Technical Information

Proportional Valve Group

PVG 32 miniBOOSTER

www.danfoss.com

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

Revision history Table of revisions

Date Changed Rev

November 2018 Updated schematics 0301

February 2018 Add new modules 0201

August 2015 Drawing updated 00.04

February 2014 Converted to Danfoss layout – DITA CMS AD

Oct 2010 - June 2013 Various changes AB-AC

June 2002 New Edition AA

2 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

Contents

General Information

PVG 32 miniBOOSTER..................................................................................................................................................................... 4

HC3-PVG32 miniBOOSTER

Technical data....................................................................................................................................................................................5

Flow rates and intensification factor.........................................................................................................................................5

Function...............................................................................................................................................................................................6

Ordering...............................................................................................................................................................................................7

M-HC-010

Technical data....................................................................................................................................................................................8

Intensification factors......................................................................................................................................................................8

Function............................................................................................................................................................................................ 10

Ordering............................................................................................................................................................................................ 10

M-HC-011

Technical data................................................................................................................................................................................. 11

Intensification factors...................................................................................................................................................................12

Function............................................................................................................................................................................................ 13

Ordering............................................................................................................................................................................................ 13

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 3

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

General Information

PVG 32 miniBOOSTER

The PVG miniBOOSTER raises the hydraulic pressure from the pump to the workload. It is ideal when you

need an extra high outlet pressure, either constantly or temporarily.

The PVG miniBOOSTER is typically used in mobile attachments, cranes, off highway equipment, injection

molding machines and hydraulic presses. It is applicable to machines with insufficient pump capacity to

prevent machine stoppage when peak pressures occur.

The PVG miniBOOSTER comes in the following three main variants:

HC3-PVG

•

M-HC-010

•

M-HC-011

•

All ordering, inquiries, technical support etc. of the miniBOOSTER products must be directed to

miniBOOSTER Hydraulics A/S. For further information and contact details please visit the miniBOOSTER

website. https://www.minibooster.com

4 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

Ă

50

G1/4"

110

28,6

178,2

5

156

64

8

44

72,5

46

37,5

39,3

16,5

35,5

105

17,5

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

HC3-PVG32 miniBOOSTER

The HC3-PVG32 is a compact unit weighing only 4.0 kg. It is ideal for use in a variety of applications where

building up and maintaining high pressure is required. The HC3-PVG32 raises supplied pressure to a

higher outlet pressure and automatically compensates for consumption of oil to maintain the high

pressure. Adjustment of the outlet pressure is carried out by varying the supplied pressure.

