MAKING MODERN LIVING POSSIBLE

Service and Parts Manual

Proportional Valves

PVG 100

powersolutions.danfoss.com

Service and Parts Manual PVG 100 Proportional Valves

Contents

Function

Installation

Service parts

PVG 100 sectional drawing .............................................................................................................................................3

Installation and plug orientation ..................................................................................................................................4

Installation and identication ........................................................................................................................................5

Maximum ow setting .................................................................................................................................................6-7

Connections .........................................................................................................................................................................8

Tightening torques ............................................................................................................................................................8

Installation of lever ............................................................................................................................................................9

Pressure setting, PVP .........................................................................................................................................................9

Adjustment of PVE .......................................................................................................................................................... 10

Installation and technical data for PVPP ................................................................................................................. 11

Pilot drain connection ................................................................................................................................................... 11

PVMR disassembly .......................................................................................................................................................... 12

PVMR/F assembly ............................................................................................................................................................ 13

Tightening torques and widths across ats ........................................................................................................... 13

Main spool assembly for PVMR .................................................................................................................................. 14

Float spool assembly for PVMF................................................................................................................................... 15

PVPF, open center pump side module ..............................................................................................................16-17

PVPE, PVPD and Pilot Shut O .............................................................................................................................. 18-19

PVPV - closed center pump side module ..........................................................................................................20-21

PVPV - closed center pump side module with integrated priority function ........................................22-23

PVB, PVBZ, PVLA, and PVLP ....................................................................................................................................24-25

PVSI, PVT, and PVTI ...................................................................................................................................................26-27

PVAS assembly kit for PVP with PVSI/PVT .........................................................................................................28-29

PVAS assembly kit for PVP with PVTI ..................................................................................................................30-31

PVBS, main spool ....................................................................................................................................................... 32-33

PVM, mechanical activation .................................................................................................................................. 34-35

PVM, PVMD, PVH, PVMR, and PVMF cover ........................................................................................................36-37

Electrical activation with Hirschmann connector ......................................................................................... 38-39

Electrical activation with AMP connector ........................................................................................................ 40-41

Seal kits for PVG 100 ....................................................................................................................................................... 42

2

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

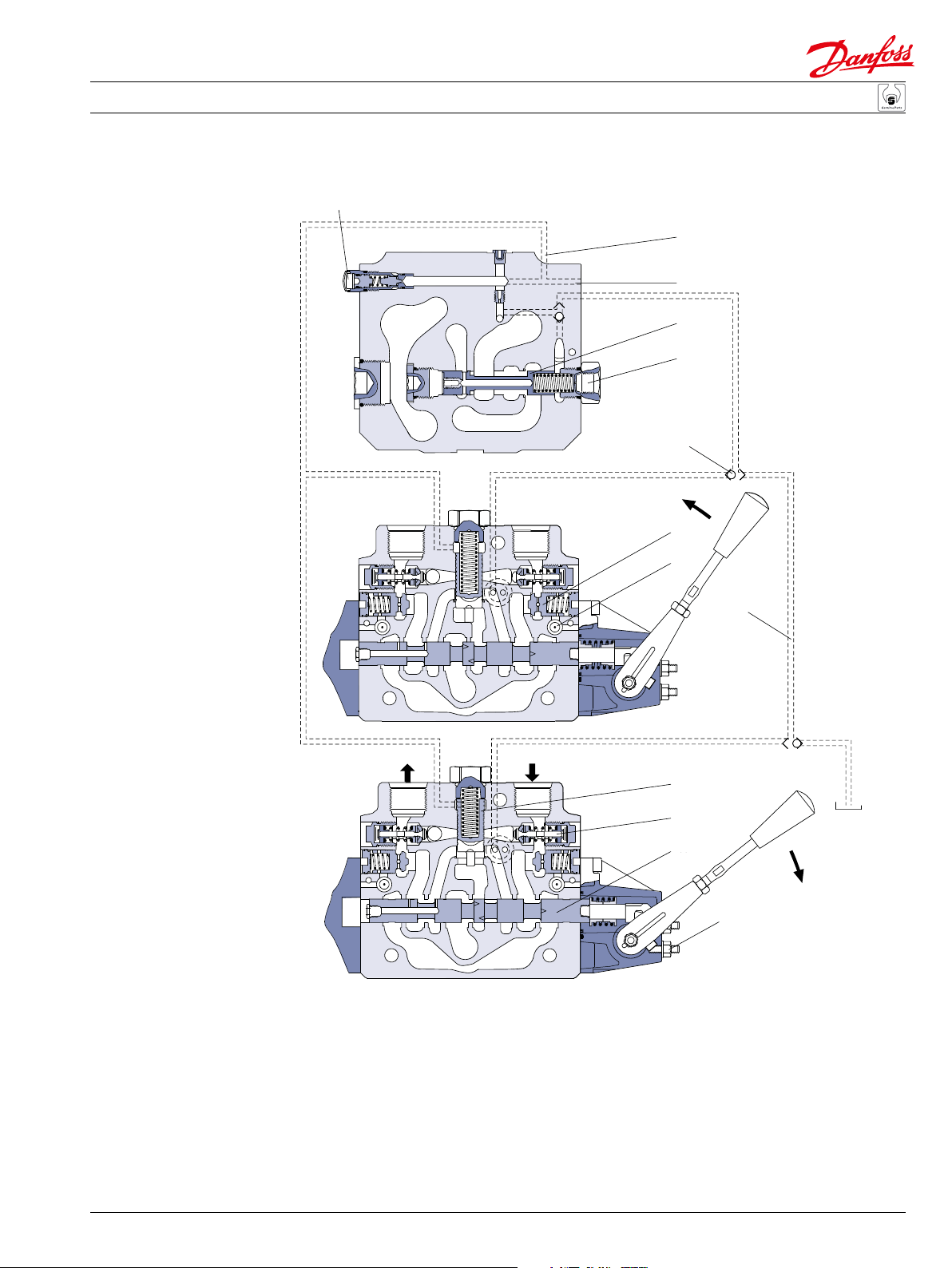

Function

PVG 100

sectional drawing

1

T

port

CF

P

T

LS

comp.

13

LS

pump

P

port

LS

ST

2

3

4

5

A

BA

6

8

7

P

T

BA

P

T

1. LS relief valve

2. LS connection

3. Priority spool for CF

4. LS connection for steering unit

5. Shuttle valve

6. Pilot operated check valve, POC

7. LS line

T

9

10

11

B

12

T

P106 002E

8. Logic cartridge for POC

9. Pressure compensator

10. Shock and suction valve, PVLP

11. Main spool, PVBS

12. Max. oil flow adjustment screws for ports A and B

13. LS comp (LS signal sent back to compensators)

520L0888 • Rev BB • Feb 2015

3

Service and Parts Manual PVG 100 Proportional Valves

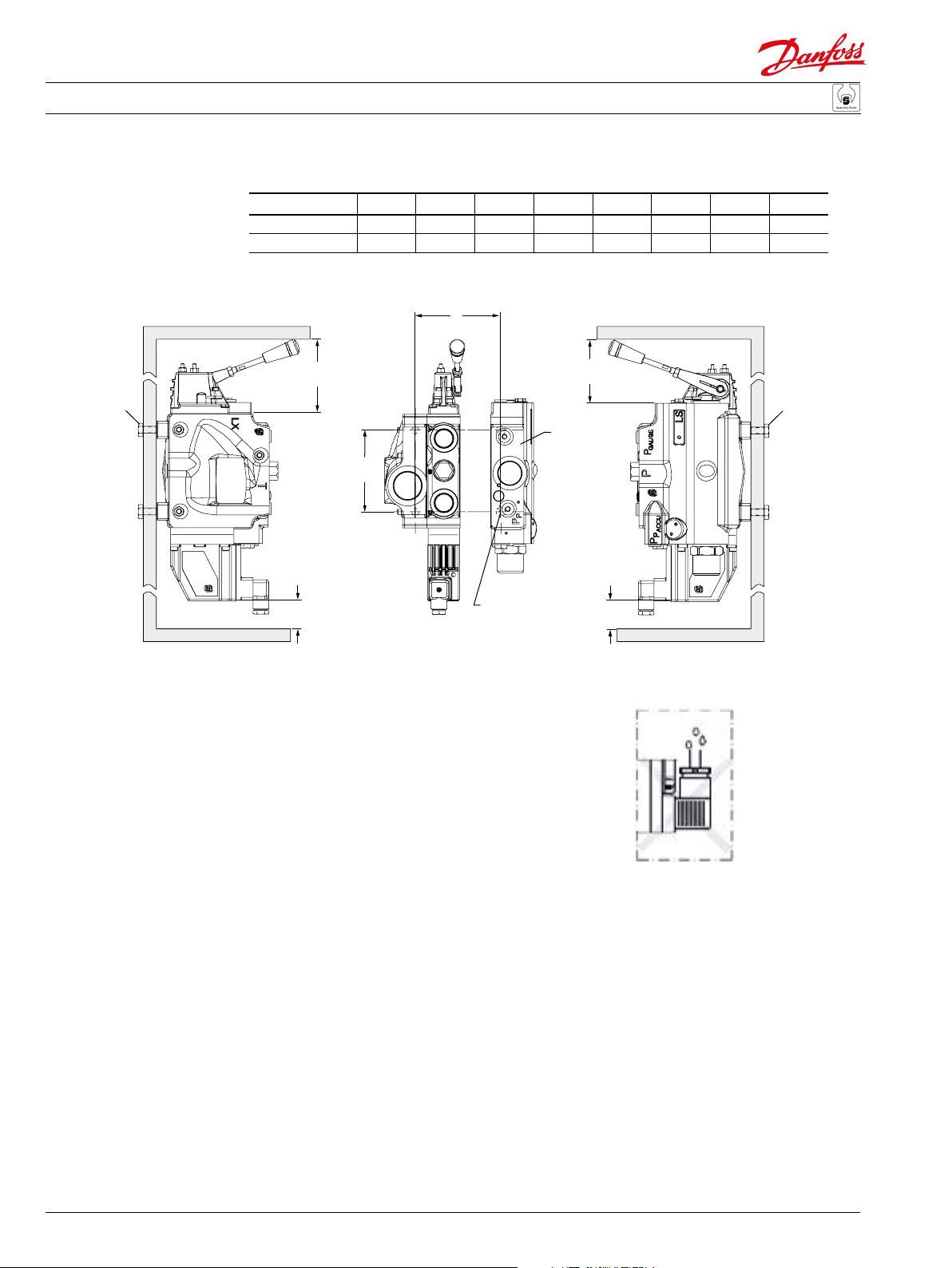

L

[530 lbf•in]

