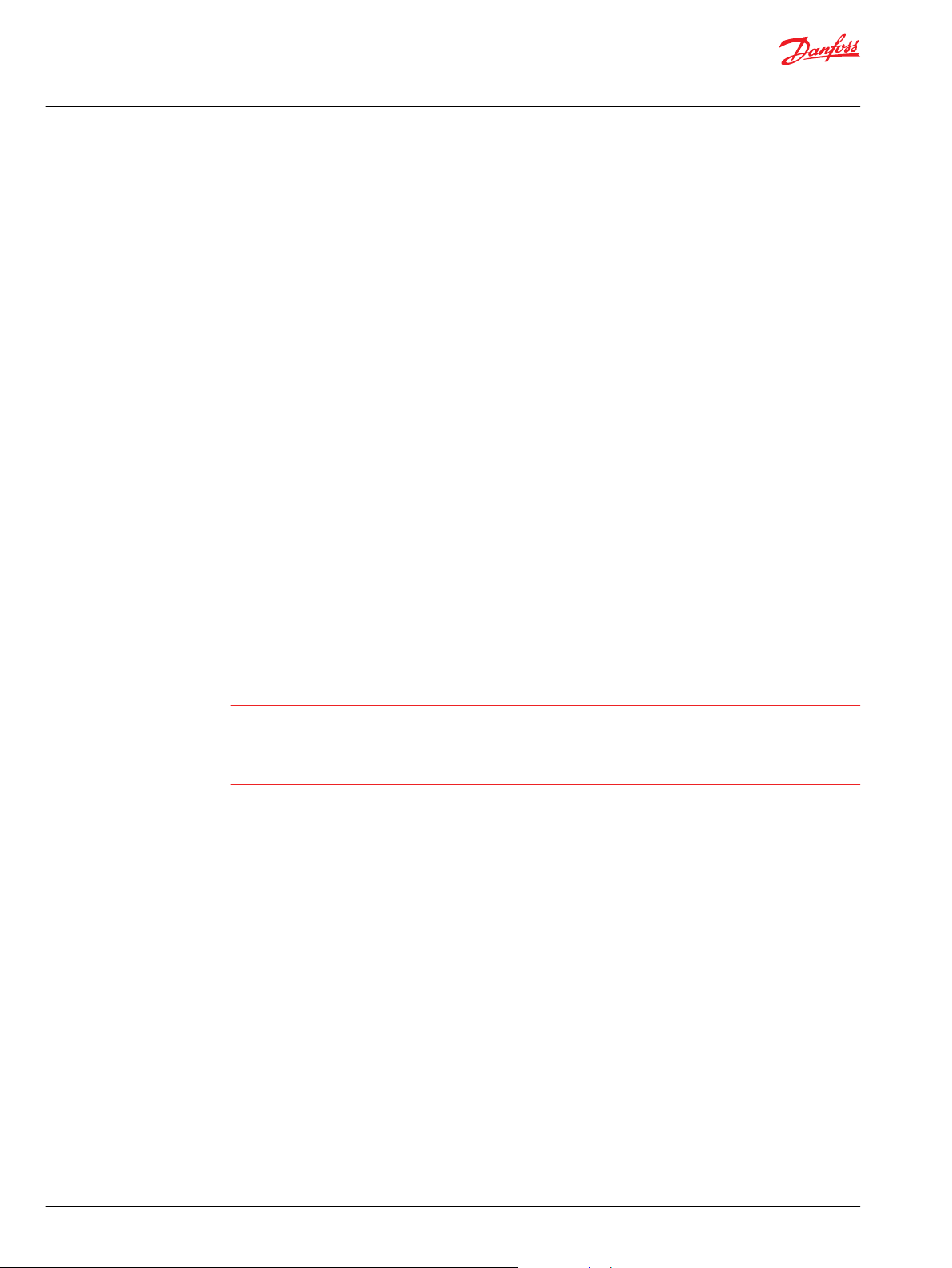

PVG-EX Introduction

Product certification........................................................................................................................................................................6

PVG-EX 32/128/256 Safety in Systems......................................................................................................................................6

Warnings..............................................................................................................................................................................................8

Nameplate description example.................................................................................................................................................9

Description of the EX code h version......................................................................................................................................10

EPL/Equipment category............................................................................................................................................................ 10

PVG-EX 32

General information......................................................................................................................................................................11

General description..................................................................................................................................................................11

Features........................................................................................................................................................................................11

Inlets..............................................................................................................................................................................................11

Work section housing............................................................................................................................................................. 11

Actuation methods.................................................................................................................................................................. 12

Sectional view............................................................................................................................................................................13

PVG-EX modules overview....................................................................................................................................................14

PVP Inlet Modules..........................................................................................................................................................................15

Open Center PVP...................................................................................................................................................................... 16

Open Center PVP with PPRV.................................................................................................................................................19

Open center PVP with HPCO and PVE PPRV................................................................................................................... 22

Closed Center PVP....................................................................................................................................................................25

Closed Center PVP with PPRV...............................................................................................................................................27

Closed center PVPV..................................................................................................................................................................29

Closed center PVPV with PPRV............................................................................................................................................ 30

Closed center PVPVM with PPRV.........................................................................................................................................32

Open/Closed center PVP with PPRV.................................................................................................................................. 34

Open/Closed center PVPM....................................................................................................................................................37

PVP Inlet Module Accessories....................................................................................................................................................38

PVPC without Check Valve.................................................................................................................................................... 39

PVPC with Check Valve...........................................................................................................................................................41

PVB Basic Modules.........................................................................................................................................................................42

Uncompensated PVB...............................................................................................................................................................44

Uncompensated PVB with load drop check valve........................................................................................................47

Uncompensated PVBZ with POC........................................................................................................................................ 50

Compensated PVB....................................................................................................................................................................51

Dampened Compensated PVB............................................................................................................................................ 54

Dampened compensated PVB with LS A/B.....................................................................................................................57

Compensated PVB with LS A/B............................................................................................................................................60

Compensated high flow PVB................................................................................................................................................64

Compensated high flow PVB with LS A/B........................................................................................................................67

Compensated PVBZ with POC............................................................................................................................................. 71

Compensated high flow PVBZ with POC......................................................................................................................... 73

Compensated high flow PVBZ with POC and manifold interface ..........................................................................75

PVB Basic Modules Accessories.................................................................................................................................................76

PVLP Shock and Anti-Cavitation Valve..............................................................................................................................76

PVLA Suction Valve.................................................................................................................................................................. 79

PVBS Main Spools...........................................................................................................................................................................80

PVBS fluid flow characteristics—Theoretical performance.......................................................................................81

PVBS Main Spools Part Numbers..............................................................................................................................................85

Flow Control Spools—Closed Neutral Position.............................................................................................................85

Flow Control Spools—Closed Neutral Position with A-float.................................................................................... 90

Flow Control Spools—Closed Neutral Position with B-float.....................................................................................91

Flow Control Spools—Closed Neutral Position with A-float for PVMF.................................................................92

Flow Control Spools—Closed Neutral Position with B-float for PVMF................................................................. 92

Flow Control Spools—Closed Neutral Position for PVMR......................................................................................... 93

Flow Control Spools—Open/Closed Neutral Position................................................................................................94

Flow Control Spools—Open/Closed A and Closed B Position.................................................................................94

Flow Control Spools—Throttled Open Neutral Position............................................................................................96

Flow Control Spools—Throttled Open Neutral Position for PVMR......................................................................100

©

Danfoss | January 2022 BC290860493426en-000301 | 3

Page 4

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

Contents

Flow Control Spools—Throttled A to T Neutral Position.........................................................................................101

Flow Control Spools—Throttled B to T Neutral Position.........................................................................................102

Linear Flow Control Spools—Closed Neutral Position.............................................................................................103

Linear Flow Control Spools—Throttled Open Neutral Position............................................................................104

Linear Flow Control Spools—Open/Closed Neutral Position................................................................................105

Single Acting Cylinder Flow Control Spools—Neutral A-port Position..............................................................105

Single Acting Cylinder Flow Control Spools—Neutral B-port Position..............................................................106

Single Acting Cylinder Linear Flow Control Spools—Neutral B-port Position................................................ 106

Flow/Pressure Control Spools—Closed Neutral Position........................................................................................107

Flow/Pressure Control Spools—Throttled Open Neutral Position...................................................................... 108

Flow/Pressure Control Spools—Throttled Open B to T in Neutral Position..................................................... 109

Flow/Pressure Control Spools—Throttled Open A to T in Neutral Position.....................................................110

Flow/Pressure Control Spools—Throttled Open B to T in Neutral Position..................................................... 111

Flow/Pressure Control Spools—Open/Closed in Neutral Position......................................................................111

Flow/Pressure Control Spools—Closed A and Open/Closed B Position............................................................111

Pressure Control Spools—Closed Neutral Position...................................................................................................112

Pressure Control Spools—Throttled Open Neutral Position..................................................................................113

Pressure Control Spools—Throttled A to T in Neutral Position............................................................................ 114

Pressure/Flow Control Spools—Closed Neutral Position........................................................................................115

Pressure/Flow Control Spools—Closed Neutral Position with B-float............................................................... 116

Pressure/Flow Control Spools—Throttled Open Neutral Position...................................................................... 116

Pressure/Flow Control Spools—Open/Closed Neutral Position...........................................................................117

Pressure/Flow Control Spools—Open/Closed A and Closed B Position............................................................117

PVBS for PVBZ Main Spools Part Numbers......................................................................................................................... 117

PVBZ Flow Control Spools—Closed Neutral Position...............................................................................................117

PVBZ Flow Control Spools—Closed Neutral Position with A-float...................................................................... 119

PVBZ Flow Control Spools—Closed Neutral Position with B-float.......................................................................120

PVBZ Flow Control Spools—Throttled Open Neutral Position with B-float..................................................... 120

PVBZ Linear Flow Control Spools—Closed Neutral Position................................................................................. 121

PVBZ Single Acting Cylinder Flow Control Spools—Closed Neutral A-port Position................................... 121

PVBZ Single Acting Cylinder Flow Control Spools—Closed Neutral B-port Position....................................122

PVBZ Single Acting Cylinder Linear Flow Control Spools—Closed Neutral B-port Position...................... 122

PVBZ–HS Single Acting Cylinder Flow Control Spools—Closed Neutral Position......................................... 122

PVG-EX 32 Actuation..................................................................................................................................................................122

PVM Manual actuation.........................................................................................................................................................124

PVMD detention covers.......................................................................................................................................................126

PVMD Detention Covers detailed information............................................................................................................126

PVH Hydraulic Actuation.....................................................................................................................................................127

PVSI End Plates............................................................................................................................................................................. 127

PVSI..............................................................................................................................................................................................127

PVSI with LX-connection..................................................................................................................................................... 129

PVSKM Full Flow Cut Off Modules.........................................................................................................................................130

PVSKM Functionality.............................................................................................................................................................131

PVSKM Spool............................................................................................................................................................................133

PVAS Stay Bolts.............................................................................................................................................................................134

PVAS Part Numbers............................................................................................................................................................... 135

PVG-EX 32 modules total length...................................................................................................................................... 135

PVG-EX 128/256

General Information................................................................................................................................................................... 136

PVG-EX 128/256 Proportional Valve Group..................................................................................................................136

PVG-EX 128/256 general description..............................................................................................................................137

Features of the PVG-EX 128/256 valve........................................................................................................................... 137

PVG-EX 128/256 PVPV Inlet Modules................................................................................................................................... 138

PVG-EX 128/256 Closed Center PPRV for PVE Activation and/or Mechanical..................................................139

PVG-EX 128/256 PPRV for PVH Activation and/or Mechanical ............................................................................. 140

PVG-EX PVB 128 Variant Overview........................................................................................................................................141

PVG-EX PVB 128 3-way Compensator.............................................................................................................................142

PVG-EX PVB 128 3-way Compensator with LS A/B.....................................................................................................145

PVG-EX PVB 128 3-way Compensator with LS A/B and PVLP.................................................................................149

4 | © Danfoss | January 2022 BC290860493426en-000301

Page 5

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

Contents

PVG-EX PVB 256 Variant Overview........................................................................................................................................154

PVG-EX PVB 256 3-way Compensator.............................................................................................................................155

PVG-EX PVB 256 3-way Compensator with LS A/B.....................................................................................................159

PVG-EX PVB 256 3-way Compensator with LSA/B and PVLP..................................................................................163

PVG-EX PVB 256 3-way Compensator with LS A/B, PVLP and Turbo...................................................................168

PVG-EX PVLP Shock and PVLA Suction Valves..................................................................................................................173

PVG-EX PVLP Overview........................................................................................................................................................ 173

PVG-EX PVLP Technical Data..............................................................................................................................................173

PVG-EX 128/256 PVBS Main Spool........................................................................................................................................ 176

PVG-EX PVBS Main Spools variant overview................................................................................................................ 176

PVG-EX Flow control spools..........................................................................................................................................176

PVG-EX PVBS main spools product details....................................................................................................................176

PVG-EX PVS Main spools part numbers......................................................................................................................... 179

PVG-EX Flow control spools..........................................................................................................................................179

PVG-EX PVM Manual Activation.............................................................................................................................................181

PVG-EX PVM Technical Data...............................................................................................................................................182

PVG-EX PVH Hydraulic Actuation.......................................................................................................................................... 183

PVG-EX PVH Technical Data............................................................................................................................................... 184

PVG-EX PVMD Cover Manual Actuation Only................................................................................................................... 185

PVG-EX PVMD Part Numbers............................................................................................................................................. 185

PVG-EX PVSI/PVGI End and Interface Plates.......................................................................................................................186

PVG-EX PVSI with or without LX-connection............................................................................................................... 187

PVG-EX PVSI with P and T port connections.................................................................................................................188

PVG-EX PVGI Interface Plate...............................................................................................................................................189

PVG-EX PVAS................................................................................................................................................................................. 190

PVG-EX PVAS for Combo..................................................................................................................................................... 190

PVG-EX PVAS Part Number Overview.............................................................................................................................191

PVG-EX 128/256 Valve Schematics........................................................................................................................................193

PVG-EX Valve Schematics....................................................................................................................................................193

Dimensions Overview................................................................................................................................................................195

Dimension Overview for PVG-EX 128/256.................................................................................................................... 195

PVG-EX Specifications example........................................................................................................................................ 197

EU declaration of conformity

EU declaration of conformity page 1....................................................................................................................................198

EU declaration of conformity page 2....................................................................................................................................199

EU declaration of conformity page 3....................................................................................................................................200

EU declaration of conformity page 4....................................................................................................................................201

EU declaration of conformity page 5....................................................................................................................................202

©

Danfoss | January 2022 BC290860493426en-000301 | 5

Page 6

W

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX Introduction

The Danfoss PVG-EX program is an explosion-proof PVG designed to be used in Ex hazardous areas like

mining and oil and gas industries.

Product certification

The PVG-EX is developed according to and in compliance with:

EU Directive 2014/34/EU Equipment for explosive atmosphere - ATEX

•

EN 60079-0:2018 Electrical apparatus for explosive gas atmospheres-part 0

•

EN 80079-36:2016 Non-electrical equipment for explosive atmospheres – Basic method and

requirements

•

EN 80079-37:2016 Non-electrical equipment for explosive atmospheres – Non-electrical type of

protection constructional safety “c”, control of ignition sources “b”, liquid immersion “k”

•

EN 80079-38:2016 Equipment and components in explosive atmospheres in underground mines

PVG-EX 32/128/256 Safety in Systems

All types and brands of control valves, including proportional valves, can fail. Therefore, the necessary

protection against the serious consequences of a functional failure should always be built into the

system.