Dimensions in mm

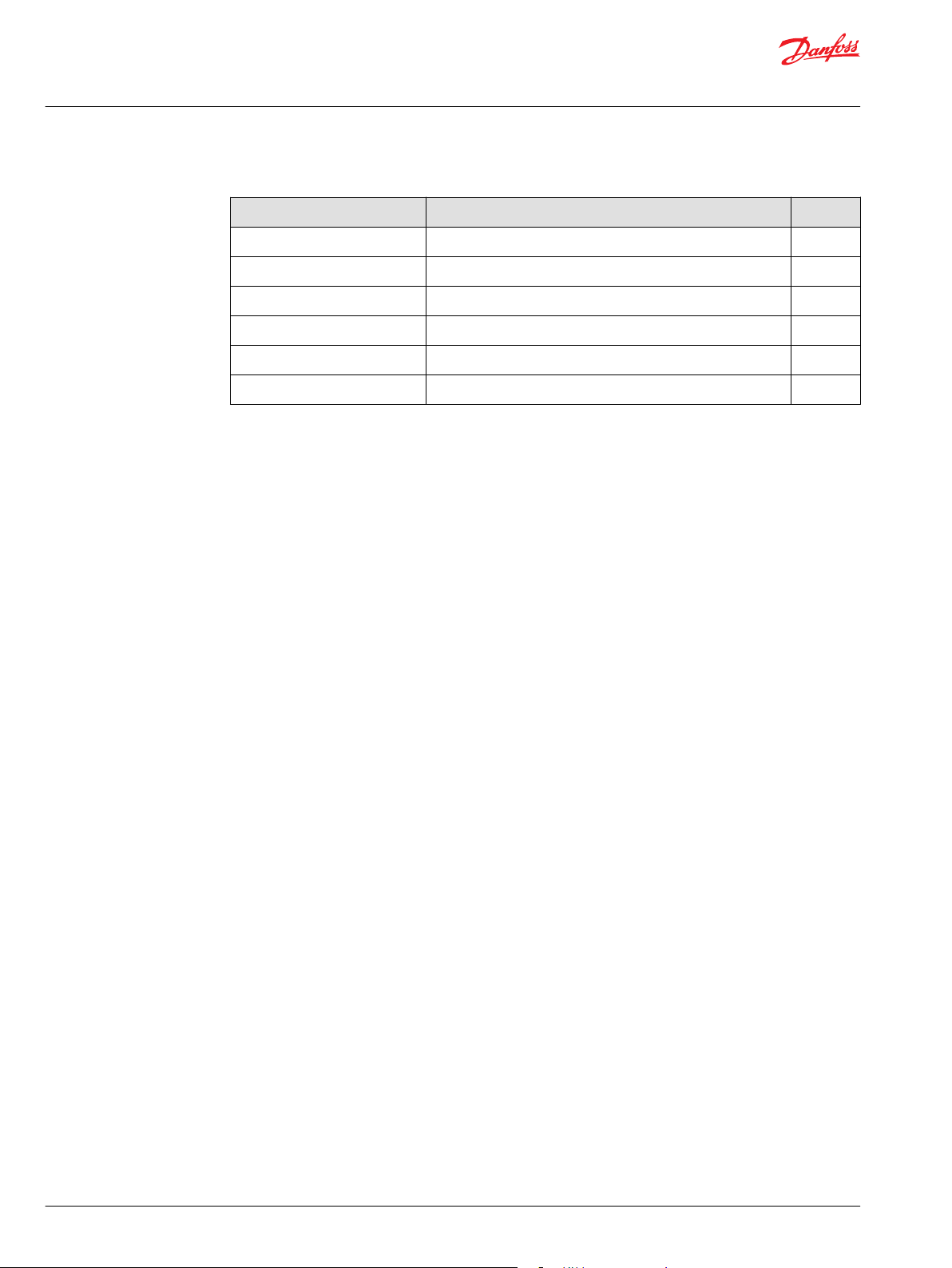

Technical data

Flow rates and intensification factor

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 5

Operating parameters

Inlet pressure range

Maximum outlet pressure

Intensification factor; i Average outlet flow l/min [US gal/

min]

1.2 1.2 [0.264] 8.0 [1.76]

1.5 1.0 [0.220] 8.0 [1.76]

2.0 0.8 [176] 8.0 [1.76]

2.8 0.6 [132] 8.0 [1.76]

3.2 2.5 [0.550] 15.0 [3.30]

4.0 2.0 [0.440] 14.0 [3.08]

5.0 1.6 [0.352] 14.0 [3.08]

20 – 200 bar [290 - 2900 psi]

800 bar [11 603 psi]

Maximum inlet flow l/min [US gal/

min]

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

HC3-PVG32 miniBOOSTER

6.6 1.3 [0.286] 13.0 [2.86]

9.0 0.9 [198] 13.0 [2.86]

13.0 0.6 [132] 12.0 [2.64]

20.0 0.3 [066] 12.0 [2.64]

Function

The basic operation is illustrated in the function diagram. Oil is fed through the proportional valve PVG32

to the IN port in the HC3-PVG, flowing freely through the check valves KV1, KV2 and DV to the high

pressure side HP. In this condition maximum flow through the booster is achieved giving a fast forward

function.

