Danfoss PVG 16, PVG 16 PVP, PVG 16 PVS, PVG 16 PVH/Covers, PVG 16 PVHC Technical Information

...Page 1

Technical Information

PVG 16

Proportional Valve Group

www.danfoss.com

Page 2

Technical Information

PVG 16 Proportional Valve Group

Revision history Table of revisions

Date Changed Rev

December 2018 Major rework of document: new sections added, data corrected. 0901

October 2018 'PVBS Main Spools' section reworked. 'Safety in Systems' and 'PVB Basic Modules

Accessories' sections added.

August 2018 Minor update - part number typo corrected 0702

May 2018 Major update. 0701

April 2018 Minor change for PVEA. 0602

January 2018 Major update. 0601

July 2017 Major update. 0501

February 2017 Major update. 0401

March 2016 Minor update in PVHC technical characteristics 0303

March 2016 Updated to Engineering Tomorrow design. 0302

February 2016 Drawing was updated in topic: How to select the correct spool 0301

September 2015 PVG 16 Step II 0200

Feb. 2013-Mar. 2015 Major layout revision, drawings change BA-BF

October 2012 New Edition AA

0801

2 | © Danfoss | December 2018 BC00000211en-000901

Page 3

Technical Information

PVG 16 Proportional Valve Group

Contents

General Information

General Description.........................................................................................................................................................................5

PVG 16 Features................................................................................................................................................................................ 5

Safety in Systems..............................................................................................................................................................................6

PVG 16 Modules Overview............................................................................................................................................................8

PVP Inlet Modules

Open Center PVP............................................................................................................................................................................10

Open Center PVP with PPRV...................................................................................................................................................... 13

Open center PVP with HPCO and PVE PPRV.........................................................................................................................17

Closed Center PVP......................................................................................................................................................................... 20

Closed Center PVP with PPRV....................................................................................................................................................22

Closed center PVPV with PPRV..................................................................................................................................................25

Closed center PVPVM with PPRV..............................................................................................................................................27

Open/Closed center PVP with PPRV........................................................................................................................................29

Open/Closed center PVPM......................................................................................................................................................... 32

PVP Inlet Module Accessories

PVPX Electrical LS Pressure Unloading Valve.......................................................................................................................33

Part numbers for PVPX............................................................................................................................................................34

PVPC without Check Valve..........................................................................................................................................................36

PVPC with Check Valve................................................................................................................................................................ 37

PVB Basic Modules

Compensated PVB.........................................................................................................................................................................39

Compensated PVB with PVLP/PVLA........................................................................................................................................42

Compensated PVB with LS A/B................................................................................................................................................. 46

Uncompensated PVB....................................................................................................................................................................50

Uncompensated PVB with PVLP...............................................................................................................................................53

PVLP Shock and Anti-Cavitation Valve...................................................................................................................................56

PVB Basic Modules Accessories

PVLP Shock and Anti-Cavitation Valve...................................................................................................................................59

PVLA Suction Valve........................................................................................................................................................................61

PVBS Main Spools

PVBS Fluid Flow Characteristics - Theoretical Performance...........................................................................................63

PVBS Main Spools Part Numbers

Flow Control Spools - Closed Neutral Position....................................................................................................................66

Flow Control Spools - Throttled Open Neutral Position.................................................................................................. 67

Flow Control Spools - Open/Closed Neutral Position.......................................................................................................68

PVG 16 Actuation

PVM Manual Actuation................................................................................................................................................................ 69

PVMD Cover................................................................................................................................................................................70

PVH Hydraulic Actuation.............................................................................................................................................................71

PVHC Electro-Hydraulic Actuation...........................................................................................................................................73

PVE Electro-hydraulic Actuation...............................................................................................................................................75

PVEO................................................................................................................................................................................................... 77

PVEO Technical Data............................................................................................................................................................... 79

PVEA Series 6 Proportional Control Actuator...................................................................................................................... 80

PVEA Technical Data................................................................................................................................................................81

PVG 16 connector variants......................................................................................................................................................... 83

Fault Monitoring and Reaction

Generic Fault Reaction.................................................................................................................................................................84

Fault Reaction Overview..............................................................................................................................................................85

PVS End Plates

PVS/PVSI ........................................................................................................................................................................................... 87

PVS/PVSI with LX-connection....................................................................................................................................................88

PVSI with P-, T-, LX- and M-connection..................................................................................................................................90

©

Danfoss | December 2018 BC00000211en-000901 | 3

Page 4

Technical Information

PVG 16 Proportional Valve Group

Contents

PVST with T-connection...............................................................................................................................................................91

PVAS Stay Bolts

PVAS Part Numbers.......................................................................................................................................................................93

PVG 16 modules total length and weight.............................................................................................................................93

PVG 32/16 Combinations............................................................................................................................................................94

PVG 256/128/32/16 Combinations..........................................................................................................................................95

PVG 16 Combinations Valve Stack Dimensions

PVG 16 Dimensions....................................................................................................................................................................... 97

PVG 32/16 Dimensions.................................................................................................................................................................98

PVG 100/16 Dimensions............................................................................................................................................................100

PVG 120/16 Dimensions............................................................................................................................................................102

PVG 128/16 Dimensions............................................................................................................................................................104

PVG 256/16 Dimensions............................................................................................................................................................106

PVG 16 Applications Schematics

PVG 16 Schematic with Basic End Plate...............................................................................................................................108

PVG 16 with P- and T-connection end plate......................................................................................................................109

4 | © Danfoss | December 2018 BC00000211en-000901

Page 5

Technical Information

PVG 16 Proportional Valve Group

General Information

General Description

PVG is a hydraulic, load-sensing proportional valve, designed for optimal machine performance and

maximum design flexibility. The PVG valve design is based on a modular concept that enables machine

designers to specify a valve solution suitable for multiple market segments across multiple applications.

The PVG 16 is a member of the PVG product platform and interfaces to other valve families enabling all

machine functions being controlled from one single valve stack.

PVG 16 controls work port flow up to 65 l/min [17 US gal/min] l/min and up to 420 bar [6090 psi] bar work

port pressure.

The load independent proportional control valve and high performance actuator technology combined

with a low pressure drop design improves the machine performance and efficiency – increasing

productivity and reducing energy consumption.

PVG 16 Features

PVG load-sensing proportional valves features and benefits summarized in bullets below:

Load-independent flow control:

•

Oil flow to an individual function is independent of the load pressure of this function

‒

Oil flow to one function is independent of the load pressure of other functions

‒

Inlet flow up to 140 l/min [37 US gal/min] 230 l/min [61 US gal/min] when used with mid-inlet

•

Easy integration with PVG 32

•

Possible combination with the rest of the PVG family, when using an interface module

•

Up to 12 basic modules per PVG 16 valve group

•

Reliable regulation characteristics across the entire flow range

•

Load sense relief valves for A and B port enables reduced energy loss at target pressure

•

Several options for connection threads and flange mount

•

Compact design, easy installation and serviceability

•

©

Danfoss | December 2018 BC00000211en-000901 | 5

Page 6

W

Technical Information

PVG 16 Proportional Valve Group

General Information

Safety in Systems

All types and brands of control valves, including proportional valves, can fail. Therefore, the necessary

protection against the serious consequences of a functional failure should always be built into the

system.

General safety considerations

For each application an assessment should be made for the consequences of the system in case of

pressure failure and uncontrolled or blocked movements.

Warning

Because the proportional valve is used in many different applications and under different operating

conditions, it is the sole responsibility of the manufacturer to ensure that all performance, safety and

warning requirements of the application is met in his selection of products and complies with relevant

machine specific and generic standards.

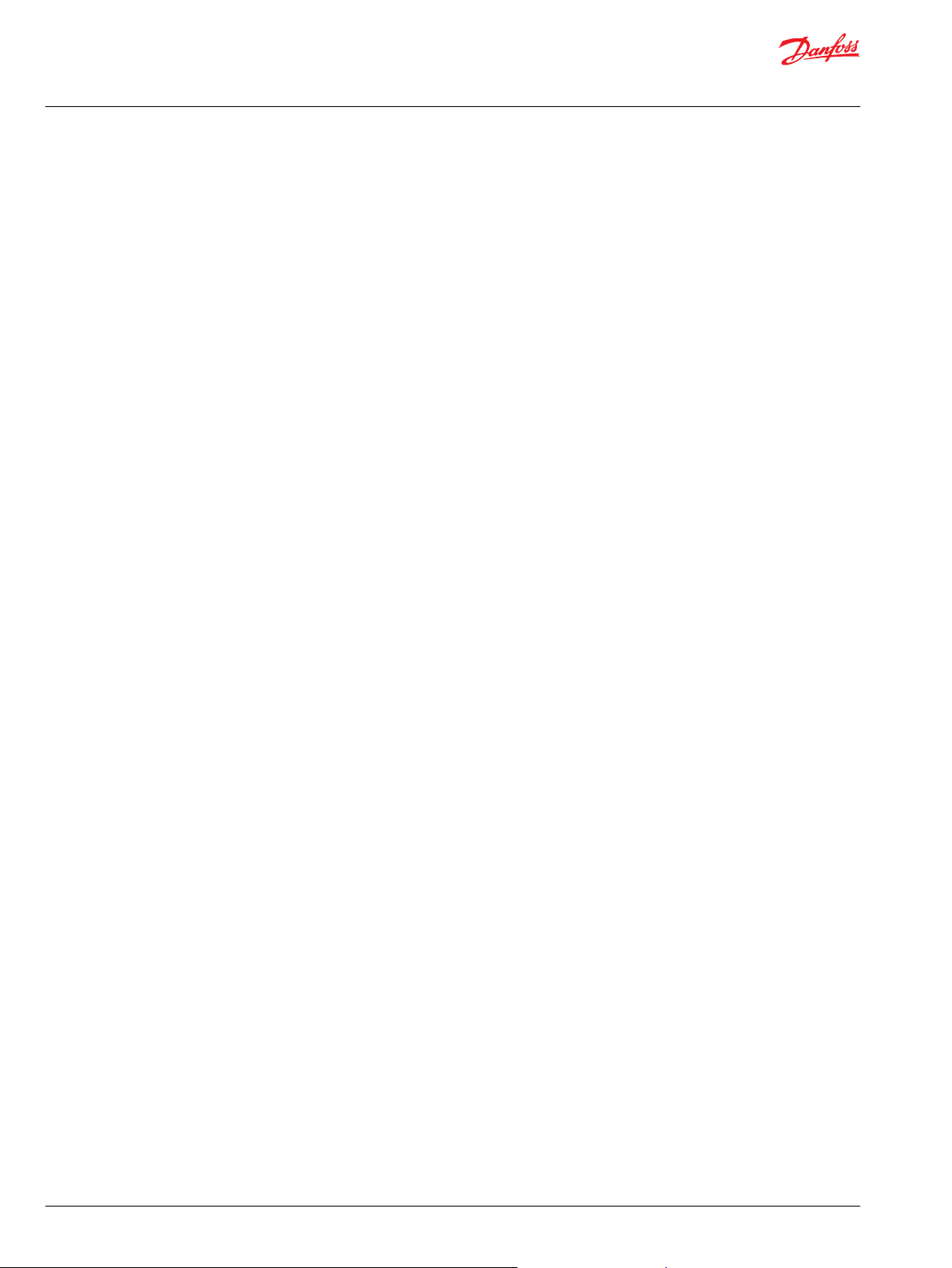

Control system example

An example of a control system using an aerial lift is shown below:

Aerial lift

This example breaks down the control system into smaller bits explaining the architecture in depth. Even

though many Danfoss components are used in the PVG control system.

The function of the control system is to use the output from the PVE together other external sensors to

ensure the PLUS+1 main controllers correct function of the aerial lift.

6 | © Danfoss | December 2018 BC00000211en-000901

Page 7

W

C

Technical Information

PVG 16 Proportional Valve Group

General Information

Electrical block diagram

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

Caution

A mix of electrical actuation and hydraulic actuation on the same valve stack is not safe. PVE and PVH are

designed for different pilot pressure.

Cost-free repairs, as mentioned in Danfoss General Conditions of Sale, are carried out only at Danfoss or

at service shops authorized by Danfoss.

©

Danfoss | December 2018 BC00000211en-000901 | 7

Page 8

PVM

PVP PVE

PVH/CoversPVBPVBS

PVS PVHC

PVAS

Technical Information

PVG 16 Proportional Valve Group

General Information

PVG 16 Modules Overview

PVG proportional valve group shown in the exploded view illustration for a quick modules navigation.

PVG 16 Modules Assembly Overview

PVG Modules Navigation:

PVP Inlet Modules on page 9

PVB Basic Modules on page 38

PVBS Main Spools on page 62

PVM Manual Actuation on page 69

PVE Electro-hydraulic Actuation on page 75

PVH Hydraulic Actuation on page 71

PVHC Electro-Hydraulic Actuation on page 73

PVS End Plates on page 86

PVAS Stay Bolts on page 92

8 | © Danfoss | December 2018 BC00000211en-000901

Page 9

112.5 [4.43]

110 [4.33]

95 [3.74]

23 [0.9]

48 [1.89]

Technical Information

PVG 16 Proportional Valve Group

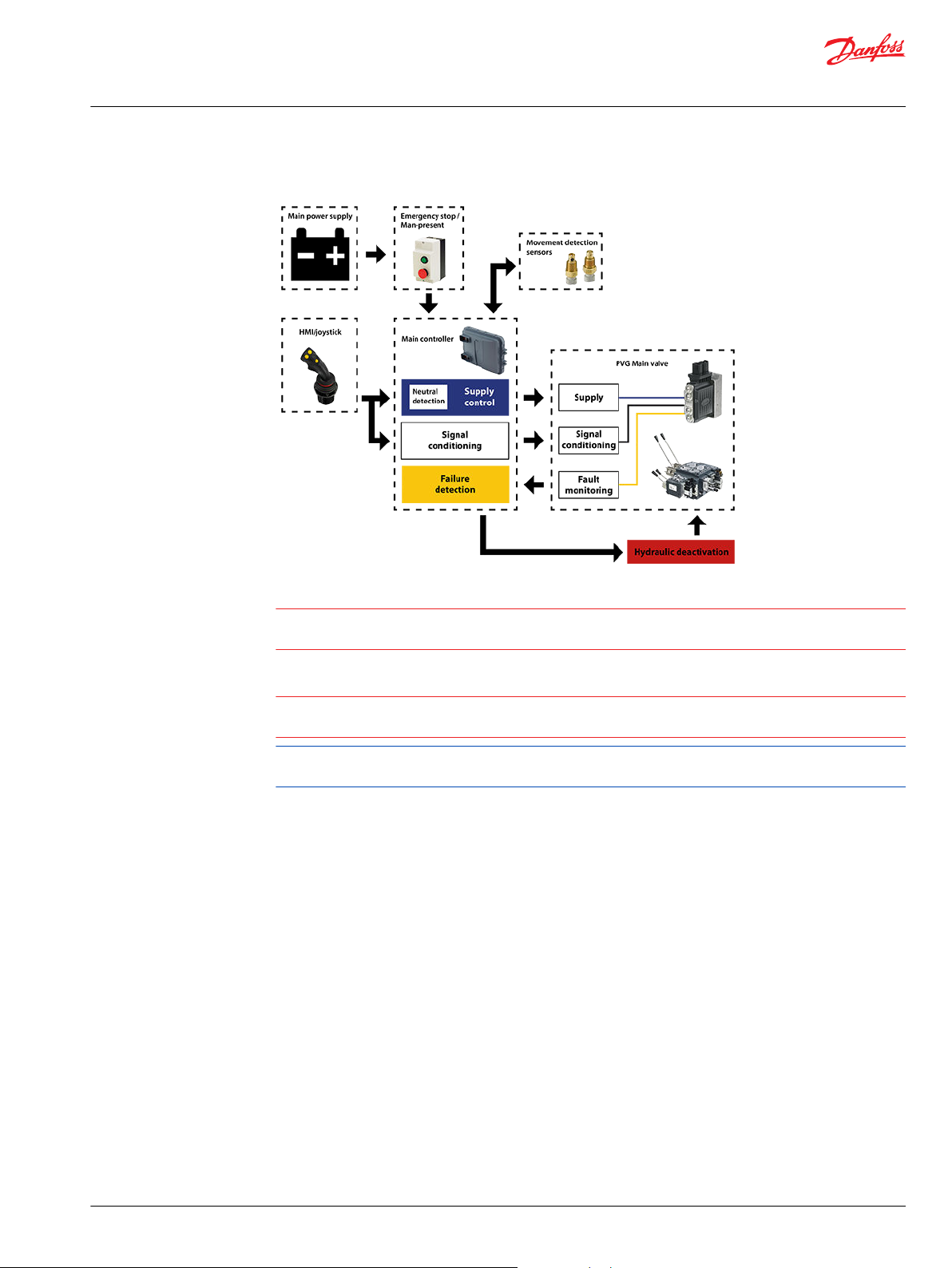

PVP Inlet Modules

The PVG 16 PVP inlet modules, also referred to as pump side modules, act as an interface between the

PVG 16 proportional valve group and the hydraulic pump and tank reservoir.

