MAKING MODERN LIVING POSSIBLE

Service Manual

Proportional Valve Group

PVG 120

powersolutions.danfoss.com

Service Manual PVG 120 Proportional Valve Group

Revision history Table of revisions

Date Changed Rev

May 2014 Converted to Danfoss layout – DITA CMS, major revision JA

Jan 2012 Pos. 3 change ID

Feb 2011 Table on page 35 changed, layout changes - all pages IC

Feb 2010 Handles on drawings IA

Jan 2010 Japan location HC

2 520L0247 • Rev JA • May 2014

Service Manual

PVG 120 Proportional Valve Group

Contents

PVG 120 service parts exploded view

PVG 120 sectional view

Safety in application

Control system example................................................................................................................................................................ 8

Examples of wiring block diagram.....................................................................................................................................10

Identification

Identification ...................................................................................................................................................................................12

Installation

Installation and plug orientation..............................................................................................................................................13

Connection, PVP, Pump Side Module.....................................................................................................................................13

Oil flow direction............................................................................................................................................................................14

Tightening Torques.......................................................................................................................................................................14

PVM, Lever Positions.....................................................................................................................................................................16

Setting of max. flow...................................................................................................................................................................... 16

Pressure Setting..............................................................................................................................................................................17

PVP, LS Relief Valve Pressure Setting.................................................................................................................................17

PVB, LS Relief Valve Pressure Setting.................................................................................................................................17

Option, Oil Flow Direction and Setting of max Flow.........................................................................................................18

Installation of PVE.......................................................................................................................................................................... 18

Bleeding.............................................................................................................................................................................................20

PVPE/PVH relief valves................................................................................................................................................................. 20

PVPH and LS connections........................................................................................................................................................... 21

PVPE technical data.......................................................................................................................................................................21

Connection PVPE............................................................................................................................................................................22

PVP

PVP, Pump Side Module.............................................................................................................................................................. 23

PVPD, PVPH, PVPE, Accessories for PVP................................................................................................................................. 25

PVLP / PVLA

PVLP / PVLA, Shock and Suction Valve Port A/B................................................................................................................. 27

PVBP, PVBR, PVBC, PVBU

PVBP, PVBR, PVBC, PVBU Accessories for PVB......................................................................................................................29

PVM

PVM, Mechanical Activating Module......................................................................................................................................31

PVMD and PVH

PVMD, Cover for PVM and PVH, Hydraulic Activation...................................................................................................... 33

PVGI

PVGI, Interface for PVG 120 and PVG 32................................................................................................................................ 34

PVEH and PVEO

PVEH and PVEO, Electrical Activating Module, ON-OFF...................................................................................................35

PVT

PVT, Tank Side Module – Upper Part.......................................................................................................................................37

PVT, Tank Side Module – Lower Part.......................................................................................................................................39

PVAS and PVGI

PVGI, Assembly Kit.........................................................................................................................................................................41

PVAS, Assembly Kit........................................................................................................................................................................41

Asssembly sequence............................................................................................................................................................... 41

Set of seals

Set of Seals .......................................................................................................................................................................................43

PVG 120 Modules Selection Chart

PVG 120 module selection chart.............................................................................................................................................. 44

Order specification

520L0247 • Rev JA • May 2014 3

Service Manual PVG 120 Proportional Valve Group

Contents

Ordering of modules for oil flow exceeding 180 l/min [47.6 US gal/min].................................................................48

Order Form.......................................................................................................................................................................................48

Reordering...................................................................................................................................................................................49

4 520L0247 • Rev JA • May 2014

13

8

7

2

3

3

3

3

11

14

12

4

5

4

14

1

9

10

5

5

5

6

V310144.A

6

6

6

Service Manual PVG 120 Proportional Valve Group

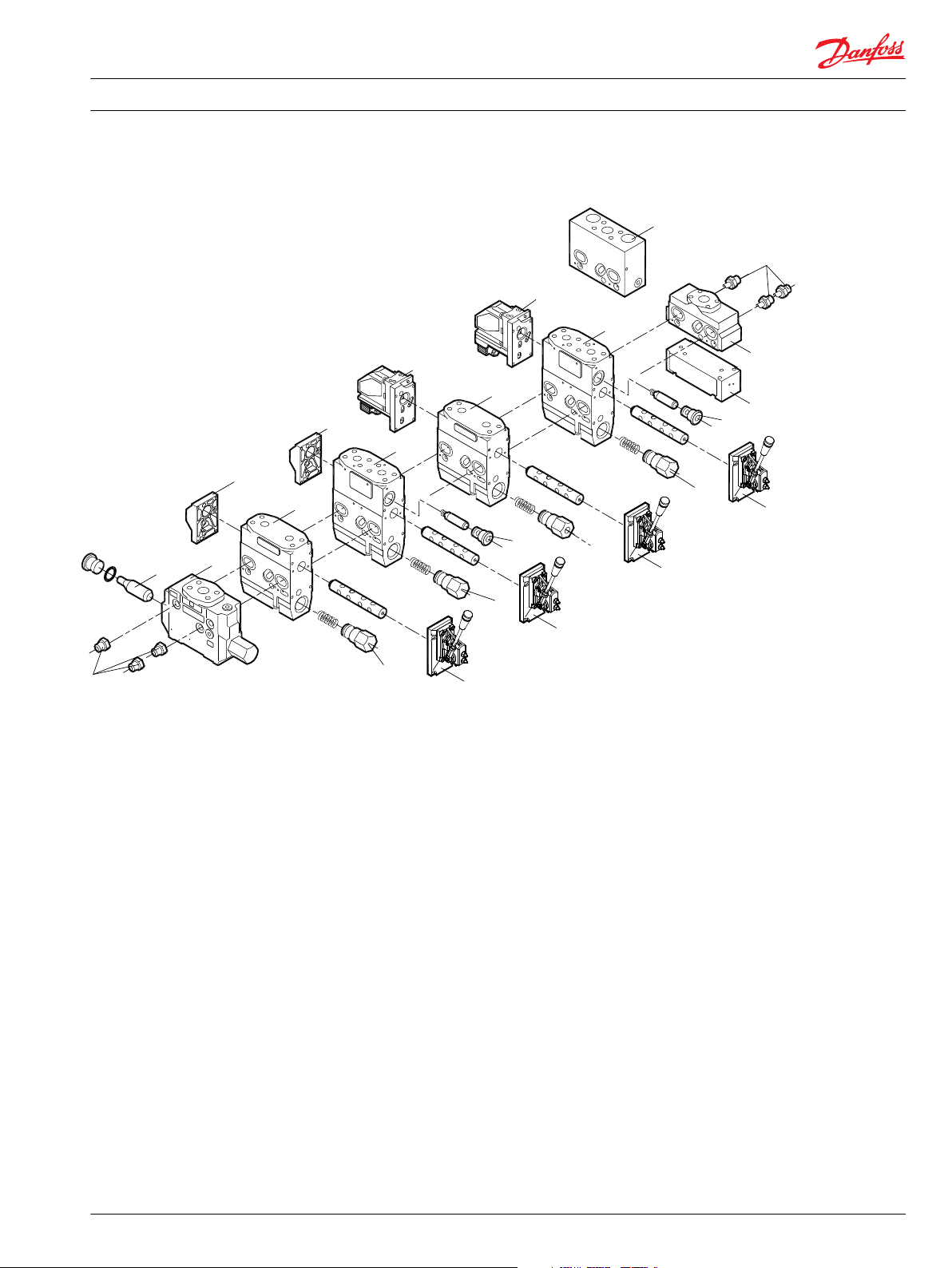

PVG 120 service parts exploded view

PVG 120 service parts exploded view

520L0247 • Rev JA • May 2014 5

4

10

12

11

11

X-X

X

X

P A

V310100.A

9

2 1

T

P

T

p

ma

A B

A B

3

7 5 1 8

T

P

T

13

6

5

LS

T

P

T

3

13

P B

Service Manual PVG 120 Proportional Valve Group

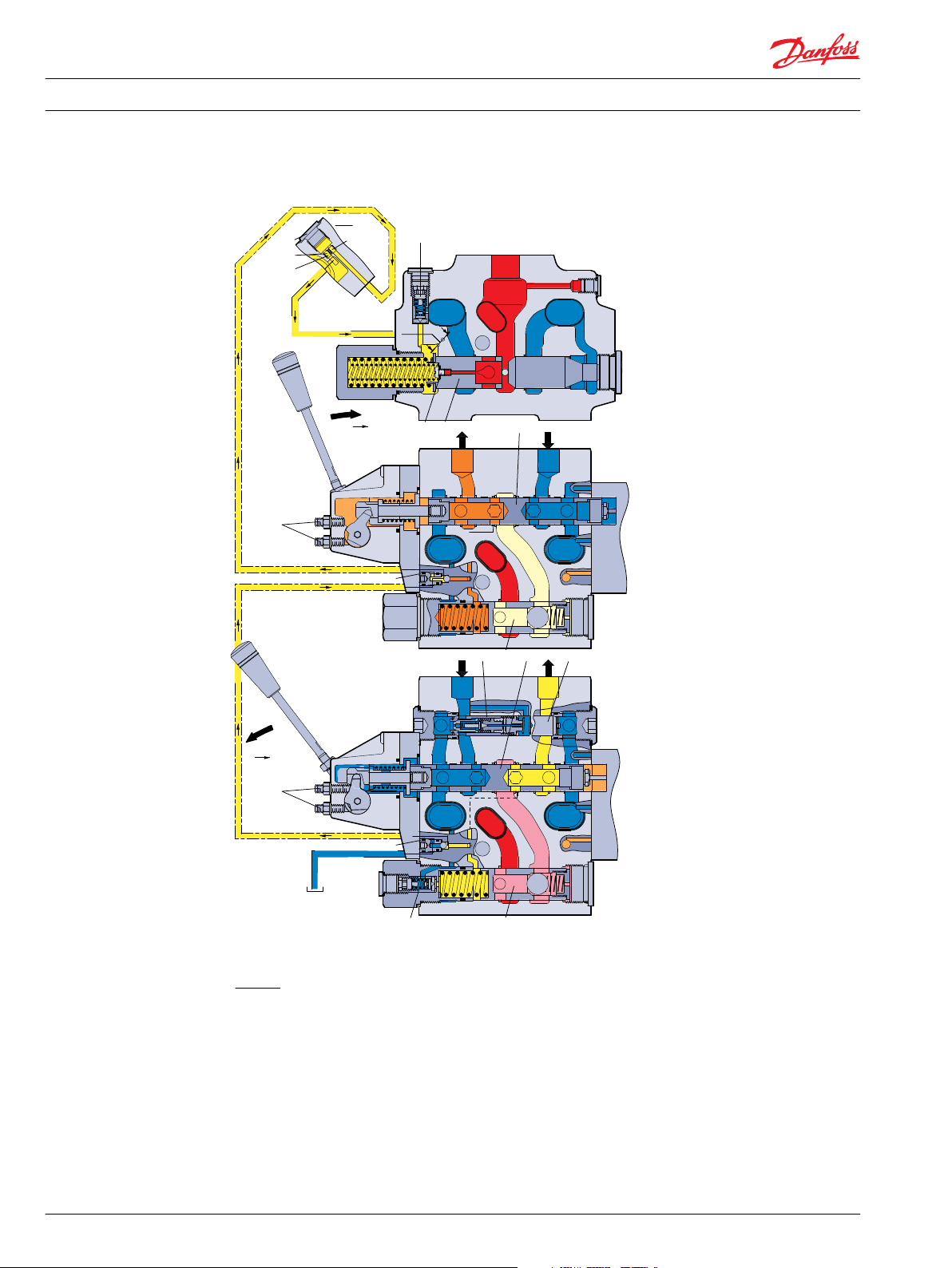

PVG 120 sectional view

PVG 120 sectional view

Legend:

1 – Main spool

2 – Pressure adjustment spool in PVP

3 – Shuttle valve

4 – Pressure relief valve in PVP

5 – Pressure compensator in PVB

6 – LS pressure relief valve in PVB

7 – Shock and suction valve PVLP

8 – Suction valve PVLA

9 – Orifice, closed center PVP; Plug, open center PVP

10 – LS connection

11 – Orifice, open center PVP

12 – Plug, closed center PVP

6 520L0247 • Rev JA • May 2014

W

Service Manual

Safety in application

PVG 120 Proportional Valve Group

All makes and all types of control valves (incl. proportional valves) can fail, thus the necessary protection

against the serious consequences of function failure should always be built into the system. For each

application an assessment should be made for the consequences of pressure failure and uncontrolled or

blocked movements.