When pump pressure is reached on the high pressure side HP, valves KV1, KV2 and DV will close. The end

pressure will be achieved by the oscillating pump unit OP. The unit will automatically stall when end

pressure on high pressure side HP is reached. If there is a pressure drop on the high pressure side due to

consumption or leakage, the OP valve will automatically operate to maintain the end pressure. Pressure

can be relieved from the high pressure side HP through the pilot operated check valve DV. By connecting

port R to the supply pressure and port IN to tank, allowing the fluid from the high pressure side HP to

flow back to tank.

6 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

A

157B6849

B

R

IN

KV2

KV1

DV

R

IN

A

B

OP

A

HP

LP

HC3-PVG32

Low pressure

High pressure

157B7000

LS

T

P

M

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

HC3-PVG32 miniBOOSTER

Schematic

Ordering

The following part numbers are for the parts you have to order through Danfoss Power Solutions. To do

so, please contact your Danfoss Power Solutions sales representative.

Part Number Type

157B6849 PVG 32: PVB basic module

157B7000 Spool flow 10 l/min [2.6 US gal/min]

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 7

www.minibooster.com/products/boosters-oil/hc3-pvg32.html )

For further details on the miniBOOSTER HC3-PVG and to order it, click here (link to https://

5,3

179,9

116,7

110

55

48,5

43,6

31,5

19

105

72,5

64

46

16

37,5

16,5

36

72

60

90

173,6

5

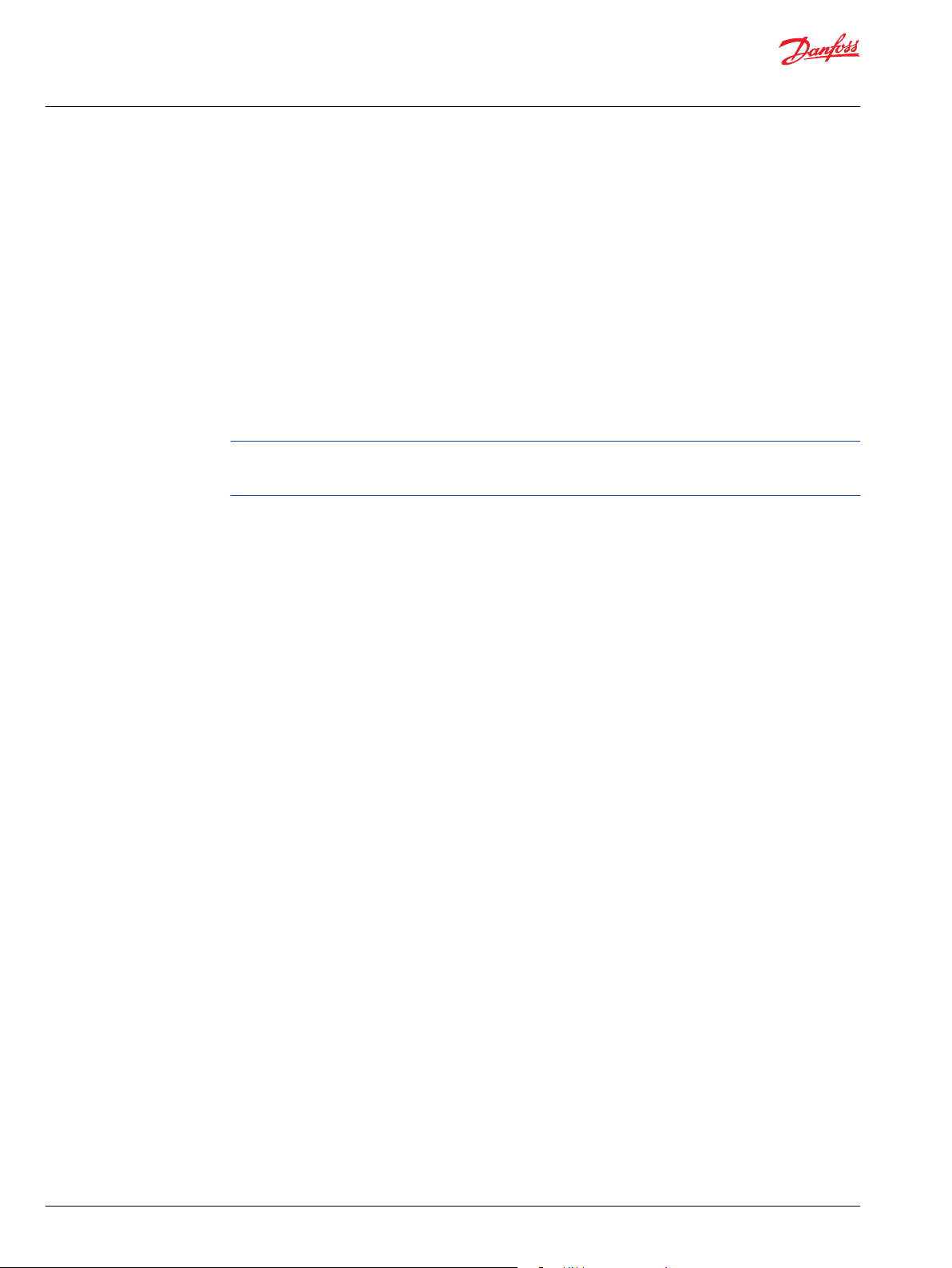

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-010

The M-HC-010 In-line Intensifier System is designed to boost the hydraulic pressure from the pump to the

workload. The system operates by solenoid activation. The operator is in full control of the system and