PVP Inlet Module PVP inlet module dimensions

Weight: 3.1 kg [6.9 lb]

Fixed displacement pump symbol Variable displacement pump symbol

The PVP inlet module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the PVP to suit the demands of any hydraulic system:

Open Center PVP on page 10 (for fixed displacement pumps)

•

Open Center PVP with PPRV on page 13 (for fixed displacement pumps)

•

Open center PVP with HPCO and PVE PPRV on page 17 (for fixed displacement pumps)

•

Closed Center PVP on page 20 (for variable displacement pumps)

•

Closed Center PVP with PPRV on page 22 (for variable displacement pumps)

•

Closed center PVPV with PPRV on page 25 (for variable displacement pumps)

•

Closed center PVPVM with PPRV on page 27 (for variable displacement pumps)

•

Open/Closed center PVP with PPRV on page 29

•

Open/Closed center PVPM on page 32

•

©

Danfoss | December 2018 BC00000211en-000901 | 9

Page 10

LS

T

P

M

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

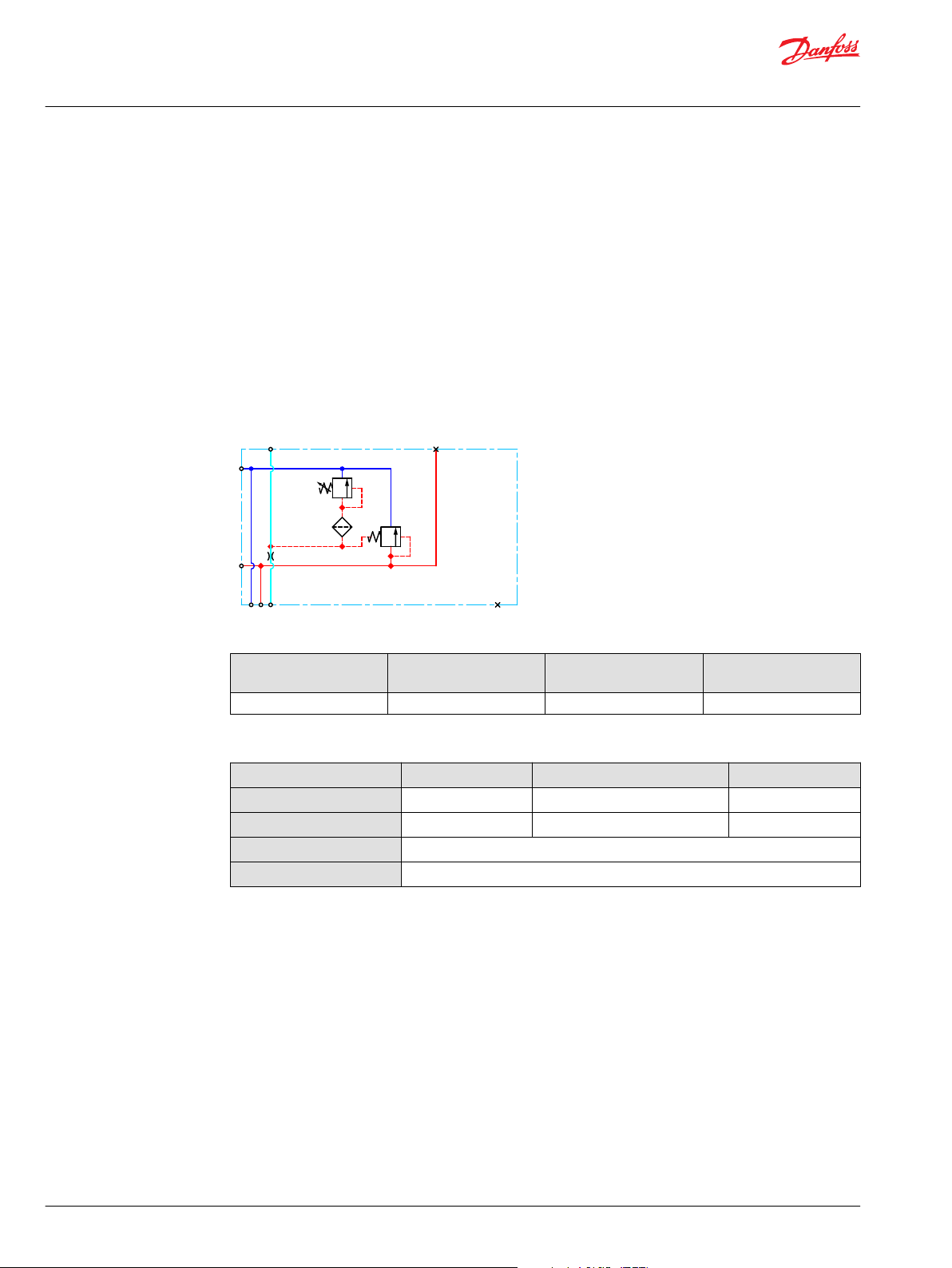

Open Center PVP

The basic Open Center PVP inlet module is intended for use with fixed displacement pumps in

applications, where a valve group with mechanically controlled work sections is desired, or where the

pilot pressure to the valve group is supplied externally.

The Open Center PVP features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Optional LS unloading valve, PVPX

•

Optional T0 facility and external T0 port

•

All modules can be manually activated with the PVM actuation.