]

orientation

Installation

Installation and plug

orientation

60 Nm

Module of PVB 1 2 3 4 5 6 7 8

L mm 80.0 128.0 176.0 224.0 272.0 320.0 368.0 416.0

L in 3.15 5.04 6.93 8.82 10.71 12.60 14.49 16.38

PVP

170*

[6.69]

60 Nm

[530 lbf•in

170*

[6.69]

118

[4.65]

A

T

P

B

100*

[4]

* Room for dismantling

M12 x 14.0

4 places

100*

[4]

P106 000E

DIN mounting

4

520L0888 • Rev BB • Feb 2015

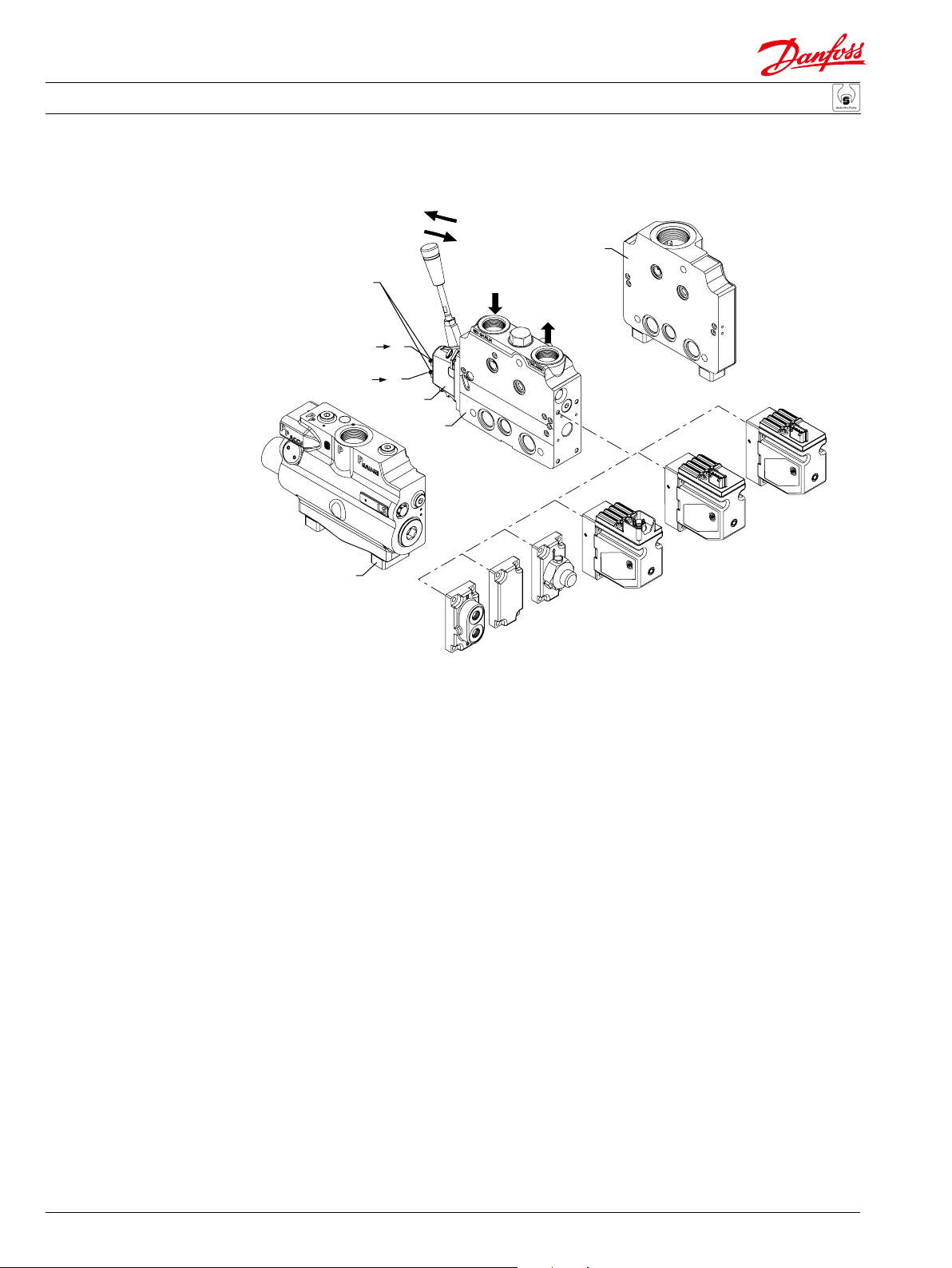

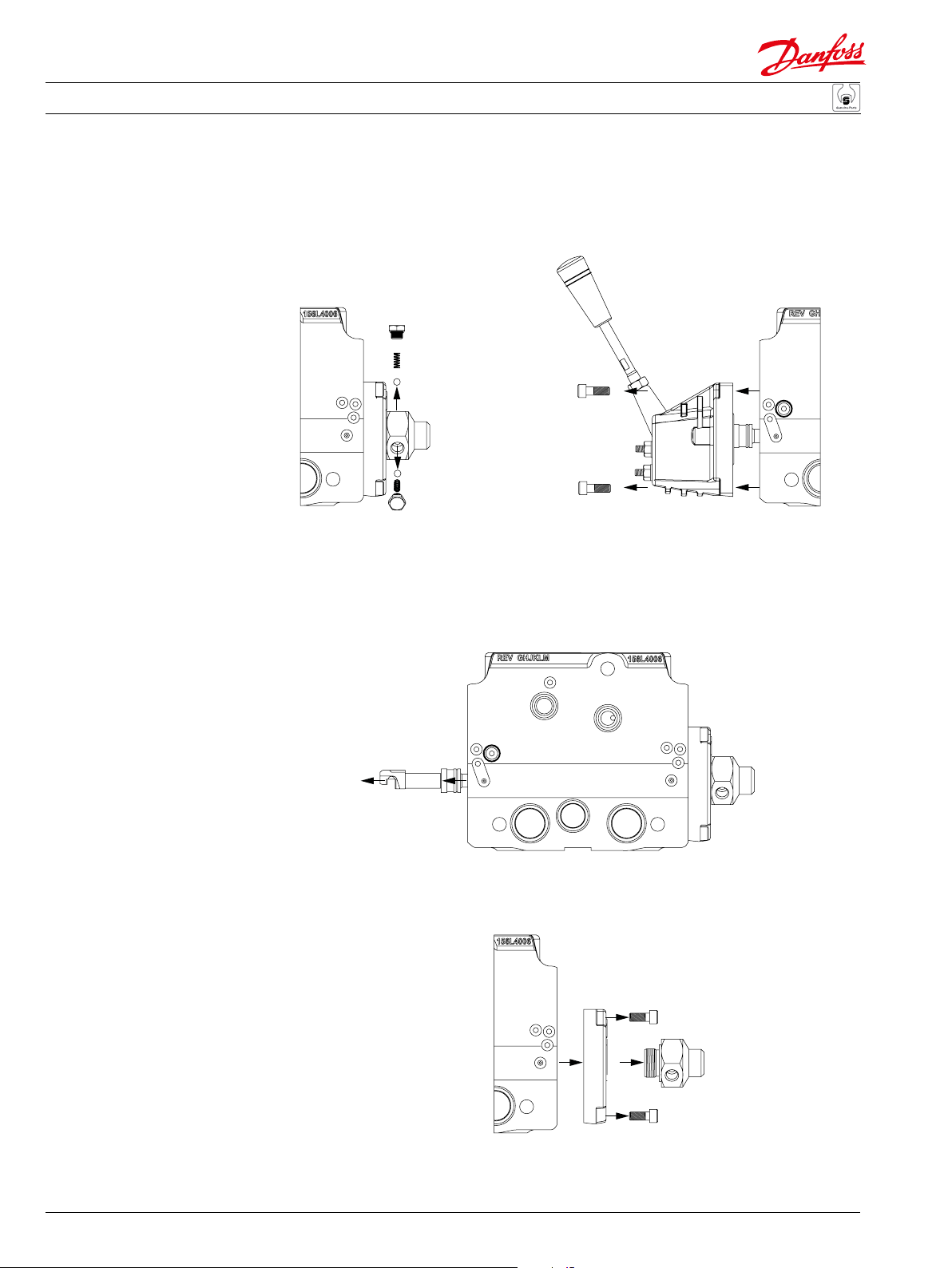

Service and Parts Manual PVG 100 Proportional Valves

E101 279E

PVEH/

C:

D:

Installation and Identication

Standard, oil ow direction

and setting of max ow

PVM to the right of PVP

Identication

PVMR/

PVMF

PVMD

PVH

PVEO

PVEA

PVB

PVES

B

A

PVM

7-9 Nm

[61-79 lbf•in]

P-A

PVS

P-B

Q max: P B

Q max: P A

PVP

Q max. A

Q max. B

01 03 A 00 0299

Week of manufacture

Year of manufacture

Day of the week

(A = Monday, B = Tuesday ...)

Issue number

Series number

PVG code number, week and year of manufacture

PVP pressure setting

C

D

Q max. B

Q max. A

3 mm

+

Q max. A

+

Q max. B

8 Nm

[70 lbf•in]

10 mm

520L0888 • Rev BB • Feb 2015

5

Service and Parts Manual PVG 100 Proportional Valves

Installation

Option, oil ow direction

and setting of max ow

PVM to the left of PVP

7-9 Nm

[61-79 lbf•in]

Q max: P A

Q max: P B

PVP

P-A

PVM

PVB

P-B

PVH

B

PVMD

A

PVMR/

PVMF

PVS

PVEO

PVEA

PVEH/

PVES

E101 284E

6

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Installation

Connections, pump side

module, PVP

end plate, PVS

Tightening torque

T

B

A

Pp gauge

(PVP-OC)

PAccu

PVP-OC shown

T0

P

Pp gauge

LS

LX

E101 285E

Maximum tightening torque

Connection

G 3/4 G 1 G 3/4 G 1/4 G 1 G 1 1/4

BSPP port connection

210 Nm 330 Nm 210 Nm 40 Nm 330 Nm 540 Nm

With steel washer

1850 lbf·in 2920 lbf·in 1850 lbf·in 350 lbf·in 2920 lbf·in 4780 lbf·in

50 Nm 70 Nm 50 Nm 20 Nm 70 Nm 100 Nm

With copper washer

445 lbf·in 620 lbf·in 445 lbf·in 180 lbf·in 620 lbf·in 885 lbf·in

110 Nm 150 Nm 110 Nm 30 Nm 150 Nm 240 Nm

With aluminum washer

970 lbf·in 1330 lbf·in 970 lbf·in 270 lbf·in 1330 lbf·in 2125 lbf·in

210 Nm 330 Nm 210 Nm 40 Nm 330 Nm 540 Nm

With cutting edge

1850 lbf·in 2920 lbf·in 1850 lbf·in 350 lbf·in 2920 lbf·in 4780 lbf·in

1 1/16 in-12 1 5/16 in-12 1 1/16 in-12 9/16 in-18 1 5/16 in-12 1 5/8 in-12

UNF port connection

120 Nm 160 Nm 120 Nm 40 Nm 160 Nm 320 Nm

With O-ring

1040 lbf·in 1420 lbf·in 1040 lbf·in 350 lbf·in 1420 lbf·in 2830 lbf·in

LS, LX, T0

P A/B Gauge: P, Pp, T

P

p Accum.