General safety considerations

For each application an assessment should be made for the consequences of the system in case of

pressure failure and uncontrolled or blocked movements.

Warning

Because the proportional valve is used in many different applications and under different operating

conditions, it is the sole responsibility of the manufacturer to ensure that all performance, safety and

warning requirements of the application is met in his selection of products and complies with relevant

machine specific and generic standards.

Control system example

An example of a control system using an aerial lift is shown below:

6 | © Danfoss | January 2022 BC290860493426en-000301

Page 7

W

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX Introduction

Aerial lift

This example breaks down the control system into smaller bits explaining the architecture in depth. Even

though many Danfoss components are used in the PVG control system.

The function of the control system is to use the output from the PVE together other external sensors to

ensure the PLUS+1 main controllers correct function of the aerial lift.

Electrical block diagram

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

©

Danfoss | January 2022 BC290860493426en-000301 | 7

Page 8

C

W

W

W

W

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX Introduction

Caution

A mix of electrical actuation and hydraulic actuation on the same valve stack is not safe. PVE and PVH are

designed for different pilot pressure.

Cost-free repairs, as mentioned in Danfoss General Conditions of Sale, are carried out only at Danfoss or

at service shops authorized by Danfoss.

Warnings

Warning

All brands and all types of directional control or proportional valves, which are used in many different

operation conditions and applications, can fail and cause serious damage.

Analyze all aspects of the application. The machine builder/system integrator alone is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met.

The process of choosing the control system and safety levels is governed by Machinery Directive

2006-42-EC, and harmonized standard EN 13849 (Safety related requirements for control systems).

Warning

All national safety regulations must be fulfilled in connection with installation, start-up and operation of

Danfoss PVG-EX.

Furthermore, the requirements of the Declaration of Conformity and national regulations for installations

in potentially explosive atmospheres applies as well. Disregarding such regulations involves a risk of

serious personal injury or extensive material damage.

Warning

Work in connection with the valve group must be performed only by professionals and qualified persons.

Warning

PVG with non-conductive coating must have preventive protection against electrostatic charge by an

earthed metal connection.

8 | © Danfoss | January 2022 BC290860493426en-000301

Page 9

PVG-Ex

Ex h db I Mb T5...T4

Ta -30° to +60°C

111328133613A147305-EX

Ԑx

I M2

MADE IN DENMARK

Nordborgvej 81

6430 Nordborg, DK

PVG

XXXXXXXXXXXXXXXXXXX

RATED P:

MADE IN DENMARK

Nordborgvej 81, 6430 Nordborg, DK

SEE INSTRUCTION

PVG

XXXXXXXX

6

1

4

5

3

2

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX Introduction

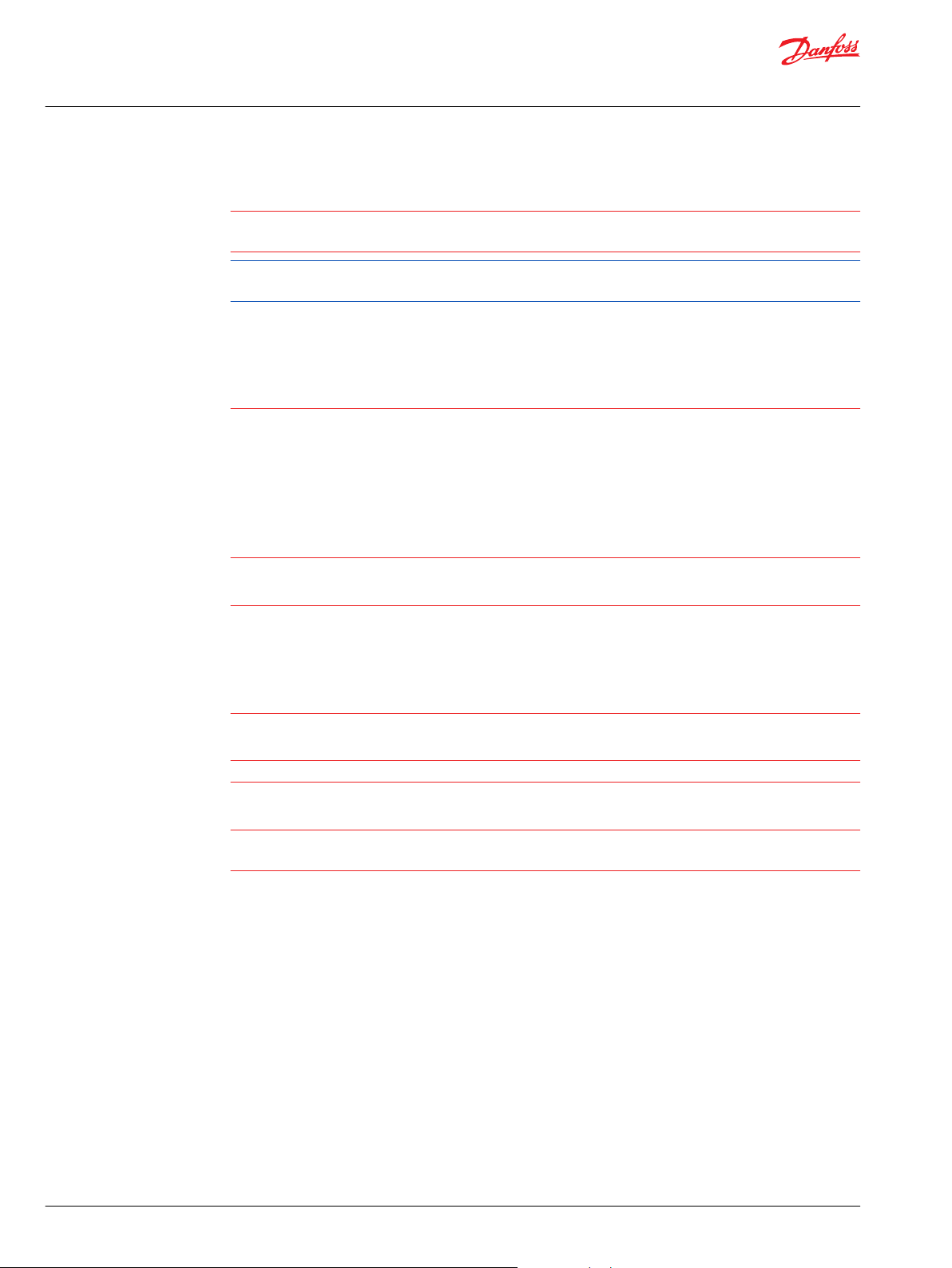

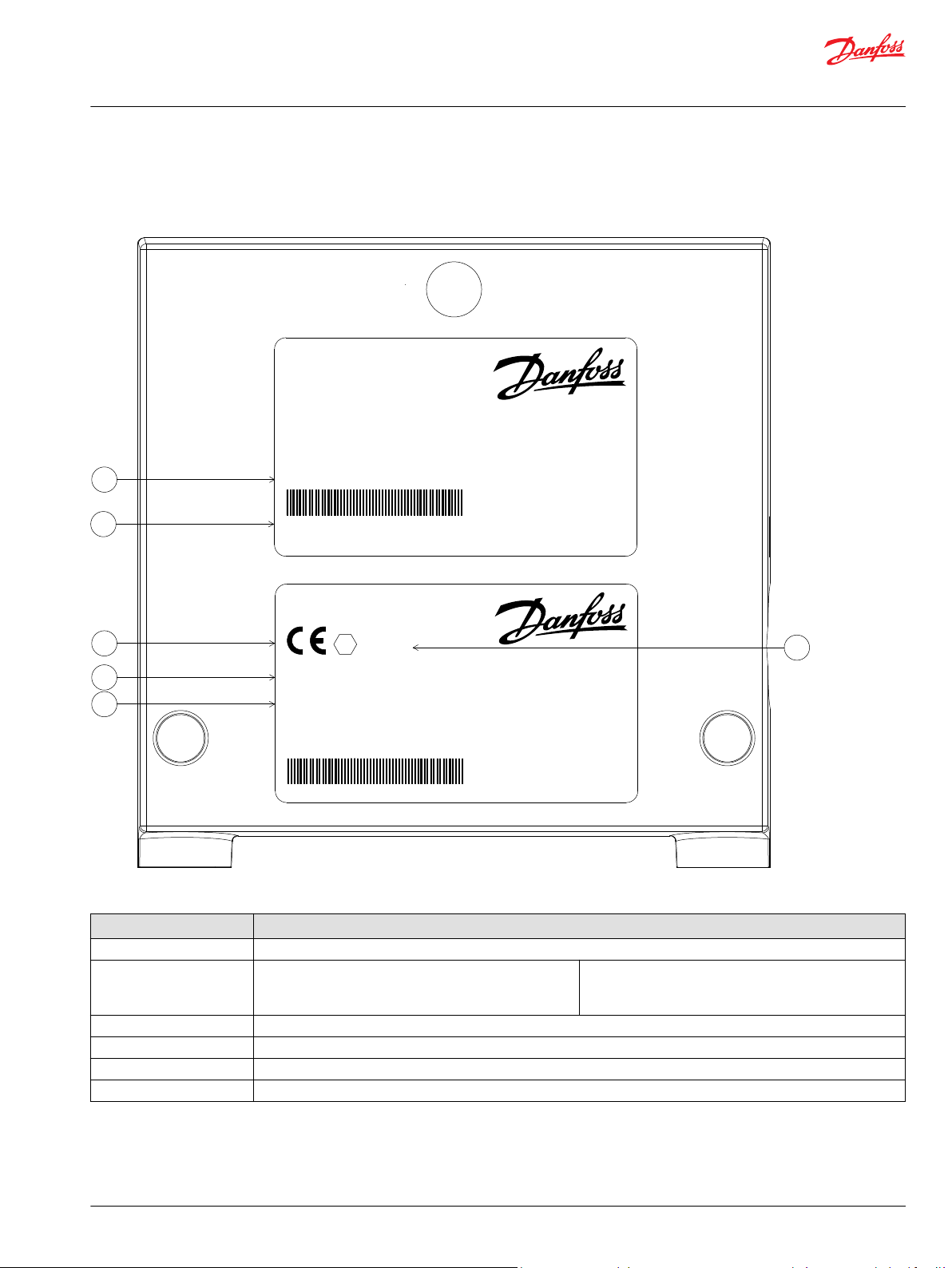

Nameplate description example

Nameplate key

Nameplate legend

Number Description

1 PVG Valve Group code number

2

3 CE Conformity marking

4 EU marking (per 80079) - Standard part

5 Ambient temperature range

6 EU marking (per 2014/34/EU) - Directive part

©

Danfoss | January 2022 BC290860493426en-000301 | 9

Code number, production date,

and serial number

Example: 42 12 C xxxxxx

Week: 42, Year: 2012,

Day: C=Wednesday (A=Monday), Serial number

Page 10

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX Introduction

T-category with ambient temperature at 65°C [149°F]

Oil inlet temperature T-category

≤ 79°C [174°F] T5

79 - 90°C [174 - 194°F] T4

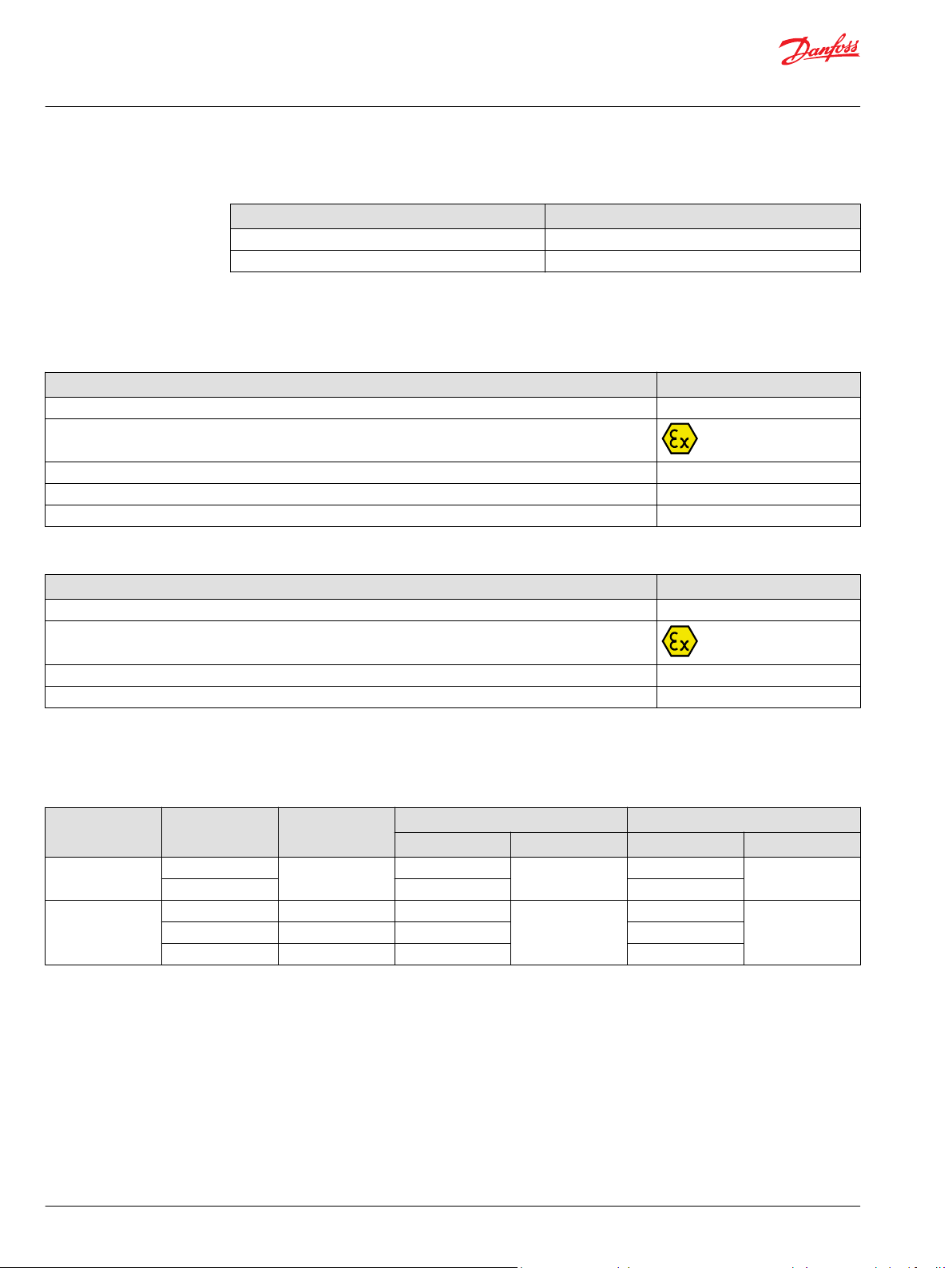

Description of the EX code h version

Ex marking (EN 80079-36 standard part)

Description EU Marking

Protection principle h

Explosion protection marking

Equipment group I / II

Equipment protection level (EPL) Mb / Gb

T-class T5...T4

Ex marking (EU Directive part)

Description EU Marking

CE conformity marking CE

Explosion protection marking

Equipment Group I / II

Equipment Category M2 / 2G

EPL/Equipment category

EPL/Equipment category

Definition Level of protection Typical zone of

application

Mines Very high N/A Ma I M1 I

High Mb M2

Gas atmosphere Very high 0 Ga II 1G II

High 1 Gb 2G

Enhanced 2 Gc 3G

IEC EU

EPL Group Category Group

10 | © Danfoss | January 2022 BC290860493426en-000301

Page 11

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

General information

General description

PVG 32 is a hydraulic load sensing (LS) valve designed to give maximum flexibility. From a simple load

sensing directional valve, to an advanced electrically controlled load-independent proportional valve.

