Installation Guide

L

[530 lbf•in]

]

orientation

Proportional valve

type PVG 100

Installation an plug

orientation

157R9 9 61

157R9 9 61

170*

60 Nm

[6.69]

A

118

[4.65]

T

P

B

100*

[4]

* Room for dismantling

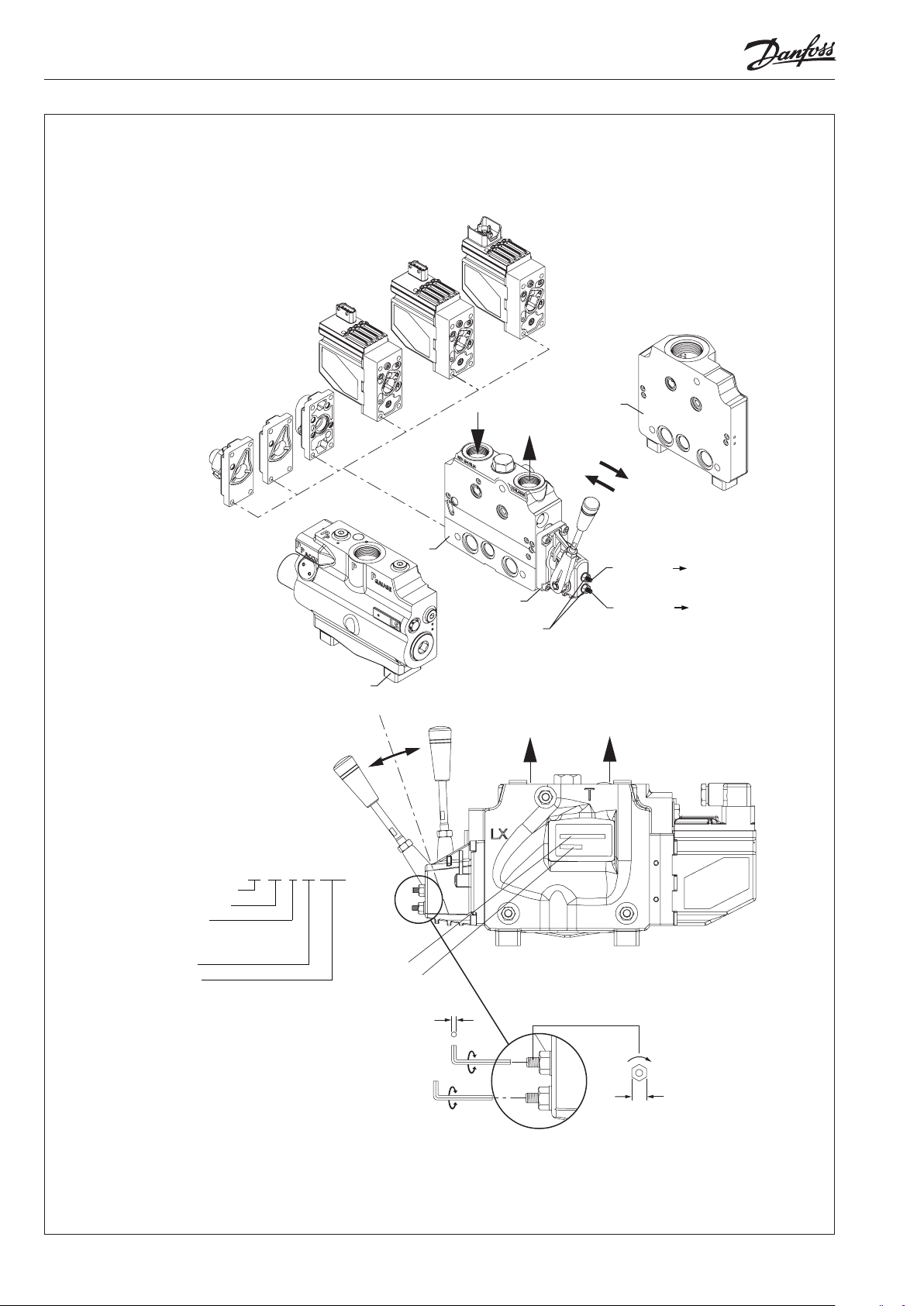

Modul og

PVB

L mm 80.0 128 .0 176.0 224.0 272.0 320.0 368.0 416 .0

L [in] [3.15 ] [5.04] [6.93] [8,82] [10.71] [12.60] [14. 49] [16 .3 8]