To determine the degree of protection that is required to be built into the application, system tools such

an FMEA (Failure Mode and Effect Analysis) and Hazard and Risk Analysis can be used.

FMEA – IEC EN 61508

FMEA (Failure Mode and Effect Analysis) is a tool used for analyzing potential risks. This analytical

technique is utilized to define, identify, and prioritize the elimination or reduction of known and/or

potential failures from a given system before it is released for production. Please refer to IEC FMEA

Standard 61508.

Hazard and risk analysis ISO 12100-1 / 14121

This analysis is a tool used in new applications as it will indicate whether there are special safety

considerations to be met according to the machine directives EN 13849. Dependent on the determined

levels conformity this analysis will detirmine if any extra requirements for the product design,

development process, production process or maintenance, i.e. the complete product life cycle.

Warning

All makes/brands and types of directional control valves – inclusive proportional valves – can fail and

cause serious damage. It is therefore important to analyze all aspects of the application.

Because the proportional valves are used in many different operation conditions and applications,

the manufacturer of the application is alone responsible for making the final selection of the products –

and assuring that all performance, safety and warning requirements of the application are met.

The process of choosing the control system – and safety levels – is governed by the machine directives

EN 13849 (Safety related requirements for control systems).

520L0247 • Rev JA • May 2014 7

Service Manual PVG 120 Proportional Valve Group

Safety in application

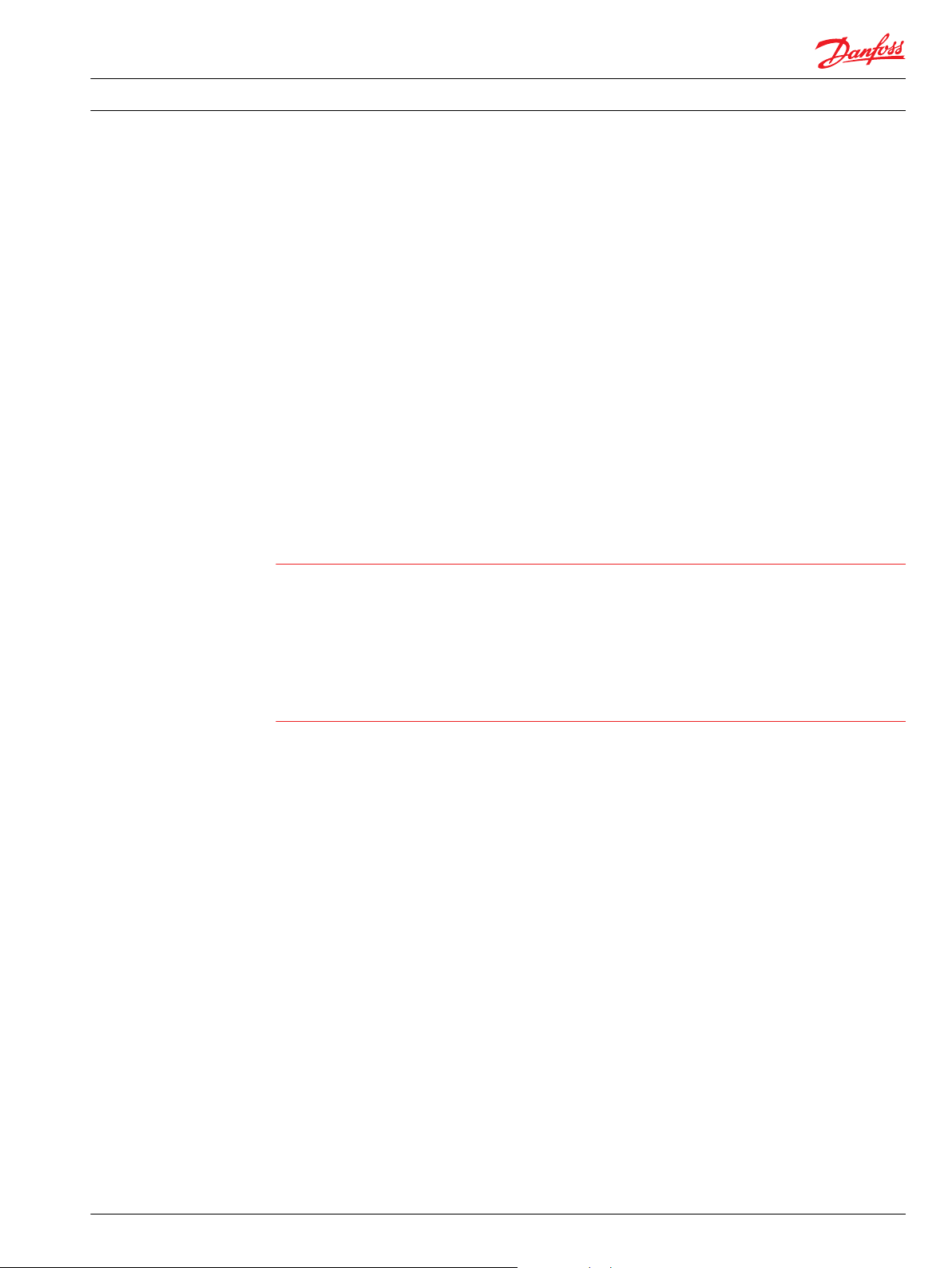

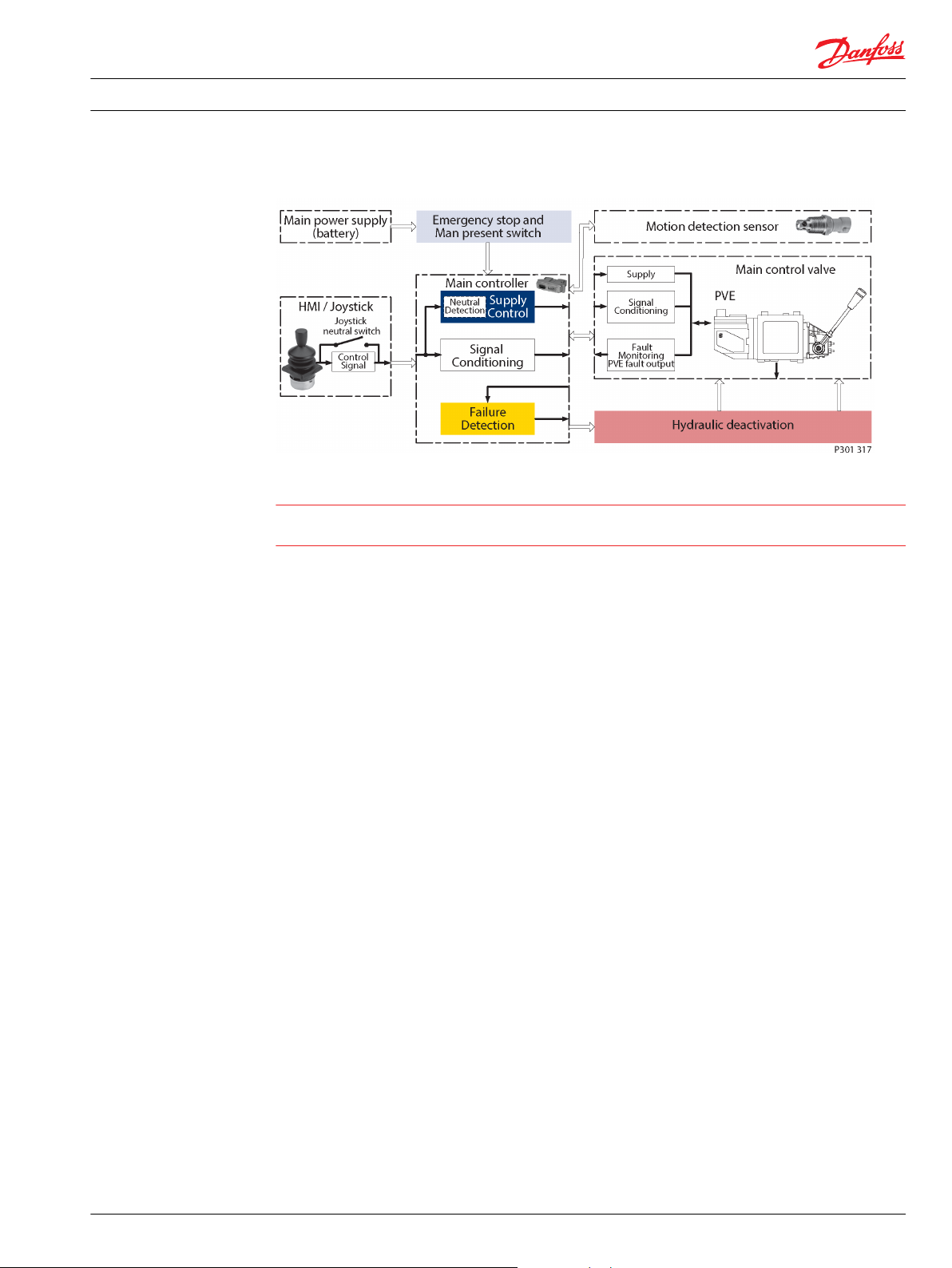

Control system example

Example of a control system for manlift using PVE Fault monitoring input signals and signals from external

sensors to ensure the PLUS+1® main controllers correct function of the manlift.

