Page 1

Technical Information

PVG 100

Proportional Valve Group

www.danfoss.com

Page 2

Technical Information

PVG 100 Proportional Valve Group

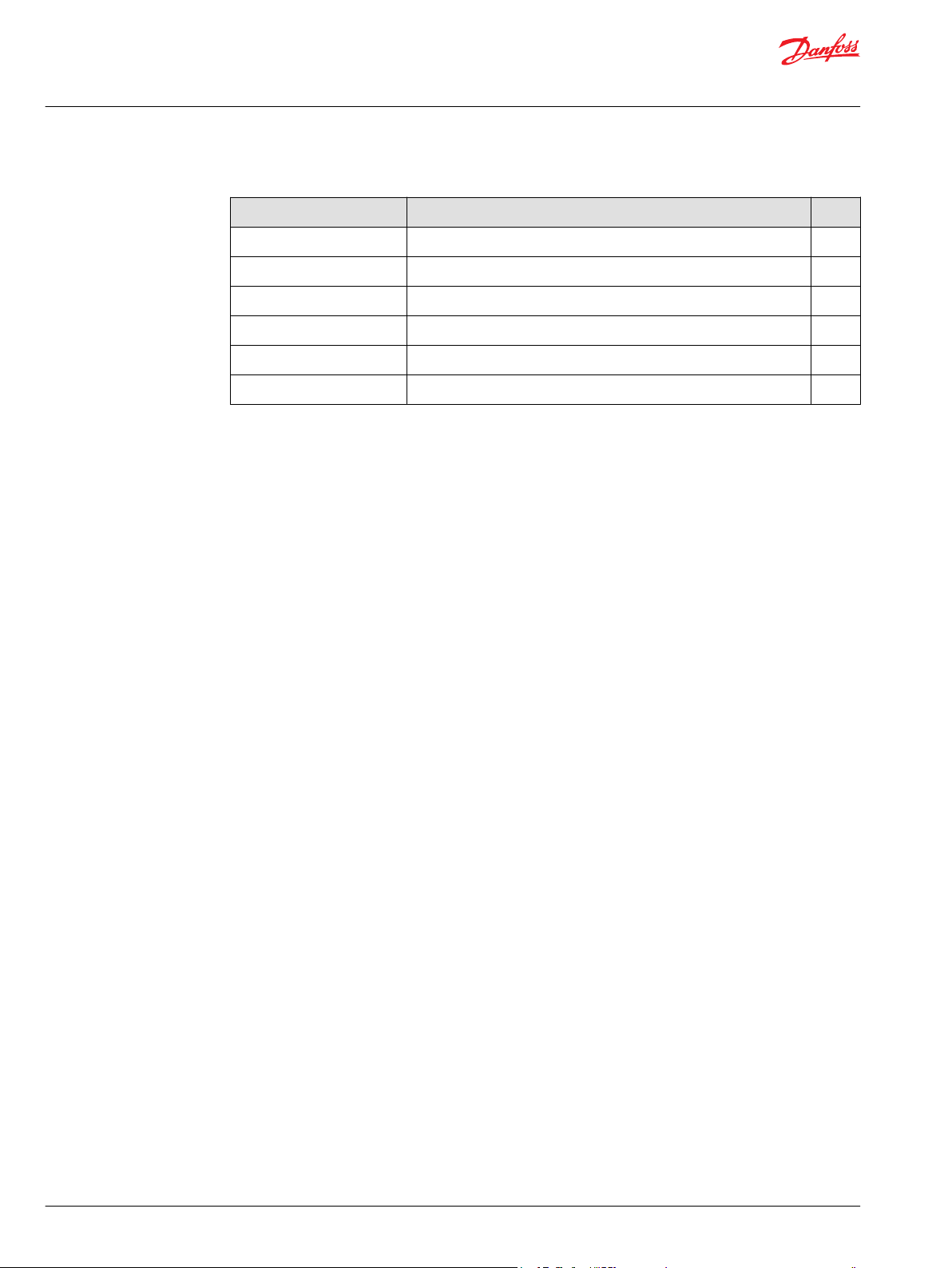

Revision history Table of revisions

Date Changed Rev

April 2021 Changed document number from 'BC00000039' to 'BC152886483475' 0606

September 2018 PVB 100 code numbers table change. 0503

May 2018 Minor change. 0502

March 2016 Updated for Engineering Tomorrow design. 0501

February 2006 - January 2014 Various changes BA - EB

February 2005 New Edition AA

2 | © Danfoss | April 2021 BC152886483475en-000606

Page 3

Technical Information

PVG 100 Proportional Valve Group

Contents

General information

Acronyms.............................................................................................................................................................................................6

General.................................................................................................................................................................................................7

PVG 100 standard oil flow direction/max flow setting..................................................................................................7

PVG 100 valve system................................................................................................................................................................7

General features PVG 100, load independent flow control.........................................................................................7

PVP - pump side module .........................................................................................................................................................8

PVB – basic module.................................................................................................................................................................... 8

Actuation module.......................................................................................................................................................................8

Remote control units ................................................................................................................................................................ 9

Function

PVG 100 with open center PVPF...............................................................................................................................................10

PVG 100 with closed center PVPV / PVPVP / PVPVM.........................................................................................................11

PVG 100 closed center priority steering PVPVP module ........................................................................................... 12

PVG 100 closed center PVPVM module ...........................................................................................................................12

PVG 100 basic modules PVB.......................................................................................................................................................12

PVG 100 tank modules ................................................................................................................................................................13

Load sensing controls...................................................................................................................................................................14

LS control with bleed orifice (do not use with PVG valves).......................................................................................14

Integral PC function.................................................................................................................................................................14

Load sensing system characteristics:.................................................................................................................................14

Remote pressure compensated controls.............................................................................................................................. 15

Remote pressure compensated system characteristics:............................................................................................ 15

PVG 100 main spool with pressure compensated control..............................................................................................15

Pressure compensated system characteristics.............................................................................................................. 16

Typical applications for pressure compensated systems.....................................................................................16

Typical applications for remote pressure compensated systems:..........................................................................16

PVMR, friction detent....................................................................................................................................................................17

PVMF, mechanical float position lock.....................................................................................................................................17

PVBS, main mpools for flow control (standard).................................................................................................................. 17

PVBS, main spools for flow control (with linear characteristic).....................................................................................18

Safety

Building in safety............................................................................................................................................................................19

FMEA (Failure Mode and Effect Analysis) IEC EN 61508............................................................................................. 19

Hazard and risk analysis ISO 12100-1/14121..................................................................................................................19