1 2 3 4 5 6 7 8

M12 x 14.0

4 places

PVP

170*

[6.69]

100*

[4]

60 Nm

[530 lbf•in

P106 000E

DIN mounting

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 1

Standard, Oil ow direction and setting of max ow

PVM on the A-port side

PVEA

PVEO

PVH

PVMD

PVMR/

PVMF

PVEH/

PVES

B

PVS

A

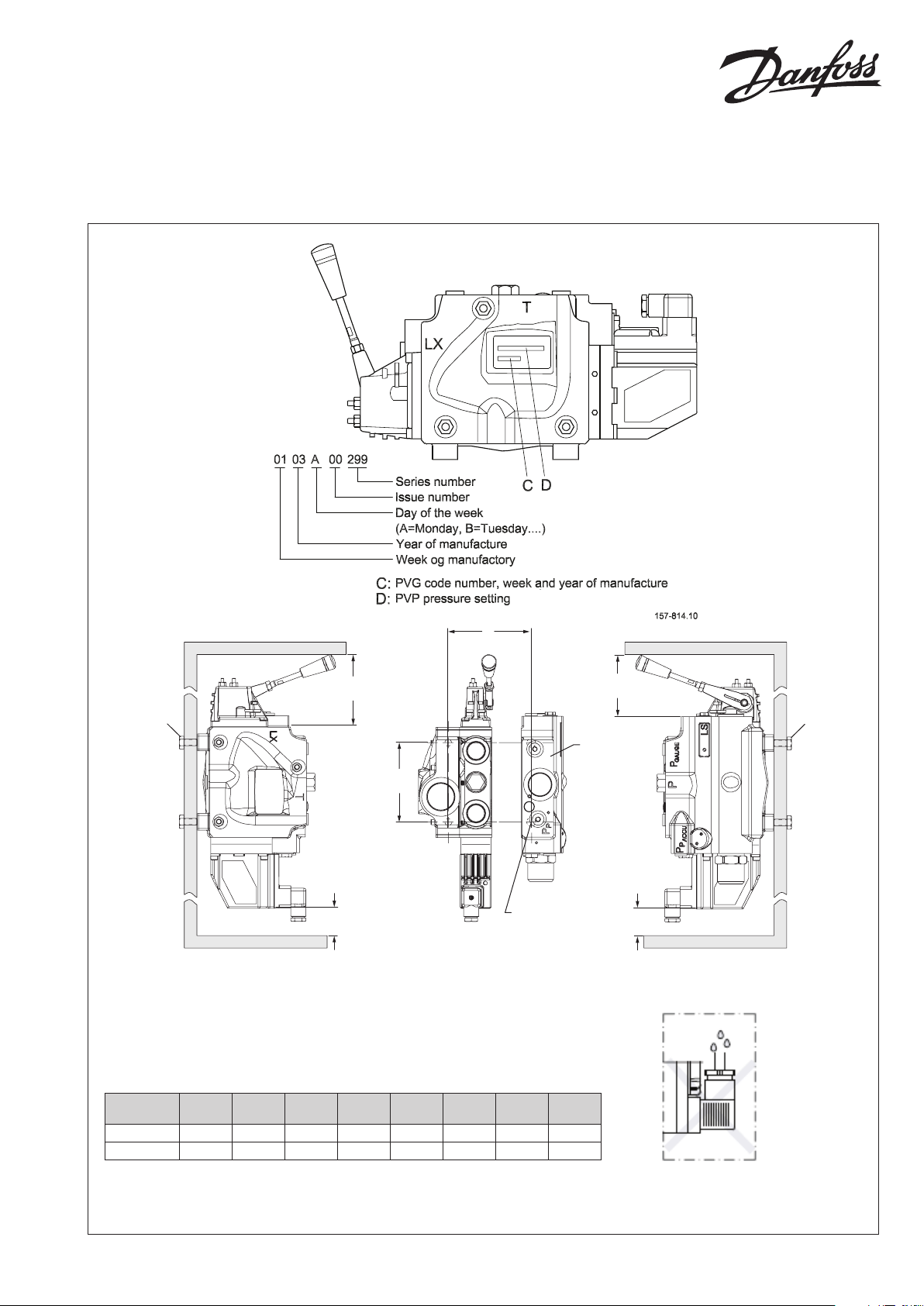

01 03 A 00 0299

Week of manufacture

Year of manufacture

Day of the week

(A = Monday, B = Tuesday ...)

