Page 1

Technical Information

Proportional Valve Group

PVG 120

powersolutions.danfoss.com

Page 2

Technical Information

PVG 120 Proportional Valve Group

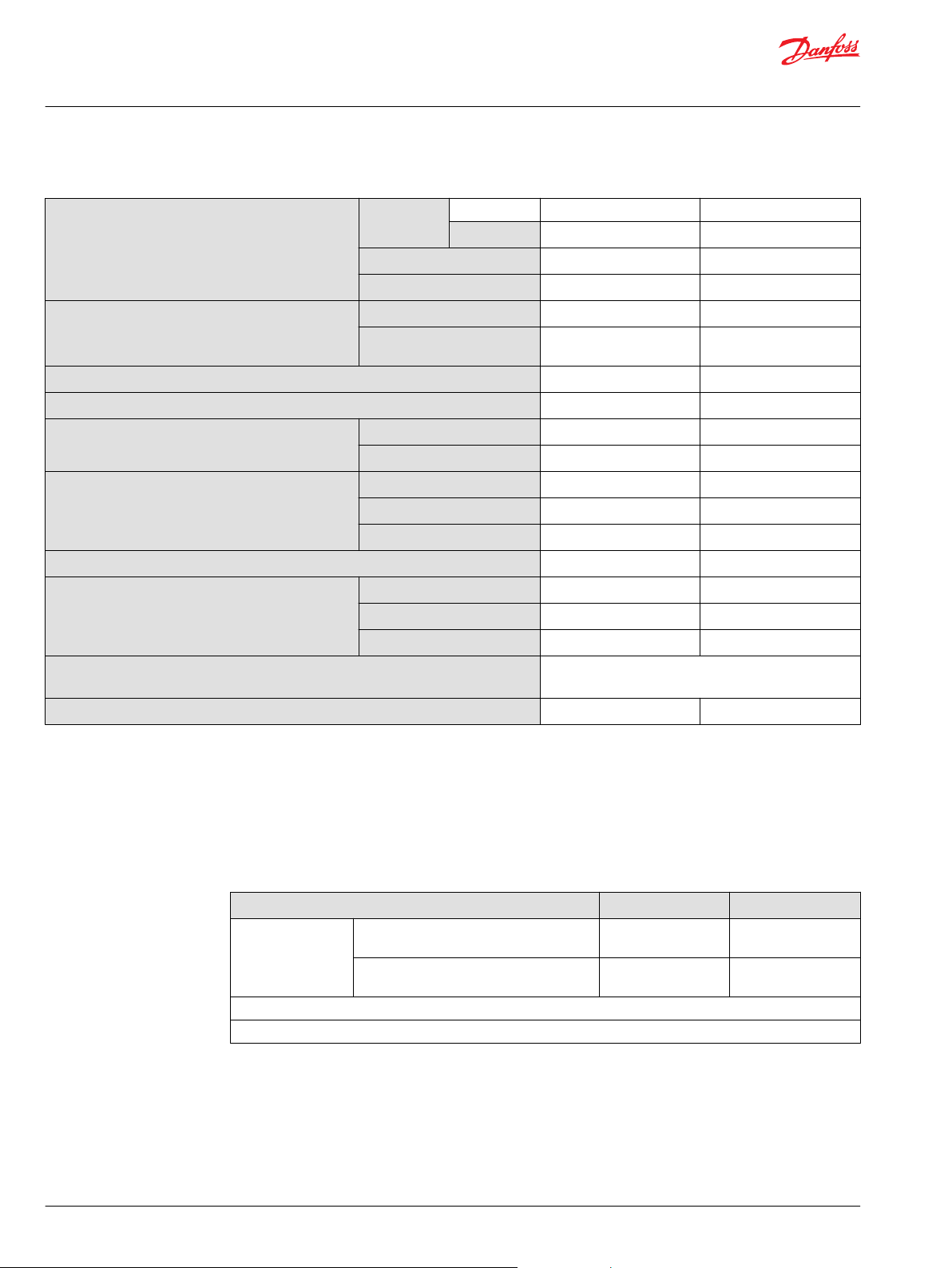

Revision history Table of revisions

Date Changed Rev

March 2017 minor updates 1002

Mar 2014 Chapters re-order, Modules selection chart JA

Dec 2013 Converted to Danfoss layout – DITA CMS ID

2006 - 2012 Various updates AB - IC

Apr 2006 New edition AA

2 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 3

Technical Information

PVG 120 Proportional Valve Group

Contents

Literature reference for PVG products

General Information

Valve System...................................................................................................................................................................................... 6

General Characteristics...................................................................................................................................................................6

Pump Side Module – PVP.............................................................................................................................................................. 6

Basic Module – PVB..........................................................................................................................................................................7

Actuation Modules...........................................................................................................................................................................7

Electronic Accessories.....................................................................................................................................................................7

Remote Controls Units....................................................................................................................................................................8

Function

PVG 120 with PVP Open Center.................................................................................................................................................. 9

PVG 120 with PVP Closed Center................................................................................................................................................9

PVG 120 sectional view

Safety in application

Control system example..............................................................................................................................................................12

Examples of wiring block diagram.....................................................................................................................................14

Technical Data

PVG 120 technical data................................................................................................................................................................ 16

PVM, mechanical actuation........................................................................................................................................................16

PVH, hydraulic actuation.............................................................................................................................................................17

PVE, electrical actuation ............................................................................................................................................................. 17

PVPE, electrical relief valve, normally open..........................................................................................................................17

Electrical Actuation

PVEO, ON-OFF................................................................................................................................................................................. 19

PVEH, proportional high..............................................................................................................................................................19

PVEH, Inductive Transducer (LVDT – Linear Variable Differential Transformer)................................................20

PVEH, Pulse Width Modulation (Integrated)...................................................................................................................21

PVEH fault monitoring..................................................................................................................................................................21

PVEH, connection to fault monitoring output...............................................................................................................22

Technical Characteristics

General...............................................................................................................................................................................................23

PVP, pump side module.............................................................................................................................................................. 23

PVB, Basic Module..........................................................................................................................................................................24

PVLP, Shock Valve Characteristic (with Pressure Relief Valve).......................................................................................26

PVLP/PVLA, Suction Function....................................................................................................................................................27

Hydraulic system examples

Example of PVG 120 with variable displacement pump..................................................................................................28

Example of PVG 120 with fixed displacement pump........................................................................................................29

Other operating conditions

Hydraulic fluids for PVG...............................................................................................................................................................30

Particle Content, Degree of Contamination.........................................................................................................................30

Filtering..............................................................................................................................................................................................30

Conversion Factors........................................................................................................................................................................31

Dimensions

PVG 120 dimensions..................................................................................................................................................................... 32

PVM, Lever Positions.....................................................................................................................................................................34

Modules and Code Numbers

PVP and PVPV, Pump Side Modules .......................................................................................................................................35

PVP, Accessories for Open Center Pump Side Modules...................................................................................................35

PVB, Basic Modules........................................................................................................................................................................36

PVB, Accessories for Basic Modules ........................................................................................................................................36

PVLA, Suction Valve.......................................................................................................................................................................37

PVLP, Shock and Suction Valves for A/B Port Connections............................................................................................ 37

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 3

Page 4

Technical Information

PVG 120 Proportional Valve Group

Contents

PVBS, Main Spools..........................................................................................................................................................................38

PVM, Mechanical Actuation....................................................................................................................................................... 38

PVMD, Cover for Mechanical Actuation.................................................................................................................................38

PVH, Hydraulic Actuation............................................................................................................................................................38

PVHC, High Current Actuator.....................................................................................................................................................39

PVE, Electrical Actuation..............................................................................................................................................................39

PVT, tank side module..................................................................................................................................................................39

PVAS, Assembly Kit........................................................................................................................................................................40

PVG 120 Modules Selection Chart

PVG 120 module selection chart.............................................................................................................................................. 41

Order specification

Ordering of modules for oil flow exceeding 180 l/min [47.6 US gal/min].................................................................45

Order Form.......................................................................................................................................................................................45

Reordering...................................................................................................................................................................................46