The PVG 32 modular system makes it possible to build up a valve group to meet the different functional

requirements precisely.

The compact external dimensions of the valve remain unchanged whatever combination is specified.

The PVG 32 interfaces to other valve families like PVG 128/256 enabling all machine functions being

controlled from one single valve stack.

Features

Features of the PVG 32 include:

•

Load-independent flow control:

Oil flow to an individual function is independent of the load pressure of this function

‒

Oil flow to one function is independent of the load pressure of other functions

‒

•

Good regulation characteristics

•

Energy-saving

•

Up to 12 basic modules per valve group

•

Several types of connection threads

•

Low weight

•

Compact design and installation

Inlets

The inlets include:

•

Built-in pressure relief valve

•

Pressure gauge connection

•

Versions for different pump types

Open Center systems with fixed displacement pumps

‒

Closed Center systems with variable displacement pumps

‒

•

Integrated pilot oil supply

Work section housing

Our work section housing includes:

•

Interchangeable spools

•

Pressure gauge connection

•

Versions for different application needs

Built-in compensator for load independent flow

‒

Built-in load holding check valve in P-channel

‒

Integrated shock/suction valve

‒

Integrated local pressure relief valve

‒

©

Danfoss | January 2022 BC290860493426en-000301 | 11

Page 12

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Actuation methods

Our actuation methods include:

•

Manual control with lever

•

Manual with friction detent

•

Hydraulic

•

Electro-hydraulic

ON/OFF control

‒

Ratiometric proportional

‒

CANbus proportional

‒

PWM proportional

‒

12 | © Danfoss | January 2022 BC290860493426en-000301

Page 13

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

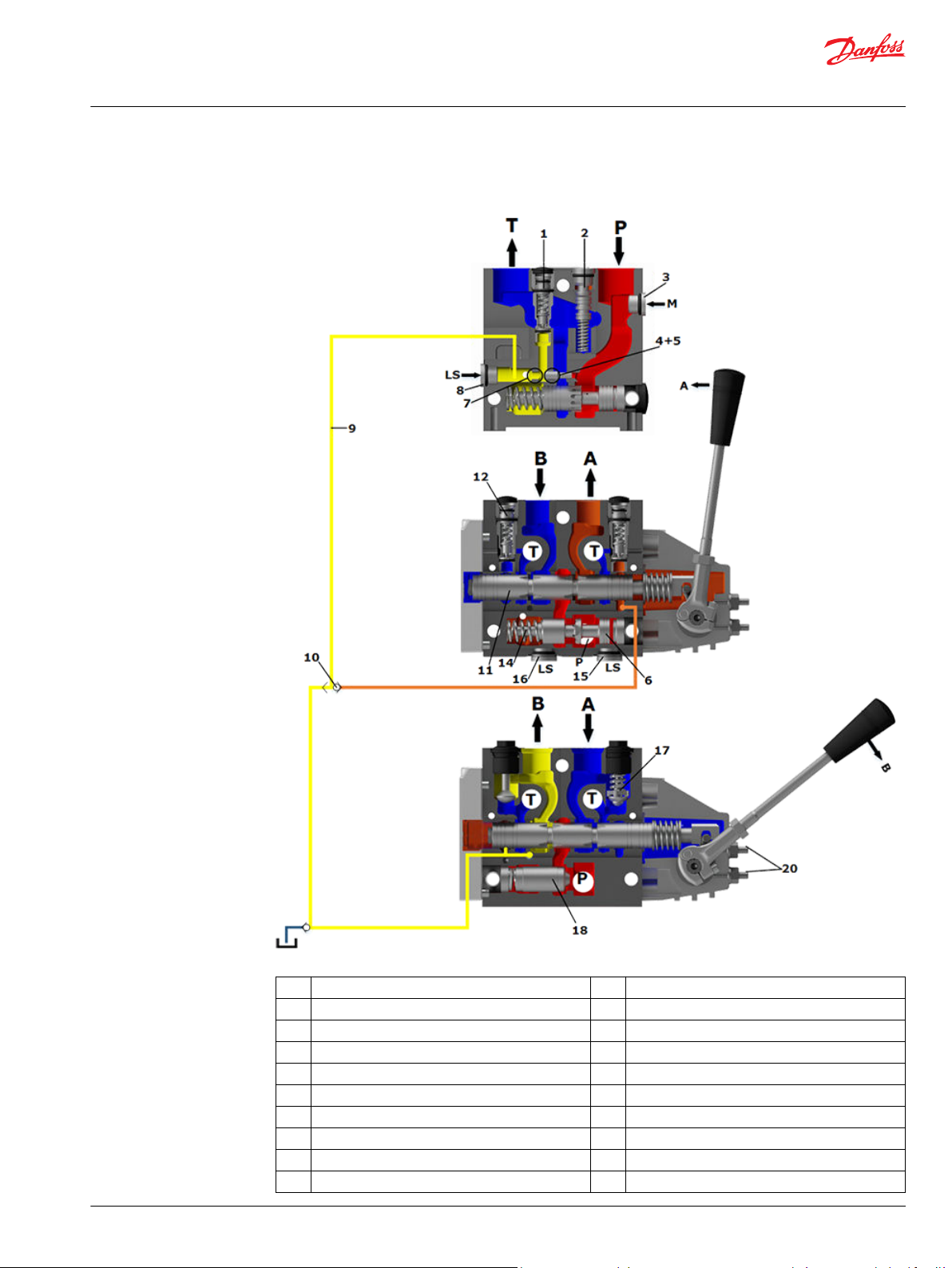

Sectional view

1. Pressure relief valve 11. Main spool

2. Pressure reduction valve for pilot oil supply 12. LS pressure limiting valve

3. Pressure gauge connection 13. Shock and suction valve, PVLP

4. Plug, open center 14. Pressure compensator

5. Orifice, closed center 15. LS connection, port A

6. Pressure adjustment spool 16. LS connection, port B

7. Plug, closed center 17. Suction valve, PVLA

8. LS connection 18. Load drop check valve

9. LS signal 19. Pilot oil supply for PVE

10. Shuttle valve 20. Maximum oil flow adjustment screws for A/B ports

©

Danfoss | January 2022 BC290860493426en-000301 | 13

Page 14

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

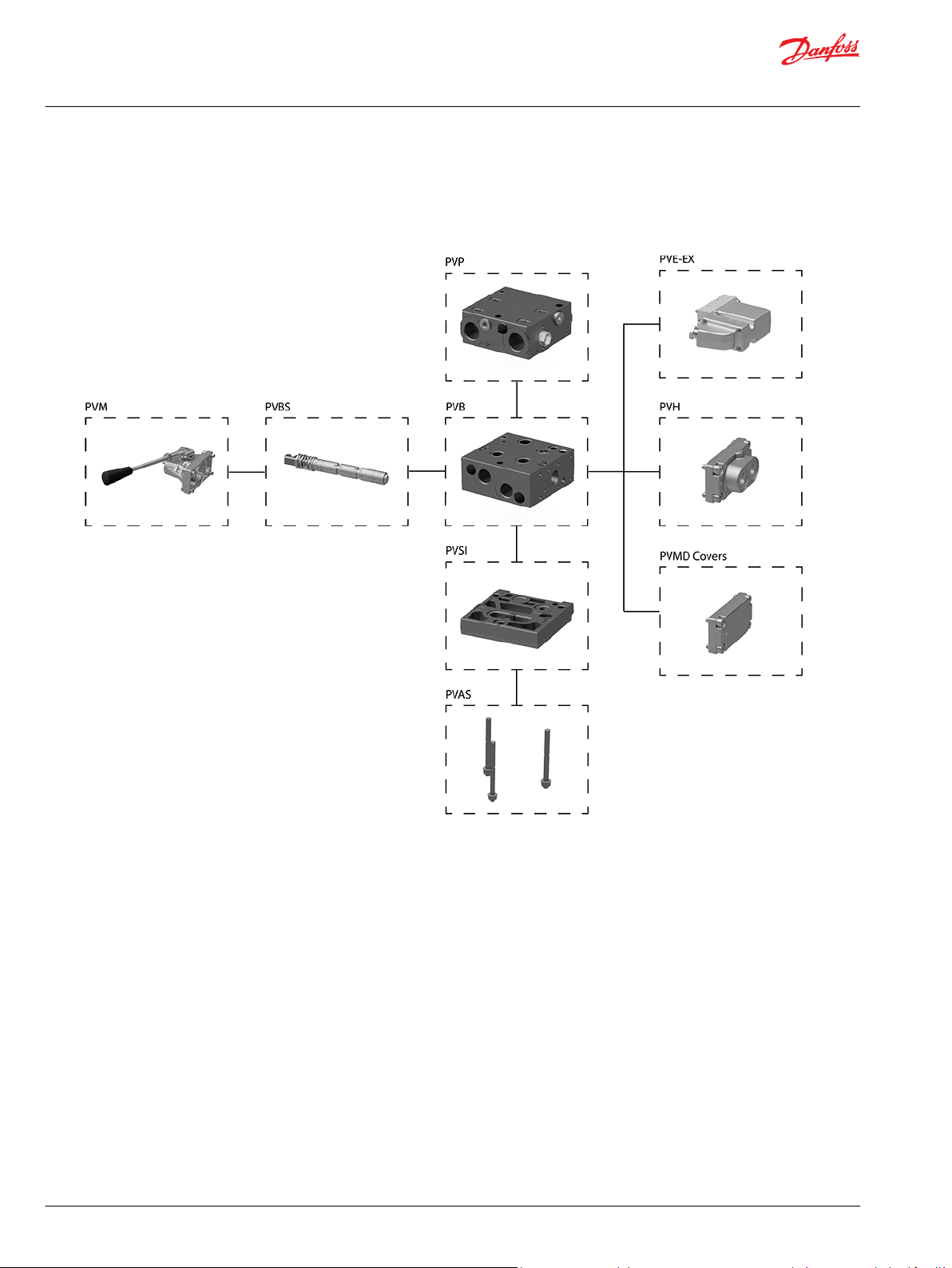

PVG-EX modules overview

PVG-EX 32 modules exploded view

PVG modules navigation

•

PVP Inlet Modules on page 15

•

PVB Basic Modules on page 42

•

PVBS Main Spools on page 80

•

PVSKM Full Flow Cut Off Modules on page 130

•

PVAS Stay Bolts on page 134

14 | © Danfoss | January 2022 BC290860493426en-000301

Page 15

112.5 [4.43]

110 [4.33]

95 [3.74]

23 [0.9]

48 [1.89]

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

PVP Inlet Modules

The PVG-EX 32 PVP inlet modules, also referred to as pump side modules, act as an interface between the

PVG-EX 32 proportional valve group and the hydraulic pump and tank reservoir.

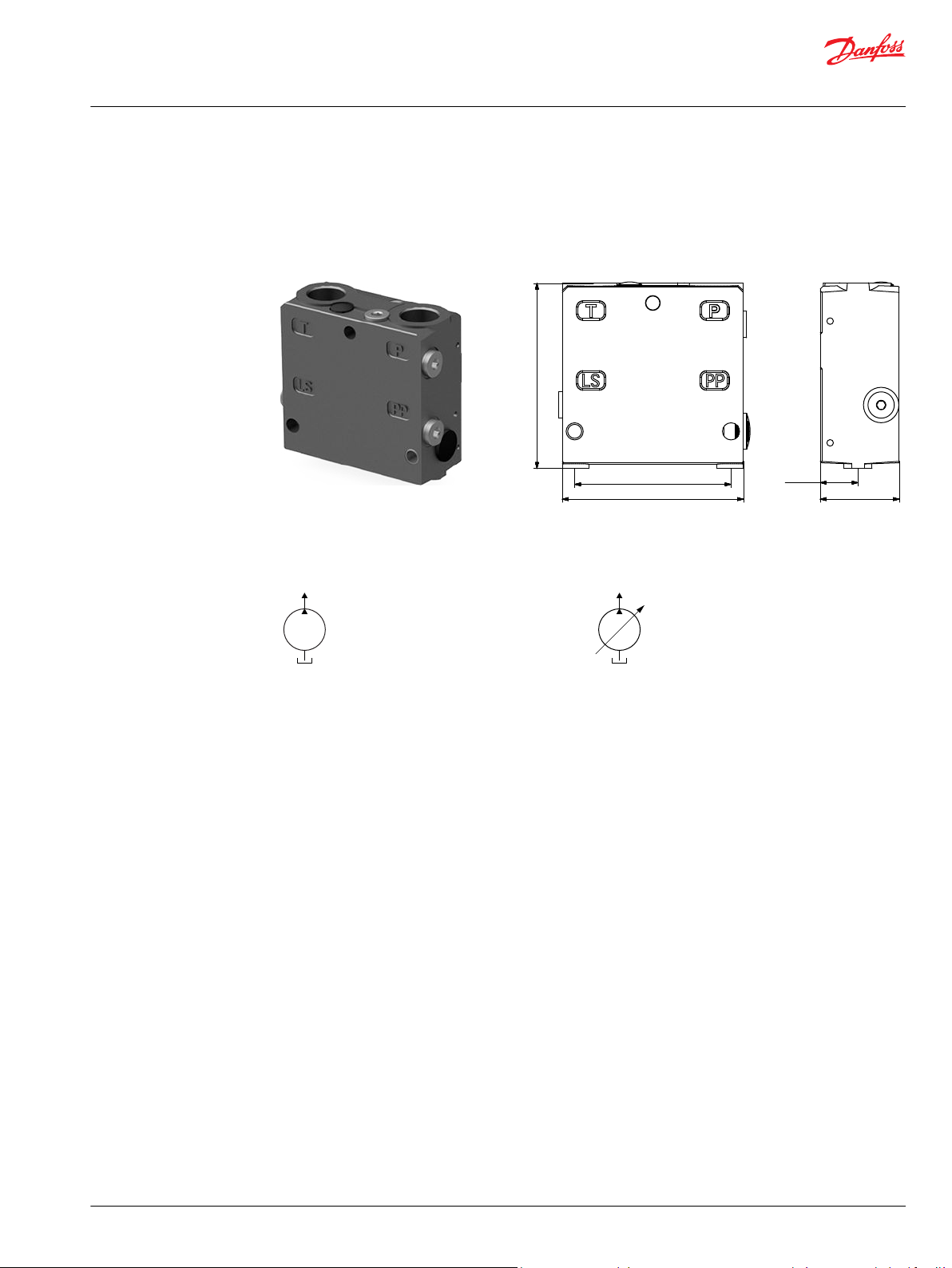

PVP Inlet Module PVP inlet module dimensions

Weight: 3.1 kg [6.9 lb]

Fixed displacement pump symbol Variable displacement pump symbol

The PVP inlet module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the PVP to suit the demands of any hydraulic system:

Open Center PVP on page 16 (for fixed displacement pumps)

•

Open Center PVP with PPRV on page 19 (for fixed displacement pumps)

•

Open center PVP with HPCO and PVE PPRV on page 22 (for fixed displacement pumps)

•

Closed Center PVP on page 25 (for variable displacement pumps)

•

Closed Center PVP with PPRV on page 27 (for variable displacement pumps)

•

Closed center PVPV with PPRV on page 30 (for variable displacement pumps)

•

Closed center PVPVM with PPRV on page 32 (for variable displacement pumps)

•

Open/Closed center PVP with PPRV on page 34

•

Open/Closed center PVPM on page 37

•

©

Danfoss | January 2022 BC290860493426en-000301 | 15

Page 16

LS

T

P

M

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Open Center PVP

The basic Open Center PVP inlet module is intended for use with fixed displacement pumps in

applications, where a valve group with mechanically controlled work sections is desired, or where the

pilot pressure to the valve group is supplied externally.