520L0888 • Rev BB • Feb 2015

7

Service and Parts Manual PVG 100 Proportional Valves

Installation

Installation of lever

Pressure setting, PVP

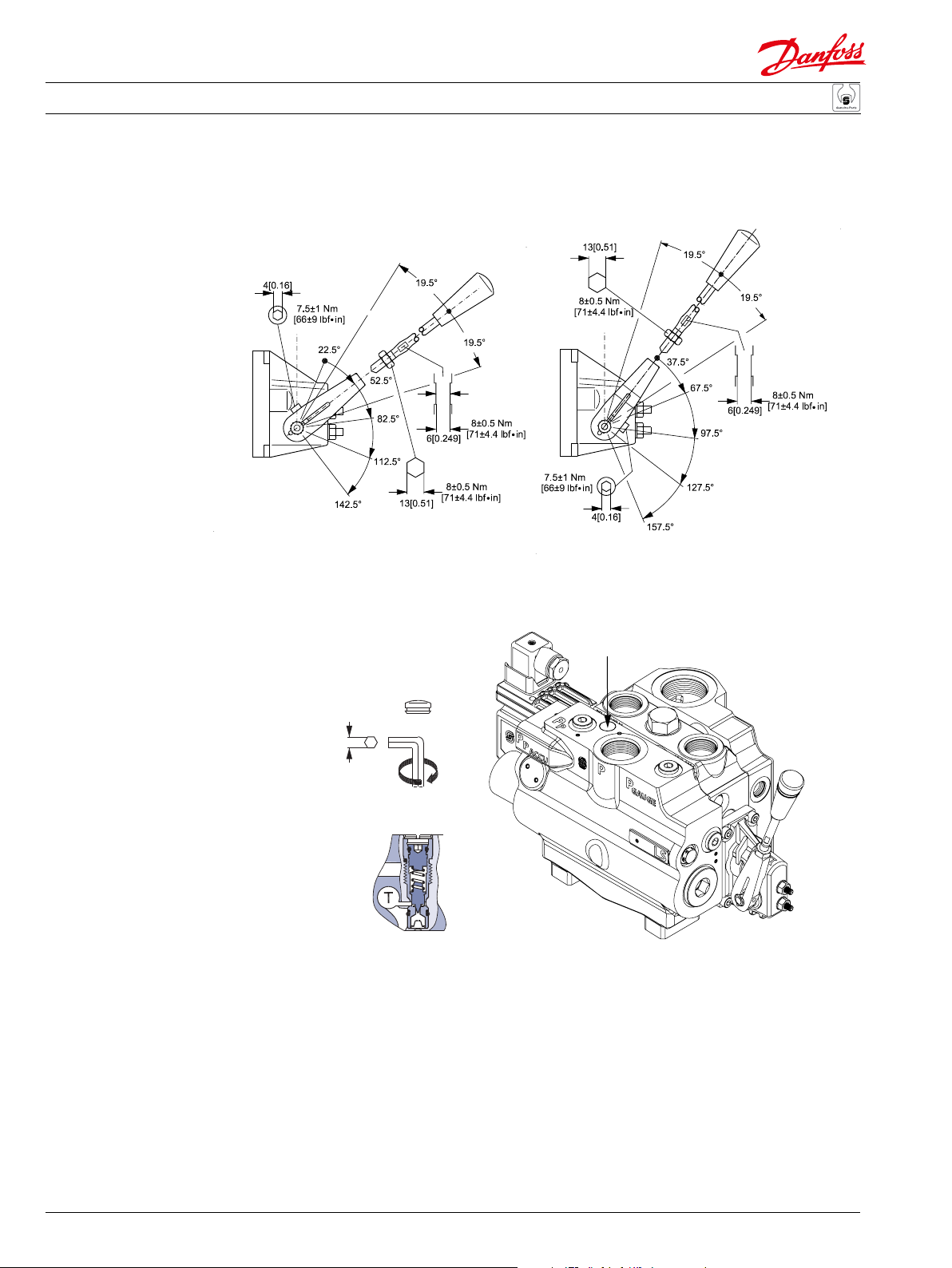

Base with an angle of 22.5° Base with an angle of 37.5°

P106 007E

PVP-CC

PVP-OC

4 mm

360° ~ 120 bar

360° ~ 1740 psi

P106 008E

8

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

0

.

0

8

]

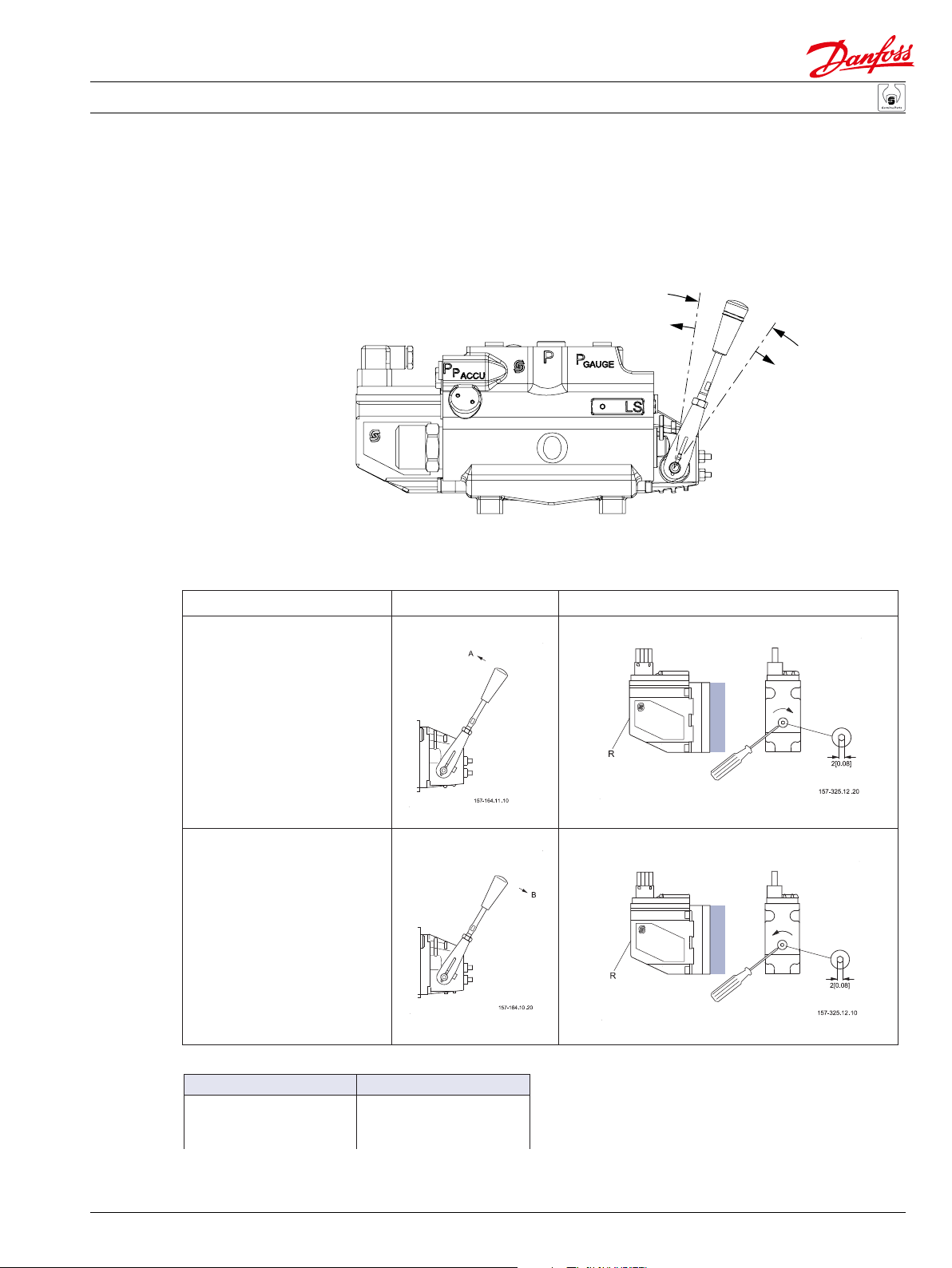

Installation

PVEH/PVEM/PVES

Adjustment of PVE

when max. lever travel is

exceeded

(PVE is factory-preset)

Lever travel exceeded in

Check maximum lever travel in neutral position.

1. Make sure the system is supplied with hydraulic power.

2. Connect supply voltage (UDC) (Signal voltage 0.5 x UDC), or cut o the signal voltage (US) on

pin 2.

[

2

.

x

a

m

A

m

a

x

.

2

B

[

0

.