4 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 5

Technical Information

PVG 120 Proportional Valve Group

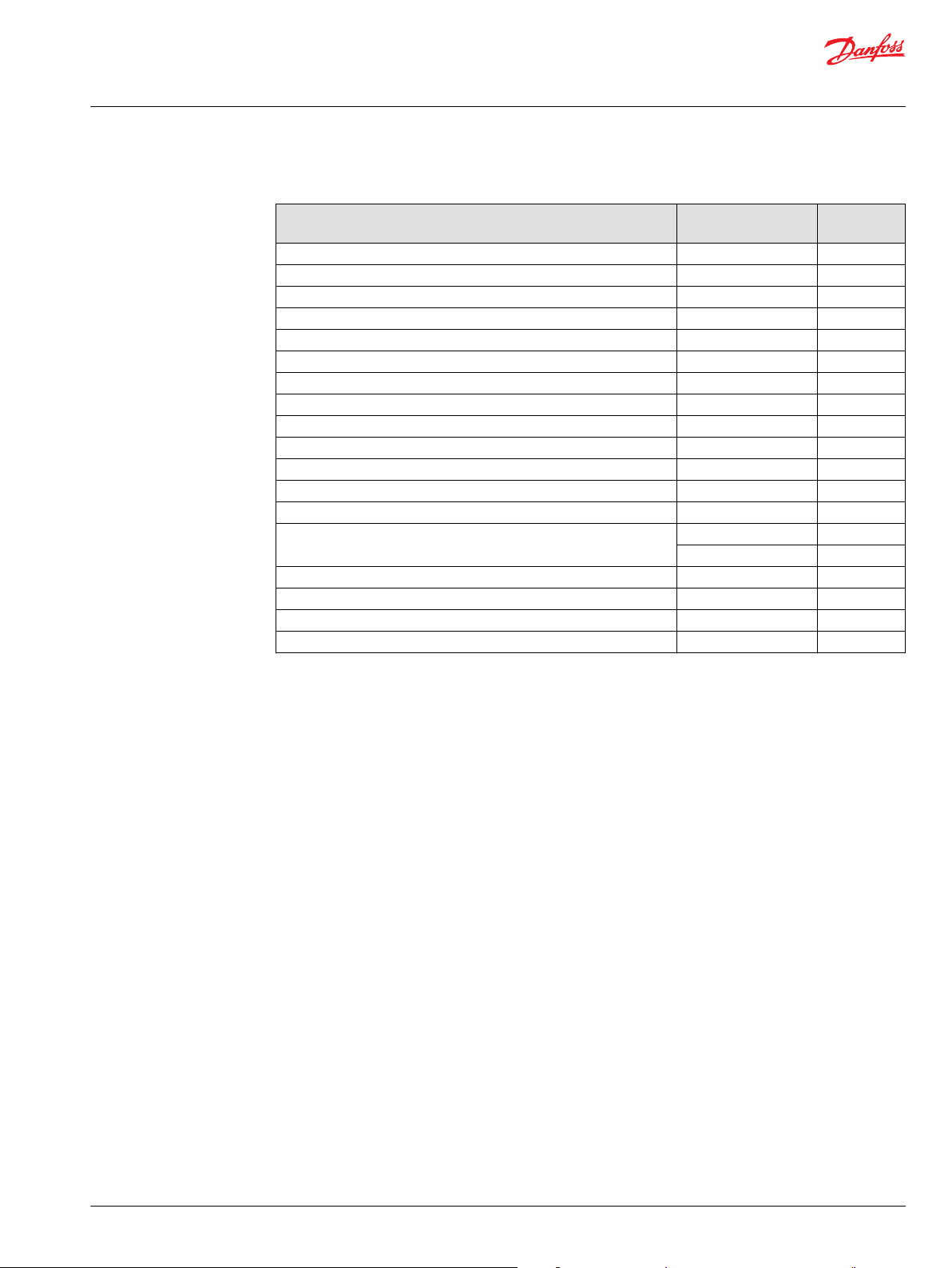

Literature reference for PVG products

Literature reference

Literature title Type Order

PVG 32 Proportional Valve Group Technical Information 520L0344

PVG 100 Proportional Valve Group Technical Information 520L0720

PVG 120 Proportional Valve Group Technical Information 520L0356

PVG 32 Metric ports Technical Information 11051935

PVE Series 4 Technical Information 520L0553

PVED-CC Electro-hydraulic actuator Technical Information 520L0665

PVED-CX Electro-hydraulic actuator Technical Information 11070179

PVE-CI Technical Information L1505234

Basic module for PVBZ Technical Information 520L0721

PVSK module with integrated diverter valve and P-disconnect function Technical Information 520L0556

PVPV / PVPM pump side module Technical Information 520L0222

Combination module PVGI Technical Information 520L0405

PVSP/M Priority module Technical Information 520L0291

Hitch Control System Description 11036124

PVBZ Data Sheet 520L0681

PVBZ-HS Data Sheet 520L0956

PVBZ-HD Data Sheet 11035599

MC024-010 and MC024-012 Controllers Data Sheet 520L0712

number

User Manual 11033753

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 5

Page 6

Technical Information

PVG 120 Proportional Valve Group

General Information

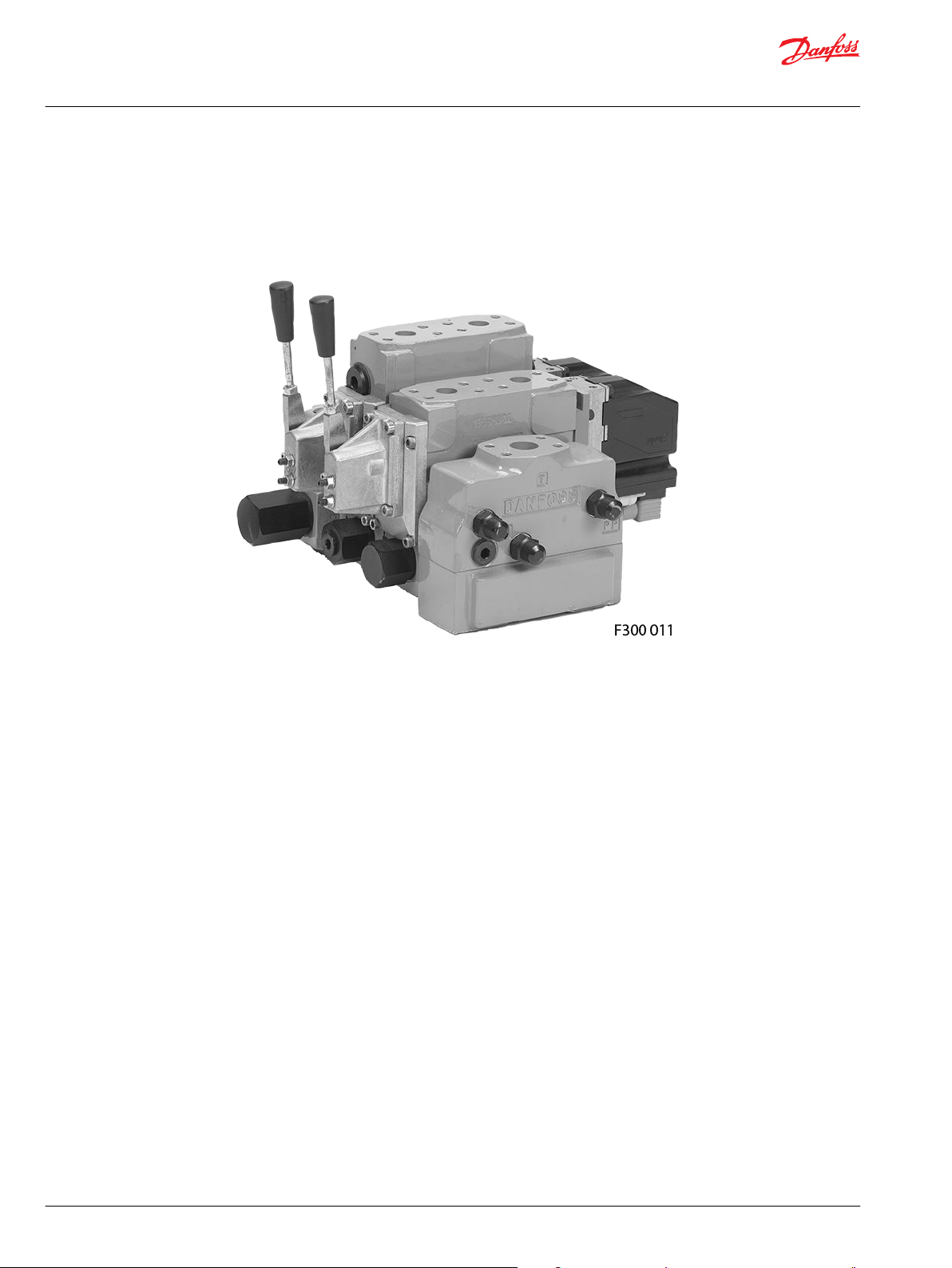

Valve System

Load sensing proportional valve type PVG 120 is a combined directional and flow control valve which is

supplied as a valve group consisting of modules specified to match particular customer needs. The

flexible nature of this valve will allow an existing valve bank to be easily adapted to suit changes in

requirements.

General Characteristics

Pump Side Module – PVP

Load-independent flow control:

•

Oil flow to an individual function is independent of the load of this function

‒

Oil flow to one function is independent of the load pressure of other functions

‒

Good regulation characteristics

•

Central pilot supply built in when the valves are actuated electrohydraulically

•

Energy-saving

•

Up to eight basic modules per valve group

•

Built-in pressure relief valve

•

System pressure up to 400 bar [5800 psi]

•

Pressure gauge connection

•

Versions:

•

Open centre version for systems with fixed displacement pumps

‒

Open centre version prepared for an extra relief module

‒

Closed centre version for systems with variable displacement pumps

‒

Closed centre version without system pressure relief valve for variable displace ment pumps with

‒

built-in pressure relief valve.

6 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 7

Technical Information

PVG 120 Proportional Valve Group

General Information

Basic Module – PVB

Integrated pressure compensator in channel P

•

Interchangeable spools

•

Depending on requirements the basic module can be supplied with:

•

Shock/suction valves

‒

Adjustable LS pressure limiting valve for ports A and B

‒

LS connection

‒

Module for oil flows exceeding 180 l/min [47.6 US gal/min]

‒

Different spool variants

‒

Actuation Modules

The basic module is always fitted with mechanical actuation PVM, which can be combined with the

following as required:

Electrical actuation:

•

PVEH - proportional, high performance (11 - 32 V )

‒

PVEO - On/off (12 V == or 24 V ==)

