Page 1

Technical Information

PVG 128/256

Proportional Valve Group

www.danfoss.com

Page 2

Technical Information

PVG 128/256 Technical Information

Revision history Table of revisions

Date Changed Rev

July 2021 Corrected PVB 256 3-way Compensator with LS A/B parts table 0510

March 2021 Corrected PVSI with P and T port dimensions 0509

May 2020 Minor revision - data corrections throughout, updated version number to match online

catalogue.

Changed document number from 'BC00000380' to 'BC220686485279' XX

June 2019 Minor changes throughout document, new images added. 0407

September 2018 Safety topic added. 0406

August 2018 Layout changes, minor edits 0405

June 2018 Table for dimensions page 90 update. 0404

March 2018 Minor edits 0403

January 2018 correction to part number pg 54 0402

October 2017 Updated port names on schematics 0401

July 2017 Updated specs and dimensions 0301

March 2017 Corrected PVAS equation 0203

March 2017 Updated PVAS tables 0202

January 2017 Changed PVEO and PVEH product data 0201

November 2016 First edition 0101

0508

2 | © Danfoss | July 2021 BC220686485279en-000510

Page 3

Technical Information

PVG 128/256 Technical Information

Contents

General Information

Safety in Systems..............................................................................................................................................................................5

PVG 128/256 Proportional Valve Group...................................................................................................................................7

PVG general description................................................................................................................................................................ 8

Features of the PVG 128/256 valve............................................................................................................................................ 8

PVPV Inlet Modules

Closed Center PPRV for PVE Activation and/or Mechanical........................................................................................... 10

PPRV for PVH/PVHC Activation and/or Mechanical ..........................................................................................................12

PVB 128 Variant Overview

PVB 128 3-way Compensator.................................................................................................................................................... 15

PVB 128 3-way Compensator with LS A/B.............................................................................................................................18

PVB 128 3-way Compensator with LS A/B and PVLP.........................................................................................................22

PVB 256 Variant Overview

PVB 256 3-way Compensator.................................................................................................................................................... 28

PVB 256 3-way Compensator with LS A/B.............................................................................................................................32

PVB 256 3-way Compensator with LSA/B and PVLP..........................................................................................................36

PVB 256 3-way Compensator with LS A/B, PVLP and Turbo...........................................................................................41

PVLP Shock and PVLA Suction Valves

PVLP Overview................................................................................................................................................................................46

PVLP Technical Data......................................................................................................................................................................46

PVBS Main Spool

PVBS Main Spools variant overview........................................................................................................................................49

Flow control spools..................................................................................................................................................................49

PVBS main spools product details........................................................................................................................................... 49

PVS Main spools part numbers................................................................................................................................................. 51

Flow control spools..................................................................................................................................................................52

Flow control spool closed neutral position............................................................................................................... 52

Flow control spool throttled open neutral position...............................................................................................52

Single acting cylinder flow control spool closed neutral position, flow control B port............................ 53

Flow control spool closed neutral position with A-float.......................................................................................54

PVM Manual Activation

PVM Technical Data.......................................................................................................................................................................56

PVH Hydraulic Actuation

PVH Technical Data....................................................................................................................................................................... 58

PVHC Electro-Hydraulic Actuator type

PVHC Technical Data.....................................................................................................................................................................60

PVMD Cover Manual Actuation Only

PVMD Part Numbers..................................................................................................................................................................... 61

PVE Electrical Actuator

PVE Series 7 Electrical Actuator.................................................................................................................................................62

PVE Variant Overview

PVE Variant Overview................................................................................................................................................................... 64

PVEO................................................................................................................................................................................................... 64

PVEO..............................................................................................................................................................................................65

PVEO Schematics and Dimensions............................................................................................................................... 66

PVEO Technical Data..........................................................................................................................................................66

PVEO 128/256 Reaction Times........................................................................................................................................67

PVEO Variants for PVG....................................................................................................................................................... 67

PVEH....................................................................................................................................................................................................68

PVEH Overview..........................................................................................................................................................................68

PVEH Schematics and Dimensions............................................................................................................................... 69

PVEH Technical Data.......................................................................................................................................................... 69

PVEH Reaction Times......................................................................................................................................................... 71

©

Danfoss | July 2021 BC220686485279en-000510 | 3

Page 4

Technical Information

PVG 128/256 Technical Information

Contents

PVEH Hysteresis and Ripple.............................................................................................................................................71

PVEH Variants for PVG....................................................................................................................................................... 72

Connector Overview

Connector Overview.....................................................................................................................................................................73

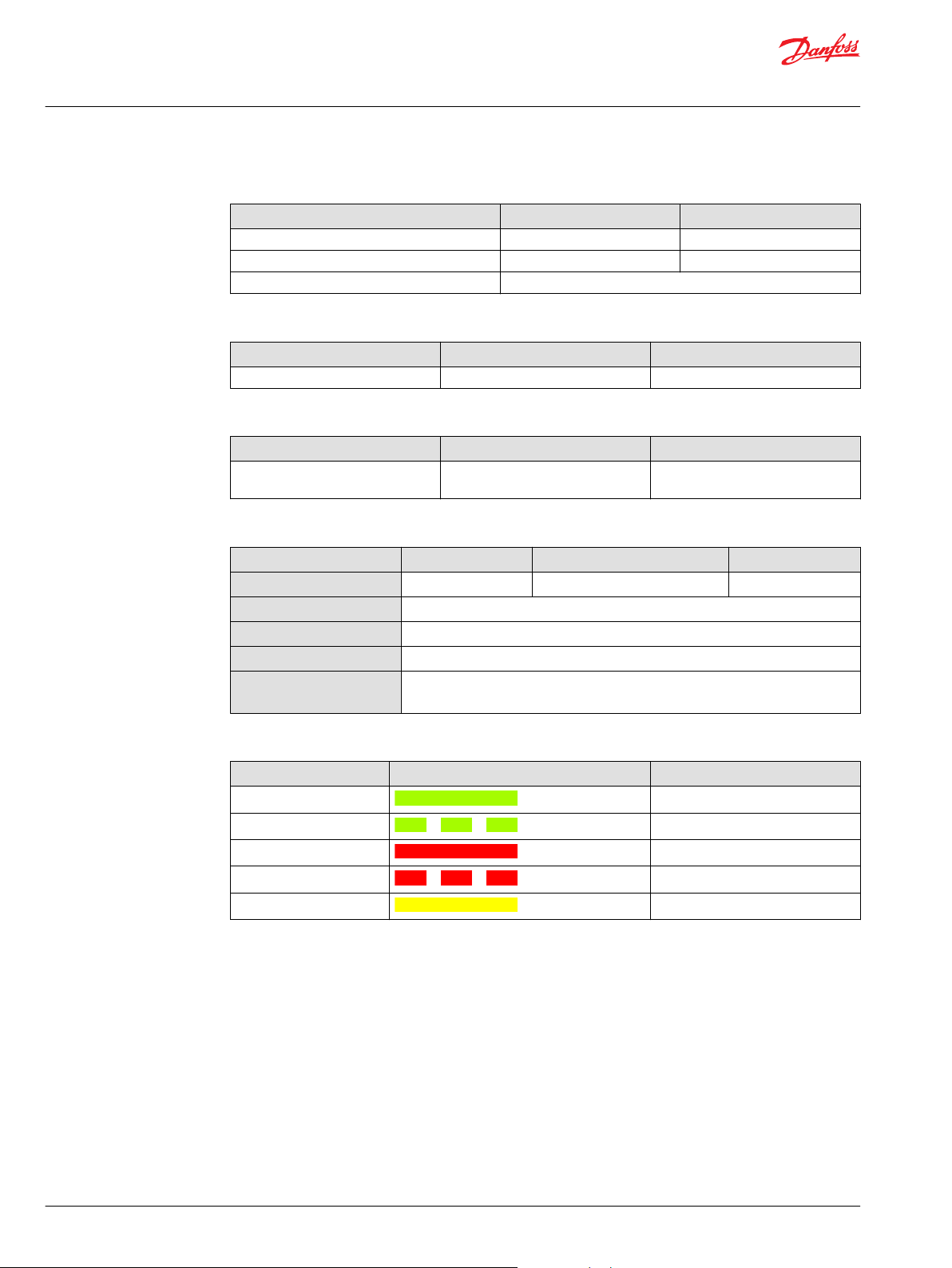

Fault Monitoring and Reaction

Generic Fault Reaction.................................................................................................................................................................74

PVEH Fault Reaction Overview..................................................................................................................................................75

Functionality Overview

Standard and Fixed US 0-10 Vdc.............................................................................................................................................. 76

PWM Voltage Control..............................................................................................................................................................76

Float A-Port (-FLA)..........................................................................................................................................................................78

PVE Power Save.............................................................................................................................................................................. 78

Special Features

Dedicated Float Pin (UF)..............................................................................................................................................................79

Disable Mode...................................................................................................................................................................................79

Performance Overview

PVG 128/256 Reaction Times.....................................................................................................................................................80

Hysteresis and Ripple................................................................................................................................................................... 81

Oil Consumption............................................................................................................................................................................ 81

PVSI/PVGI End and Interface Plates

PVSI with or without LX-connection.......................................................................................................................................83

PVSI with P and T port connections........................................................................................................................................ 84

PVGI Interface Plate.......................................................................................................................................................................85

PVAS

PVAS for Combo............................................................................................................................................................................. 87

PVAS Part Number Overview.....................................................................................................................................................88

PVG Valve Schematics

Valve Schematics............................................................................................................................................................................90

Dimension Overview

Dimension Overview for PVG 128/256...................................................................................................................................92

Specifications example................................................................................................................................................................ 95

4 | © Danfoss | July 2021 BC220686485279en-000510

Page 5

W

Technical Information

PVG 128/256 Technical Information

General Information

Safety in Systems

All types and brands of control valves, including proportional valves, can fail. Therefore, the necessary

protection against the serious consequences of a functional failure should always be built into the

system.

General safety considerations

For each application an assessment should be made for the consequences of the system in case of

pressure failure and uncontrolled or blocked movements.

Warning

Because the proportional valve is used in many different applications and under different operating

conditions, it is the sole responsibility of the manufacturer to ensure that all performance, safety and

warning requirements of the application is met in his selection of products and complies with relevant

machine specific and generic standards.

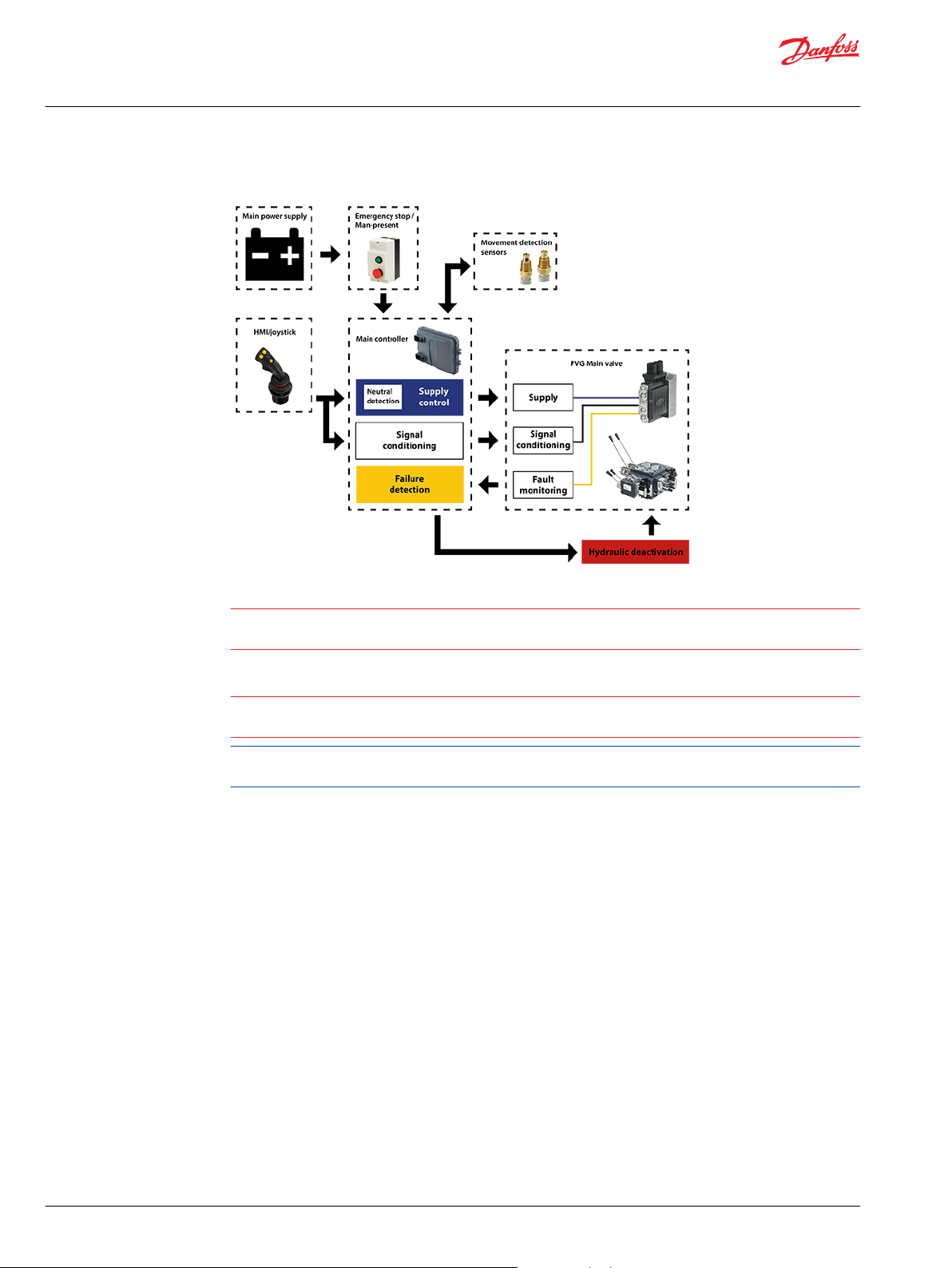

Control system example

An example of a control system using an aerial lift is shown below:

Aerial lift

This example breaks down the control system into smaller bits explaining the architecture in depth. Even

though many Danfoss components are used in the PVG control system.

The function of the control system is to use the output from the PVE together other external sensors to

ensure the PLUS+1 main controllers correct function of the aerial lift.

©

Danfoss | July 2021 BC220686485279en-000510 | 5

Page 6

W

C

Technical Information

PVG 128/256 Technical Information

General Information

Electrical block diagram

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

Caution

A mix of electrical actuation and hydraulic actuation on the same valve stack is not safe. PVE and PVH are

designed for different pilot pressure.

Cost-free repairs, as mentioned in Danfoss General Conditions of Sale, are carried out only at Danfoss or

at service shops authorized by Danfoss.