0

8

]

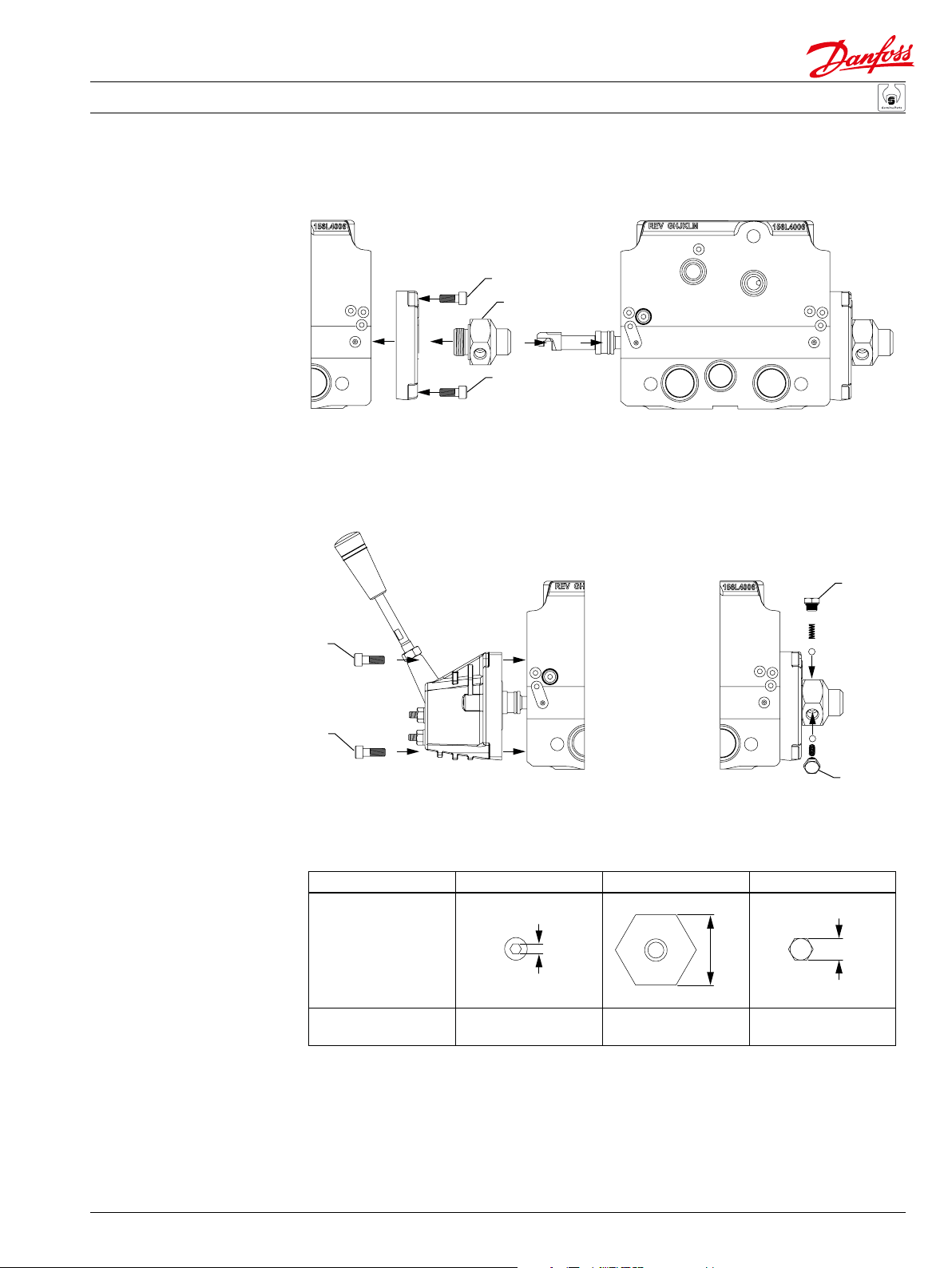

PVG 100

Direction of rotation for adjustment of position transducer

Direction A

Direction B

Turn of transducer Movement of lever

1

/4

1

/2

3

/4

1.5 mm [0.06 in]

3.0 mm [0.12 in]

4.5 mm [0.18 in]

520L0888 • Rev BB • Feb 2015

9

Service and Parts Manual PVG 100 Proportional Valves

][

][

A0

A0

W1

W1

e±

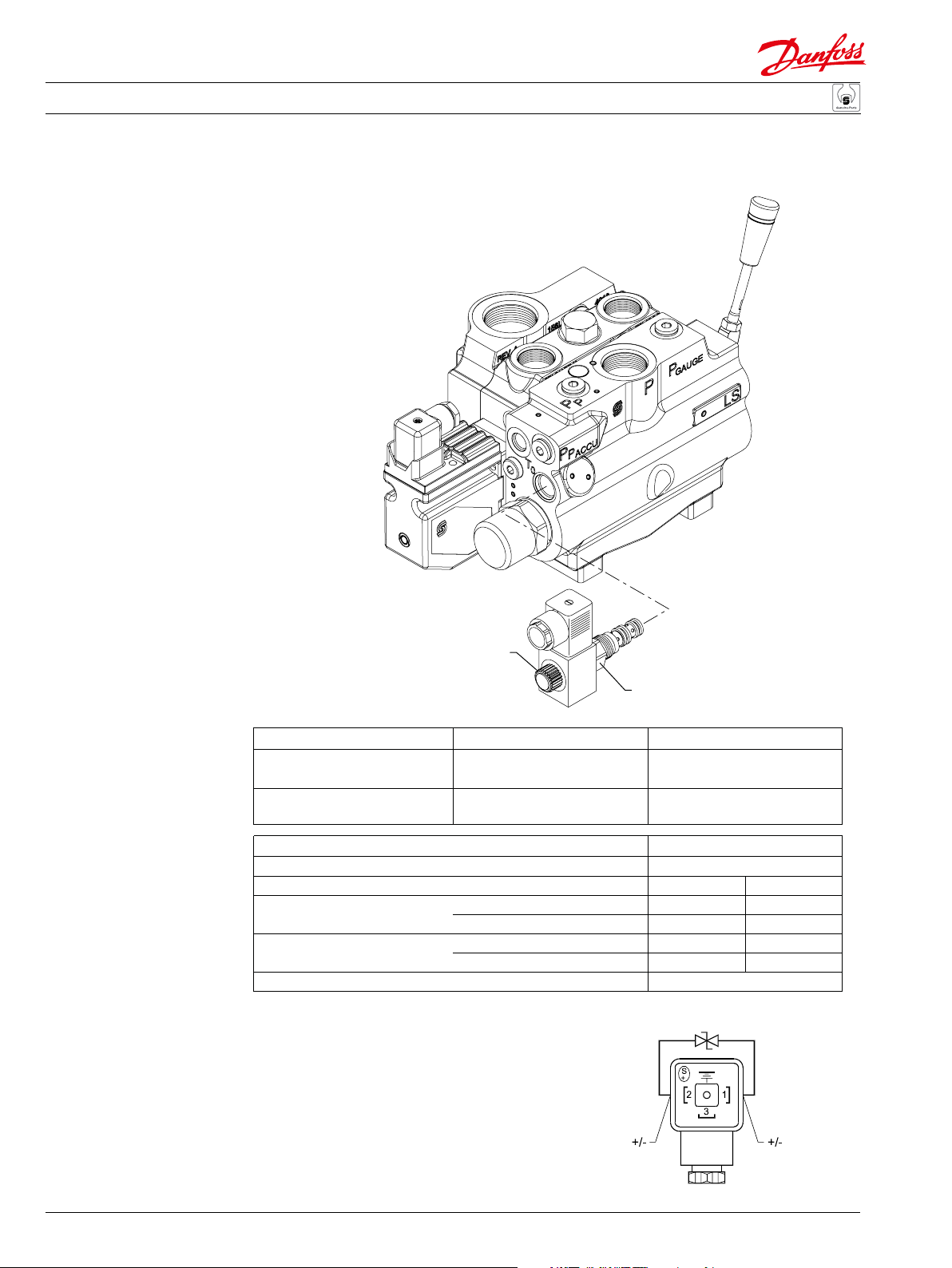

Installation

Installation and technical

data for pvpp (solenoid

operated pilot drain)

PVPP connection

2

(coil nut)

1

(cartridge valve)

Position Max. tightening torque

1

2

Max. operation pressure 350 bar [5076 bar]

Max. coil surface temperature 155°C [311°F]

Rated voltage 12 V

Current consumtion

Power consumtion

Max. permissible deviation from rated supply voltag

When installing the wire remember to

connect the built-in diode to the plug

22°C (71,6°F) coil temperature1.55

110°C (230°F) coil temperature1.00

22°C (71,6°F) coil temperature19

110°C (230°F) coil temperature12

Across flats

24 mm 45 Nm

[0.94 in

20 mm 5 Nm

[0.79 in

__

––

400 lbf·in]

44 lbf·in]

10%

pins.