‒

Cover for hydraulic remote control, PVH

•

Cover for mechanically actuated valve group, PVMD

•

Electronic Accessories

EHF, low adjustment unit

•

EHR, ramp generator

•

EHS, speed control

•

EHSC, closed loop speed control

•

EHA, alarm logic

•

EHC, closed loop position control

•

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 7

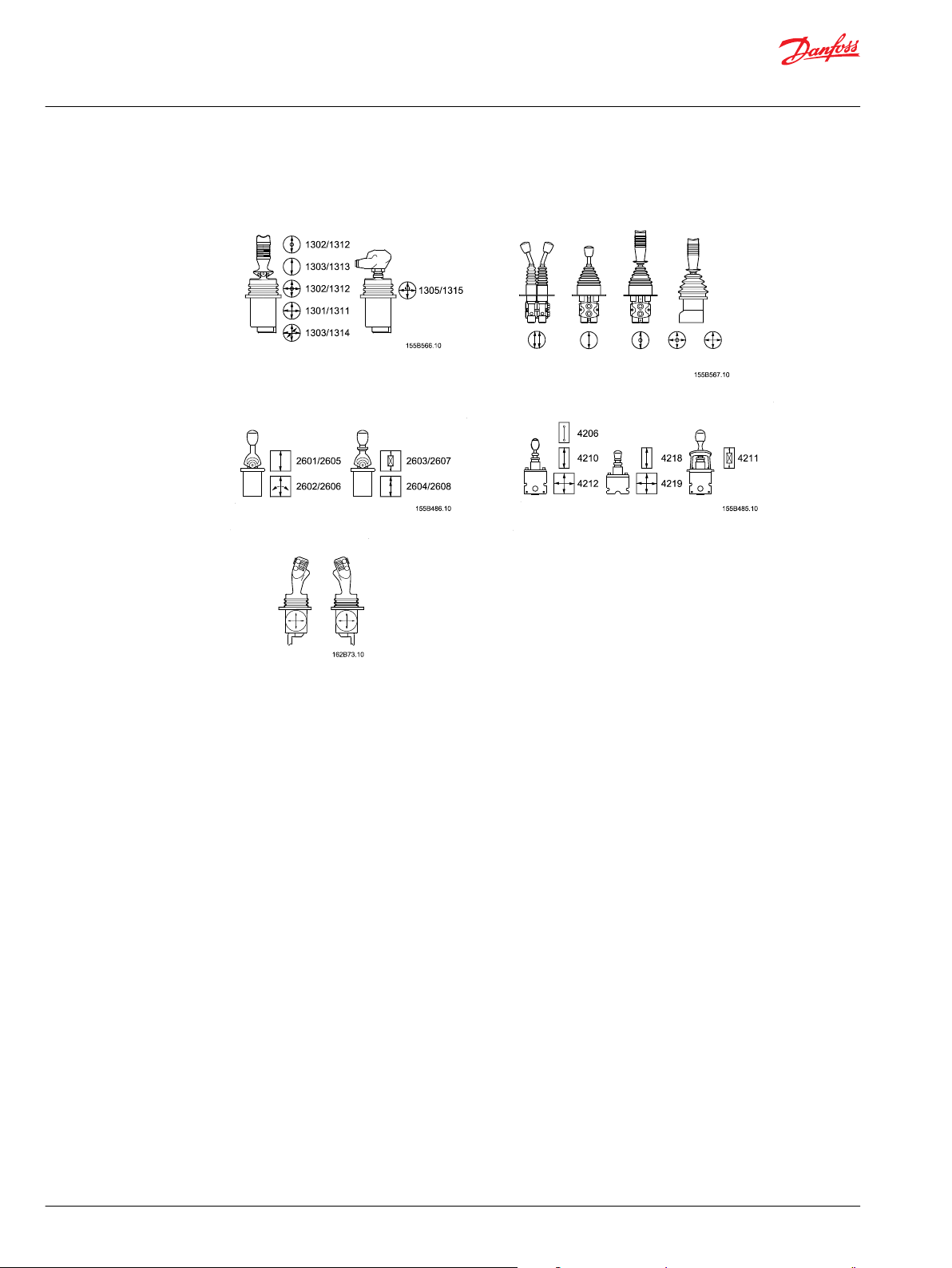

Page 8

PVRE, electrical control unit, 162F…

Prof 1, 162F…

PVREL, electrical control unit, 155U…

PVRES, electrical control unit, 155B…

PVRH, hydraulic control unit, 155N…

155N0003 155N0001 155N0004 155N0005 155N0002

Technical Information

PVG 120 Proportional Valve Group

General Information

Remote Controls Units

8 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 9

Technical Information

PVG 120 Proportional Valve Group

Function

PVG 120 with PVP Open Center

When the pump is started and the main spools (1) in the individual basic modules are in neutral position,

oil flows from the pump, through connection P, across the pressure adjustment spool (2) to tank.

The oil flow led across the pressure adjustment spool determines the pump pressure (stand-by pressure).

If a reduced stand-by pressure is required, an extra relief valve PVPH or PVPE can be used in PVP.

When the main spools are actuated the highest load pressure is distributed across the shuttle valve

circuit (3) to the spring chamber behind the pressure adjustment spool (2) and completely or partly

closes the connection to tank.

The pump pressure is applied to the right-hand side of the pressure adjustment spool (2). The pressure

relief valve (4) opens when the load pressure exceeds the set value, allowing pump flow to be diverted

back to tank.

In the basic module the compensator (5) maintains a constant pressure drop across the main spool –

both when the load changes and when a module with a higher load pressure is activated.

Shock and suction valves with a fixed setting (7) and the suction valves (8) on ports A and B are used to

protect individual working functions against overload.

In the basic module it is possible to build in an adjustable LS pressure relief valve (6) to limit the pressure

from each working function.

The LS pressure limiting valve saves energy:

•

•

PVG 120 with PVP Closed Center

In the closed center version an orifice (9) has been fitted instead of the plug. This means that the pressure

adjustment spool (2) will only open to tank when the pressure in channel P exceeds the pressure relief

valve setting (4).

In load sensing systems the load pressure is led to the pump regulator via the LS connection (10), so the

orifices (11) have been removed, and a plug (12) has been fitted instead of one of the orifices.

In neutral position the pump regulator will set the displacement so that leakage in the system is just

compensated for.

When a main spool is activated, the pump regulator will adjust the displacement so that the set

differential pressure between P and LS is maintained.

The pressure relief valve (4) in PVP is set for a pressure of about 30 bar [435 psi] above maximum system

pressure (set at the pump or an external pressure relief valve).

If the system or the pump regulation has a pressure relief valve, it is possible to use a PVPV pump side

module, without integrated pressure adjustment spool and pressure relief valve.

Without LS pressure limiting valve all the oil flow to the working function will be led across the

combined shock and suction valves to tank if the pressure exceeds the fixed setting of the valves.

With LS pressure limiting valve an oil flow of only about 2 l/min [0.5 US gal/min] will be led across the

LS pressure limiting valve to tank if the pressure exceeds the valve setting.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 9

Page 10

4

10

12

11

11

X-X

X

X

P A

V310100.A

9

2 1

T

P

T

p

ma

A B

A B

3

7 5 1 8

T

P

T

13

6

5

LS

T

P

T

3

13

P B

Technical Information

PVG 120 Proportional Valve Group

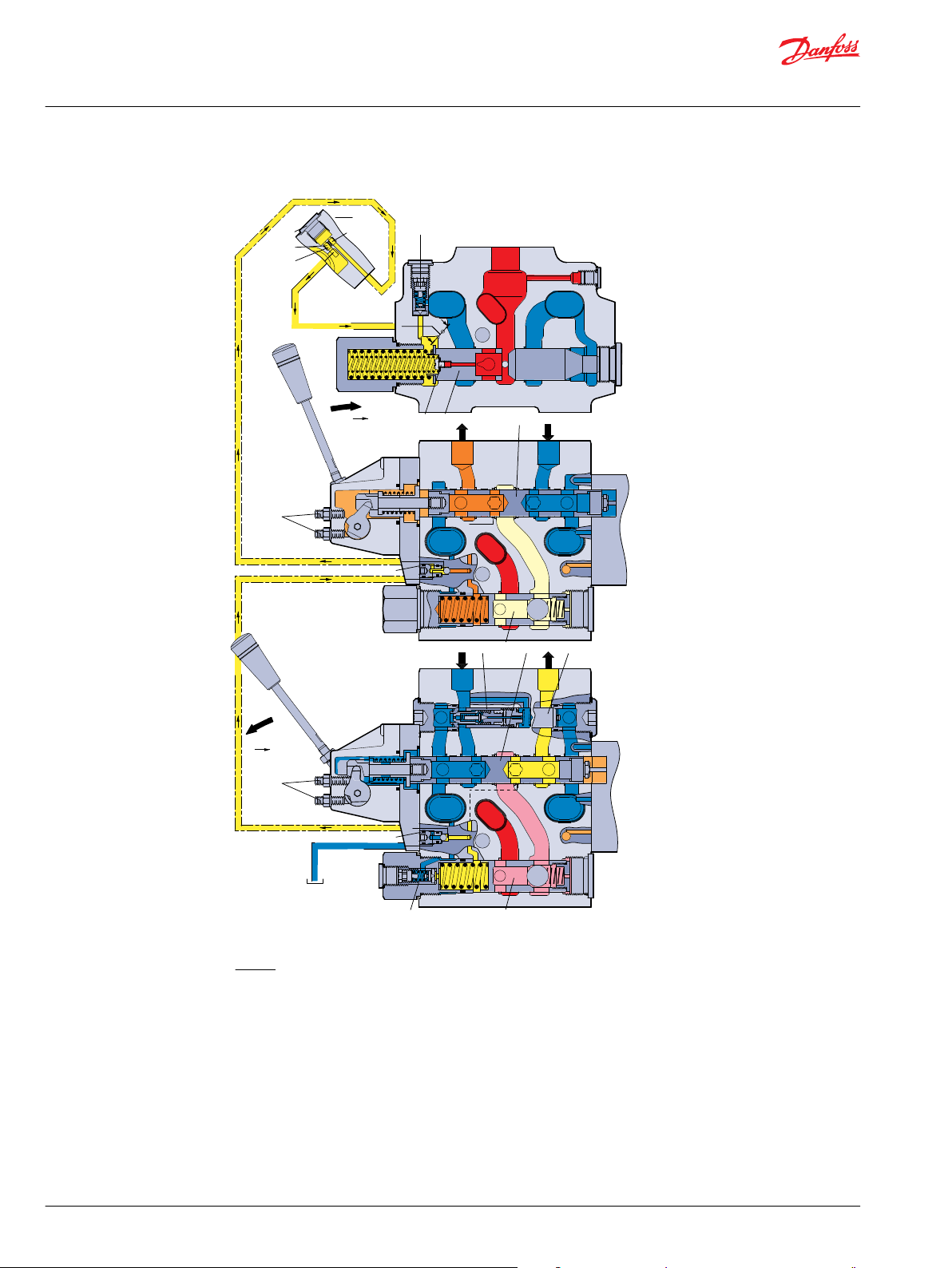

PVG 120 sectional view

PVG 120 sectional view

Legend:

1 – Main spool

2 – Pressure adjustment spool in PVP

3 – Shuttle valve

4 – Pressure relief valve in PVP

5 – Pressure compensator in PVB

6 – LS pressure relief valve in PVB

7 – Shock and suction valve PVLP

8 – Suction valve PVLA

9 – Orifice, closed center PVP; Plug, open center PVP

10 – LS connection

11 – Orifice, open center PVP

12 – Plug, closed center PVP

10 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 11

W

Technical Information

PVG 120 Proportional Valve Group

Safety in application

All types of control valves (incl. proportional valves) can fail, thus the necessary protection against the

serious consequences of function failure should always be built into the system. For each application an

assessment should be made for the consequences of pressure failure and uncontrolled or blocked

movements. To determine the degree of protection that is required to be built into the application,

system tools such an FMEA (Failure Mode and Effect Analysis) and Hazard and Risk Analysis can be used.