Legend:

1 – Main power supply

2 – Emergency stop/man present switch

3 – HMI/Joystick control

4 – Movement detection sensors

5 – Main controller

6 – PVG control valve

7 – Hydraulic deactivation

8 520L0247 • Rev JA • May 2014

W

Service Manual

Safety in application

PVG 120 Proportional Valve Group

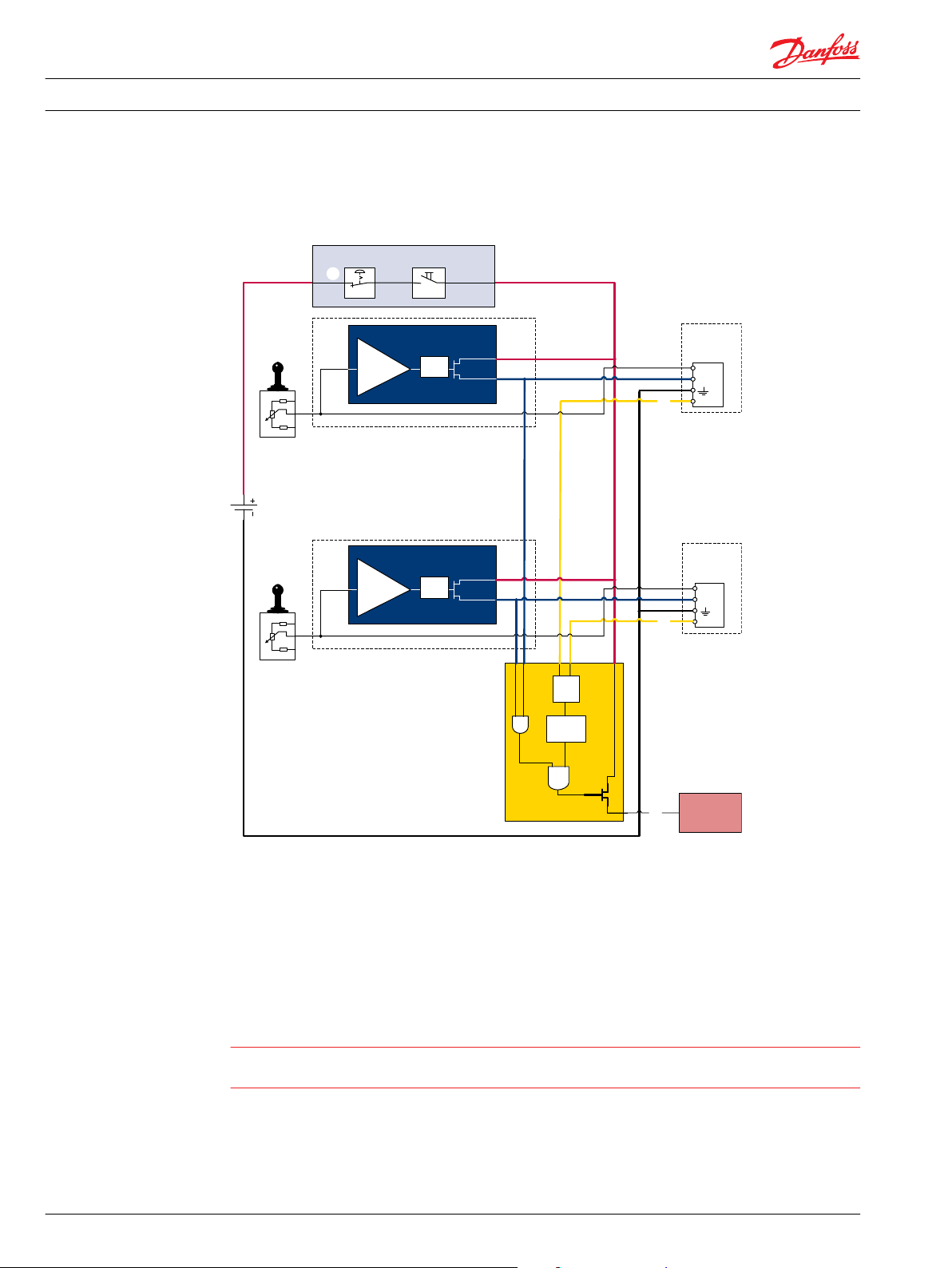

Electrical block diagram for the above illustration

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

PVG 32 – mainly used in system with fixed displacement pumps:

•

PVSK, commonly used in crane application - full flow dump

•

PVPX, LS dump to tank

PVG 100 – alternative LS dump or pilot supply disconnect:

•

PVPP, pilot oil supply shut off

•

External cartridge valve connecting LS pressure or main pressure to tank

PVG 120 – pump disconnect / block for variable pumps:

•

PVPE, full flow dump for the PVG 120

•

External cartridge valve connecting LS pressure to tank

520L0247 • Rev JA • May 2014 9

Fault detection output

high=on

low=off

Alarm

logic

2)

Memory3)

E1

E2

Output

AND

OR

U

DC2

Error

U

S

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

U

DC2

Error

U

S

PVEH

with AMP

connector

PVEH

with AMP

connector

Hydraulic

deactivation

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Emergency

stop

Man present

switch

C

C

D

B

B

A

P301 318

W

Service Manual

Safety in application

PVG 120 Proportional Valve Group

Examples of wiring block diagram

Example of a typical wiring block diagram using PVEH with neutral power off switch and fault monitoring

output for hydraulic deactivation.

A– Emergency stop / man present switch

B– PVE Fault monitoring signals

C– Neutral signal detection.

D– Hydraulic deactivation

System Control Logic e.g. PLUS+1® for signal monitoring and triggering signal for deactivation of the

hydraulic system.

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

10 520L0247 • Rev JA • May 2014

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

Fault detection output

PVEH-DI

AMP supply

connector

PVEH-DI

AMP supply

connector

PVEH-DI

AMP connector

PVEH-DI

AMP connector

AND

high=on

low=off

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

OR

Emergency

Stop

Man present

switch

P301 319

U

DC2

Error

U

S

DI-B

Error

DI-A

U

DC2

Error

U

S

Error

DI-A

Hydraulic

deactivation

W

Service Manual

Safety in application

PVG 120 Proportional Valve Group

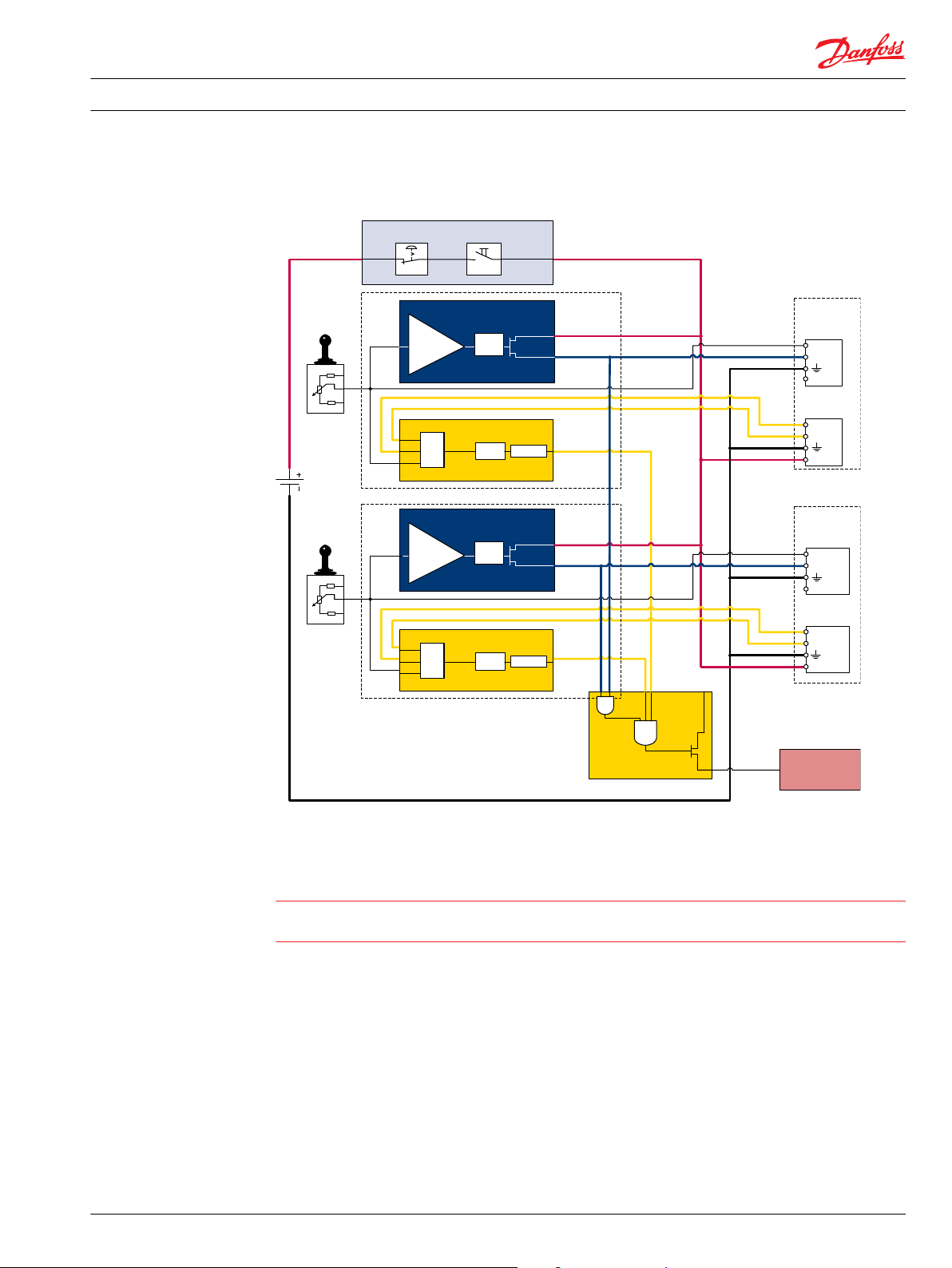

Example of fault monitoring for deactivation of the hydraulic system with extra fault inputs using the PVE’s

with DI (Direction Indication) function.

System Control Logic e.g. PLUS+1® for signal monitoring and triggering signal for deactivation of the

hydraulic system.

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

520L0247 • Rev JA • May 2014 11

PVMD

PVH

F

D

C

PVP

PVM

PVB

PVT

E

G

PVEO

PVEH

S

MA

P

PVM

V310156.A

Service Manual

Identification

Identification

PVG 120 Proportional Valve Group

PVG 120 Identification

C: PVG – number, week and year of installation

D: PVP – pressure setting

E: PVP – number, week, year and day manufacturing, issue and series No.

F: PVB – A-Port, number, week, year and day manufacturing, issue and series No.

G: PVT – week and year of manufacturing

12 520L0247 • Rev JA • May 2014

60 Nm

[530 lbf•in]

60 Nm

[530 lbf•in]

190 [7.48]*

100 [3.94]*

190 [7.48]*

100 [3.94]*

105 [4.13]

L

4xM12x18

[4x7/16-14UNCx0.7]