24 V

.78 A

.50 A

9 W

2 W

__

––

P106 004E

10

520L0888 • Rev BB • Feb 2015

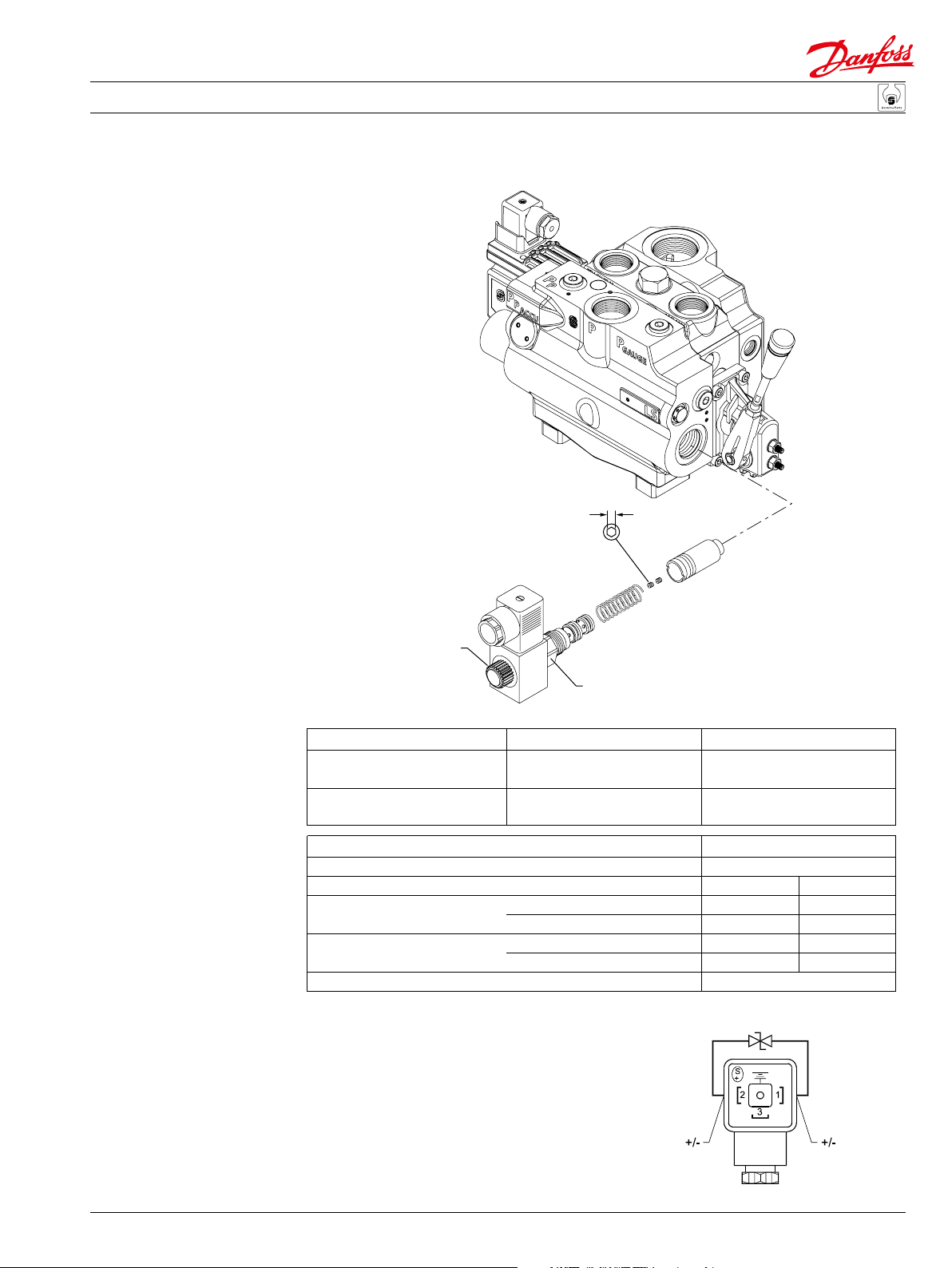

Service and Parts Manual PVG 100 Proportional Valves

][

][

W1

W1

e±

Installation

Installation and technical

data for PVPE (solenoid

relief valve)

2 Nm

[17.5 lbf•in]

2.5 mm

PVPE connection

1

(coil nut)

2

(cartridge valve)

Position Max. tightening torque

Max. operation pressure 350 bar [5076 bar]

Max. coil surface temperature 155°C [311°F]

Rated voltage 12 V

Current consumtion

Power consumtion

Max. permissible deviation from rated supply voltag

When installing the wire remember to

connect the built-in diode to the plug

1

2

22°C (71,6°F) coil temperature1.55 A0.78 A

110°C (230°F) coil temperature1.00 A0.50 A

22°C (71,6°F) coil temperature19

110°C (230°F) coil temperature12

Across flats

22 mm 5 Nm

[0.87 in

36 mm 85 Nm

[1.42 in

__

––

45 lbf·in]

750 lbf·in]

10%

pins.

24 V

9 W

2 W

__

––

520L0888 • Rev BB • Feb 2015

P106 288E

11

Service and Parts Manual PVG 100 Proportional Valves

Installation

PVMR disassembly

1. 2.

3.

4.

P106 005

12

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

2.

Installation

PVMR/F assembly

1.

X

Y

X

3. 4.

X

Z

Tightening torques and

widths across ats

X

Width across flats

Tightening torque

XYZ

5 mm

8 ± 0.5 Nm 15 ± 2 Nm 4 ± 1 Nm

[70 ± 4.5 lbf·in][135 ± 20 lbf·in][35 ± 9 lbf·in]

36 mm

Z

11 mm PVMF

P106 006

19 mm PVMR

520L0888 • Rev BB • Feb 2015

13

Service and Parts Manual PVG 100 Proportional Valves

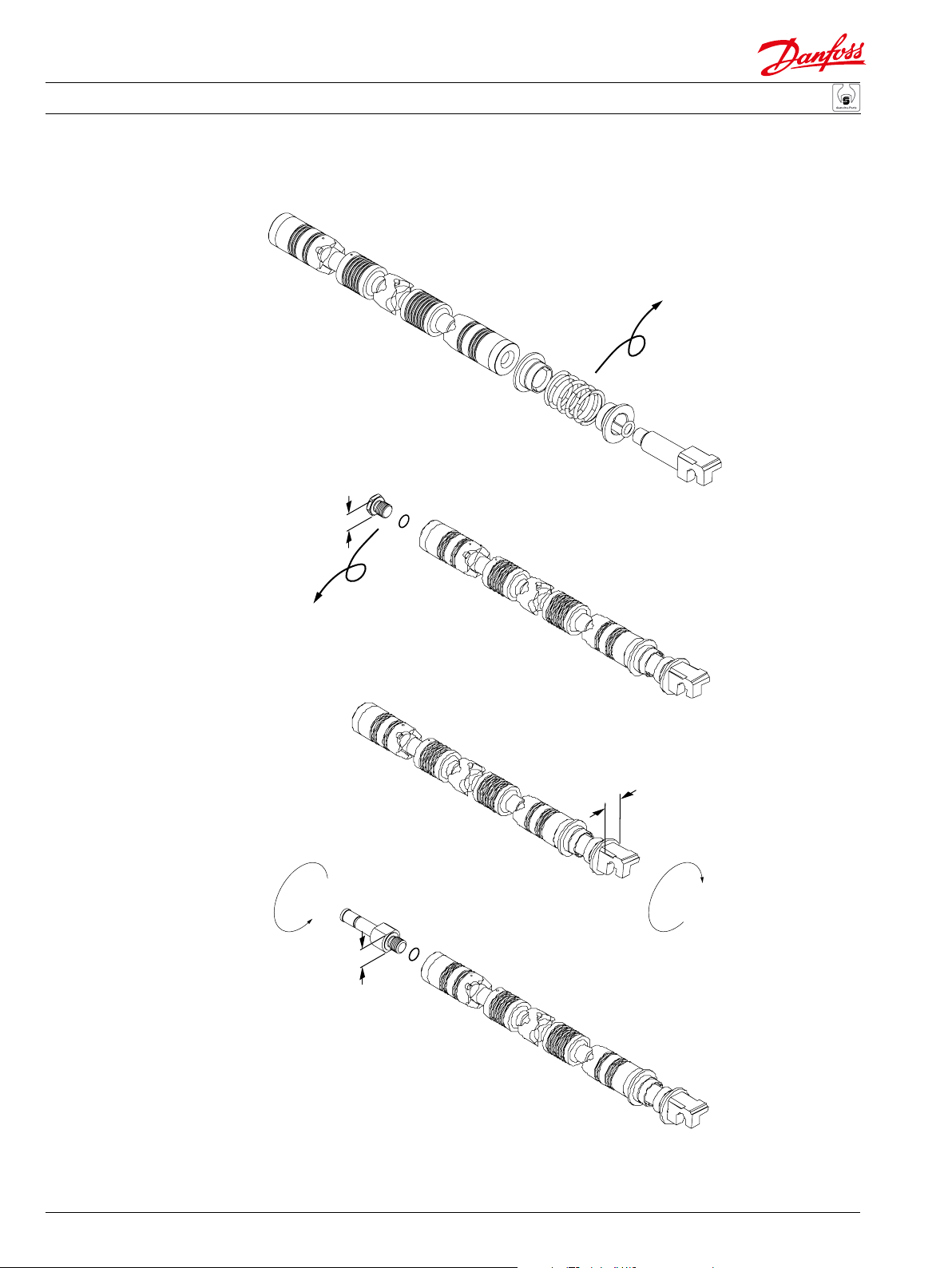

1.

2.

Installation

Standard main spool

assembly for PVMR

11 mm

3.

12.5 mm

4.

8 Nm

[70 lbf·in]

12 mm

8 Nm

[70 lbf·in]

Note: Spools must be installed with LS holes

on ‘B’ port side of PVB.

14

520L0888 • Rev BB • Feb 2015

E101 291E

Service and Parts Manual PVG 100 Proportional Valves

Installation

Standard oat spool

assembly for PVMF

A F

P

Note: Spools must be installed with LS holes

on ‘B’ port side of PVB.

11 mm

12 mm

8 Nm

[70 lbf·in]

8 Nm

[70 lbf·in]

E101 290E

520L0888 • Rev BB • Feb 2015

15

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPF, open center pump

side module

4 mm

18

[35 lbf•in]

19

4 mm

4 Nm

16

11

[177 lbf•in]

12

12

20 Nm

11

12

12

20

10

21

22

15

14

13

12

1

26

2.5 mm

11

12

17

2

3 Nm

[25 lbf•in]

6 mm

12

12

25

35 Nm

[310 lbf•in]

11

24

23

3

85 Nm

[750 lbf•in]

27

6 mm

4 Nm

[35 lbf•in]

4

41 mm

5

6

7

E101 303E

16

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

Type Description Code number

G1 thread UNF thread

PVPF 161B5110

161B5510

161B5112

161B5512

PVPF 161B5140

161B5540

161B5142

161B5542

Item Description Code No.

1 Spool, 12 bar 1 1 1 1

1 Spool, 20 bar 1 1 1 1

2 Orifice, 0.7 dia, M5 1 1 1 1 1 1 1 1

3 Washer, 19.3 x 34.0 x 3.0 [0.76 x 1.34 x 0.12] 1 1 1 1 1 1 1 1

4 Spring, 12 bar 1 1 1 1

4 Spring, 20 bar 1 1 1 1

5 Spring, 12 bar 1 1 1 1

5 Spring, 20 bar 1 1 1 1

6 O-ring, 33.3 x 2.4 [1.31 x 0.09] 1 1 1 1 1 1 1 1

7 Plug 1 1 1 1 1 1 1 1

10 Orifice, 0.7 dia, M8 x 1 1 1 1 1 1 1 1 1

11 Plug, G 1/4 thread 631X2036 4 4 4 4

11 Plug, 9/16-18 UNF thread 4 4 4 4

12 O-ring, 11.9 x 1.98 [0.47 x 0.08] 4 4 4 4

12 Washer, 13.5 x 17.5 x 1.5 [0.53 x 0.69 x 0.06] 4 4 4 4

13 LS relief valve 155L6485 1 1 1 1 1 1 1 1

14 Plastic cap 155L6377 1 1 1 1 1 1 1 1

15 Plastic plug w/O-ring (1 5/16-12 UNF thread) 156H7047 1 1 1 1

15 Plastic plug w/gasket (G1 thread) 633X0176 1 1 1 1

16 Plug assembly, w/O-ring (9/16-18 UNF thread) 30021-6A 4 4 4 4

17 Plastic plug w/gasket (9/16-18 UNF thread) 156H7043 1 1 1 1

17 Plastic plug w/gasket (G 1/4 thread) 633X0123 1 1 1 1

18 Cap plug assembly w/O-ring 1 1 1 1 1 1 1 1

19 Spring, PR 1 1 1 1 1 1 1 1

20 Spool, PR 1 1 1 1 1 1 1 1

21 Filter retainer (non-serviceable) 1 1 1 1 1 1 1 1

22 Filter, PR (non-serviceable) 1 1 1 1 1 1 1 1

23 Screw, pilot check valve (M10 x 1) 1 1 1 1

24 Spring, pilot check valve 1 1 1 1

25 Ball, pilot check valve (M6 steel) 1 1 1 1

26 Orifice, 0.4 dia (M10 x 1) 1 1 1 1 1 1 1 1

27 Plug assembly, w/seal (M12 x 1.5) 1 1 1 1 1 1 1

Seal kit (includes item 6 and 12) 11016012 1 1 1 1 1 1 1 1

LS relief valve service tool 155L6494

Open center with pilot

supply for electrical

actuation and pilot gage

port

Open center with pilot

supply for electrical

actuation, pilot gage

port, and facility for

pilot shut o

12 bar

spring

20 bar

spring

12 bar

spring

20 bar

spring

1

520L0888 • Rev BB • Feb 2015

E101 304E

17

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPE, PVPD and pilot

shut-o (PVPP)