Open center PVP schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

10 | © Danfoss | December 2018 BC00000211en-000901

Page 11

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

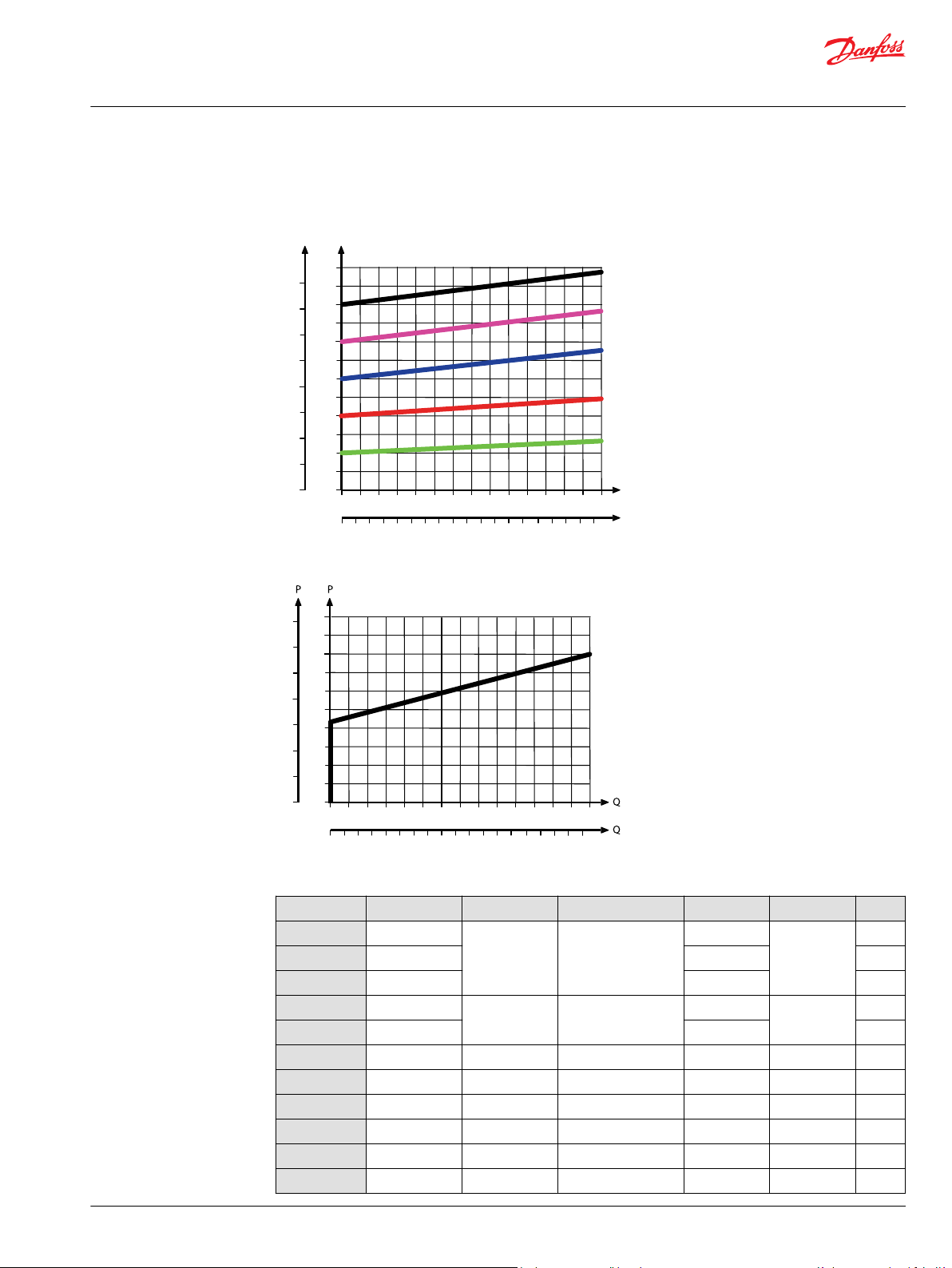

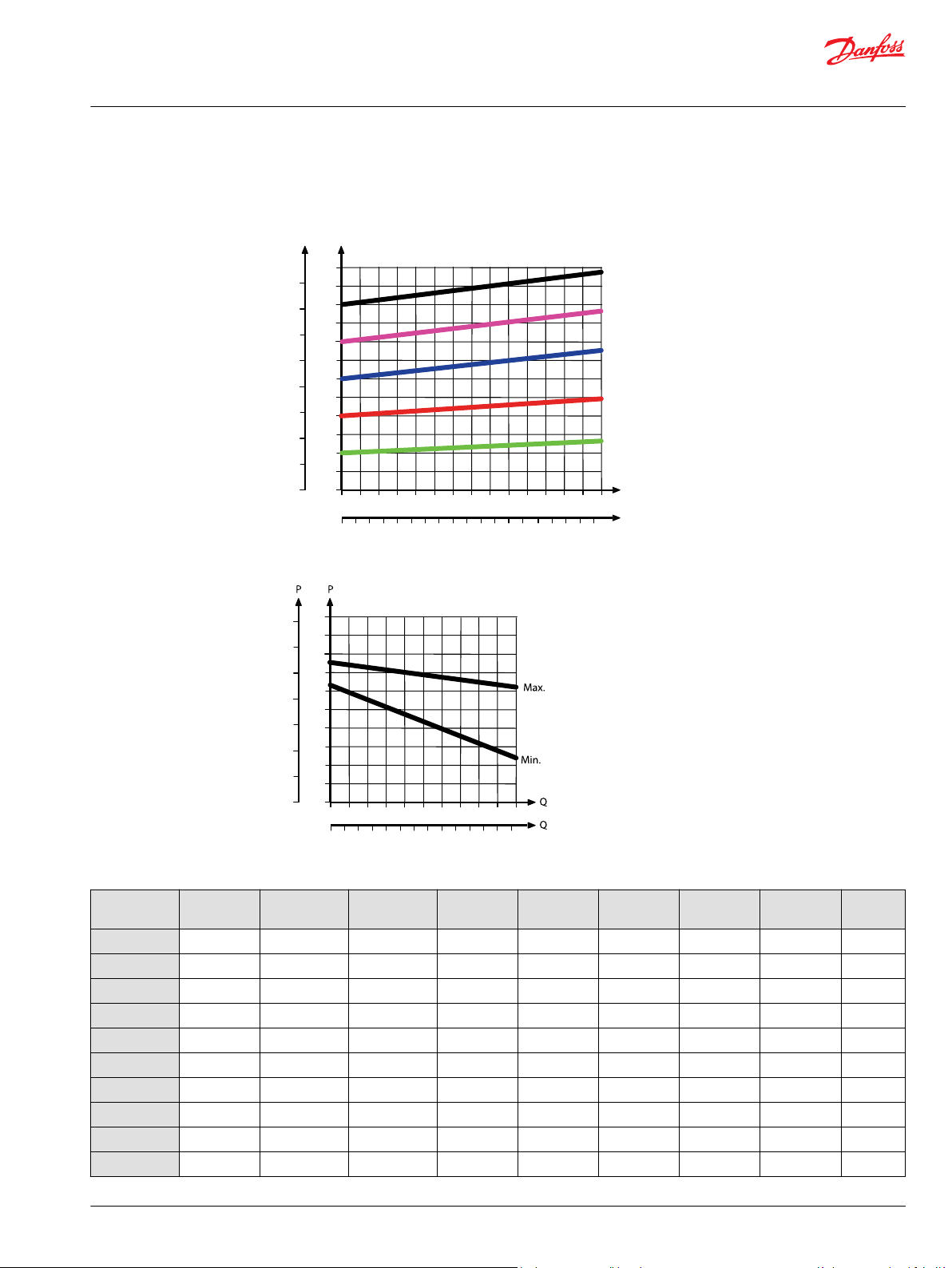

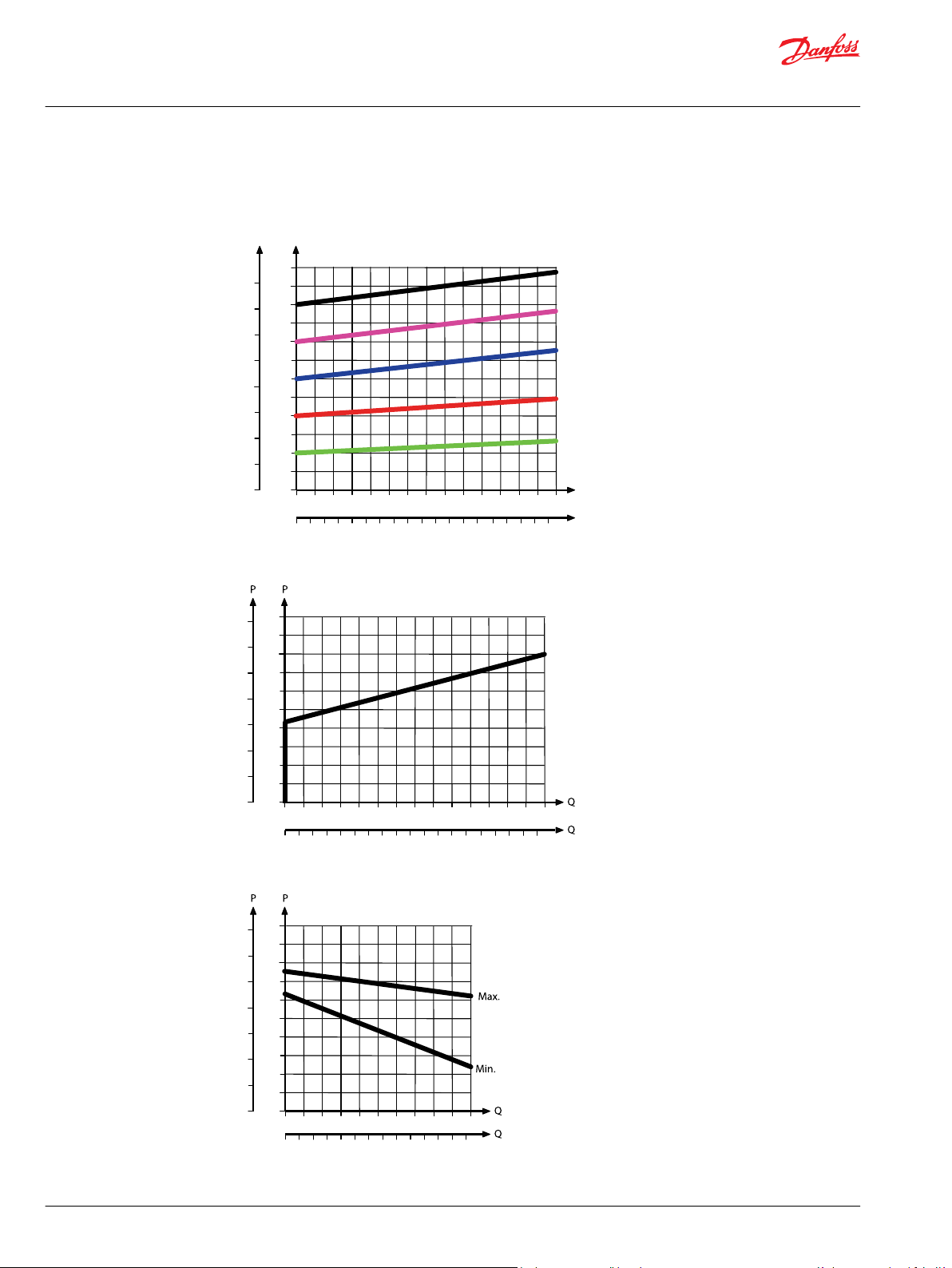

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Part numbers for Open Center PVP

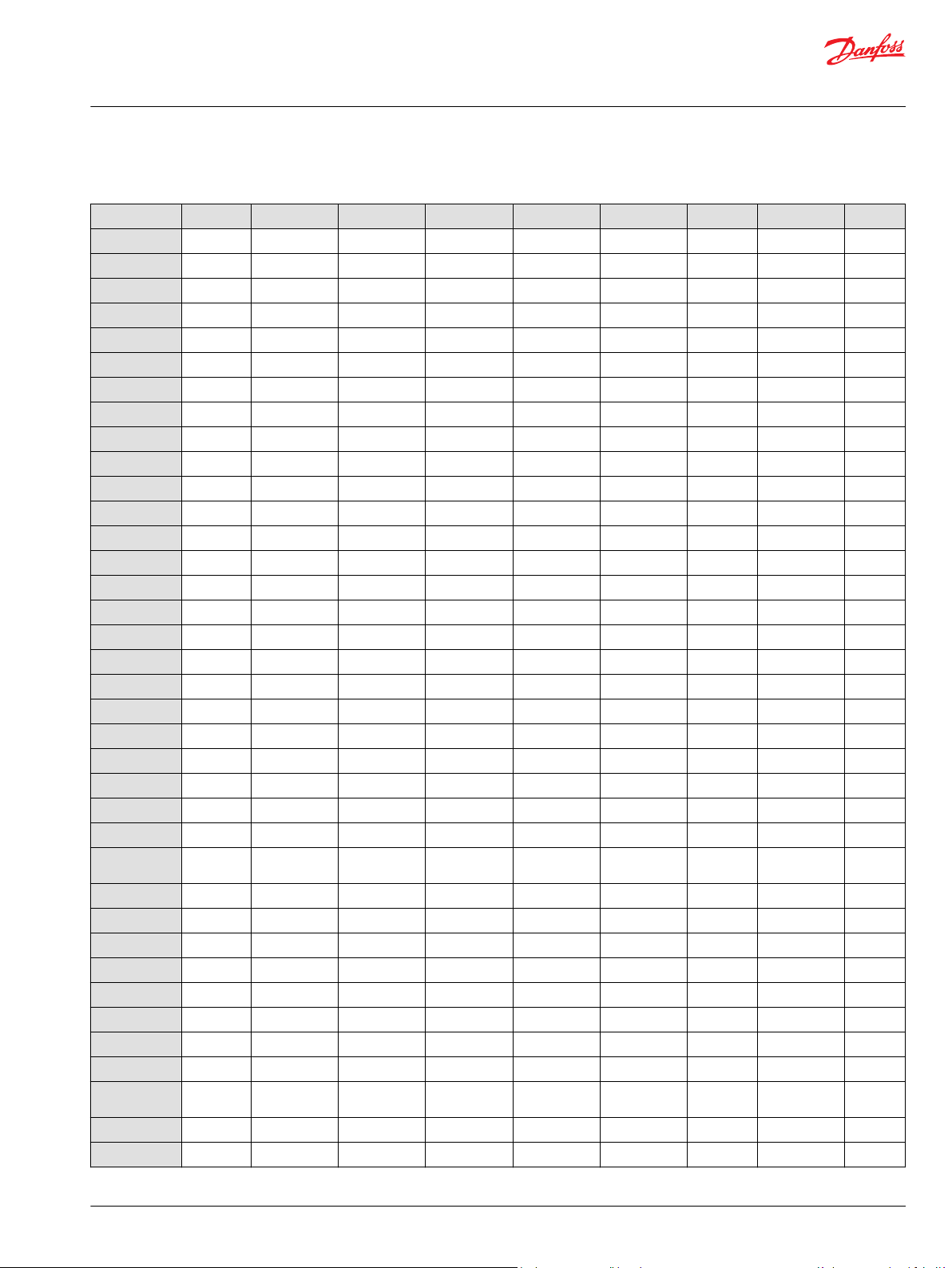

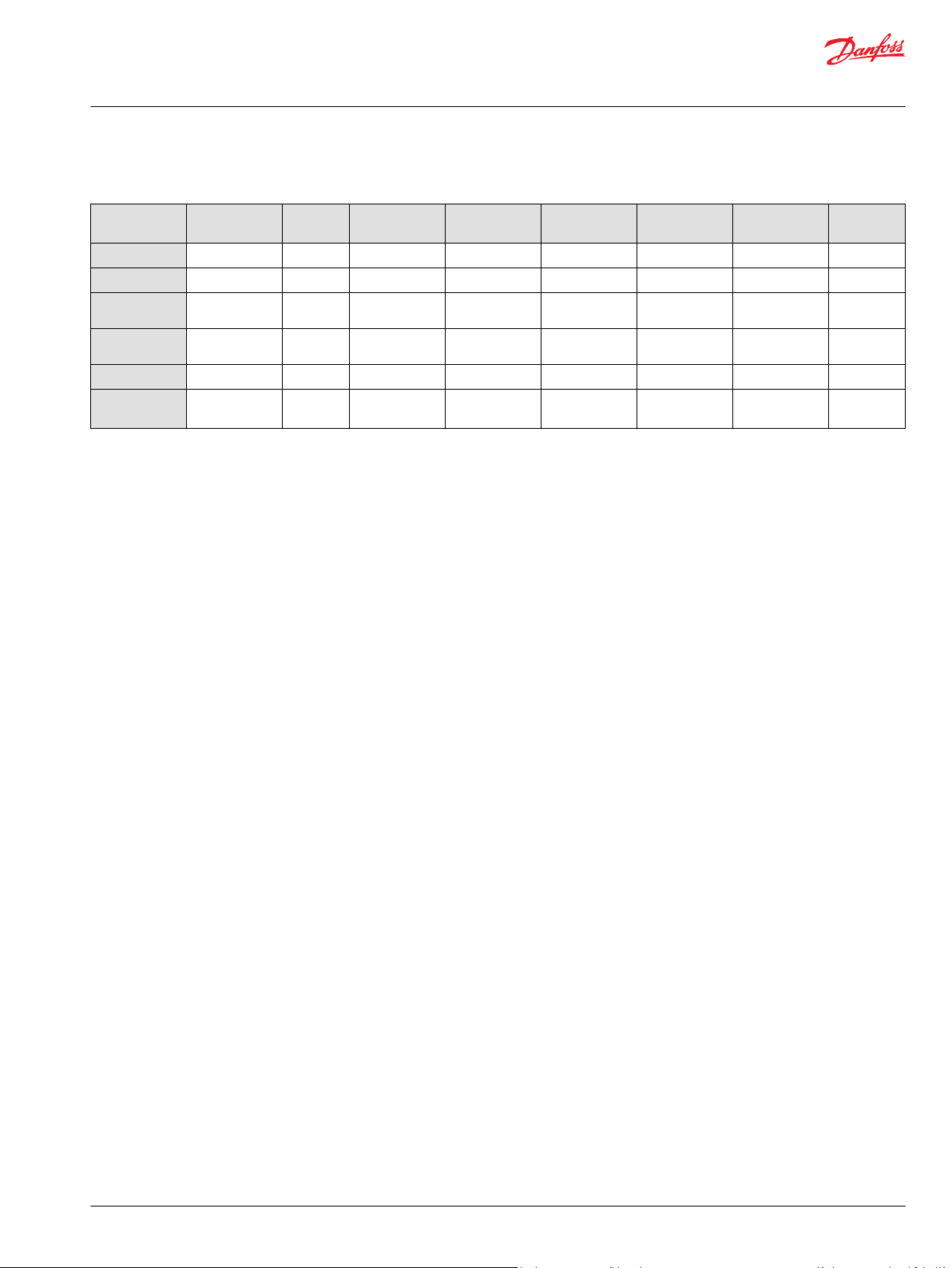

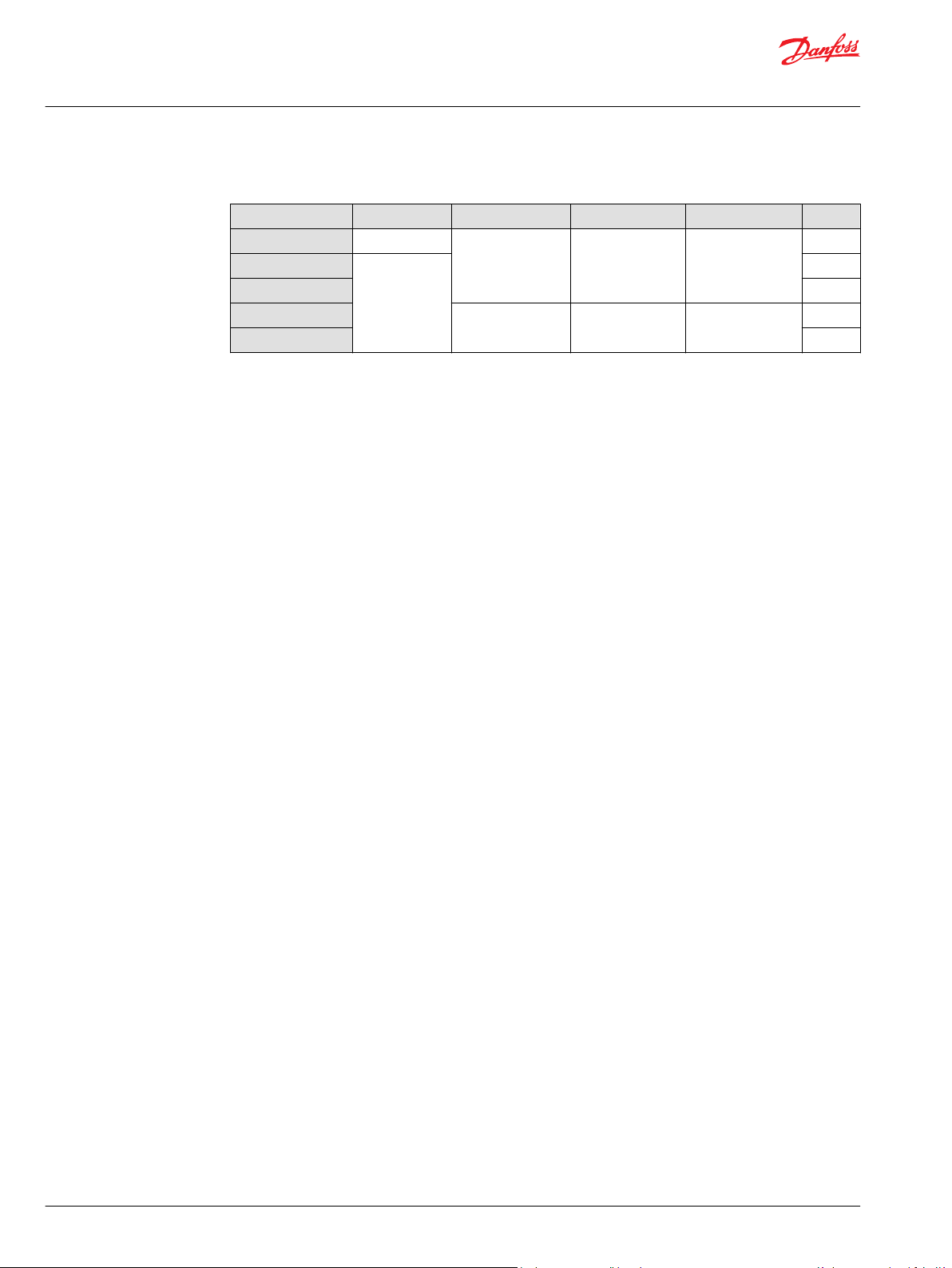

Part number P-port T-port LS-, M-port (LS1**) T0-port Mounting PVPX

157B5000

157B5100

157B5102

157B5200

157B5300

11008852

11030545

11053947

11151852

157B5908

157B5921

G1/2”

G3/4” – -

G3/4” G1/4”

G3/4” - Yes

7/8-14 UNF

1-1/16 UN - -

1 1/16-12 UNF 1/2-20 UNF

G1/2 G3/4 G1/4 (G1/8) - M8 -

G3/4 G3/4 G1/4 (G1/4) G1/4 M8 -

G3/4 G3/4 G1/4 (G1/4) G1/4 M8 -

1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF M8 -

1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF - M8 -

JIS 1/2 JIS 3/4 JIS 1/4 - M8 -

-

M8

5/16-18 UNC

*

–

-

©

Danfoss | December 2018 BC00000211en-000901 | 11

Page 12

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Open Center PVP (continued)

Part number P-port T-port LS-, M-port (LS1**) T0-port Mounting PVPX

157B5925

157B5945

157B5990

**

LS1 is an extra LS-port.

*

For more information see PVPX Electrical LS Pressure Unloading Valve on page 33.