6 | © Danfoss | July 2021 BC220686485279en-000510

Page 7

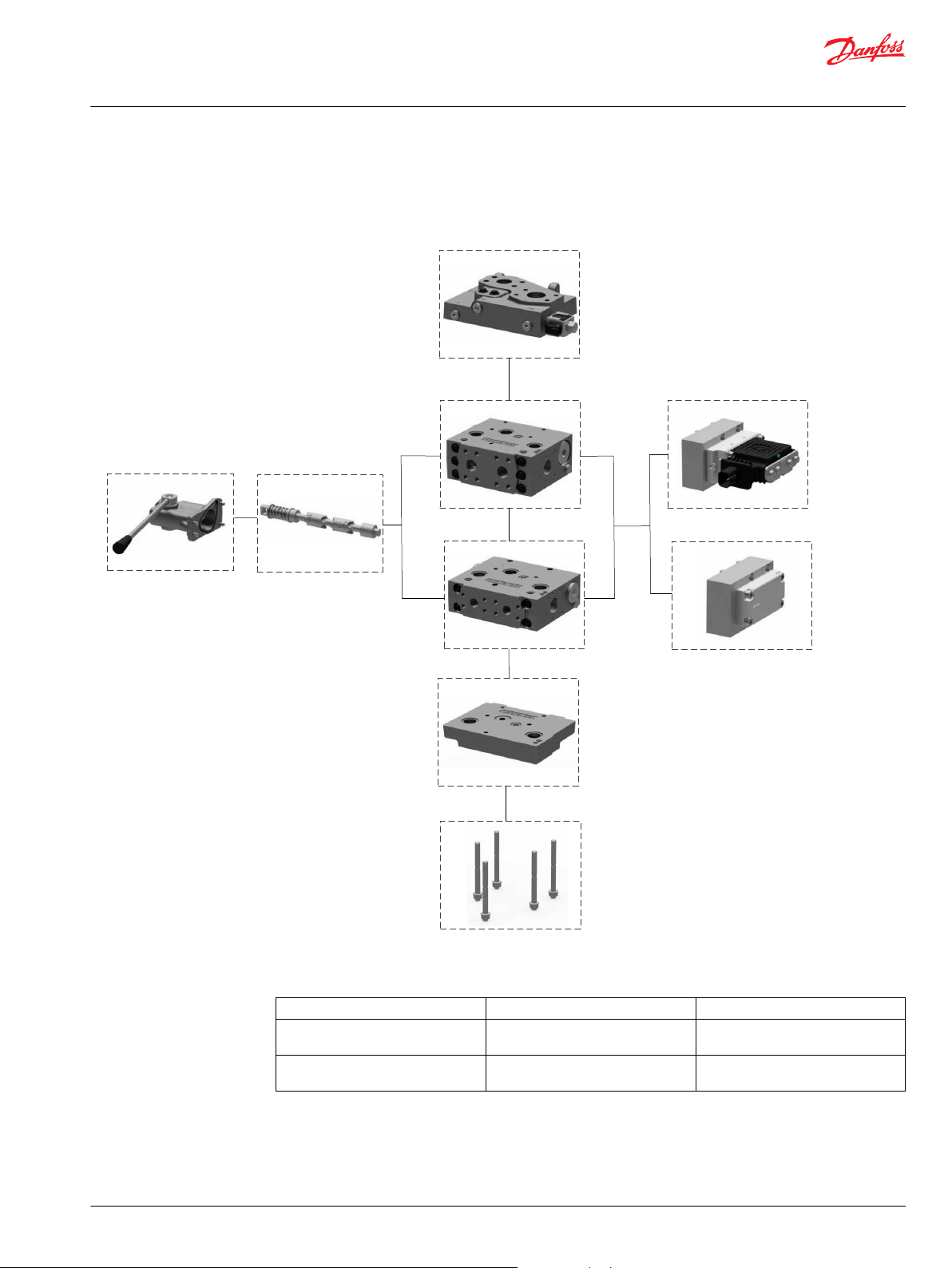

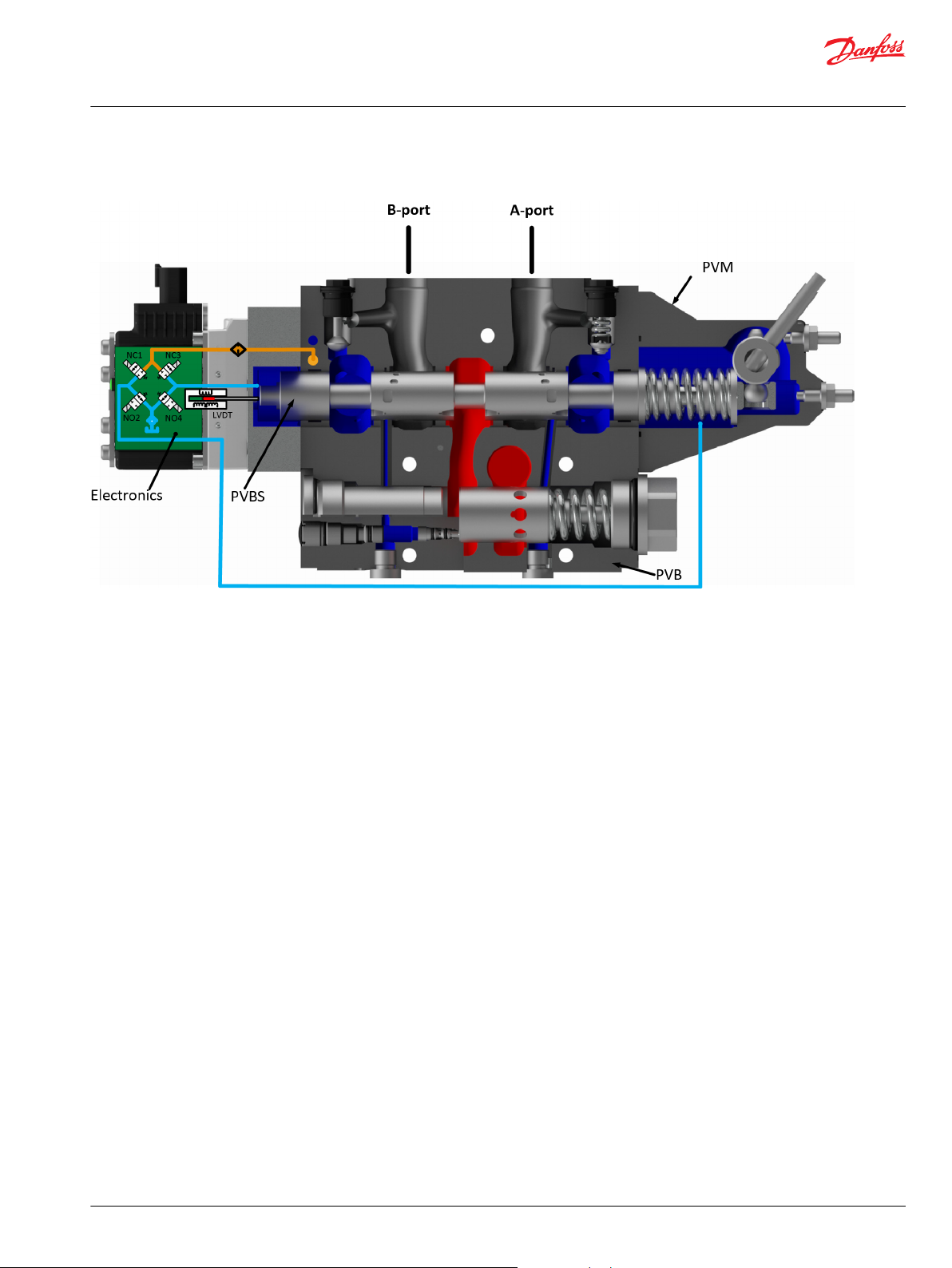

PVPV

PVE/PVHC ActuatorsPVB 256

PVM PVBS

PVB 128

PVMD/PVH Covers

PVSI/PVGI

PVAS

P109160

Technical Information

PVG 128/256 Technical Information

General Information

PVG 128/256 Proportional Valve Group

Navigation

PVPV PVB 256 PVB 128

PVBS Main Spool on page 49 PVM PVE Series 7 Electrical Actuator on

PVMD/PVH Covers PVSI/PVGI End and Interface Plates on

page 82

page 62/PVHC

PVAS

©

Danfoss | July 2021 BC220686485279en-000510 | 7

Page 8

Technical Information

PVG 128/256 Technical Information

General Information

PVG general description

PVG is a hydraulic, load-sensing proportional valve, designed for optimal machine performance and

maximum design flexibility.

The PVG valve design is based on a modular concept that enables machine designers to specify a valve

solution suitable for multiple market segments across multiple applications.

The load independent proportional control valve and high performance actuator technology combined

with a low pressure drop design improves the machine performance and efficiency – increasing

productivity and reducing energy consumption.

Features of the PVG 128/256 valve

•

Inlet flow up to 1200 l/min [317 US gal/min]

•

Compact sectional platform solution for easy integration with PVG 16 and PVG 32

•

Load-independent flow control:

Oil flow to an individual function is independent of the load pressure of this function

‒

Oil flow to one function is independent of the load pressure of other functions

‒

•

Reliable regulation characteristics across the entire flow range

•

Load sense relief valves for A and B port enables reduced energy loss at target pressure

•

Optimized for lower pressure drop and higher efficiency

•

Several options for connection threads and flange mount

•

Compact design, easy installation and serviceability

•

Static Load sense system when selecting pump control

•

Internal T0 connection in all PVSI/PVGI

8 | © Danfoss | July 2021 BC220686485279en-000510

Page 9

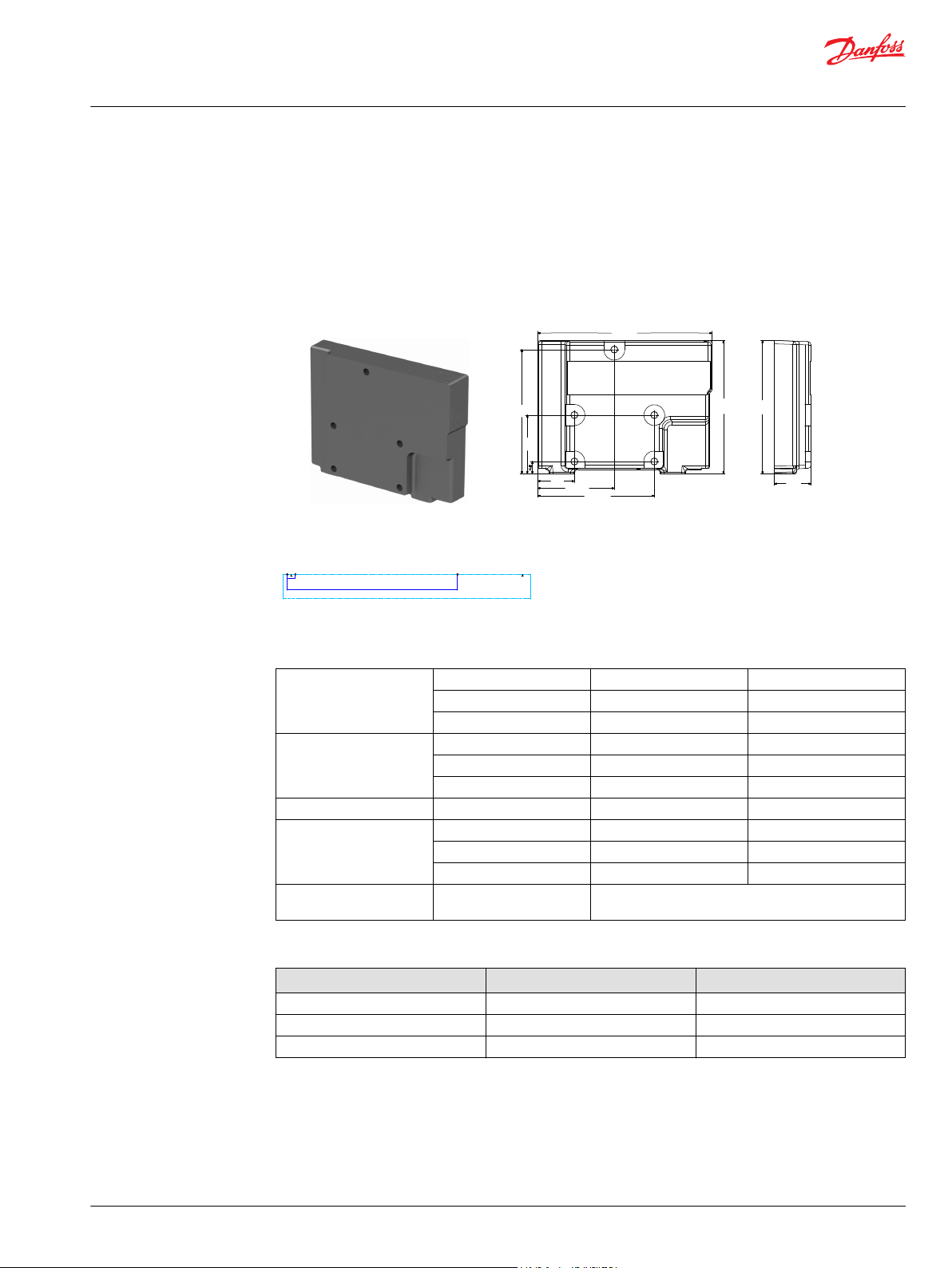

59

47.5

285.5

100.5

78.5

68

43.5

180.6

62

PVPV 256

PVPV inlet module dimensions (mm)

Weight 10 kg [22 lbs]

Technical Information

PVG 128/256 Technical Information

PVPV Inlet Modules

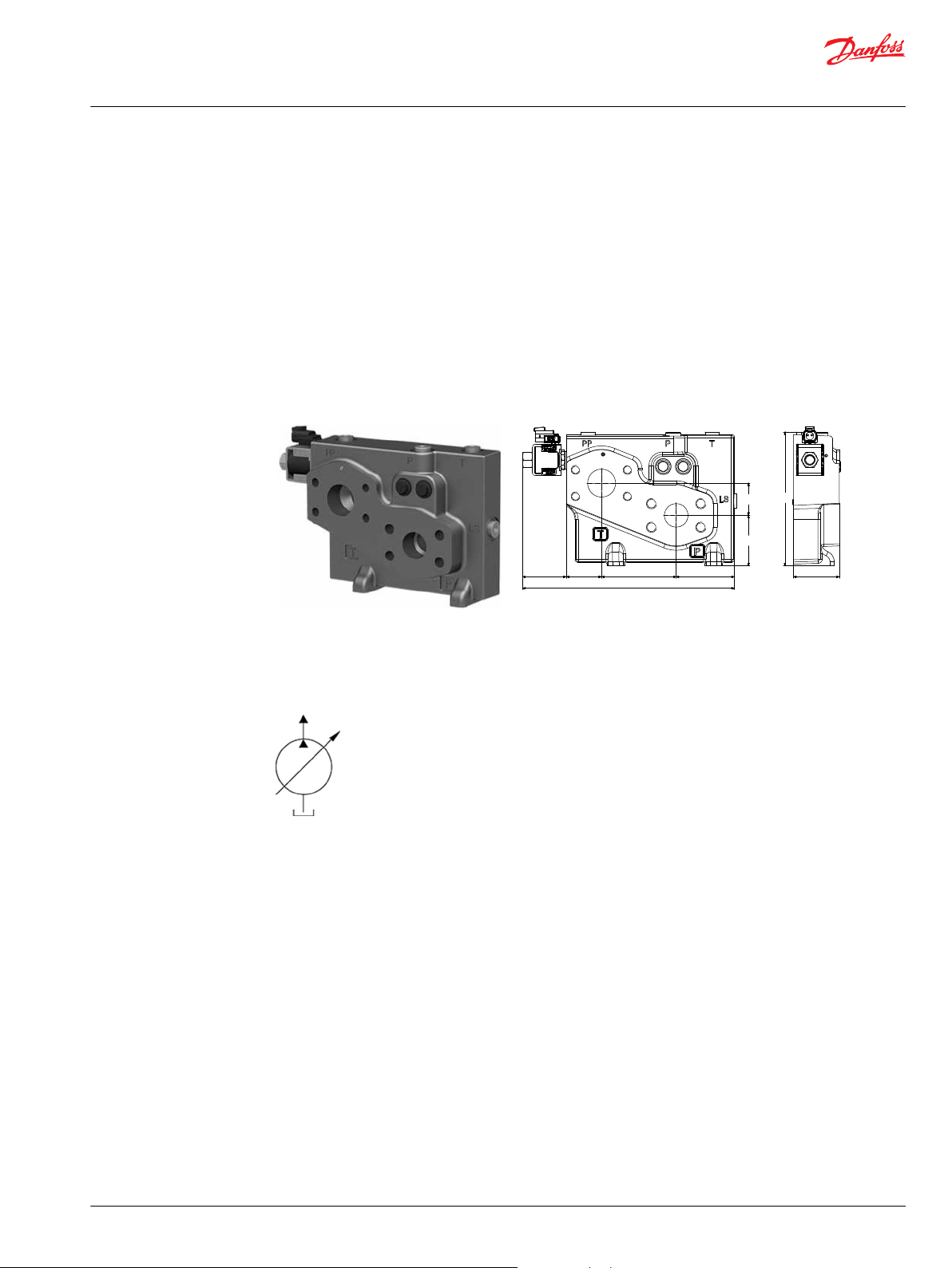

The Closed Center PVPV inlet with integrated pilot pressure reduction valve (PPRV) for PVE activation is

intended for use with variable displacement pumps in applications where a valve group with electrohydraulic or hydraulically controlled work sections is desired.

All Variants are prepared for 2xPVLP shock/anti-cavitation valves for pressure peak protection and anticavitation prevention.

PVLPs are for pressure peak protection in the system and pump.

Optional electrically actuated pilot shut off valve PVPP provides additional functional system safety by

removing pilot oil from the electrical actuation or hydraulic actuation system, disabling main spool

actuation.

All variants have internal T0 to tank connection in the PVSI and PVGI end plates.

The PVPV 256 inlet module variants are based on a generic platform with a selection of additional

features, enabling you to tailor the PVPV inlet to suit the demands of any hydraulic system.

Variable displacement pump symbol

The generic PVPV 256 inlet module platform includes the following main variants:

Closed Center PVPV with PPRV PVEClosed center inlet module for variable displacement pumps.

Closed Center PVPV with PPRV for PVH/PVHC Closed center inlet module for variable displacement pumps.

Optional feature: PVPP Electrical Pilot Shut-Off Valve - Closed center inlet module for variable

displacement pumps.

©

Danfoss | July 2021 BC220686485279en-000510 | 9

Page 10

P

Pp

T

T

LS

P

P109162

Technical Information

PVG 128/256 Technical Information

PVPV Inlet Modules

Closed Center PPRV for PVE Activation and/or Mechanical

The PVPV 256 inlet modules, also referred to as pump side modules, act as an interface between the PVG

128/256 proportional valve group and the hydraulic pump and tank reservoir.

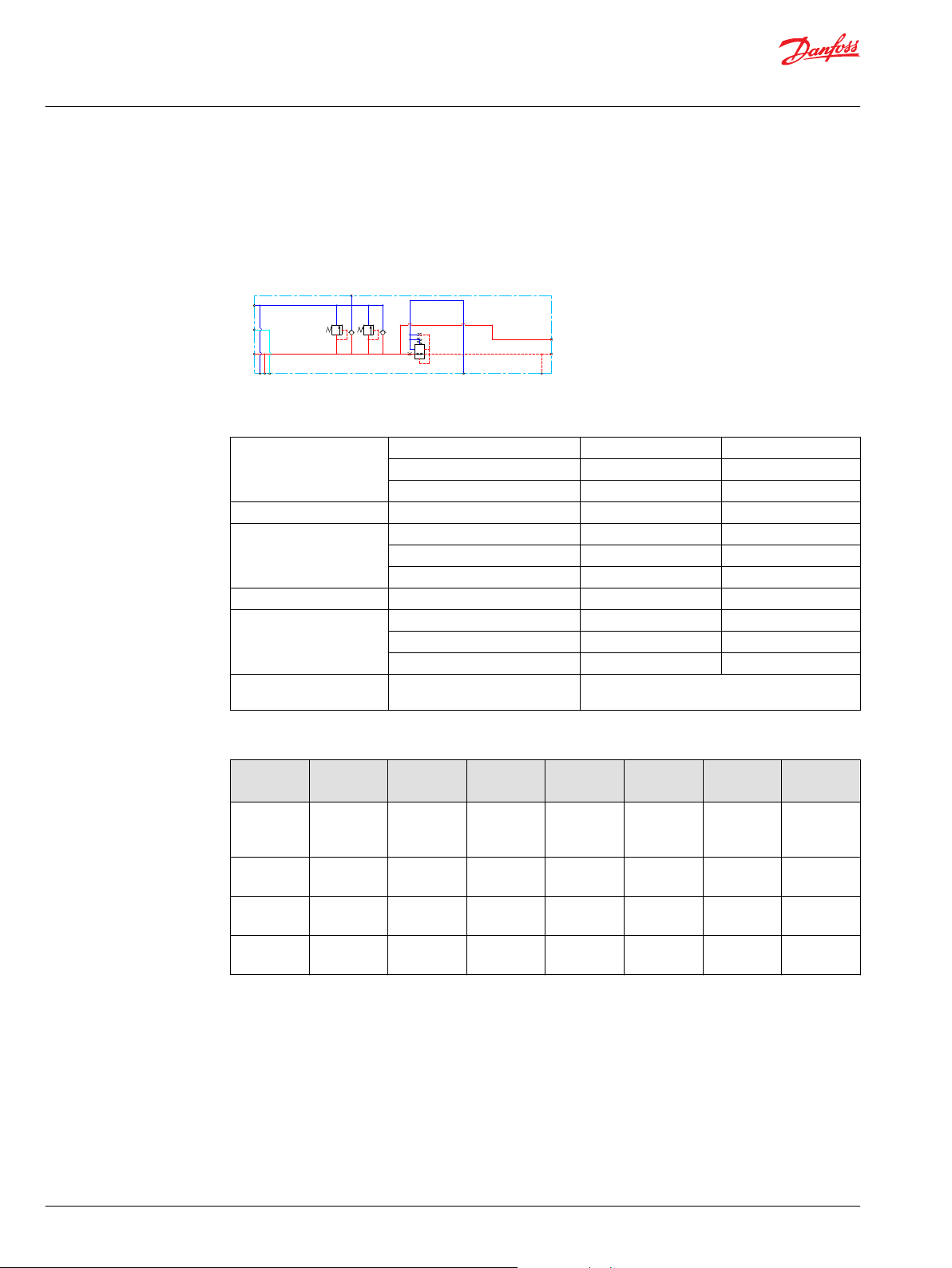

Schematic

Technical data

Max. rated pressure P-port continuous 350 bar [5076 psi]

P-port intermittent 400 bar [5800 psi]

T-port static/dynamic 25/40 bar [363/580 psi]

Rated Port P (PVPV/PVSI) P-port 600/600 l/min [159/159 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Maximum 23/19/16

Part numbers for Closed Center PVPV with PPRV for PVE

Part

number

11173130 PVE

11176703 PVE

11176691 PVE

11176702 PVE

10 | © Danfoss | July 2021 BC220686485279en-000510

PPRV P-port T-port

Metric

Flange

1-1/4”

Thread Ports

G1-1/2" BSP

SAE Flange

1-1/4” UNF

Thread Ports

1-7/8” UNF

Metric

Flange

1-1/2”

Thread Ports

G1-1/2" BSP

SAE Flange

1-1/2” UNF

Thread Ports

1-7/8” UNF

LS-port

Gauge-port

G3/8"BSP G3/8"BSP G1/4"BSP M12

G3/8"BSP G3/8"BSP G1/4"BSP M12

9/16-18 UNF 3/4-16 UNF 7/16-20 UNF M12

9/16-18 UNF 3/4-16 UNF 7/16-20 UNF M12

M-port

Gauge-port

T- and Pp

Gauge-port

Mounting

feet

Page 11

[psi] [bar]

P

Max

Min

Q

400

300

200

100

0

30

25

20

15

10

5

0

0 1 2 3 4 5

0 0.25 0.5 0.75 1.0 1.25

Q

[l/min]

[US gal/min]

