Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Proportional Valve Group

PVG 32 AG Modules

powersolutions.danfoss.com

Page 2

Technical Information PVG 32 AG Modules

Revision History Table of Revisions

Date Changed Rev

Feb 2014 Converted to Danfoss layout – DITA CMS AE

Mar 2012 Layout changes, and change in the table, page 21. AD

Mar 2010 New back cover AC

2 11051935 • Rev AE • Feb 2014

Page 3

Technical Information

PVG 32 AG Modules

Contents

Literature reference for PVG products

Introduction

Short overview...................................................................................................................................................................................5

Hitch control.......................................................................................................................................................................................5

Function

Warning................................................................................................................................................................................................6

PVG 32 cross-sectional view

Technical data

PVG 32 technical parameters....................................................................................................................................................... 8

PVBZ basic module for EH auxiliary valve functions

PVBD, PVBZ with optional diverter feature

Principle description of PVBD diverter:..................................................................................................................................10

PVBZ-HS/HD, hitch control valves

General introduction.................................................................................................................................................................... 11

PVBZ-HS basic module (hitch single-acting)........................................................................................................................11

PVBZ-HD basic module (hitch double-acting).....................................................................................................................12

PVP with integrated HPCO

Modules and code numbers

PVB, inlet basic modules..............................................................................................................................................................15

PVBZ auxiliary modules............................................................................................................................................................... 16

PVBZ-HS/-HD modules, PVBD diverter, multi-valve (for PVBZ-HD)............................................................................. 17

PVBS spools......................................................................................................................................................................................19

PVE.......................................................................................................................................................................................................19

End plates compatible with Metric PVG 32 program........................................................................................................20

Activation characteristics

Characteristic of oil flow, spool travel and voltage............................................................................................................22

Pressure drop characteristics

Pressure drop characteristics of float spools........................................................................................................................23

Single acting spools characteristics for PVBZ-HS .........................................................................................................26

Pressure drop characteristic in lower mode position, max. spool travel..............................................................26

Spools characteristics for PVBZ-HD....................................................................................................................................26

Dimensions and schematic examples

Drawings for 5-section group....................................................................................................................................................29

Drawings for 3-section group....................................................................................................................................................30

Drawings for 2-section group....................................................................................................................................................32

11051935 • Rev AE • Feb 2014 3

Page 4

Technical Information PVG 32 AG Modules

Literature reference for PVG products

Literature reference

Literature title Type Order

PVG 32 Proportional valve group Technical Information 520L0344

PVG 100 Proportional valve group Technical Information 520L0720

PVG 120 Proportional valve group Technical Information 520L0356

PVG 32 Metric ports Technical Information 11051935

PVE series 4

PVED-CC Electro-hydraulic actuator Technical Information 520L0665

PVED-CX Electro-hydraulic actuator Technical Information 11070179

Basic module for PVBZ Technical Information 520L0721

PVSK module with integrated diverter valve and P-disconnect function Technical Information 520L0556

PVPV / PVPM pump side module Technical Information 520L0222

Combination module PVGI Technical Information 520L0405

PVSP/M Priority module Technical Information 520L0291

Hitch Control

PVBZ Data sheet 520L0681

PVBZ-HS Data sheet 520L0956

PVBZ-HD Data sheet 11035599

MC024-010 and MC024-012 Controllers Data sheet 520L0712

Technical Information

System Description

User Manual

number

520L0553

11036124

11033753

4 11051935 • Rev AE • Feb 2014

Page 5

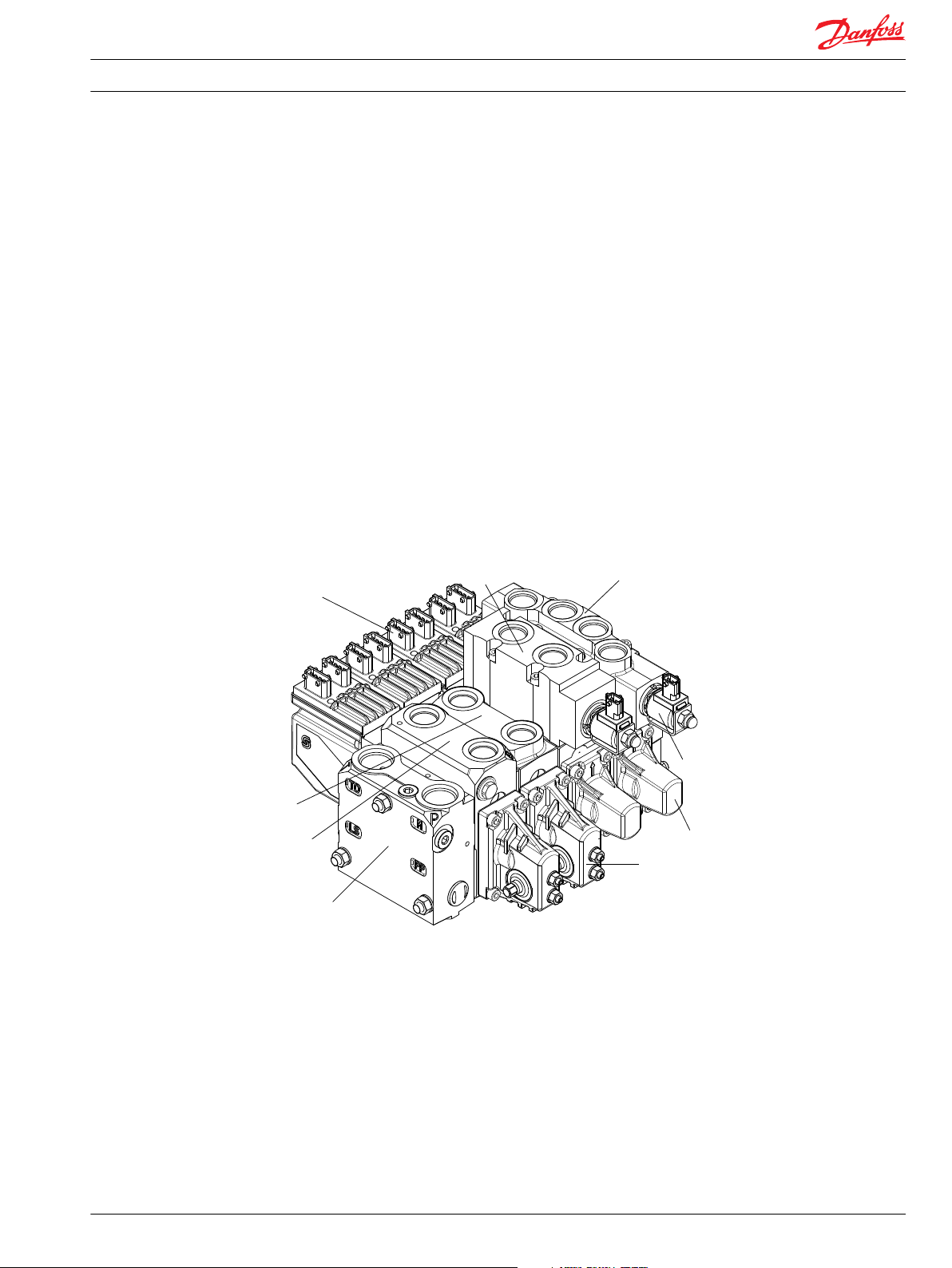

V310070.A

PVE

PVBZ-HS

PVP

PVM

PVML

PVC

PVBZ with Diverter

PVBZ-HD

PVBZ

Technical Information

Introduction

Short overview

PVG 32 AG Modules

The PVG 32 valve was originally launched with a range of high-performance electrical actuators in 1988.

During recent years, several AG (agricultural) customer projects have motivated several innovations, and

today our valve program offers components and features as compiled in this Technical Information or

referred to the Literature reference.

Metric ports

We have developed a range of modules with metric ports. These modules comprise of various inlets,

working modules for auxiliary functions, hitch modules, special top mounted modules and endplates.

The range of our PVE - Series 4 is used as actuation.

The target application area for this product range is mainly Agriculture – especially complete EH valve

solutions for tractors, but also other applications can benefit from the offered features.

Besides the inlets suited for fixed as well as for LS-controlled variable piston pumps, you will find a range

of valve modules listed. These valves enable you to assemble a valve solution using EH Aux valves and

hitch valves for tractors.