*

JIS 1/2 JIS 3/4 JIS 1/4 - M8 -

G1/2 G3/4 G1/4 - M8 -

1 1/16-12 UNF 1 1/16-12 UNF - - M8 -

12 | © Danfoss | December 2018 BC00000211en-000901

Page 13

Pp

LS

T

P

M

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

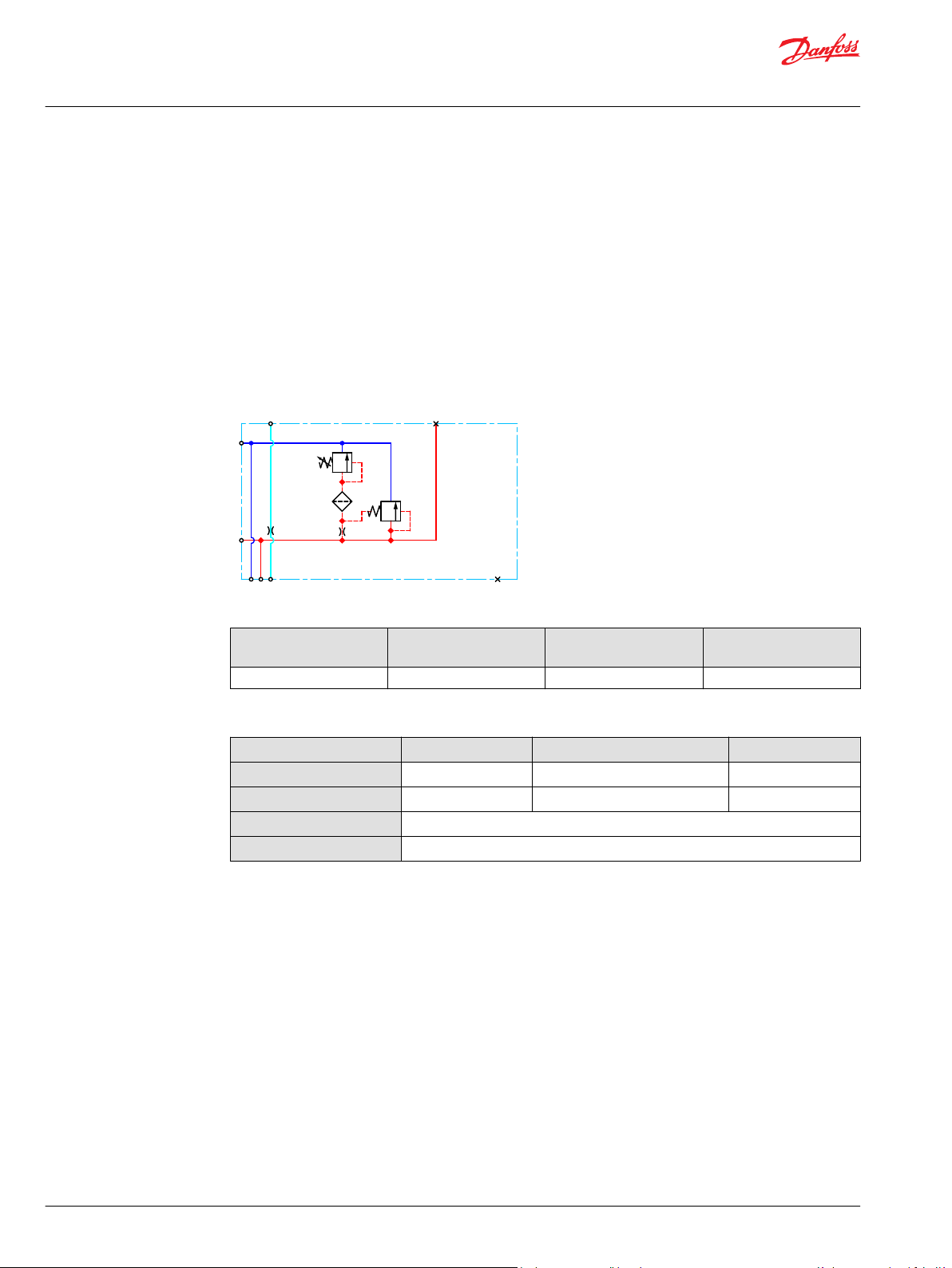

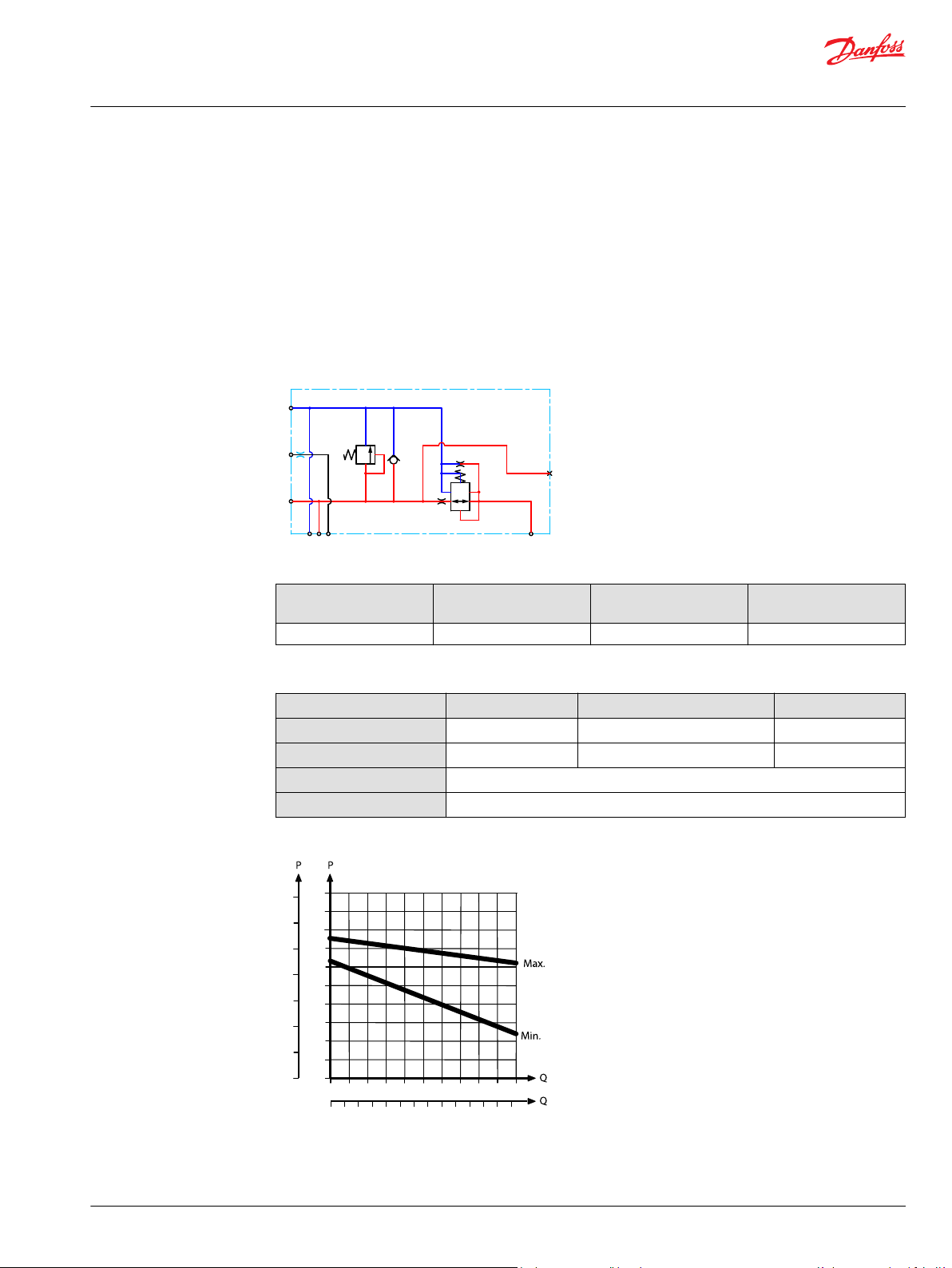

Open Center PVP with PPRV

The Open Center PVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

fixed displacement pumps in applications, where a valve group with electro-hydraulically or hydraulically

controlled work sections is desired (PVE or PVH/PVHC).

The Open Center PVP with PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional external pilot pressure port (Pp)

•

Optional LS unloading valve, PVPX

•

All modules can be manually activated with the PVM actuation.

Open center PVP with PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | December 2018 BC00000211en-000901 | 13

Page 14

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

14 | © Danfoss | December 2018 BC00000211en-000901

Page 15

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

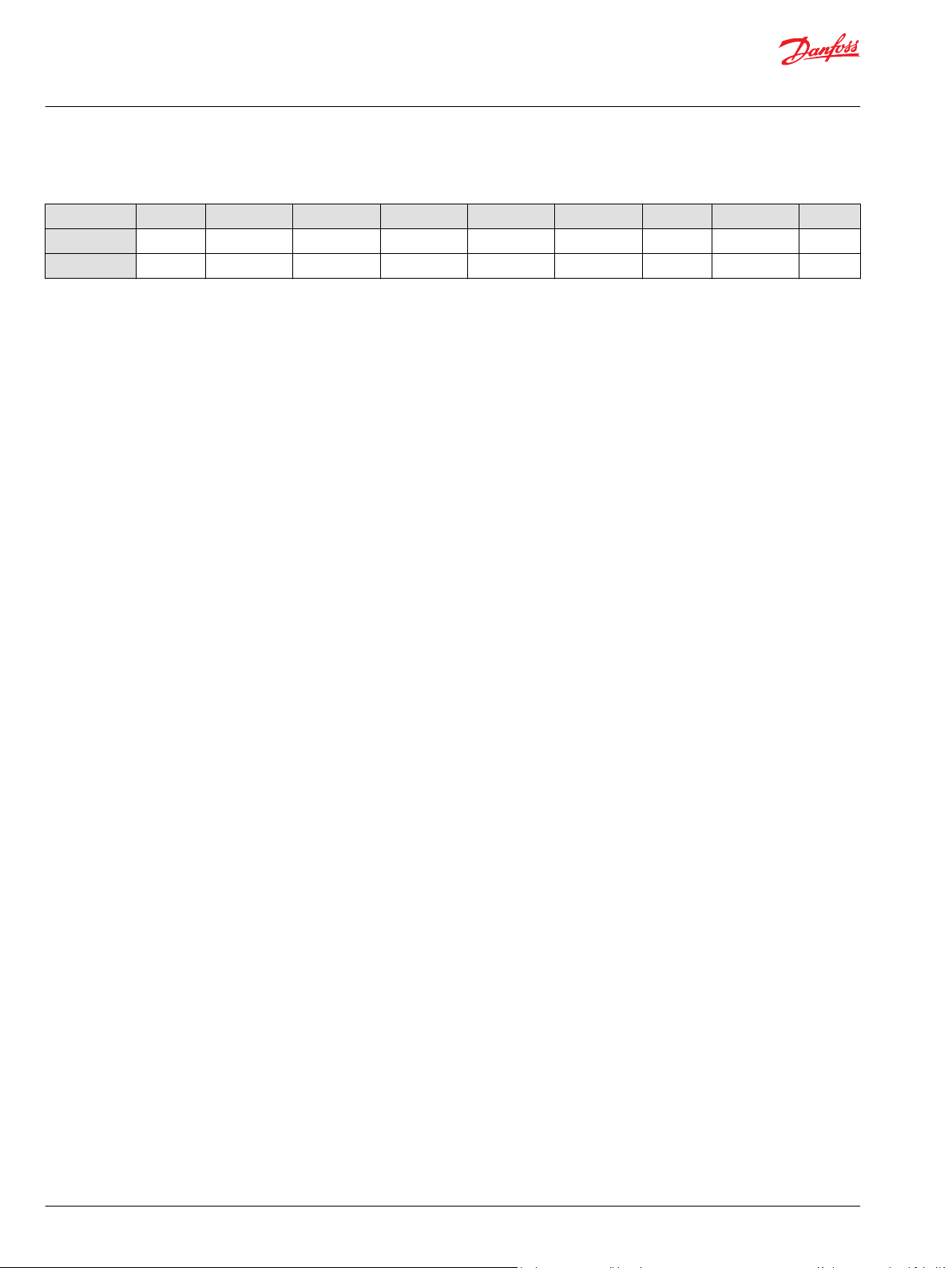

Part numbers for Open Center PVP with PPRV

Part number Actuation P-port T-port LS-port M-port Pp-port T0-port Mounting PVPX

157B5010

157B5012

157B5110

157B5112

157B5180

157B5190

157B5210

157B5212

157B5310

157B5312

157B5380

157B5390

11008850

11013317

11020964

11087590

11090453

11119429

11124965

11124966

11130941

11167773

11187356

11190123

11196947

11225941

157B5135

157B5904

157B5923

157B5926

157B5934

157B5943

157B5953

157B5954

157B5960

157B5966

157B5976

PVE G1/2” G3/4” G1/4” G1/4” - - M8 -

PVE G1/2” G3/4” G1/4” G1/4” - - M8 Yes

PVE G3/4” G3/4” G1/4” G1/4” - - M8 -

PVE G3/4” G3/4” G1/4” G1/4” - - M8 Yes

PVE G3/4” G3/4” G1/4” G1/4” G1/4” - M8 -

PVH/PVHC G3/4” G3/4” G1/4” G1/4” G1/4” - M8 -

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC -

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC Yes

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC -

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC Yes

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC -

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC -

PVE G3/4 G3/4 G1/4 G1/4 - - M8 Yes

1

PVE G3/4 G3/4 G1/4 G1/4 G1/4 G1/4 M8 -

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - M8 -

1

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

PVE JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 JIS 1/4 JIS 1/4 M8 -

2

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8 Yes

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

2

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC -

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC Yes

PVE G1/2 G3/4 G1/4 G1/4 - - M8 Yes

PVH/PVHC G1/2 G3/4 G1/4 G1/4 - - M8 Yes

PVE G3/4 G3/4 G1/4 G1/4 - G1/4 M8 -

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18

5/16-18 UNC -

UNF

3

PVE G3/4 G3/4 G1/4 G1/4 G1/4 G1/4 M8 -

2

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

PVE JIS 1/2 JIS 3/4 JIS 1/4 JIS 1/4 - - M8 -

PVE JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 - - M8 -

PVE G3/4 G3/4 G1/4 G1/4 - - M8 -

2

PVH/PVHC G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

2

PVE G3/4 G3/4 G1/4 G1/4 - - M8 Yes

PVE G3/4 G3/4 G1/4 G1/4 G1/4 - M8 -

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF - 9/16-18

5/16-18 UNF -

UNF

PVE G3/4 G3/4 G1/4 G1/4 - - M8 Yes

PVE G3/4 G3/4 G1/4 G1/4 - - M8 Yes

*

©

Danfoss | December 2018 BC00000211en-000901 | 15

Page 16

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Open Center PVP with PPRV (continued)

Part number Actuation P-port T-port LS-port M-port Pp-port T0-port Mounting PVPX

1,4

157B5977

11101194

*

For more information please see the topic PVPX Electrical LS Pressure Unloading Valve.

1

Dampened LS response

2

Pressure adjustment spool with check valve

3

Internal T0 connection

4

Low flow pressure adjustment spool

PVE G3/4 G3/4 G1/4 G1/4 - - M8 -

PVE M22 x 1.5 M22 x 1.5 M12 x 1.5 M10 x 1 - M16 x 1.5 M8 -

All modules can be manually activated with the PVM. For more information please see PVM Manual

Actuation on page 69.