The Open Center PVP features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Optional T0 facility and external T0 port

•

All modules can be manually activated with the PVM actuation.

Open center PVP schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

16 | © Danfoss | January 2022 BC290860493426en-000301

Page 17

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

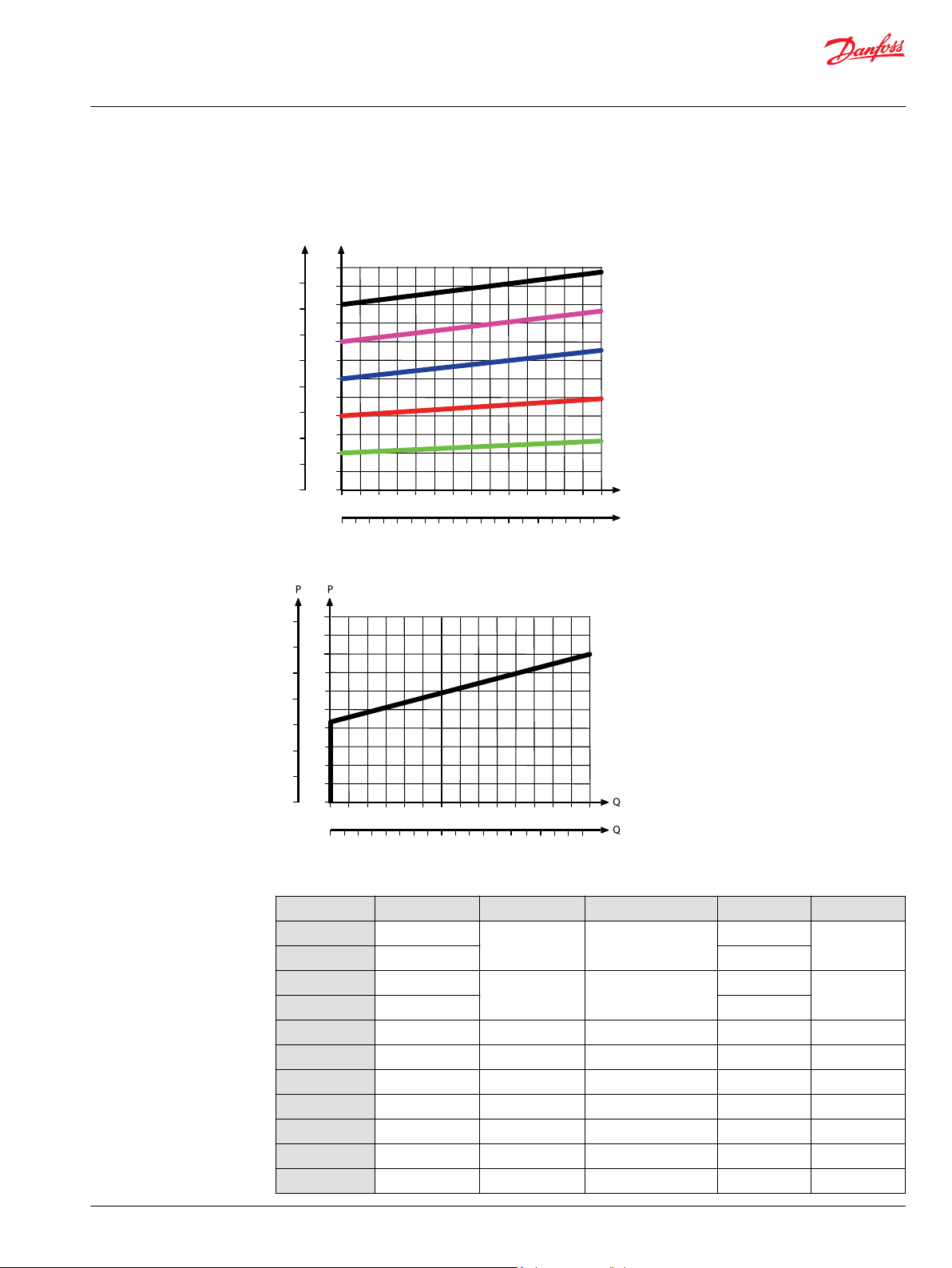

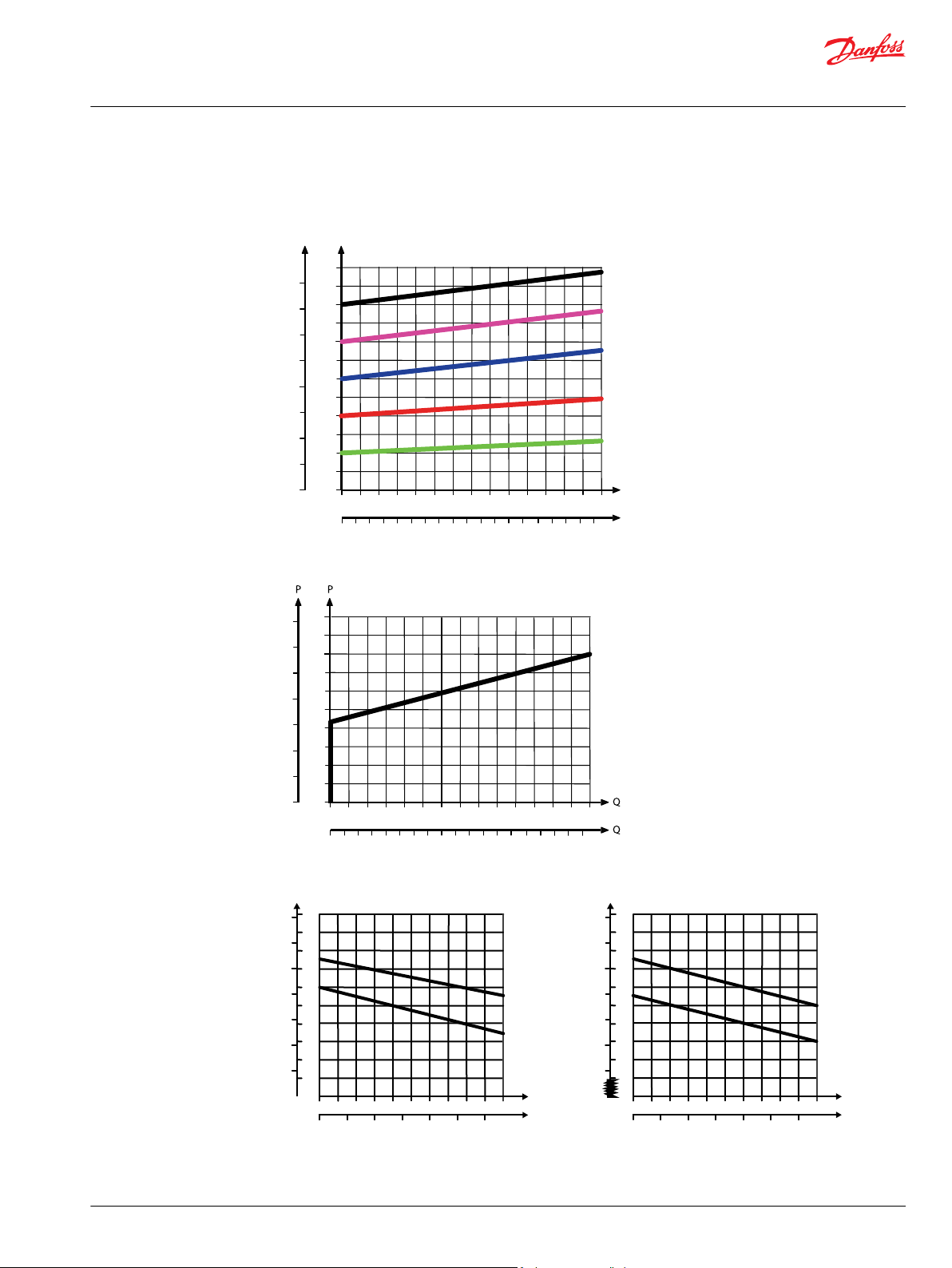

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Part numbers for Open Center PVP

Part number P-port T-port LS-, M-port (LS1*) T0-port Mounting

157B5000

157B5100

157B5200

157B5300

11008852

11030545

11053974

11151852

157B5908

157B5921

157B5925

G1/2”

G3/4” –

G3/4” G1/4”

7/8-14 UNF

1-1/16 UN -

1

G1/2 G3/4 G1/4 (G1/8) - M8

1 1/16-12 UNF 1/2-20 UNF

G3/4 G3/4 G1/4 (G1/4) G1/4 M8

G3/4 G3/4 G1/4 (G1/4) G1/4 M8

1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF M8

1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF - M8

JIS 1/2 JIS 3/4 JIS 1/4 - M8

JIS 1/2 JIS 3/4 JIS 1/4 - M8

M8

5/16-18 UNC

©

Danfoss | January 2022 BC290860493426en-000301 | 17

Page 18

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Part numbers for Open Center PVP (continued)

Part number P-port T-port LS-, M-port (LS1*) T0-port Mounting

157B5945

157B5990

*

LS1 is an extra LS-port.

1

Dampened LS response

2

No relief valve

G1/2 G3/4 G1/4 (G1/8) - M8

2

1 1/16-12 UNF 1 1/16-12 UNF - - M8

18 | © Danfoss | January 2022 BC290860493426en-000301

Page 19

LS

T

P

M

Pp

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Open Center PVP with PPRV

The Open Center PVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

fixed displacement pumps in applications, where a valve group with electro-hydraulically or hydraulically

controlled work sections is desired (PVE or PVH/PVHC).

The Open Center PVP with PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional T0 facility and external T0 port

•

Optional external pilot pressure port (Pp)

•

All modules can be manually activated with the PVM actuation.