The PVE Series 4 generation with either analogue and digital pilot heads offers multiple possibilities of

customizing valves for individual needs – ranging from simple analogue versions to fully ISOBUS

compliant actuators with numerous variants in between, analogue as well as digital.

PVG 32 parts description

Hitch control

Together with the introduction of this product range, Danfoss has developed a hitch control SW block

available in our PLUS+1® GUIDE which on base of a PLUS+1 controller can offer a Hitch control system for

tractors.

These components allow for design of hitch systems that incorporate intuitive control as well as a

number of innovative new solutions. The components available offer significant advantages in

controlling both the single and double acting systems, including easy understanding of both Force and

Slip control. In addition to performing state of the art operation of hitch, the software block contains logic

that ensures the full potential of the Danfoss hitch valves are exploited.

The technical information references mentioned describes the Danfoss concept behind the operation of

a hydraulic hitch system, and the different types of systems and components available from Danfoss.

11051935 • Rev AE • Feb 2014 5

Page 6

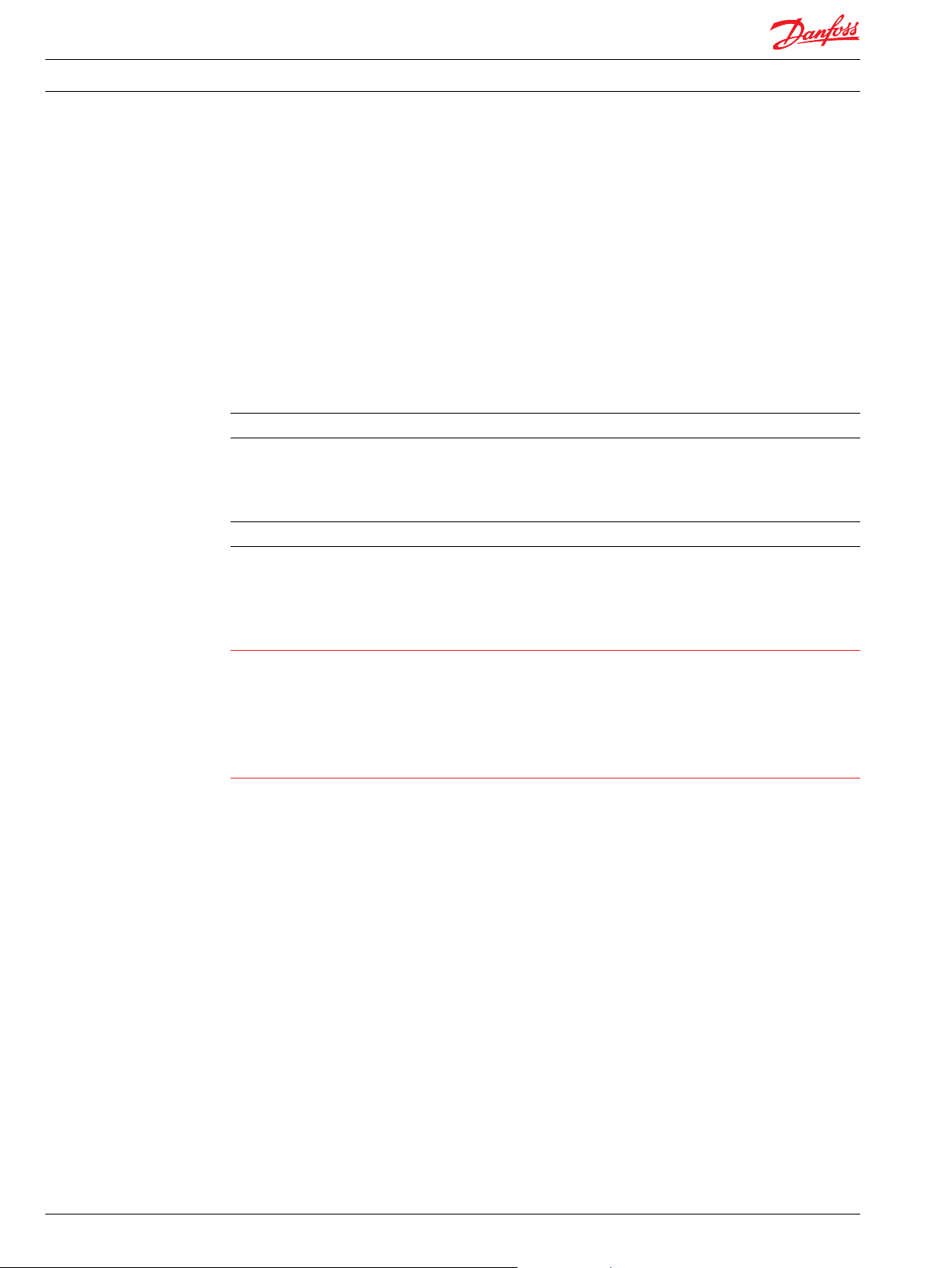

W

Technical Information

Function

PVG 32 AG Modules

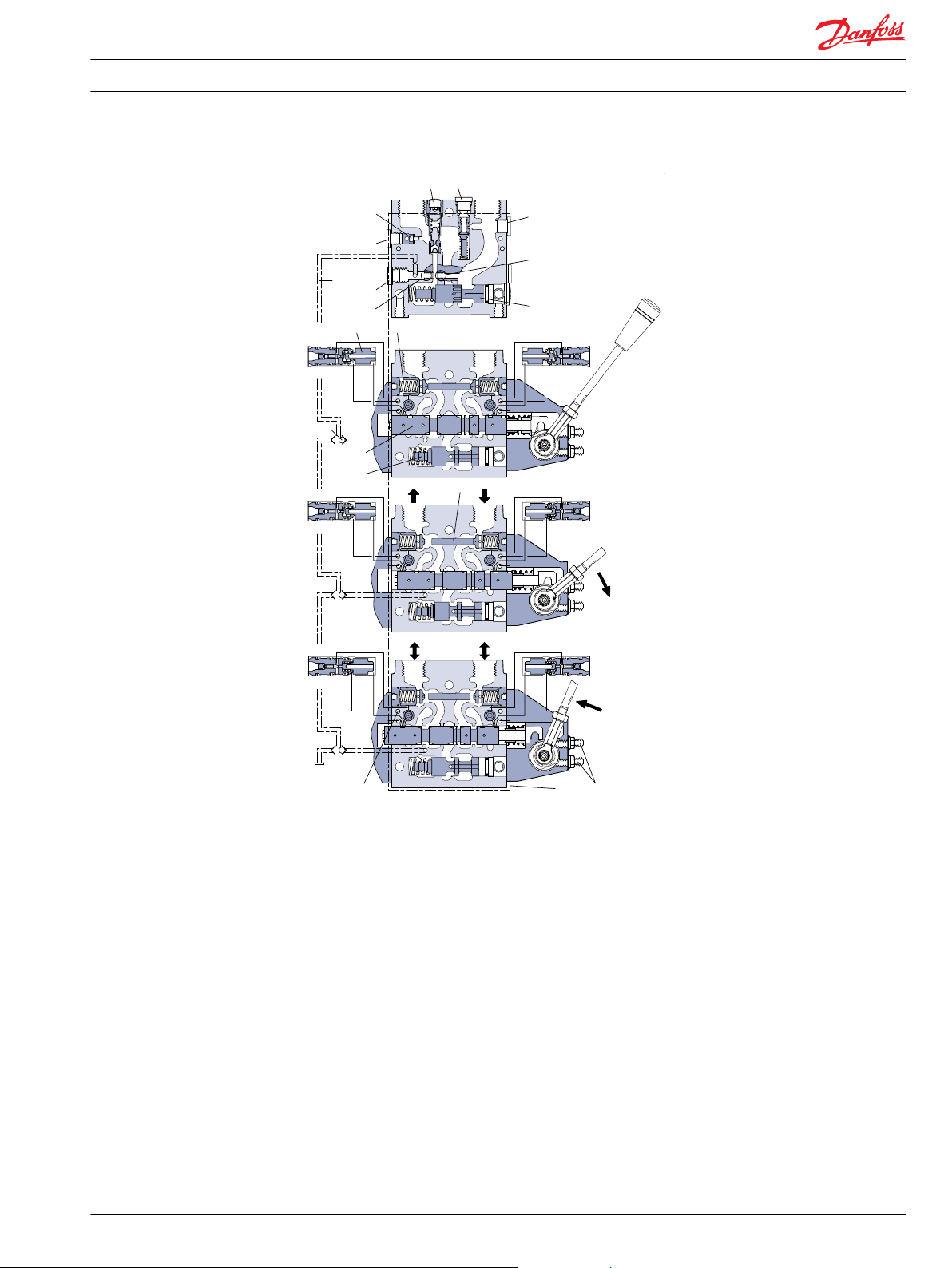

When main spools (15) are in neutral position, the pilot operated check valves (hereafter PO Check

valves) are kept closed by a spring plus the work port load, which is directed to the spring side of the PO

Check valves (14) via a small orifice.