85 Nm

[750 lbf•in]

17 mm

1

2

10

9

36 mm

85 Nm

[750 lbf•in]

2.5 mm

3

4

5

6

11

7

8

1

2 Nm

[17.5 lbf•in]

15

16

18

19

20

17

24 mm

13

13

5 Nm

[44.2 lbf•in]

12

14

35-40 Nm

[310-354 lbf•in]

E101 305E

18

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPE, PVPD and pilot

shut-o (PVPP)

Type Code No.

12 volt 155G5052

PVPE

24 volt 155G5054

PVPD Accessory plug (PVPF only) 155G5041

Electrical pilot shut-o valve 12 volt 161B5052

PVPP

(PVPV or PVPF) 24 volt 161B5054

Item Description Code No.

1 Electrical plug 155G5451 1 1 1 1

2 Electrical relief valve, 12 volt (item 3, 4, and 5 included) 155G5013 1

2 Electrical relief valve, 24 volt (item 3, 4, and 5 included) 155G5025 1

3 O-ring, 29.82 x 2.62 [1.18 x 0.10] 1 1

4 Back-up ring 27.0 x 2.0 [1.06 x 0.08] 1 1

5 O-ring, 26.7 x 1.78 [1.05 x 0.07] 1 1

6 Spring 1 1

7 Orifice, M5 x 0.5 dia. [ 0.2 x 0.02] 2 2

8 Spool 1 1

9 Plug (item 10 included) 1

10 O-ring, 30.3 x 2.4 [1.19 x 0.09] 1

11 Insert (item 9 and 10 included) 155G5041 1

12 Coil nut (item 13 included) 173800588 1 1

13 O-ring, 6-065 viton, 75D, 12 x 2 [0.47 x 0.08] 2 2

14 Coil, 12 volt, 22w DIN 171139819 1

14 Coil, 24 volt, 22w, DIN 171140019 1

15 Solenoid valve (item 12, 16, 17, 18, 19, and 20 included) 805339919 1 1

16 O-ring, 16.4 x 2.2 [0.65 x 0.09](3-908)D 1 1

17 Back-up ring, 8-014, 11.02 x 13.8 x 0.7 [0.43 x 0.54 x 0.03] 2 2

18 O-ring, 2-014 1 1

19 O-ring, 2-013 1 1

20 Back-up ring, 8-013 2 2

PVPE seal kit (includes item 3, 4, and 5) 155G8527 1 1

PVPP seal kit (includes item 10, 13, 16, 17, 18, 19, and 20) 35400321 1 1

Extra electrical relief

( PVPF only)

520L0888 • Rev BB • Feb 2015

E101 306E

19

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPV, closed center pump

side module

35 ± 3 Nm

[310 ± 5 lbf•in]

23

6 mm

24

6 mm

16

25

Service tool

torque

20 Nm

[177 lbf•in]

17

16

35 ± 3 Nm

[310 ± 5 lbf•in]

14

13

15

11

12

6 mm

16

22

35 ± 3 Nm

[310 ± 5 lbf•in]

10

17

21

20

13 mm

85 Nm

[750 lbf•in]

19

18

20

E101 334E

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPV, closed center pump

side module

Type Description Code number

G1 thread UNF thread

161B5111

Closed center with pilot supply for

electrical actuation and pilot gage port

161B5511

11013069

PVPV 11013070

161B5141

161B5541

11013075

11013076

Item Description Code No.

10 Orifice, 0.7 dia, M8 x 1 1 1 1 1 1 1 1 1

11 Plug, G 1/4 thread 631X2037 3 3 2 2

11 Plug, 9/16-18 UNF thread 3 3 2 2

12 Washer, 13.5 x 17.5 x 1.5 [0.53 x 0.69 x 0.06] 3 3 2 2

12 O-ring, 11.9 x 1.98 [0.47 x 0.08] 3 3 2 2

13 LS relief valve 1 1 1 1 1 1 1 1

14 Plastic cap 155L6377 1 1 1 1 1 1 1 1

15 Plastic plug w/O-ring (1 5/16-12 UNF thread) 156H7047 1 1 1 1

15 Plastic plug w/gasket (G1 thread) 633X0176 1 1 1 1

16 Plug assembly, w/O-ring (9/16-18 UNF thread) 30021-6A 3 3 2 2

17 Plastic plug w/gasket (9/16-18 UNF thread) 156H7043 2 2 2 2

17 Plastic plug w/gasket (G 1/4 thread) 2 2 2 2

18 Cap plug assembly w/O-ring 156H7051 1 1 1 1 1 1 1 1

19 Spring, PVE 1 1 1 1

19 Spring, PVH 1 1 1 1

20 Spool, PR 1 1 1 1 1 1 1 1

21 Filter retainer (non-serviceable) 1 1 1 1 1 1 1 1

22 Filter, PR (non-serviceable) 1 1 1 1 1 1 1 1

23 Screw, pilot check valve (M10 x 1) 1 1 1 1 1 1 1 1

24 Spring, pilot check valve 1 1 1 1 1 1 1 1

25 Ball, pilot check valve (M6 steel) 1 1 1 1 1 1 1 1

Seal kit (includes item 12 and 18) 11016013

LS relief valve service tool 155L6494

Closed center with pilot supply for

hydraulic actuation and pilot gage port

Closed center with pilot supply for

electrical actuation, pilot gage port,

and facility for pilot shut o

Closed center with pilot supply for

hydraulic actuation, pilot gage port,

and facility for pilot shut o

520L0888 • Rev BB • Feb 2015

P106 299E

21

Service and Parts Manual PVG 100 Proportional Valves

E101 309E

Service parts

PVPV - closed center pump

side module

.625 in

140 Nm

[103 lbf•ft]

10 mm

60 Nm

[44 lbf•ft]

26

24

25

17 mm

[28-31 lbf•ft]

Service tool

16

18

5

19

38-42 Nm

20 Nm

[177 lbf•in]

15

3

5

20

14

13

22

21

11

12

23

.375 in

23

13 Nm

[115 lbf•in]

11

12

10

1

27 mm

22

12

11

2

[44 lbf•ft]

3

60 Nm

6 mm

[35 lbf•in]

22

6

4

4 Nm

5

7

9

13 mm

25 Nm

[221 lbf•in]

22

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVPV - closed center pump

side module with integrated

priority function

Item Description Code No.

1 Spool, priority valve 1 1

2 Spring, priority valve 1 1

3 O-ring, 19.30 x 2.20 [0.76 x 0.09] 2 2

4 Plug, priority valve, M22 x 1.5 (LSt: int. thread 9/16-18 UNF) 1

4 Plug, priority valve, M22 x 1.5 (LSt: internal thread G 1/4)

5 Plastic plug w/gasket (9/16-18 UNF thread) 156H7043 3

5 Plastic plug w/gasket (G 1/4 UNF thread) 633X0123 3

6 Spool, pressure reducer 1 1

7 Spring, pressure reducer 1 1

9 Cap plug assembly w/O-ring 1 1

10 Shuttle disk assembly 1 1

11 Plug, G 1/4 thread

11 Plug, 9/16-18 UNF thread 3

12 Washer, 13.5 x 17.5 x 1.5 [0.53 x 0.69 x 0.06]

12 O-ring, 11.9 x 1.98 [0.47 x 0.08] 3

13 LS relief valve 155L6485 1 1

14 Plastic cap 155L6377 1 1

15 O-ring, 29.72 x 2.95 [1.17 x 0.12] (3-916) 1 1

16 Plug, 1 5/16-12 UNF thread 1 1

18 Plug, M22 x 1.5 thread 1 1

19 Plastic plug w/gasket (1 5/16-12 UNF thread) 156H7047 1

19 Plastic plug w/gasket (G1 thread) 633X0176 1

20 Plastic plug w/gasket (3/4-16 UNF thread) 156H7044 1

20 Plastic plug w/gasket (G 1/2 thread) 633X0126 1

21 Plastic plug w/gasket (1 1/16-12 UNF thread) 156H7046 1

21 Plastic plug w/gasket (G 3/4 thread) 633X0128 1

22 Plug assembly, w/O-ring (9/16-18 UNF thread) 30021-6A 3

22 Plug assembly, w/o washer (G 1/4 thread) 631X2036 3

23 Orifice, 0.40 dia, M10 x 1 1 1

24 Mounting bracket 1 1

25 Washer 2 2

26 Screw, M10 2 2

Seal kit (includes item 3, 9, 12, and 15) 11016014

E101 310E

LS relief valve service tool 155L6494 1 1

Type Description Code number

P=G 3/4 thread P=1 1/16 thread

T=G 1 thread T=1 5/16 thread

PVPV Closed center pump side module 161B5211

161B5611

1

3

3

520L0888 • Rev BB • Feb 2015

23

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVB, basic module, PVLA,

anti-cavitation valve

PVLP, shock and anticavitation valve

PVBZ, poppet valves

12

3

27 mm

60 Nm

[44 lbf•ft]

1

same as

opposite

side of

housing

6

3

2

10

5

9

10

10

13

7

6

11

13

PVLP

11

4

8

PVLA

40 Nm

[354 lbf•in]

13 mm

E101 311E

24

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVB, basic module

PVB, PVBZ, PVLA, and PVLP

Type Description Code number

G

Without

PVLP

PVB

Post compensated

With

PVLP

3

/4 thread 1 1/

161B6250

161B6260

16

-14 thread

PVBZ

PVB

PVBZ

Post compensated w/pilot

operated check valves on

work port A and B

Post compensated

Post compensated w/pilot

operated check valves on

work port A and B

Without

PVLP

With

PVLP

Without

PVLP

With

PVLP

Without

PVLP

With

PVLP

161B6252

161B6262

161B6650

161B6660

161B6652

161B6662

Item Description Code No.