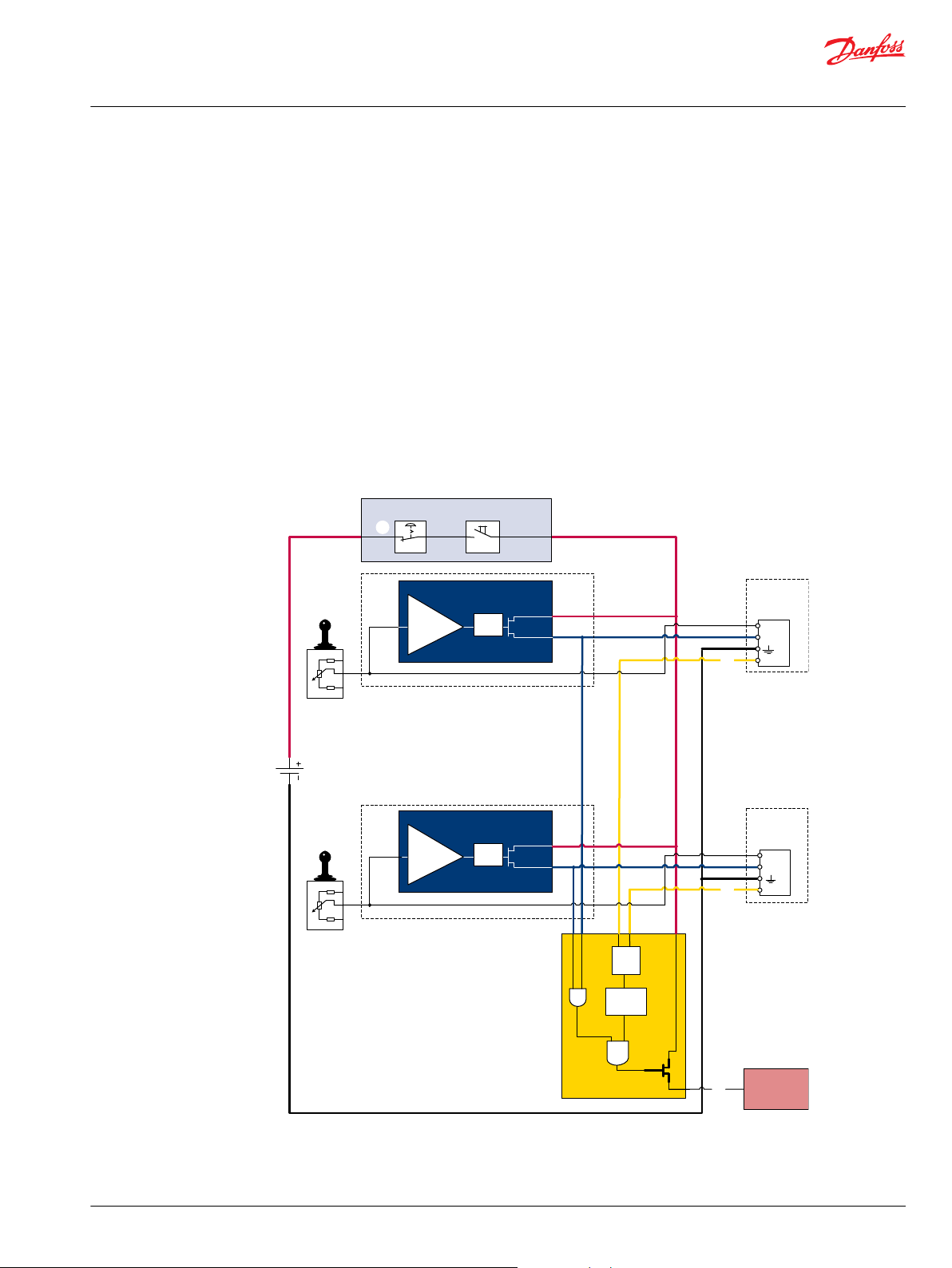

Example of a control system for manlift................................................................................................................................20

Examples of wiring block diagram.....................................................................................................................................21

Example of fault monitoring.................................................................................................................................................23

PVG 32 – Mainly used in system with fixed displacement pumps..........................................................................24

PVG 100 – Alternative LS dump or pilot supply disconnect..................................................................................... 24

PVG 120 – Pump disconnect/block for variable pumps.............................................................................................24

Technical data

PVG 100 technical data................................................................................................................................................................ 25

PVH, hydraulic actuation.............................................................................................................................................................25

PVG 100 PVM operating force................................................................................................................................................... 26

PVG 100 PVE reaction time and oil consumption.............................................................................................................. 26

PVEO power supply and consumption.............................................................................................................................27

PVEA, PVEH and PVES..............................................................................................................................................................27

Technical characteristics

PVPF, pump side module............................................................................................................................................................28

Open center flow rating.............................................................................................................................................................. 28

Closed center flow rating............................................................................................................................................................28

PVG 100 pressure drop for PVB, basic module....................................................................................................................29

PVB with pressure compensation, closed center PVP...................................................................................................... 30

PVHC characteristic - Spool stroke vs current......................................................................................................................33

Hydraulic systems

©

Danfoss | April 2021 BC152886483475en-000606 | 3

Page 4

Technical Information

PVG 100 Proportional Valve Group

Contents

PVG 100 with variable displacement pump schematic example................................................................................. 34

Electrically actuated PVG 100, variable displacement pump, PVB 100 with integrated pilot operated

check valves............................................................................................................................................................................. 34

Electrically actuated PVG 100/32, fixed displ. pump, PVB 100/32 with integrated pilot operated

check valves............................................................................................................................................................................. 35

Other operating conditions

Oil.........................................................................................................................................................................................................36

Mineral oil....................................................................................................................................................................................36

Non-flammable fluids............................................................................................................................................................. 36

Biodegradable oils....................................................................................................................................................................36

Particle Content, Degree of Contamination.........................................................................................................................36

Filtration............................................................................................................................................................................................ 36

Mounting

Standard mounting vs. option mounting.............................................................................................................................38