can decide if a boosted pressure to the workload should be applied.

The system is dynamical by means of being able to provide flow at high pressure for intermittent use (<

10 min duty cycle).

A relief valve is installed to control the maximum allowable pressure that the system can output, and

allowing the booster to go for a higher end pressure producing flow at the decided pressure.

Dimensions in mm

Technical data

Operating parameters

Inlet pressure range 20-207 bar [290-3000 psi]

Maximum outlet pressure 700 bar [11603 psi]

Bypass flow 100 l/min [26 US gal/min]

Intensification factors

8 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

HC2D HC3

1.6 1.5

1.9 2.0

2.2 2.8

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-010

2.6 3.2

3.2 4.0

4.0 5.0

5.0 6.6

6.6 9.0

9.0 -

The intensification factor depends on available inlet and desired outlet pressure. To calculate the initial

factor, use the following formula:

i = Desired high pressure / pump pressure

Desired pressure: 500 bar

Pump pressure: 200 bar

i = 500 / 200 = 2.5

For static use: Select an intensification factor higher or equal to the calculated value. In this case i = 2.8

with HC3 booster. The desired pressure of 500 bar is finally adjusted with the HP relief valve.

For dynamic use: Select an intensification factor 60% higher than the calculated value. In this case i =

500 / 200 = 2.5 + 60% = 4.0 The desired pressure of 500 bar is finally adjusted with the HP relief valve.

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 9

A

M-HC-010

B

LS

T

P

M

157B7000

H

P

T

1

3

1: Directional Valve

3: Relief Valve

2: Pilot Operated Check Valve

4: Check Valve

2

Z

4

4

Port details:

P: Flow from pump.

A or B port on directional valve.

T: Flow to tank.

A or B port on directional valve.

H: High pressure port to cylinder.

Z: Low pressure port to cylinder.

