Page 1

Application Guide

PVG 32

Improve stability in open center systems

by reducing pressure spikes

powersolutions.danfoss.com

Page 2

Application Guide

Improve stability in open center systems by reducing pressure spikes

Revision history Table of revisions

Date Changed Rev

Feb 2017 First edition 0101

2 | © Danfoss | Feb 2017 AB00000078en-US0101

Page 3

W

C

Application Guide

Improve stability in open center systems by reducing pressure spikes

About this document

References

Related literature: PVG 32 Proportional Valve Group Technical Information, 520L0344, BC00000038

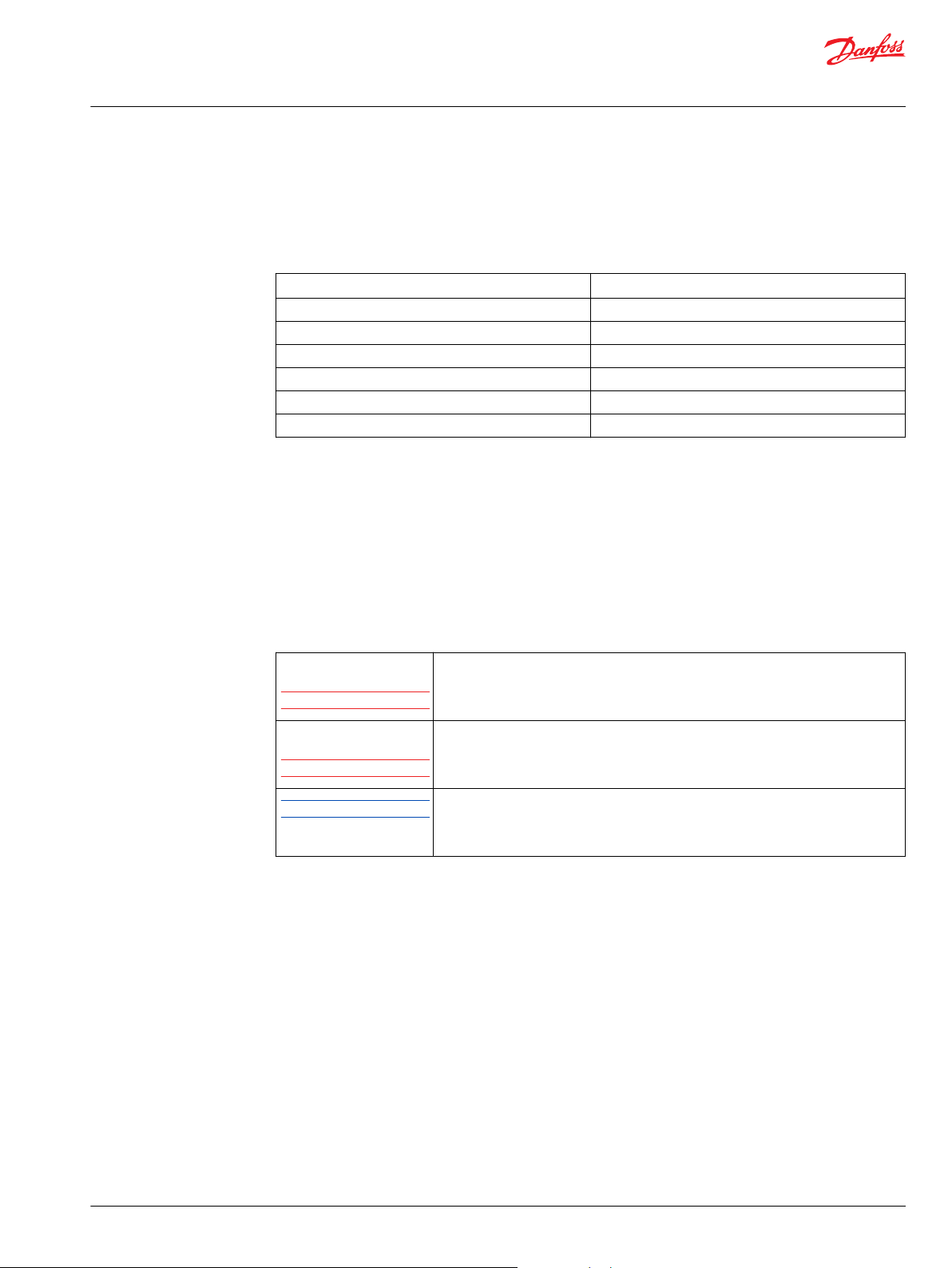

Terms and definitions

Term Definition

OC Open Center

Important user information

P

LS

PVE Proportional Valve Electrohydraulic actuator

PVG Proportional Valve Group

PVP Proportional Valve Pump side module

T0 Low Pressure Tank Line

Danfoss is not responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included for illustration purposes. Due to the many

variables and requirements associated with any particular installation, Danfoss cannot assume

responsibility or liability for the actual used bases on the examples and diagrams.