PVP

Q max. B

PVB

Q max. A

PVM

6 ±1 N•m

[53 ±9 lbf•in]

Q max. A

P-A

P-B

Q max: P B

Q max: P A

Q max. B

Issue number

Series number

C: PVG code number, week and year of manufacture

D: PVP pressure setting

2 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

C

D

Q max. B

Q max. A

3 mm

+

+

10 mm

6 ±1 N•m

[53 ±9 lbf•in]

E101 279E

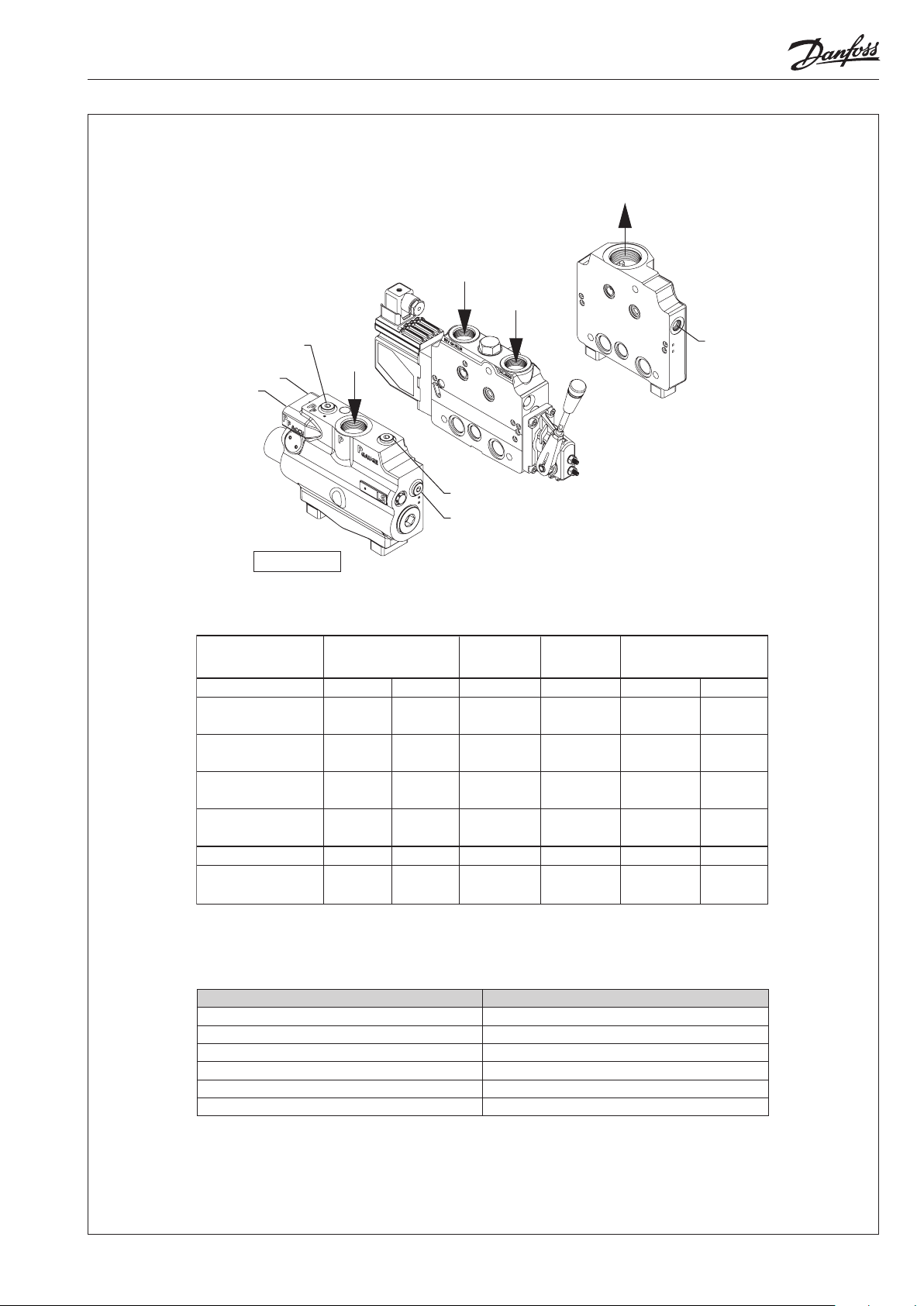

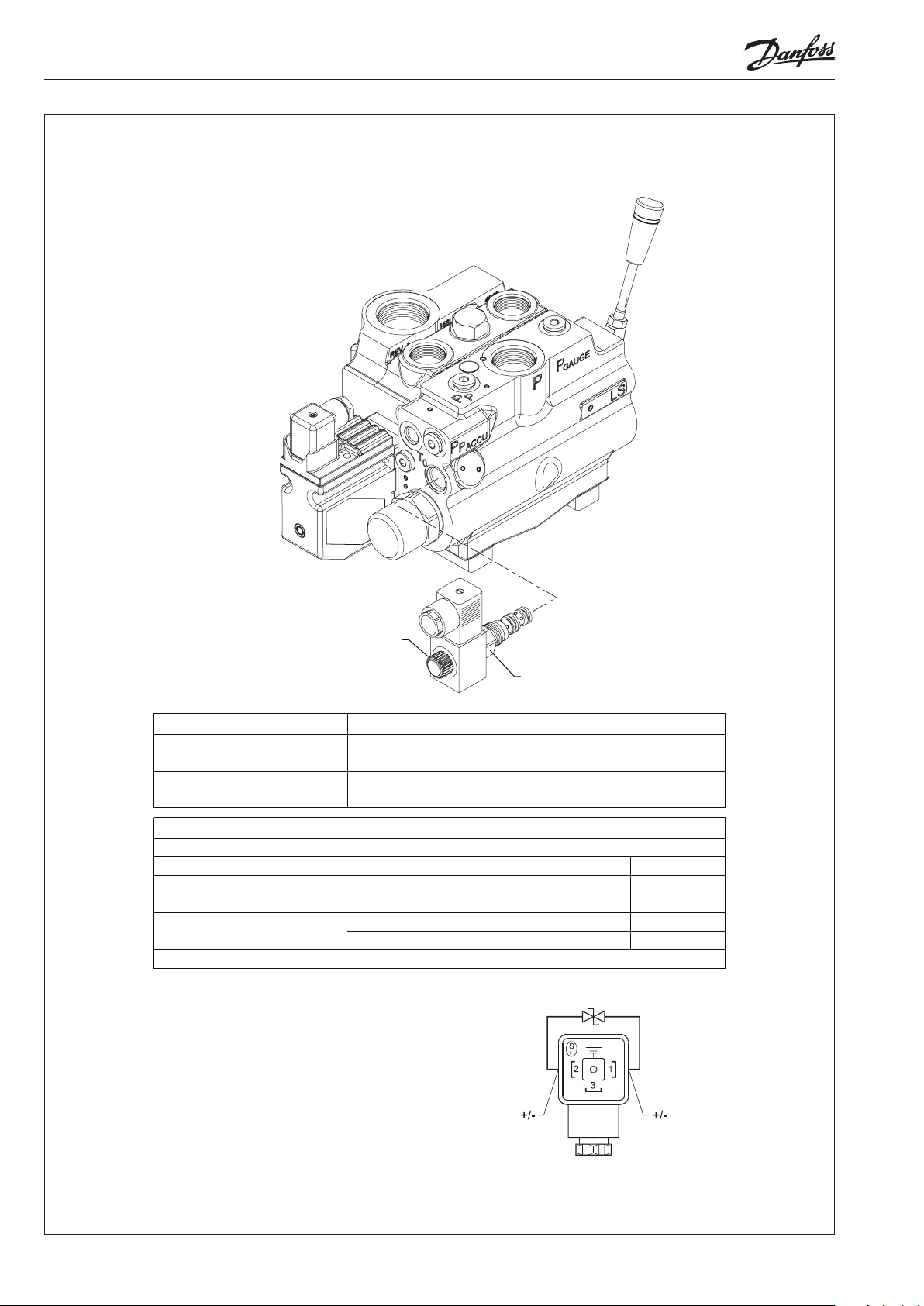

Connections, pump side modul, PVP

basic module PVB end plate, PVS

T

B

A

LX

PAccu

Pp gauge

(PVP-OC)