V310179.A

Service Manual

PVG 120 Proportional Valve Group

Installation

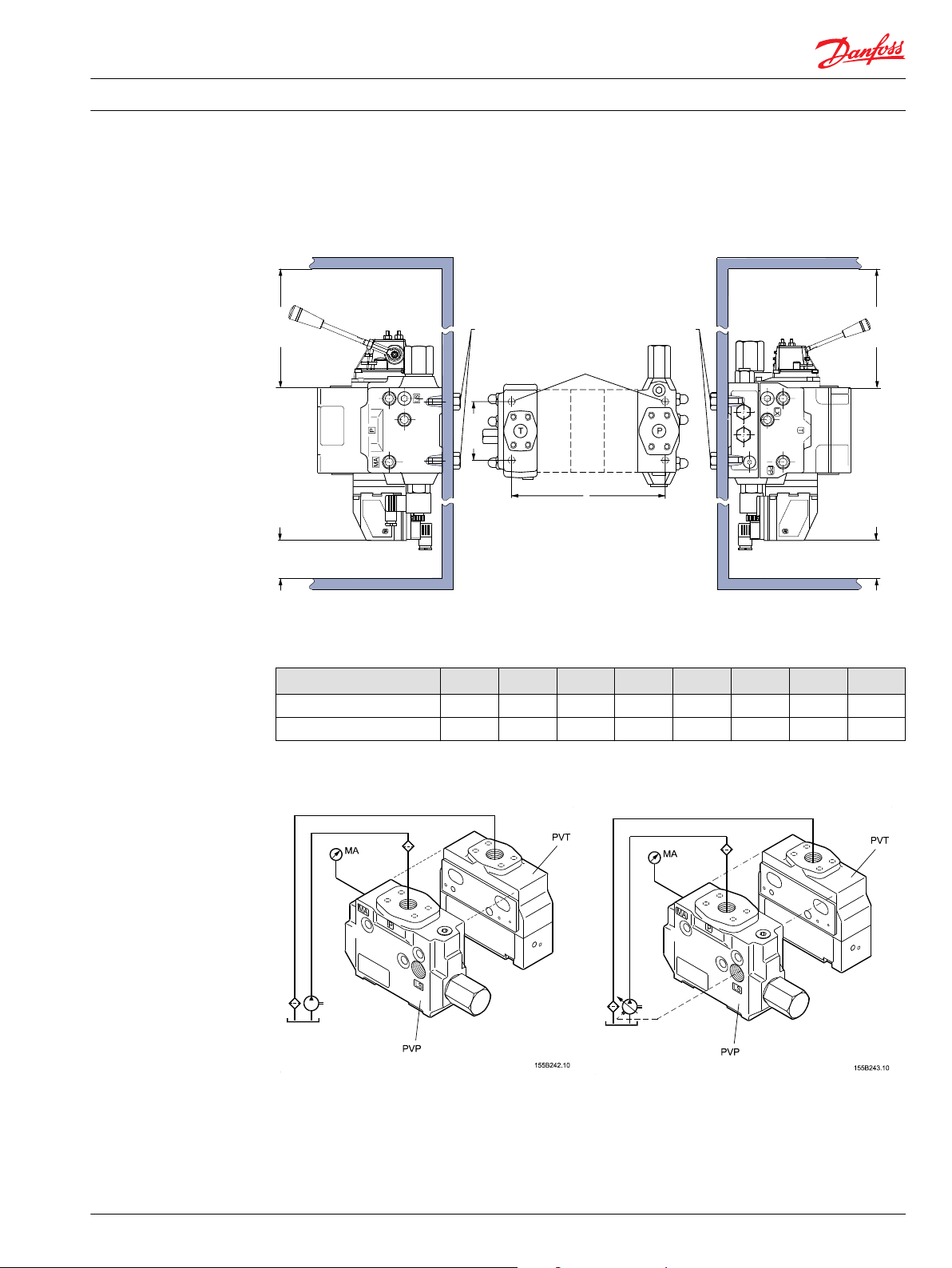

Installation and plug orientation

Installation Dimensions

* Room for dismantling

Module of PVB 1 2 3 4 5 6 7 8

L mm 168 235 302 369 436 503 570 637

L in 6.61 9.25 11.88 14.53 17.17 19.80 22.44 25.08

Connection, PVP, Pump Side Module

520L0247 • Rev JA • May 2014 13

A

B

P B

V310169.A

A

P A

PA

PB

P

B

V310163.A

A

B

P B

V310162.A

A

P A

PA

PB

P

B

V310170.A

Service Manual PVG 120 Proportional Valve Group

Installation

Oil flow direction

Mechanical / electrical actuation Mechanical / hydraulic actuation

Tightening Torques

Max. tightening torques – Connection Threads Type G (ISO 228/1)

Max. tightening torques

Ports PA, PB MA LS, LX, PP

Sealing thread G 1/4 G 1/4 G 3/8

With steel washer 35 N•m [310 lbf·in] 40 N•m [350 lbf·in] 60 N•m [530 lbf·in]

With cooper washer 30 N•m [270 lbf·in] 20 N•m [180 lbf·in] 35 N•m [310 lbf·in]

With aluminium washer 30 N•m [270 lbf.in] 30 N•m [270 lbf.in] 40 N•m [350 lbf·in]

With cutting edge 35 N•m [310 lbf.in] 40 N•m [350 lbf.in] 60 N•m [530 lbf·in]

14 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

Installation

Max. tightening torques – Mounting Threads in SAE J 518c Flanges

Port Size Threads Tightening torque

P 1 in M12, 18 deep 68 N•m

7/16 - 14 UNC 0.7” deep [600 lbf·in]

A/B 3/4 in M10, 17 deep 45 N•m

3/8 - 16 UNC 0.7” deep [400 lbf·in]

T 1 in M10, 17 deep 45 N•m

3/8 - 16 UNC 0.7” deep [400 lbf·in]

Max. tightening torques – UN and UNF Connection Threads – O-ring Boss Port

Max. tightening torques

Ports P A/B T PA/PB MA LS, LX, PP

Sealing

/Thread

O-ring 160 N•m 120 N•m 160 N•m 30 N•m 30 N•m 60 N•m

1 5/16 in-12 UN 1 1/16 in-12 UN 1 5/16 in-12 UN ½ in-20 UNF ½ in-20 UNF ¾ in-20 UNF

[1410 in•lbs] [1060 in•lbs] [1410 in•lbs] [270 in•lbs] [270 in•lbs] [530 in•lbs]

Ports identification

520L0247 • Rev JA • May 2014 15

37.5˚

67.5˚

97.5˚

127.5˚

157.5˚

187.5˚

19.5˚

19.5˚

V310018.A

22.5˚

52.5˚

82.5˚

112.5˚

142.5˚

172.5˚

19.5˚

19.5˚

V310014.A

10[0.39]

8 Nm

-

+

+

-

B

A

max.B

[70 lbf in]

LX

T

PP

3[0.12]

Q

Q

max.A

max.Qmax.

Q

max.B

Q

max.A

Q

V310101.A

Service Manual PVG 120 Proportional Valve Group

Installation

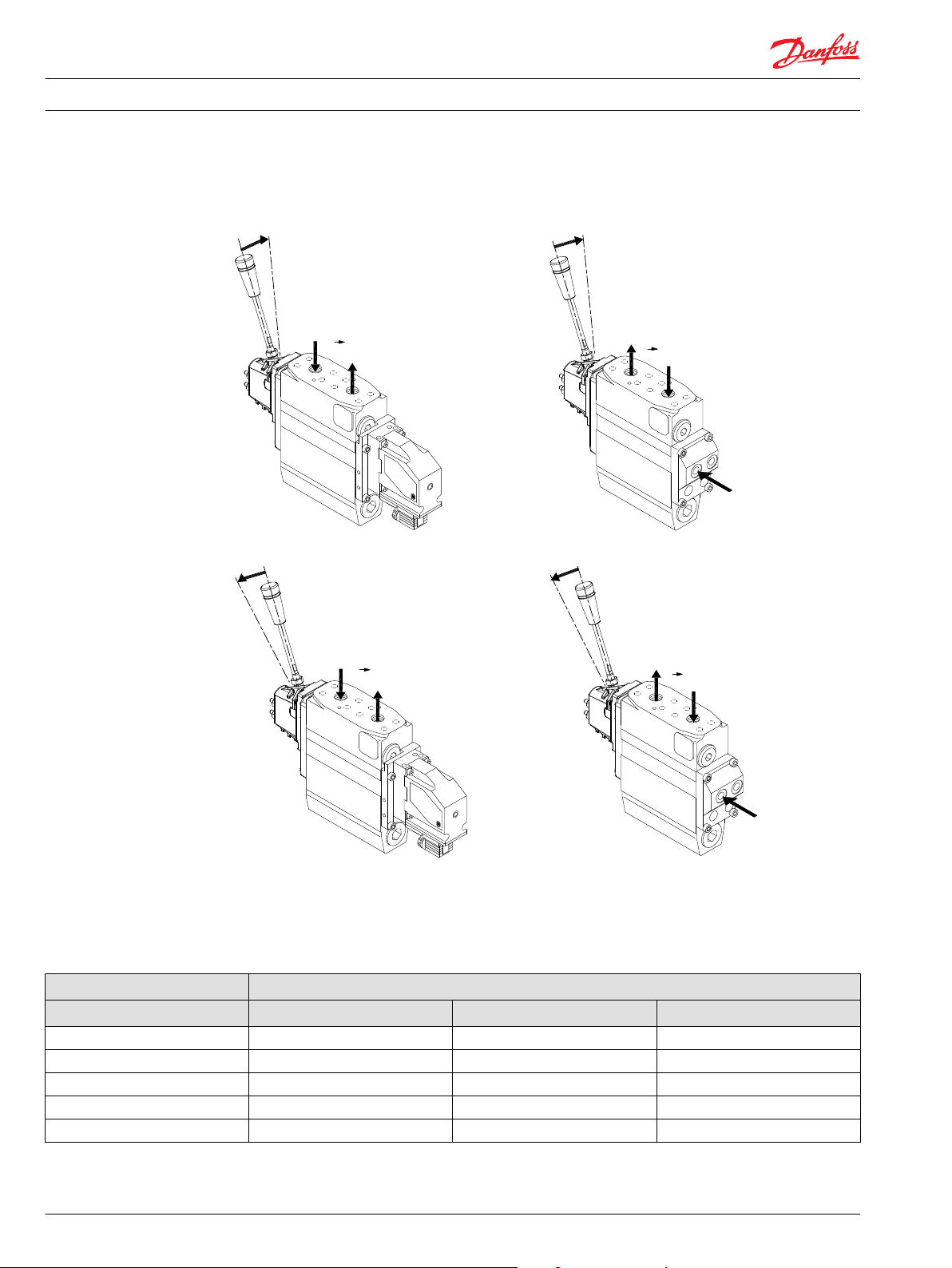

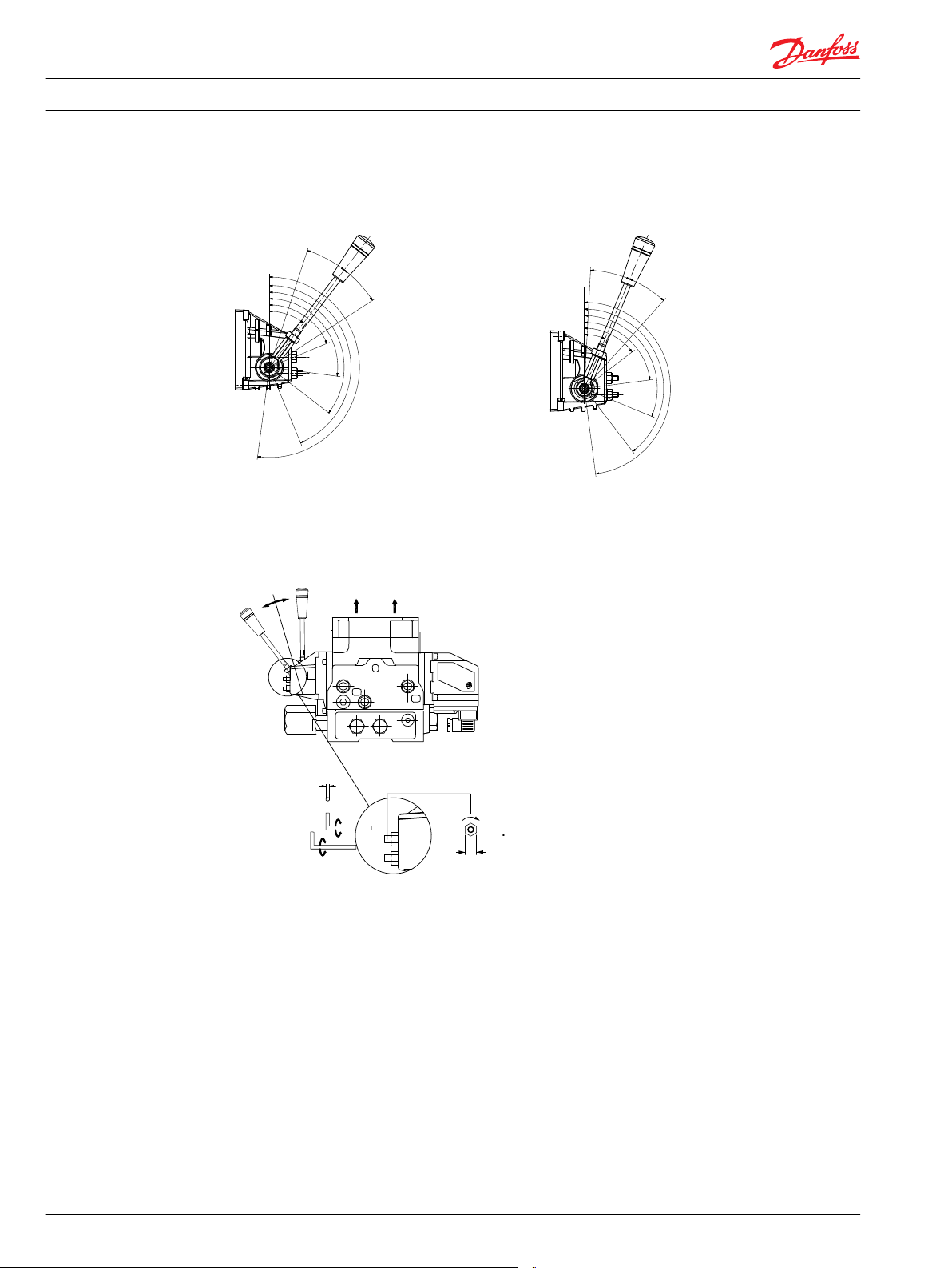

PVM, Lever Positions

Base with an angle of 37.5° Base with an angle of 22.5°

Setting of max. flow

Setting of Max. Flow

16 520L0247 • Rev JA • May 2014

8[0.31]