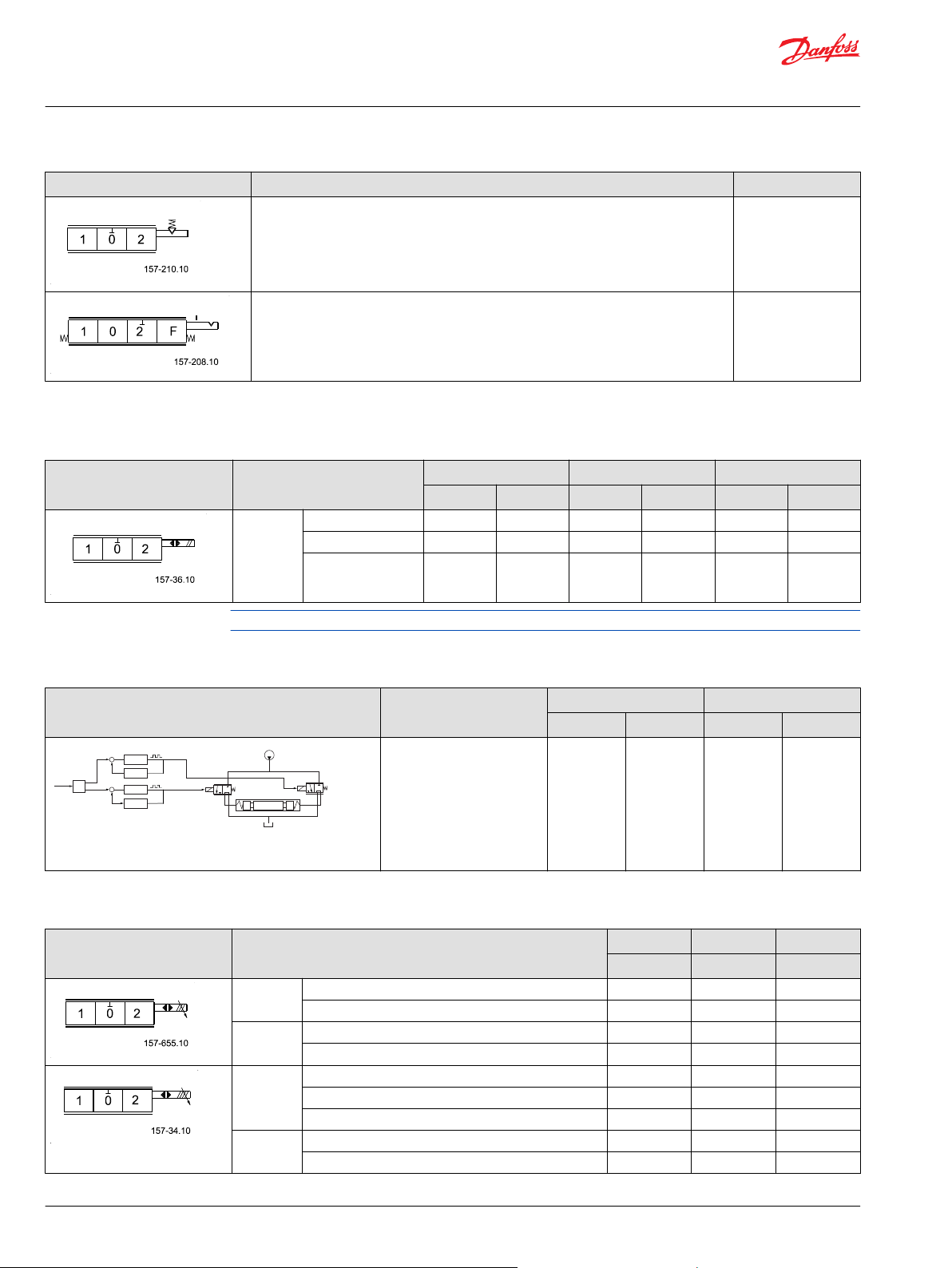

Modules and code numbers

PVPF (Open Center) Inlet Modules - for Pumps with Fixed Displacement .............................................................. 39

PVPF Accessories for Pump Side Modules............................................................................................................................39

PVP (Open and Closed) Accessories for Pump Side Modules........................................................................................40

PVPV (Closed Center) Inlet Modules....................................................................................................................................... 40

PVPVP, Closed Center Priority Side Modules - for Pumps with Variable Displacement.......................................41

PVPVM, Closed Center Mid Inlet Modules - for Pumps with Variable Displacement............................................ 41

PVB 100 Basic Modules (Standard Spools)............................................................................................................................42

PVB 100 Basic Modules (Exposed spools)..............................................................................................................................42

PVB 100 Basic Modules (High Flow Spools)..........................................................................................................................43

PVG 100 PVM code numbers..................................................................................................................................................... 43

PVM / PVH, Covers......................................................................................................................................................................... 43

PVEO, ON/OFF Actuation............................................................................................................................................................ 44

PVHC - main spool control.................................................................................................................................................... 44

PVEA/PVEH/PVES, Proportional Actuation............................................................................................................................44

PVLA, Anti-Cavitation Valve Fitted into PVB.........................................................................................................................45

PVLP, Shock / Anti-Cavitation Valve Fitted into PVB......................................................................................................... 46

PVT 100, Tank Module..................................................................................................................................................................46

PVTI 100/32, Interface Module*................................................................................................................................................ 47

PVG 100 PVSI / PVT, Assembly Kit.............................................................................................................................................47

PVBE (End Bodies), Assembly Kit.............................................................................................................................................. 47

PVG 100 / PVTI, Interface Module Assembly Kit..................................................................................................................47

PVB 32, Assembly Kit.....................................................................................................................................................................47

PVG 32 Basic Modules with T0, PVBZ (Compatible with PVG 100)...............................................................................48

PVG 32 Basic Modules with T0, PVB (Compatible with PVG 100)................................................................................. 49

Standard Spools for Electrical and Mechanical Actuation Progressive Flow Characteristics.............................50

Standard Spools for Hydraulic Actuation Progressive Flow Characteristics.............................................................50

Spools for Friction Detent, PVMR (not compatible with PVBZ 100) Progressive Flow Characteristics...........51

Spools for Mechanical Float position, PVMF (not compatible with PVBZ 100) Progressive Flow

Characteristics......................................................................................................................................................................... 51

Standard Spools (Electrical and Mechanical Actuation) Linear Flow Characteristics............................................51

Standard Spools (Electrical and Mechanical Actuation) Throttled Open in Neutral, Linear Flow

Characteristics......................................................................................................................................................................... 52

Standard Spools (Hydraulic and Mechanical Actuation), Throttled Open in Neutral, Linear Flow

Characteristics......................................................................................................................................................................... 52

Standard Spools (Electrical and Mechanical Actuation), Full Open in Neutral; Progressive Flow

Characteristics ........................................................................................................................................................................ 52

Standard Spools (Hydraulic and Mechanical Actuation), Full Open in neutral; Linear Flow

Characteristics ........................................................................................................................................................................ 52

High Flow Spools (Electrical and Mechanical Actuation) Progressive Flow Characteristics...............................53

High Flow Spools (Hydraulic and Mechanical Actuation) Progressive Flow Characteristics..............................53

High Flow Spools, Full Open A/B → T and Neutral; Progressive Flow Characteristics ........................................ 54

Exposed spools Progressive Flow Characteristics..............................................................................................................54