P109211

Technical Information

PVG 128/256 Technical Information

PVPV Inlet Modules

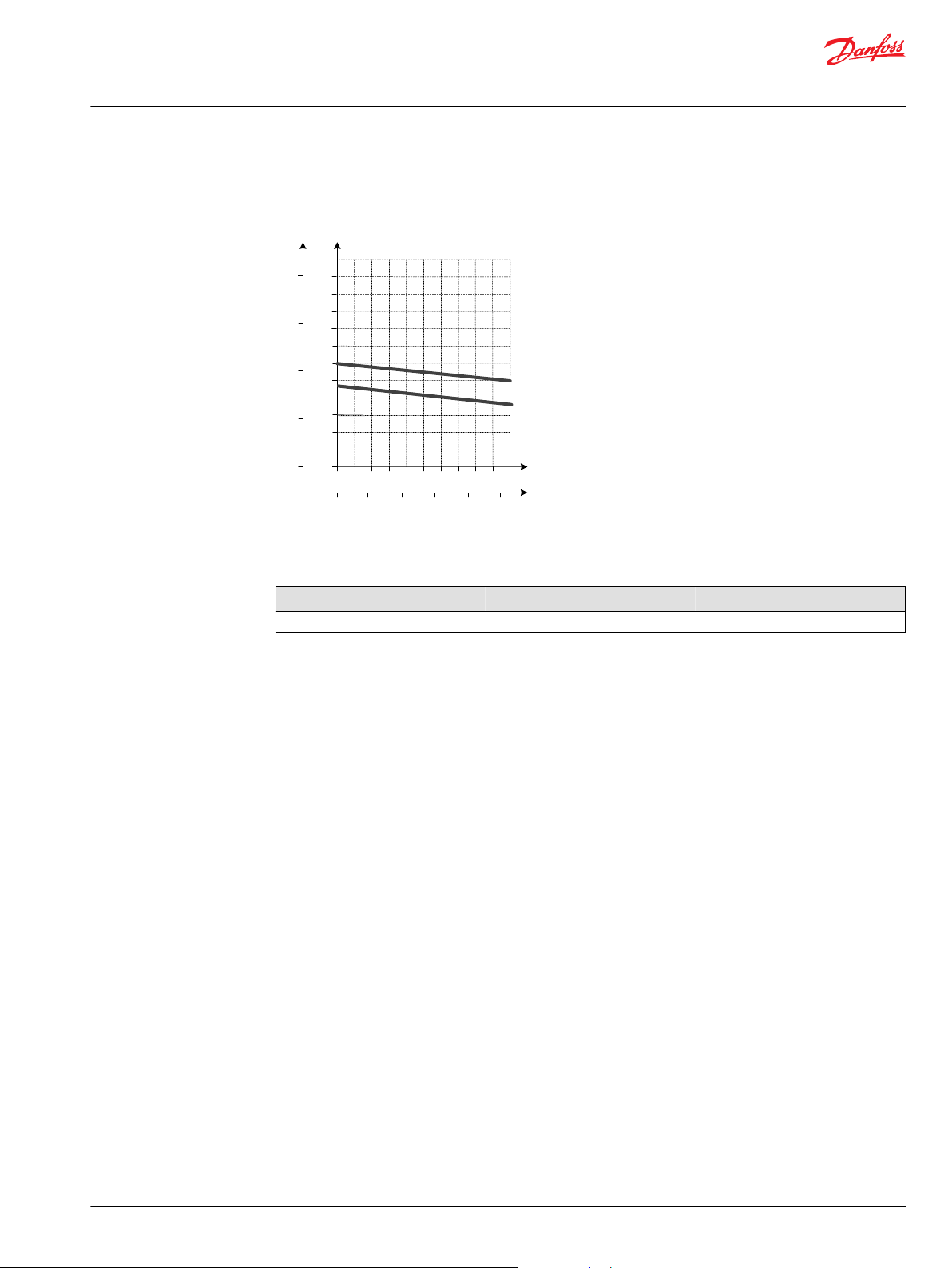

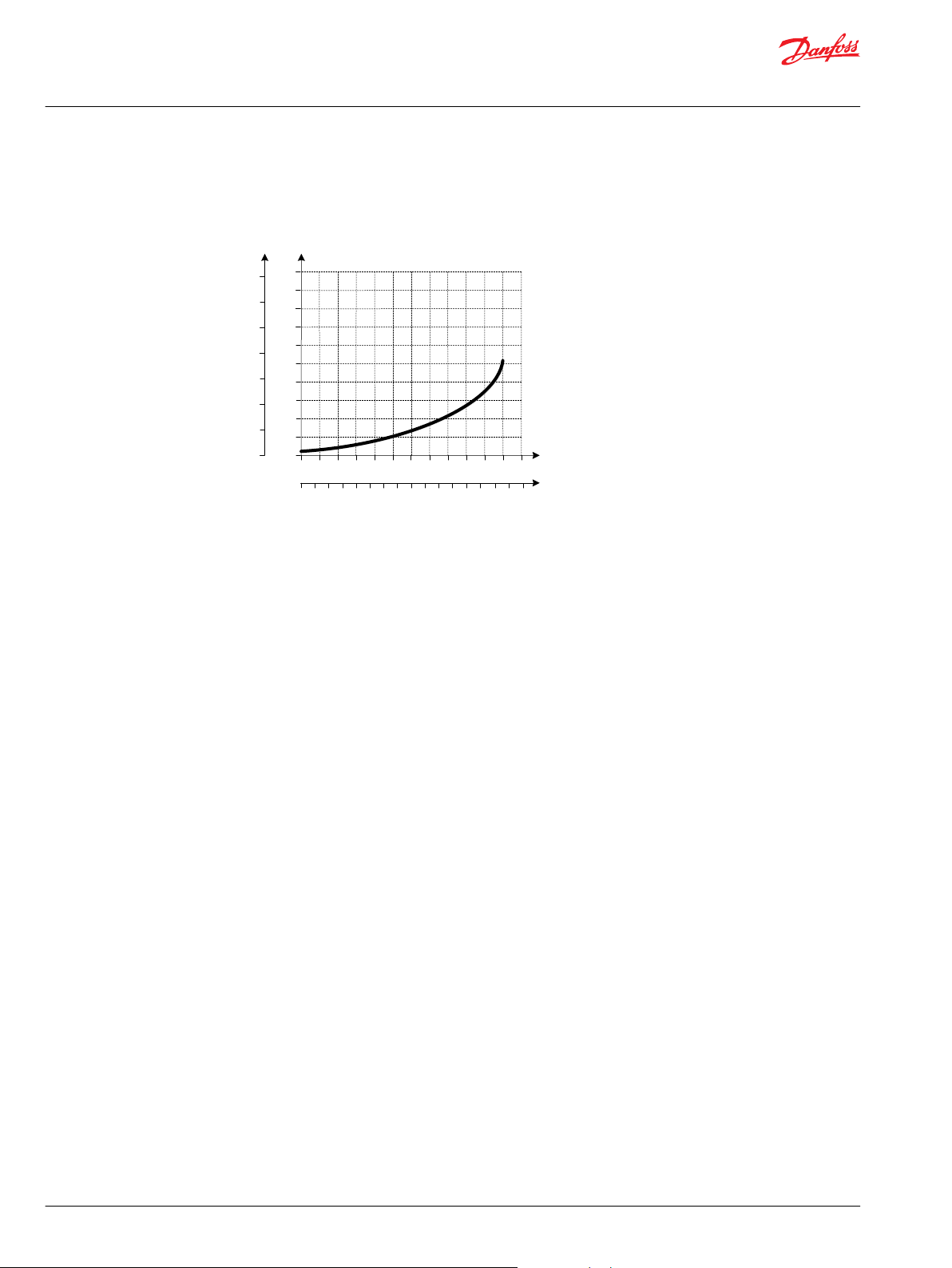

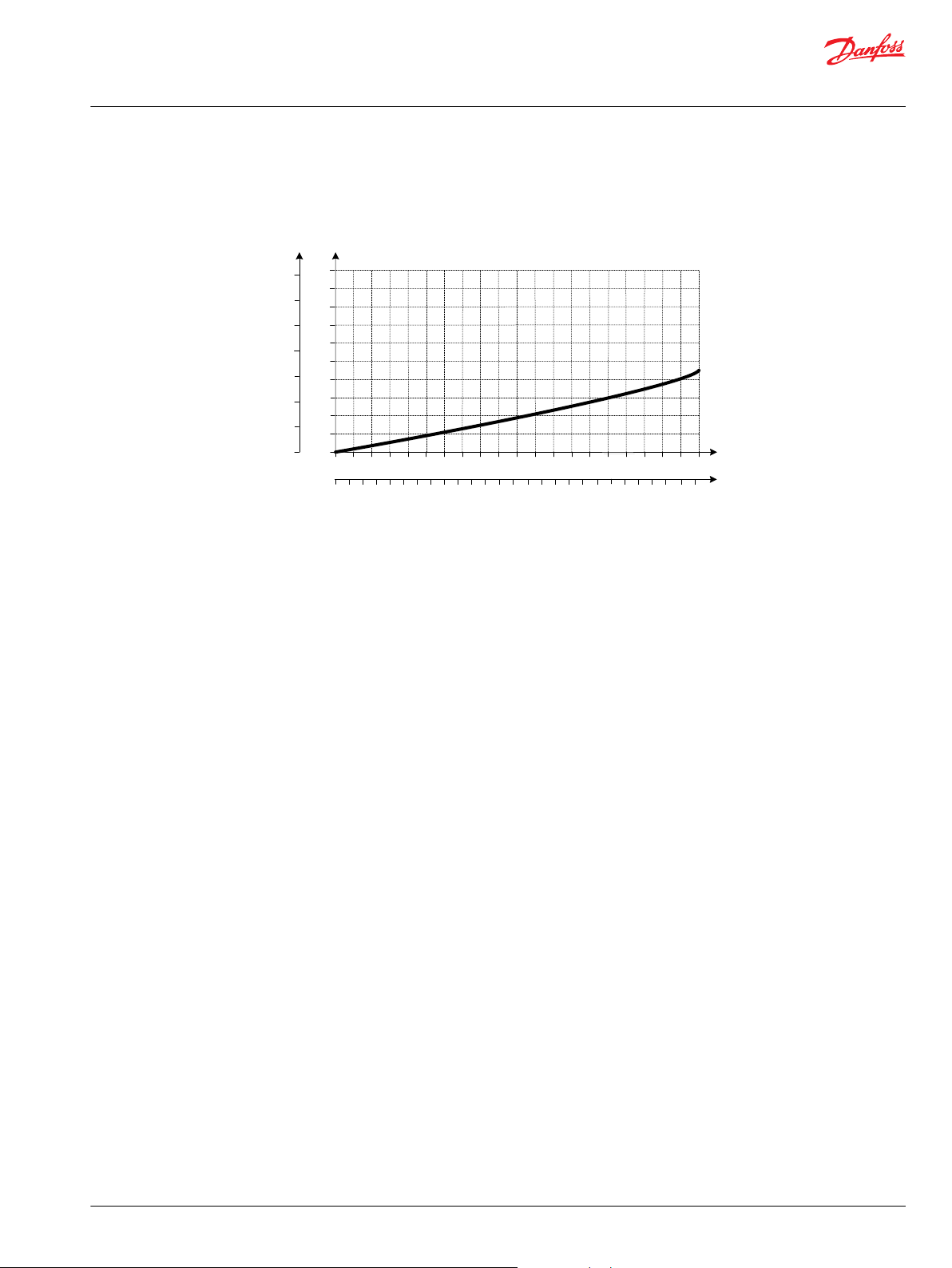

Pilot Pressure Reduction Valve Performance

Accessory module for PVPV 256

Ordering information 12 V 24 V

PVPP Pilot shut off valve 11160318 11160319

©

Danfoss | July 2021 BC220686485279en-000510 | 11

Page 12

P

Pp

T

T

LS

P

P109163

Technical Information

PVG 128/256 Technical Information

PVPV Inlet Modules

PPRV for PVH/PVHC Activation and/or Mechanical

The Closed Center PVPV inlet with integrated pilot pressure reduction valve (PPRV) for PVH/PVHC

activation is intended for use with variable displacement pumps in applications where a valve group with

PVH/PVHC controlled work sections is desired.

All Variants are prepared for 2xPVLP shock/anti-cavitation valves for pressure peak protection and anticavitation prevention.

Optional electrically actuated pilot shut off valve PVPP provides additional functional system safety by

removing pilot oil from the electrical actuation or hydraulic actuation system, disabling main spool

actuation.

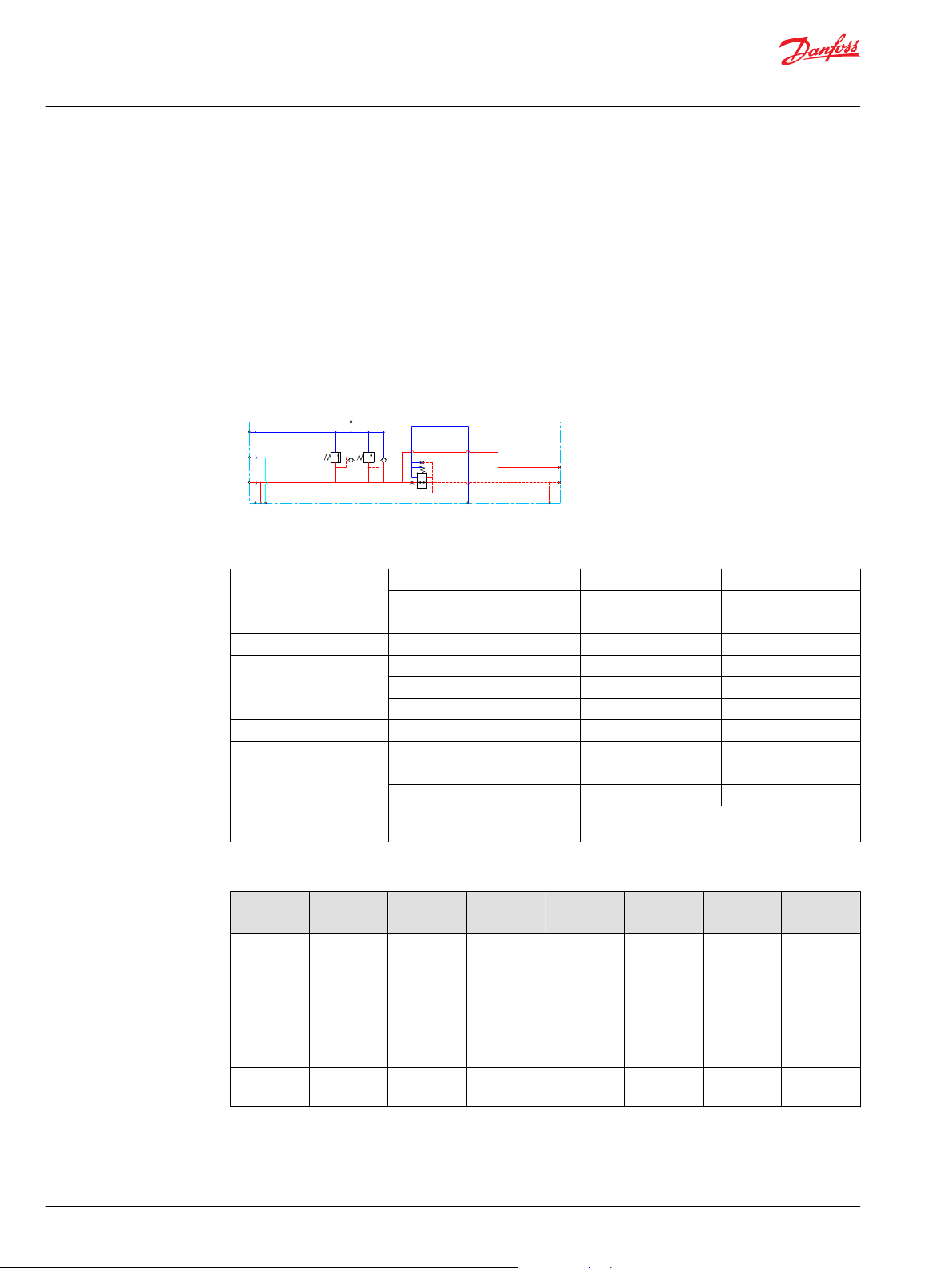

Schematic

Technical data

Max. rated pressure P-port continuous 350 bar [5076 psi]

P-port intermittent 400 bar [5800 psi]

T-port static/dynamic 25/40 bar [363/580 psi]

Rated Port P (PVPV/PVSI) P-port 600/600 l/min [159/159 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Maximum 23/19/16

Part numbers for Closed Center PVPV with PPRV for PVH/PVHC

Part

number

11178095 PVH/PVHC

11178098 PVH/PVHC

11178117 PVH/PVHC

11178119 PVH/PVHC

PPRV P-port T-port

Metric

Flange

1-1/4”

Thread Ports

G1-1/2" BSP

SAE Flange

1-1/4” UNF

Thread Ports

1-7/8” UNF

Metric

Flange

1-1/2”

Thread Ports

G1-1/2" BSP

SAE Flange

1-1/2” UNF

Thread Ports

1-7/8” UNF

LS-port

Gauge-port

G3/8"BSP G3/8"BSP G1/4"BSP M12

G3/8"BSP G3/8"BSP G1/4"BSP M12

9/16-18 UNF 3/4-16 UNF 7/16-20 UNF M12

9/16-18 UNF 3/4-16 UNF 7/16-20 UNF M12

M-port

Gauge-port

T- and Pp

Gauge-port

Mounting

feet

12 | © Danfoss | July 2021 BC220686485279en-000510

Page 13

1 2 3 4 5

5

0

0

P

Max

Min

Q

Q

[psi] [bar]

400

300

200

100

0

30

25

20

15

10

0 0.25 0.5 0.75 1.0 1.25

[l/min]

[US gal/min]