1 Compensator valve assembly 1 1 1 1 1 1 1 1

2 Housing 1 1 1 1 1 1 1 1

3

3 Plastic plug, G

3 Plastic plug, 1 1/

/4 633X0128 2 2 2 2

-14 156H7046 2 2 2 2

16

4 Pilot operated check valve assembly 2 2 2 2

5 Shuttle disk assembly 1 1 1 1 1 1 1 1

6 Logic check valve assembly 2 2 2 2

7 PVLP see below 2 2 2 2

8 PVLA 157B2001 2 2 2 2

9 PVLA plug 157B2002 2 2 2 2

10 O-ring, 15.6 x 1.78 [0.61 x 0.07] 2 2 2 2

11 O-ring 2 2 2 2

12 O-ring 1 1 1 1 1 1 1 1

13 Pilot cartridge seal kit 11016017 2 2 2 2

* Seal kit (includes item 10, 12, and 13) 11016018 1 1 1 1 1 1 1 1

Description Code No.

PVLP 157B2 _ _ _

Pressure setting (bar)

520L0888 • Rev BB • Feb 2015

32 = 157B2032

50 = 157B2050

63 = 157B2063

100 = 157B2100

125 = 157B2125

140 = 157B2140

150 = 157B2150

160 = 157B2160

190 = 157B2190

210 = 157B2210

230 = 157B2230

240 = 157B2240

250 = 157B2250

265 = 157B2265

280 = 157B2280

300 = 157B2300

320 = 157B2320

350 = 157B2350

E101 312E

25

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVT & PVTI - end plate

PVT100 - tank module

PVTL 100/32 - interface

module

7

1

4

10

13 mm

40 Nm

[354 lbf•in]

7

2

6

5

10

26

E101 313E

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVT & PVTI - end plate

PVT100 - tank module

PVTL 100/32 - interface

module

Type Description Code number

1

G 1

161B2500

PVT

161B2520

1612505

PVT

161B2525

161B2200

PVTI

161B2220

End plate with tank port and

PVLP shock valve facility

End plate with tank port and LX port

and PVLP shock valve facility

100/32 interface module with tank

port and PVLP shock valve facility

Item Description Code No.

1 PVTI 100/32 interface housing with tank port 1 1

2 PVT 100 end plate housing with tank port 1 1 1 1

4 PVLP see below 1 1 1 1 1 1

5 PVLA 157B2001 1 1 1 1 1 1

6 Shipping plug, 9/16 - 18 156H7043 1

1

6 Shipping plug, G

/4 633X0123 1

7 Shipping plug, 1 5/8 - 12 1587058 1 1 1

7 Shipping plug, G 1

1

/4 156H7057 1 1 1

10 Plug w/O-ring 157B2002 1 1 1 1 1 1

/4 thread 1 5/8 -12 thread

Description Code No.

PVLP 157B2 _ _ _

Pressure setting (bar)

520L0888 • Rev BB • Feb 2015

32 = 157B2032

50 = 157B2050

63 = 157B2063

100 = 157B2100

125 = 157B2125

140 = 157B2140

150 = 157B2150

160 = 157B2160

190 = 157B2190

210 = 157B2210

230 = 157B2230

240 = 157B2240

250 = 157B2250

265 = 157B2265

280 = 157B2280

300 = 157B2300

320 = 157B2320

350 = 157B2350

E101 314E

27

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVAS assembly kit for PVP

with PVT

PVT

5

6

*

6

PVB

5

17 mm

38-42 Nm

1

2

3

[28-31 lbf•ft ]

6

*

6

9

6

9

7

8

7

6

8

E101 316E

28

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVAS assembly kit for PVP

with PVT

Type Description Code No.

PVAS for 1 PVB basic module 161B8001

PVAS for 2 PVB basic modules 161B8002

PVAS for 3 PVB basic modules 161B8003

PVAS for 4 PVB basic modules 161B8004

PVAS for 5 PVB basic modules 161B8005

PVAS for 6 PVB basic modules 161B8006

PVAS for 7 PVB basic modules 161B8007

PVAS for 8 PVB basic modules 161B8008

Item Description Code No.

1 Nut, M10 x 1.5 3 3 3 3 3 3 3 3

2 Washer 3 3 3 3 3 3 3 3

3 Stay bolt, M10 x 111 mm [4.37 in] 3

Stay bolt, M10 x 159 mm [6.26 in] 3

Stay bolt, M10 x 207 mm [8.15 in] 3

Stay bolt, M10 x 255 mm [10.04 in] 3

Stay bolt, M10 x 303 mm [11.93 in] 3

Stay bolt, M10 x 351 mm [13.82 in] 3

Stay bolt, M10 x 399 mm [15.71 in] 3

Stay bolt, M10 x 447 mm [17.60 in] 3

5 O-ring, 16.0 x 2.5 x [0.63 x 0.1] 18 16 14 12 10 8 6 4

6 O-ring, 5.0 x 2.0 [0.19 x 0.08] 29 26 23 20 17 14 11 8

7 O-ring, 24.0 x 3.0 [0.94 x 0.12] 18 16 14 12 10 8 6 4

8 O-ring, 20.0 x 3.0 [0.79 x 0.12] 9 8 7 6 5 4 3 2

9 O-ring, 14.0 x 2.0 [0.55 x 0.08] 16 14 12 10 8 6 4 2

Seal kit (includes item 5, 6, 7, 8, and 9) 11003451

E101 317E

520L0888 • Rev BB • Feb 2015

29

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVAS assembly kit for PVP

with PVTI

PVTI

5

6

*

6

PVB

5

10 mm

38-42 Nm

[28-31 lbf•ft ]

1

2

3

6

*

6

9

6

9

7

8

7

6

8

E101 318E

30

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVAS assembly kit for PVP

with PVTI

Type Description Code No.

PVAS for 1 PVB basic module 161B8021

PVAS for 2 PVB basic modules 161B8022

PVAS for 3 PVB basic modules 161B8023

PVAS for 4 PVB basic modules 161B8024

PVAS for 5 PVB basic modules 161B8025

PVAS for 6 PVB basic modules 161B8026

PVAS for 7 PVB basic modules 161B8027

PVAS for 8 PVB basic modules 161B8028

Item Description Code No.

1 Nut, M10 x 1.5 3 3 3 3 3 3 3 3

2 Washer 3 3 3 3 3 3 3 3

3 Stay bolt, M10 x 111 mm [4.37 in] 3

Stay bolt, M10 x 159 mm [6.26 in] 3

Stay bolt, M10 x 207 mm [8.15 in] 3

Stay bolt, M10 x 255 mm [10.04 in] 3

Stay bolt, M10 x 303 mm [11.93 in] 3

Stay bolt, M10 x 351 mm [13.82 in] 3

Stay bolt, M10 x 399 mm [15.71 in] 3

Stay bolt, M10 x 447 mm [17.60 in] 3

5 O-ring, 16.0 x 2.5 x [0.63 x 0.1] 18 16 14 12 10 8 6 4

6 O-ring, 5.0 x 2.0 [0.19 x 0.08] 29 26 23 20 17 14 11 8

7 O-ring, 24.0 x 3.0 [0.94 x 0.12] 18 16 14 12 10 8 6 4

8 O-ring, 20.0 x 3.0 [0.79 x 0.12] 9 8 7 6 5 4 3 2

9 O-ring, 14.0 x 2.0 [0.55 x 0.08] 16 14 12 10 8 6 4 2

Seal kit (includes item 5, 6, 7, 8, and 9) 11003451

E101 319E

520L0888 • Rev BB • Feb 2015

31

Service and Parts Manual PVG 100 Proportional Valves

Detent

Service parts

PVBS main spool

Friction

detent

10

3

11 mm

Mechanical

float

12 mm

8 Nm

[70 lbf·in]

8 Nm

[70 lbf·in]

9

3

1

Note: Spools must be installed with LS holes

on ‘B’ port side of PVB.

2

12 mm

1

7

8 Nm

[70 lbf·in]

5

1

8 Nm

[70 lbf·in]

4

4

3

4

5

4

3

Main spool

6

8 Nm

[70 lbf·in]

12.5 mm

6

Float

8

11

3

6

B-port

8 Nm

[70 lbf·in]

E101 320E

3

32

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVBS main spool

Type Description Code No.

PVBS Standard

PVBS Electric float position, B port

PVBS Mechanical float position, B port

PVBS Friction detent

Item Description Code No.

1 Main spool 1 1 1 1

2 Plug 1 1

3 O-ring, 6.0 x 1.5 [0.24 x 0.06] 2 2 2 2

4 Spring stop, black 2 2

5 Spring 1 1 1

5 Spring, hydraulic actuation 155L7504 1

6 Tension rod 1 1 1 1

7 Spring stop (float position), gold 1 1

8 Bushing (float position) 1 1

9 Float position, B port (item 3 included) 155L9152 1

10 Friction detent (item 3 included) 155L0390 1

11 Spring stop (float position), silver 1 1

E101 321E

520L0888 • Rev BB • Feb 2015

33

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVM, mechanical activation

4

6

5

8

9

10

9

4 mm

10

8

7.5 Nm

[66 lbf•in]

3 mm

8 Nm

[70 lbf•in]

7

2

10 mm

1

3

8 Nm

[70 lbf•in]

5 mm

34

8 Nm

[70 lbf•in]

13 mm

520L0888 • Rev BB • Feb 2015

6 mm

11

E101 322E

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVM, mechanical activation

Type Description Angle Code No.

PVM Adjustable 22.5° 157B3171

PVM Adjustable 37.5° 157B3172

PVM Adjustable, without lever and base - 157B3173

PVM Adjustable, without lever 37.5° 157B3174

PVM Adjustable, without lever 22.5° 157B3175

PVM Non-adjustable 22.5° 157B3191

PVM Non-adjustable 37.5° 157B3192

PVM Non-adjustable, without lever and base - 157B3193

PVM Non-adjustable, without lever 37.5° 157B3194

PVM Non-adjustable, without lever 22.5° 157B3195

Item Description Code No.