M

IN

R

H

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-010

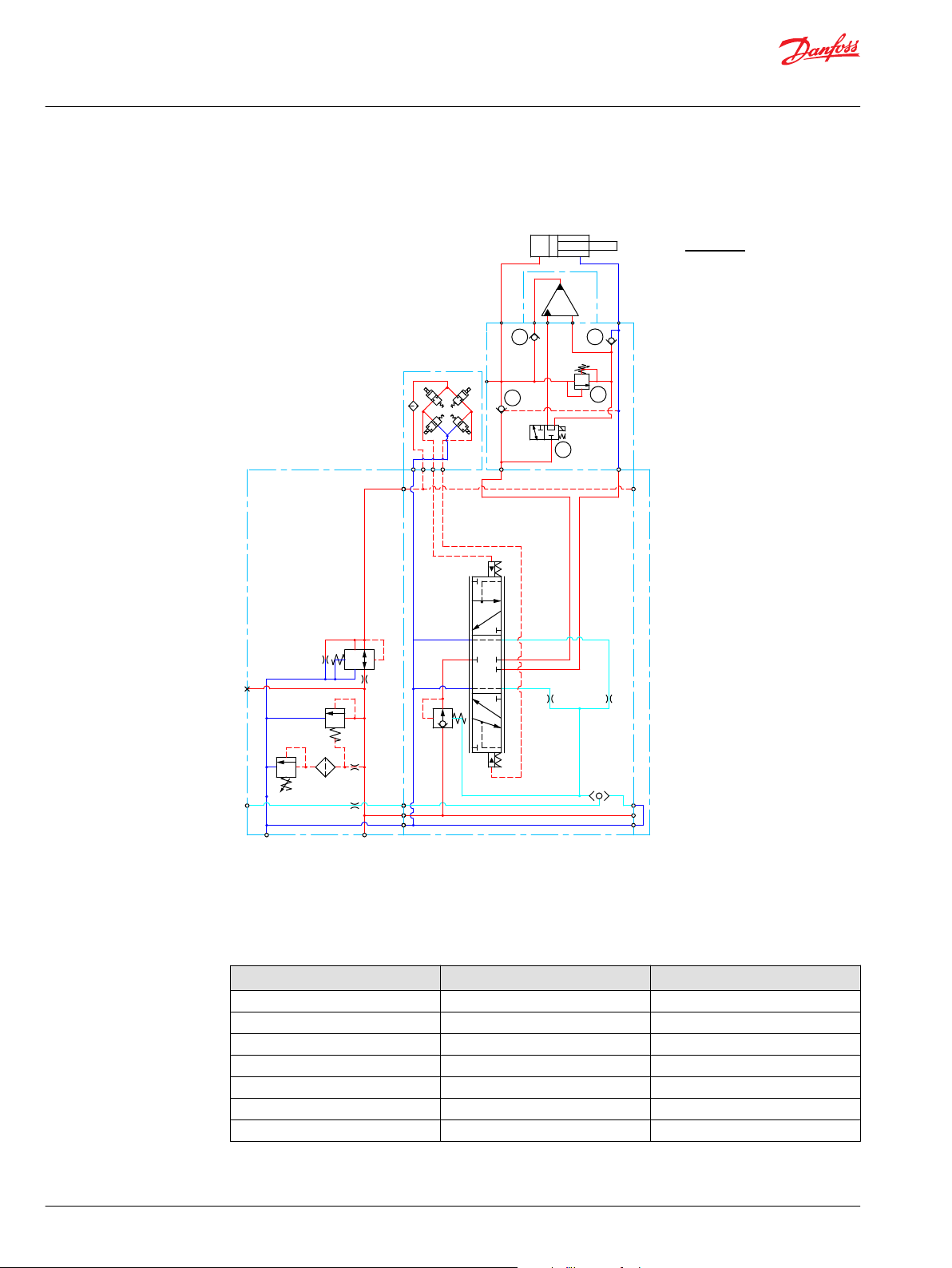

Function

Schematic

Ordering

The following part numbers are for the parts you have to order through Danfoss Power Solutions. To do

so, please contact your Danfoss Power Solutions sales representative.