3[0.12]

360° ~ 130 bar

[360° ~ 1900 psi]

35 Nm

[310 lbf•in]

3 Nm

[27 lbf•in]

P

MA

LS

6[0.24]

6[0.24]

3[0.12]

3[0.12]

V310102.A

360° ~ 130 bar

[360° ~ 1900 psi]

3 Nm

[27 lbf•in]

LX

T

PP

3[0.12]

6[.24]

8[0.31]

3[0.12]

6[.24]

3[0.12]

[510 lbf•in]

35 Nm

V310094.A

Service Manual

Installation

Pressure Setting

PVG 120 Proportional Valve Group

PVP, LS Relief Valve Pressure Setting

PVP, LS Relief Valve Setting

PVB, LS Relief Valve Pressure Setting

PVB, LS Relief Valve Setting

520L0247 • Rev JA • May 2014 17

PVEO

PVEH

B

A

B

A

P A

P B

MA

P

S

V310158.A

C

Service Manual

PVG 120 Proportional Valve Group

Installation

Option, Oil Flow Direction and Setting of max Flow

Oil flow direction

Installation of PVE

For security reasons, any replacement of O-rings between valve block 1 and intermediate plate 2 may

only be effected at service shops authorized by Danfoss.

Caution

Mixing up PVE series 2 for PVG 120 may lead to self-actuation.

18 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

Installation

PVEH, PVEO

520L0247 • Rev JA • May 2014 19

*

190[7.48]

*

100[3.94]

T

LX

PP

V310105.A

S

MA

P

2.5[0.098]

2 Nm

[17.5 lbf•in)

L

PVP

PVPH

2

LS

LS

V310157.A

1

PVPE

Service Manual

Installation

Bleeding

PVG 120 Proportional Valve Group

PVG 120 installed vertically

PVPE/PVH relief valves

If the group is installed vertically, it is recommended to bleed it at the adjusting screws.

Max. tightening torque for PVPE/PVH

Position Across flats Max. tightening torque

1 22 mm [0.87 in] 5 N•m [45 lbf•in]

2 36 mm [1.42 in] 85 N•m [750 lbf•in]

3 36 mm [1.42 in] 85 N•m [750 lbf•in]

Tightening PVPE/PVH

20 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

Installation

PVPH and LS connections

Max. tightening torque for PVPH and LS

Sealing Threads, DS/ISO 228/1

Steel washer PVPH: G ¼ 40 Nm [350 lbf·in]

LS: G 3∕

Cupper washer PVPH: G ¼ 20 Nm [180 lbf·in]

LS: G 3∕

Aluminium washer PVPH: G ¼ 30 N•m [270 lbf·in]

LS: G 3∕

Cutting edge PVPH: G ¼ 40 Nm [350 lbf·in]

LS: G 3∕

PVPE technical data

PVPE technical data

Max. operation pressure

Max. pressure drop a an flow of 0.20 l/min. [0.053 US gal/min]

Oil temperature

(inlet temperature)

Max. coil surface temperature

Ambient temperature

Oil viscosity Operating range

Response time for pressure relief to tank

Enclosure to. IEC 529

Rated voltage

Max. permissible deviation from rated supply voltage

Current consumption at

rated voltage

Recommended temperature

Min. temperature

Max. temperature

Min. viscosity

Max. viscosity

at 22°C [72°F] coil temperature

at 85°C [230°F] coil temperature

at 22°C [72°F] coil temperature

at 85°C [230°F] coil temperature

Max. tightening torque

8

8

8

8

60 Nm [530 lbf·in]

35 N•m [310 lbf·in]

40 Nm [350 lbf·in]

60 Nm [530 lbf·in]

350 bar [5085 psi]

1.2 bar [17 psi]

30 to 60°C [86 to 140°F]

–30°C [–22°F]

90°C [194°F]

155°C [311°F]

–30 to 60°C [–22 to 140°F]

12 to 75 mm²/s [65 to 347 SUS]

4 mm²/s [39 SUS]

460 mm²/s [2128 SUS]

600 ms

IP 65

12 V 24 V

± 10 % ± 10 %

1.55 A 0.78 A

1 A 0.5 A

19 W 19 W

12 W 12 W

520L0247 • Rev JA • May 2014 21

Service Manual PVG 120 Proportional Valve Group

Installation

Connection PVPE

Installing the wire

When installing the wire remember to connect the built-in diode to the plug pins.

22 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVP

PVP, Pump Side Module

520L0247 • Rev JA • May 2014 23

Item Description Code No.

1 Plug

631X2036 1 1 1 1

155L6405 1 1 1 1 1 1 1 1

2* Bonded seal 14.7 × 1.5 [0.58 × 0.06 in] 633B9017 1 1 1 1 1 1 1 1 1 1 1 1

3 Plug 155G6212 1 1 1

4* O-ring 30.3 × 2.4 [1.19 × 0.09 in] 633B1441 1 1 1

5 Insert incl. item 3, 4 155G5041 1 1 1

6 Plug 155G5325 1 1 1 1 1 1 1 1 1

7* O-ring 13.3 x 2.4 [0.52 × 0.09 in] 633B1462 1 1 1 1 1 1 1 1 1

8 Relief valve incl. pos. 9 155G8561 1 1 1 1 1 1 1 1 1

9* Washer 7.0 × 14.0 × 1.5 [0.28 × 0.55 × 0.06 in] 684X2367 1 1 1 1 1 1 1 1 1

10 Pump side housing – 1 1 1 1 1 1 1 1 1 1 1 1

11 Plug

631X2038 1 1 1 1

631X9716 1 1 1 1 1 1 1 1

12* Bonded seal 17.4 × 1.5 [0.69 × 0.06 in] 633B9018 1 1 1 1

O-ring 16.36 × 2.21 [0.64 × 0.09 in] 633B0046 1 1 1 1 1 1 1 1

13 Plug 681X3019 1 1 1

× ∅0.5 [0.2 × 0.02 in] 155G5318 1 1 1 1 1 1

14 × ∅0.5 [0.2 × 0.02 in] 155G5318 1 1 1 1 1 1

15 Plug 155G5314 1 1 1 1 1 1 1 1 1

16* O-ring 33.3 x 2.4 [1.31 × 0.09 in] 633B1029** 1 1 1 1 1 1 1 1 1

17 Spring

155G5330 1 1 1 1 1 1

155G5333** 1 1 1

18 Spring

155G5331 1 1 1 1 1 1

155G5334** 1 1 1

19 Washer 19.3 × 34.0 × 3.0 [0.76 × 1.34 × 0.12 in] 155G5317** 1 1 1 1 1 1 1 1 1

20 ∅0.5 [0.2 × 0.02 in] 155G5318 1 1 1

Screw M5 [0.2 in] 681X3019 1 1 1

22 Spool

155G5312 1 1 1 1 1 1

155G5321** 1 1 1

23 Plug 070-2741 1 1 1 1 1 1 1 1 1

24* Bonded seal 10.35 × 2.0 [0.41 × 0.08 in] 633B9016 1 1 1 1 1 1 1 1 1

25 Pin – 1 1 1 1 1 1 1 1 1

26 Name plate 155A5021 1 1 1 1 1 1 1 1 1 1 1 1

27 Drive srew 681Z8055 2 2 2 2 2 2 2 2 2 2 2 2

28 Plastic plug

633X1028 1 1 1 1 1 1 1 1

633X0064 1 1 1 1

* S et of seals 155G8501 1 1 1 1 1 1 1 1 1 1 1 1

** Uprating set for PVP ( PVB incl. 155G6035 see page 42) 155G5035

With O-ring Boss port connection 1 5/16 in - 12 UN Code No.

PVP – closed center incl. PVPD 155G5022

PVP – open center excl. PVPD, PVPH, PVPE 155G5023

PVP – open center incl. uprating kit excl. PVPD, PVPH, PVPE 155G5028

PVP – closed center without relief valve 155G5031

7

/16 - 14 UNC Code No.

PVP – closed center incl. PVPD 155G5038

PVP – open center excl. PVPD, PVPH, PVPE 155G5037

PVP – open center incl. uprating kit excl. PVPD, PVPH, PVPE 155G5029

PVP – closed center without relief valve 155G5032

× 18 deep Code No.

PVP – closed center incl. PVPD 155G5020

PVP – open center excl. PVPD, PVPH, PVPE 155G5021

PVP – open center incl. uprating kit excl. PVPD, PVPH, PVPE 155G5027

PVP – closed center without relief valve 155G5030

Service Manual PVG 120 Proportional Valve Group

PVP

24 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVP

PVPD, PVPH, PVPE, Accessories for PVP

520L0247 • Rev JA • May 2014 25

Type Code No.

PVPE – extra electrical relief valve

12 V 155G5052

24 V 155G5054

PVPD – Plug 155G5041

PVPH – extra hydraulic relief valve 155G5061

Item Description Code No.

1 Electrical plug 155G5451 1 1

2 Electrical relief valve incl. item 3, 4, 5

155G5013 1

155G5025 1

3* O-ring 29.82 × 2.62

[1.18 × 0.10 in]

633B0069 1 1

4* Back-up ring 27.0 × 2.0

[1.06 × 0.08 in]

633B0068 1 1

5* O-ring 26.7 × 1.78

[1.05 × 0.07 in]

633B0070 1 1

6 Spring 155G5332 1 1

7

× ∅

0.5

[0.2 × 0.02 in]

155G5318 2 2 2

8 Spool 155G5311 1 1 1

9 Plug 631X2040 1

10* O-ring 30 × 3 × 2.4

[1.18 × 0.09 in]

633B1441 1 1

11 Insert incl. item 9, 10 155G5041 1

12 Plastic plug 633X7018

13 Nut 155G5404 2

14 Bushing 155G5403 1

15* Back-up ring 155G2316 1

16* O-ring 25.3 × 2.4

[1.0 × 0.09 in]

633B1440 1

17 Spool 155G5405 1

18 Cone 155G5406 1

19 Seat 155B4478 1

20 Spring 155G3317 1

* Set of seals

155G8527 1 1

155G8526 1

Service Manual PVG 120 Proportional Valve Group

PVP

Additional Module for PVP Open Center

26 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVLP / PVLA

PVLP / PVLA, Shock and Suction Valve Port A/B

520L0247 • Rev JA • May 2014 27

Item Description Code No.

14 Plug 155G1386 1 1

15* Back-up ring 633B0014 1 1

16* Back-up ring 633B0016 1 1

17* O-ring 20.35 x 1.78

[0.80 × 0.07 in]

633B0015 1 1

PVLP 50 bar

[725 psi]

155G0051 1

PVLP 75 bar

[1087 psi]

155G0076 1

PVLP 100 bar

[1450 psi]

155G0101 1

PVLP 125 bar

[1813 psi]

155G0126 1

PVLP 150 bar

[2175 psi]

155G0151 1

PVLP 175 bar

[2538 psi]

155G0176 1

PVLP 200 bar

[2900 psi]

155G0201 1

18 PVLP 225 bar

[3263 psi]

155G0226 1

PVLP 250 bar

[3625 psi]

155G0251 1

PVLP 275 bar

[3988 psi]

155G0276 1

PVLP 300 bar

[4351 psi]

155G0301 1

PVLP 325 bar

[4713 psi]

155G0326 1

PVLP 350 bar

[5076 psi]

155G0351 1

PVLP 375 bar

[5438 psi]

155G0376 1

PVLP 400 bar

[5801 psi]

155G0401 1

19 Plastic plug to protect cartridge 633X0053 1

20 Spring 155G1387 1 1

21 PVLA 155G1066 1

* Set of seals 155G8525 1 1

Type Code No.