Reproduction of whole or part of the contents of this manual is prohibited.

The following notes are used to raise awareness of safety considerations.

Load Sense Pressure

Xxxxx

Xxxx

Note

Warning

Caution

Identifies information about practices or circumstances that can cause a hazardous

situation, which may lead to personal injury or death, damage or economic loss.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequence

Identifies information that is critical for successful application and understanding of the

product.

Identifies a typical use of a functionality or parameter value. Use recommendations as a

starting point for the final configuration process of the system.

©

Danfoss | Feb 2017 AB00000078en-US0101 | 3

Page 4

Application Guide

Improve stability in open center systems by reducing pressure spikes

Application overview

When using a small orifice in the load sense line within an open center (OC) system, there will be rapid

changes from high pressure to low pressure in the load sense signal due to the quick return of the main

spool to its neutral position.

In this document you can read about the difference of using a small orifice in the load sense line and

using a combined orifice and check valve. The purpose is to show why and how using the combined

orifice and check valve can lead to reduced pressure peaks and thereby improved stability.

4 | © Danfoss | Feb 2017 AB00000078en-US0101

Page 5

Application Guide

Improve stability in open center systems by reducing pressure spikes

Explanation of the rapid pressure drop

When you are using a PVG valve together with a fixed displacement pump, the pump module is

configured to run in an open center mode. This means that the pressure adjustment spool leads the flow

across to a tank connection that determines the pump stand-by pressure when no work sections are

actuated. When pressure is needed at a work section to perform a task, this tank connection is partially or

fully closed by the internal load sense network.

The force of the neutral adjustment spring causes the main spool of a working section to quickly return to

its neutral position. This causes the load sense signal to rapidly switch from high pressure to low pressure.

When the load sense signal changes the pressure adjustment spool in the PVG inlet module, the spool

must return to neutral and the tank connection will then reopen and relieve the pressure. The fast

change in the load sense signal will create a pressure peak. This peak is especially undesirable when using

a PVE in a valve stack that is not configured with T0.

These pressure peaks in the tank line can be reduced by replacing the small orifice in the load sense line

from the work sections with a combined orifice and check valve as seen in the following figure.

Combined orifice and check valve

Comparison of modules on page 6 shows a module with small orifice and a module with combined

orifice and check valve.

©

Danfoss | Feb 2017 AB00000078en-US0101 | 5

Page 6

Application Guide

Improve stability in open center systems by reducing pressure spikes

Explanation of the rapid pressure drop

Comparison of modules

Left schematic Default OC PVP with orifice

Right schematic Special OC PVP with combined orifice and check valve

6 | © Danfoss | Feb 2017 AB00000078en-US0101

Page 7

Application Guide

Improve stability in open center systems by reducing pressure spikes

Pressure drop comparison

In a module with a small orifice, the load sense signal will be relieved to tank in approximately 150 ms

through the Ø1-mm orifice when the work sections are moved to neutral position.

In a module with a combined orifice and check valve, the load sense signal will be relieved to tank in

approximately 350 ms through the combined check valve and Ø1-mm orifice.

See the following comparison of the pressure drop in the two different modules.

Pressure drop comparison

A Pressure (bar)

B Time (seconds)

C PLS orifice only

D PLS orifice and check valve

When the time to relieve the load sense signal to tank is increased, there will also be an increased

possibility that pressure peaks will be created in the pump line.

This scenario is especially important to consider if the valve uses full pump flow, and if the valve is not

ramped back to neutral but shifts suddenly due to the force of the neutral adjustment spring in the main

spool.

In addition, you should consider whether the connection leaves enough flexibility to absorb the pressure

peaks. For example, there might not be enough flexibility if you use a rigid connection between the

pump and P-port of the pump module, or if you place the valve stack close to the pump with a very small

connection of any sort. As a result, the pressure peaks will be transferred to the pump and possibly

increase wear.

Our recommendation is to use a relatively long hose connection between the pump and the P-port of the

pump module. The flexibility of this hose connection will absorb the pressure peaks.

©

Danfoss | Feb 2017 AB00000078en-US0101 | 7

Page 8

Application Guide

Improve stability in open center systems by reducing pressure spikes

Summary

Using an open center inlet module with a combined orifice and check valve will increase the time it takes

to relieve the load sense pressure in the tank line. This will lead to reduced pressure peaks in the tank line.

However, this will also increase the possibility of pressure peaks in the pump line. But with a relatively

long hose connection between the pump and the P-port of the pump module, these pressure peaks will

be absorbed. Combining an open center inlet module with a combined orifice and check valve together

with a relatively long hose connection has been used to increase stability with great results.

For test purposes, you can acquire a combined check valve and orifice by ordering part number

155L5230.

8 | © Danfoss | Feb 2017 AB00000078en-US0101

Page 9

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | Feb 2017 AB00000078en-US0101

Loading...

Loading...