Part Number Type Flow l/min [US gal/min]

157B6849 PVG 32: PVB basic module

157B7005 Spool 5 [1.3]

157B7000 Spool 10 [2.6]

157B7001 Spool 25 [6.6]

157B7002 Spool 40 [10.6]

157B7003 Spool 65 [1732]

157B7004 Spool 100 [26.4]

For further details on the miniBOOSTER M-HC-010 PVG and to order it, click here (link to https://

www.minibooster.com/products/intensifier-systems-2/m-hc-010.html )

10 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

5,3

116,7

110

72

36

16

105

37,5

72,5

19

46

64

5

48,5

16,5

55

31,5

43,6

205,6

90

60

242,6

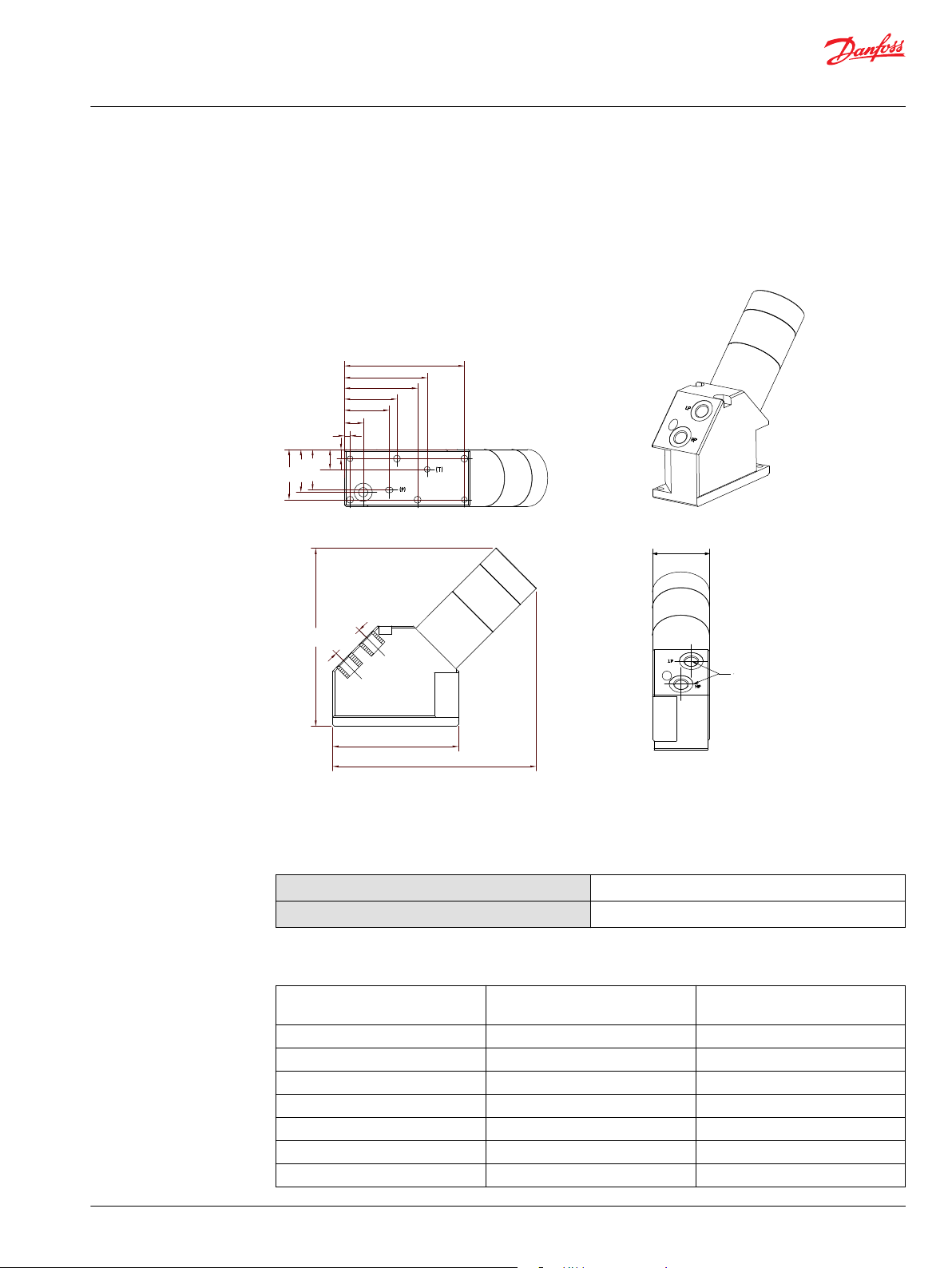

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-011

The M-HC-011 In-line Intensifier System is designed to boost the hydraulic pressure from the pump to the

workload. It operates only when needed, to save energy.