If a main spool is actuated to have flow out of the B port, the meter out flow forces the respective PO

Check valves valve to open. At the same time, pilot pressure is guided via the main spool to the back side

of a small pilot valve (12) on the A port side. This will ensure that the load pressure behind the PO Check

valves is released to a separate tank T0 (20) via a seat valve and allow the PO Check valves to open and let

return flow pass across the main spool back to tank.

For float function, both PO Check valves are released to tank at the same time as described above.

In some applications with low load pressure, it is necessary to force open the PO Check valves by a pin

(17). This pin is actuated by means of pump pressure on the A port side.

PVBZ modules cannot be optionally mounted (PVM on A - Port side only).

The separate tank connection T0 is needed to ensure proper performance of the PO Check valvess

regardless of the pressure in main tank line T. It is therefore necessary to connect the T0 port in the Inlet

PVP direct to the oil reservoir with a separate hose, see dimensional drawing examples.

All the valve modules in this technical information have a T0 gallery.

Warning

When using PVP with HPCO function (T port can be pressurised) please make sure to lead return flow

from the A and B ports to tank via a separate tank port in the end plate PVST.

Warning

All makes and all types of directional control valves – inclusive proportional valves – can fail and cause

serious damage. It is therefore important to analyse all aspects of the application.

Because the proportional valves are used in many different operation conditions and applications, the

manufacturer of the application is responsible for making the final selection of the products- and

assuring that all performance, safety and warning requirements of the application are met.

The process of choosing the control system – and safety level – could e.g. be governed by ISO 13849

(Safety related parts of control system).

6 11051935 • Rev AE • Feb 2014

Page 7

LS

13

P

T

A

B

B A

B A

V310138.A

21

3

4+5

6

12

7

11

8

M

A

9

10

15

14

16

B

18

19

17

PVP

PVBZ

PVBZ

PVBZ

20

Technical Information PVG 32 AG Modules

PVG 32 cross-sectional view

1 – Pressure relief valve

2 – Pressure reduction valve for pilot oil supply

3 – Pressure gauge connection

4 – Plug, open center

5 – Orifice, closed center

6 – Pressure adjustment spool

7 – Plug, closed center

8 – LS connection

9 – T0 connection

10 – Plug - to be removed for internal T0*

11 – LS signal

12 – Pilot operated check valves

13 – Shuttle valve

14 – Pilot operated check valves

15 – Main spool

16 – Compensator

17 – Shuttle pin

18 – Max. oil adjustment screws for ports A and B

19 – Pilot oil supply for PVE

20 – Separate tank line (T0)

* for 157B: 5130, 5131, 5330 and 5331 only.

11051935 • Rev AE • Feb 2014 7

Page 8

Technical Information PVG 32 AG Modules

Technical data

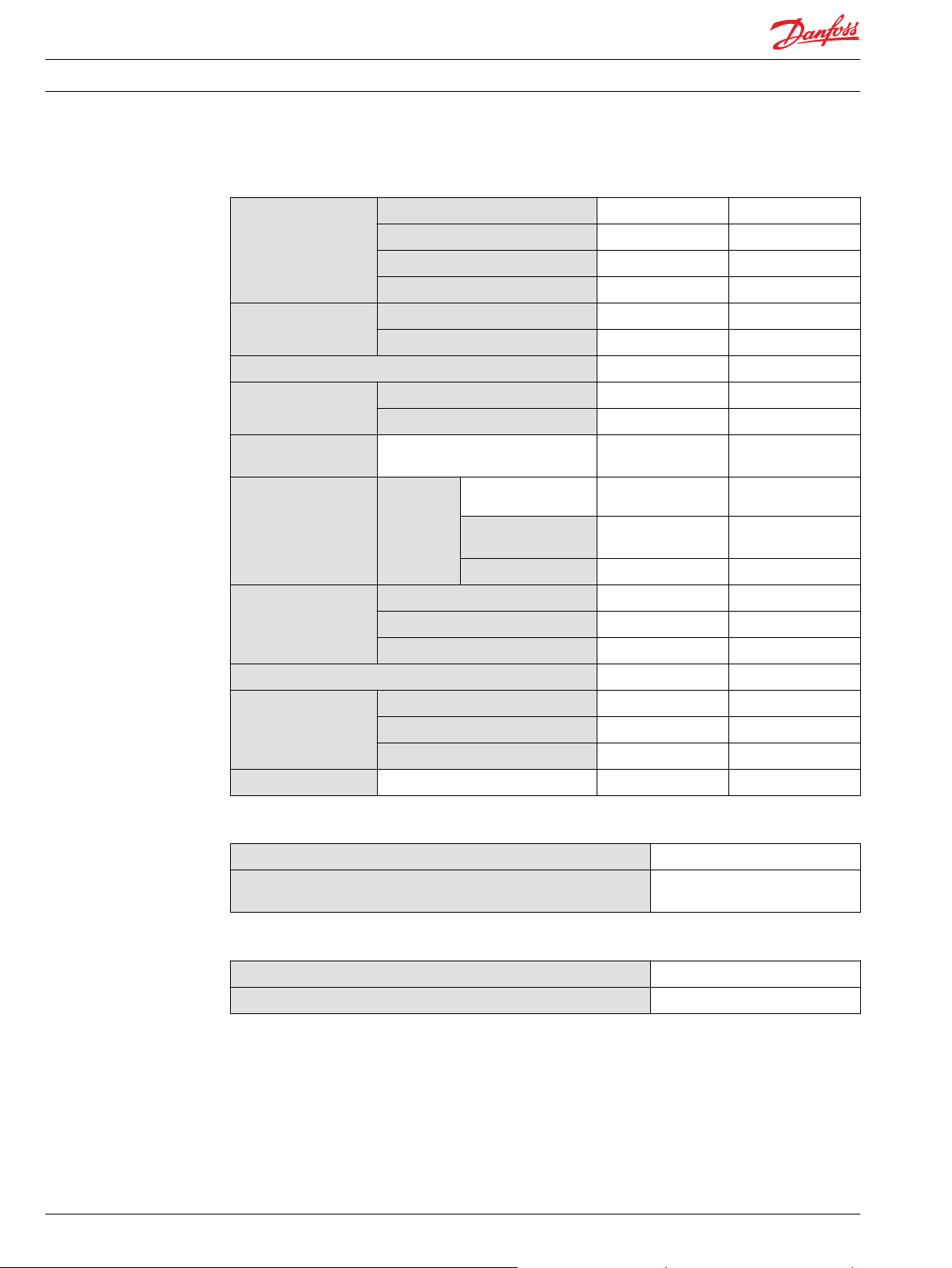

PVG 32 technical parameters

Max. pressure Port P continuous

Port A/B / without P/O checks

Port T, static/dynamic

Port T Hitch Single-Acting Module

Oil flow, rated Port P

Port A/B, with press. comp.