FMEA – IEC EN 61508

FMEA (Failure Mode and Effect Analysis) is a tool used for analyzing potential risks. This analytical

technique is utilized to define, identify, and prioritize the elimination or reduction of known and/or

potential failures from a given system before it is released for production. Please refer to the standard IEC

FMEA 61508.

Hazard and risk analysis ISO 12100-1/14121

This analysis is a tool used in new applications as it will indicate whether there are special safety

considerations to be met according to the machine directives EN 13849. Dependent on the determined

levels conformity this analysis will detirmine if any extra requirements for the product design,

development process, production process or maintenance, example the complete product life cycle.

Warning

All brands and all types of directional control or proportional valves, which are used in many different

operation conditions and applications, can fail and cause serious damage.

Analyze all aspects of the application. The machine builder/system integrator alone is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met. The process of choosing the control system and safety levels is

governed by the machine directives EN 13849 (Safety related requirements for control systems).

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 11

Page 12

Technical Information

PVG 120 Proportional Valve Group

Safety in application

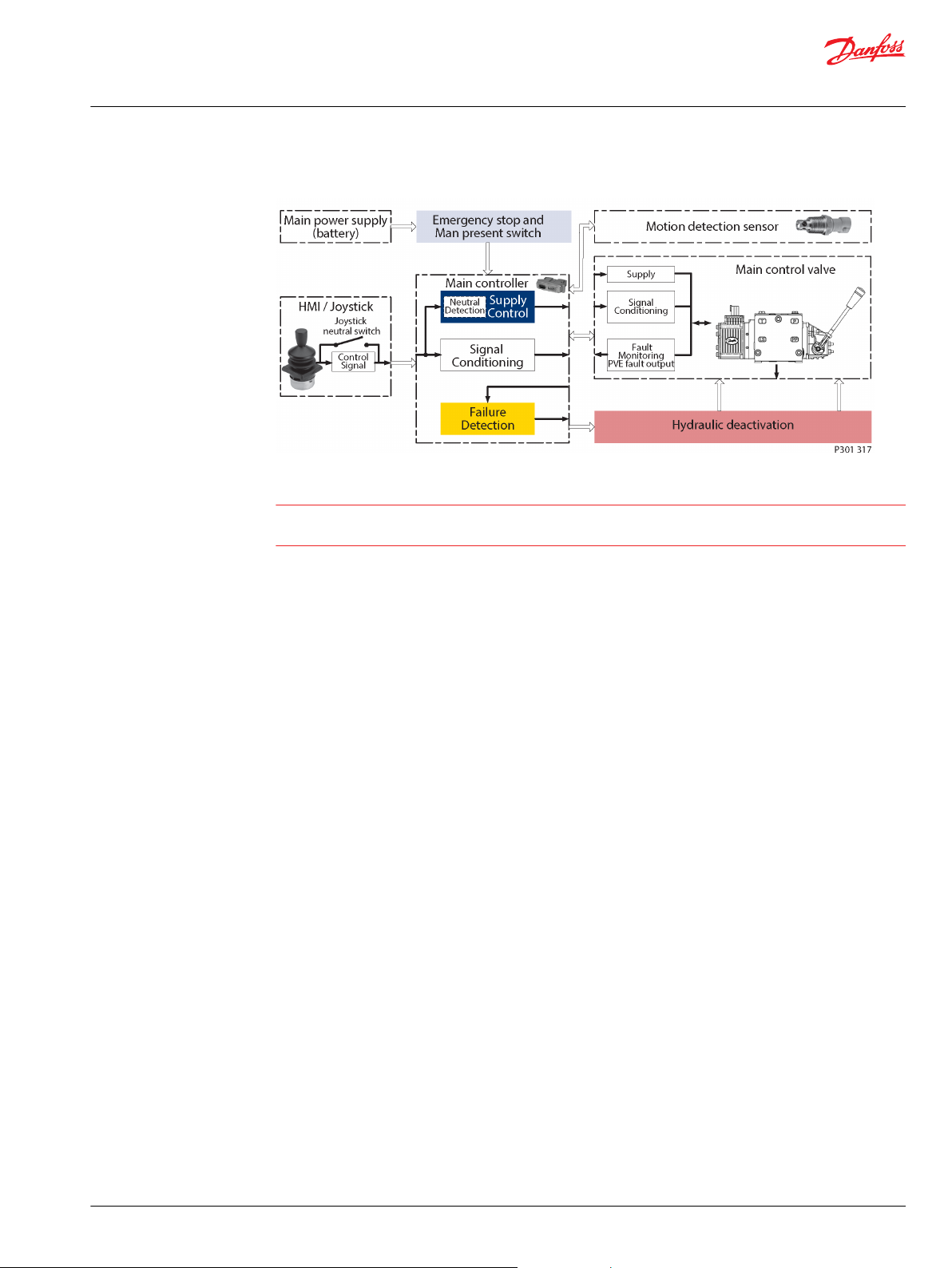

Control system example

Example of a control system for manlift using PVE Fault monitoring input signals and signals from external sensors to ensure the PLUS+1® main

controllers correct function of the manlift.

12 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 13

W

Technical Information

PVG 120 Proportional Valve Group

Safety in application

Electrical block diagram for the above illustration

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

PVG 32 – mainly used in system with fixed displacement pumps:

•

PVSK, commonly used in crane application - full flow dump

•

PVPX, LS dump to tank

PVG 100 – alternative LS dump or pilot supply disconnect:

•

PVPP, pilot oil supply shut off

•

External cartridge valve connecting LS pressure or main pressure to tank

PVG 120 – pump disconnect / block for variable pumps:

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 13

Page 14

Fault detection output

high=on

low=off

Alarm

logic

2)

Memory3)

E1

E2

Output

AND

OR

U

DC2

Error

U

S

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

U

DC2

Error

U

S

PVEH

with AMP

connector

PVEH

with AMP

connector

Hydraulic

deactivation

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Emergency

stop

Man present

switch

C

C

D

B

B

A

P301 318

W

Technical Information

PVG 120 Proportional Valve Group

Safety in application

•

PVPE, full flow dump for the PVG 120

•

External cartridge valve connecting LS pressure to tank

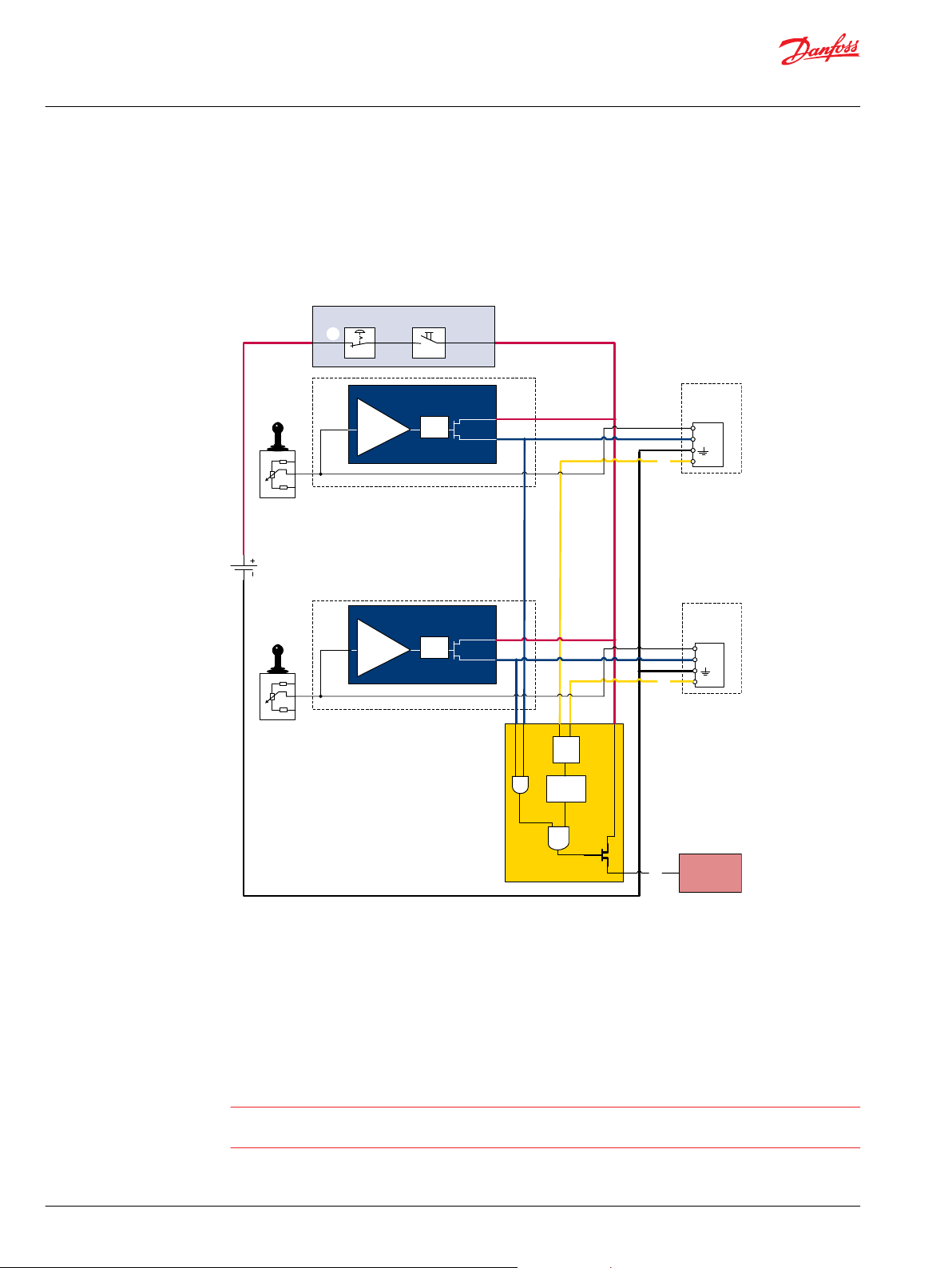

Examples of wiring block diagram

Example of a typical wiring block diagram using PVEH with neutral power off switch and fault monitoring

output for hydraulic deactivation.

A– Emergency stop / man present switch

B– PVE Fault monitoring signals

C– Neutral signal detection.