PVLP, pressure setting: 50, 75, 100, 125, 175, 200, 225, 250, 275, 300, 325, 350,

375, 400 bar [725, 1087, 1450, 1813, 2538, 2900, 3263, 3625, 3988, 4351, 4713,

5076, 5438, 5801 psi]

PVLA 155G1065

155G0...

Service Manual PVG 120 Proportional Valve Group

PVLP / PVLA

28 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVBP, PVBR, PVBC, PVBU

PVBP, PVBR, PVBC, PVBU Accessories for PVB

520L0247 • Rev JA • May 2014 29

Item Description Code No.

1 Plug 155G5325 1

2* O-ring 13.3 × 2.4 [0.52 × 0.09 in] 633B1462 1

3 Relief valve incl. item 4 155G8561 1

4* Washer 7.0 × 14.0 × 1.5 [0.28 × 0.55 × 0.06 in] 684X2367 1

5 Plug 155G2313 1

6* O-ring 30.3 × 2.4 [1.19 × 0.09 in] 633B1441 1 1 1 1

7* Back-up ring 155G2316 1 1 1 1

8* O-ring 25.3 × 2.4 [1.0 × 0.09 in] 633B1440 1 1 1 1

9** Adjustment disc. 155G2315 4 4 4 4

10 Spring 155G2317 1 1 1

11 Plug 155G2322 1

12 Plug 631X2036 1 1

13 Bonded seal 14.7 × 1,5 [0.58 × 0.06 in] 633B9017 1

14 Plug 155G2323 1

15 Spring 155G2324 1

16 Plug 155G2319 1

17 Washer 13.5 × 17.5 × 1.5 [0.53 × 0.69 × 0.06 in] 684X2120 1

* Set of seals 155G8502 1 1 1 1

Type Code No.

PVBU - uprating kit for PVB 155G6035

PVBR - LSA/B relief valve 155G6080

PVBP - plug 155G6081

PVBC - connection for external LS-signal 155G6082

Service Manual PVG 120 Proportional Valve Group

PVBP, PVBR, PVBC, PVBU

30 520L0247 • Rev JA • May 2014

9

8

3

13

12

11

10

5[0.20]

[70±10 lbf•in]

8±1 Nm

[70±4.5 lbf•in]

8± 0.5 Nm

4

7

6

5

8±1Nm

[70±9 lbf•in]

5[0.20]

8±1 Nm

[70±9 lbf•in]

PVM

10[0.39]

6 mm

13 mm

[22±9 lbf•in]

2.5±1 Nm

3[0.12]

3

1

V310171.A

[71±9 lbf•in]

8±1 Nm

8±1 Nm

[70±9 lbf•in]

[0.24 in]

[0.51 in]

4 mm

[0.12 in]

14

2

Service Manual PVG 120 Proportional Valve Group

PVM

PVM, Mechanical Activating Module

520L0247 • Rev JA • May 2014 31

Item Description Code No.

1 Handle, black knob, including nut 1 1

2 Base, including set screw 22.5° / 37.5° 1 1

3 Screw M6 × 20 [0.24 × 0.78 in] 681X9266 8 8

4 PVM housing 155L3431 1 1

5 Seal nut M6 681X8270 2 2

6 Threaded pin M6 × 25 [0.80 × 0.07 in] 681X0323 2 2

7* 155L3430 1 1

8 Intermediate plate 155G3301 1 1

9* O-ring 42.0 × 2.0 [1.65 × 0.08 in] 633B1005 1 1

10 Spool control pin 155G3313 1 1

11 Stop 155G3314 1 1

12 Spring

155G3317 1

155G3318 1

13 Stop 155G3315 1 1

Type Code No.

PVM with PVMD or PVE 22.5° / 37.5° 155G3040

PVM with PVH 22.5° / 37.5° 155G3050

Spare Part, Kits Available

Item Description Code no.

14 Lever, with black knob handle and base 11046724

* Set of seals 155G8518

Lever, with red knob handle and base 11064640

1 Handle, black knob, including nut 11077262

2 Base, including set screw 11064641

Service Manual PVG 120 Proportional Valve Group

PVM

32 520L0247 • Rev JA • May 2014

Type Code No.

PVM + PVH assy - UNF 155G4021

PVH assy - BSP.F - thread 155G4022

PVMD assy 155G4061

Item Description Code No.

17 Screw M6 × 25

[0.80 × 0.07 in]

681X1198 4 4 4

18 Plastic plug

633X7018 2

633X0018 2

19 Cover

155G4301 1

155G4201 1

20* O-ring 6.0 × 2.0

[0.24 × 0.78 in]

633B1460 4 4 4

21* O-ring 27.0 × 2.0

[1.06 × 0.78 in]

633B0407 1 1 1

22 Cover 155G4402 1

* Set of seals 155G8505 1 1 1

Service Manual PVG 120 Proportional Valve Group

PVMD and PVH

PVMD, Cover for PVM and PVH, Hydraulic Activation

520L0247 • Rev JA • May 2014 33

• Rev IE • Oct 2012

Type Code No.

155G7033

PVGI sddy 1 5/16 in - 12 UN 155G7031

3

/8 in - 16 UNC 155G7032

Item Description Code No.

1 Combination module – 1 1 1

2 O-ring 24.0 × 2.0

[0.94 × 0.08 in]

633B1428 1 1 1

3 O-ring 10.0 × 2.0

[0.39 × 0.08 in]

633B1461 2 2 2

4 Bonded seal 14.7 × 1.5

[0.58 × 0.06 in]

633B9017 1 1 1

5 Plug

G 1/4 631X2036 1

1

/2 - 20 UNF 155L6405 1 1

6 Plug 631X2040 3 3 3

7 O-ring 30.3 × 2.4

[1.19 × 0.08 in]

633B1441 3 3 3

8 Plastic plug

633X1028 1 1

633X0019 1

Service Manual PVG 120 Proportional Valve Group

PVGI

PVGI, Interface for PVG 120 and PVG 32

34 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVEH and PVEO

PVEH and PVEO, Electrical Activating Module, ON-OFF

520L0247 • Rev JA • May 2014 35

Item Description Code No.

155G4284

155G4282

155G4274

155G4272

155G4095

155G4093

155G4094

155G4092

1 El. plug DIN 43650 Black PG 9 984L3156 1 1 1 1

2 Plastic plug 155U2779 1 1 1 1 1 1 1 1

3 PVEH assy – 1 1

PVEH assy. with passive fault monitoring – 1 1

PVEO assy – 1 1 1 1

4 Screw M6; l = 15 [0.24 in] 681X9266 4 4 4 4 4 4 4 4

5* O-ring 7 × 2 [0.28 × 0.78 in] 633B1148 1 1 1 1 1 1 1 1

6* O-ring 15 × 2 [0.59 × 0.78 in] 633B1030 1 1 1 1 1 1 1 1

7* O-ring 10 × 2 [0.39 × 0.78 in] 633B1267 2 2 2 2 2 2 2 2

8* O-ring 27 × 2 [1.06 × 0.78 in] 633B0407 1 1 1 1 1 1 1 1

* Set of seals 155G8519 1 1 1 1 1 1 1 1

Type Connector Code No.

PVEH

Fault monitoring active,

11-32V

Hirschman 155G4092

AMP 155G4094

Fault monitoring passive,

11-32V

Hirschman 155G4093

AMP 155G4095

PVEO

12V

Hirschman

155G4272

24V 155G4274

12V

AMP

155G4282

24V 155G4284

Service Manual PVG 120 Proportional Valve Group

PVEH and PVEO

36 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVT

PVT, Tank Side Module – Upper Part

520L0247 • Rev JA • May 2014 37

With LX-connection Code No.

PVT, SAE UNF, mounting thread 3/8 in - 16 UNC 155G7025

PVT, Boss port connection 1 5/16 in - 12 UN 155G7024

× 23 deep 155G7023

Item Description Code No.

1 Plug

631X2038 2 2

631X9716 2 2 2 2

2* Bonded seal 17.4 x 1.5

[0.69 × 0.06 in]

633B9018 2 2

O-ring 16.36 x 2.21

[0.64 × 0.09 in]

633B0046 2 2 2 2

3** Screw M5; l = 6

[0.2 in]

681X1925 1 1 1

4** Bonded seal 5.7 x 1.0

[0.22 × 0.04 in]

633B9029 1 1 1

5** Plug (item 3 and 4) 155G8555

6* O-ring 10.0 x 2.0

[0.39 × 0.08 in]

633B1461 2 2 2 2 2 2

7* O-ring 24.0 x 2.0

[0.94 × 0.08 in]

633B1428 1 1 1 1 1 1

8 Plastic plug

633X1028 1 1 1 1

633X0064 1 1

9 Tank part assy - 1 1 1 1 1 1

* Set of seals 155G8507 1 1 1 1 1 1

** Used only when load signal is carried to LX-port 155G8555 1 1 1 1 1 1

Without LX-connection Code No.

PVT, SAE UNF, mounting thread 3/8 in - 16 UNC 155G7022

PVT, Boss port connection 1 5/16 in - 12 UN 155G7021

× 23 deep 155G7020

Service Manual PVG 120 Proportional Valve Group

PVT

38 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVT

PVT, Tank Side Module – Lower Part

520L0247 • Rev JA • May 2014 39

Item Description Code No.

10 Screw M8 x 60

[0.31 × 2.36 in]

681X1146 3 3 3 3

11 Tank part assy - 1 1 1 1

12 Plug 155G7372 1 1

13* O-ring 17.5 x 2.4

[0.69 × 0.09 in]

633B1335 1 1

14* Filter 155B4056 1 1

15 Plug 155G7373 1 1

16* O-ring 19.3 x 1.5

[0.76 × 0.06 in]

633B1136 1 1

17 Stop 155G7376 1 1

18 Washer 10.0 x 16.0 x 0.5

[0.39 × 0.63 × 0.02 in]

684X2094 2 2

19 Spring 155G7375 1 1

20 Spool 155G7374 1 1

21 Plug 155L1373 1 1

22* O-ring 16.0 x 1.5

[0.63 × 0.06 in]

633B1813 1 1

23 Stop 155G7382 1 1

24 Washer 7.4 x 11.5 x 1.0

[0.29 × 0.45 × 0.04 in]

684X2547 2 2

25 Spring 155G7381 1 1

26 Ball 689X1040 1 1

* Set of seals 155G8524 1 1

Kit for hydraulic activation 155G7041 1 1

UNC Code No.

PVT with pilot supply for PVE 155G7042

PVT without pilot supply for PVE 155G7062

BSP.F. thread Code No.

PVT with pilot supply for PVE 155G7040

PVT without pilot supply for PVE 155G7060

Service Manual PVG 120 Proportional Valve Group

PVT

40 520L0247 • Rev JA • May 2014

W

Service Manual

PVAS and PVGI

PVGI, Assembly Kit

PVG 120 Proportional Valve Group

PVAS, Assembly Kit

Asssembly sequence

1.

Mount nut on short thread and torque 10 N•m

2.

Mount seal

3.

Assemble PVG

4.

Mount seal and nut on long thread and torque 10 N•m

5.