Spool travel, standard

Spool travel,

float position spool

Dead band,

flow control spool

Max. internal leakage

at 200 bar [2900 psi]

and 21 mm2/s [102 SUS]

Oil temperature

(inlet temperature)

Ambient temperature

Oil viscosity Operating range

Filtration

Proportional range

Float position

Standard ± 0.8 mm [±0.03 in]

A/B → T

Recommended

Min. temperature

Max. temperature

Min. viscosity

Max. viscosity

Max. contamination (ISO 4406) 18/16/13 18/16/13

PVBZ with PO Check

valves

PVBZ with PO Check

valves and PVLP

PVB with PVLP

250 bar [3625 psi]

280 bar [4061 psi]

25 / 40 bar [362 / 580 psi]

25 bar [362 psi]

140 l/min [37.0 US gal/min]

100 l/min [26.4 US gal/min]

± 7 mm [±0.28 in]

± 5.5 mm [±0.22 in]

7.5 mm [±0.30 in]

1 cm3/min [0.06 in3/min]

6 cm3/min [0.37 in3/min]

25 cm3/min [1.53 in3/min]

30 → 60°C [86 → 140°F]

-30°C [–22°F]

+90°C [194°F]

-30 → +60°C [–22 → +140°F]

12 - 75 mm2/s [65 - 347 SUS]

4 mm2/s [39 SUS]

460 mm2/s [2128 SUS]

PVBD, 6/2 diverter valve

Max pressure PVBZ module with mounted diverter PVBD, Port A/B

Oil flow max recommended, rated PVBZ module with mounted diverter

PVBD

Multi-valve, Single-action / Double-action

Max pressure PVBZ module with mounted multi valve, Port A/B

Oil flow, rated PVBZ module with mounted multi valve, Port A/B

8 11051935 • Rev AE • Feb 2014

280 bar [4061 psi]

80 l/min [21.1 US gal/min]

280 bar [4061 psi]

100 l/min [26.4 US gal/min]

Page 9

P301 015

Pilot Valves

PO Check valves Forced Opening Shuttle Pin

Analogue or Digital

CAN ISOBUS

PVE Actuator

Inductive LVDT Sensor PVM Manual Actuator Pressure Compensator with bleed off

A

B

Technical Information PVG 32 AG Modules

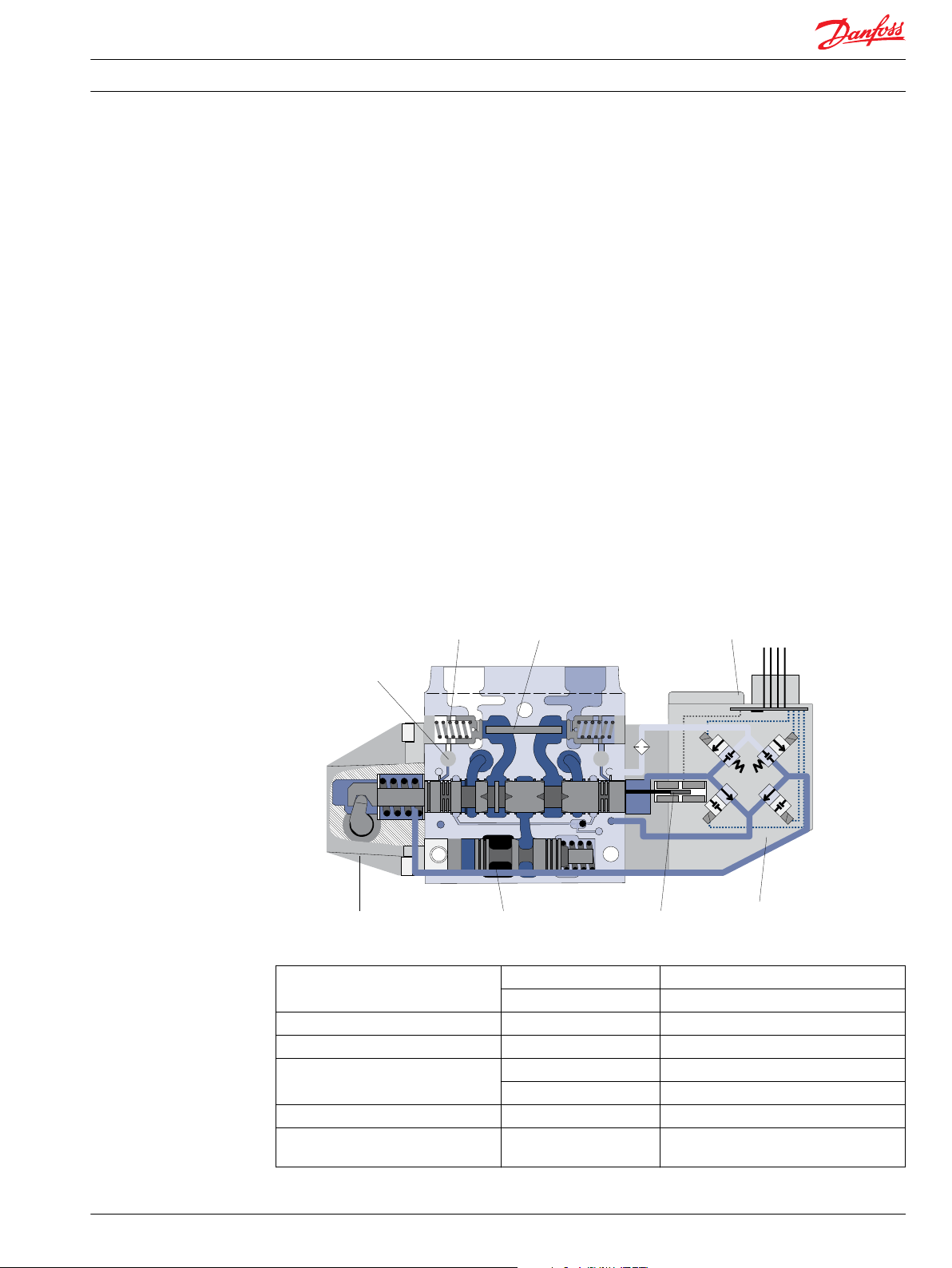

PVBZ basic module for EH auxiliary valve functions

The PVBZ valve is a load and pressure compensated valve module with two pilot operated check valves

(PO Check valves) in the A- and B-ports. These are limiting the work port leakage to a very low limit,

below 1 cm3/min.

PVBZ modules will always have 2 PO Check valves one in each work port.

Besides compensation, the pressure compensator can limit the work port pressure blow up to 4 - 5 bar.

The special PVBZ load compensated module was developed for applications that require integrated pilot

operated check valves in the work ports that required to limit the port leakage to zero. See Technical data.

The PVBZ basic module can be mixed with basic modules PVB (with additional tank line T0).

Features:

Integrated pilot operated check valves for limited internal leakage

•

Can be mixed with PVB with T0 gallery

•

LS a/b shuttle for float spools

•

Standard 4/4 float spools

•

Integrated thermo relief valve as option (modules with threaded ports only)

•

Manifold version for Danfoss designed valves or customer designed quick coupler block

•

Compensator with bleed off

•

Auxiliary valve on tractors for function control on implements; cylinder positioning and speed control

•

of hydraulic motors.

PVBZ, load and pressure compensated valve module with two PO check valves in A/B-ports

PVBZ parameters

Maximum pressure Port P continuous 250 bar [3625 psi]

Oil flow, rated Port A/B, with press. comp. 100 l/min [26.4 US gal/min]

Spool travel, standard ± 7 mm [±0.28 in]

Spool travel, float position spool Proportional range ± 5.5 mm [±0.22 in]

Dead band,flow control spool Standard ± 0.8 mm [±0.03 in]

Max. internal leakage at 150 bar [2175

psi] and 21 mm2/s [102 SUS]

Port A/B 280 bar [4061 psi]

Float position 7.5 mm [±0.30 in]

A/B → T 1 cm3/min [0.06 in3/min]

11051935 • Rev AE • Feb 2014 9

Page 10

PVE

Actuator

Pressure compensator with bleed off

PVM Manual

Actuator

Inductive LVDT Sensor

A

B

Analogue or

Digital CAN

ISOBUS

PVBD (Diverter)