D– Hydraulic deactivation

System Control Logic e.g. PLUS+1® for signal monitoring and triggering signal for deactivation of the

hydraulic system.

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

14 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 15

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

Fault detection output

PVEH-DI

AMP supply

connector

PVEH-DI

AMP supply

connector

PVEH-DI

AMP connector

PVEH-DI

AMP connector

AND

high=on

low=off

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

OR

Emergency

Stop

Man present

switch

P301 319

U

DC2

Error

U

S

DI-B

Error

DI-A

U

DC2

Error

U

S

Error

DI-A

Hydraulic

deactivation

W

Technical Information

PVG 120 Proportional Valve Group

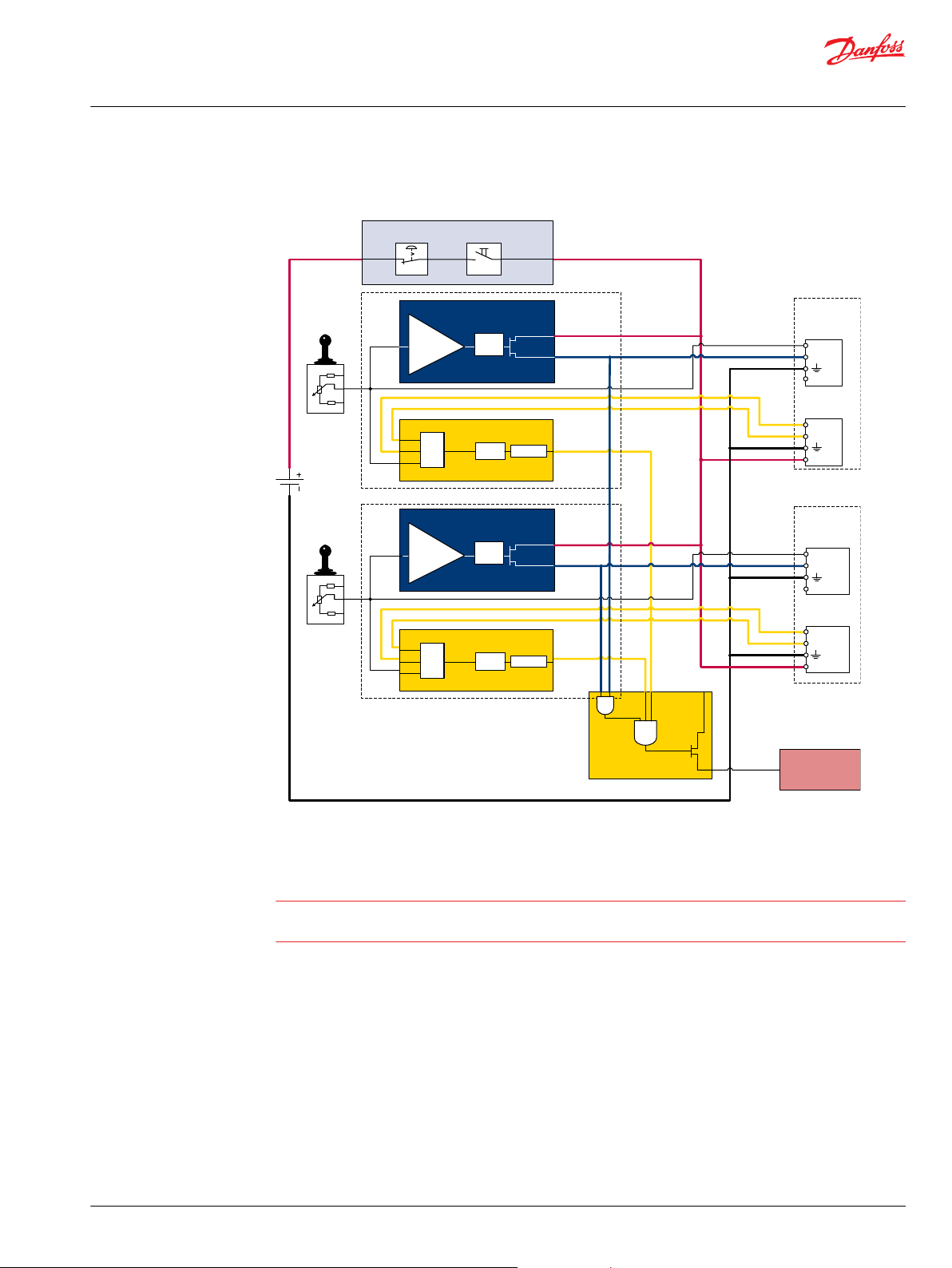

Safety in application

Example of fault monitoring for deactivation of the hydraulic system with extra fault inputs using the PVE’s

with DI (Direction Indication) function.

System Control Logic e.g. PLUS+1® for signal monitoring and triggering signal for deactivation of the

hydraulic system.

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 15

Page 16

Technical Information

PVG 120 Proportional Valve Group

Technical Data

PVG 120 technical data

Maximum pressure Port P

Port A/B

Port T, static/dynamic

Oil flow

See

Oil flow characteristics

Spool travel

Dead band (± 25%)

Maximum internal leakage

at 100 bar, 21 mm2/s

Oil temperature (inlet temperature) Recommended temperature

Ambient temperature

Oil viscosity Operating range

Filtering / Max. contamination (ISO 4406)

See

Filtering

Oil consumption in pressure reduction valve for PVT at PVE pilot-oil supply

for more information.

for more information.

Port P, rated max.

Port A/B

A/B→T, without shockvalve

A/B→ T, with shockvalve

Min. temperature

Max. temperature

Min. viscosity

Max. viscosity

continuous 350 bar [5075 psi]

intermittent

2)

1)

400 bar [5800 psi]

400 bar [5800 psi]

25 bar/40 bar [365/580 psi]

240/300 l/min [63.4/79.3 US gal/min]

65/95/130/180/ 210/240

l/min

± 8 mm [± 0.32 in]

± 2 mm [± 0.08 in]

90 cm3/min [5.5 in3/min]

95 cm3/min [5.6 in3/min]

30 to 60°C [86 to 140°F]

–30°C [–22°F]

+90°C [+194°F]

–30 to +60°C [–22 to +140°F]

12 to 75 mm2/s [65 SUS to 347 SUS]

4 mm2/s [39 SUS]

460 mm2/s [2128 SUS]

23/19/16

0.4 l/min [0.1 US gal/min]

[17.2/25.1/34.3/47.6/

55.5/63.4 US gal/min]

PVM, mechanical actuation

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

See Order Form for more information regarding the ordering or conversion of valve groups for oil flows

exceeding 180 l/min [47.6 US gal/min].

PVM, Mechanical Actuation

PVM data

Operating force PVM + PVMD

PVM + PVE (without voltage)

PVM + PVH 4.7 ± 0.2 N•m

Possible control lever positions: 2 × 5

Regulation range, control lever: ±19,5°

Neutral position Max. spool travel

2.8 ± 0.2 N•m

[24.8 ± 1.8 lbf•in]

[41.6 ± 1.8 lbf•in]

4.0 ± 0.2 N•m

[35.5 ± 1.8 lbf•in]

12.8 ± 0.2 N•m

[113.3 ± 1.8 lbf•in]

16 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 17

Technical Information

PVG 120 Proportional Valve Group

Technical Data

PVH, hydraulic actuation

PVH, Hydraulic Actuation

PVH data Pressure, bar [psi]

Control range 5 to 15 [75 to 220]

Maximum pilot pressure, static 35 [510]

Maximum pressure on port T

(It is recommended that the tank connection from the hydraulic remote control unit

PVRH is taken directly to tank.)

PVE, electrical actuation

PVE, electrical actuation

PVE actuation PVEO ON/OFF PVEH Proportional

Hysteresis (applies to the electrical

actuation only)

Reaction time from neutral position to max.

spool travel

Reaction time from max. spool travel to

neutral position

Pilot oil flow pr. PVE Neutral position without voltage 0 l/min / [0 US gal/min]

Enclosure to IEC 529 IP65

3 [45 ]

High

1)

2)

Locked with voltage

Typical - 4%

Typical 250 ms 250 ms

Maximum 350 ms 280 ms

Typical 240 ms 150 ms

Maximum 330 ms 200 ms

3)

0 l/min / [0 US gal/min]

1)

The hysteresis is stated at rated and f = 0,02 Hz for a cycle. One cycle includes the movement from

neutral position to max. spool travel direction A, via neutral position to max. spool travel in direction B,

and back to neutral position. Further information can be obtained by contacting the Danfoss Power

Solutions Sales Organization.

2)

Reaction times for PVEH is reduced by 20 by 30 ms if the voltage is not interrupted during the neutral

positioning (remote control lever without neutral position switch).

3)

Total oil consumtion for a spool movement from N to full A or B: 0.0035 l [0.0009 US gal].

PVPE, electrical relief valve, normally open

PVPE, electrical relief valve, normally open

Maximum operation pressure

Maximum pressure drop at flow of 0.2 l/min [0.053 US gal/min]

Oil temperature (inlet

temperature)

Maximum coil surface temperature

Ambient temperature

Recommended temperature

Min. temperature

Max. temperature

350 bar [5085 psi]

1.2 bar [17 psi]

30 to 60 °C [86 to 140 °F]

–30 °C [–22 °F]

90 °C [194 °F]

155 °C [311 °F]

–30 to +60 °C [–22 to +140 °F]

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 17

Page 18

Technical Information

PVG 120 Proportional Valve Group

Technical Data

PVPE, electrical relief valve, normally open (continued)

Oil viscosity Operating range

Response time for pressure relief to tank

Enclosure to IEC 529

Rated voltage

Maximum permissible deviation from rated supply voltage

Current consumption at rated

voltage

Power consumption at 22 °C [72 °F] coil temperature

Min. viscosity

Max. viscosity

at 22 °C [72 °F] coil temperature

at 85 °C [230 °F] coil temperature

at 85 °C [230 °F] coil temperature

12 to 75 mm2/s [65 to 347 SUS]

4 mm2/s [39 SUS]

460 mm2/s [2128 SUS]

600 ms

IP 65

12 V 24 V

± 10 % ± 10 %

1.55 A 0.78 A

1.0 A 0.5 A

19 W 19 W

12 W 12 W

18 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 19

V310185.A

P

A

T

P

T

p

B

Technical Information

PVG 120 Proportional Valve Group

Electrical Actuation

PVEO, ON-OFF

The main features of PVEO:

Compact

•

Robust operation

•

Hirschmann or AMP connector

•

Low electrical power

•

PVEH, proportional high

PVEO parameters

Supply voltage U

Current consumption at rated voltage

Signal voltage (PVEM) neutral

Signal current at rated voltage (PVEM)

Input impedance in relation to 0.5 • U

Power consumption

DC

rated

range

maximum ripple

A-port ↔ B-port

DC

12 V

DC

11 V to 15 V 22 V to 30 V

5%

0.65 A @ 12 V 0.33 A @ 24 V

0.5 x U

DC

0.25 • UDC to 0.75 • U

0.25 mA 0.50 mA

12 KΩ

8 W

24 V

DC

DC

PVEH adjusts the main spool position so that it corresponds to an electrical control signal – for example

from a remote control unit.