The system is dynamical by means of being able to provide flow at high pressure for intermittent use (<

10 min duty cycle).

The hydraulic oil is by-passed directly from the pump to the workload at maximum flow when back

pressure from the workload has reached a set point close to the maximum pressure of pump.

A sequence valve opens and directs the oil to the booster, which makes the pressure rise. The shift

between maximum pump pressure and high pressure happens without intervention from the user and

ensures that the workload at all times will be driven at a maximum speed in relation to the required high

pressure.

A relief valve is installed to control the maximum allowable pressure that the system can output, and

allowing the booster to go for a higher end pressure producing flow at the decided pressure.

Dimensions in mm

This is the dimensional drawings for the M-HC2D-011-FL100-PVG32. For the dimensional drawings for the

M-HC3-011-FL100-PVG32, click here (https://www.minibooster.com/fileadmin/user_upload/PDF/m-

hc_-011/M-HC3-011-FL100-PVG32-00._Assembly_drawing_01.pdf )

Technical data

Operating parameters

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 11

Inlet pressure range 20-207 bar [290-3000 psi]

Maximum outlet pressure 700 bar [11603 psi]

Bypass flow 100 l/min [26 US gal/min]

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-011

Intensification factors

HC2D HC3

1.6 1.5

1.9 2.0

2.2 2.8

2.6 3.2

3.2 4.0

4.0 5.0

5.0 6.6

6.6 9.0

9.0 -

The intensification factor depends on available inlet and desired outlet pressure. To calculate the initial

factor, use the following formula:

i = Desired high pressure / pump pressure

Desired pressure: 500 bar

Pump pressure: 200 bar

i = 500 / 200 = 2.5

For static use: Select an intensification factor higher or equal to the calculated value. In this case i = 2.8

with HC3 booster. The desired pressure of 500 bar is finally adjusted with the HP relief valve.

For dynamic use: Select an intensification factor 60% higher than the calculated value. In this case i =

500 / 200 = 2.5 + 60% = 4.0 The desired pressure of 500 bar is finally adjusted with the HP relief valve.

12 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

A

M-HC-011

B

LS

T

P

M

157B7000

1: Sequence Valve

3: Relief Valve

2: Pilot Operated Check Valve

4: Check Valve

Port details:

P: Flow from pump.

A or B port on directional valve.

T: Flow to tank.

A or B port on directional valve.

H: High pressure port to cylinder.

Z: Low pressure port to cylinder.