PVC

P301 096

A1 A2 B1 B2

Pilot supply

T0

Pilot Valve

PO Check valve

Technical Information

PVG 32 AG Modules

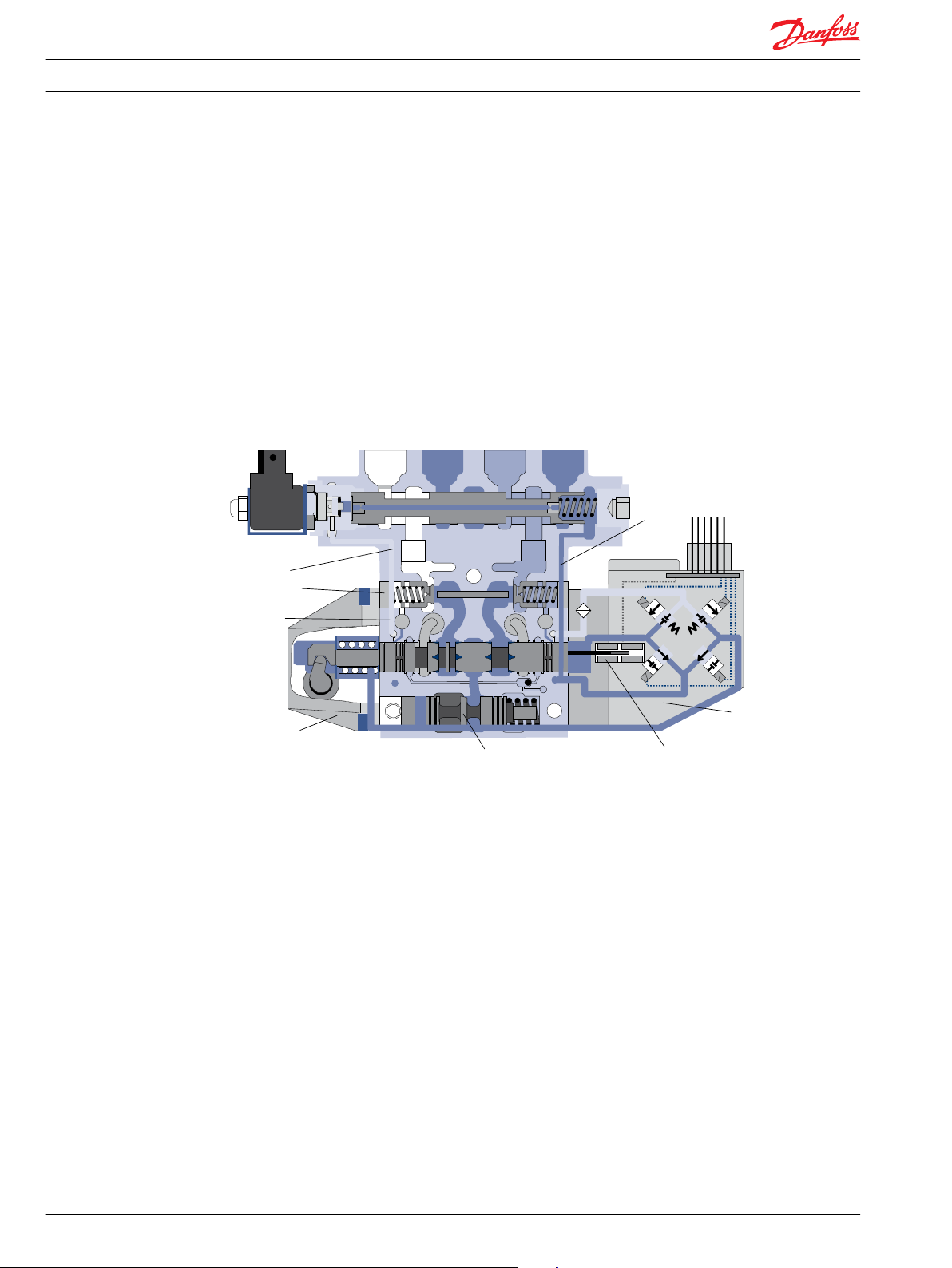

PVBD, PVBZ with optional diverter feature

The utilization of a PVBZ module can be further enhanced by adding a diverter valve. Mounted on top of

the PVBZ valve slice, a 6/2 PVBD diverter valve can direct valve flow to either of two set of ports (A1/B1 or

A2/B2). The PVBD diverter spool (shift spool) is actuated by the PVC solenoid valve by means of pilot

pressure.

Features:

Enlarge the application range (2 functions)

•

To be mounted on top of PVB or PVBZ modules

•

Pilot operated with PVC

•

Auxiliary valve on tractors for function control on implements: cylinder positioning when the demand

•

on neutral port leakage is limited.

PVBD, PVBZ with optional diverter feature

Principle description of PVBD diverter:

PVC off: The shift spool is held in position (flow to A1/B1) by the spring in the right hand side

•

(opposite the PVC). The spring chamber is always connected to the T0 gallery in the PVBZ body.

PVC on: Pilot pressure is led into the chamber next to the PVC. A limited flow is passing through the

•

shift spool and the two orifices and into the spring chamber connected to T0. Pressure-drop across

the orifices creates the shift force moving the shift spool towards the spring. As a result, port A2/B2

becomes active.

Leakage (along the spool clearance) from pressurized work ports A1/B1 or A2/B2 will always be drained

to T0 either directly in the spring chamber or through the shift spool. This secures safe positioning of the

shift spool as leakage never will build up pressure up in the control chambers.

Safety recommendation: Shift of the diverter should only be possible when the main spool is in neutral.

This has to be ensured through a proper set-up in the controller/MMI hardware.

10 11051935 • Rev AE • Feb 2014

Page 11

Technical Information

PVG 32 AG Modules

PVBZ-HS/HD, hitch control valves

General introduction

Two types of hitch valves are available for hitch or similar applications. The two valve options offered are

the PVBZ-HS, single acting and the PVBZ-HD, double acting.

The PVBZ-HS matches the market standard whereby implements are raised hydraulically and lowered

only by the pull of gravity. The PVBZ-HD has the unique ability to raise and lower either as single- or

double-acting.

The benefits of the PVBZ-HD reflect a departure from old hitch norms - increased comfort when attaching

implements due to the same speed up and down and safer detachment of heavy implements from the

driver’s seat.

The full benefit of the possibilities with the PVBZ-HD is easily obtained by use of the PLUS+1® hitch core

application block. The core application block shifts the valve between single- and double-acting hitch

according to the most suitable operation.

The operator will not have to select the operation but will notice the benefits during normal operation of

the hitch. Work-modes are single-acting as it is standard today, but manual operation up and down are

double-acting to increase comfort, functionality and safety.

For further info and more details please see the Danfoss Hitch control System description, see Literature

reference.

PVBZ-HS basic module (hitch single-acting)

Single acting PVBZ-HS slice for standard hitch application.

It has its own tank port to direct the return flow directly into the tank with a minimum of back pressure.

This prevents tank-line pressure influence, especially when lowering the un-loaded (empty) hitch under

cold conditions (high oil viscosity).

Similar to the auxiliary slice, the single acting PVBZ-HS slice is a pressure-compensated valve slice with

one P/O check valve on B-port only. The same technology as in the PVBZ module is used.

Besides the flow paths, the spool is directing the pilot pressure to the pilot valve for P/O check valve

pressure release as well as to the shuttle pin in order to force the P/O popped to open under low load

conditions. This ensures a fully open flow path in lower mode.

The B-port is normally equipped with a PVLP shock valve.

PVBZ-HS incorporates a compensator with bleed-off to prevent pressure building up between the pump

gallery and the work ports.

A special 3/3 spool with optimized flow characteristics, both in meter-out as well as in meter-in direction,

has to be controlled by a high performance actuator.

Features:

Low leakage work port

•

Separated tank port

•

Integrated PVLP shock/anti cavitation valves

•

Can be mixed with PVB/ PVBZ with T0 gallery

•

Compensator with bleed off

•

Rear-Hitch on tractors

•

Header control on combines and harvesters

•

11051935 • Rev AE • Feb 2014 11

Page 12

B

T

P301 095

PVLP 63

PO Check valve

Pilot supply

Pressure Compensator with bleed off

Analogue or

Digital CAN

ISOBUS

Pilot Valve

PVM Manual

Actuator

Inductive LVDT Sensor

PVE Actuator

Technical Information

PVG 32 AG Modules

PVBZ-HS/HD, hitch control valves

Hitch single-acting valve module

PVBZ-HD basic module (hitch double-acting)

PVBZ-HS parameters

Maximum pressure Port P continuous 250 bar [3625 psi]

Port B 280 bar [4061 psi]

Port T, static/dynamic 25 bar/40 bar [365/580 psi]

Oil flow, rated, Port B, with press. comp. 100 l/min [26.4 US gal/min]

Spool travel, standard ± 7 mm [±0.28 in]

Dead band, flow control spool, standard ± 0.8 mm [±0.03 in]

Max. internal leakage at 150 bar [2175 psi] and

B → T, with PVLP 6.0 cm3/min [0.37 in3/min]

21 mm2/s [102 SUS]

Safety recommendations for the OEM and user.

To avoid unintended raise of the empty hitch the tank port on PVBZ-HS always has to be connected

direct to tank without any restriction or pressure build up possibilities.

This also ensures lowering in lower mode under cold conditions (high viscosity oil).

In case of manual actuation of the Hitch function (limp home mode) the power supply to the PVE has to

be disabled before the PVM (hexagon) can be actuated.