P109212

Technical Information

PVG 128/256 Technical Information

PVPV Inlet Modules

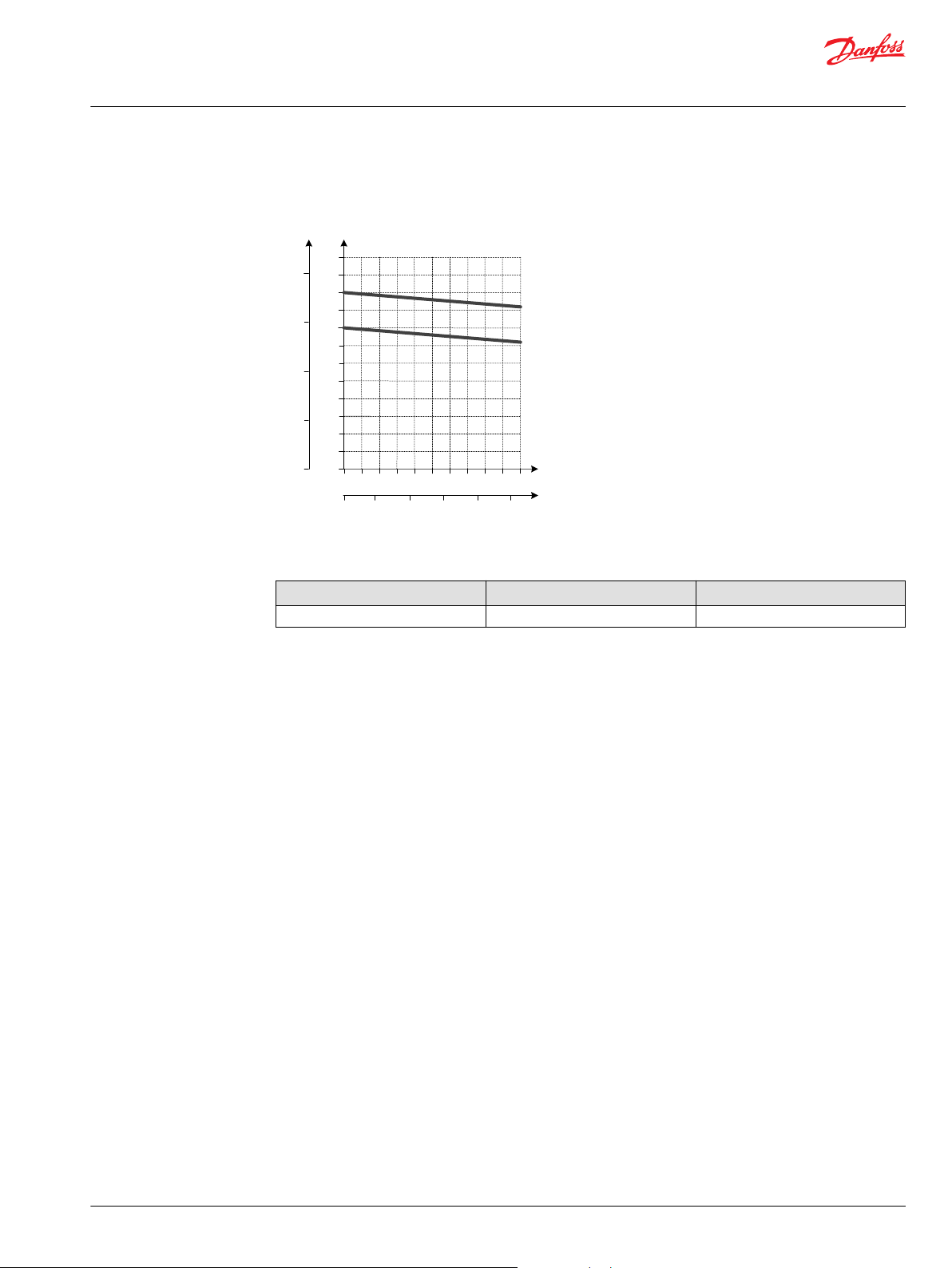

Pilot Pressure Reduction Valve Performance

Accessory module for PVPV 256

Ordering information 12 V 24 V

PVPP Pilot shut off valve 11160318 11160319

©

Danfoss | July 2021 BC220686485279en-000510 | 13

Page 14

182.2

205

23.5

66

107

178.8

33

PVB 128

PVB 128 basic module dimensions (mm)

Weight 10 kg [22 lbs]

W

Technical Information

PVG 128/256 Technical Information

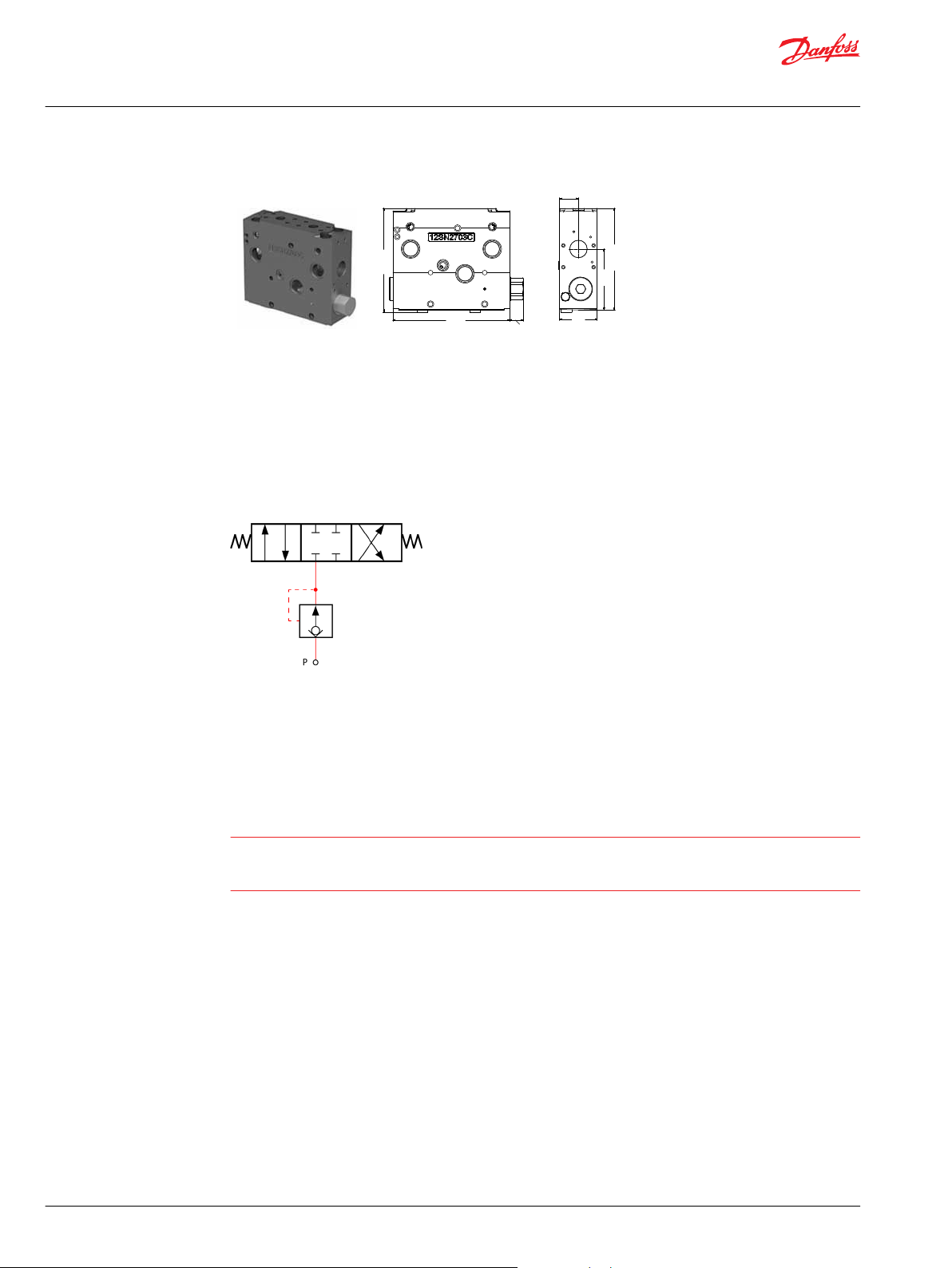

PVB 128 Variant Overview

The PVG 128 Basic modules (PVB), also referred to as work sections, is the interface between the PVG 128

proportional valve group and the work function such as a cylinder or a motor.

The PVB basic module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the PVB to suit the demands of any hydraulic system.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Symbol - compensated PVB

The generic PVB basic module platform includes the following main variants:

PVB 128 Compensated basic module.

Compensated PVB 128 w LSA/B Compensated basic module with LSA/B relief valve for each work port.

Compensated PVB 128 with LSA/B and PVLP Compensated basic module with LSA/B relief valve for each

work port and 2xPVLPs for each work port.

Warning

Risk of leak

The module will leak if the flange mount screws are not properly secured.

Flange mount screws according to ISO 6162-2.

14 | © Danfoss | July 2021 BC220686485279en-000510

Page 15

A

B

P109173

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

PVB 128 3-way Compensator

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

Max. rated flow

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

*

Rated flow at 15 bar margin pressure

A/B port intermittent 400 [5800 psi]

*

A/B port 250 l/min [66 US gal/min]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 80 cm3/min [4.88 in3/min

Part numbers for Compensated PVB 128

Part number A/B-port PVLP/PVLA LS A/B-port

11170522 Metric Flange 3/4” - 11170528 G 1" BSP - 11170524 SAE Flange 3/4” UNC - 11170526 Thread Ports 1 5/16 UNC - -

©

Danfoss | July 2021 BC220686485279en-000510 | 15

Page 16

AP

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

00.040.080.120.160.200.240.28

PVEH

U

s

U

DC

8

0.31

910

0.350.39

5

10

15

20

25

30

35

40

45

50

55

60

65

A

B

C

D

E

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310.280.240.20

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

321

0

0.120.080.04

0.75

A

B

C

D

E

PVEH

PVEH-U

5.0

7.5

PVEH-U

0.450.40.350.3

0.25

0.5

2.5

5.0

[V]

[V]

0

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

5

10

15

20

25

30

35

40

45

50

55

60

65

250225200175150125

100

755025

0

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[b ar]

[p si]