4 | © Danfoss | April 2021 BC152886483475en-000606

Page 5

Technical Information

PVG 100 Proportional Valve Group

Contents

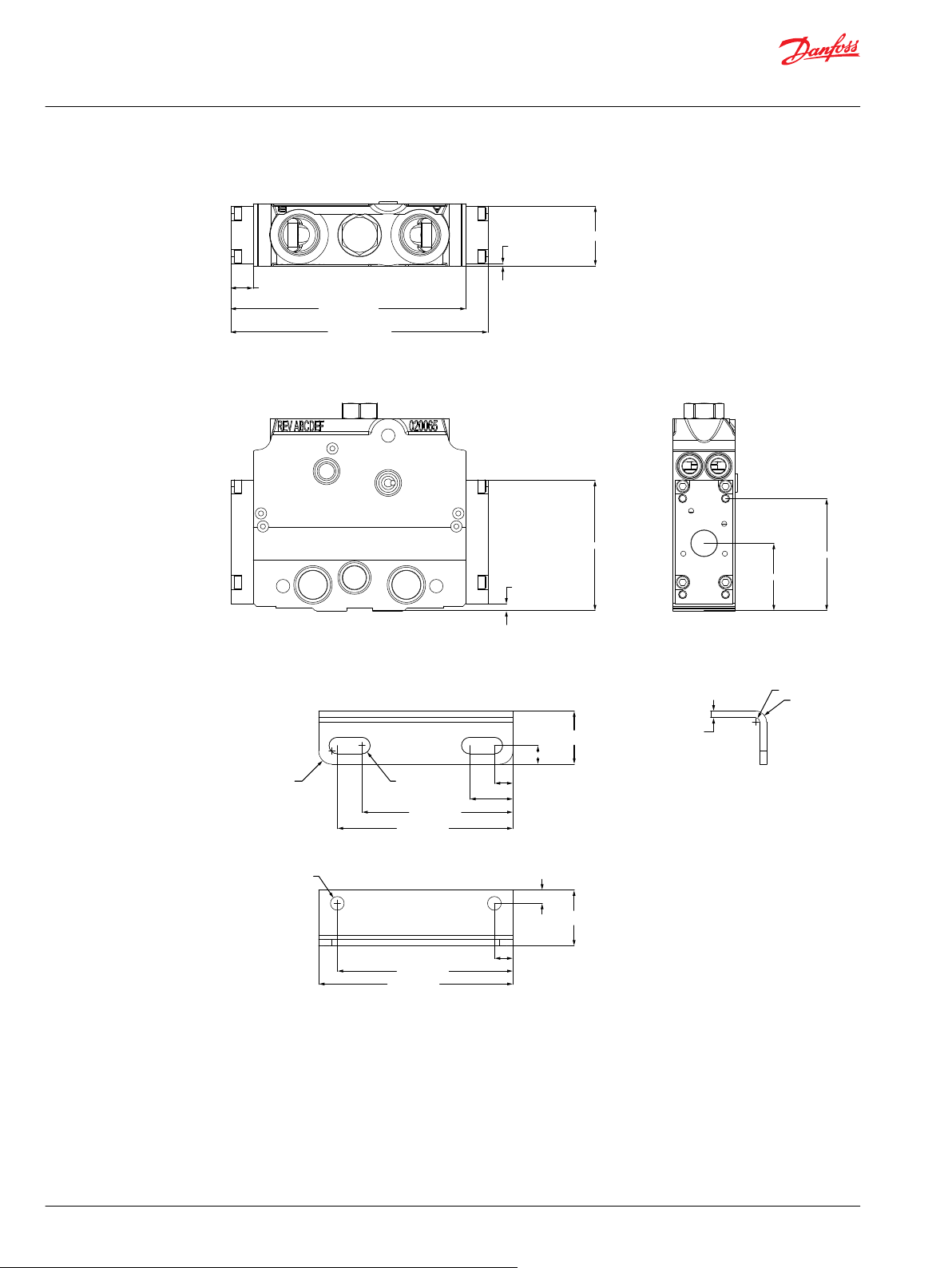

Dimensions

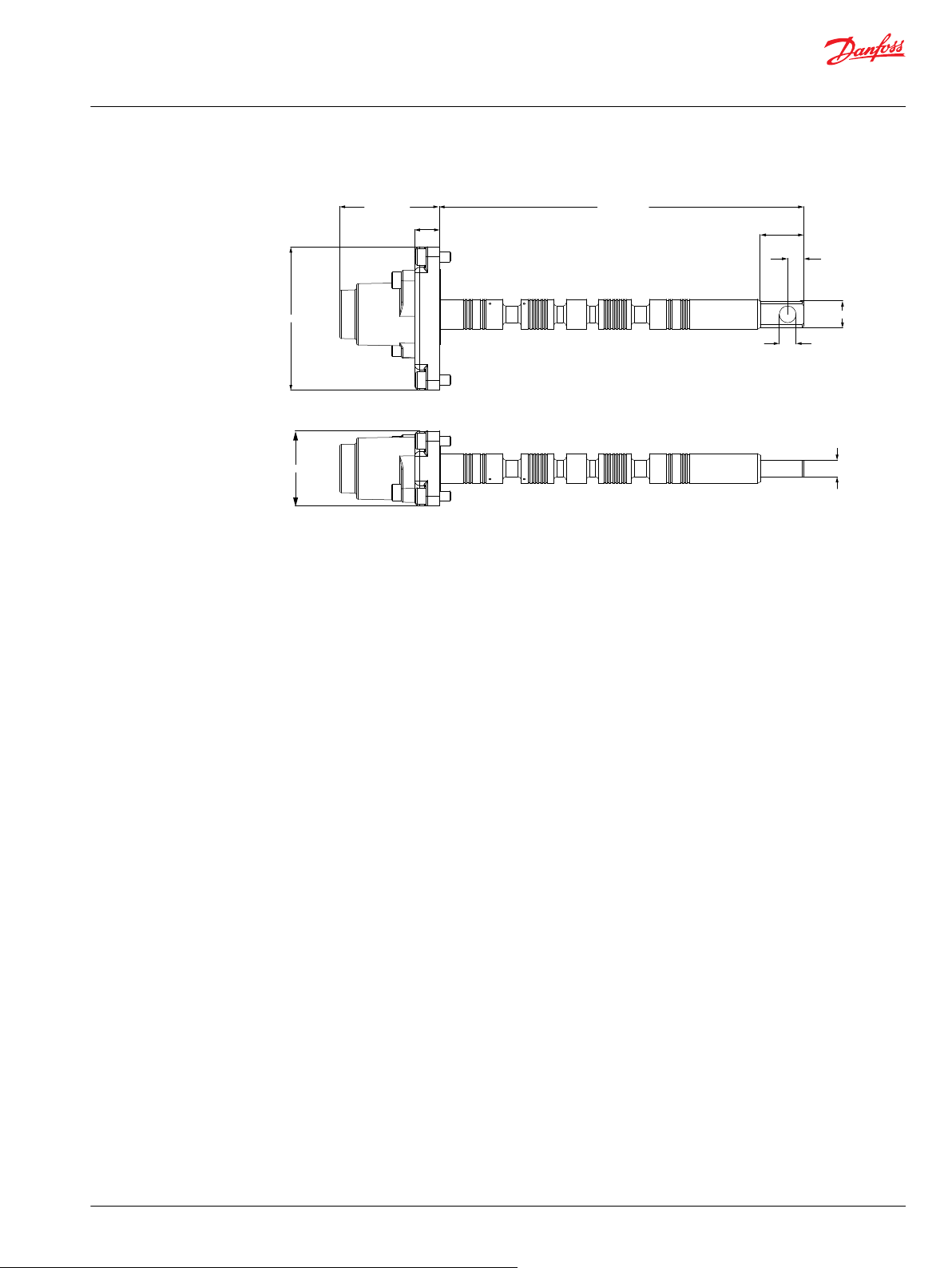

PVG 100 dimensions in general................................................................................................................................................55

PVG 100 with open center PVPF dimensions.......................................................................................................................56

PVG 100/32, closed center PVPV.............................................................................................................................................. 57

PVG 100, Closed Center PVP with Integrated Priority Valve ..........................................................................................58

Examples........................................................................................................................................................................................... 59

Module selection chart

Exploded view for module selection ..................................................................................................................................... 64

PVG 100 order specification

Please state.......................................................................................................................................................................................69

Standard and option assembly.................................................................................................................................................69

Reordering........................................................................................................................................................................................70

Specification sheet

Specification form..........................................................................................................................................................................71

Specification example for PVPVM............................................................................................................................................72