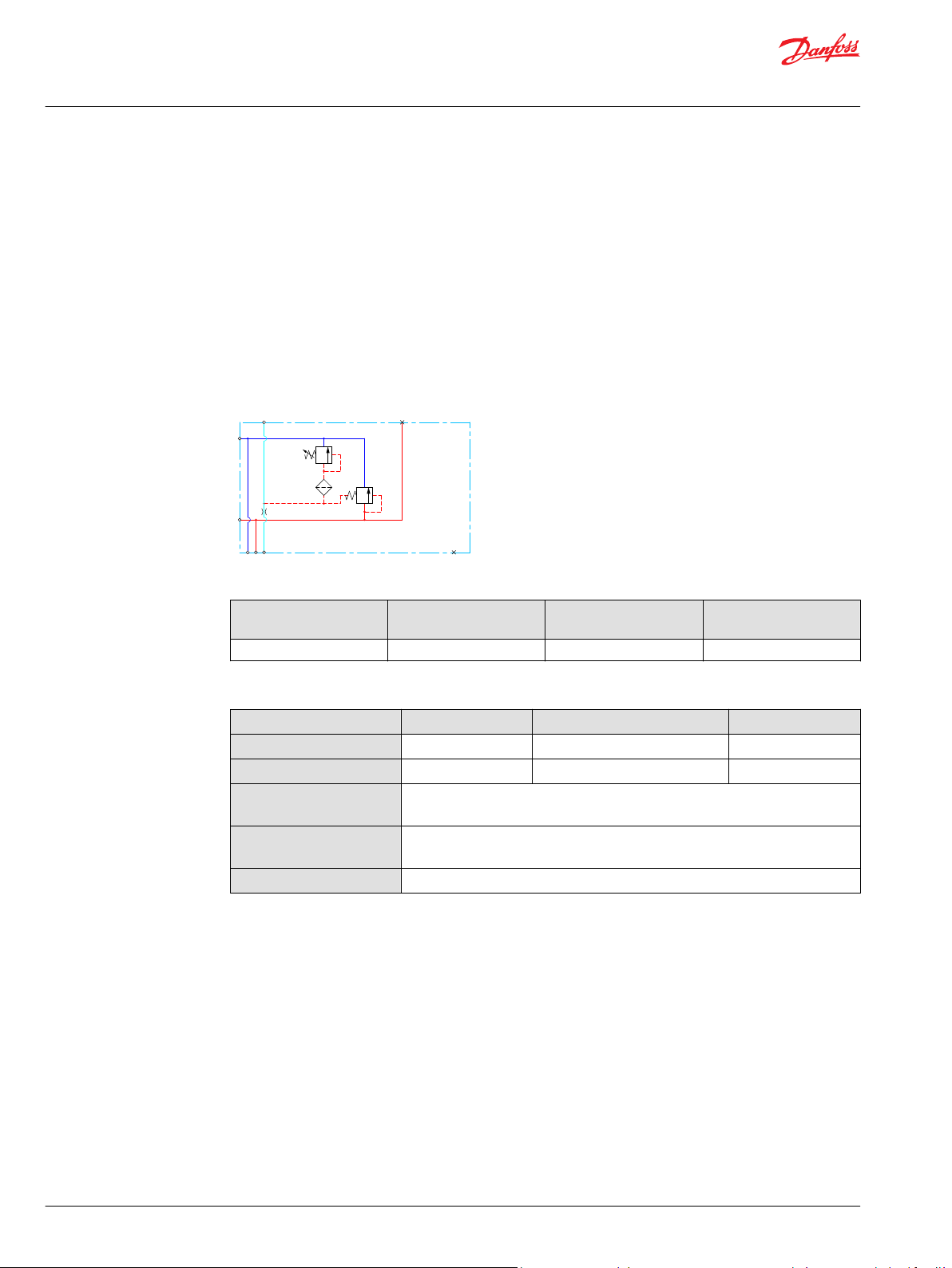

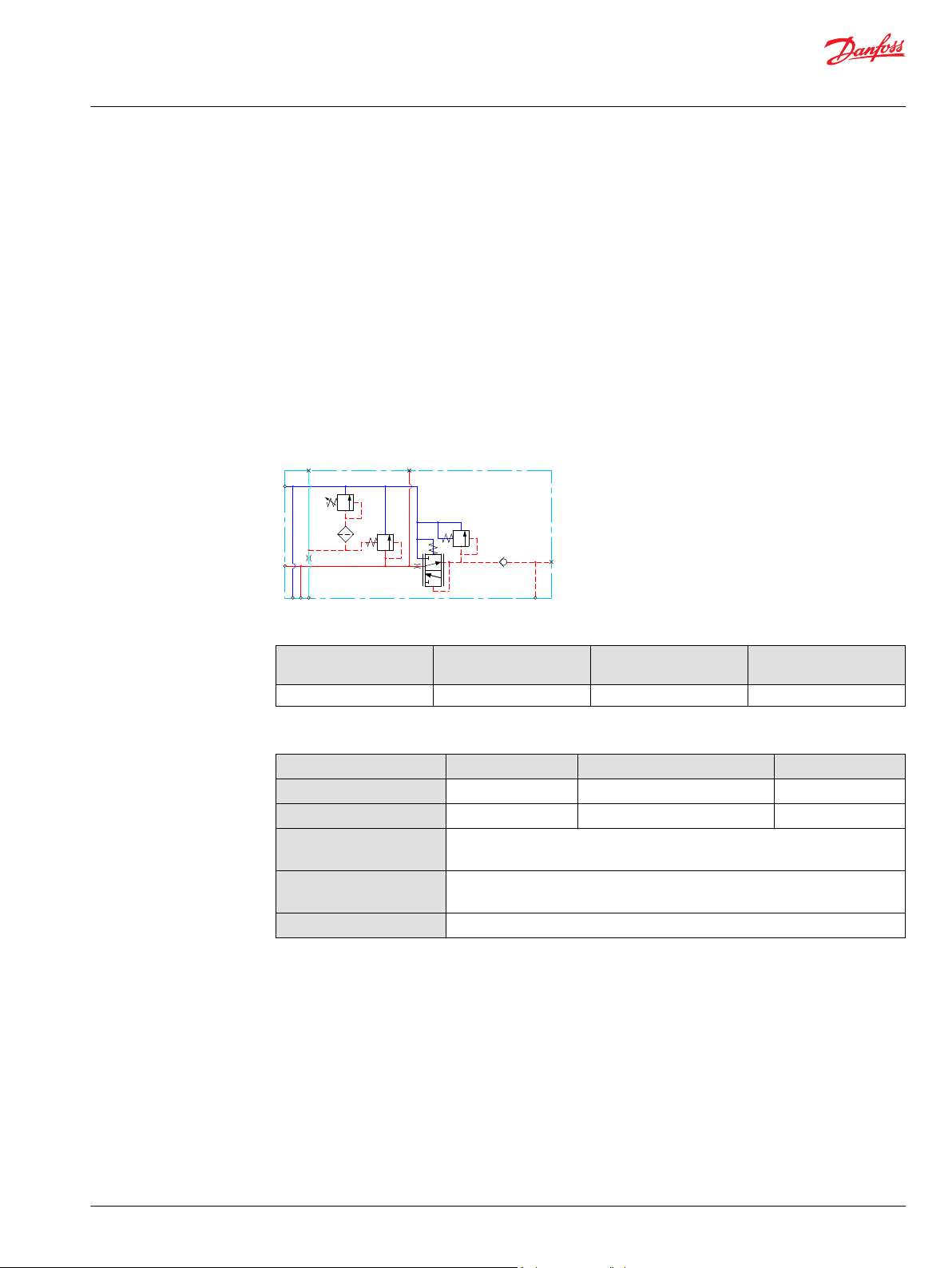

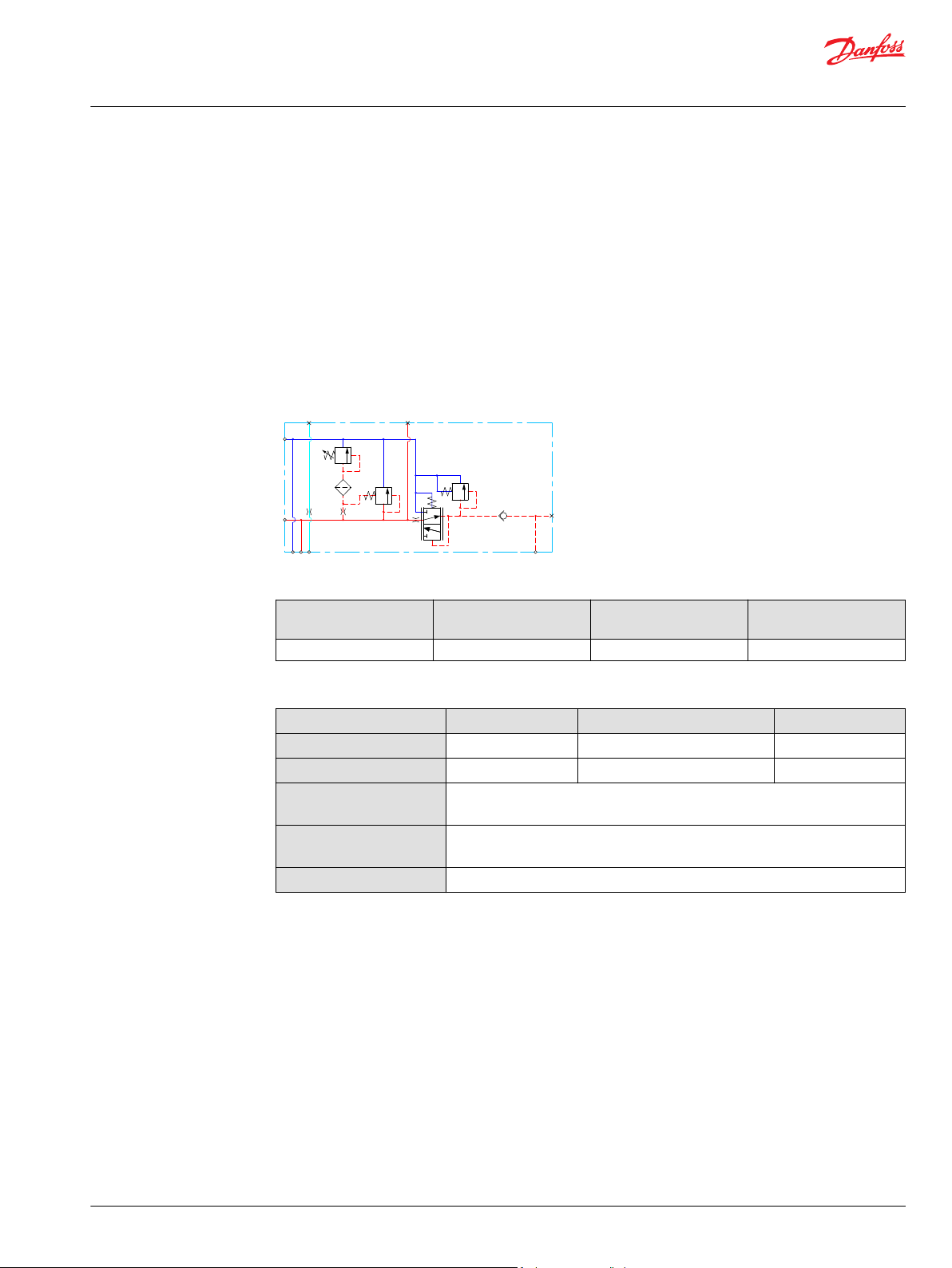

Open center PVP with PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | January 2022 BC290860493426en-000301 | 19