P109213

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

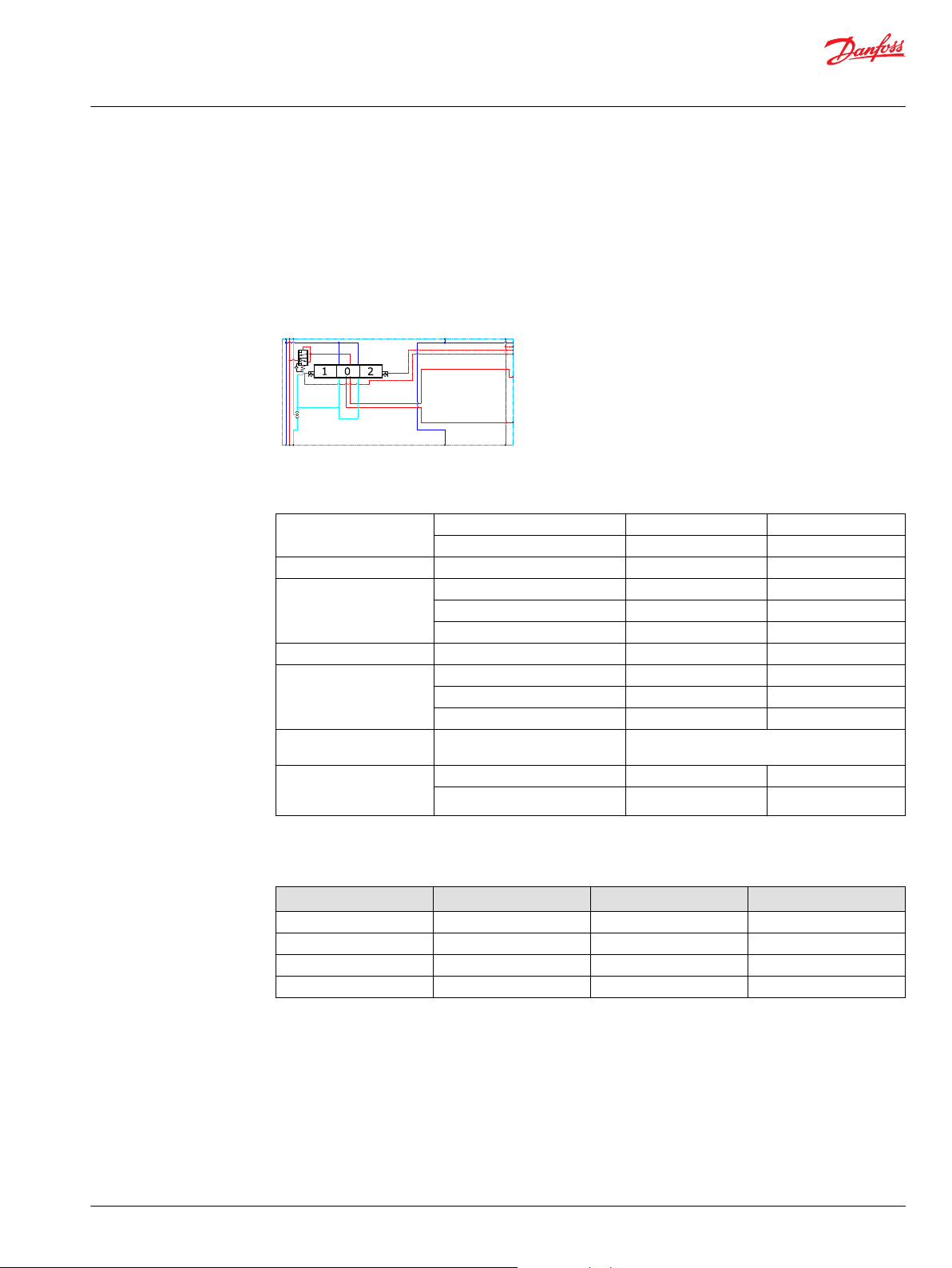

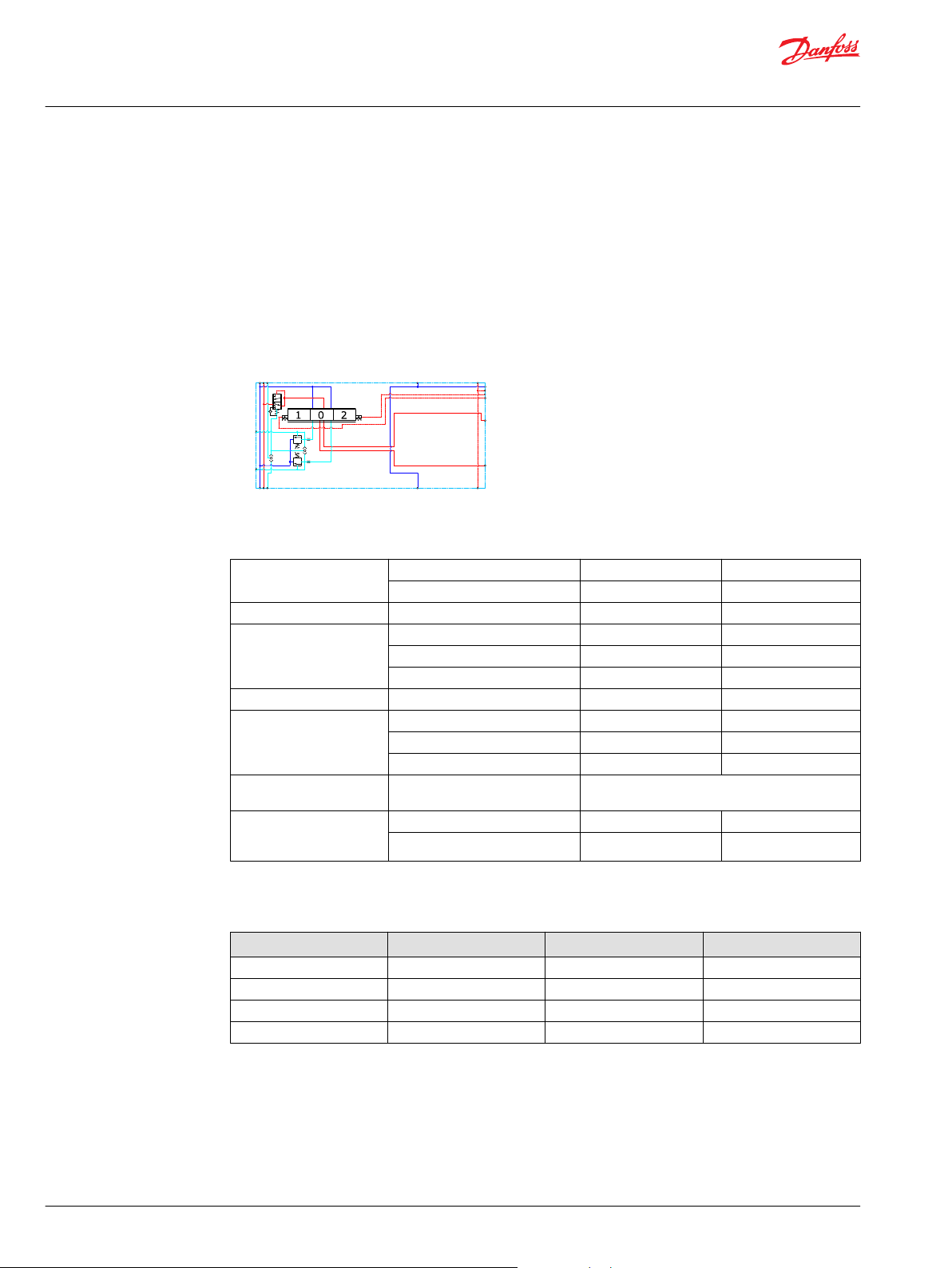

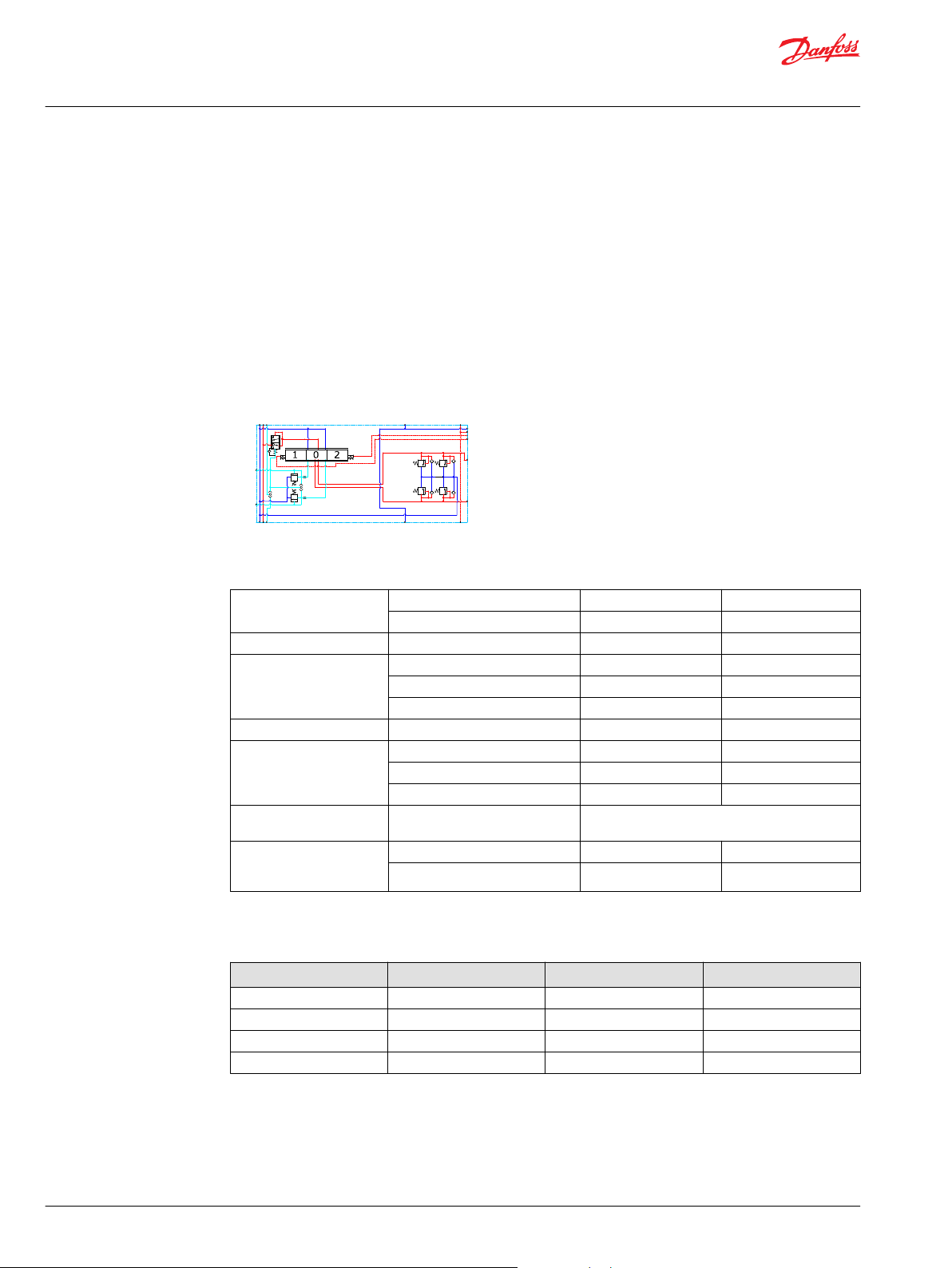

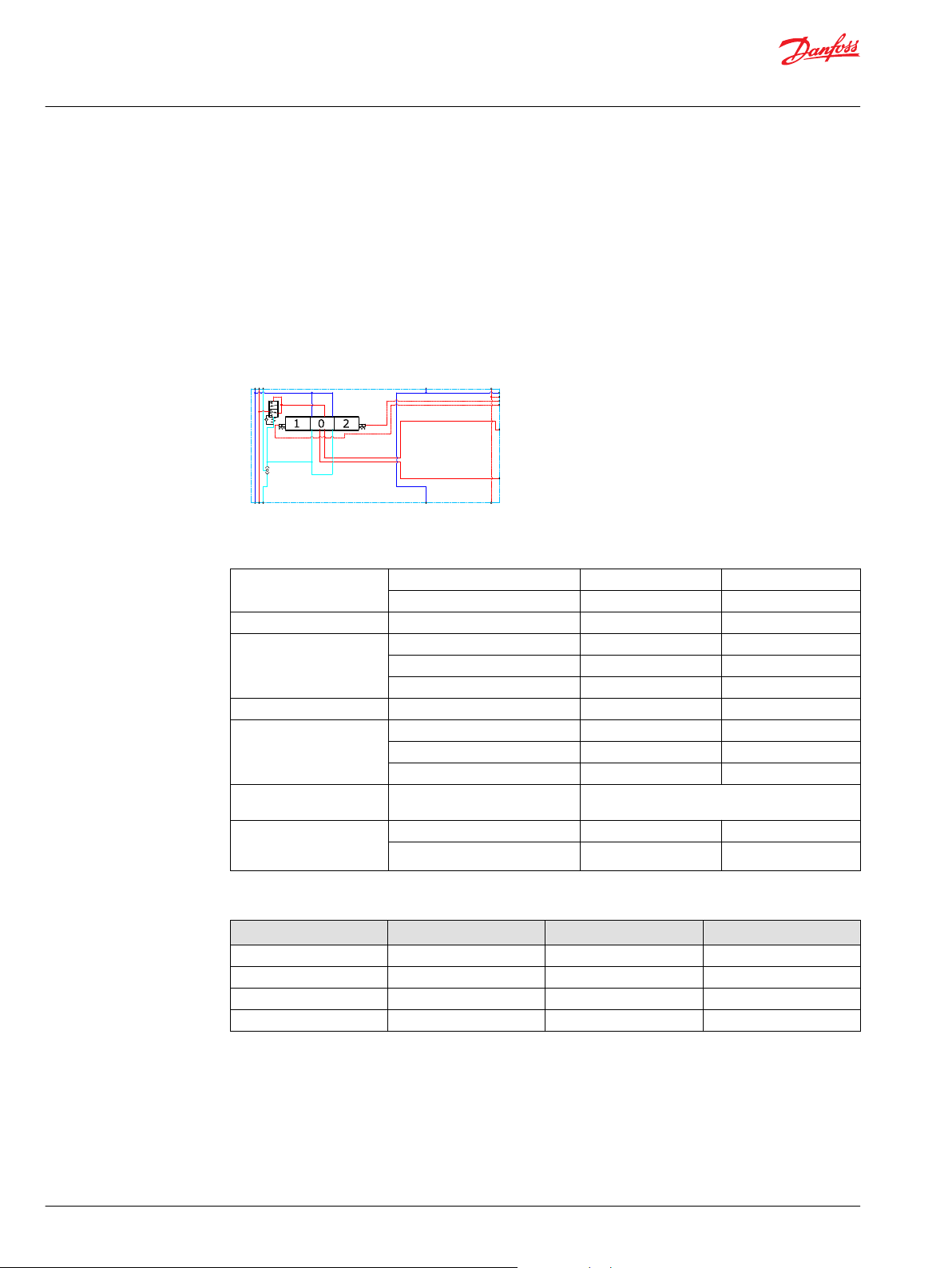

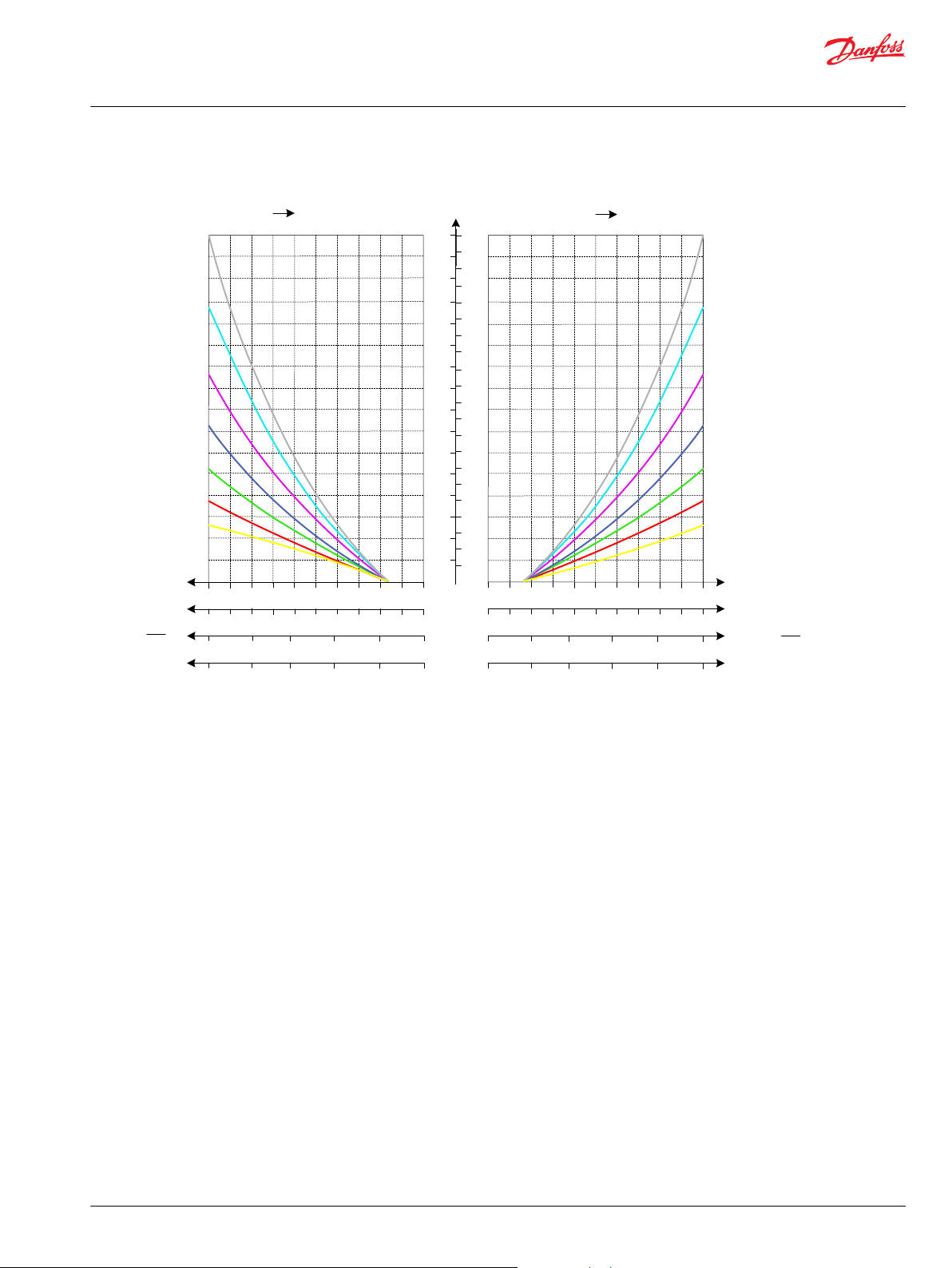

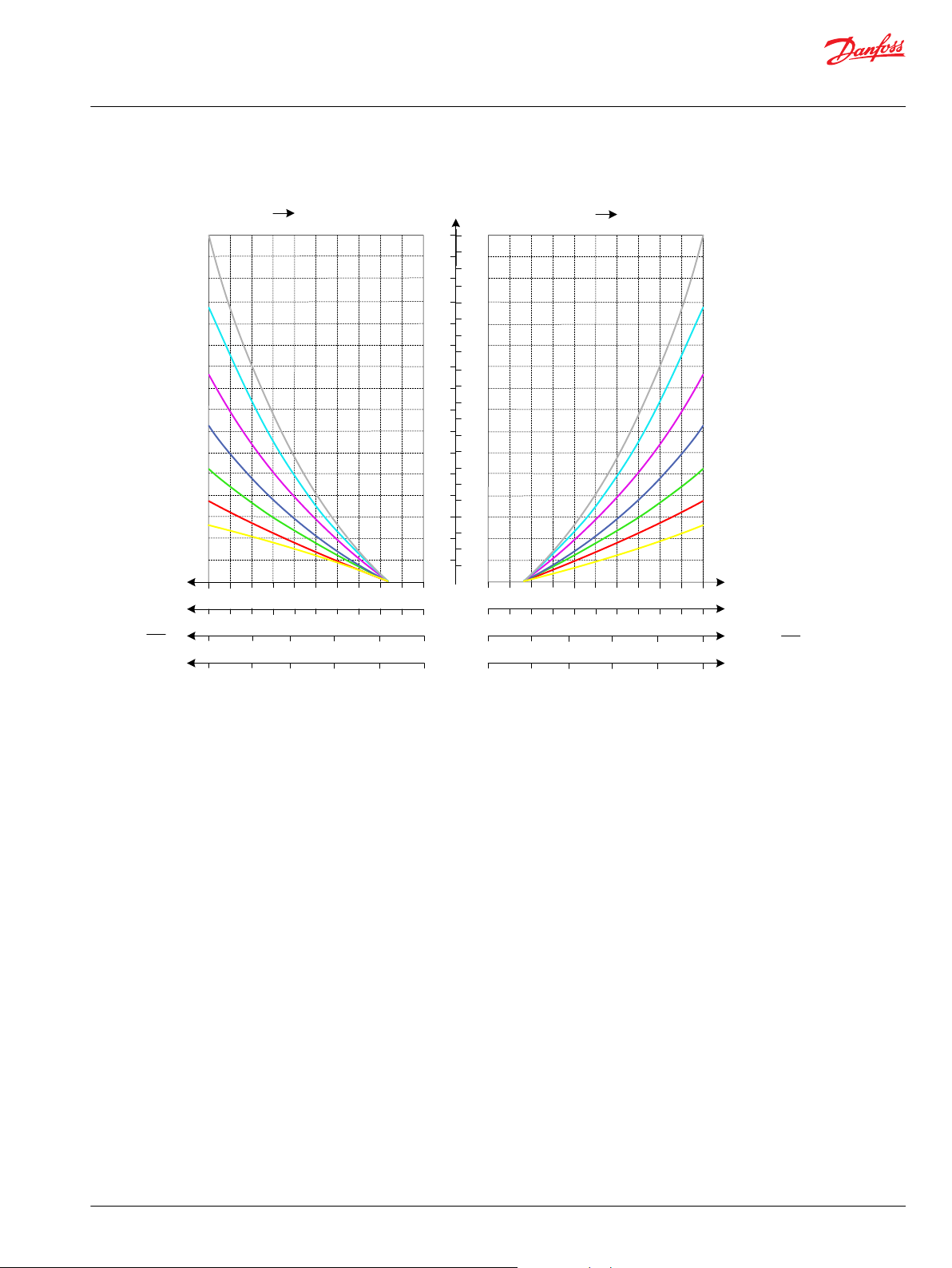

Oil flow as function of spool travel

Load Independent Oil Flow, Pressure Compensated

16 | © Danfoss | July 2021 BC220686485279en-000510

Page 17

25 50 75 100 125 150 175 200 225 250 275 300

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

25

20

15

10

5

0

250

200

150

100

50

0

350

300

0

0

Port P to Port A/B at full spool stroke

E = Spool 240 l/min

P

Q

Q

[psi] [bar]

[l/min]

[US gal/min]

P109240

5

0

0

P

Port A/B to Tank at full spool stroke

Q

Q

[psi] [bar]

350

300

200

150

100

50

250

0 25 50 75 100 125 150 175 200 225 250 275 300

25

20

15

10

0 5 10 15 20 25 30 35 404550

55 60

65 70 75 80

E = Spool 240 l/min

[l/min]

[US gal/min]