*

16 | © Danfoss | December 2018 BC00000211en-000901

Page 17

LS

HPCO

P

M

T0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

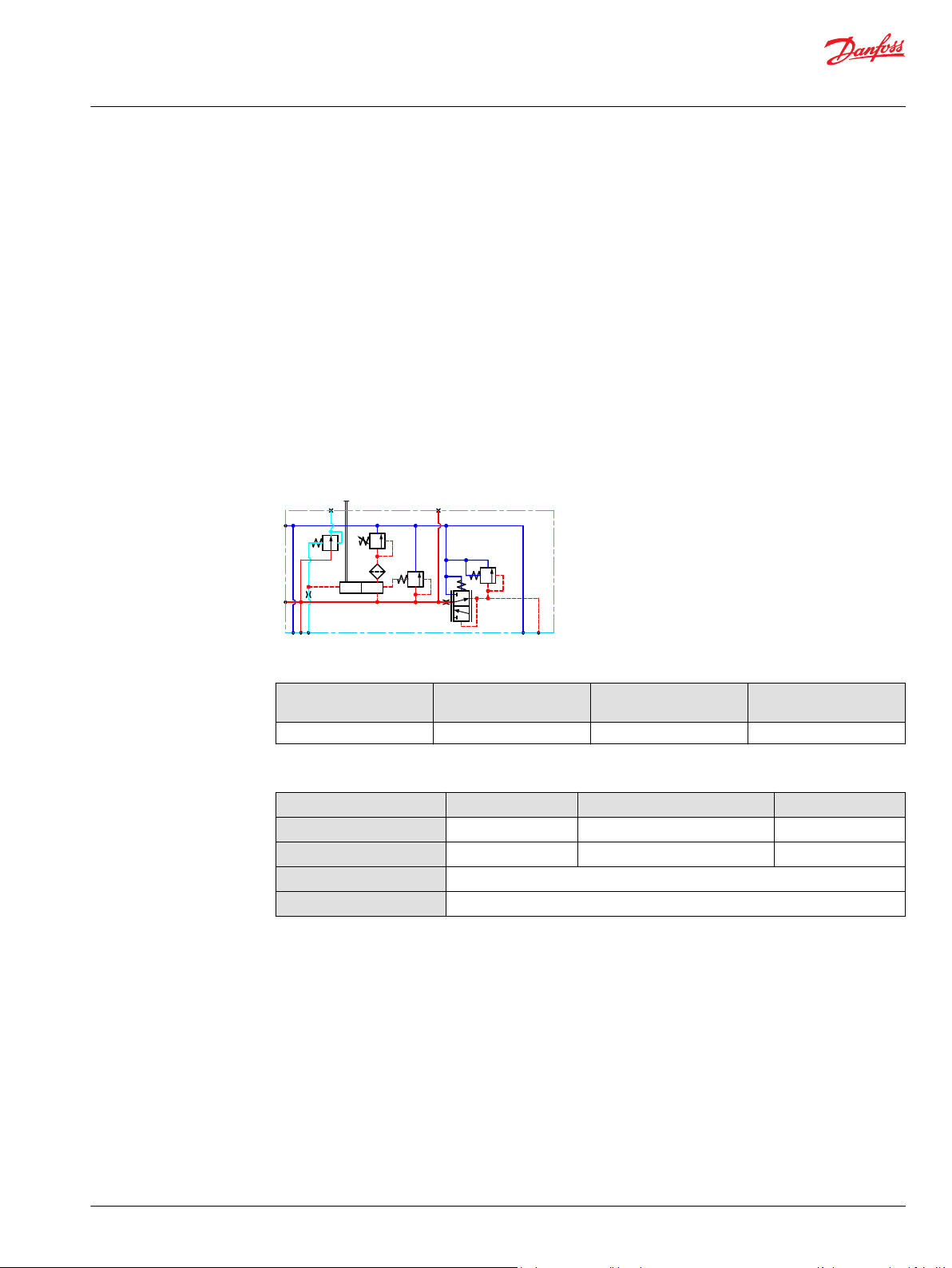

Open center PVP with HPCO and PVE PPRV

The Open Center PVP inlet with integrated High Pressure Carry Over (HPCO) functionality is intended for

use with fixed displacement pumps in applications where one pump supply for multiple hydraulic

subsystems is desired.

The integrated HPCO functionality guides the excess flow of the PVG 16 valve group to the external

hydraulic subsystem(s), giving priority to the PVG 16 work functions.

The Open Center PVP with HPCO and PVE PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS/HPCO and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE

•

Optional T0 facility and external T0 port

•

Optional external pilot pressure port (Pp)

•

Optional LS unloading valve, PVPX

•

Only applicable with PVST end plates with separate T-port due to blocked T-lines for HPCO functionality.

Open Center PVP with HPCO, PVE PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | December 2018 BC00000211en-000901 | 17

Page 18

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

18 | © Danfoss | December 2018 BC00000211en-000901

Page 19

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for OC PVP (HPCO and PPRV)

Part number P-port HPCO-

157B5140

157B5142

157B5340

157B5342

157B5961

11101195

*

For more information please see the topic PVPX Electrical LS Pressure Unloading Valve.

G3/4” G3/4" G1/4” G1/4” G1/4” G1/4” M8 -

G3/4” G3/4" G1/4” G1/4” G1/4” – M8 Yes

1 1/16-12 UNF 1 1/16-12

1 1/16-12 UNF 1 1/16-12

M27x2 M27x2 M14x1.5 M14x1.5 – M14x1.5 M8 –

M22x1.5

M16x1.5 (P2)

port

UNF

UNF

M22x1.5 M12x1.5 M10x1 – M16x1.5 M8 –

LS-port M-port Pp-port T0-port Mounting PVPX

1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 1/2-20 UNF 5/16-18 UNC -

1/2-20 UNF 1/2-20 UNF 1/2-20 UNF – 5/16-18 UNC Yes

*

©

Danfoss | December 2018 BC00000211en-000901 | 19

Page 20

LS

T

P

M

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Closed Center PVP

The basic Closed Center PVP inlet is intended for use with variable displacement pumps in applications

where a valve group with mechanically controlled work sections is desired, or where the pilot pressure to

the valve group is supplied externally.

The Closed Center PVP features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Optional LS unloading valve, PVPX

•

Optional T0 facility and external T0 port

•

Closed center PVP schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

20 | © Danfoss | December 2018 BC00000211en-000901

Page 21

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

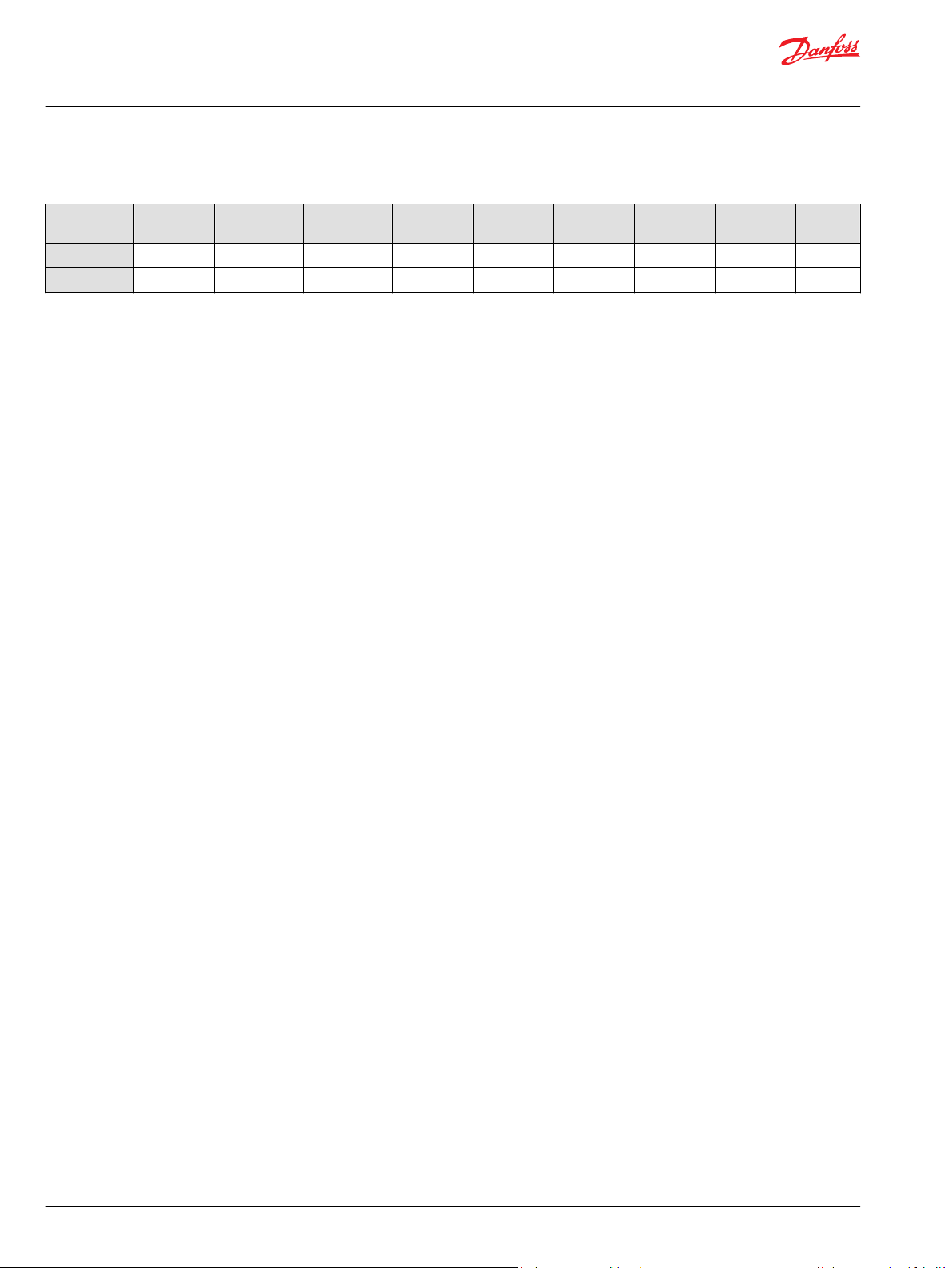

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Part numbers for Closed Center PVP

Part

number

P-port T-port LS-port

(LS1**)

M-port T0-port Mounting PVPX

11030683 G3/4 G3/4 G1/4 (G1/4) G1/4 G1/4 M8 157B5001 G1/2 G3/4 G1/4 G1/4 - M8 157B5101 G3/4 G3/4 G1/4 G1/4 - M8 157B5103 G3/4 G3/4 G1/4 G1/4 - M8 Yes

157B5201 7/8-14 UNF 1 1/16-12

1/2-20 UNF 1/2-20 UNF -- 5/16-18 UNC -

UNF

157B5301 1 1/16-12

UNF

15B5907 1 1/16-12

UNF

1 1/16-12

UNF

1 1/16-12

UNF

1/2-20 UNF 1/2-20 UNF - 5/16-18 UNC -

1/2-20 UNF 1/2-20 UNF - M8 -

157B5922 JIS 1/2 JIS 3/4 JIS 1/4 JIS 1/4 - M8 157B5927 JIS 3/4 JIS 3/4 JIS 1/4 JIS 1/4 - M8 157B5946 G1/2 G3/4 G1/4 (G1/8) G1/4 - M8 -

**

LS1 is an extra LS-port

*

For more information see PVPX Electrical LS Pressure Unloading Valve on page 33

*

©

Danfoss | December 2018 BC00000211en-000901 | 21

Page 22

Pp

LS

T

P

M

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Closed Center PVP with PPRV

The Closed Center PVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

variable displacement pumps in applications where a valve group with electro-hydraulic or hydraulically

controlled work sections is desired.

The Closed Center PVP with PPRV features:

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional external pilot pressure port (Pp)

•

Optional LS unloading valve, PVPX

•

Closed center PVP with PPRV schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

22 | © Danfoss | December 2018 BC00000211en-000901

Page 23

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Pilot pressure reduction valve characteristics

Part numbers for Closed Center PVP with PPRV

Part number Actuation P-port T-port LS-port

157B5011

157B5013

157B5111

157B5113

157B5181

157B5191

157B5211

157B5213

157B5311

157B5313

©

Danfoss | December 2018 BC00000211en-000901 | 23

PVE G1/2” G3/4” G1/4” G1/4” - - M8 -

PVE G1/2” G3/4” G1/4” G1/4” - - M8 Yes

PVE G3/4” G3/4” G1/4” G1/4” - - M8 -

PVE G3/4” G3/4” G1/4” G1/4” - - M8 Yes

PVE G3/4” G3/4” G1/4” G1/4” G1/4” - M8 -

PVH/PVHC G3/4” G3/4” G1/4” G1/4” G1/4” - M8 -

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC -

PVE 7/8-14 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC Yes

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC -

PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - - 5/16-18 UNC Yes

(LS1

**

M-port Pp-port T0-port Mounting PVPX

*

Page 24

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Closed Center PVP with PPRV (continued)

Part number Actuation P-port T-port LS-port

157B5381

157B5391

**

LS1 is an extra LS-port

*

For more information please see PVPX Electrical LS Pressure Unloading Valve on page 33

PVE 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC -

PVH/PVHC 1 1/16-12 UNF 1 1/16-12 UNF 9/16-18 UNF 9/16-18 UNF 9/16-18 UNF - 5/16-18 UNC

(LS1

**

All modules can be manually activated with the PVM actuation.

For more information, please see PVM Manual Actuation on page 69.