The OEM /end user needs to be aware of the dangerous operation when performing manual raise/

lowering of the hitch and be close to the hitch arms.

The double-acting hitch slice consists of the PVBZ valve-section with a flanged-on single/double-acting

selector (multi-valve) actuated by a PVC valve.

By energizing or de-energizing the PVC, the multi-valve shifts the slice between single- or double-acting

work-modes. This is of great benefit in hitch applications both for rear and front hitches. When the slice is

operating as single-acting, the A-port is connected to tank in the PVBZ body.

The PVBZ base of the PVBZ-HD has similar features as the PVBZ valve-slice. That is PO Check valves for low

leakage as well as compensator with bleed-off to eliminate pressure build-up between compensator and

work-ports.

12 11051935 • Rev AE • Feb 2014

Page 13

PVE

Actuator

Pressure Compensator with bleed off

PVM Manual

Actuator

Inductive LVDT sensor

A

B

Analogue or

Digital CAN

ISOBUS

PVC

P301 094

A B

PVLP 63

LS

Tank

Mode shift spool

PO Check valves

Pilot Valve

Pilot Supply

Technical Information PVG 32 AG Modules

PVBZ-HS/HD, hitch control valves

The flanged on multi-valve contains the shifting spool to switch port A between T and port A of the PVBZ.

It also contains a PVLP shock/suction valve on port B.

The change between single- and double-acting modes is operated independently of valve-flow

command.

Features:

Low leakage work port (B-port)

•

Standard 4/4 float spools to be used

•

Electrical mode shift into pure 3/3 single acting functionality of double acting cylinder

•

Integrated PVLP shock/anti cavitation valves (B-port)

•

Single and Double Acting (see Hitch Control System Description for detailed set-up and benefits)

•

Compensator with bleed off

•

Rear and front hitch linkages on medium and higher performance tractors.

•

Header control on combines and harvesters.

•

Hitch double-acting valve module

PVBZ-HD parameters

Maximum pressure Port P continuous 250 bar [3625 psi]

Oil flow, rated Port A/B, with press. comp. 100 l/min [26.4 US gal/min]

Pilot oil consumtion PVC off / PVC on 0 / 0.3 l/min

Environmental specifications Temperature oil viscosity etc. See PVBZ parameters

PVC solenoid (NC) Connector type Zener diode included AMP JPT 2 Pin

11051935 • Rev AE • Feb 2014 13

Port A/B 280 bar [4061 psi]

Page 14

Technical Information PVG 32 AG Modules

PVP with integrated HPCO

Together with the introduction of PVBZ (and PVB with separate tank line T0). Danfoss can now also

supply PVG 32 valves with integrated HPCO functionality (High Pressure Carry Over).

The HPCO function will guide the pump flow not used in the PVG 32 valve group via the HPCO port to for

example a directional valve. The PVP pump side module with integrated HPCO function can only be

mixed with PVB, PVBZ and PVST.

Features:

HPCO functionality

•

Prioritized flow for PVG 32

•

Reduced plumbing

•

14 11051935 • Rev AE • Feb 2014

Page 15

M

T

P

LST0

P301 032

M

T(HPCO)

P

LS

T0

P301 033

T

P

P2 LSMT0

Pp

P301 034

M

T (HPCO)

P

LS

T0

Pp

P2

PVP 157B5965

Inlet

w. HPCO

P301 035

T

LS

P

T0 M

P301 036

T2

T

LS

P

T0

T2

P2

T02

P301 037

Technical Information PVG 32 AG Modules

Modules and code numbers

PVB, inlet basic modules

PVB, inlet basic modules

Symbol Descriptions: PVP / PVPV / PVB Ports Code number

PVP, Open centre pump side module for pumps

with fixed displacement.

External T0. With pilot supply for electrical

actuation.

P: M27x2

T: M27x2

M: M14x1.5

LS: M14x1.5

T0: M14x1.5

11072195

(ISO 6149)

PVP, Open centre pump side module for pumps

with fixed displacement.

External T0. With pilot supply for electrical

actuation.

Prepared for HPCO - use Tport.

PVG group requires PVST (end plate with T port).

PVP, Open centre pump side module for pumps

with fixed displacement

External T0

With pilot supply for electrical actuation.

Measure port for pilot supply.

PVP, Open centre pump side module for pumps

with fixed displacement.

External T0. With pilot supply for electrical

actuation.

Prepared for HPCO - use Tport.

PVG group requires PVST (end plate with T port).

PVPV, Closed centre pump side module for

pumps with variable displacement.

External T0.

With pilot supply for electrical actuation.

Prepared for PVLP.

P: M27x2

T: M27x2

(HPCO)

M: M14x1.5

LS: M14x1.5

T0: M14x1.5

P: M22x1.5

P2: M16x1.5

T: M22x1.5

M: M10x1

LS: M12x1.5

T0: M16x1.5

Ppilot: M10x1

P: M22x1.5

P2: M16x1.5

T: M22x1.5

(HPCO)

M: M10x1

LS: M12x1.5

T0: M16x1.5

Ppilot: M10x1

P: M33x2

T: M33x2

T2: M14x1.5

M: M14x1.5

LS: M14x1.5

T0: M16x1.5

157B5961

(ISO 6149)

157B5964

(DIN 3851)

157B5965

(DIN 3851)

157B5969

(ISO 6149)

PVPV, Closed centre pump side module for

pumps with variable displacement.

External T0.

With pilot supply for electrical actuation.

11051935 • Rev AE • Feb 2014 15

P, T: M27x2

P2, T2:

M14x1.5

LS: M14x1.5

T0, T02:

M14x1.5

11003806

(ISO 6149)

Page 16

P

T

LS

T0

P2

T2

T02

V310061.A

A

B

T0 Pp LSPT

P301 038

P301 039

A

B

Pp

T0

A

B

P301 040

A

B

P301 041

Technical Information PVG 32 AG Modules

Modules and code numbers

PVB, inlet basic modules (continued)

Symbol Descriptions: PVP / PVPV / PVB Ports Code number

PVPV,

Closed centre pump side module for pumps with

variable displacement.

External T0 without pilot supply.

P: M27x2

P2: M14x1.5

T: M27x2

T2: M14x1.5

LS: M14x1.5

T0: M16x1.5

T02: M14x1.5

11055758

(ISO 6149)

PVB,

With compensator, without thermal relief valve

T0 facility

LS a/b shuttle valve

Prepared for PVLP shock valves

PVB,

With compensator

T0 facility

LS a/b shuttle valve

Prepared for manifold PVBD

M22 x 1.5 157B6850

(ISO 6149)

Manifold PVBD 157B6969

PVBZ auxiliary modules

PVBZ auxiliary modules

Symbol Description PVB / PVBZ Port Code number

PVBZ as PVB

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve

Without thermal relief valve

M22 x 1.5 157B6955

(ISO 6149)

16 11051935 • Rev AE • Feb 2014

PVBZ 2 PO check valves

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve. Shuttle pin.

Without thermal relief valve

M22 x 1.5 157B6957

(ISO 6149)

Page 17

A

B

P301 042

A

B

T0 Pp LS PT

P301 043

A

B

Pp

T0

P301 044

A

B

T0

T0

P301 045

T

B

P301 046

Technical Information PVG 32 AG Modules

Modules and code numbers

PVBZ auxiliary modules (continued)

Symbol Description PVB / PVBZ Port Code number

PVBZ 2 PO check valves.

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve. Shuttle pin.

Without thermal relief valve

M22 x 1.5 11024817

(DIN 3851)

PVBZ 2 PO check valves.

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve. Shuttle pin.

With thermal relief valve

PVBZ 2 PO check valves.

Shuttle pin.

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve, LS return

With thermal relief valve

PVBZ 2 PO check valves.

Shuttle pin.

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve, LS return

Quick coupler block manifold

PVBZ-HS/-HD modules, PVBD diverter, multi-valve (for PVBZ-HD)

M22 x 1.5 157B6954

(ISO 6149)

Manifold PVBD 157B6958

Manifold

Special

interface

11005475

PVBZ-HS/-HD modules

Symbol Description PVBZ Port Code number

PVBZ-HS with PO Check valve in B port.

Compensator w. bleed off and check valve

T0 facility

Valve for 3/3 spool - single acting only!

B-port prepared for PVLP

Own T port - enables lowering of no loaded

actuator.