P109241

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

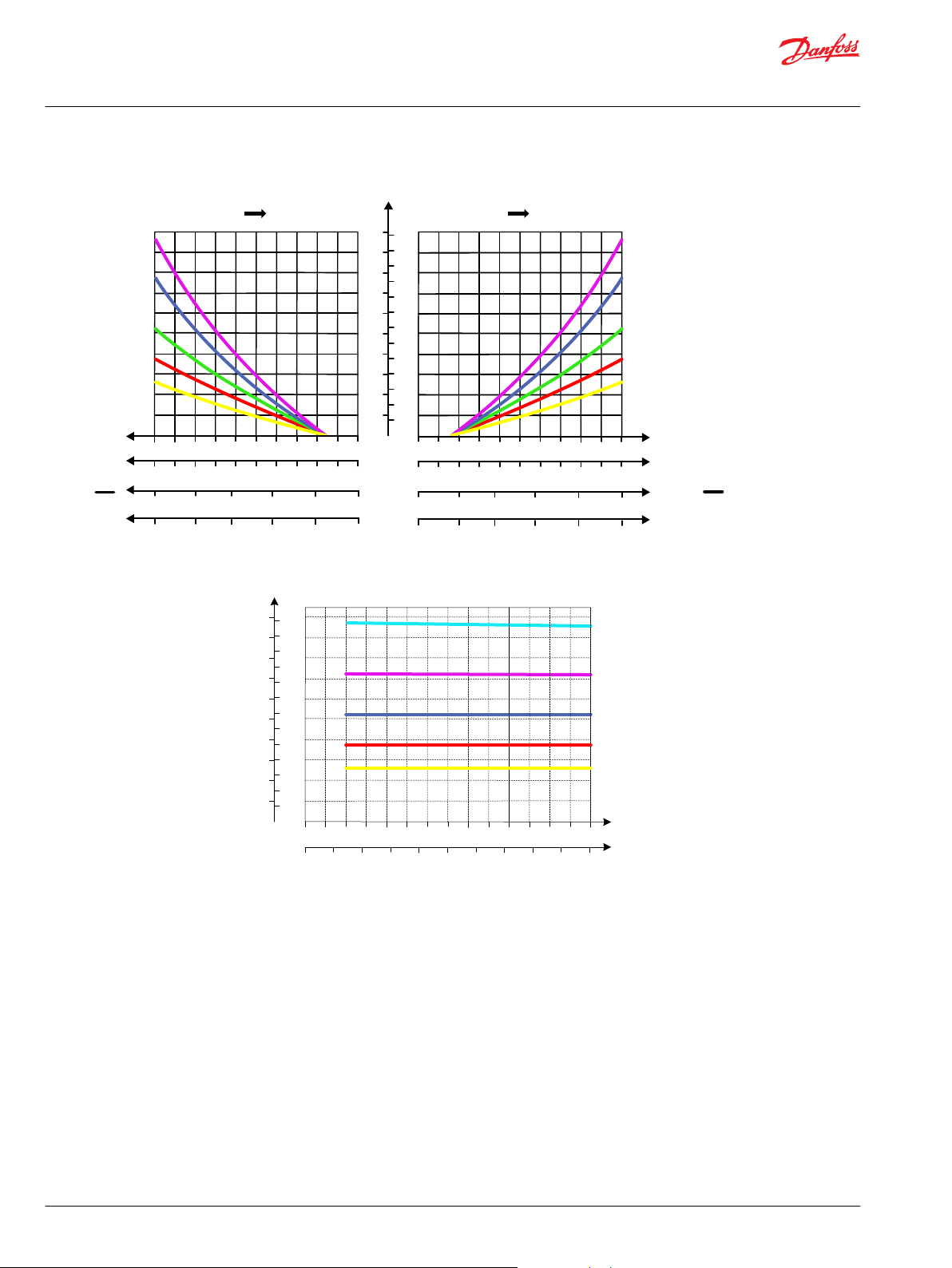

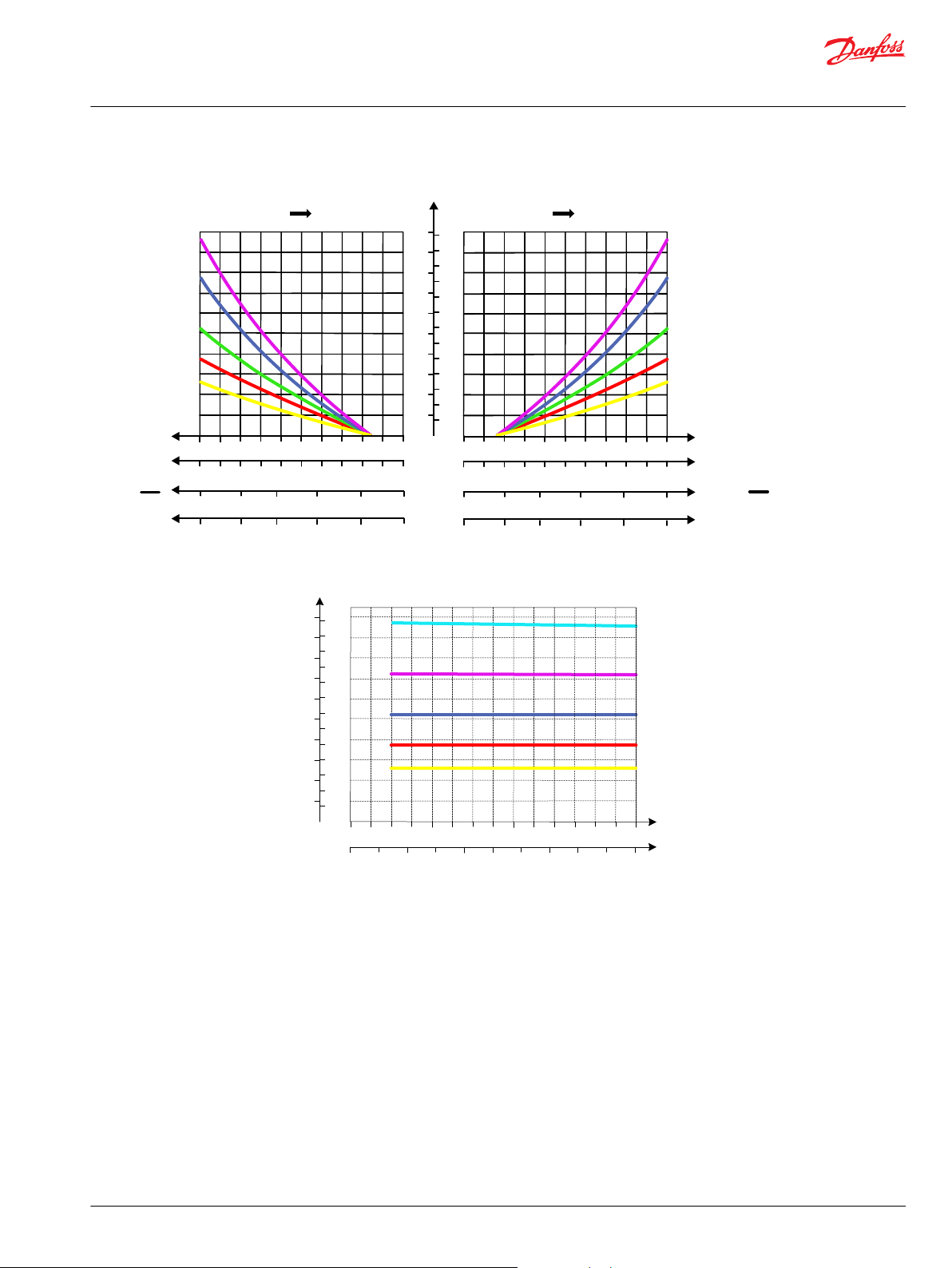

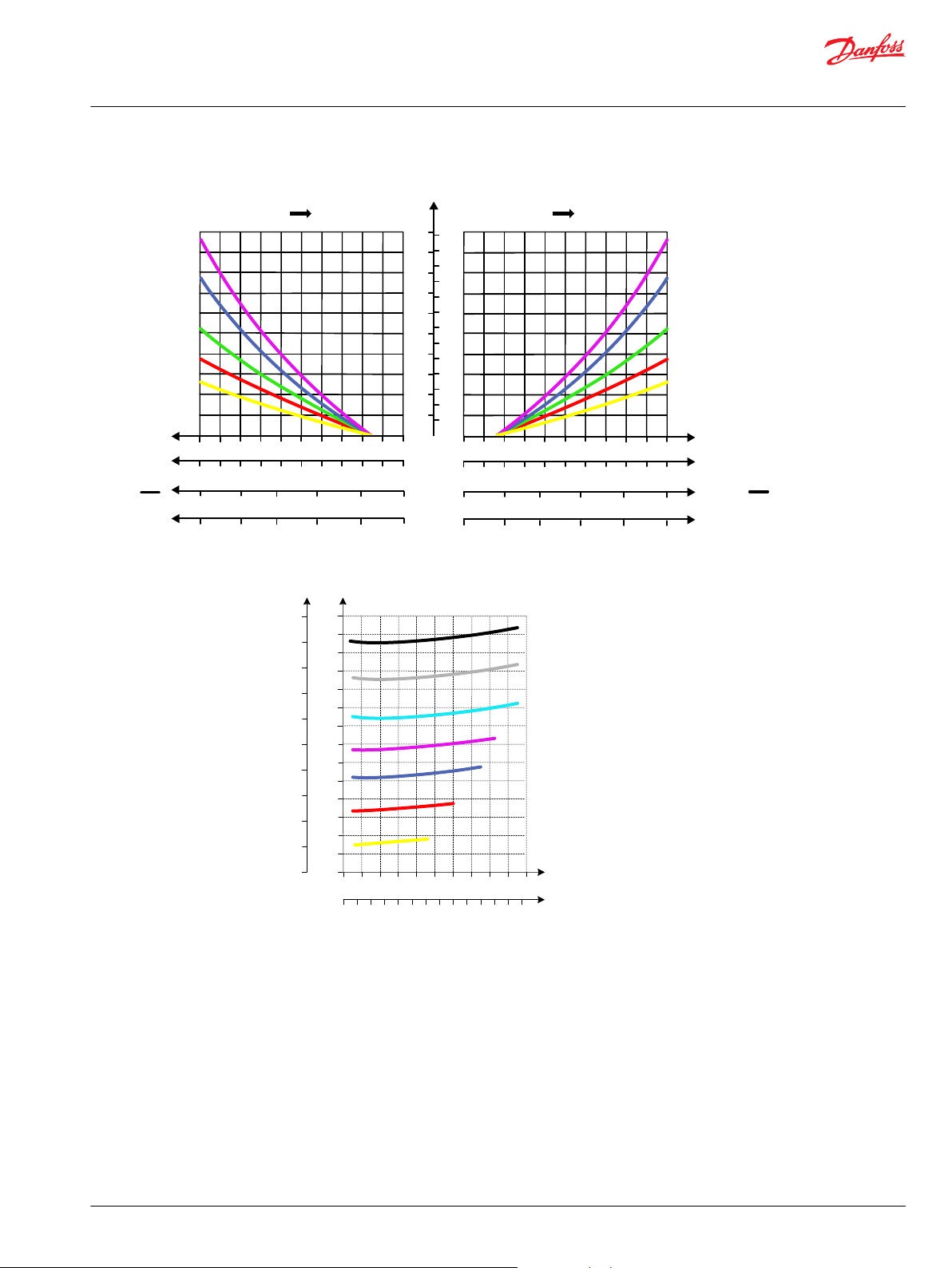

PVB 128 Upstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 17

PVB 128 Downstream Performance

Page 18

A

B

LS/B

LS/A

P109186

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

PVB 128 3-way Compensator with LS A/B

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LSA/B relief valves are used to limit the maximum work port pressure on the A and B-ports

individually.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 [5800 psi]

Max. rated flow

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

*

Rated flow at 15 bar margin pressure

*

A/B port 250 l/min [66 US gal/min]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 80 cm3/min [4.88 in3/min

Part numbers for Compensated PVB with LS A/B

Part number A/B-port PVLP/PVLA LS A/B-port

11176915 Metric Flange 3/4” - G1/4"BSP

11176918 G 1" BSP - G1/4"BSP

11176916 SAE Flange 3/4” UNC - 7/16-20 UNC

11176917 Thread Ports 1 5/16 UNC - 7/16-20 UNC

18 | © Danfoss | July 2021 BC220686485279en-000510

Page 19

AP

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

00.040.080.120.160.200.240.28

PVEH

U

s

U

DC

8

0.31

910

0.350.39

5

10

15

20

25

30

35

40

45

50

55

60

65

A

B

C

D

E

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310.280.240.20

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

321

0

0.120.080.04

0.75

A

B

C

D

E

PVEH

PVEH-U

5.0

7.5

PVEH-U

0.450.40.350.3

0.25

0.5

2.5

5.0

[V]

[V]

0

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

5

10

15

20

25

30

35

40

45

50

55

60

65

250225200175150125

100

755025

0

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[b ar]

[p si]

P109213

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

Oil flow as function of spool travel

Load Independent Oil Flow, Pressure Compensated

©

Danfoss | July 2021 BC220686485279en-000510 | 19

Page 20

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

5

10

15

20

25

30

35

40

45

50

55

60

65

250225200175150125

100

755025

0

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

0

[bar]

[psi]

P109215

25 50 75 100 125 150 175 200 225 250 275 300

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

25

20

15

10

5

0

250

200

150

100

50

0

350

300

0

0

Port P to Port A/B at full spool stroke

E = Spool 240 l/min

P

Q

Q

[psi] [bar]

[l/min]

[US gal/min]

P109240

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

LS A/B Pressure Relief Valve

PVB 128 Upstream Performance

20 | © Danfoss | July 2021 BC220686485279en-000510

Page 21

5

0

0

P

Port A/B to Tank at full spool stroke

Q

Q

[psi] [bar]

350

300

200

150

100

50

250

0 25 50 75 100 125 150 175 200 225 250 275 300

25

20

15

10

0 5 10 15 20 25 30 35 404550

55 60

65 70 75 80

E = Spool 240 l/min

[l/min]

[US gal/min]

P109241

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

PVB 128 Downstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 21

Page 22

LS/B

LS/A

B

A

P109172

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

PVB 128 3-way Compensator with LS A/B and PVLP

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LS A/B relief valves are used to limit the maximum work port pressure on the A and Bports individually.

Featuring 2xPVLP shock/anti-cavitation valves on each work port for pressure peak protection and anticavitation prevention

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 [5800 psi]

Max. rated flow

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

*

Rated flow at 15 bar margin pressure

*

A/B port 250 l/min [66 US gal/min]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 80 cm3/min [4.88 in3/min

Part numbers for Compensated PVB 128 with LSA/B and PVLP

Part number A/B-port PVLP/PVLA LS A/B-port

11165621 Metric Flange 3/4” 2 PVLP/PVLA G1/4"BSP

11170527 G 1" BSP 2 PVLP/PVLA G1/4"BSP

11170523 SAE Flange 3/4” UNC 2 PVLP/PVLA 7/16-20 UNC

11170525 Thread Ports 1 5/16 UNC 2 PVLP/PVLA 7/16-20 UNC

22 | © Danfoss | July 2021 BC220686485279en-000510

Page 23

AP

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

00.040.080.120.160.200.240.28

PVEH

U

s

U

DC

8

0.31

910

0.350.39

5

10

15

20

25

30

35

40

45

50

55

60

65

A

B

C

D

E

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310.280.240.20

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

321

0

0.120.080.04

0.75

A

B

C

D

E

PVEH

PVEH-U

5.0

7.5

PVEH-U

0.450.40.350.3

0.25

0.5

2.5

5.0

[V]

[V]

0

25 50 75 100 125 150 175 200 225 250

[l/min]

[USgal/min]

5 10 15 20 25 30 35 40 45 50 55 60 65

250

225

200

175

150

125

100

75

50

25

0

Q

350

325

300

275

PP

2500

2000

1500

1000

500

0

3500

3000

4000

5000

4500

0

[psi] [bar]

0

Q

P109216

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

Oil flow as function of spool travel

©

Danfoss | July 2021 BC220686485279en-000510 | 23

2xPVLP Shock Valve

Page 24

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/min]

350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

50

45

40

35

30

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

70

65

60

55

PP

500

400

300

200

100

0

700

600

800

1000

900

0

[ps i] [ bar ]

0

Q

Po rt A /B

P109217

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

5

10

15

20

25

30

35

40

45

50

55

60

65

250225200175150125

100

755025

0

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[b ar]

[p si]

P109213

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

2xPVLA Suction Valve

Load Independent Oil Flow, Pressure Compensated

24 | © Danfoss | July 2021 BC220686485279en-000510

Page 25

25

50

75

100

125

150

175

200

225

250

[l/min] [US gal/min]

5

10

15

20

25

30

35

40

45

50

55

60

65

250225200175150125

100

755025

0

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

0

[bar]

[psi]

P109215

25 50 75 100 125 150 175 200 225 250 275 300

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

25

20

15

10

5

0

250

200

150

100

50

0

350

300

0

0

Port P to Port A/B at full spool stroke

E = Spool 240 l/min

P

Q

Q

[psi] [bar]

[l/min]

[US gal/min]

P109240

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

LS A/B Pressure Relief Valve

PVB 128 Upstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 25

Page 26

5

0

0

P

Port A/B to Tank at full spool stroke

Q

Q

[psi] [bar]

350

300

200

150

100

50

250

0 25 50 75 100 125 150 175 200 225 250 275 300

25

20

15

10

0 5 10 15 20 25 30 35 404550

55 60

65 70 75 80

E = Spool 240 l/min

[l/min]

[US gal/min]

P109241

Technical Information

PVG 128/256 Technical Information

PVB 128 Variant Overview

PVB 128 Downstream Performance

26 | © Danfoss | July 2021 BC220686485279en-000510

Page 27

182.2

205

23.5

86

107

178.5

43

PVB 256

PVB 256 basic module dimensions (mm)

Weight 16 kg [35.3 lbs]

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

The PVG 256 Basic modules (PVB), also referred to as work sections, is the interface between the PVG 256

proportional valve group and the work function such as a cylinder or a motor.

The PVB basic module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the PVB to suit the demands of any hydraulic system.

The compensator is a 3-way type which includes load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up.

The generic PVB basic module platform includes the following main variants.

Compensated PVB 256 Compensated basic module.

Compensated PVB 256 with LS A/B Compensated basic module with LSA/B relief valve for each work port.

Compensated PVB 256 with LS A/B and PVLP Compensated basic module with LSA/B relief valve for each

work port and 3xPVLPs for each work port.

Compensated PVB 256 with Turbo compensator feature Compensated basic module with LS A/B relief valve

for each work port and 3xPVLPs for each work port.

©

Danfoss | July 2021 BC220686485279en-000510 | 27

Page 28

A

B

P109168

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 3-way Compensator

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LS A/B relief valves are used to limit the maximum work port pressure on the A and Bports individually.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 bar [5800 psi]

Max. rated flow A/B port 450 l/min [119 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 85 cm3/min [5.19 in3/min]

Part numbers for Compensated PVB 256

Part number A/B port PVLP/PVLA LS A/B port

11169244 Metric Flange 1” - 11169252 G1 BSP - 11169248 SAE Flange 1” UNC - 11177020 Thread Ports 1-5/16-12 UNC - -

28 | © Danfoss | July 2021 BC220686485279en-000510

Page 29

A

P

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

0

0.04

0.080.120.160 .20

0.24

0.28

PVEH

U

s

U

DC

0.50.45

0.40.350.3

8

0.31

0.25

9

10

350

375

400

0.35

0.39

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310. 280.240.20

PVEH

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

3210

0.120.080.040

0.75

PVEH-U

5.0

2.5

PVEH-U

5.0

7.5

[V]

[V]

A

B

C

D

E

F

G

A

B

C

D

E

F

G

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Oil Flow as Function of Spool Travel

©

Danfoss | July 2021 BC220686485279en-000510 | 29

Page 30

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

250225200175150125

100

755025

0

425

450

475

500

110

115

120

125

130

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[bar]

[psi]

P109219

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425

110

250

200

150

100

50

0

350

300

0

0

P

[psi] [bar]

Q

Q

[l/min]

[US gal/min]

Port P to Port A/B at full spool stroke

G = Spool 400 l/min

P109243

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Load Independent Oil Flow, Pressure Compensated

PVB 256 Upstream Performance

30 | © Danfoss | July 2021 BC220686485279en-000510

Page 31

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

P

250

200

150

100

50

0

350

300

0

0

Q

G/H = Spool 400 l/min

[psi] [bar]

[l/min]

[US gal/min]

Port A/B to Tank at full spool stroke

P109244

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 Downstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 31

Page 32

LS/B

LS/A

A

B

P109167

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 3-way Compensator with LS A/B

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LS A/B relief valves are used to limit the maximum work port pressure on the A and Bports individually.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 [5800 psi]

Max. rated flow A/B port 450 l/min [119 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 85 cm3/min [5.19 in3/min]

Part numbers for Compensated PVB 256 with LSA/B

Part number A/B-port PVLP/PVLA LS A/B-port

11177015 Metric Flange 1” - G1/4"BSP

11177017 G1-1/4 BSP - G1/4"BSP

11177016 SAE Flange 1” UNC - 7/16-20 UNC

11177019 Thread Ports 1-5/16-12 UNC - 7/16-20 UNC

32 | © Danfoss | July 2021 BC220686485279en-000510

Page 33

A

P

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

0

0.04

0.080.120.160 .20

0.24

0.28

PVEH

U

s

U

DC

0.50.45

0.40.350.3

8

0.31

0.25

9

10

350

375

400

0.35

0.39

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310. 280.240.20

PVEH

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

3210

0.120.080.040

0.75

PVEH-U

5.0

2.5

PVEH-U

5.0

7.5

[V]

[V]

A

B

C

D

E

F

G

A

B

C

D

E

F

G

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Oil Flow as Function of Spool Travel

©

Danfoss | July 2021 BC220686485279en-000510 | 33

Page 34

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

250225200175150125

100

755025

0

425

450

475

500

110

115

120

125

130

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[bar]

[psi]

P109219

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

250225200175150125100

7550250

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

LS A/B Pressure Limitation

0

[bar]

[psi]

425

450

475

500

525

110

115

120

125

130

135

550

140

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Load Independent Oil Flow, Pressure Compensated

LS A/B Pressure Limitation

34 | © Danfoss | July 2021 BC220686485279en-000510

Page 35

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425

110

250

200

150

100

50

0

350

300

0

0

P

[psi] [bar]

Q

Q

[l/min]

[US gal/min]

Port P to Port A/B at full spool stroke

G = Spool 400 l/min

P109243

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

P

250

200

150

100

50

0

350

300

0

0

Q

G/H = Spool 400 l/min

[psi] [bar]

[l/min]

[US gal/min]

Port A/B to Tank at full spool stroke

P109244

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 Upstream Performance

PVB 256 Downstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 35

Page 36

LS/B

LS/A

A

B

P109166

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 3-way Compensator with LSA/B and PVLP

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LS A/B relief valves are used to limit the maximum work port pressure on the A and Bports individually.

Featuring 3xPVLP shock/anti-cavitation valves on each work port for pressure peak protection and anticavitation prevention.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 bar [5800 psi]

Max. rated flow A/B port 450 l/min [119 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 85 cm3/min [5.19 in3/min]

Part numbers for Compensated PVB 256 with LSA/B and PVLP

Part number A/B port PVLP/PVLA LS A/B port

11169243 Metric Flange 1” 3 PVLP/PVLA G1/4"BSP

11169251 G1 BSP 3 PVLP/PVLA G1/4"BSP

11169247 SAE Flange 1” UNC 3 PVLP/PVLA 7/16-20 UNC

11177018 Thread Ports 1-5/16-12 UNC 3 PVLP/PVLA 7/16-20 UNC

36 | © Danfoss | July 2021 BC220686485279en-000510

Page 37

A

P

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

0

0.04

0.080.120.160 .20

0.24

0.28

PVEH

U

s

U

DC

0.50.45

0.40.350.3

8

0.31

0.25

9

10

350

375

400

0.35

0.39

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

BP

[mm]

PVM

1098765

[in]

PVM

0.390.350.310. 280.240.20

PVEH

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

3210

0.120.080.040

0.75

PVEH-U

5.0

2.5

PVEH-U

5.0

7.5

[V]

[V]

A

B

C

D

E

F

G

A

B

C

D

E

F

G

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/min]

350 375

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

250

225

200

175

150

125

100

75

50

25

0

Q

350

325

300

275

PP

2500

2000

1500

1000

500

0

3500

3000

4000

5000

4500

0

[psi] [bar]

0

Q

P109221

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Oil Flow as Function of Spool Travel