When all three stay bolts are mounted, torque full to 80 N•m

Warning

Do not reuse stay bolts or loosen torque. The stay bolts are not designed as motor bolts and do not keep

strength when remounted.

520L0247 • Rev JA • May 2014 41

Type Code No.

PVGI for 0 basic module 155G8040

PVGI for 1 basic module 155G8041

PVGI for 2 basic module 155G8042

PVGI for 3 basic module 155G8043

PVGI for 4 basic module 155G8044

Item Description Code No.

1 Nut 155G8312 3 3 3 3 3 3 3 3 3 3 3 3 3

2* / 2** Bonded seal 17.4 x 1.5

[0.69 × 0.06 in]

633B9018 6 6 6 6 6 6 6 6 6 6 6 6 6

Stay bolt M12 [0.47]; l = 234 [9.21 in] 155G8201 3

Stay bolt M12 [0.47]; l = 302 [11.89 in] 155G8202 3

Stay bolt M12 [0.47]; l = 369 [14.53 in] 155G8203 3

Stay bolt M12 [0.47]; l = 436 [17.17 in] 155G8204 3

Stay bolt M12 [0.47]; l = 503 [19.80 in] 155G8205 3

3 Stay bolt M12 [0.47]; l = 571 [22.48 in] 155G8206 3

Stay bolt M12 [0.47]; l = 638 [25.12 in] 155G8207 3

Stay bolt M12 [0.47]; l = 705 [27.76 in] 155G8208 3

Stay bolt M12 [0.47]; l = 124.5 [4.90 in] 155G8330 3

Stay bolt M12 [0.47]; l = 192.5 [7.58 in] PVGI 155G8331 3

Stay bolt M12 [0.47]; l = 260.5 [10.24 in] PVGI 155G8332 3

Stay bolt M12 [0.47]; l = 328.5 [12.93 in] PVGI 155G8333 3

Stay bolt M12 [0.47]; l = 396.5 [15.61 in] PVGI 155G8334 3

4* / 4** Pin 682L2006 18 16 14 12 10 8 6 4 10 8 6 4 2

5* / 5** O-ring 33.3 x 2.4

[1.31 × 0.09 in]

633B1029 18 16 14 12 10 8 6 4 10 8 6 4 2

6* / 6** O-ring 28.24 x 2.62

[1.118 × 0.10 in]

633B1956 9 8 7 6 5 4 3 2 5 4 3 2 1

7* / 7** O-ring 11.91 x 2.62

[0.47 × 0.10 in]

633B1955 18 16 14 12 10 8 6 4 10 8 6 4 2

8 O-ring 5.0 x 2.0

[0.20 × 0.08 in]

633B1809 2 2 2 2 2

9 O-ring 16.0 x 2.5

[0.63 × 0.10 in]

633B1817 4 4 4 4 4

11 O-ring 10.0 x 2.5

[0.39 × 0.10 in]

633B0120 1 1 1 1 1

* 155G8522 1 1 1 1 1 1 1 1 1 1 1 1

** Set of seals for additionel sections 155G8523 7 6 5 4 3 2 1 3 2 1

PVGI, Assembly Kit (continued)

Type Code No.

PVAS for 1 basic module 155G8031

PVAS for 2 basic module 155G8032

PVAS for 3 basic module 155G8033

PVAS for 4 basic module 155G8034

PVAS for 5 basic module 155G8035

PVAS for 6 basic module 155G8036

PVAS for 7 basic module 155G8037

PVAS for 8 basic module 155G8038

PVAS, Assembly Kit (continued)

Service Manual PVG 120 Proportional Valve Group

PVAS and PVGI

42 520L0247 • Rev JA • May 2014

Type Code No.

PVP 155G8501

PVB / PVB additional module 155G8502

PVPH 155G8526

PVPE 155G8527

PVLP / PVLA 155G8525

PVM 155G8518

PVEH / PVEO 155G8519

PVH / PVMD 155G8505

PVT, Upper part 155G8507

PVT (with pilot supply), Lower part 155G8524

155G8522

PVAS for additional sections 155G8523

Item Description Code No.