T0

P

Pp gauge

LS

PVP-OC shown

E101 285E

Maximum tightening torque

Connection

G 3/4 G 1 G 3/4 G 1/4 G 1 G 1 1/4

BSPP port connection

210 Nm 330 Nm 210 Nm 40 Nm 330 Nm 540 Nm

With steel washer

1850 lbf·in 2920 lbf·in 1850 lbf·in 350 lbf·in 2920 lbf·in 4780 lbf·in

50 Nm 70 Nm 50 Nm 20 Nm 70 Nm 100 Nm

With copper washer

445 lbf·in 620 lbf·in 445 lbf·in 180 lbf·in 620 lbf·in 885 lbf·in

110 Nm 150 Nm 110 Nm 30 Nm 150 Nm 240 Nm

With aluminum washer

970 lbf·in 1330 lbf·in 970 lbf·in 270 lbf·in 1330 lbf·in 2125 lbf·in

210 Nm 330 Nm 210 Nm 40 Nm 330 Nm 540 Nm

With cutting edge

1850 lbf·in 2920 lbf·in 1850 lbf·in 350 lbf·in 2920 lbf·in 4780 lbf·in

1 1/16 in-12 1 5/16 in-12 1 1/16 in-12 9/16 in-18 1 5/16 in-12 1 5/8 in-12

UNF port connection

120 Nm 160 Nm 120 Nm 40 Nm 160 Nm 320 Nm

With O-ring

1040 lbf·in 1420 lbf·in 1040 lbf·in 350 lbf·in 1420 lbf·in 2830 lbf·in

LS, LX, T0

P A/B Gauge: P, Pp, T

P

p Accum.

Rated pressure

Product Rated pressure

PVG 100 350 bar [5076 psi]

PVG 100 w. HIC steel 350 bar [5076 psi]

PVG 100 w. HIC aluminium 210 bar [3046 psi]

PVG 100/32 w. PVBZ 210 bar [3046 psi]

PVG 100/32 w. PVS 300 bar [4351 psi]

PVG 100/32 w. PVSI 350 bar [5076 psi]