1 Seal nut 681X8270 2 2 2 2 2

2 Threaded pin 681X0323 2 2 2 2 2

3 Screw, M6 x 15 SHCS 4 4 4 4 4 4 4 4 4 4

4 O-ring, 5.0 x 2.0 [0.2 x 0.08] 2 2 2 2 2 2 2 2 2 2

5 Profile O-ring 1 1 1 1 1 1 1 1 1 1

6 Housing 1 1 1 1 1 1 1 1 1 1

7 Lever with nut 1 1 1 1

8 Base kit, 22.5° 155L3450 1 1 1 1

8 Base kit, 37.5° 1 1 1 1

9 Screw, M5 x 25 SS SHCS 1 1 1 1 1 1 1 1

10 Washer 1 1 1 1 1 1 1 1

11 Base/lever kit, 22.5° 155L3154 1 1

11 Base/lever kit, 37.5° 1 1

Seal kit (includes item 4 and 5) 157B3999 1 1 1 1 1 1 1 1 1 1

E101 323E

520L0888 • Rev BB • Feb 2015

35

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVH, PVMD, PVMF, and

PVMR covers

19 mm PVMR

11 mm PVMF

4 Nm

[35 lbf•in]

15 Nm

[133 lbf•in]

36mm

26

28

31

30

29

27

24

8 Nm

[70 lbf•in]

PVMR/

PVMF

5 mm

25

22

21

24

35

23

22

PVMD

24

33

22

32

21

PVH

36

E101 324E

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Service parts

PVH, PVM, PVMD, PVMF,

and PVMR covers

Type Description Code No.

PVMD Mechanical activated cover 157B0001

Hydraulic activated cover, G 1/4 - thread 157B0008

PVH

Hydraulic activated cover, 9/

PVMR Mechanical detent 157B0015

PVMF Mechanical float 157B0005

Item Description Code No.

21 Profile O-ring 1 1 1

22 O-ring, 5.0 x 2.0 [0.2 x 0.08] 1 1 4 4 1

23 Cover 1

24 Screw, M6 x 15 4 4 4 4 4

25 Cover (PVMF/PVMR) 1

26 O-ring, 19.3 x 2.4 [0.76 x 0.09] (PVMF/PVMR) 1 1

27 Plug (PVMF) 1

27 Plug (PVMR) 1

28 Ball, 5 mm [0.5] (PVMF/PVMR) 3 3

29 Spring (PVMR) 3

29 Spring (PVMF) 3

30 O-ring, 6.0 x 1.5 [0.24 x 0.59] (PVMF) 3

30 O-ring, 14.0 x 2.0 [0.55 x 0.08] (PVMR) 3

31 Plug (PVMF) 3

31 Plug (PVMR) 3

32 O-ring, 21.3 x 2.4 [0.84 x 0.09] 1 1

33 Cover, G

33 Cover, 9/

1

/4 - thread 1

16

- 18 UNF thread 1

35 Sealing plug, G 1/4 - thread 2

35 Sealing plug, 9/

16

- 18 UNF thread 2

Seal kit (includes item 21, 22, 26, 30, and 32) 157B3999 1 1 1 1 1

16

- 18 UNF thread 157B0007

E101 325E

520L0888 • Rev BB • Feb 2015

37

Service and Parts Manual PVG 100 Proportional Valves

Service parts

Electrical activation,

Hirschmann conn.

3

PVEH/PVES

5

6

5 mm

8 Nm

[70 lbf•in ]

PVEO/

PVEO-R

8 Nm

[70 lbf•in ]

5 mm

11

12

13

9

8

7

10

9

4

5

9

11

12

13

9

8

7

38

520L0888 • Rev BB • Feb 2015

10

9

9

E101 326E

Service and Parts Manual PVG 100 Proportional Valves

Service parts

Electrical activation,

Hirschmann conn.

On/O actuation Code No.

On/O, 12 volt, Hirschmann connector 157B4216

PVEO

On/O, 24 volt, Hirschmann connector 157B4228

On/O with ramp, 12 volt, Hirschmann connector 157B4217

PVEO-R

On/O with ramp, 24 volt, Hirschmann connector 157B4229

Proportional actuation Code No.

Standard, active fault monitoring, 11-32 volt, Hirschmann conn. 157B4032

PVEH

Standard, passive fault monitoring, 11-32 volt, Hirschmann conn. 157B4033

Float, active fault monitoring, 11-32 volt, Hirschmann conn. 157B4332

0% hysteresis active fault monitoring, 11-32 volt, Hirschmann conn. 157B4832

PVES

0% hysteresis passive fault monitoring, 11-32 volt, Hirschmann conn. 157B4832

Item Description Code No.

3 Electric plug, DIN 43650, gray, PG 11 984L3286 1 1 1 1 1

4 Electric plug, Din 43650, black, PG 9 984L3156 1 1 1 1

5 Screw, M6 x 33 4 4 4 4 4 4 4 4 4

6 Plug 1 1 1 1 1

7* O-ring, 30.0 x 2.5 [1.18 x 0.10] 1 1 1 1 1 1 1 1 1

8* O-ring, 8.0 x 2.0 [ .35 x 0.08] 1 1 1 1 1 1 1 1 1

9* O-ring. 10.0 x 2.0 [0.39 x 0.08] 3 3 3 3 3 3 3 3 3

10* Filter 1 1 1 1 1 1 1 1 1

11* O-ring, 4.0 x 1.0 [0.16 x 0.04] 3 3 3 3 3 3 3 3 3

12 Check valve 2 2 2 2 2 2 2 2 2

13 Orifice, 1.0 mm [0.04] 1 1 1 1 1

Orifice, 0.8 mm [0.03] 1 1 1 1

Seal kit (includes item 7, 8, 9, 10, and 11) 157B4997 1 1 1 1 1 1 1 1 1

E101 327E

520L0888 • Rev BB • Feb 2015

39

Service and Parts Manual PVG 100 Proportional Valves

Service parts

Electrical activation,

AMP connector

2

5

PVEA/PVEH/PVES

6

5 mm

5 mm

5

8 Nm

[70 lbf•in ]

8 Nm

[70 lbf•in ]

11

12

13

9

8

7

10

9

3

2

5 mm

8 Nm

[70 lbf•in ]

5

9

2

PVEA-DI/

PVEH-DI

6

PVED

40

PVEO/

PVO-R

11

12

10

9

520L0888 • Rev BB • Feb 2015

9

13

11

12

9

8

7

10

9

13

9

8

7

9

E101 332E

Service and Parts Manual PVG 100 Proportional Valves

Service parts

Electrical activation, AMP

connector

On/O actuation Code No.

On/O, 12 volt, AMP connector 157B4901

PVEO

On/O, 24 volt, AMP connector 157B4902

On/O with ramp, 12 volt, AMP connector 157B4903

PVEO-R

On/O with ramp, 24 volt, AMP connector 157B4904

Proportional actuation Code No.

Standard, active fault monitoring, 11-32 volt, AMP conn. 157B4734

PVEA

Standard, passive fault monitoring, 11-32 volt, AMP conn. 157B4735

Standard, active fault monitoring, 11-32 volt, AMP conn. 157B4736

PVEA-DI

Standard, passive fault monitoring, 11-32 volt, AMP conn. 157B4737

Standard, active fault monitoring, 11-32 volt, AMP conn. 157B4034

PVEH

Standard, passive fault monitoring, 11-32 volt, AMP conn. 157B4035

Standard, active fault monitoring, 11-32 volt, AMP conn. 157B4036

PVEH-DI

Standard, passive fault monitoring, 11-32 volt, AMP conn. 157B4037

0% hysteresis active fault monitoring, 11-32 volt, AMP conn. 157B4834

PVES

0% hysteresis passive fault monitoring, 11-32 volt, AMP conn. 157B4835

PVED 0% hyst., passive or acrive fault monitoring, 11-32 volt, AMP 157B4943

Item Description Code No.

2 AMP female connector, gray 157B4992 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

3 AMP female connector, black 157B4993 1 1 1 1 1 1

5 Screw, M6 x 33 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

6 Plug 1 1 1 1 1 1 1 1 1 1 1

7 O-ring, 30.0 x 2.5 [1.18 x 0.10] 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

8 O-ring, 8.0 x 2.0 [ .35 x 0.08] 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

9 O-ring. 10.0 x 2.0 [0.39 x 0.08] 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

10 Filter 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

11 O-ring, 4.0 x 1.0 [0.16 x 0.04] 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

12 Check valve 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

13 Orifice, 1.0 mm [0.04] 1 1 1 1 1 1 1 1 1 1 1

Orifice, 0.8 mm [0.03] 1 1 1 1

Seal kit (includes item 7, 8, 9, 10, and 11) 157B4997 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

E101 333E

520L0888 • Rev BB • Feb 2015

41

Service and Parts Manual PVG 100 Proportional Valves

Seal kits

Seal kits for PVG 100

Module Code No. Page No.

PVM / PVH / PVMD / PVMR / PVMF 157B3999 35, 37

PVEO/PVEA/PVEH/PVES/PVEH-DI/PVED 157B4997 39, 41

PVPV/PVPF/PVB/PVT/PVTI (for each sealing face) 11003451 29, 31

PVPP 35400321 19

PVPE 155G8527 19

P106 300E

42

520L0888 • Rev BB • Feb 2015

Service and Parts Manual PVG 100 Proportional Valves

Notes

520L0888 • Rev BB • Feb 2015

43

Products we oer:

Danf

already on order pr

All trademarks in this material are proper

Danfoss

Building #22, No. 1000 Jin Hai Rd

Danfoss

Power Solutions US Compan

2800 East 13th Street

Ames, IA 50010, USA

Phone:

y Bent Axis Motors

y Closed Circuit Axial Piston

Pumps and Motors

y Displays

y Electrohydraulic Power

Steering

y Electrohydraulics

y Hydraulic Power Steering

y Integrated Systems

y Joysticks and Control

Handles

y Microcontrollers and

Software

y Open Circuit Axial Piston

Pumps

y Orbital Motors

y P LUS+1® GUIDE

y Proportional Valves

y Sensors

y Steering

y Transit Mixer Drives

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile o-highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of o-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o-highway vehicles are at work, so is Danfoss.

We oer expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

+1 515 239 6000

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

520L0888 • Rev BB • Feb 2015

ovided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

Local address:

Danfoss

y

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

ty of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Power Solutions

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Loading...

Loading...