©

Danfoss | April 2021 BC152886483475en-000606 | 5

Page 6

Technical Information

PVG 100 Proportional Valve Group

General information

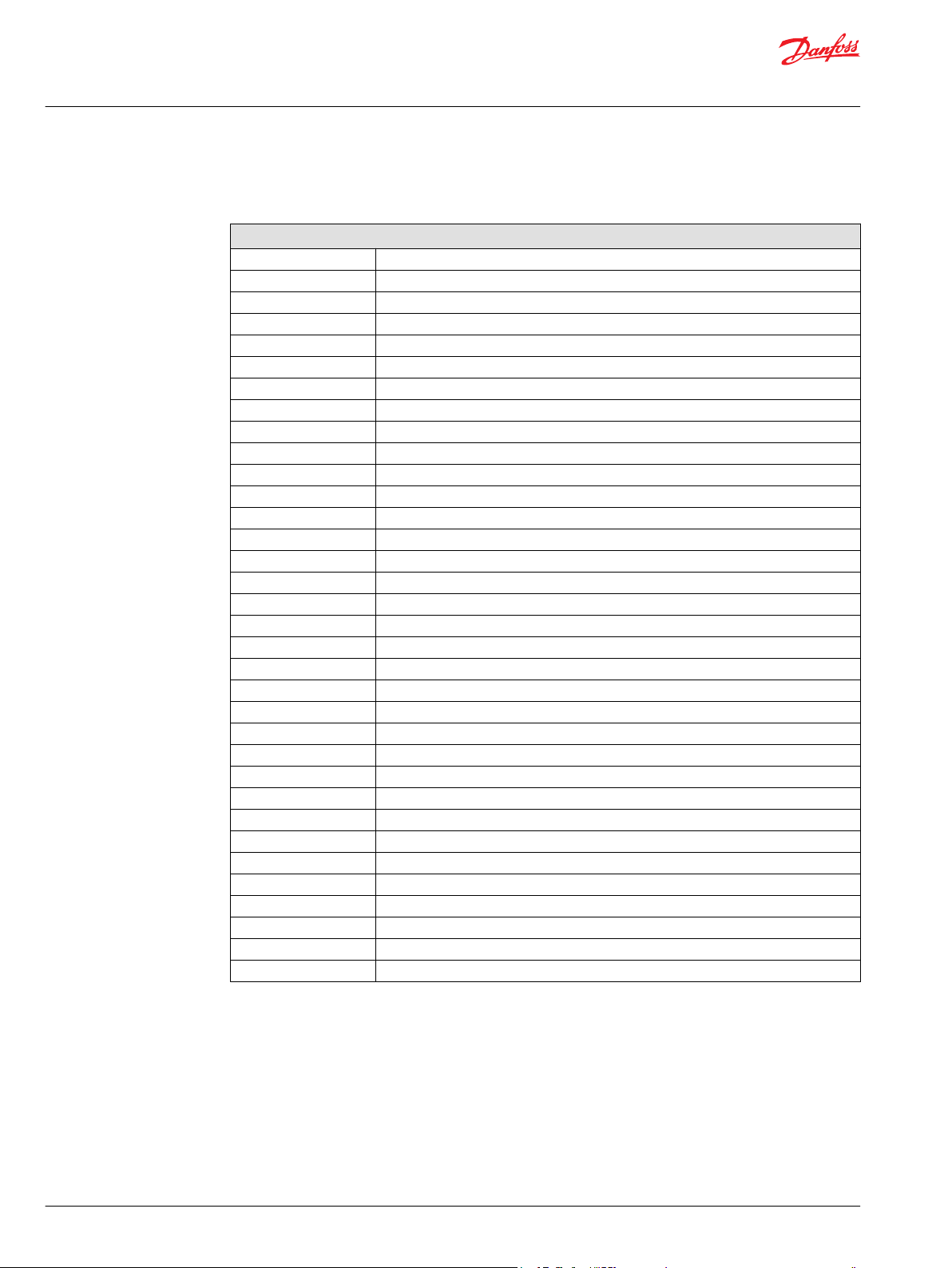

Acronyms

This table provides a definition of some commonly used terms

PVG = Proportional Valve Group

PVAS Assembly (Tie Rod) Kit

PVB Basic Module (Body)

PVBE Basic End Module (Body)

PVBO Basic Open Ended Module (Body)

PVBS Main Spool for PVB

PVBSO Main Spool for PVBO

PVBZ Basic Module (Body) Zero Leak

PVE Electrical Actuator

PVEA Electrical Actuator-Fine Proportional

PVED Electrical Actuator-Digital

PVEH Electrical Actuator-High Proportional

PVEO Electrical Actuator-ON/OFF

PVES Electrical Actuator-Super Proportional

PVH Cover for Hydraulic Actuation

PVHC Electrical Actuator-High Current

PVLA Anti-Cavitation Valve

PVLP Shock Valve

PVM Mechanical Actuator

PVMD Cover for Mechanical Activation

PVMF Cover for Mechanical Float

PVMR Cover for Friction Detent

PVP Pump Side Module (Inlet)

PVPC Plug for external pilot oil supply

PVPD Open Center PVPF Dummy Spool

PVPE Electrical Unloading Valve for PVPF

PVPF Open Center PVP

PVPH Hydraulic Unloading Valve for PVPF

PVPP Electrical Pilot Shut-Off Valve

PVPV Closed Center PVP

PVPV/M Pump side module

PVPVP Closed Center PVP w/Priority

PVPX, LS LS Unloading valve

PVT Tank Side Module

PVTI Interface Module

6 | © Danfoss | April 2021 BC152886483475en-000606

Page 7

PVEH/PVES

PVEA

PVEO

PVH

PVMD

PVMR/PVMF

PVP

PVM

PVB

PVT

B

A

P-A

P-B

7-9 N•m

[61-79 lbf•in]