M-port Pp-port T0-port Mounting PVPX

*

24 | © Danfoss | December 2018 BC00000211en-000901

Page 25

T

LS

P

M

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

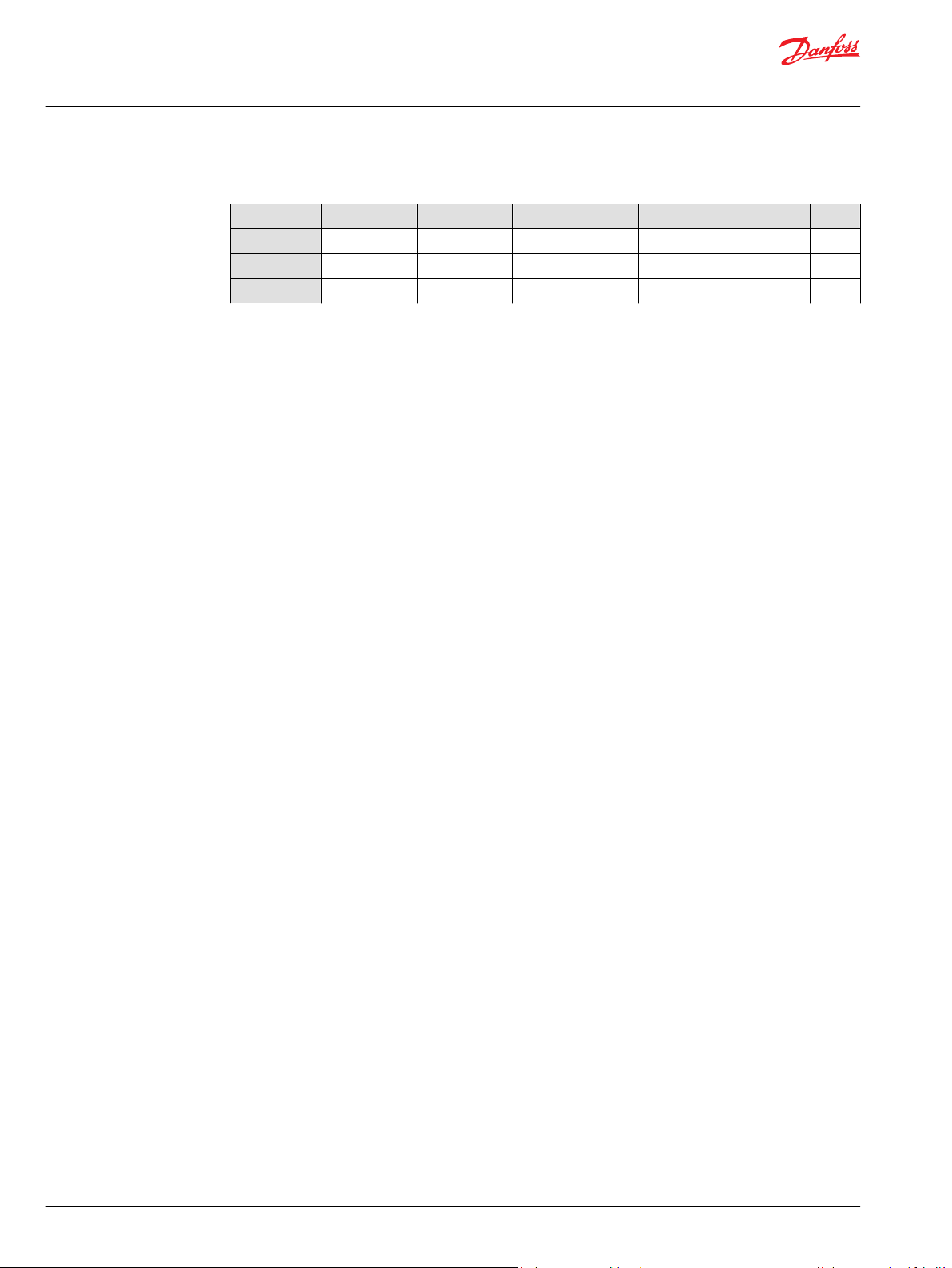

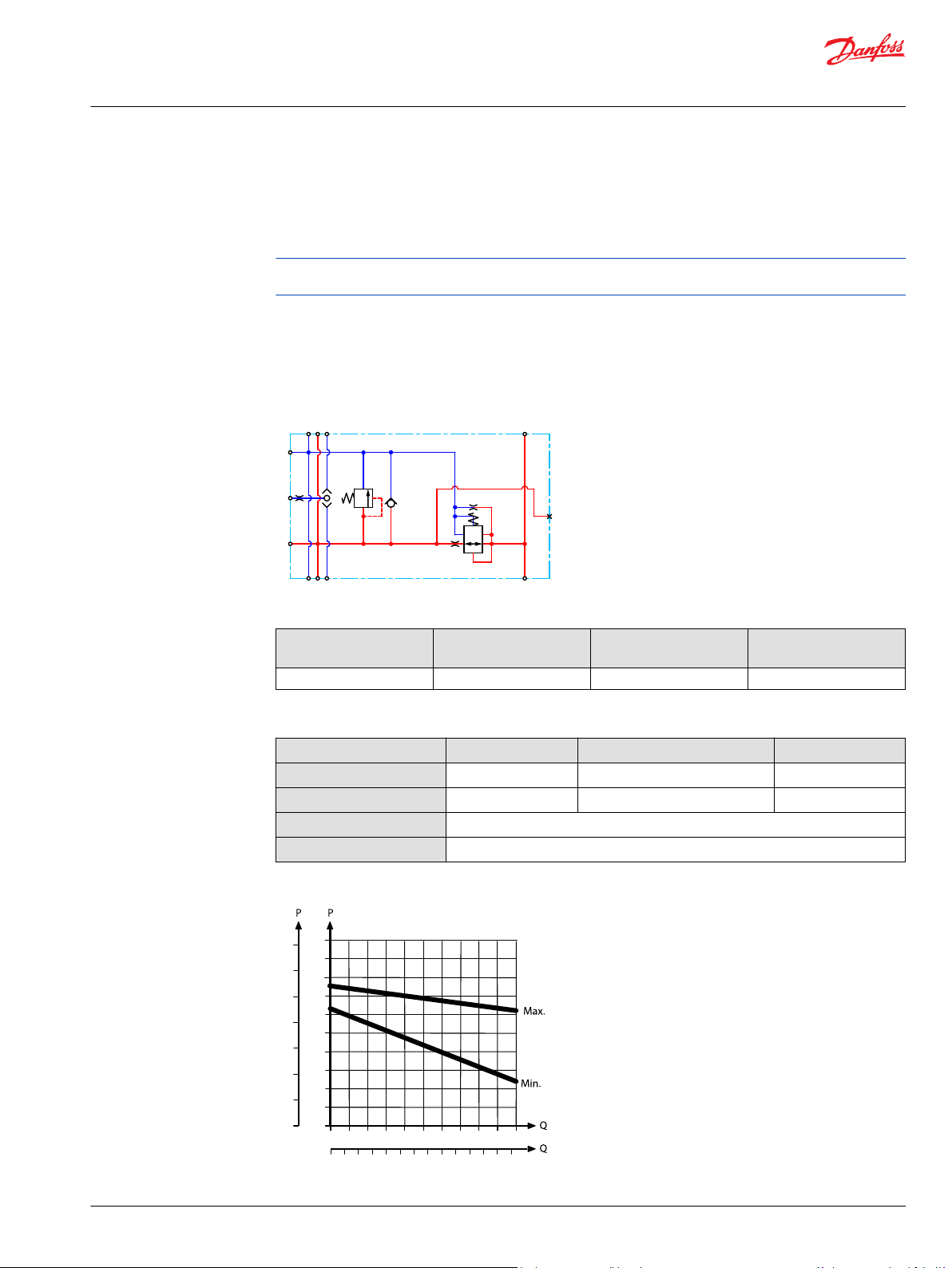

Closed center PVPV with PPRV

The Closed Center PVPV inlet with integrated pilot pressure reduction valve (PPRV) is intended for use

with variable displacement pumps in applications where a valve group with electro-hydraulic or

hydraulically controlled work sections is desired.

The Closed Center PVPV with PPRV features:

Optional shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Pilot pressure reduction valve characteristics

©

Danfoss | December 2018 BC00000211en-000901 | 25

Page 26

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Closed Center PVPV with PPRV

Part number Actuation P-, T-port LS-, M-port Mounting TO-port PVPX

11008856

11051803

11003806

157B5911

157B5913

157B5938

157B5941

157B5969

*

For more information please see the topic PVPX Electrical LS Pressure Unloading Valve.

All modules can be manually activated with the PVM actuation.

PVH/PVHC

PVE

G1” G1/4” M8 – Yes

1 5/16-12 UN 9/16-18 UNF 5/16-18 UNC – Yes

M27x2

M14x1.5 (P2)

1 5/16-12 UN 9/16-18 UNF 5/16-18 UNC

G1” G1/4”

M33x2

M14x1.5 (T2)

M14x1.5 M8 M14x1.5 –

– –

– Yes

– –

M8

M14x1.5 M16x1.5 Yes

– Yes

*

26 | © Danfoss | December 2018 BC00000211en-000901

Page 27

T

LS

P

M

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Closed center PVPVM with PPRV

The Closed Center PVPVM mid-inlet module with integrated pilot pressure reduction valve (PPRV) is

intended for use with variable displacement pumps in applications where a valve group with electrohydraulic or hydraulically controlled work sections is desired.

Using a PVPVM module in a valve group requires a 180° degree rotation of the PVG work sections on one

side.

The Closed Center PVPVM with PPRV features:

Optional shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Pilot pressure reduction valve characteristics

©

Danfoss | December 2018 BC00000211en-000901 | 27

Page 28

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Closed Center PVPVM with PPRV

Part number Actuation P-, T-port LS-, M-port Mounting PVLP

11083156

157B5912

157B5914

157B5937

157B5940

All modules can be manually activated with the PVM actuation.

PVH/PVHC

PVE

1 5/16-12 UN 9/16-18 UNF 5/16-18 UNC

G1” G1/4” M8

Yes

-

Yes

-

Yes

28 | © Danfoss | December 2018 BC00000211en-000901

Page 29

LS

T

P

M

OC

CC

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

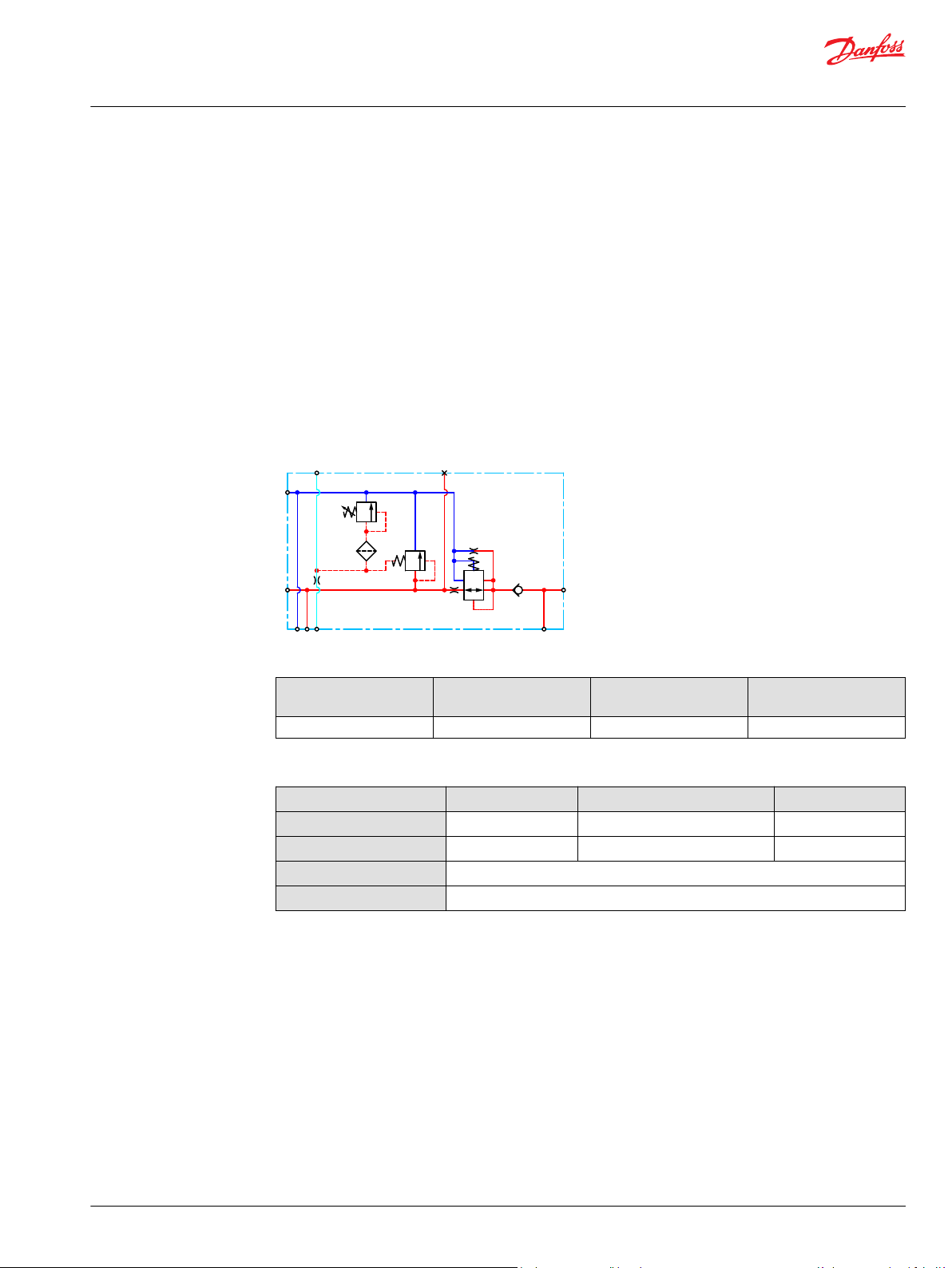

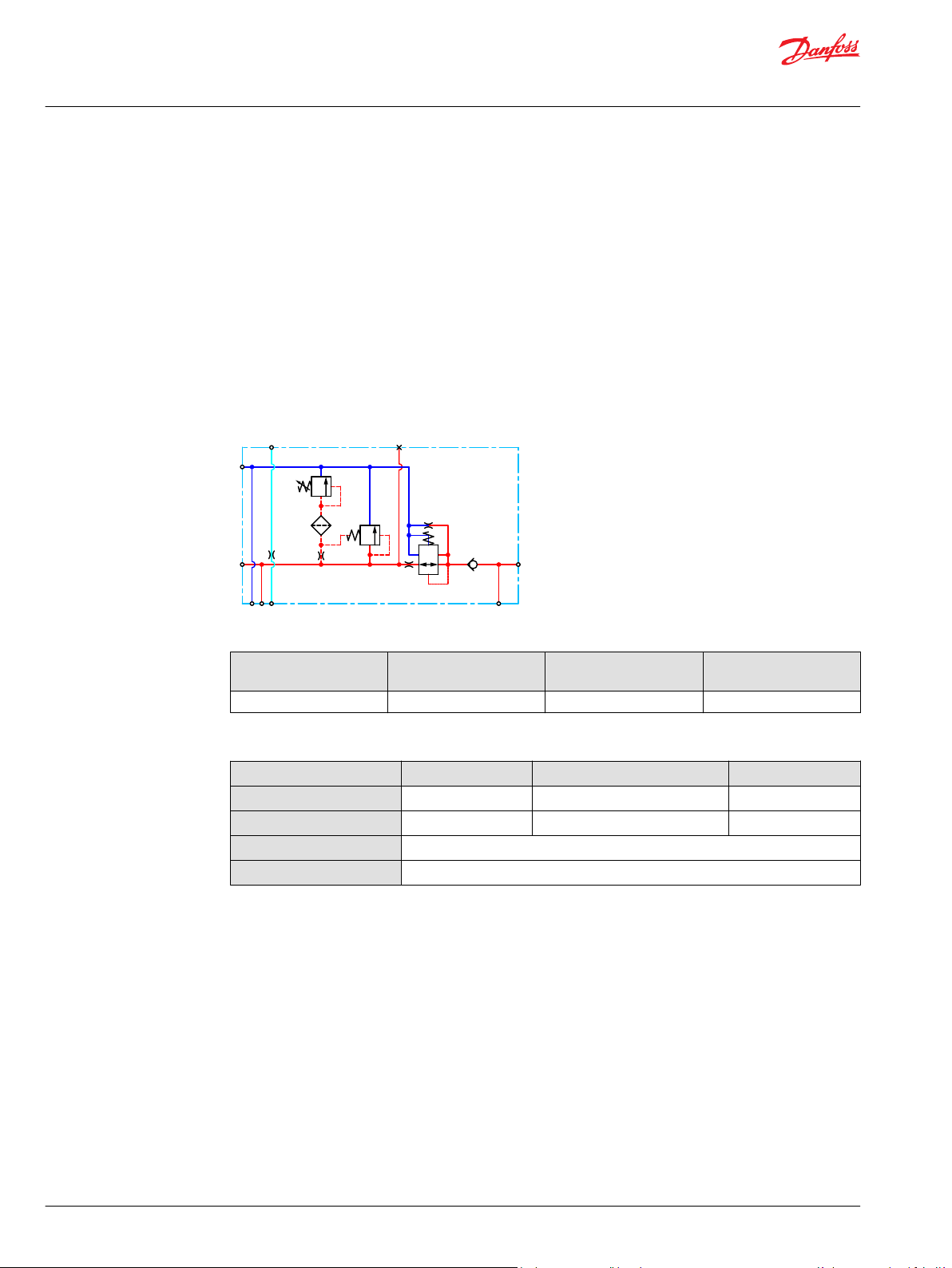

Open/Closed center PVP with PPRV

The Open Center/Closed Center PVP with integrated pilot pressure reduction valve (PPRV) is intended for

use with fixed or variable displacement pumps in applications where the application manufacturer does

not determine the pump type.

The modules allow an easy switch between Open Center and Closed Center configuration by means of an

external hexagon selector key. Variants also feature an LS boost functionality, increasing the LS pressure

to the pump LS regulator with a constant 6 bar, compensating for potential LS bleed-off and leakage.