The control signal (set-point signal) is converted into a hydraulic pressure which moves the main spool.

The position of the main spool is converted in the positional transducer (C) to an electric signal (feedback signal). This signal is registered by the electronics.

The variation between the set-point signal and feed-back signal actuates the solenoid valves, thus the

hydraulic pressure moves the main spool into the correct position.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 19

Page 20

V310099.A

P

A

T

P

T

B

p

C

Technical Information

PVG 120 Proportional Valve Group

Electrical Actuation

The main features of PVEH:

Inductive transducer

•

Integrated pulse width modulation

•

Low hysteresis

•

Fast reaction time

•

Hirschmann or AMP connector

•

Fault monitoring with transistor output for signal source

•

Low electrical power

•

No set-up procedure

•

PVEH parameters

Supply voltage U

Current consumption at rated voltage

Signal voltage Neutral

Signal current at rated voltage

Input impedance in relation to 0.5 • U

Input capacitor

Power consumption

PVEH Maximum load

DC

Reaction

time at fault

Rated and Range

Maximum ripple

A-port ↔ B-port

DC

Active / Passive 500 ms 250 ms

11 V to 32 V

5%

0.57 (0.33) A @ 12 V 0.3 (0.17) A @ 24 V

0.5 x U

DC

0.25 • UDC to 0.75 • U

0.25 mA to 0.70 mA

12 KΩ

100 ηF

7 (3.5) W

100 mA 60 mA

DC

PVEH, Inductive Transducer (LVDT – Linear Variable Differential Transformer)

When the main spool is moved a voltage is induced proportional to the spool position. The use of LVDT

gives contact-free (proximity) registration of the main spool position. This means an extra-long working

life and no limitation as regards the type of hydraulic fluid used. In addition, LVDT gives a precise position

signal of high resolution.

20 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 21

Technical Information

PVG 120 Proportional Valve Group

Electrical Actuation

PVEH, Pulse Width Modulation (Integrated)

Positioning of the main spool in PVEH is based on the pulse width modulation principle. As soon as the

main spool reaches the required position, modulation stops and the spool is locked in position.

PVEH fault monitoring

A fault monitoring system is provided in all PVEA, PVEH and PVES modules.

The system is available in two versions:

The active fault monitoring type, which provides a warning signal, deactivates the solenoid valves

•

and drives the spool in neutral.

The passive fault monitoring type, which provides a warning signal only.

•

Both active and passive fault monitoring systems are triggered by three main events:

1. Input signal monitoring – The input signal voltage is continuously monitored. The permissible

range is between 15% and 85% of the supply voltage. Outside this range the section will switch into

an active error state.

2. Transducer supervision – If one of the wires to the LVDT sensor is broken or short-circuited, the

section will switch into an active error state.

3. Supervision of the closed loop – The actual position must always correspond to the demanded

position (input signal). If the actual spool position is further than the demanded spool position

(>12%, PVEA: >25%), the system detects an error and will switch into an active error state. On the

other hand, a situation where the actual position is closer to neutral than that demanded will not

cause an error state. This situation is considered “in control”.When an active error state occurs, the

fault monitoring logic will be triggered.

Active fault monitoring:

•

A delay of 500 ms (PVEA: 750 ms) before anything happens.

•

The solenoid valve bridge will be disabled and all solenoid valves will be released.

•

An alarm signal is sent out through the appropriate pin connection.

•

This state is memorized and continues until the system is actively reset (by turning off the supply

voltage).

Passive fault monitoring:

•

A delay of 250 ms (PVEA: 750 ms) before anything happens.

•

The solenoid valve bridge will not be disabled but still control the main spool position.

•

An alarm signal is sent out through the appropriate pin connection.

•

This state is not memorized. When the erroneous state disappears, the alarm signal will turn to

passive again. However, the signal will always be active for a minimum of 100 ms when triggered.

To prevent the electronics from going into an undefined state, a general supervision of the power supply

and the internal clock frequency is made. This function applies to PVEH - and will not activate fault

monitoring:

1. High supply voltage – The solenoid valves are disabled when the supply voltage exceeds 36 V, and

the main spool will return/stay in neutral.

2. Low supply voltage – The solenoid valves are disabled when the supply voltage falls below 8.5 V,

and the main spool will return/stay in neutral.

3. Internal clock – The solenoid valves are disabled when the internal clock frequency fails, and the

main spool will return/stay in neutral.

The fault monitoring does not work if the supply voltage to PVEH is cut off - for example by a neutral

position switch. When using PVEH with passive fault monitoring it is up to the customer to decide on

the degree of safety required for the system (See Safety in Application for more information about

different degrees of safety).

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 21

Page 22

Technical Information

PVG 120 Proportional Valve Group

Electrical Actuation

Fault monitoring specification

Type Fault

monitoring

PVEO No fault monitoring

PVEH Active 500 ms No fault Low < 2 V Green -

Passive 250 ms No fault Low < 2 V Green -

*

Measured between fault output pin and ground.

†

Reset needed

Delay

before

error out

Error mode Error

output

status

Input signal faults High ∼U

Transducer (LVDT) Constant red

Close loop fault

Input signal faults High ~U

Transducer (LVDT) Constant red

Close loop fault

Fault

output on

PVE*

DC

DC

LED light Memory†

*

Flashing red Yes

Flashing red No

†

PVEH, connection to fault monitoring output

Normal Fault

Transistor output function – Green Transistor output function – Red

A: External relay, B: Solenoid valve (e.g. PVPE) A: External relay, B: Solenoid valve (e.g. PVPE)

Via an external relay pin 3 can be connected to an electrically actuated valve which will relieve pump oil

flow to tank, e.g. PVPE.

Other possible connections:

a valve to relieve the LS signal

•

a signal lamp, an alarm horn

•

a pump cut-out, etc.

•

22 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 23

Technical Information

PVG 120 Proportional Valve Group

Technical Characteristics

General

All characteristics and values in the technical information are typical measured results. For the hydraulic

system a mineral based hydraulic oil with a viscosity of 21mm2/s [102 SUS] and a temperature of 50°C

[122°F] was used.

PVP, pump side module

PVP, pressure relief valve characteristic

The pressure relief valve is adjustable within the 50-400 bar [725-6225 psi] range by means of a screw.

PVP, neutral flow pressure in PVP, open center

U = PVP for PVB oil flow > 180 l/min [47.6 US gal/min]

S = PVP, standard

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 23

Page 24

Technical Information

PVG 120 Proportional Valve Group

Technical Characteristics

PVB, Basic Module

Oil flow characteristics

US= Signal voltage;

UDC= Supply voltage

Port conditions at rated oil flow

Port Metric units US units

A

B

C

D

D.I *

D.II **

* Closed center system with basic module for oil flow > 180 l/min [47.6 US gal/min].

** Open center system with basic module for oil flow > 180 l/min [47.6 US gal/min] and pump side module

155G5027 / 155G5028 /155G5029.

65 l/min [17.2 US gal/min]

95 l/min [25.1 US gal/min]

130 l/min [34.3 US gal/min]

180 l/min [47.6 US gal/min]

240 l/min [63.4 US gal/min]

210 l/min [55.5 US gal/min]

24 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 25

Technical Information

PVG 120 Proportional Valve Group

Technical Characteristics

Load independent oil flow

Pressure drop Q T in neutral position /spools with open neutral position, (p). The oil flow Q is shown as a

function of the load (p).

Pressure drop A/B → T at full spool travel

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 25

Page 26

Technical Information

PVG 120 Proportional Valve Group

Technical Characteristics

Pressure drop A/B → T, spools with open neutral position

PVLP, Shock Valve Characteristic (with Pressure Relief Valve)

PVLP, shock valve characteristic (with Pressure Relief Valve)

The shock valve PVLP is designed to absorb shock effects. Consequently, it shall not be used as a pressure

relief valve.

26 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 27

Technical Information

PVG 120 Proportional Valve Group

Technical Characteristics

PVLP/PVLA, Suction Function

PVLP/PVLA, suction function characteristic

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 27

Page 28

Technical Information

PVG 120 Proportional Valve Group

Hydraulic system examples

Example of PVG 120 with variable displacement pump

28 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 29

Technical Information

PVG 120 Proportional Valve Group

Hydraulic system examples

Example of PVG 120 with fixed displacement pump

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 29

Page 30

Technical Information

PVG 120 Proportional Valve Group

Other operating conditions

Hydraulic fluids for PVG

Oils

The main duty of the oil in a hydraulic system is to transfer energy; but it must also lubricate the moving

parts in hydraulic components, protect them against corrosion, and transport dirt particles and heat out

of the system. It is therefore important to choose the correct oil with the correct additives. This gives

problem-free operation and long working life.

Mineral oils

Danfoss Power Solutions recommends for systems with PVG 120 valves to use mineral-based hydraulic

oils containing additives: Type H-LP (DIN 51524) or HM (ISO 6743/4).

Non-flammable fluids

Phosphate-esters (HFDR fluids) can be used without special precautions. However, dynamic seals must be

replaced with FPM (Viton) seals. Please contact the Danfoss Power Solutions Sales Organisation if the PVG

120 valve is to be used with phosphate-esters.