Page 20

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

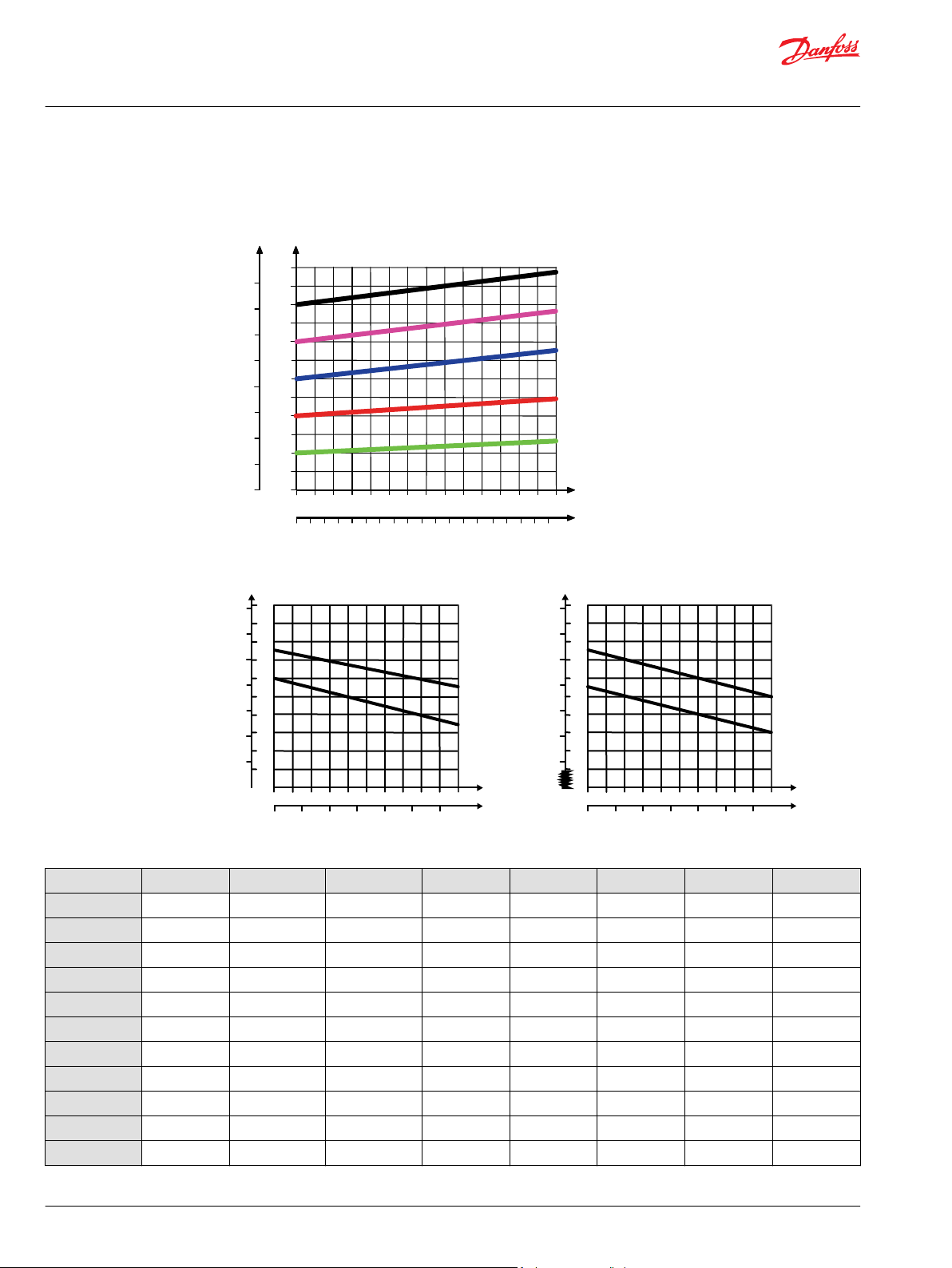

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

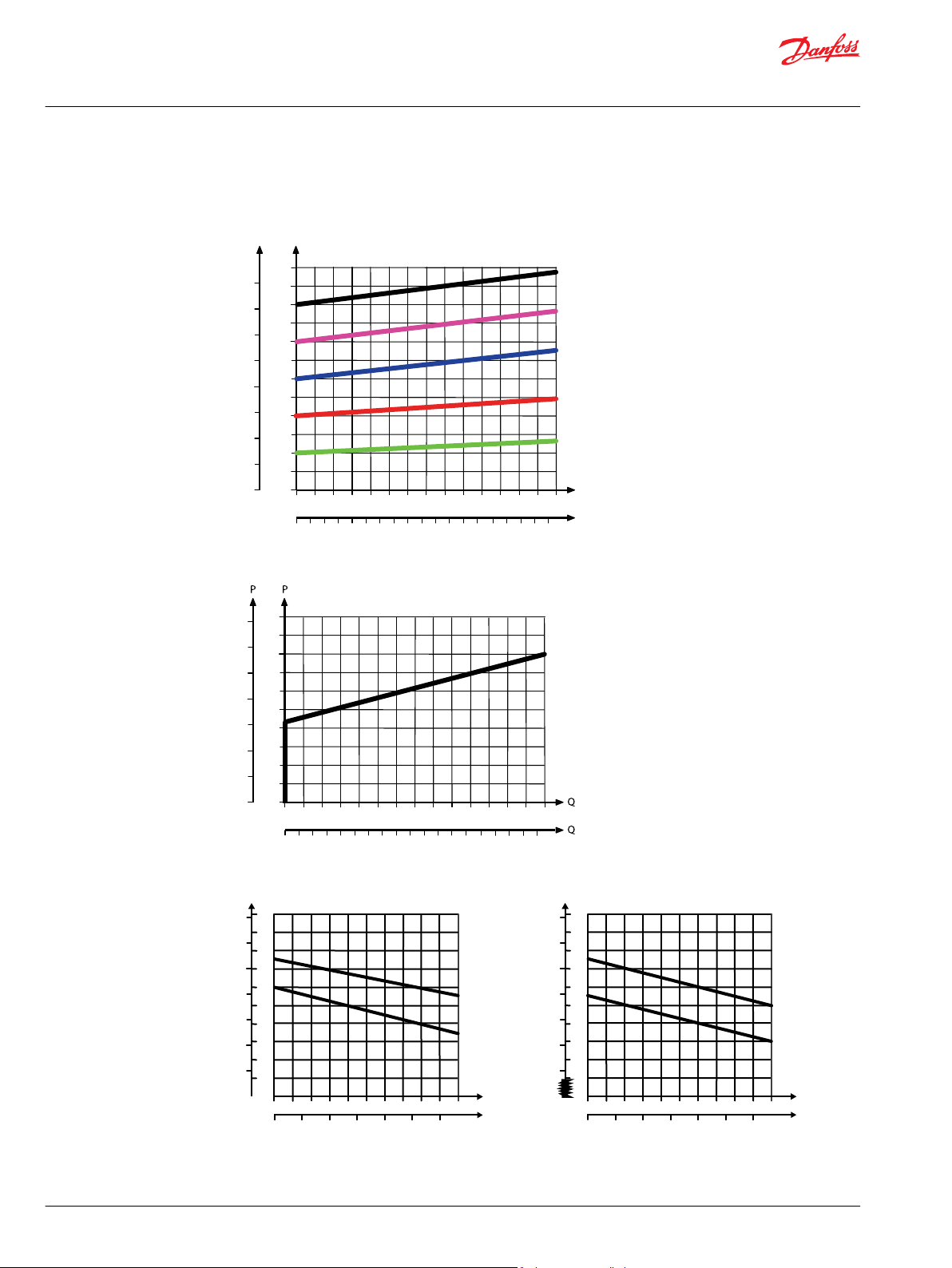

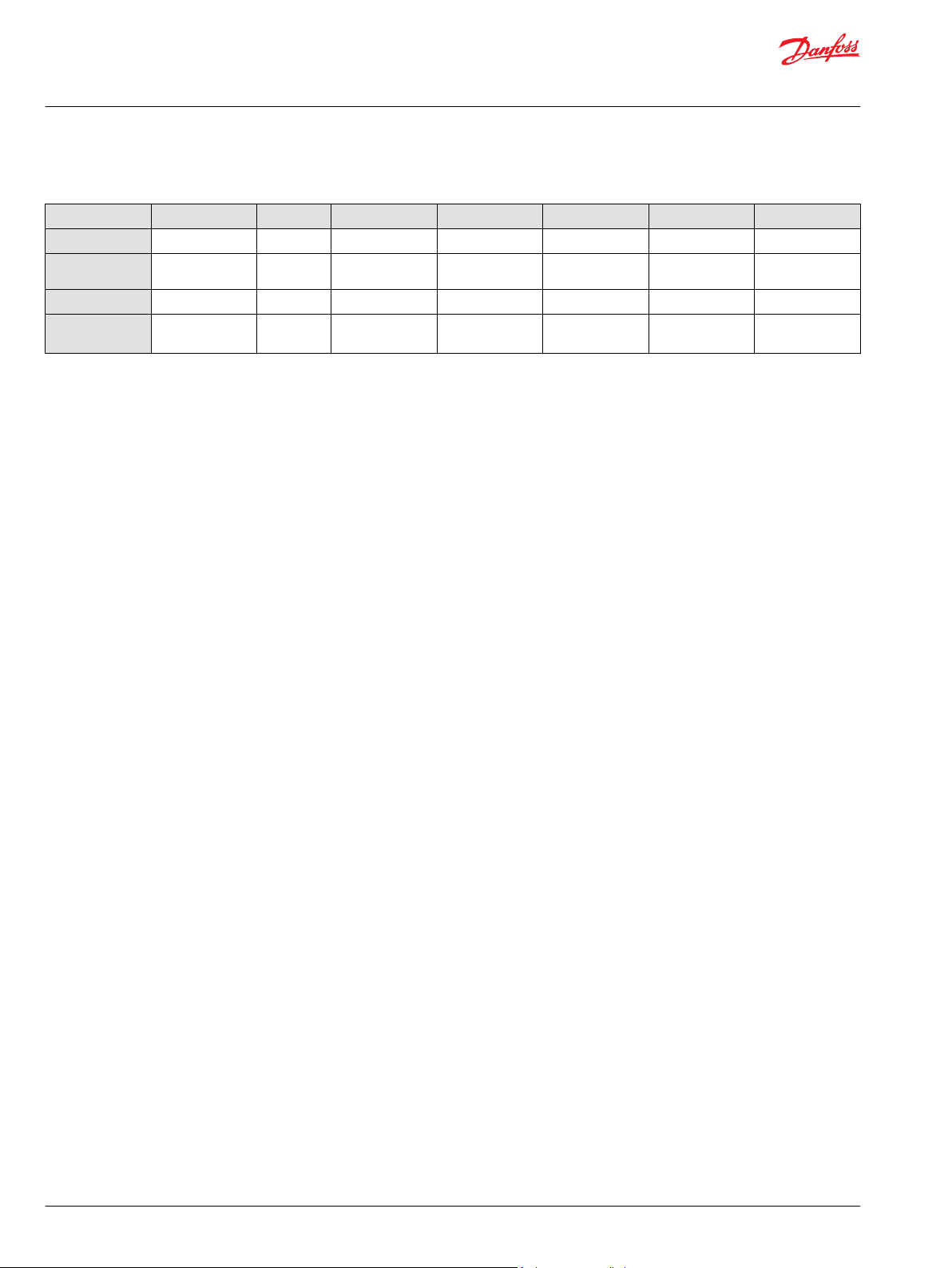

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

20 | © Danfoss | January 2022 BC290860493426en-000301

Page 21

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Part numbers for Open Center PVP with PPRV

Part number Actuation P-port T-port LS-port M-port Pp-port T0-port Mounting

1

11008849

11008851

11072195

157B5010

157B5110

157B5130

157B5180

157B5190

157B5210

157B5310

157B5312

157B5330

157B5380

157B5390

11101194

11013317

11020964

11087590

11090453

11119429

11124966

11130941

11196947

11225941

157B5135

157B5904

157B5923

157B5926

157B5934

157B5943

157B5954

157B5960

157B5977

11101194

1

Dampened LS response

2

Pressure adjustment spool with check valve

3

Internal T0 connection

4

Low flow pressure adjustment spool

PVE G3/4” G3/4” G1/4” G1/4” - - M8

1

PVH/PVHC G3/4” G3/4” G1/4” G1/4” G1/4” - M8

PVE M27x2 M27x2 M14x1.5 M14x1.5 - M14x1.5 M8

PVE G1/2” G3/4” G1/4” G1/4” - - M8

PVE G3/4” G3/4” G1/4” G1/4” - - M8

PVE G3/4” G3/4” G1/4” G1/4” G1/4” G1/4” M8

PVE G3/4” G3/4” G1/4” G1/4” G1/4” - M8

PVH/PVHC G3/4” G3/4” G1/4” G1/4” G1/4” - M8

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

PVE

M22x1.5

M22x1.5 M12x1.5 M10x1 - M16x1.5 M8

M16x1.5 (P2)

1

PVE G3/4 G3/4 G1/4 G1/4 G1/4 G1/4 M8

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - M8

1

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8

PVE JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 JIS 1/4 JIS 1/4 M8

2

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8

2

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

PVE G3/4 G3/4 G1/4 G1/4 - G1/4 M8

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18

UNF

3

PVE G3/4 G3/4 G1/4 G1/4 G1/4 G1/4 M8

2

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8

PVE JIS 1/2 JIS 3/4 JIS 1/4 JIS 1/4 - - M8

PVE JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 - - M8

PVE G3/4 G3/4 G1/4 G1/4 - - M8

2

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF - 9/16-18

UNF

1,4

PVE G3/4 G3/4 G1/4 G1/4 - - M8

PVE M22 x 1.5 M22 x 1.5 M12 x 1.5 M10 x 1 - M16 x 1.5 M8

5/16-18 UNC

5/16-18 UNF

©

Danfoss | January 2022 BC290860493426en-000301 | 21

Page 22

LS

P

Pp

M

HPCO

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Open center PVP with HPCO and PVE PPRV

The Open Center PVP inlet with integrated High Pressure Carry Over (HPCO) functionality is intended for

use with fixed displacement pumps in applications where one pump supply for multiple hydraulic

subsystems is desired.

The integrated HPCO functionality guides the excess flow of the PVG-EX 32 valve group to the external

hydraulic subsystem(s), giving priority to the PVG-EX 32 work functions.

The Open Center PVP with HPCO and PVE PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS/HPCO and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE

•

Optional T0 facility and external T0 port

•

Optional external pilot pressure port (Pp)

•

Only applicable with PVST end plates with separate T-port due to blocked T-lines for HPCO functionality.

Open Center PVP with HPCO, PVE PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

22 | © Danfoss | January 2022 BC290860493426en-000301

Page 23

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

©

Danfoss | January 2022 BC290860493426en-000301 | 23

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

Page 24

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Part numbers for OC PVP (HPCO and PPRV)

Part number P-port HPCO-port LS-port M-port Pp-port T0-port Mounting

157B5140

157B5340

157B5961

11101195

G3/4” G3/4" G1/4” G1/4” G1/4” G1/4” M8

1 1/16-12 UNF 1 1/16-12

M27x2 M27x2 M14x1.5 M14x1.5 – M14x1.5 M8

M22x1.5

M16x1.5 (P2)

UNF

M22x1.5 M12x1.5 M10x1 – M16x1.5 M8

1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 5/16-18 UNC

24 | © Danfoss | January 2022 BC290860493426en-000301

Page 25

LS

T

P

M

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Closed Center PVP

The basic Closed Center PVP inlet is intended for use with variable displacement pumps in applications

where a valve group with mechanically controlled work sections is desired, or where the pilot pressure to

the valve group is supplied externally.

The Closed Center PVP features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Optional T0 facility and external T0 port

•

Closed center PVP schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | January 2022 BC290860493426en-000301 | 25

Page 26

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

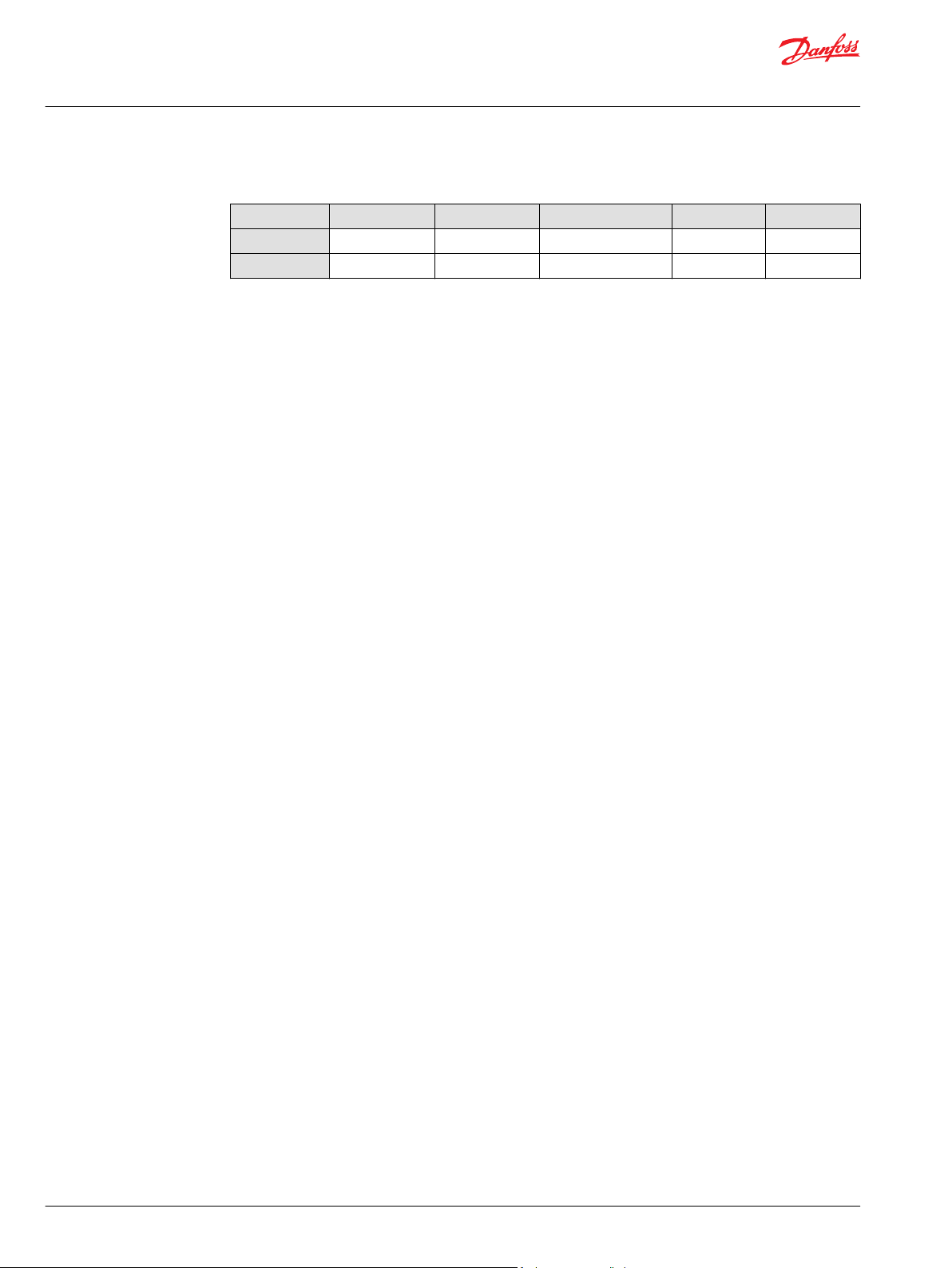

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

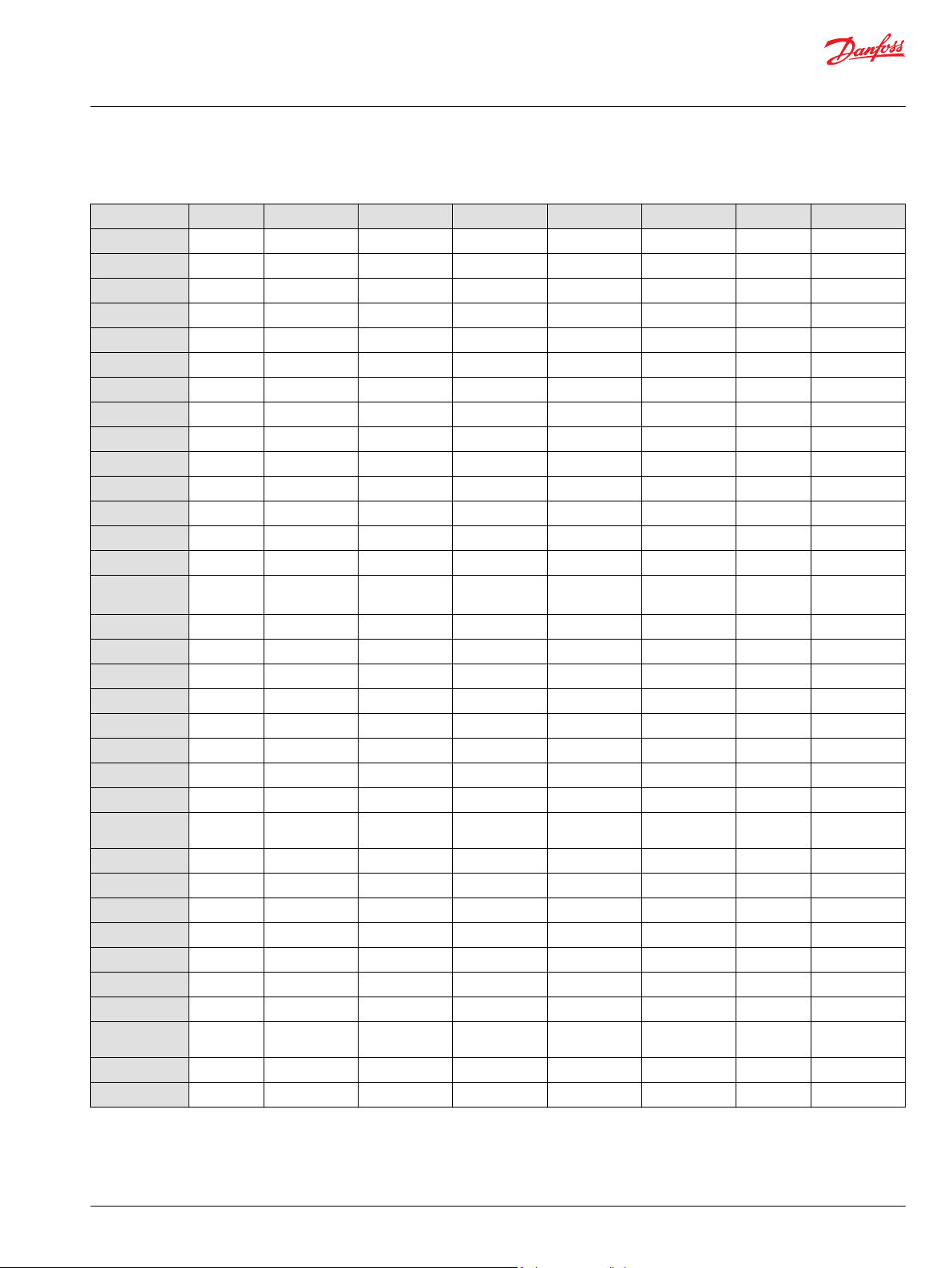

Part numbers for Closed Center PVP

Part number P-port T-port LS-port

(LS1**)

11030683 G3/4 G3/4 G1/4 (G1/4) G1/4 G1/4 M8

157B5001 G1/2 G3/4 G1/4 G1/4 - M8

157B5101 G3/4 G3/4 G1/4 G1/4 - M8

157B5201 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF -- 5/16-18 UNC

157B5301 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - 5/16-18 UNC

15B5907 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - M8

157B5922 JIS 1/2 JIS 3/4 JIS 1/4 JIS 1/4 - M8

157B5927 JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 - M8

157B5946 G1/2 G3/4 G1/4 (G1/8) G1/4 - M8

**

LS1 is an extra LS-port

M-port T0-port Mounting

26 | © Danfoss | January 2022 BC290860493426en-000301

Page 27

LS

T

P

M

Pp

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Closed Center PVP with PPRV

The Closed Center PVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

variable displacement pumps in applications where a valve group with electro-hydraulic or hydraulically

controlled work sections is desired.