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 3

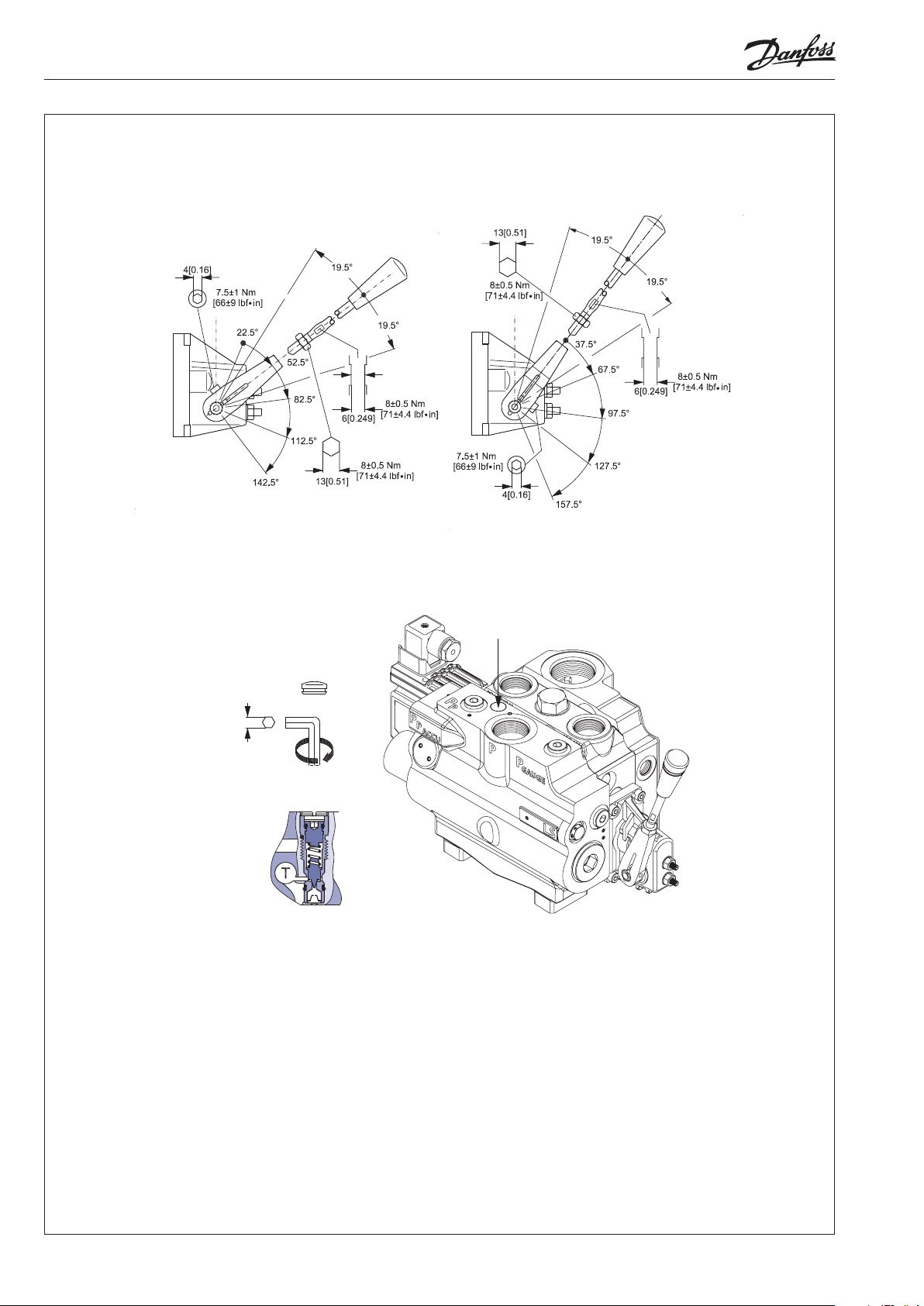

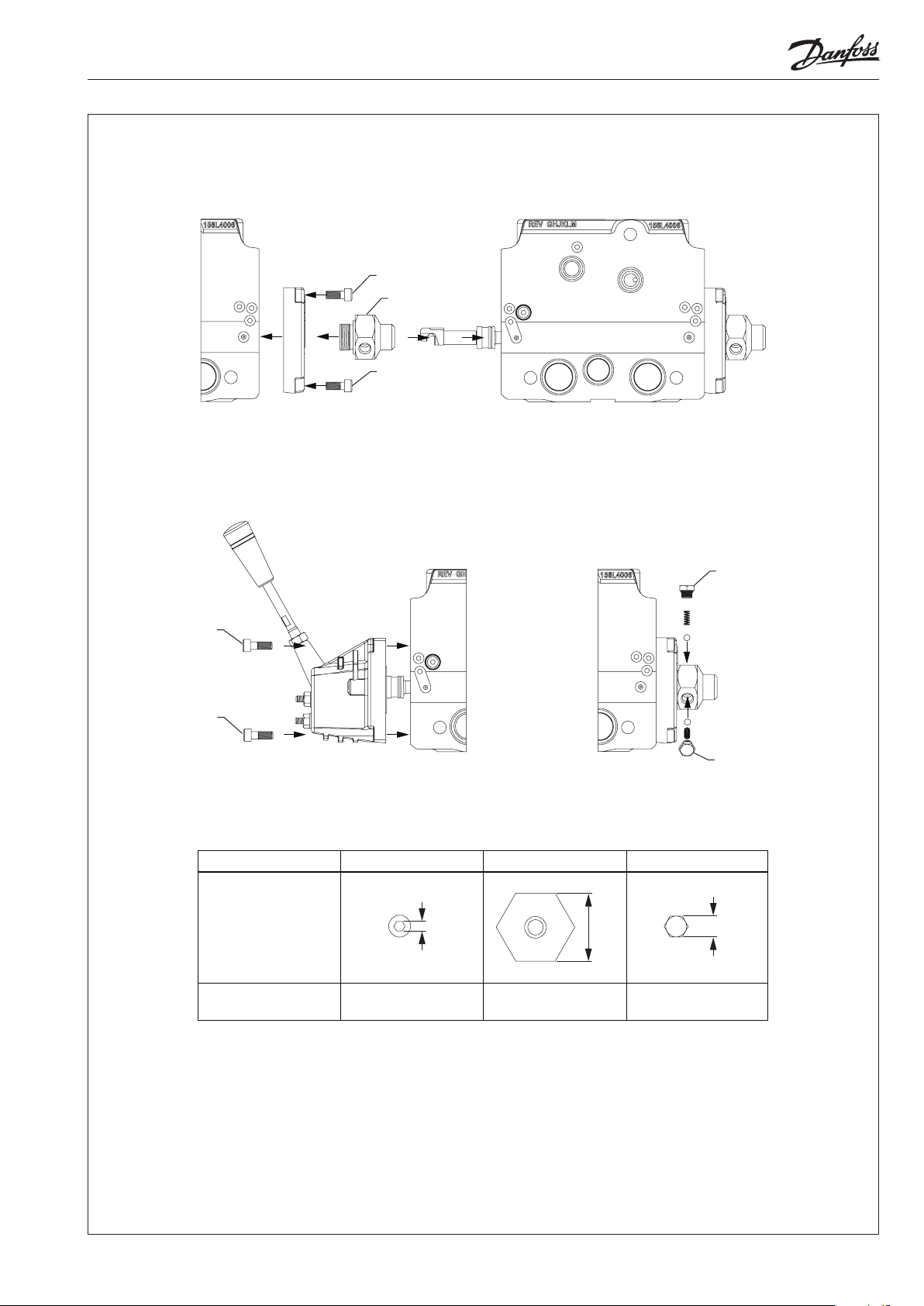

Installation of lever

Pressure setting

Base with an angle of 22.5° Base with an angle of 37.5°

P106 007E

4 mm

360° ~ 120 bar

360° ~ 1740 psi

PVP-CC

PVP-OC

P106 008E

4 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

PVEH/PVEM/PVES

Adjestment of PVE when

max. lever travel is

exceeded (PVE is factory

preset)

Check maximum lever travel in neutral position.

1. Make sure the system is supplied with hydraulic power.

2. Connect supply voltage (UDC) (Signal voltage 0.5 • UDC) or cut o th signal volatage (US) on

pin 2.

8

0

.

]

0

[

2

.

x

a

m

A

m

a

x

.

2

B

[

0

.

0

8

]

Lever travel exceeded in

Direction A

Direction B

PVG 100

Direction of rotation for adjustment of position transducer

Turn of transducer Movement of lever

1

/4

1

/2

3

/4

1.5 mm [0.06 in]

3.0 mm [0.12 in]

4.5 mm [0.18 in]

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 5

Installation and technical data for PVPP

(Solenoid operated pilot drain)

2

(coil nut)

1

(cartridge valve)

Position Max. tightening torque

Max. operation pressure 350 bar [5076 bar]

Max. coil surface temperature 155°C [311°F]