The Open/closed center PVPV with PPRV features:

Integrated OC/CC selector

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure reducing valve (PPRV) for PVE or PVH/PVHC

•

Optional LS boost functionality

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | December 2018 BC00000211en-000901 | 29

Page 30

[l/min]

[US gal/min]

200

150

100

50

20

40

60

80

100

120

140

Q

300

250

P

P

2000

1000

0

0

0

204 8

28

24

32

36

12

16

0

3000

4000

[psi] Q(bar)

(l/min)

[US gal/min]

20

20

40

60 80

100

120

140

16

12

8

4

160

80

0

0

0

240

[psi] (bar)

4

8

12

16

20

24

28

32

36

0

(l/min)

[US gal/min]

20

10

20

30 40

50

16

18

12

14

10

8

4

6

2

100

20

60

0

0

0

220

140

180

260

[psi]

(bar)

6

122

4

8

10

0

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Theoretical Performance Graphs

Integrated LS pressure relief valve characteristics

Neutral by-pass pressure drop characteristics

Pilot pressure reduction valve characteristics

30 | © Danfoss | December 2018 BC00000211en-000901

Page 31

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Part numbers for Open/Closed Center PVP with PPRV

Part number Actuation P-port T-port LS-port (LS1**) M-port T0-port Mounting LS Boost

11093273 PVE G3/4 G3/4 - G1/4 - M8 Yes

11119094 PVE G3/4 G3/4 - G1/4 - M8 11119095 PVE 1 1/16-12 UNF 1 1/16-12 UNF 1/2-20 UNF 1/2-20 UNF - M8 11131344 PVH/PVHC G3/4 G3/4 - G1/4 - M8 Yes

111686081PVE G3/4 G3/4 - G1/4 - M8 Yes

**

LS1 is an extra LS-port

1

Dampened LS response

All modules can be manually activated with the PVM actuation.

©

Danfoss | December 2018 BC00000211en-000901 | 31

Page 32

T

P

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Modules

Open/Closed center PVPM

The Open Center/Closed Center PVPM mid-inlet acts as a simple manifold and is intended for use with

fixed or variable displacement pumps. The PVPM features no logic other than a PVLP shock/anticavitation valve facility for pressure peak protection and anti-cavitation prevention.

The PVPM module must be configured together with an Open Center PVP module for fixed

displacement pumps and for variable displacement pumps can be configured together with a PVSI

start plate or a Closed Center PVP/PVPV module.

The Open center/closed center PVPM features:

Integrated shock/anti-cavitation valve facility (PVLP)

•

Threaded ports for P/T

•

Pilot pressure and T0 lines through module

•

Hydraulic schematic

Technical specification for PVP

Max. P-port continuous Max. P-port intermittent Max. T-port static/

dynamic

350 [5076 psi] 400 bar [5800 psi] 25/40 bar [365/580 psi] 140 l/min [37 US gal/min]

Max. rated flow

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for Open Center/Closed Center PVPM

Part number P-, T-port Mounting PVLP

11093682

11093684

1 5/16-12 UN 5/16-18 UNC Yes

G1” M8 Yes

32 | © Danfoss | December 2018 BC00000211en-000901

Page 33

P

T

MLS

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Module Accessories

The generic PVP inlet module accessory platform includes the PVPX Electrical LS pressure unloading

valve, External pilot pressure adapters PVPC with or without check valve for all Open Center PVP with

PPRV.

PVPX Electrical LS Pressure Unloading Valve on page 33

•

PVPC without Check Valve on page 36

•

PVPC with Check Valve on page 37

•

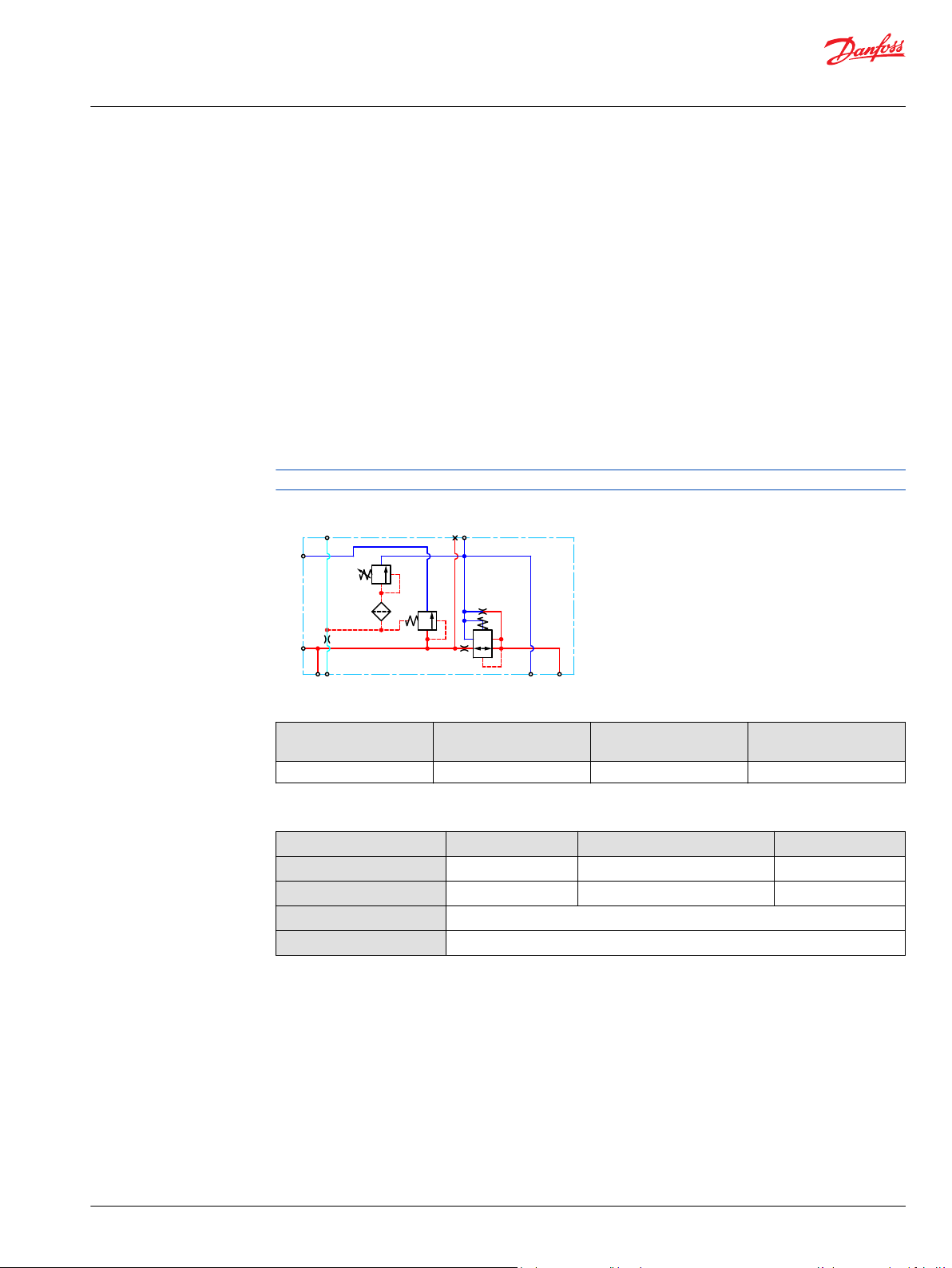

PVPX Electrical LS Pressure Unloading Valve

The electrical LS pressure unloading valve is an accessory available for PVP inlet modules with PVPX

facility. The PVPX consist of a solenoid valve and a magnetic coil package, allowing the operator to relieve

the LS pressure to tank electrically.

Configuration variants also feature a Manual Override functionality to activate the PVPX manually:

Normally Open (NO),

•

Normally Open with Manual Override (NOMO)

•

There are two types of NOMO-configurations - PUSH, and PUSH & TURN. With the TURN function you can

keep the override function until you unlock it again.

Normally Closed (NC)

•

Configuration variants

Normally Open (NO) Normally Open with MOR (NOMO) Normally Closed (NC)

Relieving the LS pressure to tank results in a reduced system pressure level, which is determined by:

the sum of the tank and neutral by-pass pressure drop in a Open Center PVP configuration

•

the sum of the tank and standby-pressure in a Closed Center PVP configuration

•

PVPX with NOMO schematic

PVPX technical data

Voltage supply

Resistance @ 12 V

Resistance @ 24 V

Power consumption

Maximum LS response time

Max. pressure drop @ 0.1 l/min [2.6 US gal/min]

DC

DC

12/24 VDC ± 10%

7.2 Ω ± 7%

28.2 Ω ± 7%

20 W

300 ms

2 bar [30 psi]

©

Danfoss | December 2018 BC00000211en-000901 | 33

Page 34

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Module Accessories

PVPX technical data (continued)

Max. coil surface temperature

Thread size

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

Part numbers for PVPX

Part numbers for PVPX, NO and NC configuration

Part number Configuration Voltage Supply Connector IP Rating

157B4236

157B4238

157B4246

157B4248

157B4976

157B4981

157B4982

157B4983

157B4984

11180766

11180767

11180768

11180769

11225108

11225109

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

NO 12 V

NO 24 V

NC 12 V

NC 24 V

NC 26 V

NO 12 V

NO 24 V

NC 12 V

NC 24 V

NO 12 V

NO 24 V

NC 12 V

NC 24 V

NO 26 V

NC 26 V

155°C [311°F]

3/4-16 UNF

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

DC

1x2 DIN IP 65

1x2 AMP IP 66

1x2 DEUTSCH IP 67

Part numbers for PVPX, NOMO configuration

Part number Manual Override Voltage Supply Connector IP Rating

157B4256

157B4257

157B4258

157B4259

157B4260

157B4985

157B4986

PUSH 12 V

PUSH & TURN 12 V

PUSH 24 V

PUSH & TURN 24 V

PUSH 26 V

PUSH 12 V

PUSH 24 V

DC

DC

DC

DC

DC

DC

DC

1x2 DIN IP 65

1x2 AMP IP 66

34 | © Danfoss | December 2018 BC00000211en-000901

Page 35

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Module Accessories

Part numbers for PVPX, NOMO configuration (continued)

Part number Manual Override Voltage Supply Connector IP Rating

11193839

11193836

11225111

11225110

PUSH 12 V

PUSH 24 V

PUSH

PUSH & TURN

26 V

DC

DC

DC

1x2 DEUTSCH IP 67

©

Danfoss | December 2018 BC00000211en-000901 | 35

Page 36

LS

T

P

M

Pp

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Module Accessories

PVPC without Check Valve

The PVPC external pilot pressure adapter without check valve is an accessory in the M-port available for

PVP inlet modules with integrated pilot pressure reduction valve (PPRV).

The PVPC without check valve cuts off the integrated PPRV to the PVE or PVH/PVHC in the valve group

and enables an external pilot pressure supply through the PVPC adapter.

PVPC without Check Valve

PVP with PVPC without check valve schematic

One application example for the PVPC without check valve is where it is a wanted feature to supply the

valve group with oil from a manually operated emergency pump without directing oil flow to the PPRV.

When the main pump is running in its normal operation mode, the oil is directed through the PVPC

adapter via the PPRV to the PVE electrical actuators.

When the main pump flow fails, the external shuttle valve ensures that the oil flow from the manually

operated emergency pump is used to pilot open the over-center valve and lower the load. The load is

only possible to lower when using the mechanical operating lever of the PVG work sections.

Part numbers for Open Center/Closed Center PVPM

Part number 157B5400 158X1000

Thread G1/2” 1/2-20 UNF

36 | © Danfoss | December 2018 BC00000211en-000901

Page 37

LS

T

P

M

Pp

Technical Information

PVG 16 Proportional Valve Group

PVP Inlet Module Accessories

PVPC with Check Valve

The PVPC external pilot pressure adapter with check valve is an accessory in the M-port available for PVP

inlet modules with integrated pilot pressure reduction valve (PPRV).

The PVPC with check valve enables an external pilot pressure supply through the PVPC adapter and the

PPRV, while also allowing the main pump to supply the PPRV through the P-gallery as a standard Open

Center PVP with PPRV.

PVPC with Check Valve

PVP with PVPC with check valve schematic

One application example for the PVPC with check valve is where it is a wanted feature to operate the

valve group by means of the PVE electrical actuators without pump flow.

When the external solenoid valve is opened, oil from the pressure side of the cylinder is fed via the PVPC

through the PPRV to act as the pilot supply for the PVE electrical actuators. This means that it is possible

to lower a load by means of the PVE electrical actuators without starting the pump.

The built-in check valve prevents the oil from flowing via the pressure adjustment spool to tank. With the

pump functioning normally the external solenoid valve is closed to ensure that the load is not lowered

due to the pilot supply oil flow requirement of approximately 1 l/min [0.25 US gal/min].

With a Closed Center PVP the external pilot oil supply can be connected to the pressure gauge

connection without the use of a PVPC plug.

Part numbers for Open Center/Closed Center PVPM

Part number 157B5600 157B5700

Thread G1/2” 1/2-20 UNF

©

Danfoss | December 2018 BC00000211en-000901 | 37

Page 38

114 [4.49]

109 [4.29]

110 [4.33]

20 [0.79]

40 [1.57]

P

P

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

The PVG 16 PVB basic modules, also referred to as work sections, are the interface between the PVG 16

proportional valve group and the work function such as a cylinder or a motor.

PVB Basic Module PVB 16 dimensions

Weight: 2,6 kg [5,7 lb]

Uncompensated PVB schematic symbol

Compensated PVB schematic symbol

The PVB basic module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the PVB to suit the demands of any hydraulic system. The generic PVB basic

module platform includes the following main variants:

Compensated basic module; Compensated PVB on page 39

•

Compensated basic module with facilities for shock and anti-cavitation valves (PVLP/PVLA);

•

Compensated PVB with PVLP/PVLA on page 42

Compensated basic module with one common adjustable LS valve for port A and port B;

•

Compensated PVB with LS A/B on page 46

Uncompensated basic module with optional integrated load drop check valve; Uncompensated PVB

•

on page 50

Uncompensated basic module with facilities for shock valves (PVLP) and optional integrated load

•

drop check valve; Uncompensated PVB with PVLP on page 53

38 | © Danfoss | December 2018 BC00000211en-000901

Page 39

1

0

2

A

Pp

T0

LX

P

T

B

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Compensated PVB

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independence on the load pressure of other functions used

simultaneously.