Q max: P B

Q max: P A

Technical Information

PVG 100 Proportional Valve Group

General information

General

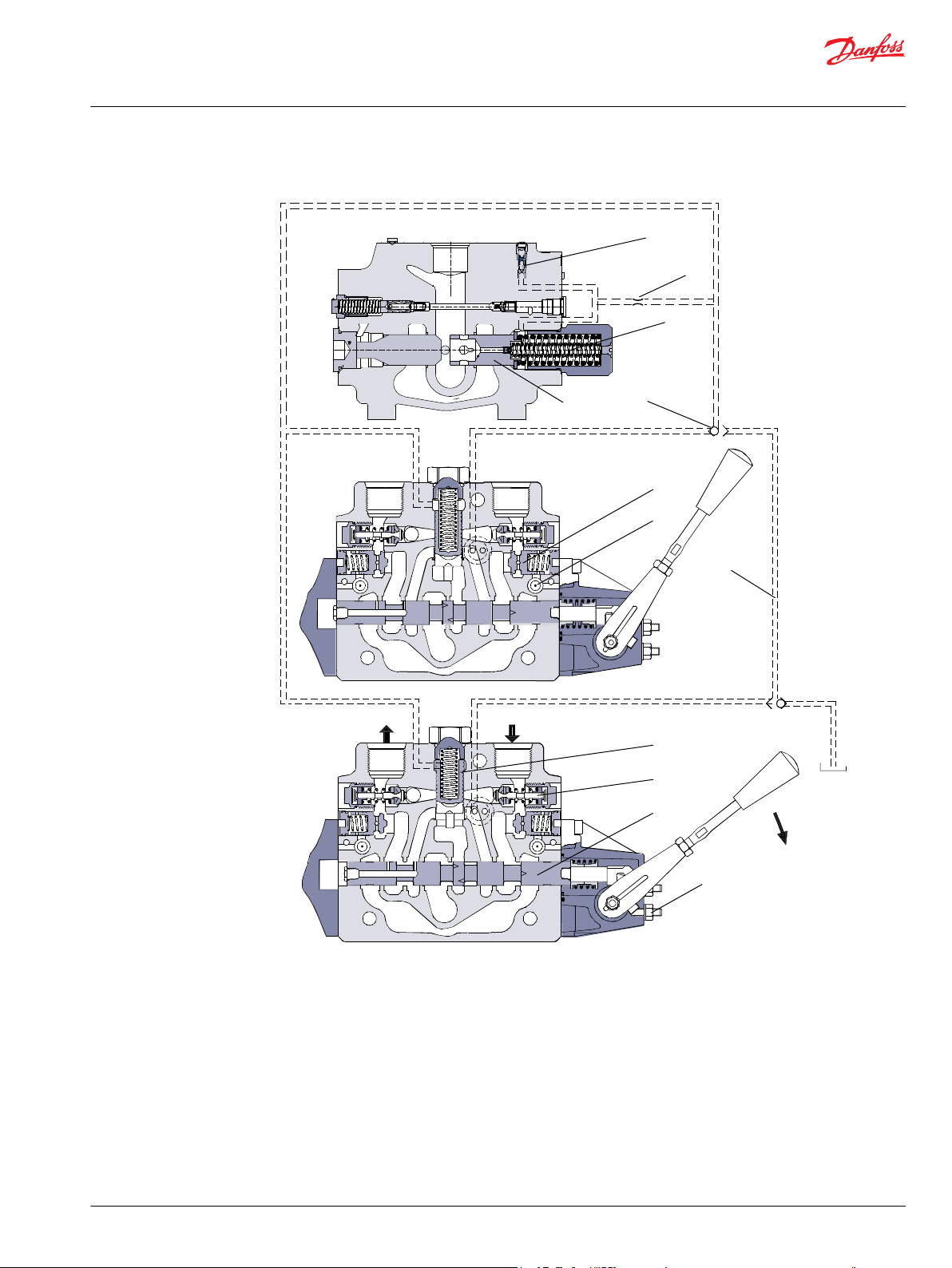

PVG 100 standard oil flow direction/max flow setting

Adjustment screws are used to change the amount of oil flowing from ports P to B or P to A.

PVM to the right of PVP

PVG 100 valve system

PVG 100 is a hydraulic load sensing valve, designed to fulfill efficiency requirements.

From a simple load sensing directional valve to an advanced electrohydraulic controlled load

independent proportional valve the PVG 100 modular system makes it possible to build up a valve group

to fulfill customer requirements. The compact external dimensions of the valve remain unchanged

whatever combination is specified.

General features PVG 100, load independent flow control

Flow sharing for maximum controllability and safety

•

Load-independent flow control for precise operation and improved productivity

•

Oil flow to an individual function is independent of the load pressure of this function regardless of

‒

sufficient or insufficient pump flow.

Oil flow to one function is independent of the load pressure of other functions regardless of

‒

sufficient or insufficient pump flow.

Load-sensing technology for higher efficiency, safety, reduced energy consumption, and longer

•

system lifetime

Configurable as an advanced electrical, hydraulic or mechanically operated proportional load-sensing

•

valve

Open spool-ends for system integrating mechanical cable or linkage actuation

•

©

Danfoss | April 2021 BC152886483475en-000606 | 7

Page 8

Technical Information

PVG 100 Proportional Valve Group

General information

Modular design providing a wide range of configuration possibilities

•

Up to eight different sections per valve group (maximum flow per section: 240 l/min [63.4 gal/min])

•

Can be configured in combination with PVG 32 (with T0) for maximum flexibility (up to 20 basic valve

•

modules per valve group)

Optimized return flow characteristics, which minimizes pressure loss

•

Low weight

•

Compact design and installation

•

BSP and UNF connection threads

•

PVP - pump side module

Build in load sense relief valve

•

System pressure up to 350 bar (5075 psi)

•

Full Flow dump valve (open center only)

•

Pilot supply shut off (optional) ••Accumulator gauge connection

•

Pressure gauge connection

•

Pilot gauge connection

•

Integrated pilot supply valve

•

Versions:

•

Open center version for systems with fixed displacement pumps

‒

Closed center versions for systems with variable displacement pump

‒

Integrated priority valve for dynamic steering integration

‒

PVB – basic module

Integrated pilot operated check valves in A and B work ports for low internal leakage

•

Integrated pressure compensator

•

Interchangeable spools

•

Single and Dual Shock/suction valves for A and B ports

•

Different interchangeable spool variants

•

All versions suitable for mechanical, hydraulic and electrical actuation

•

Versions:

•

PVG100-HF (High Flow) version for less total pressure loss at increased flow

‒

End module version for extra space savings

‒

Open spool-end version for extended mechanical actuation possibilities

‒

Actuation module

The basic module is always fitted with mechanical actuator PVM, which can be combined with the

following as required:

Electrical actuator (11 – 32 V

•

PVES – proportional, Super

‒

PVEH – proportional, high performance

‒

PVEH-F – proportional high performance, Float

‒

PVEA – proportional low hysteresis (not recommended for PVG 100-HF High Flow)

‒

PVEM – proportional, medium performance

‒

PVEO – ON/OFF

‒

PVEU – proportional, voltage control, 0-10 V

‒

AC/DC

):

8 | © Danfoss | April 2021 BC152886483475en-000606

Page 9

PVRE, electrical control unit, 162F…

Prof 1, 162F…

PVREL, electrical control unit, 155U…

PVRES, electrical control unit, 155B…

PVRH, hydraulic control unit, 155N…

155N0003 155N0001 155N0004 155N0005 155N0002

Technical Information

PVG 100 Proportional Valve Group

General information

PVED-CC – Digital CAN controlled J1939/ISOBUS

‒

PVED-CX – Digital CAN controlled CAN open extra vehicle system safety

‒

PVEP – PVM controlled (11-32 V)

‒

PVHC – High Current actuator for PVG

‒

PVMD, cover for Mechanical actuation

•

PVMR, cover for Mechanical detent (not compatible with PO check modules)

•

PVMF, cover for Mechanical Float (not compatible with PO check modules)

•

PVH, cover for Hydraulic actuation.