Rated voltage 12 V

Current consumtion

Power consumtion

Max. permissible deviation from rated supply voltage±10%

1

2

22°C (71,6°F) coil temperature1.55 A0.78 A

110°C (230°F) coil temperature1.00 A0.50 A

22°C (71,6°F) coil temperature19 W19 W

110°C (230°F) coil temperature12 W12 W

Across flats

24 mm 45 Nm

[0.94 in][400 lbf·in]

20 mm 5 Nm

[0.79 in][44 lbf·in]

__

––

24 V

__

––

When installing the wire remember to

connect the built-in diode to the plug

pins.

P106 004E

6 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

Installation and technical data for PVPE

(Solenoid relief valve)

2.5 mm

2 Nm

[17.5 lbf•in]

1

(coil nut)

2

(cartridge valve)

Position Max. tightening torque

Max. operation pressure 350 bar [5076 bar]

Max. coil surface temperature 155°C [311°F]

Rated voltage 12 V

Current consumtion

Power consumtion

Max. permissible deviation from rated supply voltage±10%

1

2

22°C (71,6°F) coil temperature1.55 A0.78 A

110°C (230°F) coil temperature1.00 A0.50 A

22°C (71,6°F) coil temperature19 W19 W

110°C (230°F) coil temperature12 W12 W

Across flats

22 mm 5 Nm

[0.87 in][45 lbf·in]

36 mm 85 Nm

[1.42 in][750 lbf·in]

__

––

24 V

__

––

When installing the wire remember to

connect the built-in diode to the plug

pins.