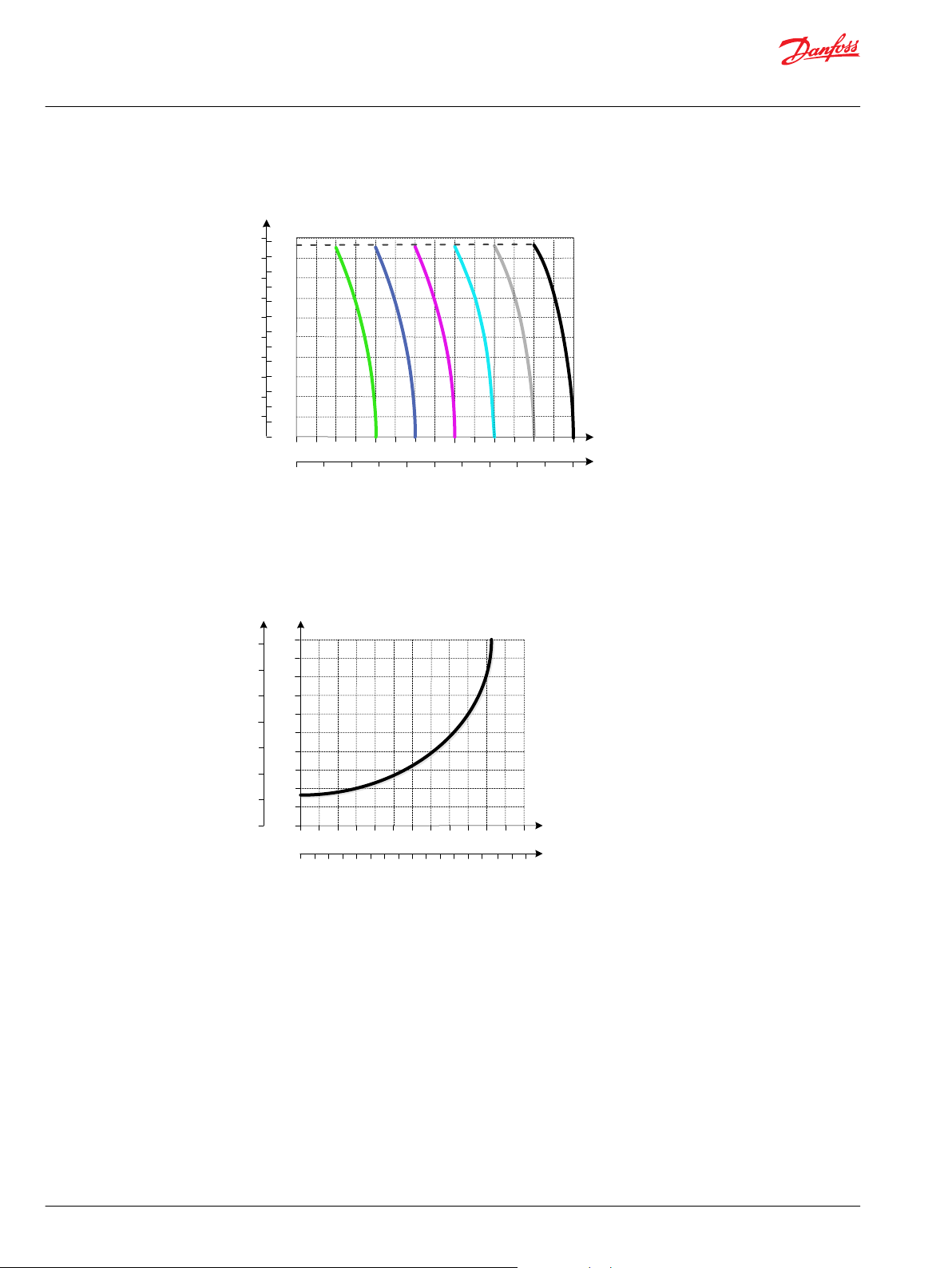

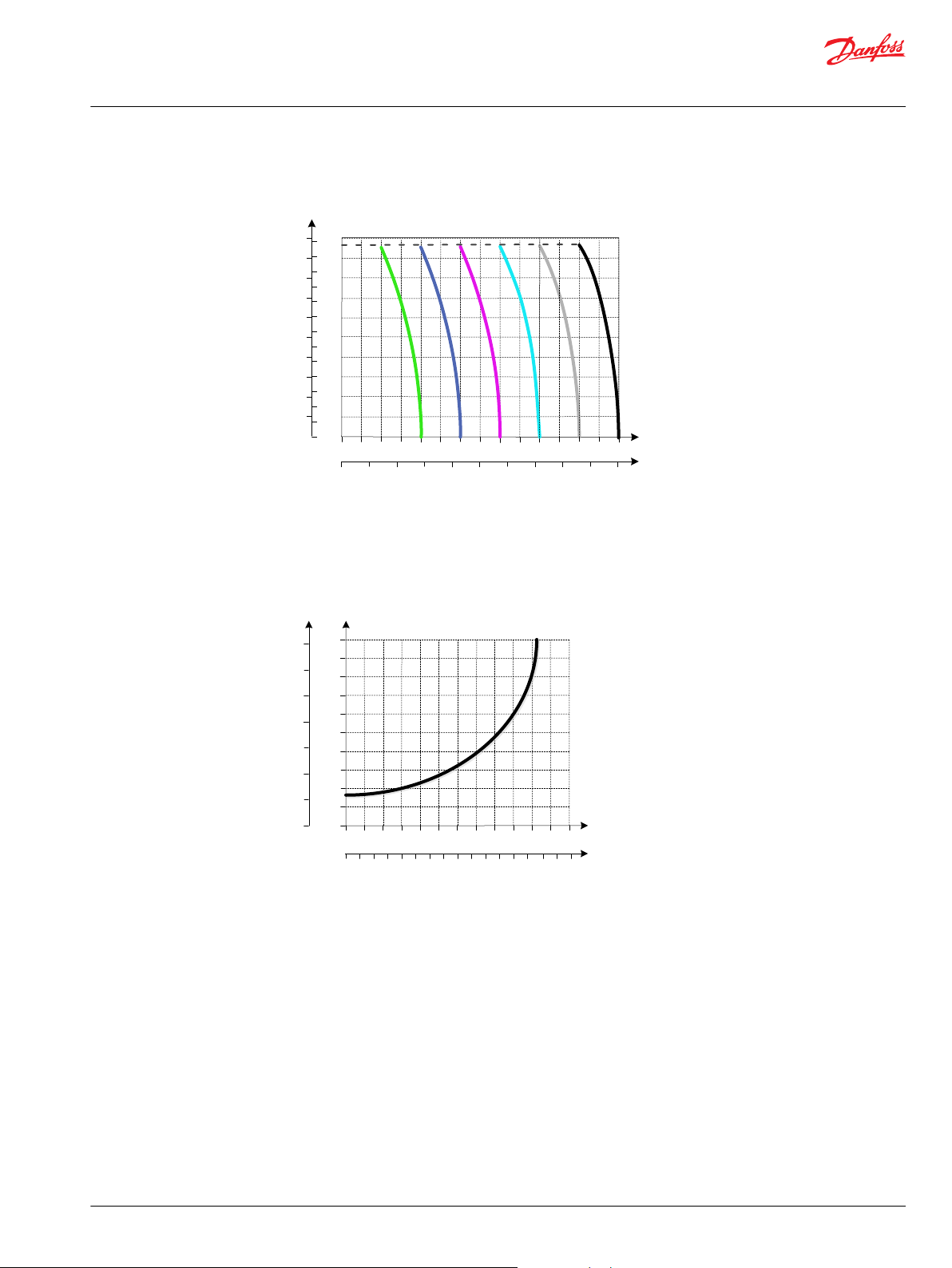

3xPVLP Shock Valve

©

Danfoss | July 2021 BC220686485279en-000510 | 37

Page 38

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/ min]

350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

50

45

40

35

30

25

20

15

10

5

0

425 450 475 500

110115120 125 130

Q

70

65

60

55

PP

500

400

300

200

100

0

700

600

800

1000

900

0

[psi] [bar]

0

Q

Port A/B

P109224

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

25022 52001 751501251 00

7550250

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

LS A/B Pressure Limitation

0

[bar]

[psi]

425

450

475

500

525

110

115

120

125

130

135

550

140

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

3xPVLA Suction Valve

LS A/B Pressure Limitation

38 | © Danfoss | July 2021 BC220686485279en-000510

Page 39

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

250225200175150125

100

755025

0

425

450

475

500

110

115

120

125

130

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[bar]

[psi]

P109219

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425

110

250

200

150

100

50

0

350

300

0

0

P

[psi] [bar]

Q

Q

[l/min]

[US gal/min]

Port P to Port A/B at full spool stroke

G = Spool 400 l/min

P109243

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Load Independent Oil Flow, Pressure Compensated

PVB 256 Upstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 39

Page 40

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

P

250

200

150

100

50

0

350

300

0

0

Q

G/H = Spool 400 l/min

[psi] [bar]

[l/min]

[US gal/min]

Port A/B to Tank at full spool stroke

P109244

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 Downstream Performance

40 | © Danfoss | July 2021 BC220686485279en-000510

Page 41

LS/B

LS/A

A

B

P109169

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 3-way Compensator with LS A/B, PVLP and Turbo

The compensated PVB is intended for controlling a work function where the function behavior in terms

of flow and pressures requires independency on the load pressure of other functions used

simultaneously.

The integrated LS A/B relief valves are used to limit the maximum work port pressure on the A and Bports individually.

Featuring 3xPVLP shock/anti-cavitation valves on each work port for pressure peak protection and anticavitation prevention.

The compensator is a 3-way type which include load drop check valve functionality, compensator

function and neutral relief which avoid A and B port pressure build up in neutral.

Schematic

Technical data

Max. rated pressure A/B port continuous 350 bar [5076 psi]

A/B port intermittent 400 bar [5800 psi]

Max. rated flow A/B port 500 l/min [132 US gal/min]

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Max. internal leakage at 100

bar [1450 psi] and 21 mm2/s

[102 SUS]

Maximum 23/19/16

A/B→T without shock valve 70 cm3/min [4.27 in3/min]

A/B→T with shock valve 85 cm3/min [5.19 in3/min]

Part numbers for Compensated PVB 256 with LSA/B, PVLP and Turbo

Part number A/B port PVLP/PVLA LS A/B port

11183379 Metric Flange 1” 3 PVLP/PVLA G1/4"BSP

11183406 G1 BSP 3 PVLP/PVLA G1/4"BSP

11183404 SAE Flange 1” UNC 3 PVLP/PVLA 7/16-20 UNC

11183402 Thread Ports 1-5/16-1 UNC 3 PVLP/PVLA 7/16-20 UNC

©

Danfoss | July 2021 BC220686485279en-000510 | 41

Page 42

A

P

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min]

[US gal/min]

[mm]

PVM

0

1

2

3

4

5

6

7

[in]

PVM

0

0.040.080.120.1 60.20

0.24

0.28

PVEH

U

s

U

DC

0.5

0.45

0.40.35

0.3

8

0.31

0.25

9

10

350

375

400

0.350.39

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

B

P

[mm]

PVM

10

987

65

[in]

PVM

0.390.35

0.310.280.240.20

PVEH

U

s

U

DC

0.7

0.65

0.6

0.55

4

0.16

0.5

32

10

0.120.08

0.04

0

0.75

425

450

475

500

110

115

120

125

130

PVEH-U

5.0

2.5

PVEH-U

5.0

7.5

[V]

[V]

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

Oil Flow as Function of Spool Travel

42 | © Danfoss | July 2021 BC220686485279en-000510

Page 43

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/min]

350 375

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

250

225

200

175

150

125

100

75

50

25

0

Q

350

325

300

275

PP

2500

2000

1500

1000

500

0

3500

3000

4000

5000

4500

0

[psi] [bar]

0

Q

P109221

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/ min]

350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

50

45

40

35

30

25

20

15

10

5

0

425 450 475 500

110115120 125 130

Q

70

65

60

55

PP

500

400

300

200

100

0

700

600

800

1000

900

0

[psi] [bar]

0

Q

Port A/B

P109224

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

3xPVLP Shock Valve

3xPVLA Suction Valve

©

Danfoss | July 2021 BC220686485279en-000510 | 43

Page 44

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

25022 52001 751501251 00

7550250

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

LS A/B Pressure Limitation

0

[bar]

[psi]

425

450

475

500

525

110

115

120

125

130

135

550

140

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

350

375

400

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

250225200175150125

100

755025

0

425

450

475

500

110

115

120

125

130

Q

350

325300275

P

P

25002000150010005000 35003000 4000 50004500

[bar]

[psi]

P109219

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

LS A/B Pressure Limitation

Load Independent Oil Flow, Pressure Compensated

44 | © Danfoss | July 2021 BC220686485279en-000510

Page 45

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

P

250

200

150

100

50

0

350

300

0

0

Q

H = Spool 400 l/min w Turbo

[psi] [bar]

[l/min]

[US gal/min]

Port P to Port A/B at full spool stroke

P109245

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

25

20

15

10

5

0

425 450 475 500

110115120 125130

Q

P

250

200

150

100

50

0

350

300

0

0

Q

G/H = Spool 400 l/min

[psi] [bar]

[l/min]

[US gal/min]

Port A/B to Tank at full spool stroke

P109244

Technical Information

PVG 128/256 Technical Information

PVB 256 Variant Overview

PVB 256 Turbo Upstream Performance

PVB 256 Downstream Performance

©

Danfoss | July 2021 BC220686485279en-000510 | 45

Page 46

P109174

Port pressure

P109175

Port pressure

Technical Information

PVG 128/256 Technical Information

PVLP Shock and PVLA Suction Valves

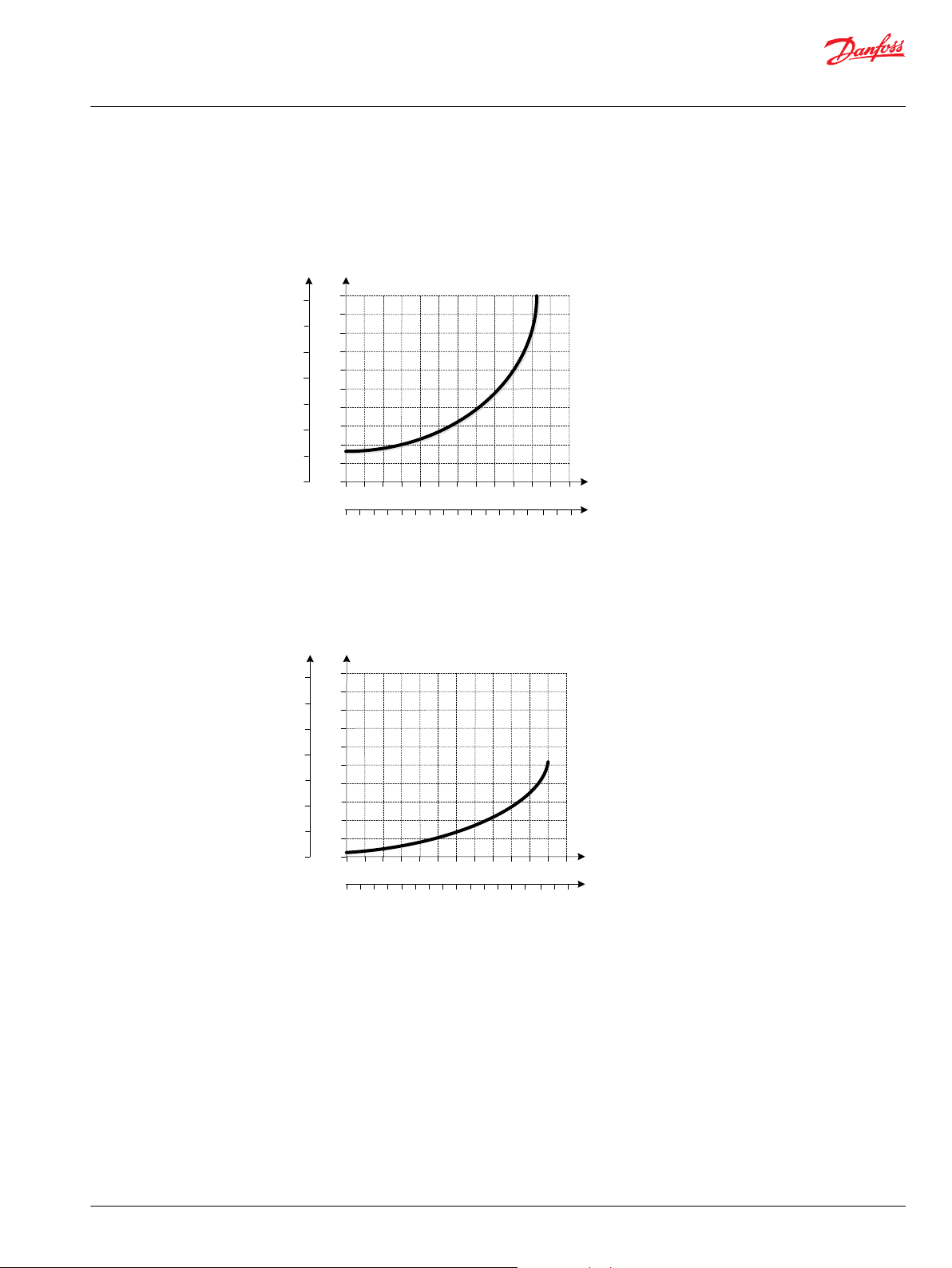

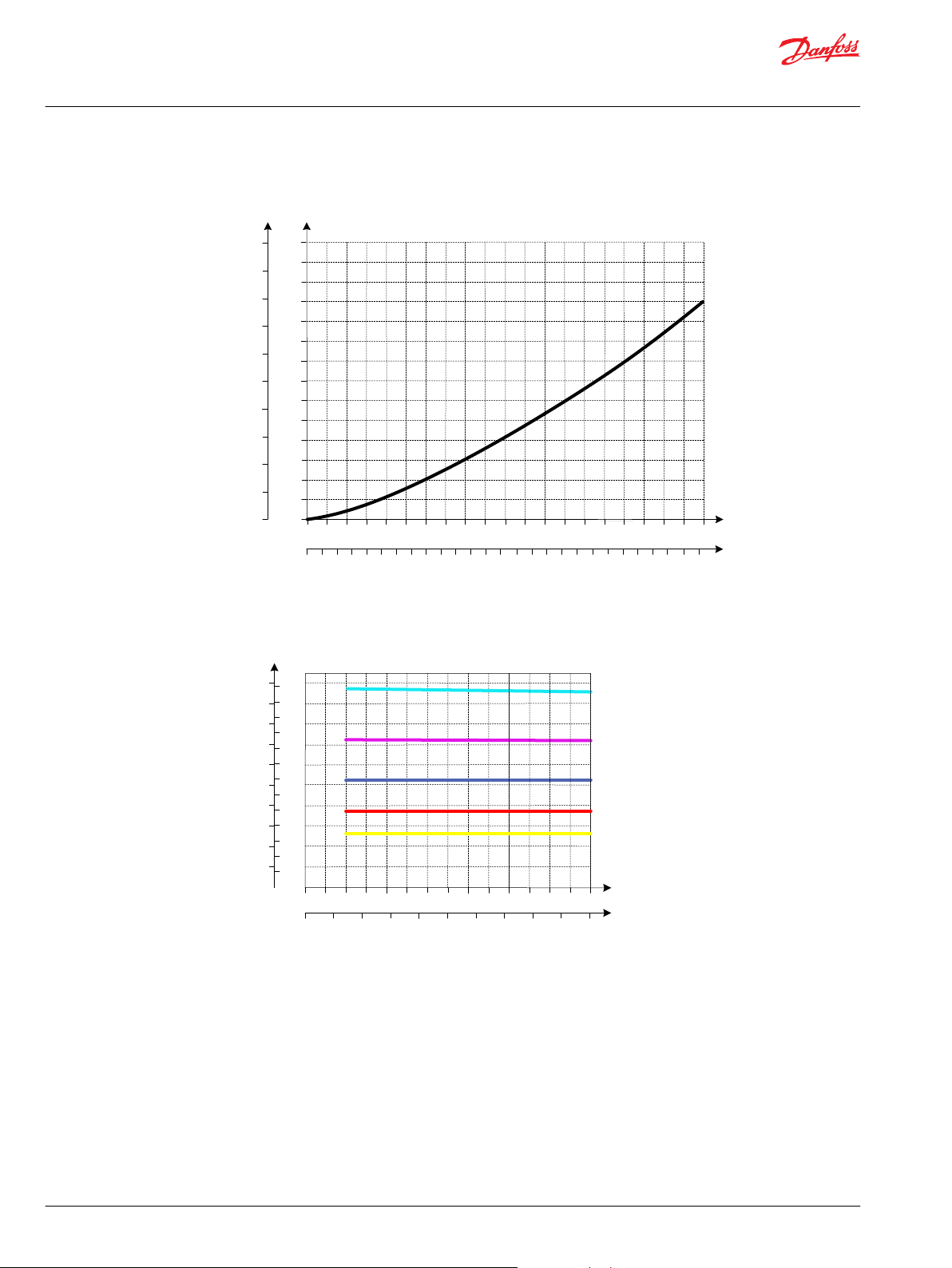

PVLP Overview

PVLP is set at an oil flow of 10 l/min [2.6 US gal/min] per unit.

The shock valve PVLP is designed to absorb shock effects. Consequently, it should not be used as a

pressure relief valve.

If the working function requires the use of a pressure relief valve, a PVB basic module with built-in LSA/B

pressure limiting valve should be used.