The Closed Center PVP with PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional T0 facility and external T0 port

•

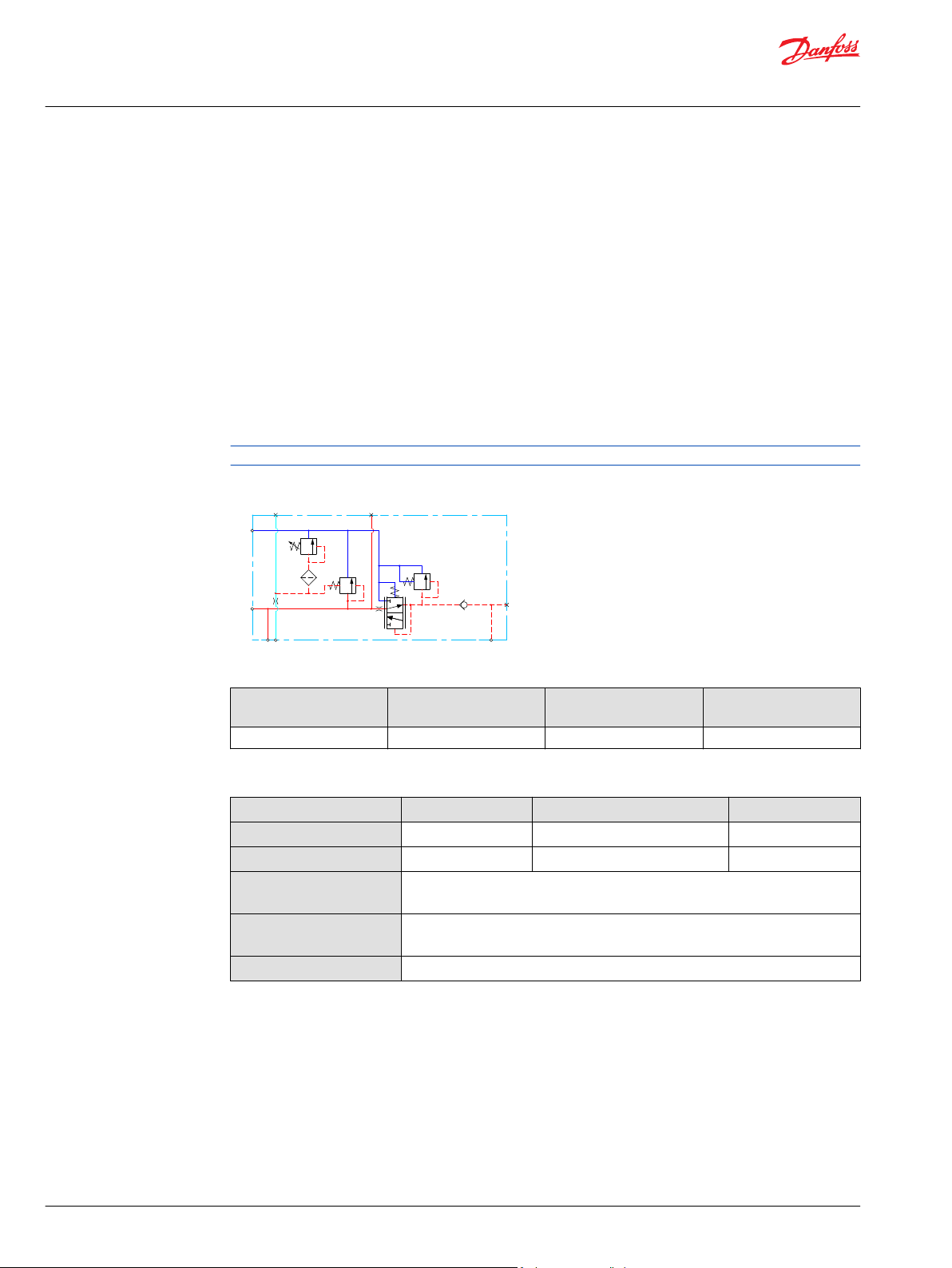

Closed center PVP with PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | January 2022 BC290860493426en-000301 | 27

Page 28

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Pilot pressure reduction valve characteristics

Part numbers for Closed Center PVP with PPRV

Part number Actuation P-port T-port LS-port (LS1**M-port Pp-port T0-port Mounting

11051802

157B5011

157B5111

157B5131

157B5181

157B5191

157B5211

157B5311

157B5331

157B5381

157B5391

**

LS1 is an extra LS-port

28 | © Danfoss | January 2022 BC290860493426en-000301

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 5/16-18 UNC

PVE G1/2” G3/4” G1/4” G1/4” - - M8

PVE G3/4” G3/4” G1/4” G1/4” - - M8

PVE G3/4” G3/4” G1/4” G1/4” G1/4” G1/4” M8

PVE G3/4” G3/4” G1/4” G1/4” G1/4” - M8

PVH/PVHC G3/4” G3/4” G1/4” G1/4” G1/4” - M8

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 5/16-18 UNC

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

Page 29

T

LS

P

M

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

All modules can be manually activated with the PVM actuation.

Closed center PVPV

The Closed Center PVPV inlet is intended for use with variable displacement pumps in applications where

a valve group with mechanical controlled work sections is desired.

The Closed center PVPV features:

•

Optional T0 facility and port

•

Threaded ports for P/T/LS and M measuring gauge

•

Optional additional threaded ports for P2, T2, and T02

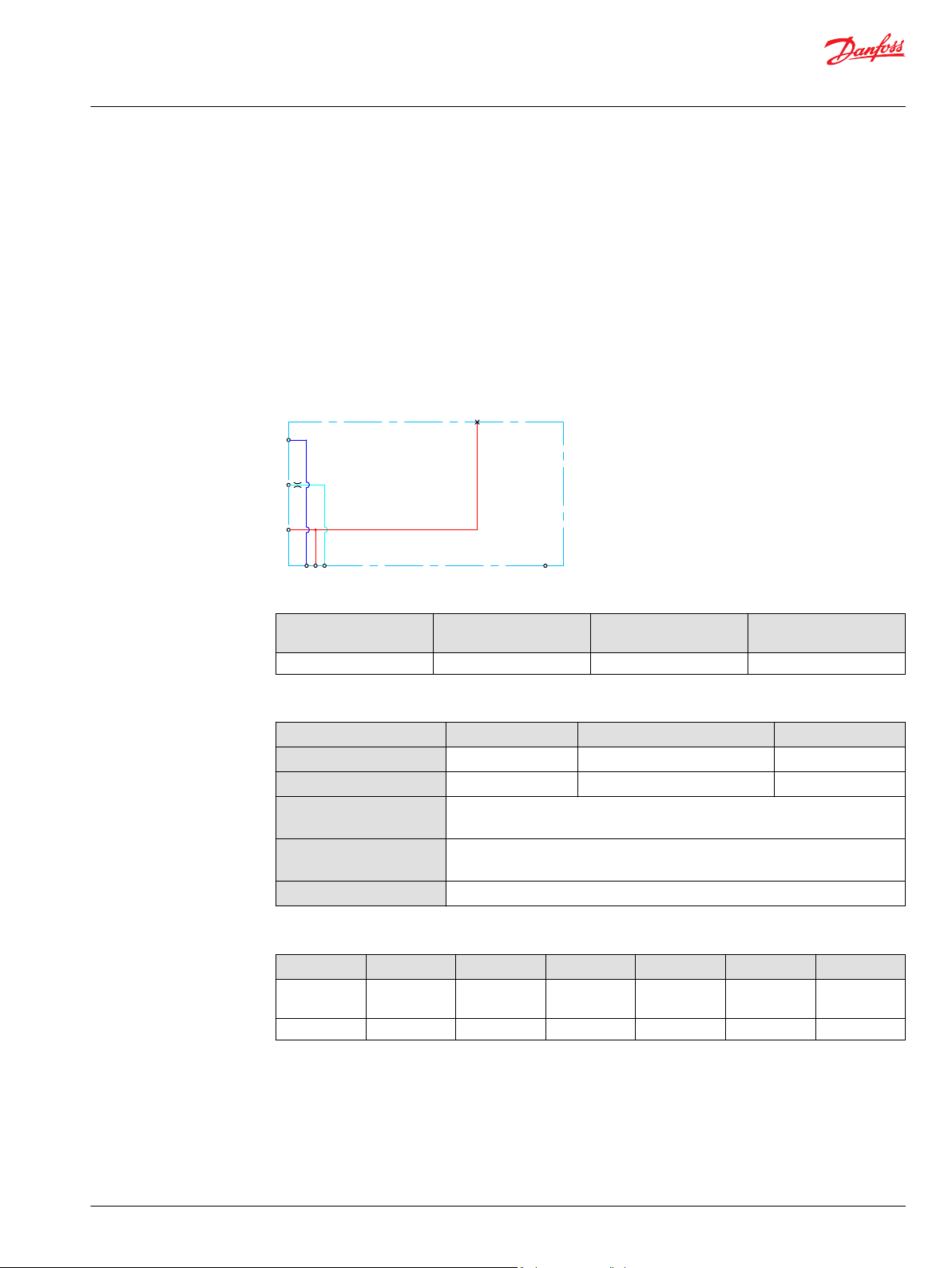

PVPV Schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for Closed Center PVPV

Part number P-port (P2) T-port (T2) LS-port M-port T0-port (T02) Mounting

11055758

11067570 M27x2.0 M33x2.0 M14x1.5 M14x1.5 - M8

M27x2.0

(M27x2.0)

M27x2.0

(M14x1.5)

M14x1.5 M14x1.5 M14x1.5

(M14x1.5)

M8

©

Danfoss | January 2022 BC290860493426en-000301 | 29

Page 30

T

LS

P

M

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

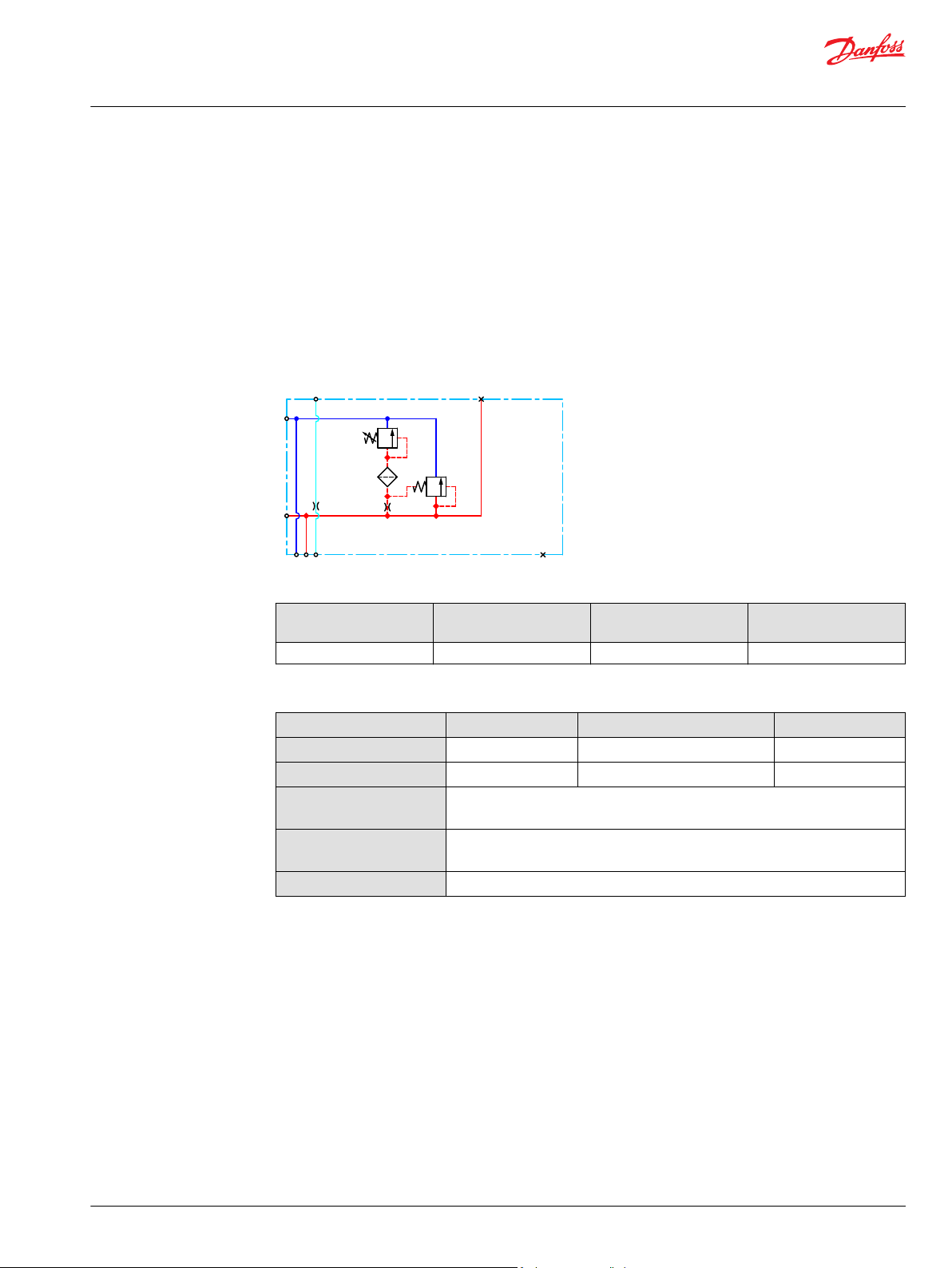

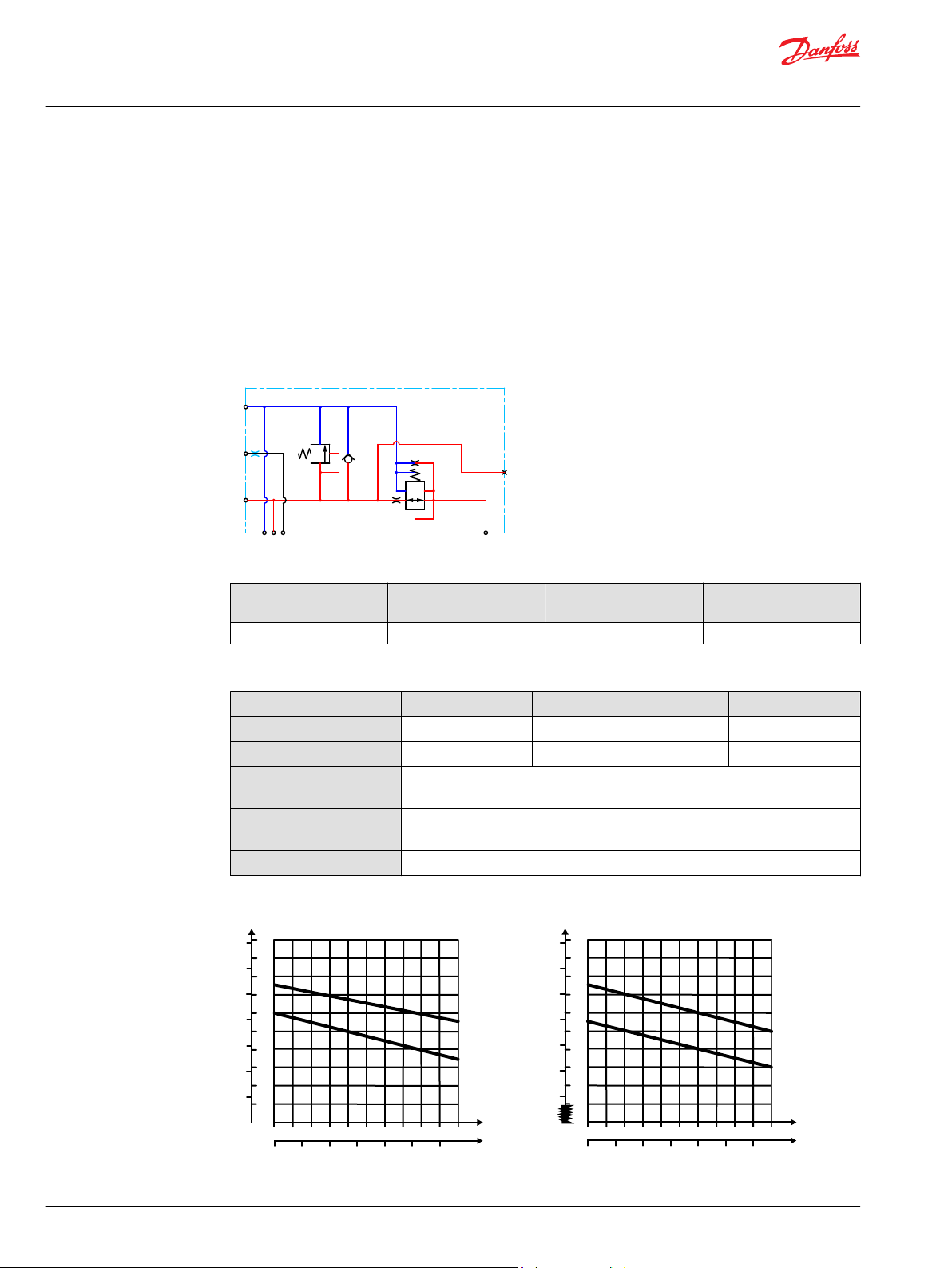

Closed center PVPV with PPRV

The Closed Center PVPV inlet with integrated pilot pressure reduction valve (PPRV) is intended for use

with variable displacement pumps in applications where a valve group with electro-hydraulic or

hydraulically controlled work sections is desired.