•

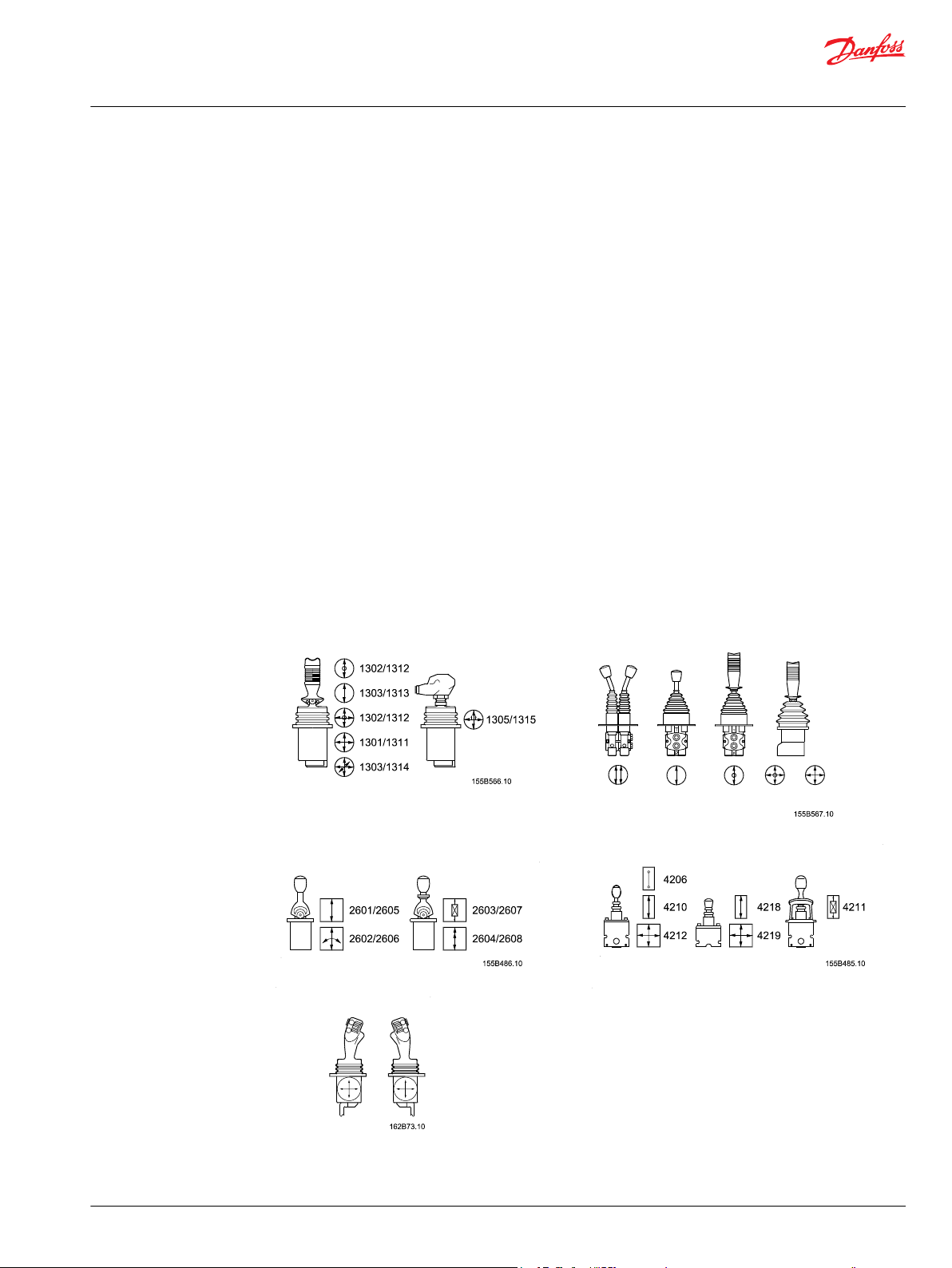

Remote control units

Electrical remote control units:

•

‒

PVRE, PVRET

‒

PVREL

‒

PVRES

‒

Prof 1

‒

Prof 1 CIP

‒

JS120

Hydraulic remote control unit: PVRHH

•

Electrical and hydraulic remote control units

‒

JS1000 Ball grip

‒

JS1000 PRO grip

‒

JS2000

‒

JS6000

‒

JS7000

©

Danfoss | April 2021 BC152886483475en-000606 | 9

Page 10

Technical Information

PVG 100 Proportional Valve Group

Function

PVG 100 with open center PVPF

When the pump is started and the main spools in the individual basic modules are in the neutral position,

oil flows from the pump, through connection P, across the pressure matching spool (11) to tank. The oil

flow led across the pressure matching spool determines the pump pressure (stand-by pressure).

When one or more of the main spools are actuated, the highest load pressure is fed through the shuttle

valve circuit (4, 7) to the spring chamber (10) behind the pressure matching spool, and completely or

partially closes the connection to tank. Pump pressure is applied to the opposite side of the pressure

matching spool. The pressure relief valve (1) will open should the load pressure exceed the set value,

diverting pump flow back to tank.

Optional PVPC with check valve option may be used in systems where it is necessary to operate the PVG

100 valve by means of the electrical remote control without pump flow.

For additional information about PVPC refer to the publication BC152886483664.

Optional electrically actuated pilot shut off valve PVPP provides additional functional system safety by

removing pilot oil from the electrical actuation or hydraulic actuation system, disabling main spool

actuation. When the PVPP is used with the PVBZ P.O. check valve system it is possible to disable actuation