M22 x 1.5 157B6968

(ISO 6149)

11051935 • Rev AE • Feb 2014 17

Page 18

A

B

T0

LS

T

Pp

P301 047

A1

B1

A2

B2

A

B

Pp

T0

P301 048

157B1503

A

B

A

B

T0

LS

T

Pp

P301 049

Technical Information PVG 32 AG Modules

Modules and code numbers

PVBZ-HS/-HD modules (continued)

Symbol Description PVBZ Port Code number

PVBZ with PO check valves.

Compensator w. bleed off and check valve

T0 facility

LS a/b shuttle valve; LS return; Shuttle pin

manifold for multi-valve for PVBZ-HD

manifold for

multi-valve

PVBD diverter, multi-valve (for PVBZ-HD)

Symbol Description Port Code Number

PVBD 6/2 shift valve.

Valve shifts between A1 & B1 / A2 & B2.

Actuated with included PVC solenoid; PVC NC; 12

VDC; 14 bar.

Port max. pressure: 280 bar

Connector type: AMP JPT 2 PIN

M22 x 1.5 157B1501

11032961

(ISO 6149)

18 11051935 • Rev AE • Feb 2014

Multi-valve for PVBZ 11032961

Valve shifts A-port between PVBZ A or tank

gallery, i.e. shifts between single and double

acting actuation.

B-port prepared for PVLP

Actuated with included PVC solenoid; PVC NC; 12

VDC; 14 bar.

Port max. pressure: 280 bar

Connector type: AMP JPT 2 PIN

M22 x 1.5 11027604

(ISO 6149)

Page 19

Technical Information PVG 32 AG Modules

Modules and code numbers

PVBS spools

PVBS spools

Symbol Description PVBS Pressure compensated flow l/min

5 [1.32] 10 [2.64] 25 [6.6] 40 [10.57] 65 [17.17] 100 [22]

Standard FC-spools for PVBZ

(Electrical and Mechanical actuation)

Tension bar for PVM

Check valves in spool

4-way, 3-position

Deadband: 0,8 mm

For PVBZ with LS A/B shuttle

Standard FC -spools for PVBZ and PVBZHD

(Electrical and Mechanical actuation)

Tension bar for PVM

Check valve in spool

4-way, 4-position

Float >A>F

Deadband: 0,8 mm

For PVBZ with LS A/B shuttle

Standard FC float spools for PVBZ

(Electrical actuation)

Tension bar for PVML

Check valve in spool

4-way, 4-position

Float >A>F

Deadband: 0,8 mm

For PVBZ with LS A/B shuttle

P -> B / B -> T 50/30 75/50 100/65

Standard FC spools for PVBZ-HS

(Electrical and Mechanical actuation)

Tension bar for PVM

3-way, 3-position

Deadband: 0,8 mm

11051945 11019630 11019631 11019633 11019634 11019635

157B9415 157B9410 157B9411 157B9412 157B9413 157B9414

157B9434

11023550 11023551 11023552

PVE

PVE

Symbol Description of PVE* Code Number

AMP Deutsch

PVEH-F

Ratiometric proportional high, Active fault monitoring

Multi-voltage 11-32 V, hysteresis: 4% rated

Float P>A>F by additional input signal.

Recommended use: PVB_ PVBZ with float spools.

PVEP-F

PWM proportional high, Active fault monitoring

Multi-voltage 11-32 V, hysteresis: 5% rated

Float P>A>F by additional input signal.

Recommended use: PVB_ PVBZ with float spools.

11051935 • Rev AE • Feb 2014 19

157B4338

157B4753

Page 20

V310062.A

V310063.A

LX

V310062.A

V310063.A

LX

V310064.A

T

Technical Information PVG 32 AG Modules

Modules and code numbers

PVE (continued)

Symbol Description of PVE* Code Number

AMP Deutsch

PVED-CC

Can bus proportional high, Programmable

Multi-voltage 11-32 V, hysteresis: ~ 0%

Recommended use: PVB_ PVBZ with float spools.

157B4943 157B4944

PVED-CC

Can bus proportional high, Programmable

Multi-voltage 11-32 V, hysteresis: 4% rated

Recommended use: PVBZ-HS or PVBZ-HD hitch valves

PVEP

Proportional actuation, Active fault monitoring

11026781 11015692

11034832

* For further information see PVE series 4 Technical Information, 520L0553.

End plates compatible with Metric PVG 32 program

End plates compatible with Metric PVG 32 program

Symbol Description PVS Port Code Numbers

ISO DIN

PVS aluminum

Without active elements

No connections

PVS aluminum

Without active elements

LX connection

LX: M12x1.5 157B2913

157B2000 157B2000

20 11051935 • Rev AE • Feb 2014

PVSI steel

Without active elements

No connections

PVSI steel

Without active elements

LX connection

PVST steel

Without active elements

T-port

M8 for mounting

157B2014 157B2014

LX: M12x1.5 157B2910

T: M22x1.5 11004462 157B2912

Page 21

T2

T0

Pp

LX

LX on/off

PpLSPT

V310060.A

T0

Pp

LSPT

V310076.A

Technical Information PVG 32 AG Modules

Modules and code numbers

End plates compatible with Metric PVG 32 program (continued)

Symbol Description PVS Port Code Numbers

ISO DIN

PVSI Steel

With pilot supply for electrical actuation

and pilot dump.

LX-connection

LX on/off

350 bar

12 V

DC

LX: M14x1.5

T2: M22x1.5

Pp: M14x1.5

11050065

PVSI Steel

350 bar

With pilot supply for electrical actuation

T0: M14x1.5 157B2917

Separate specification pads with 50 sheets are available under the literature no. 520L0515.

11051935 • Rev AE • Feb 2014 21

Page 22

Technical Information PVG 32 AG Modules

Activation characteristics

Characteristic of oil flow, spool travel and voltage

The spools have 5.5 mm spool travel in direction B and 7.5 mm travel in direction A:

•

5.5 mm spool displacement in direction A gives max. oil flow to port A

•

5.5 mm spool displacement in direction B gives max. oil flow to port B

•

7.5 mm spool displacement in direction A gives completely open float position A/B → T

•

Characteristic of oil flow, spool travel and voltage

22 11051935 • Rev AE • Feb 2014

Page 23

Pressure drop A/B to T : PVBS 157B9414 &157B9434

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 087

Pressure drop A/B to T : PVBS 157B9413

0

5

10

15

20

25

30

35

40

45

50

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 088

Technical Information

PVG 32 AG Modules

Pressure drop characteristics

Pressure drop characteristics of float spools

A/B → T at max. spool travel 5.5 mm (A or B) or 7.5 mm float position. Shown curves are typical average

values of return pressure drops on 1. Position in a PVBZ module (157B5957) to the T-port (M27) on a PVPV

inlet.

Pressure drop A/B → T characteristic for PVBS: 157B9414 and 157B9434

Pressure drop A/B → T characteristic for PVBS: 157B9413

11051935 • Rev AE • Feb 2014 23

Page 24

Pressure drop A/B to T : PVBS 157B9642

0

5

10

15

20

25

30

35

40

45

50

55

60

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 089

Pressure drop A/B to T : PVBS 157B9411

0

5

10

15

20

25

0 10 20 30 40 50 60 70 80

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 090

Technical Information PVG 32 AG Modules

Pressure drop characteristics

Pressure drop A/B → T characteristic for PVBS: 157B9642

Pressure drop A/B → T characteristic for PVBS: 157B9411

24 11051935 • Rev AE • Feb 2014

Page 25

Pressure drop A/B to T : PVBS 157B9410

0

5

10

15

20

25

0 10 20 30 40 50 60

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 091

Pressure drop A/B to T : PVBS 157B9415

0

5

10

15

20

25

30

35

40

45

50

04030

2

010

Q (A/B) [l/min]

Pressure drop A/B - T [bar]

A → T (5.5 mm)

A → T (float)

B → T (5.5 mm)

B → T (float)

P301 092

Technical Information

PVG 32 AG Modules

Pressure drop characteristics

Pressure drop A/B → T characteristic for PVBS: 157B9410

Pressure drop A/B → T characteristic for PVBS: 157B9415

11051935 • Rev AE • Feb 2014 25

Page 26

0.50 0.55 0.60 0.65 0.70 0.75

U

s

U

DC

PVE

3/3 spools for PVBZ-HS

Characteristics; Oil flow, spool travel and voltage

0 1 2 3 4 5 6 7

Spool travel

Flow /l/min)

P301 093

mm

0

20

40

60

80

100

120

50 L _11023550

75 L _11023551

100L _11023552

Pressure drop B to T: PVBS 11023550, 11023551 & 11023552

0

20

40

60

80

100

120

0 10 20 30 40 50 60 70 80 90 100 110

Q (B) [l/min]

Pressure drop B - T [bar]

B → T (7 mm)

50 L _11023550

B → T (7 mm)

75 L _11023551

B → T (7 mm)

100L _11023551

P301 097

Technical Information

PVG 32 AG Modules

Pressure drop characteristics

Single acting spools characteristics for PVBZ-HS

3/3 spools characteristic for PVBZ-HS 157B9411 Oil flow, spool travel and voltage

B → T at max. spool travel 7.0 mm. Shown curves are typical average values of return pressure drops on 1.