1 O-ring 8.3 x 2.4 [0.33 × 0.09 in] 633B0011 1

2 O-ring 20.35 x 1.78 [0.80 × 0.07 in] 633B0015 1

3 O-ring 16.36 x 2.21 [0.64 × 0.09 in] 633B0046 2 1

4 O-ring 29.82 x 2.62 [1.17 × 0.10 in] 633B0062 1

5 O-ring 26.7 x 1.78 [1.05 × 0.07 in] 633B0071 1

6 O-ring 27.0 x 2.0 [1.06 × 0.08 in] 633B0407 1 1

7 O-ring 6.3 x 2.4 [0.25 × 0.09 in] 633B1004 2

8 O-ring 42.0 x 2.0 [1.65 × 0.08 in] 633B1005 1

9 O-ring 33.3 x 2.4 [1.37 × 0.09 in] 633B1029 2 4 1

10 O-ring 15.0 x 2.0 [1.59 × 0.08 in] 633B1030 1

11 O-ring 8.0 x 2.0 [0.31 × 0.08 in] 633B1056 1

12 O-ring 19.3 x 2.4 [0.76 × 0.09 in] 633B1136 1

13 O-ring 8.0 x 2.0 [0.31 × 0.08 in] 633B1148 1

14 O-ring 10.0 x 2.0 [0.39 × 0.08 in] 633B1267 2

15 O-ring 17.5 x 2.4 [0.69 × 0.09 in] 633B1335 1

16 O-ring 24.0 x 2.0 [0.94 × 0.08 in] 633B1428 1

17 O-ring 25.3 x 2.4 [1.00 × 0.09 in] 633B1440 1 1

18 O-ring 30.3 x 2.4 [1.19 × 0.09 in] 633B1441 1 2 1

19 O-ring 6.0 x 2.0 [0.24 × 0.08 in] 633B1460 4 1

20 O-ring 10.0 x 2.0 [0.39 × 0.08 in] 633B1461 2

21 O-ring 13.3 x 2.4 [0.52 × 0.09 in] 633B1462 1 1

22 O-ring 20.3 x 2.4 [0.78 × 0.09 in] 633B1521 1

23 O-ring 16.0 x 1.5 [0.63 × 0.06 in] 633B1813 1

24 O-ring 10.52 x 1.83 [0.41 × 0.07 in] 633B1834 1

25 O-ring 11.91 x 2.62 [0.47 × 0.10 in] 633B1955 2 4

26 O-ring 28.24 x 2.62 [1.11 × 0.10 in] 633B1956 1 2

27 × 0.09 in] 155L3430 1

28 Washer 7.0 x 14.0 x 1.5 [0.28 × 0.55 × 0.06 in] 684X2367 1 1

29 Washer 16.2 x 19.9 x 1.5 [0.64 × 0.78 × 0.08 in] 684X2565 1 1

30 Bonded seal 10.35 x 2.0 [0.41 × 0.08 in] 633B9016 1

31 Bonded seal 14.7 x 1.5 [0.58 × 0.06 in] 633B9017 1

32 Bonded seal 17.4 x 1.5 [0.69 × 0.06 in] 633B9018 6 6 2 1

33 Bonded seal 5.7 x 1.0 [0.22 × 0.04 in] 633B9029 1

34 Back-up ring 633B0014 1

35 Back-up ring 633B0016 1

36 Back-up ring 633B0068 1

37 Back-up ring 155G2316 1 1

38 Filter 155G4710 1

39 Filter 155B4056 1

40 Seal nut 681X8270 2

41 Pin 682L2006 2 4

Service Manual PVG 120 Proportional Valve Group

Set of seals

Set of Seals

520L0247 • Rev JA • May 2014 43

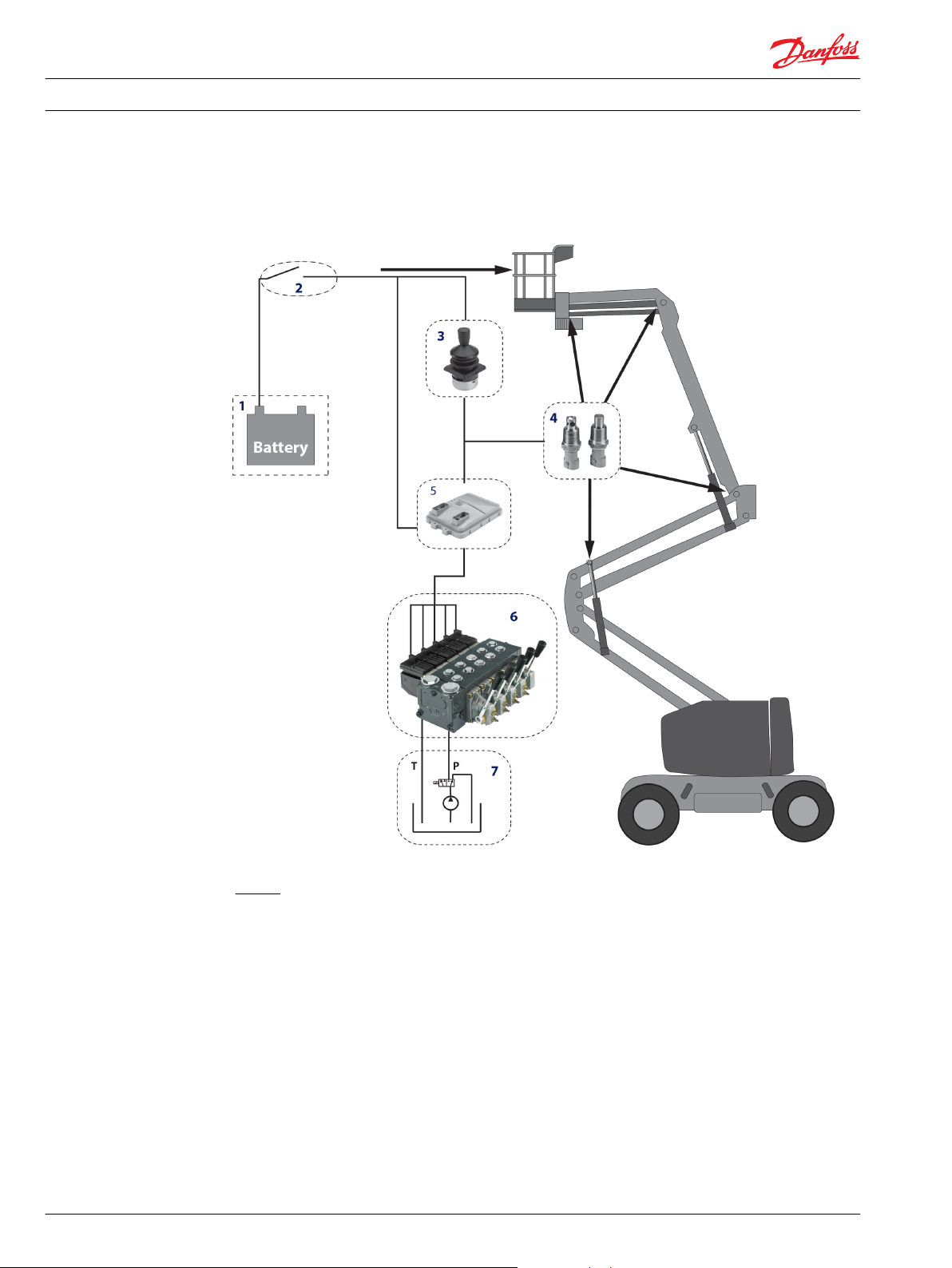

P

LS

P

T

f

e

a

0

1-8

d

10

9

11

c

b

V310173.A

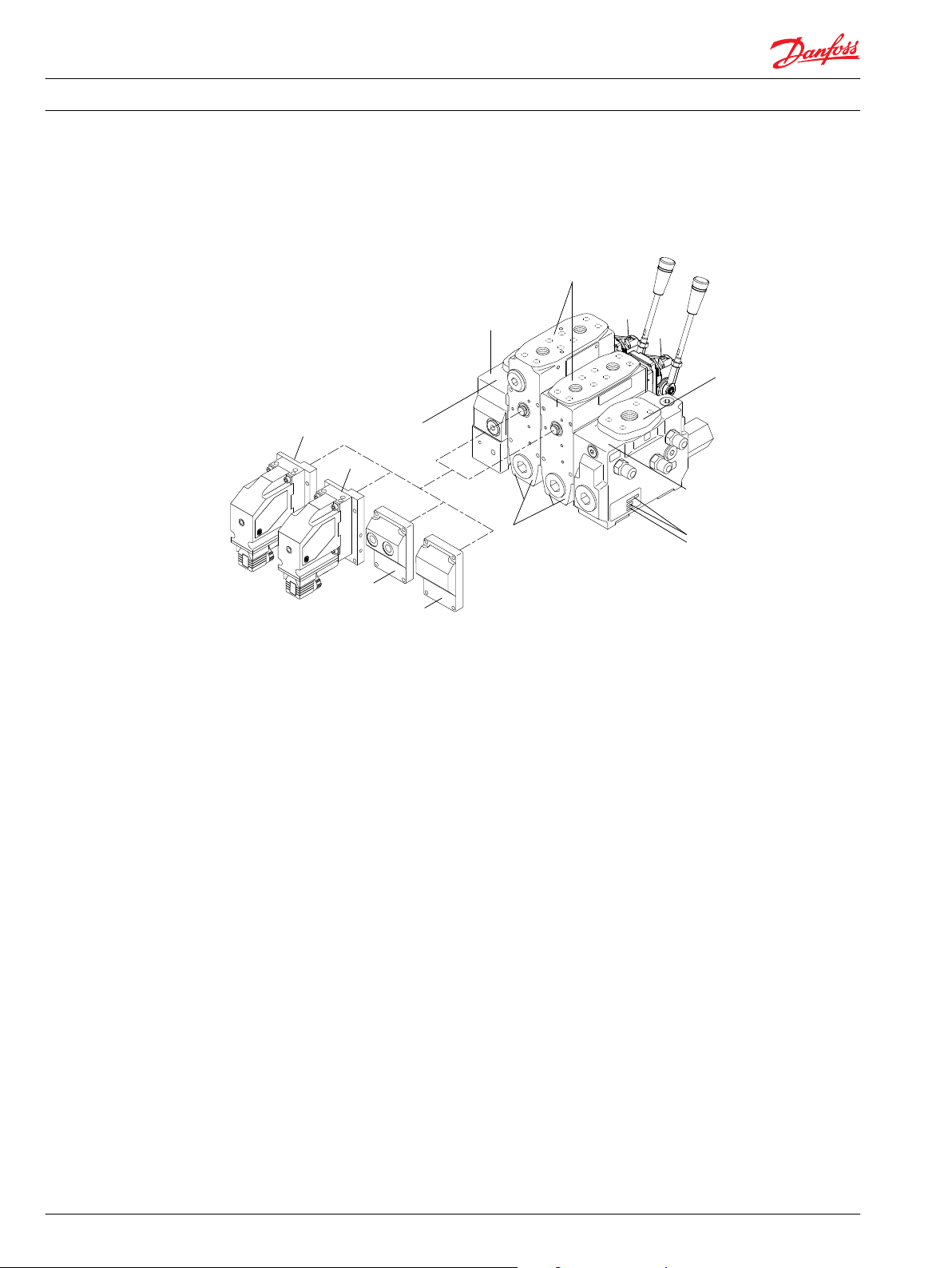

Service Manual PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVG 120 module selection chart

PVG 120 modules exploded view

PVB, high basic module

SAE

flange

Facilities for shock valves AB 155G6007 155G6006 155G6005 10.2 [22.5]

O-ring

Boss

Metric flange Weight

PVB, low basic module

No facilities for shock valves AB 155G6016 155G6015 155G6014 8.9 [19.6]

SAE

flange

O-ring

Boss

Metric flange Weight

kg [lb]

kg [lb]

44 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

Accessory modules for PVB

Plug, PVBP 155G6081 0.4 [0.9]

LS

press. relief valve, PVBR 155G6080

A/B

External LS connection, PVBC 155G6082

Module for oil flow > 180 l/min [47.6 US gal/min], PVBU 155G6035

PVBS, mechanical actuation

Oil flow, l/min [US

gal]

A

65 [17.2]

155G6452 155G6454 155G6456 155G6458

Code number

B

95 [25.1]

155G6464 155G6466 155G6468

C

130 [34.3]

Weight, kg [lb]

D

180 [47.6]

155G6476 155G6478

Weight, kg [lb] 0.35 [0.8]

PVM, mechanical actuation

PVM + PVMD or

PVM + PVE

PVM + PVH

Weight

155G3040

155G3041

155G3050

155G3051

kg [lb] 0.5 [1.1]

22.5°

37.5°

22.5°

37.5°

PVMD, cover for PVM

Code number

155G4061 0.3 [0.7]

Weight, kg [lb]

PVT, tank side module

Code number

Upper part excl. LX connection 155G7022 155G7021 155G7020 4.6 [10.1]

Upper part incl. LX connection 155G7025 155G7024 155G7023

Lower part incl. pilot oil supply for PVE 155G7042 155G7040 4.4 [9.7]

Lower part excl. pilot oil supply for PVE 155G7062 155G7060

Lower part incl. pilot oil supply for PVH 155G7044 155G7043

SAE

flange

O-ring

Boss

Metric

flange

Weight

kg [lb]

520L0247 • Rev JA • May 2014 45

Service Manual PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVP, pump side module

Code number

Open

centre

Closed

centre

Accessory modules for open centre PVP

Description Code number

Plug, PVPD 155G5041 0.4 [0.9]

Hydraulic relief valve, PVH 155G5061 0.5 [1.1]

Electrical relief valve, PVPE 12 V 155G5052 0.7 [1.5]

Excl. PVPD, PVPH, PVPE 155G5023 155G5037 155G5021 10.0 [22.1]

For PVB-oil flow > 180 l/min [47.6

US gal/min]

Excl. PVPD, PVPH, PVPE

Incl. pressure relief valve and plug

PVPD

Excl. pressure relief valve 155G5031 155G5032 155G5030 11.0 [24.3]

24 V 155G5054

O-ring

Boss

155G5028 155G5029 155G5027

155G5022 155G5038 155G5020 10.2 [22.5]

SAE

flange

Metric flange Weight

kg [lb]

Weight

kg [lb]

PVH, cover for PVRHH

Port Code number

1/2 in - 20 UNF 155G4021 0.4 [0.9]

G 1/4 155G4022

Weight, kg [lb]

PVE, electrical actuation

Connector PVEH fault monitoring PVEO voltage

Active Passive 12 V 24 V

Hirschmann 155G4092 155G4093 155G4272 155G4274

AMP 155G4094 155G4095 155G4282 155G4284

Weight, kg [lb]

1.25 [2.76] 1 [2.2]

PVLA suction valve A/B

Code number

155G1065 0.2 [0.4]

Weight

kg [lb]

PVLP, shock and suction valve A/B

Pressure setting

bar [psi]

50 725 155G0050

75 1100 155G0075

100 1450 155G0100

125 1800 155G0125

150 2200 155G0150

Code number

46 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVLP, shock and suction valve A/B (continued)

Pressure setting

175 2550 155G0175

200 2900 155G0200

225 3250 155G0225

250 3650 155G0250

275 4000 155G0275

300 4350 155G0300

325 4700 155G0325

350 5100 155G0350

375 5400 155G0375

400 5800 155G0400

Weight, kg [lb]

PVAS, assembly kit

PVB’s 1 2 3 4 5 6 7 8

Code number

Weight kg 0.8 1.0 1.1 1.2 1.4 1.7 1.9 2.1

155G8031 155G8032 155G8033 155G8034 155G8035 155G8036 155G8037 155G8038

[lb] [1.8] [2.2] [2.4] [2.6] [3.1] [3.7] [4.2] [4.6]

0.175 [0.386]

520L0247 • Rev JA • May 2014 47

Service Manual

PVG 120 Proportional Valve Group

Order specification

Ordering of modules for oil flow exceeding 180 l/min [47.6 US gal/min]

Modules for pump with fixed displacement

1. Ordering: Order accessory module 155G6035, main spool D, and pump side modules 155G5027 /

155G5028 / 155G5029.

2. Conversion: In open center systems a max. oil flow exceeding 180 l/min [47.6 US gal/min] can be

achieved by changing the following parts in the pump side and basic modules:

Open center pump side module

•

– Pressure adjustment spool

– The springs behind the pressure adjustment spool

– The plug behind the pressure adjustment spool

Parts from kit 155G5035 may be used.

Closed center pump side module (A closed center pump side module can be changed into an

•

upgraded open center pump side module by means of kit 155G5035.)

Basic module

•

– Spring behind pressure compensator

– The plug behind the pressure compensator

Order Form

Spring and plug with code number 155G6035 (PVBU, accessory module).

Modules for pump with variable displacement

1. Ordering: Order accessory module 155G6035 and main spool D.

2. Conversion:In closed center systems a max. oil flow exceeding 180 l/min [47.6 US gal/min] can be

achieved by changing the following basic module parts:

– The spring behind the pressure compensator.

– The plug behind the pressure compensator.

The code number of the spring and plug is 155G6035 (PVBU, accessory module).

An order form for PVG 120 hydraulic valve is shown on next page. The form can be obtained from the

Danfoss Power Solutions Sales Organisation.

The module selection chart on the next page and the order form are divided into fields.

Each module has its own field:

0: PVP, pump side modules

d: PVPD, PVPH and PVPE, accessory modules

1-8: PVB, basic modules

e: PVBS, main spools

f: PVBP, PVBR, PVBU and PVBC, accessory modules

a: PVM, mechanical actuation

c: PVMD, cover for mechanical operation; PVH, cover for hydraulic operation; PVEO and PVEH, electrical

actuations

b: PVLP, shock and suction valve; PVLA, suction valve

9: PVT, tank side module

10: PVAS, assembly kit

48 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

Order specification

Please state:

•

Code numbers of all modules required

•

Required setting (p) for pump side module

•

Required setting of LS

Reordering

The space at the top right-hand corner of the form is for Danfoss to fill in. The code number for the whole

of the specified valve group (PVG No.) is entered here. In the event of a repeat order all you have to do is

enter the number Danfoss has given on the initial confirmation of order.

If PVG 120 is to be used with phosphate-esters this must be stated on the order form (See Non-flammable

Fluids for more information).

pressure relief valves, if accessory module PVBR is ordered.

A/B

520L0247 • Rev JA • May 2014 49

Service Manual PVG 120 Proportional Valve Group

Order specification

50 520L0247 • Rev JA • May 2014

Service Manual PVG 120 Proportional Valve Group

520L0247 • Rev JA • May 2014 51

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile off -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of off -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off -highway vehicles are at work, so is Danfoss.

We off er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we off er:

• Bent Axis Motors

• Closed Circuit Axial Piston

Pumps and Motors

• Displays

• Electrohydraulic Power

Steering

• Electrohydraulics

• Hydraulic Power Steering

• Integrated Systems

• Joysticks and Control

Handles

• Microcontrollers and

Software

• Open Circuit Axial Piston

Pumps

• Orbital Motors

• PLUS+1® GUIDE

• Proportional Valves

• Sensors

• Steering

• Transit Mixer Drives

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed..

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

520L0247 • Rev JA • May 2014 www.danfoss.com

©

Danfoss A/S, 2014

Loading...

Loading...