IN

R

H

H

P

T

1

3

2

Z

4

4

M

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

M-HC-011

Function

Schematic

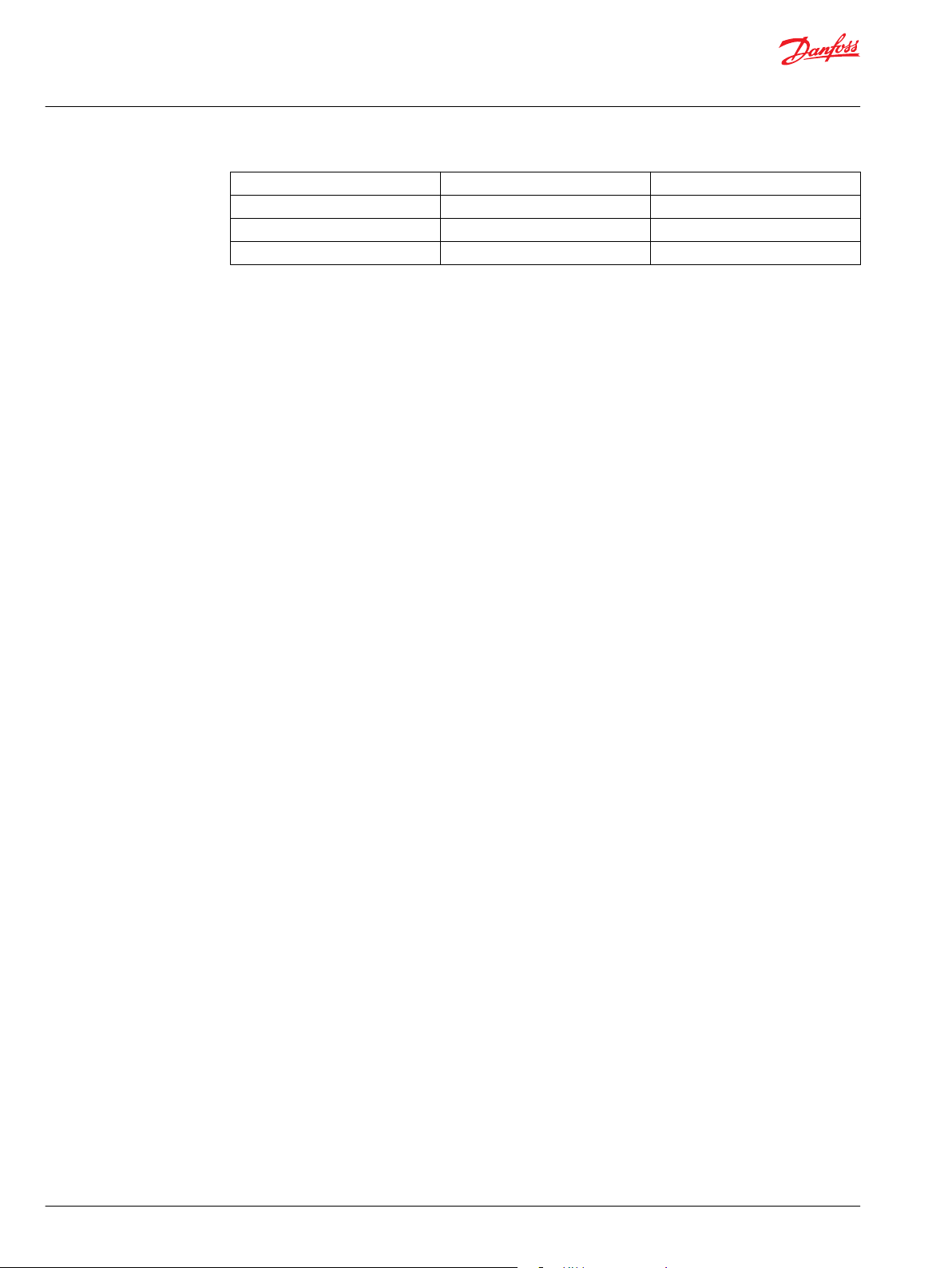

Ordering

The following part numbers are for the parts you have to order through Danfoss Power Solutions. To do

so, please contact your Danfoss Power Solutions sales representative.

Part Number Type Flow l/min [US gal/min]

157B6849 PVG 32: PVB basic module

157B7005 Spool 5 [1.3]

157B7000 Spool 10 [2.6]

157B7001 Spool 25 [6.6]

157B7002 Spool 40 [10.6]

157B7003 Spool 65 [1732]

157B7004 Spool 100 [26.4]

For further details on the miniBOOSTER M-HC-011 PVG and to order it, click here (link to https://

www.minibooster.com/products/intensifier-systems-2/m-hc-011.html )

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 13

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

14 | © Danfoss | November 2018 520L0543 | BC00000103en-000301

Technical Information

PVG 32 Proportional Valve Group miniBOOSTER

©

Danfoss | November 2018 520L0543 | BC00000103en-000301 | 15

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | November 2018 520L0543 | BC00000103en-000301

Loading...

Loading...