Position in a PVBZ_HS module to the T-port (M27) on a PVPV inlet.

Pressure drop characteristic in lower mode position, max. spool travel

Pressure drop B → T characteristic for PVBS 111023550, 111023551 and 111023552

26 11051935 • Rev AE • Feb 2014

Spools characteristics for PVBZ-HD

Normally float spools as for PVBZ basic modules are recommended for the PVBZ-HD solution. See

Activation characteristics.

Pressure drop characteristics for the PVBZ-HD valve are shown in the following example using a 100l float

spool code no.: 157B9414 at the respective spool travel and multi-valve mode position.

Page 27

Pressure drop B to T - PVBS 157B9414

PVBZ-HD Double acting mode

0

5

10

15

20

25

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (B) [l/min]

Pressure drop B - T [bar]

B → T (5.5 mm)

P301 098

Pressure drop A to T - PVBS 157B9414

PVBZ-HD Double acting mode

0

5

10

15

20

25

30

35

40

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (A) [l/min]

Pressure drop A - T [bar]

A → T (5.5 mm)

A → T (float)

P301 099

Technical Information PVG 32 AG Modules

Pressure drop characteristics

Shown curves are typical average values of return pressure drops on 1. Position in a PVBZ-HD module to

the T-port (M27) on a PVPV inlet.

Pressure drop B → T characteristic for PVBS 157B9414; PVBZ-HD double acting mode

Pressure drop A → T characteristic for PVBS 157B9414; PVBZ-HD double acting mode

11051935 • Rev AE • Feb 2014 27

Page 28

Pressure drop A to T

PVBZ-HD Single acting mode

0

10

20

30

40

50

60

70

80

90

100

110

120

0 10 20 30 40 50 60 70 80 90 100 110 120

Q (A) [l/min]

Pressure drop A - T [bar]

PVBS

independently

P301 100

Technical Information PVG 32 AG Modules

Pressure drop characteristics

Pressure drop A → T characteristic; PVBZ-HD single acting mode

28 11051935 • Rev AE • Feb 2014

Page 29

T

LS

P

T0

T2 P2

T02

A BA B

A

B

A1 B1A2 B2

A

B

PVPV

11003806

PVBZ-HD

11032961

11027604

PVBZ-PVBD

157B6958

157B1503

PVBZ

157B6957

PVBZ

157B6957

PVB

157B6850

PVS

157B2000

P301 077

Technical Information PVG 32 AG Modules

Dimensions and schematic examples

Drawings for 5-section group

Example of PVG 32: 5 sections valve group with 1 double acting hitch (PVBZ-HD), with 1 aux. valve

•

PVBZ with PVBD diverter valve slice, 2 aux. valves PVBZ and 1 aux. valve PVB.

To be supplied with LS variable piston pump.

•

PVED-CC with APM-JPT connector.

•

Example of PVG 32: 5 sections valve group with 1 double acting hitch (PVBZ-HD), with 1 PVBZ with PVBD diverter, 2 PVBZ, 1 PVB

11051935 • Rev AE • Feb 2014 29

Page 30

34

19,5

69,3

46

23

68

89,6

62

336

35

33,5

125,5

95

12

12

36

37,5

48

172

172

38

95

302,6

34

38,5

140

48

X X

View

X-X

F

G

H

I

K

N

L

J

O

M

P

P301 076

Technical Information

PVG 32 AG Modules

Dimensions and schematic examples

Drawing for 5-section valve group

Drawings for 3-section group

F: Port T2; M14 x 1.5

G: Port T0; M14 x 1.5

H: Port LS; M14 x 1.5

I: Port T02; M14 x 1.5

J: PVB A and B port; M22 x 1.5

L: PVBZ A and B port; M22 x 1.5

M: Port P and T; M27 x 2.0

N: Port P2; M14 x 1.5

O: PVBZ-HD work port; M22 x 1.5

P: PVBD work port; 4 x M22 x 1.5

K: Fixing holes; M8 x min. 10

Example of PVG 32: 3 section valve group,with 1 htch single acting (PVBZ-HS) and 2 aux. valve slices.

•

To be supplied with LS variable piston pump.

•

PVED-CC with Deutsch DT connector.

•

30 11051935 • Rev AE • Feb 2014

Page 31

T

LS

P

T0

T2 P2

T02

A BA B

T B

PVPV

11003806

PVBZ

157B6957

PVBZ

157B6957

PVS

157B2000

PVBZ-HS

157B6968

P301 079

Technical Information PVG 32 AG Modules

Dimensions and schematic examples

Example of PVG 32: 3 sections valve group with 1 single acting hitch (PVBZ-HS) and 2 aux. valve slices.

11051935 • Rev AE • Feb 2014 31

Page 32

48

48

68

35

133,3

276

12

129,8

23

95

37,5

238

62

38,5

View

X-X

X X

H

G

K

J

F

I

L

M

N

P301 078

Technical Information

PVG 32 AG Modules

Dimensions and schematic examples

Drawing for 3-section valve group

Drawings for 2-section group

F: Port T2; M14 x 1.5

G: Port T0; M14 x 1.5

H: Port LS; M14 x 1.5

I: Port T02; M14 x 1.5

K: Fixing holes; M8 x min. 10

L: PVBZ-HS work port B and T; M22 x 1.5

M: Port P and T; M27 x 2.0

N: Port P2; M14 x 1.5

J: PVB A and B port; M22 x 1.5

PVG 32: 2 section valve group, typical example for Loader application for tractors.

•

To be supplied with fixed pump.

•

The PVP inlet has HPCO feature, consequently the PVT has tank port.

•

PVED-CC with APM-JPT connector.

•

32 11051935 • Rev AE • Feb 2014

Page 33

A B A B

M

HPCO P

LS

T0

PVEH PVEH

T

PVBZ

157B6957

PVST

11004462

PVBZ

157B6957

PVP

157B5961

P301 081

Technical Information PVG 32 AG Modules

Dimensions and schematic examples

Example of PVG 32: 2 section valve group, typical example for Loader application for tractors.

11051935 • Rev AE • Feb 2014 33

Page 34

View

X-X

X X

K

F

J

M

L

L

G

H

72,5

124,8

22,5

29

276

87,5

20,5

125,5

32

16

189

68

48

36,5

I

P301 080

Technical Information PVG 32 AG Modules

Dimensions and schematic examples

Drawing for 2-section valve group

F: Port T; M22 x 1.5

G: Port T0; M14 x 1.5

H: Port LS; M14 x 1.5

I: Port M gauge; M14 x 1.5

34 11051935 • Rev AE • Feb 2014

J: Port A and B; M22 x 1.5

K: Fixing holes; M8 x min. 10

L: Port P & HPCO; M27 x 2.0

M: Pressure relief valve

Page 35

Technical Information PVG 32 AG Modules

11051935 • Rev AE • Feb 2014 35

Page 36

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile off -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of off -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off -highway vehicles are at work, so is Danfoss.

We off er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions

(Shanghai) Co. Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we off er:

• Bent Axis Motors

• Closed Circuit Axial Piston

Pumps and Motors

• Displays

• Electrohydraulic Power

Steering

• Electrohydraulics

• Hydraulic Power Steering

• Integrated Systems

• Joysticks and Control

Handles

• Microcontrollers and

Software

• Open Circuit Axial Piston

Pumps

• Orbital Motors

• PLUS+1® GUIDE

• Proportional Valves

• Sensors

• Steering

• Transit Mixer Drives

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11051935 • Rev AE • Feb 2014 www.danfoss.com

©

Danfoss A/S, 2014

Loading...

Loading...