The Closed Center PVPV with PPRV features:

Optional shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

(mechanical activation)

Fluid cleanliness

18/16/13 (according to ISO 4406)

(PVE activation)

Operating temperature

Ambient: -30 to 60°C [-22 to 140°F]

Pilot pressure reduction valve characteristics

30 | © Danfoss | January 2022 BC290860493426en-000301

Page 31

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Part numbers for Closed Center PVPV with PPRV

Part number Actuator P-port T-port (T2) LS-port M-port Pp-port

T0-port

(T02)

11012350

11003806 M27x2.0

11008854

1

2

M27x2.0 M33x2.0 M14x1.5 M14x1.5 G1/4 - M8 -

M27x2.0

(M14x1.5)

M14x1.5 M14x1.5 G1/4

M14x1.5

(M14x1.5)

G1 G1 G1/4 G1/4 G1/4 - M8 Yes

11124107 1 5/16-12 1 1/16-12 9/16-18 9/16-18 G1/4 - M8 Yes

11196949 G1 G1 - - - - M8 Yes

157B5911 1 5/16-12 1 5/16-12 9/16-18 9/16-18 G1/4 - 5/16-18 -

PVE

157B5913 1 5/16-12 1 5/16-12 9/16-18 9/16-18 G1/4 - 5/16-18 Yes

157B5938 G1 G1 G1/4 G1/4 G1/4 - M8 157B5941 G1 G1 G1/4 G1/4 G1/4 - M8 Yes

157B5948

157B5973

3

4

G1 G1 G1/4 G1/4 G1/4 - M8 Yes

G1 G1 G1/4 G1/4 G1/4 - M8 Yes

157B5978 M27x2.0 M33x2.0 M14x1.5 M14x1.5 G1/4 - M8 11008856

11051803 1 5/16-12 1 5/16-12 9/16-18 9/16-18 G1/4 - 5/16-18 Yes

157B5916 1 5/16-12 1 5/16-12 9/16-18 9/16-18 G1/4 - 5/16-18 -

PVH/PVHC

G1 G1 G1/4 G1/4 G1/4 - M8 Yes

157B5963 1 1/16-12 1 1/16-12 7/16-20 - M18x1.5 9/16-18 M8 -

1

No LS-orifice

2

Internal T0 connection

3

0.4 mm hole in the pilot reduction cone (standard 0.8 mm)

4

HPCO-facility

Mounting PVLP

M8 -

All modules can be manually activated with the PVM actuation.

©

Danfoss | January 2022 BC290860493426en-000301 | 31

Page 32

T

LS

P

M

Pp

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Closed center PVPVM with PPRV

The Closed Center PVPVM mid-inlet module with integrated pilot pressure reduction valve (PPRV) is

intended for use with variable displacement pumps in applications where a valve group with electrohydraulic or hydraulically controlled work sections is desired.

Using a PVPVM module in a valve group requires a 180° degree rotation of the PVG work sections on one

side.

The Closed Center PVPVM with PPRV features:

Optional shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 230 l/min [61 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

32 | © Danfoss | January 2022 BC290860493426en-000301

Page 33

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Pilot pressure reduction valve characteristics

Part numbers for Closed Center PVPVM with PPRV

Part number Actuator P-port T-port LS-port M-port Pp-port Mounting PVLP

157B5914

157B5937 G1 G1 G1/4 G1/4 G1/4 M8 157B5940 G1 G1 G1/4 G1/4 G1/4 M8 Yes

11083156

157B5912 1 5/16-12

157B5986 G1 G1 G1/4 G1/4 G1/4 M8 Yes

PVE

PVH/PVHC

1 5/16-12

UNF

1 1/16-12

UNF

UNF

1 5/16-12

UNF

1 1/16-12

UNF

1 5/16-12

UNF

9/16-18 UNF 9/16-18 UNF G1/4 5/16-18 UNC Yes

9/16-18 UNF 9/16-18 UNF G1/4 5/16-18 UNC Yes

9/16-18 UNF 9/16-18 UNF G1/4 5/16-18 UNC -

©

Danfoss | January 2022 BC290860493426en-000301 | 33

All modules can be manually activated with the PVM actuation.

Page 34

LS

T

P

M

OC

CC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Open/Closed center PVP with PPRV

The Open Center/Closed Center PVP with integrated pilot pressure reduction valve (PPRV) is intended for

use with fixed or variable displacement pumps in applications where the application manufacturer does

not determine the pump type.

The modules allow an easy switch between Open Center and Closed Center configuration by means of an

external hexagon selector key. Variants also feature an LS boost functionality, increasing the LS pressure

to the pump LS regulator with a constant 6 bar, compensating for potential LS bleed-off and leakage.

The Open/closed center PVPV with PPRV features:

Integrated OC/CC selector

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional LS boost functionality

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

34 | © Danfoss | January 2022 BC290860493426en-000301

Page 35

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4 0.6 0.8

1.0

1.2

20

16

12

8

4

0

Q

P

240

160

80

0

0

[psi] [bar]

0

Q

Max.

Min.

280

200

120

40

2

18

14

10

6

1 2 3 4 5

[l/min]

[US gal/min]

0.2

0.4

0.6 0.8 1.0 1.2

30

26

22

18

14

0

Q

P

440

360

280

0

0

[psi] [bar]

0

Q

Max.

Min.

480

400

320

240

12

28

24

20

16

PVE PVH/PVHC

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

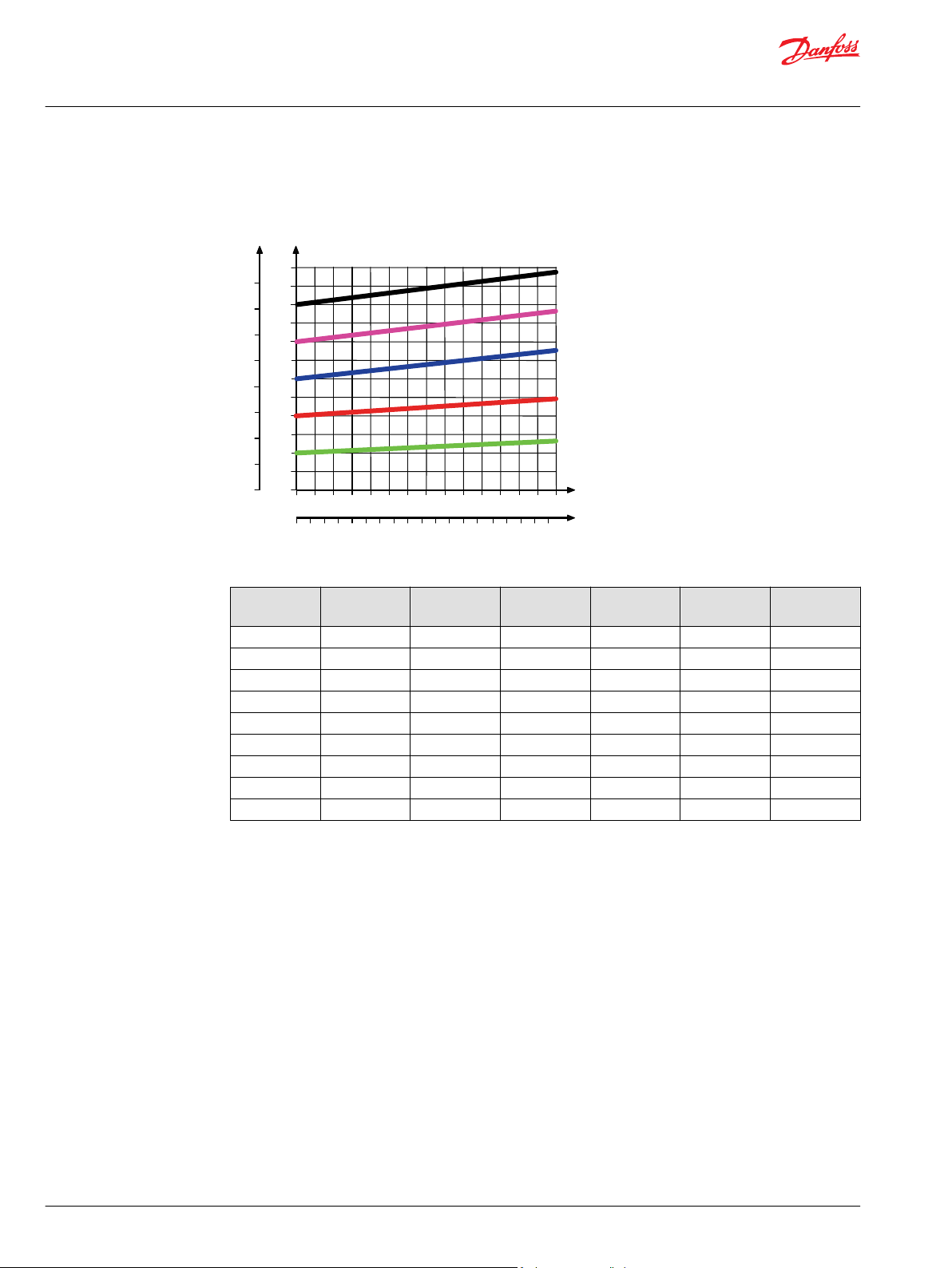

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

©

Danfoss | January 2022 BC290860493426en-000301 | 35

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

Page 36

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Part numbers for Open/Closed Center PVP with PPRV

Part number Actuation P-port T-port LS-port (LS1**) M-port T0-port Mounting LS Boost

11093273 PVE G3/4 G3/4 - G1/4 - M8 Yes

11119094 PVE G3/4 G3/4 - G1/4 - M8 11119095 PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - M8 11131344 PVH/PVHC G3/4 G3/4 - G1/4 - M8 Yes

111686081PVE G3/4 G3/4 - G1/4 - M8 Yes

**

LS1 is an extra LS-port

1

Dampened LS response

All modules can be manually activated with the PVM actuation.

36 | © Danfoss | January 2022 BC290860493426en-000301

Page 37

T

P

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

Open/Closed center PVPM

The Open Center/Closed Center PVPM mid-inlet acts as a simple manifold and is intended for use with

fixed or variable displacement pumps. The PVPM features no logic other than a PVLP shock/anticavitation valve facility for pressure peak protection and anti-cavitation prevention.

The PVPM module must be configured together with an Open Center PVP module for fixed

displacement pumps and for variable displacement pumps can be configured together with a PVSI

start plate or a Closed Center PVP/PVPV module.

The Open center/closed center PVPM features:

Integrated shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T

•

Pilot pressure and T0 lines through module

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 230 l/min [61 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

(mechanical activation)

Fluid cleanliness

(PVE activation)

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

18/16/13 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for Open Center/Closed Center PVPM

Part number P-, T-port Mounting PVLP

11093682

11093684

1 5/16-12 UN 5/16-18 UNC Yes

G1” M8 Yes

©

Danfoss | January 2022 BC290860493426en-000301 | 37

Page 38

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

PVP Inlet Module Accessories

The generic PVP inlet module accessory platform includes the PVPX Electrical LS pressure unloading

valve, External pilot pressure adapters PVPC with or without check valve for all Open Center PVP with

PPRV.

PVPC without Check Valve on page 39

•

PVPC with Check Valve on page 41

•

38 | © Danfoss | January 2022 BC290860493426en-000301

Page 39

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

PVPC without Check Valve

The PVPC external pilot pressure adapter without check valve is an accessory in the M-port available for

PVP inlet modules with integrated pilot pressure reduction valve (PPRV).

The PVPC without check valve cuts off the integrated PPRV to the PVE or PVH/PVHC in the valve group

and enables an external pilot pressure supply through the PVPC adapter.

PVPC without Check Valve

©

Danfoss | January 2022 BC290860493426en-000301 | 39

Page 40

LS

T

P

M

A

B

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

PVP with PVPC without check valve schematic

One application example for the PVPC without check valve is where it is a wanted feature to supply the

valve group with oil from a manually operated emergency pump without directing oil flow to the PPRV.

When the main pump is running in its normal operation mode, the oil is directed through the PVPC

adapter via the PPRV to the PVE electrical actuators.

When the main pump flow fails, the external shuttle valve ensures that the oil flow from the manually

operated emergency pump is used to pilot open the over-center valve and lower the load. The load is

only possible to lower when using the mechanical operating lever of the PVG work sections.

Part numbers for Open Center/Closed Center PVPM

Part number 157B5400 158X1000

Thread G1/2” 1/2-20 UNF

40 | © Danfoss | January 2022 BC290860493426en-000301

Page 41

LS

T

P

M

A

B

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32

PVPC with Check Valve

The PVPC external pilot pressure adapter with check valve is an accessory in the M-port available for PVP

inlet modules with integrated pilot pressure reduction valve (PPRV).

The PVPC with check valve enables an external pilot pressure supply through the PVPC adapter and the

PPRV, while also allowing the main pump to supply the PPRV through the P-gallery as a standard Open

Center PVP with PPRV.

PVPC with Check Valve

PVP with PVPC with check valve schematic

One application example for the PVPC with check valve is where it is a wanted feature to operate the

valve group by means of the PVE electrical actuators without pump flow.

©

Danfoss | January 2022 BC290860493426en-000301 | 41

Page 42

114 [4.49]

109 [4.29]

110 [4.33]

22.5 [0.89]

48 [1.89]

49 [1.93]

P

P

Technical Information

PVG-EX 32/128/256 Proportional Valve Group

PVG-EX 32