The following fluids should only be used according to agreement with the Danfoss Power Solutions Sales

Organisation:

•

Water-glycol mixtures (HFC fluids)

•

Water-oil emulsions (HFB fluids)

•

Oil-water emulsions (HFAE fluids)

Biodegradable fluids

PVG 120 valves can be used in systems using rape-seed oil. The use of rape-seed oil is conditional on:

it complying with the demands on viscosity, temperature and filtration, etc.

•

the operating conditions being adapted to the recommendations of the oil supplier.

•

Before using other biodegradable fluids, please consult the Danfoss Power Solutions Sales Organisation.

Particle Content, Degree of Contamination

Oil filtration must prevent the particle content from exceeding an acceptable level, i.e. an acceptable

degree of contamination.

Maximum contamination for PVG 120 is 23/19/16 (see ISO 4406).

Calibration in accordance with the ACFTD method.

In our experience a degree of contamination of 23/19/16 can be maintained by using a filter fineness as

described in the next section.

Filtering

Effective filtration is the most important precondition in ensuring that a hydraulic system performs

reliably and has a long working life. Filter manufacturers issue instructions and recommendations. It is

advisable to follow them.

System filters

Where demands for safety and reliability are very high a pressure filter with bypass and indicator is

recommended. Experience shows that a 10 µm nominal filter (or finer) or a 20 µm absolute filter (or finer)

is suitable.

It is our experience that a return filter is adequate in a purely mechanically operated valve system.

The fineness of a pressure filter must be selected as described by the filter manufacturer so that a particle

level of 23/19/16 is not exceeded. See Particle content, degree of contamination for more information.

30 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 31

Technical Information

PVG 120 Proportional Valve Group

Other operating conditions

The filter must be fitted with pressure gauge or dirt indicator to make it possible to check the condition of

the filter.

In systems with differential cylinders or accumulators the return filter must be sized to suit the max.

return oil flow. Pressure filters must be fitted to suit max. pump oil flow.

Internal filters

The filters built into PVG 120 are not intended to filter the system but to protect important components

against large particles.

Such particles can appear in the system as a result of pump damage, hose fracture, use of quickcouplings, filter damage, starting up, contamination, etc.

The filter that protects the pilot supply in the tank side module has a mesh of 125 µm. It is obtainable as a

spare part and is easy to replace.

The filter protecting the essential PVE parts has a mesh of 125 µm.

Conversion Factors

1 N•m = 885.1 lbf•in

1 N = 22.48 lbf

1 bar = 14.50 psi

1 mm = 0.0394 in

1 cm3 = 0.061 in

1 l = 0.22 UK gal

1 l = 0.264 US gal

°F = 1.8 • °C + 32

3

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 31

Page 32

55.5[2.185]

T

P

21.5[0.846]

L

42[1.65]

120[4.72]

147[5.79]

220[8.66]

L

L

2

1

185[7.28]

147[5.79]

95[3.74]

68[2.68]

10.5[0.413]

38[1.50]

52.4[2.063]

50.8

26.2[1.031]

23.8[0.937]

27.8

66.5[2.618]

67[2.638]

73.5[2.893]

36.5[1.437]

A A

BB

T P

DC

J

K

57.2[2.252]

M

E

N

F

H

33.5

~165[6.50]

max.61[2.40]

69

[2.72]

37

44[1.73]

113.5[4.468]

28

G

105[4.13]

LX

T

33.5

PP

152[5.98]

158[6.22]

PG 9 [on-off ]

PG 11 [prop.]

DIN 43650

V310153.B

35.5

max. 262.5[10.335]

111[4.37]

25[0.98]

27[1.06]

15[0.59]

[1.46]

[1.398]

[1.319]

[1.319]

[1.10]

23.8[0.937]

[1.094]

38[1.50]

[2.000]

Technical Information

PVG 120 Proportional Valve Group

Dimensions

PVG 120 dimensions

PVB 1 2 3 4 5 6 7 8

170 [6.69] 237 [9.33] 304 [11.97] 371 [14.61] 438 [17.24] 505 [19.88] 572 [22.51] 639 [25.16]

263.5 [10.38] 330.5 [13.02] 397.5 [15.66] 464.5 [18.30] 531.5 [20.94] 598.5 [23.58] 665.5 [26.22] 732.55 [28.86]

255 [10.05] 322 [12.69] 389 [15.33] 456 [17.97] 523 [20.61] 590 [23.25] 657 [25.89] 724 [28.53]

L mm

[in]

L1 mm

[in]

L2 mm

[in]

Port

C 1 in SAE flange (210 bar) 15∕16–12 UN O-ring Boss (3045 psi)

32 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 33

31.5[1.240]

14(49)

32[1.25]

F

13[0.51]

108.5[4.272]

*

27(62)

99[3.90]

PVHPVMD/PVH

PBPA

*

120[4.72]

141[5.55]

max.372.5[14.665]

77[3.03]

max. 284[11.18]

23[0.91]

48.5[1.909]

48.5[1.909]

[1.06(2.44)]

*

[0.55(1.93)]

*

V310103.A

*

*

[0.413(1.791)]

10.5(45.5)

Technical Information

PVG 120 Proportional Valve Group

Dimensions

Port

D ¾ in SAE flange (415 bar) 11∕16–12 UN O-ring Boss (6020 psi)

E 1 in SAE flange (415 bar) 15∕16–12 UN O-ring Boss (6020 psi)

F G ¼ ½–20 UNF

G G 3∕

H M12; 18 mm deep

J M10; 17 mm deep

K M10; 17 mm deep

M M12; 18 mm deep

N G 3∕

PVG 120 Outline dimensions

8

8

¾–16 UNF

7

∕16–14 UNC; 0.7 in deep

3

∕8–16 UNC; 0.7 in deep

3

∕8–16 UNC; 0.7 in deep

7

∕16–14 UNC; 0.7 in deep

¾–16 UNF

F: G ¼ [1/2 –20 UNF]

* Dimensions in parenthesis apply to high basic modules.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 33

Page 34

37.5˚

67.5˚

97.5˚

127.5˚

157.5˚

187.5˚

19.5˚

19.5˚

V310018.A

22.5˚

52.5˚

82.5˚

112.5˚

142.5˚

172.5˚

19.5˚

19.5˚

V310014.A

Technical Information

PVG 120 Proportional Valve Group

Dimensions

PVM, Lever Positions

Base with an angle of 37.5° Base with an angle of 22.5°

34 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 35

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVP and PVPV, Pump Side Modules

Symbol Description

Open center PVP for pumps with fixed displacement.

Pressure gauge connection.

Open center PVP for oil flow exceeding

180 l/min [47.55 US gal/min].

For pumps with fixed displacement.

Pressure gauge connection.

Closed center PVP for pumps with variable

displacement.

Pressure gauge connection.

Closed center PVPV without pressure relief valve.

For pumps with variable displacement.

Pressure gauge connection.

Port type

Metric flange 155G5021

SAE flange 155G5037

O-ring boss 155G5023

Metric flange 155G5027

SAE flange 155G5029

O-ring boss 155G5028

Metric flange 155G5020

SAE flange 155G5038

O-ring boss 155G5022

Metric flange 155G5030

SAE flange 155G5032

O-ring boss 155G5031

Code number

Port connections:

P = 1 in SAE flange; 415 bar [11∕16–12 UN O-ring Boss; 6020 psi]

MA = G ¼ [½–20 UNF O-ring Boss]

LS = G 3∕8 [3∕4–16 UNF O-ring Boss]

PVP, Accessories for Open Center Pump Side Modules

Symbol Description Code number

– Prop., PVPD 155G5041

PVPH,

Hydraulically actuated relief valve

PVPE,

Electrically actuated relief valve.

Normally open solenoid valve.

12 V 155G5052

24 V 155G5054

155G5061

* Connection for

external pilot

pressure: available

with G1/4 thread

only.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 35

Page 36

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVB, Basic Modules

Symbol Description Code number

No facilities for

shock valves A/B

(low modules)

Pressure compensated

Port connections:

A/B: 3/4 SAE flange; 415 bar

[1 1/16–12 UN O-ring Boss; 6020 psi]

Metric flange 155G6014 155G6005

SAE flange 155G6016 155G6007

O-ring boss 155G6015 155G6006

PVB, Accessories for Basic Modules

Symbol Description Code number

PVBP, plug 155G6081

Facilities for shock

valves A/B (high

modules)

PVBU, module for oil flow exceeding 180 l/min [47.6 US gal/min].

Connection for external LS pressure relief.

PVBC, connection for external LS pressure relief. 155G6082

PVBR, LS-pressure relief valve for ports A/B-port 155G6080

Port connection: G 1/4 available with G 1/4 thread only.

155G6035

36 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 37

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVLA, Suction Valve

Symbol Code number

155G1065

PVLP, Shock and Suction Valves for A/B Port Connections

Symbol Fixed setting

bar [psi]

50 [725] 155G0050

75 [1100] 155G0075

100 [1450] 155G0100

125 [1800] 155G0125

150 [2200] 155G0150

175 [2550] 155G0175

200 [2900] 55G0200

225 [3240] 155G0225

250 [3650] 155G0250

275 [4000] 155G0275

300 [4350] 155G0300

325 [4700] 155G0325

350 [5100] 155G0350

375 [5450] 155G0375

400 [5800] 155G0400

Code number

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 37

Page 38

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVBS, Main Spools

Symbol ISO Symbol Description Code number Size

A

65 l/min

[17.2 US

gal/min]

4-way, 3-position.

Closed neutral position

155G6452 155G6454 155G6456 155G6458

B

95 l/min

[25.1 US

gal/min]

C

130 l/min

[34.3 US

gal/min]

1)

D

180 l/min

[47.6 US

gal/min]

4-way, 3-position.

Throttled, open neutral

position

3-way, 3-position

P → B

1)

Main spool D is used for oil flow exceeding 180 l/min [47.6 US gal/min].

–

– –

155G6464 155G6466 155G6468

155G6476 155G6478

PVM, Mechanical Actuation

PVM, Mechanical Actuation

Symbol Description Code number

PVM,

Standard, spring centered mechanical actuation.

Individual oil flow adjustment to ports A and B.

PVM,

Mechanical actuation for hydraulically operated valves.

Individual oil flow adjustment to ports A and B.

22.5° 155G3040

37,5° 155G3041

22,5° 155G3050

37,5° 155G3051

PVMD, Cover for Mechanical Actuation

Symbol Description Code number

PVMD, cover for purely mechanically operated valve. 155G4061

PVH, Hydraulic Actuation

Symbol Description Code number

PVH,

cover for hydraulically operated valve.