P106 288E

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 7

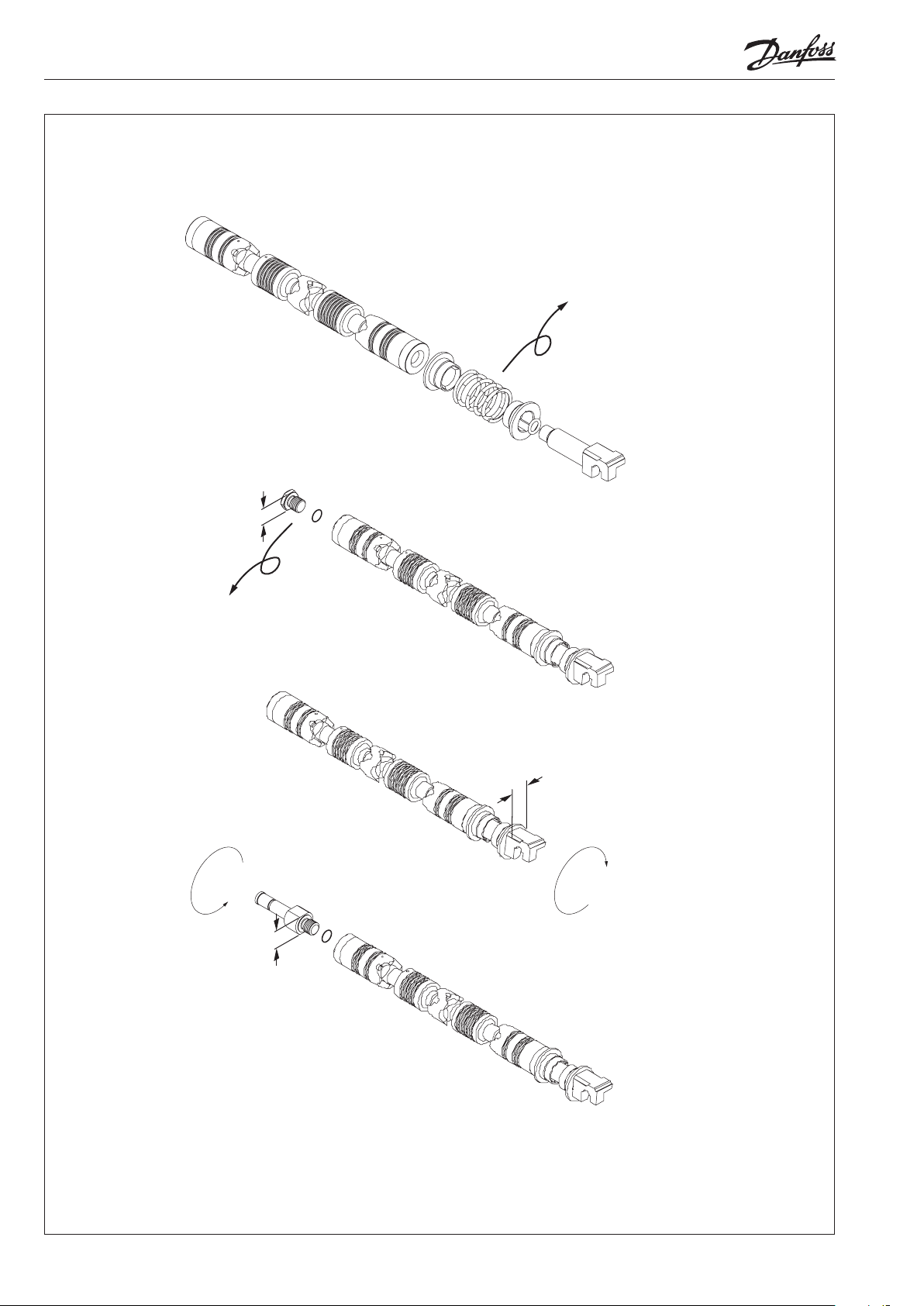

PVMR Disassembly

1. 2.

3.

4.

P106 005

8 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

PVMR/F Assembly

1.

2.

X

Y

X

3. 4.

Z

X

X

Z

Tightening torques and

widths across ats

XYZ

Width across flats

Tightening torque

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 9

8 ± 0.5 Nm 15 ± 2 Nm 4 ± 1 Nm

[70 ± 4.5 lbf·in][135 ± 20 lbf·in][35 ± 9 lbf·in]

5 mm

36 mm

11 mm PVMF

P106 006

19 mm PVMR

Standard main spool assembly

1.

for PVMR

2.

11 mm

3.

4.

8 Nm

[70 lbf·in]

12.5 mm

8 Nm

[70 lbf·in]

12 mm

10 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

Standard oat spool assembly

for PVMR

Not:

Spools must be installed with LS

holes on 'B' port side of PVB

A F

P

11 mm

8 Nm

[70 lbf·in]

12 mm

8 Nm

[70 lbf·in]

E101 290E

© Danfoss A/S, 2015-02 11038042 • Rev BC • Feb 2015 11

12 11038042 • Rev BC • Feb 2015 © Danfoss A/S, 2015-02

Loading...

Loading...