PVLP schematic

PVLA schematic

PVLP Technical Data

Technical data

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Oil contamination

according to ISO 4406

Maximum 23/19/16

46 | © Danfoss | July 2021 BC220686485279en-000510

Page 47

Technical Information

PVG 128/256 Technical Information

PVLP Shock and PVLA Suction Valves

Part numbers for PVLP Shock and PVLA Suction Valves

Description Pressure setting in bar Part number

PVLA - 157B2001

PVLP 32 157B2032

PLUG - 157B2002

50 157B2050

63 157B2063

80 157B2080

100 157B2100

125 157B2125

140 157B2140

150 157B2150

160 157B2160

175 157B2175

190 157B2190

210 157B2210

230 157B2230

240 157B2240

250 157B2250

265 157B2265

280 157B2280

300 157B2300

320 157B2320

350 157B2350

380 157B2380

©

Danfoss | July 2021 BC220686485279en-000510 | 47

Page 48

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/min]

350 375

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

250

225

200

175

150

125

100

75

50

25

0

Q

350

325

300

275

PP

2500

2000

1500

1000

500

0

3500

3000

4000

5000

4500

0

[psi] [bar]

0

Q

P109221

25 50 75 100 125 150 175 200 225 250 275 300 325

[l/min]

[US gal/ min]

350 375 400

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100105

50

45

40

35

30

25

20

15

10

5

0

425 450 475 500

110115120 125 130

Q

70

65

60

55

PP

500

400

300

200

100

0

700

600

800

1000

900

0

[psi] [bar]

0

Q

Port A/B

P109224

Technical Information

PVG 128/256 Technical Information

PVLP Shock and PVLA Suction Valves

3xPVLP Shock Valve

3xPVLA Suction Valve

48 | © Danfoss | July 2021 BC220686485279en-000510

Page 49

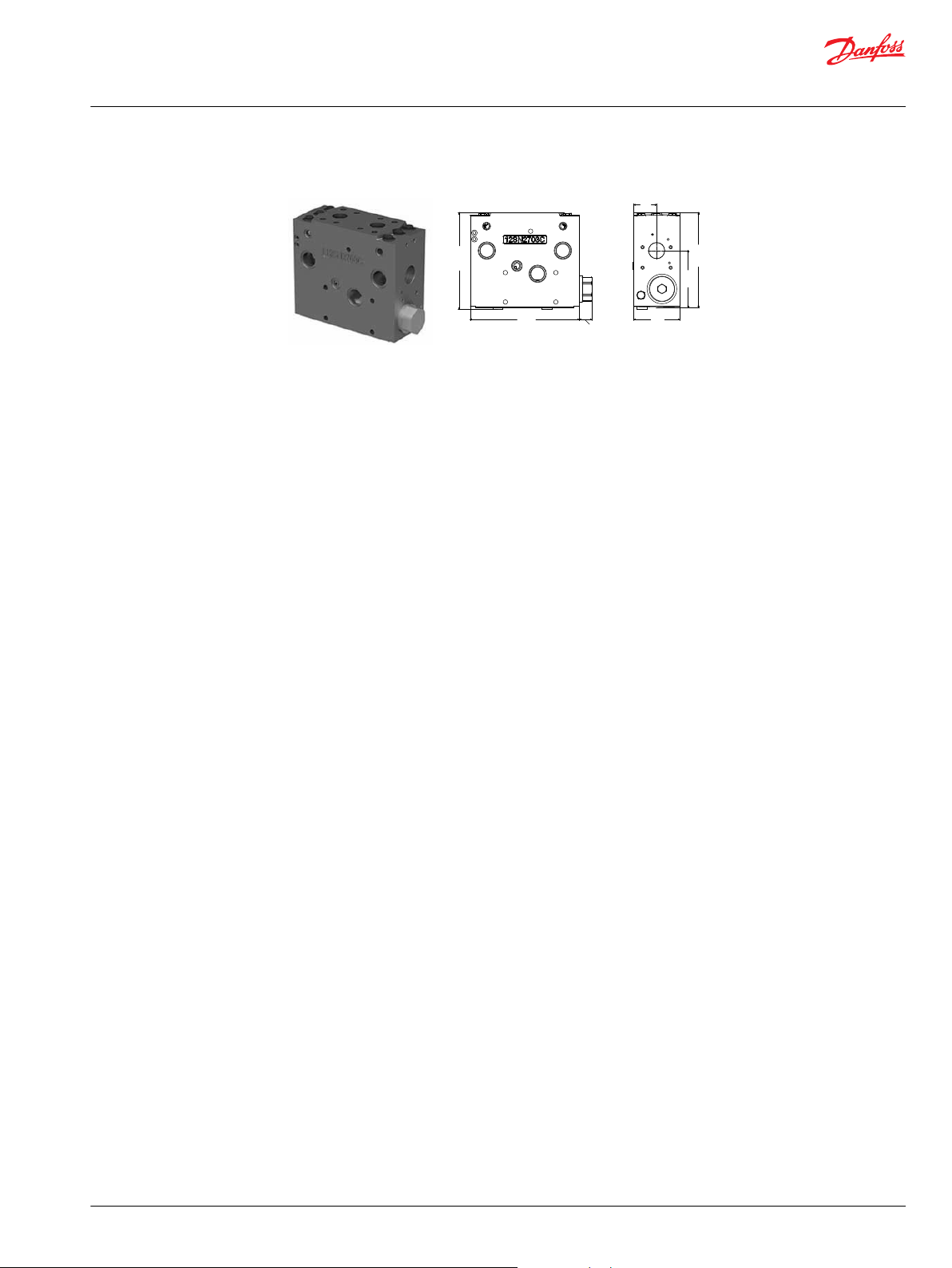

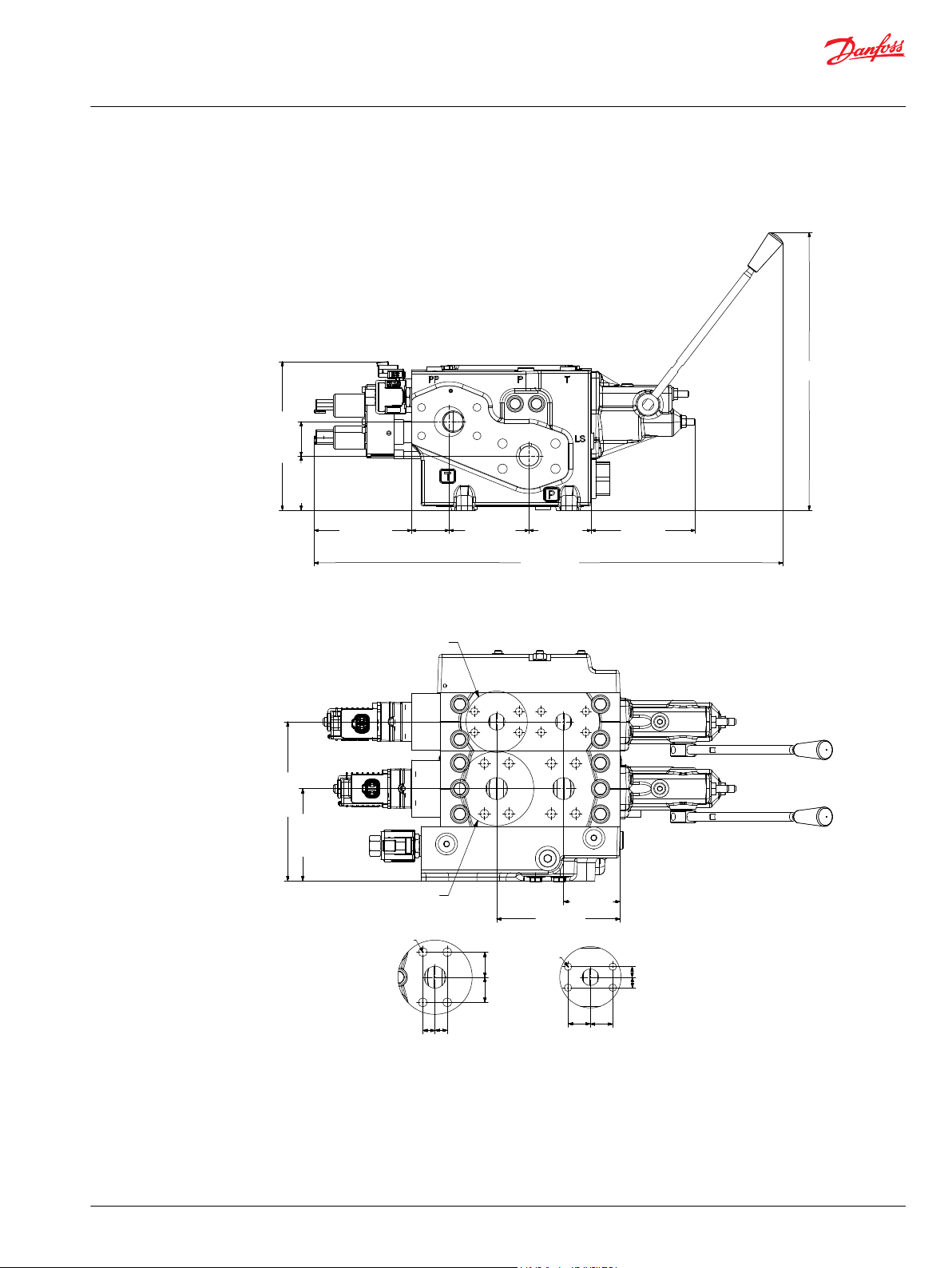

230

83.5

30

P109176

Technical Information

PVG 128/256 Technical Information

PVBS Main Spool

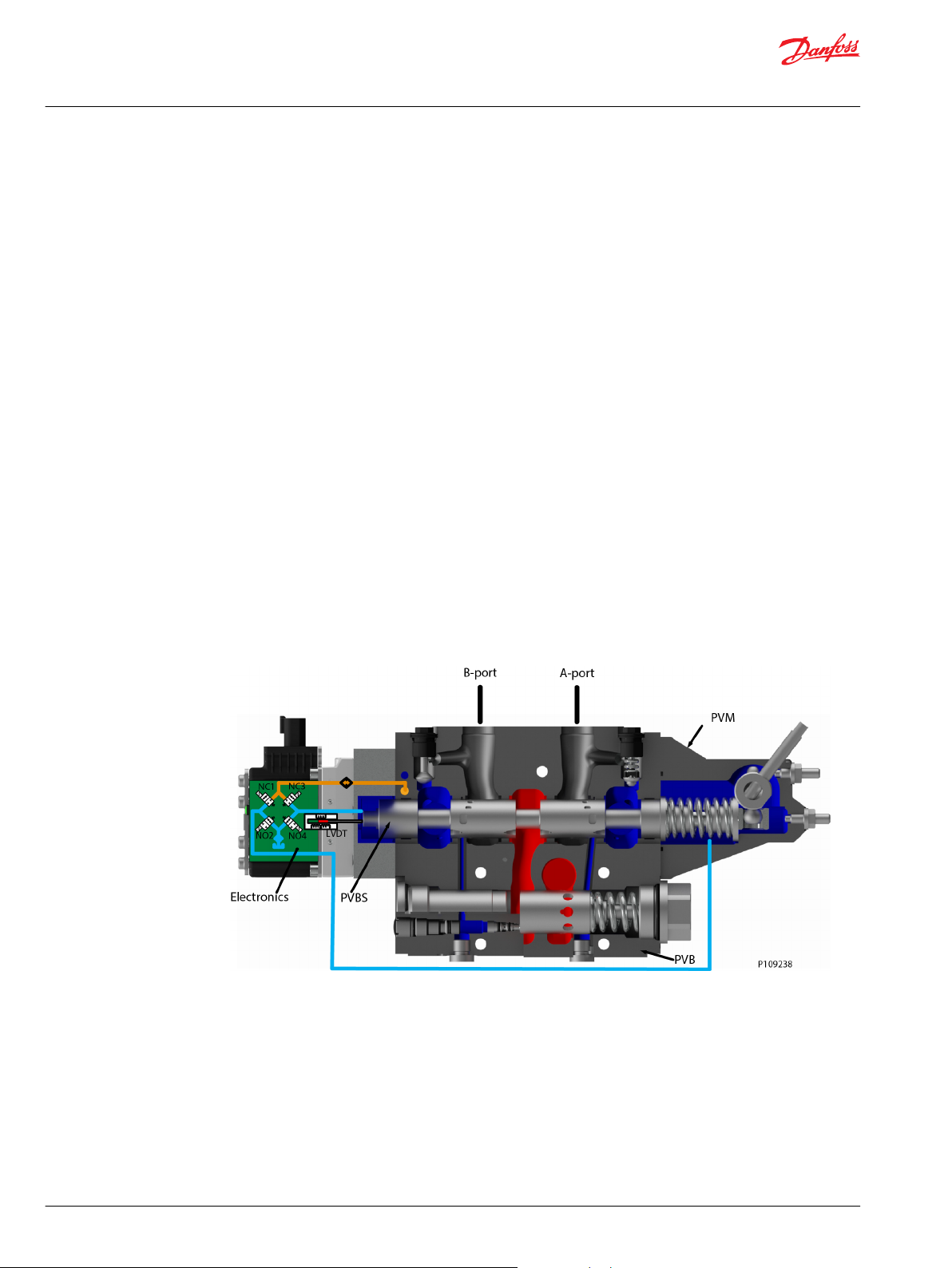

The PVG 128/256 main spools (PVBS) determines the flow out of the work section.

The PVBS main spool variants are based on a generic platform with a wide selection of additional

features, enabling you to tailor the PVBS to suit the demands of any hydraulic system and any function.

The PVBS main spool can be activated in three different ways:

•

Mechanically by a PVM lever

•

Electrically by either a PVE or a PVHC actuator

•

Hydraulically by a PVH actuator

All spools can be mechanically activated.

PVBS Main Spool

PVBS Main Spool dimensions

PVBS Main Spools variant overview

Flow control spools

•

Flow control spool closed neutral position

•

Flow control spool throttled open neutral position

•

Single acting cylinder flow control spool closed neutral position, flow control B port

•

Flow control spool closed neutral position with A-float

PVBS main spools product details

Technical data

Oil temperature Recommended 30 to 60°C [86 to 140°F]

Ambient temperature Recommended -30 to 60°C [-22 to 140°F]

Oil viscosity Operating range 12 to 75 mm2/s [65 to 347 SUS]

Oil contamination

according to ISO 4406

Minimum -30°C [-22°F]

Maximum 90° [194°F]

Minimum 4 mm2/s [39 SUS]

Maximum 460 mm2/s [2128 SUS]

Maximum 23/19/16

©

Danfoss | July 2021 BC220686485279en-000510 | 49

Page 50

A

P

25

50

75

100

125

150

175

200

225

250

275

300

325

[l/min] [US gal/min]

[mm]

PVM

0

1

2

3

4

5

67

[in]

PVM

00.040.08

0.120.160.20

0.240.28

PVEH

U

s

U

DC

0.50.45

0.4

0.350.3

8

0.31

0.25

910

350

375

400

0.350.39

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

BP

[mm]

PVM

109

8

765

[in]

PVM

0.390.350.310.280.240.20

PVEH

U

s

U

DC

0.70.650.60.55

4

0.16

0.5

3210

0.120.080.040

0.75

425

450

475

500

110

115

120

125

130

PVEH-U

5.0

2.5

PVEH-U

5.0

7.5

[V]

[V]

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

Technical Information

PVG 128/256 Technical Information

PVBS Main Spool

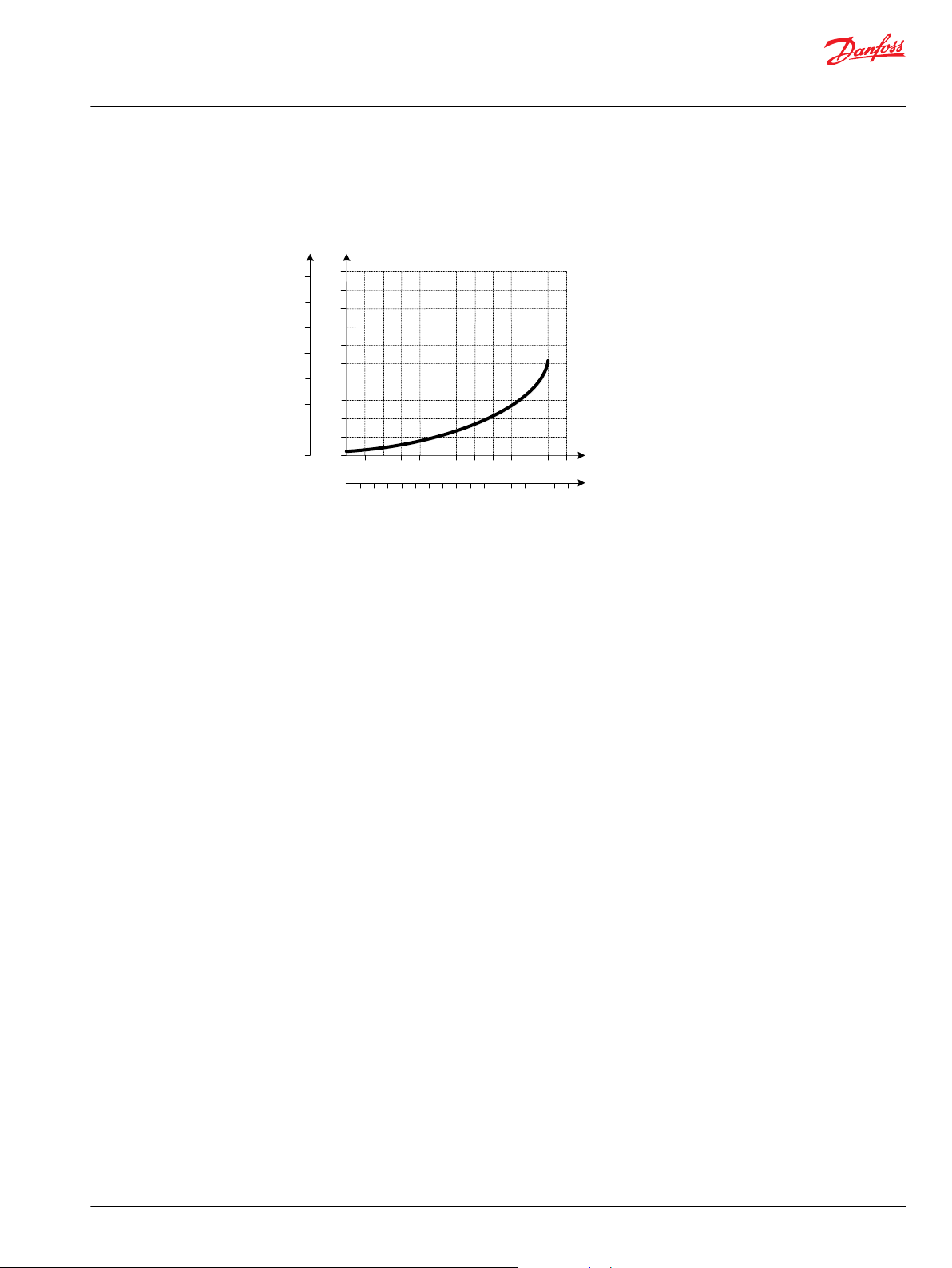

Progressive Oil Flow as Function of Spool Travel

50 | © Danfoss | July 2021 BC220686485279en-000510

Page 51

504540353025

20

15105

0

70

656055

Q

Q

1086420 1412 18

16

250

225

200

175

150

125

100

75

50

25

0

350

325

300

275

P

2500

2000

1500

1000

500

0

3500

3000

4000

5000

4500

A/B to T

[psi] [bar]