G 1/

4

1

/2–20 UNF 155G4021

155G4022

38 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 39

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVHC, High Current Actuator

Symbol Description Code number

Hirschmann AMP Deutsch

PVHC 12 V – – 11110597

24 V – – 11110598

PVE, Electrical Actuation

Symbol Description Code number

Hirschmann AMP Deutsch

PVEO,

ON/OFF

12 V 155G4272 155G4282 11110601

24 V 155G4274 155G4284 11110652

PVEH, Proportional high.

Puls width modulation, short reaction time, low hysteresis,

active fault monitoring, inductive transducer

PVEH, Proportional high.

Puls width modulation, short reaction time, low hysteresis,

passive fault monitoring, inductive transducer

PVES Proportional Super.

Puls width modulation, short reaction time, 0% hysteresis

passive fault monitoring, inductive transducer

PVED-CC, CAN-Bus SAE J 1939/ISOBUS – 11111117 11111113

PVT, tank side module

PVT, tank side module

Symbol Description

Upper part without active elements Metric flange 155G7020

Upper part with LX connection Metric flange 155G7023

155G4092 155G4094 –

155G4093 155G4095 11111206

11111210 – 11111207

Port type

SAE flange 155G7022

O-ring boss 155G7021

SAE flange 155G7025

O-ring boss 155G7024

Code number

Lower part without active elements Mounting 155G7060

Mounting thread

UNF

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 39

155G7062

Page 40

Technical Information

PVG 120 Proportional Valve Group

Modules and Code Numbers

PVT, tank side module (continued)

Symbol Description

Lower part of PVE,

pilot oil supply for electrical actuations.

Filter mesh: 125 µm

Port type

Mounting thread

metric

Mounting thread

UNF

Code number

155G7040

155G7042

Lower part of PVH,

pilot oil supply for hydraulic actuations.

Filter mesh: 125 µm

Mounting thread

metric

Mounting thread

UNF

155G7043

155G7044

Port connections:

T = 1 in SAE flange, 210 bar [15/16–12 UN O-ring Boss, 3045 psi];

PP = G 3/8 [3/4–16 UNF O-ring Boss]

LX = G 3/8 [3/4–16 UNF O-ring Boss]

PVAS, Assembly Kit

Code number 155G...

Nr. of modules

Tie bolts and seals 155G8031 155G8032 155G8033 155G8034 155G8035 155G8036 155G8037 155G8038

1 PVB 2 PVB 3 PVB 4 PVB 5 PVB 6 PVB 7 PVB 8 PVB

40 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 41

P

LS

P

T

f

e

a

0

1-8

d

10

9

11

c

b

V310173.A

Technical Information

PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVG 120 module selection chart

PVG 120 modules exploded view

PVB, high basic module

SAE

flange

Facilities for shock valves AB 155G6007 155G6006 155G6005 10.2 [22.5]

PVB, low basic module

SAE

flange

No facilities for shock valves AB 155G6016 155G6015 155G6014 8.9 [19.6]

O-ring

Boss

O-ring

Boss

Metric flange Weight

kg [lb]

Metric flange Weight

kg [lb]

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 41

Page 42

Technical Information

PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

Accessory modules for PVB

Plug, PVBP 155G6081 0.4 [0.9]

LS

press. relief valve, PVBR 155G6080

A/B

External LS connection, PVBC 155G6082

Module for oil flow > 180 l/min [47.6 US gal/min], PVBU 155G6035

PVBS, mechanical actuation

Oil flow, l/min [US

gal]

Code number

A

65 [17.2]

155G6452 155G6454 155G6456 155G6458

B

95 [25.1]

155G6464 155G6466 155G6468

C

130 [34.3]

Weight, kg [lb]

D

180 [47.6]

155G6476 155G6478

Weight, kg [lb] 0.35 [0.8]

PVM, mechanical actuation

PVM + PVMD or

PVM + PVE

PVM + PVH

Weight

155G3040

155G3041

155G3050

155G3051

kg [lb] 0.5 [1.1]

22.5°

37.5°

22.5°

37.5°

PVMD, cover for PVM

Code number

155G4061 0.3 [0.7]

Weight, kg [lb]

PVT, tank side module

Code number

Upper part excl. LX connection 155G7022 155G7021 155G7020 4.6 [10.1]

Upper part incl. LX connection 155G7025 155G7024 155G7023

Lower part incl. pilot oil supply for PVE 155G7042 155G7040 4.4 [9.7]

Lower part excl. pilot oil supply for PVE 155G7062 155G7060

Lower part incl. pilot oil supply for PVH 155G7044 155G7043

SAE

flange

O-ring

Boss

Metric

flange

Weight

kg [lb]

42 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 43

Technical Information

PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVP, pump side module

Code number

Open

centre

Closed

centre

Accessory modules for open centre PVP

Description Code number

Plug, PVPD 155G5041 0.4 [0.9]

Hydraulic relief valve, PVPH 155G5061 0.5 [1.1]

Electrical relief valve, PVPE 12 V 155G5052 0.7 [1.5]

Excl. PVPD, PVPH, PVPE 155G5023 155G5037 155G5021 10.0 [22.1]

For PVB-oil flow > 180 l/min [47.6

US gal/min]

Excl. PVPD, PVPH, PVPE

Incl. pressure relief valve and plug

PVPD

Excl. pressure relief valve 155G5031 155G5032 155G5030 11.0 [24.3]

O-ring

Boss

155G5028 155G5029 155G5027

155G5022 155G5038 155G5020 10.2 [22.5]

24 V 155G5054

SAE

flange

Metric flange Weight

kg [lb]

Weight

kg [lb]

PVH, cover for PVRHH

Port Code number

1/2 in - 20 UNF 155G4021 0.4 [0.9]

G 1/4 155G4022

Weight, kg [lb]

PVE, electrical actuation

Connector PVEH fault monitoring PVEO voltage

Active Passive 12 V 24 V

Hirschmann 155G4092 155G4093 155G4272 155G4274

AMP 155G4094 155G4095 155G4282 155G4284

Weight, kg [lb]

1.25 [2.76] 1 [2.2]

PVLA suction valve A/B

Code number

155G1065 0.2 [0.4]

Weight

kg [lb]

PVLP, shock and suction valve A/B

Pressure setting

bar [psi]

50 725 155G0050

75 1100 155G0075

100 1450 155G0100

125 1800 155G0125

150 2200 155G0150

Code number

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 43

Page 44

Technical Information

PVG 120 Proportional Valve Group

PVG 120 Modules Selection Chart

PVLP, shock and suction valve A/B (continued)

Pressure setting

175 2550 155G0175

200 2900 155G0200

225 3250 155G0225

250 3650 155G0250

275 4000 155G0275

300 4350 155G0300

325 4700 155G0325

350 5100 155G0350

375 5400 155G0375

400 5800 155G0400

Weight, kg [lb]

PVAS, assembly kit

PVB’s 1 2 3 4 5 6 7 8

Code number

Weight kg 0.8 1.0 1.1 1.2 1.4 1.7 1.9 2.1

[lb] [1.8] [2.2] [2.4] [2.6] [3.1] [3.7] [4.2] [4.6]

0.175 [0.386]

155G8031 155G8032 155G8033 155G8034 155G8035 155G8036 155G8037 155G8038

44 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 45

Technical Information

PVG 120 Proportional Valve Group

Order specification

Ordering of modules for oil flow exceeding 180 l/min [47.6 US gal/min]

Modules for pump with fixed displacement

1. Ordering: Order accessory module 155G6035, main spool D, and pump side modules 155G5027 /

155G5028 / 155G5029.

2. Conversion: In open center systems a max. oil flow exceeding 180 l/min [47.6 US gal/min] can be

achieved by changing the following parts in the pump side and basic modules:

Open center pump side module

•

– Pressure adjustment spool

– The springs behind the pressure adjustment spool

– The plug behind the pressure adjustment spool

Parts from kit 155G5035 may be used.

Closed center pump side module (A closed center pump side module can be changed into an

•

upgraded open center pump side module by means of kit 155G5035.)

Basic module

•

– Spring behind pressure compensator

– The plug behind the pressure compensator

Order Form

Spring and plug with code number 155G6035 (PVBU, accessory module).

Modules for pump with variable displacement

1. Ordering: Order accessory module 155G6035 and main spool D.

2. Conversion:In closed center systems a max. oil flow exceeding 180 l/min [47.6 US gal/min] can be

achieved by changing the following basic module parts:

– The spring behind the pressure compensator.

– The plug behind the pressure compensator.

The code number of the spring and plug is 155G6035 (PVBU, accessory module).

An order form for PVG 120 hydraulic valve is shown on next page. The form can be obtained from the

Danfoss Power Solutions Sales Organisation.

The module selection chart on the next page and the order form are divided into fields.

Each module has its own field:

0: PVP, pump side modules

d: PVPD, PVPH and PVPE, accessory modules

1-8: PVB, basic modules

e: PVBS, main spools

f: PVBP, PVBR, PVBU and PVBC, accessory modules

a: PVM, mechanical actuation

c: PVMD, cover for mechanical operation; PVH, cover for hydraulic operation; PVEO and PVEH, electrical

actuations

b: PVLP, shock and suction valve; PVLA, suction valve

9: PVT, tank side module

10: PVAS, assembly kit

Please state:

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 45

Page 46

Technical Information

PVG 120 Proportional Valve Group

Order specification

•

Code numbers of all modules required

•

Required setting (p) for pump side module

•

Required setting of LS

Reordering

The space at the top right-hand corner of the form is for Danfoss to fill in. The code number for the whole

of the specified valve group (PVG No.) is entered here. In the event of a repeat order all you have to do is

enter the number Danfoss has given on the initial confirmation of order.

If PVG 120 is to be used with phosphate-esters this must be stated on the order form.

pressure relief valves, if accessory module PVBR is ordered.

A/B

46 | © Danfoss | March 2017 520L0356 | BC00000040en_US1002

Page 47

Technical Information

PVG 120 Proportional Valve Group

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002 | 49

Page 48

Local address:

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | March 2017 520L0356 | BC00000040en_US1002

Loading...

Loading...