The Compensated PVB features:

Integrated LS shuttle network

•

Integrated compensator

•

Compensated PVB schematic

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

350 bar [5067 psi] 420 bar [6090 psi] 60 l/min [15 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | December 2018 BC00000211en-000901 | 39

Page 40

B

P

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

0

1

2

3

4

5

6

7

0

0.04

0.08

0.12

0.16

0.20

0.24

0.28

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

70

75

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A

P

mm

5

4

3

in

mm

in

PVM

0.39

0.35

0.31

0.28

0.24

0.20

0.3

0.35

0.4

0.45

2

0.16

0.5

1

0

0.120.080.04

0

0.25

PVH

bar

AA

B

C

D

A

5791113

15

131197

5

15

73

218

73

218

psi

psi

bar

189

160

131

102

102 131

160 189

U

s

U

DC

U

s

U

DC

1

1

6

6

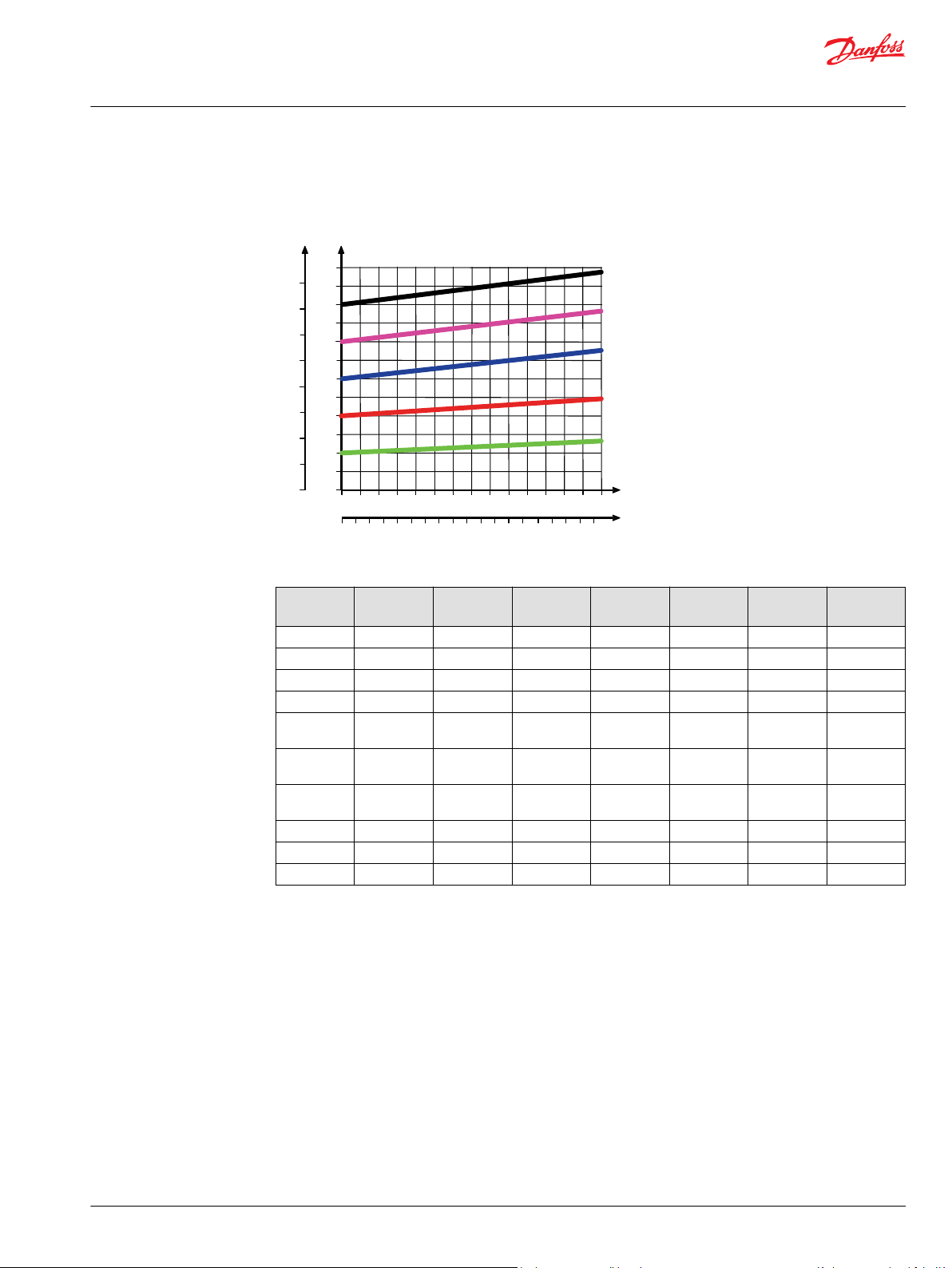

Spool types:

AA = 5/min

A = 10 l/min

B = 15 l/min

C = 25 l/min

D = 40 l/min

1 = First PVB after PVP

6 = Sixth PVB after PVP

PVEA

17

19

276

247

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

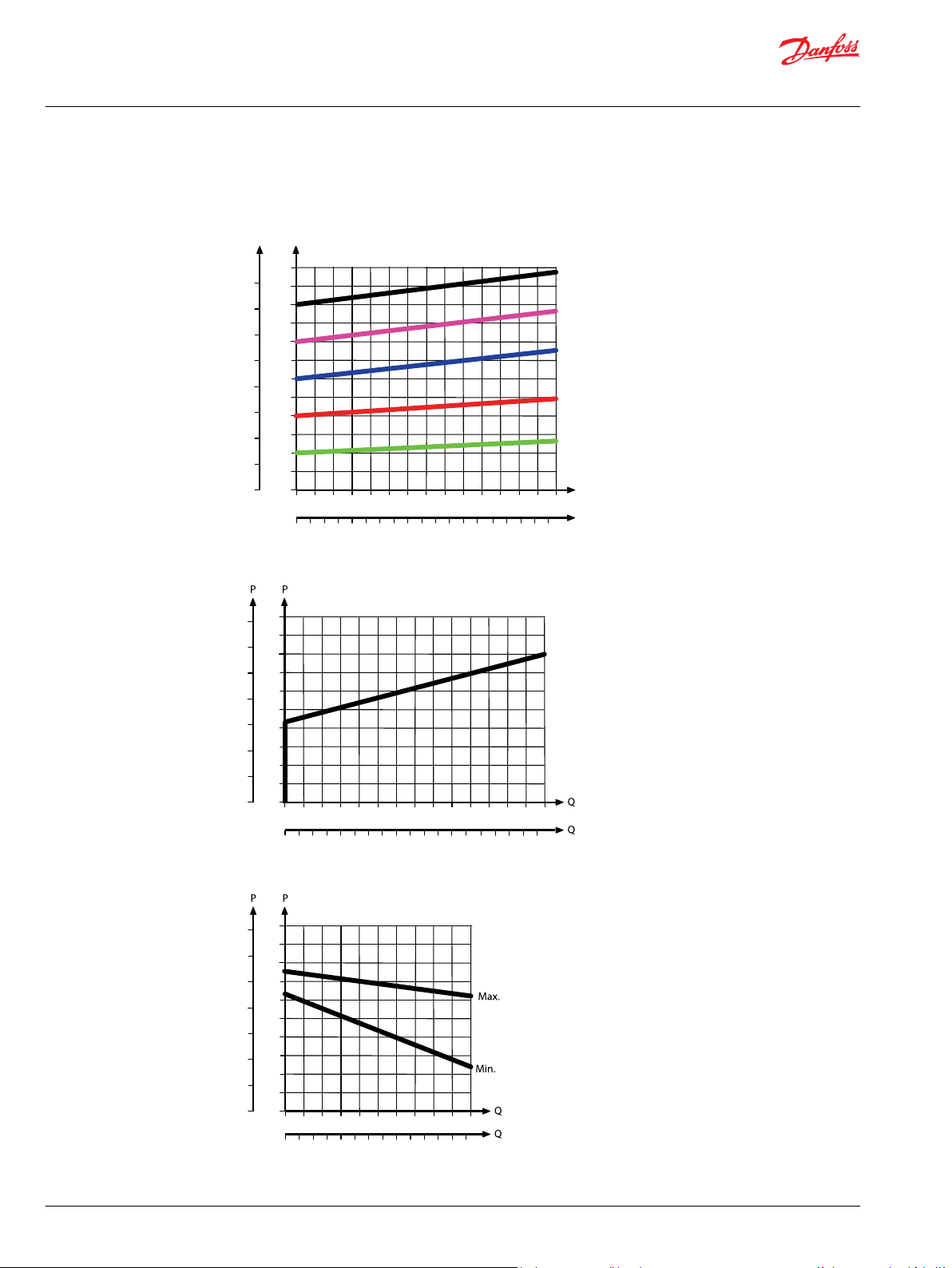

Performance graphs (Theoretical)

Fluid flow as a function of spool travel

40 | © Danfoss | December 2018 BC00000211en-000901

Page 41

5

10

15

20

25

30

35

40

45

50

55

60

65

(l/min)

[US gal/min]

70

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

0 25 50 75 100 125 150 175 200 225 250 275 300

0 500 1000 1500 2000 2500 3000 3500 4000

P

AA

B

C

D

A

P

(bar)

[psi]

A = 10 l/min

B = 15 l/min

AA = 5/min

C = 25 l/min

D = 40 l/min

Q

Q

P

[psi]

(l/min)

[US gal/min]

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

50

50

40

30

20

10

0

70

75

25

5 10

15

20 25

30

35

40

100

125

150

60

0

0

Port A/B

T-line

P-line

P

(bar)

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Load Independent Fluid Flow – Pressure Compensated PVB

©

Danfoss | December 2018 BC00000211en-000901 | 41

PVB pressure compensated P-line and T-line characteristics

Part numbers for compensated PVB

Part number A/B-port

3/8” BSP

3/4” – 16 UNF

11130976

11130977

Page 42

1

0

2

A

Pp

LX

P

T

B

T0

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Compensated PVB with PVLP/PVLA

The compensated PVB featuring an optional PVLP/PVLA shock and anti-cavitation valves on each work

port for pressure peak protection and anti-cavitation prevention.

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independence on the load pressure of other functions used

simultaneously.

Featuring an optional shock and anti-cavitation valves (PVLP/PVLA ) on each work port for pressure peak

protection and anti-cavitation prevention.

The Compensated PVB with PVLP/PVLA features:

Integrated LS shuttle network

•

Integrated compensator

•

Optional shock/anti-cavitation and suction valves facility (PVLP/PVLA)

•

Compensated PVB with PVLP/PVLA schematic

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

380 bar [5510 psi] 420 bar [6090 psi] 60 l/min [15 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

42 | © Danfoss | December 2018 BC00000211en-000901

Page 43

B

P

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

0

1

2

3

4

5

6

7

0

0.04

0.08

0.12

0.16

0.20

0.24

0.28

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

70

75

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A

P

mm

5

4

3

in

mm

in

PVM

0.39

0.35

0.31

0.28

0.24

0.20

0.3

0.35

0.4

0.45

2

0.16

0.5

1

0

0.120.080.04

0

0.25

PVH

bar

AA

B

C

D

A

5791113

15

131197

5

15

73

218

73

218

psi

psi

bar

189

160

131

102

102 131

160 189

U

s

U

DC

U

s

U

DC

1

1

6

6

Spool types:

AA = 5/min

A = 10 l/min

B = 15 l/min

C = 25 l/min

D = 40 l/min

1 = First PVB after PVP

6 = Sixth PVB after PVP

PVEA

17

19

276

247

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Performance graphs (Theoretical)

Fluid flow as a function of spool travel

©

Danfoss | December 2018 BC00000211en-000901 | 43

Page 44

(l/min)

[US gal/min]

P

Q

Q

(bar)

[psi]

20 40 60 80 100 120 140

5

10 15 20 25 30 35 40 45

400

350

300

250

200

150

100

50

0

5000

4000

3000

2000

1000

0

6000

0

0

5 10 15 20 25 30 35 40 45 50 55 60 65

[l/min]

[US gal/min]

70 75 80

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

20

18

16

14

12

10

8

6

4

2

0

85 90 95 100

22 23 24 25 26

Q

28

26

24

22

P

P

200

160

120

80

40

0

280

240

320

400

360

0

[psi] [bar]

0

Q

105 110 115 120

27 28 29 30 31

PVLP

PVLA

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

PVLP shock valve characteristics

PVLP/PVLA suction valve characteristics

44 | © Danfoss | December 2018 BC00000211en-000901

Page 45

5

10

15

20

25

30

35

40

45

50

55

60

65

(l/min)

[US gal/min]

70

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

0 25 50 75 100 125 150 175 200 225 250 275 300

0 500 1000 1500 2000 2500 3000 3500 4000

P

AA

B

C

D

A

P

(bar)

[psi]

A = 10 l/min

B = 15 l/min

AA = 5/min

C = 25 l/min

D = 40 l/min

Q

Q

P

[psi]

(l/min)

[US gal/min]

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

50

50

40

30

20

10

0

70

75

25

5 10

15

20 25

30

35

40

100

125

150

60

0

0

Port A/B

T-line

P-line

P

(bar)

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Load Independent Fluid Flow – Pressure Compensated PVB

©

Danfoss | December 2018 BC00000211en-000901 | 45

PVB pressure compensated P-line and T-line characteristics

Part numbers for Compensated PVB with PVLP/PVLA

Part number A/B-port PVLP/PVLA

3/8” BSP 1

3/4” – 16 UNF 1

11130978

11130979

Page 46

1

0

2

A

Pp

T0

LX

P

T

B

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Compensated PVB with LS A/B

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously. The integrated LS

A/B-ports individually.

The compensated PVB with LS

Integrated LS shuttle network

•

Integrated compensator

•

Compensated PVB with LS A/B schematic

relief valve is used to limit the maximum work port build-up on the

A/B

features:

A/B

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

350 bar [5076 psi] 420 bar [6090 psi] 60 l/min [15 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

46 | © Danfoss | December 2018 BC00000211en-000901

Page 47

B

P

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

0

1

2

3

4

5

6

7

0

0.04

0.08

0.12

0.16

0.20

0.24

0.28

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

70

75

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A

P

mm

5

4

3

in

mm

in

PVM

0.39

0.35

0.31

0.28

0.24

0.20

0.3

0.35

0.4

0.45

2

0.16

0.5

1

0

0.120.080.04

0

0.25

PVH

bar

AA

B

C

D

A

5791113

15

131197

5

15

73

218

73

218

psi

psi

bar

189

160

131

102

102 131

160 189

U

s

U

DC

U

s

U

DC

1

1

6

6

Spool types:

AA = 5/min

A = 10 l/min

B = 15 l/min

C = 25 l/min

D = 40 l/min

1 = First PVB after PVP

6 = Sixth PVB after PVP

PVEA

17

19

276

247

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Performance graphs (Theoretical)

Fluid flow as a function of spool travel

©

Danfoss | December 2018 BC00000211en-000901 | 47

Page 48

(l/min)

[US gal/min]

P

Q

P

(bar)

[psi]

5

10

15

20

25

30

35

40

45

50

55

60

65

70

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

250225200175150125

100

755025

0

350

325300275

25002000150010005000 35003000 4000 50004500

0

5

10

15

20

25

30

35

40

45

50

55

60

65

(l/min)

[US gal/min]

70

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

0 25 50 75 100 125 150 175 200 225 250 275 300

0 500 1000 1500 2000 2500 3000 3500 4000

P

AA

B

C

D

A

P

(bar)

[psi]

A = 10 l/min

B = 15 l/min

AA = 5/min

C = 25 l/min

D = 40 l/min

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

PVB pressure compensated for LS A/B characteristics

Load Independent Fluid Flow – Pressure Compensated PVB

48 | © Danfoss | December 2018 BC00000211en-000901

Page 49

Q

Q

P

[psi]

(l/min)

[US gal/min]

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

50

50

40

30

20

10

0

70

75

25

5 10

15

20 25

30

35

40

100

125

150

60

0

0

Port A/B

T-line

P-line

P

(bar)

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

PVB pressure compensated P-line and T-line characteristics

Part numbers for Compensated PVB with LS A/B

Part number A/B-port

11130982

11130983

©

Danfoss | December 2018 BC00000211en-000901 | 49

3/8” BSP

3/4” – 16 UNF

Page 50

1

0

2

A

Pp

T0

LX

P

T

B

Technical Information

PVG 16 Proportional Valve Group

PVB Basic Modules

Uncompensated PVB

The uncompensated PVB is intended for controlling a work function where the function behavior in

terms of flow and pressures requires independence on the load pressure of other functions used

simultaneously.

The Uncompensated PVB features:

Integrated LS shuttle network

•

Optional load drop check valve

•

Uncompensated PVB

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

380 bar [5510 psi] 420 bar [6090 psi] 65 l/min [17 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

50 | © Danfoss | December 2018 BC00000211en-000901

Page 51

B

P

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

0

1

2

3

4

5

6

7

0

0.04