during mechanical actuation

10 | © Danfoss | April 2021 BC152886483475en-000606

Page 11

B A

B A

B

9

8

7

6

3

5

4

T T

P

T T

P

1

10

12

11

2

T

P

P

Port

PVPD / PVPE

Facility

Pilot

Supply

Pressure Matching

Spool

Technical Information

PVG 100 Proportional Valve Group

Function

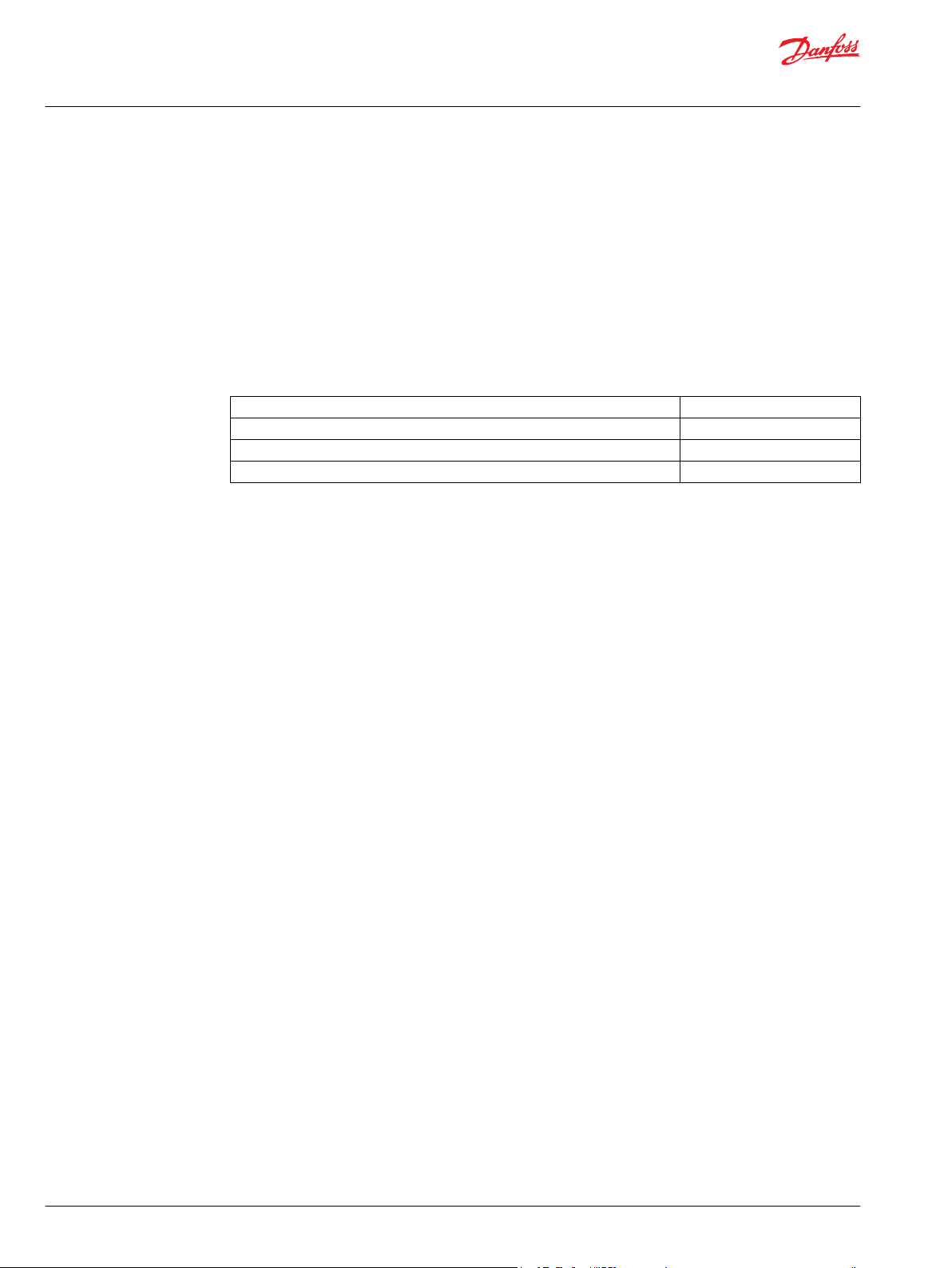

PVG 100 sectional view PVP with open center

1 – LS relief valve 7 – Shock and suction valve, PVLP

2 – Shuttle valve 8 – Main spool, PVBS

3 – Pilot operated check valve, POC 9 – Max. oil flow adjustment screws for ports A and B

4 – LS line 10 – Spring 12 or 20 bar

5 – Logic cartridge for POC 11 – Pressure matching spool

6 – Pressure compensator 12 – Orifice

PVG 100 with closed center PVPV / PVPVP / PVPVM

In load sensing systems the load pressure is led to the pump control via the LS connection (2 in the

diagram below). When the work functions are in the spring neutral position the LS pressure is drained to

©

Danfoss | April 2021 BC152886483475en-000606 | 11

Page 12

Technical Information

PVG 100 Proportional Valve Group

Function

tank via the PVG valve. In this condition the pump control sets the displacement so that leakage in the

system is compensated for, to maintain the set stand-by pressure (pump margin). When a main spool is

actuated the pump control will adjust the displacement so that the set differential pressure between P

and LS is maintained.

The PVG100 Inlet LS relief valve (1) is specifically designed to ensure a constant margin pressure across

the main spool, providing demanded regulated flow during maximum load pressure conditions. This

relief adjustment is critical when there are two or more functions being operated together. An incorrectly

adjusted Inlet relief could result in a vast reduction in regulated flow from the adjacent functions that

operate at a lower load pressure. To accurately adjust the inlet LS relief, the pump standby pressure must

be known in addition to the maximum operating load pressure.

Example

Pressure comp pressure level 172 bar [2500 psi]

LS standby pressure requirement that delivers the desired flow -20 bar [-290 psi]

Maximum load pressure requirement 152 bar [2210 psi]

Inlet relief pressure setting 152 bar [2210 psi]

Optional PVPC with check valve option may be used in systems where it is necessary to operate the PVG

100 valve by means of the electrical remote control without pump flow.

For additional information about PVPC refer to publication BC152886483664.

Optional electrically actuated pilot shut off valve PVPP provides additional functional system safety by

removing pilot oil from the electrical actuation or hydraulic actuation system, disabling main spool

actuation. When the PVPP is used with the PVBZ P.O. check valve system it is possible to disable actuation

during mechanical actuation.

PVG 100 basic modules PVB

PVG 100 closed center priority steering PVPVP module

The priority steering version of the PVPV will accommodate pump flows up to 250 l/min [66 US gal/min]

and Control Flow (CF) up to 60 l/min [16 US gal/min] for dynamic steering systems. Additional return port

is included with the PVPVP module.

PVG 100 closed center PVPVM module

The mid-inlet version of the PVPV will accommodate pump flows up to 400 l/min [106 US gal/min]

providing greater efficiency and flexibility when combined with standard and high flow work function

modules.

In the pressure-compensated basic module the compensator (9) maintains a constant pressure drop

across the main spool (11) - both when the load changes and when a module with a higher load pressure

is actuated.

Besides independent flow the other advantage of post-compensated work sections is the ability to

control multifunction operation when flow demand exceeds pump capacity. This means that all work

sections will continue to function regardless of differences in their load and regardless of the pump flow.

The flow relationships specified between functions will be maintained over the full flow range of the

pump.

The shock valves PVLP (10) with fixed setting and the suction valves PVLA on ports A and B are used for

the protection of the individual working function against intermittent pressure overload and/or

cavitation. Optional facilities for dual shock valves for ports A and B provide extra passage area reducing

pressure drop for anti-cavitation applications.

Pilot operated check valve system PVBZ option (6, 8) on ports A and B are uses to reduce the work port to

tank leakage eliminating the need for external actuator load holding in non-critical load holding

applications. All PVG 100 modules contain an integrated T0 drain system to insure optimal performance

12 | © Danfoss | April 2021 BC152886483475en-000606

Page 13

Technical Information

PVG 100 Proportional Valve Group

Function

for PVBZ and all electrical actuation offerings. T0 is most effective when connected directly to the

hydraulic system reservoir independent of the main Tank return system.

PVG 100 tank modules

Designed for low pressure drop at high return flows all PVT modules include facilities for PVLP shock

valves insuring pressure passage spike protection during pump starvation recovery.

1 – LS relief valve 8 – Logic cartridge for POC

2 – LS connection 9 – Pressure compensator

©

Danfoss | April 2021 BC152886483475en-000606 | 13

Page 14

0

0

P101 968E

PC setting

Flow

Pressure

Q max

P101 967

Technical Information

PVG 100 Proportional Valve Group

Function

3 – Priority spool for CF 10 – Shock and suction valve, PVLP

4 – LS connection for steering unit 11 – Main spool, PVBS

5 – Shuttle valve 12 – Max. oil flow adjustment screws for ports A and B

6 –Pilot operated check valve, POC 13 – LS comp (LS signal sent back to compensators)

7 – LS line

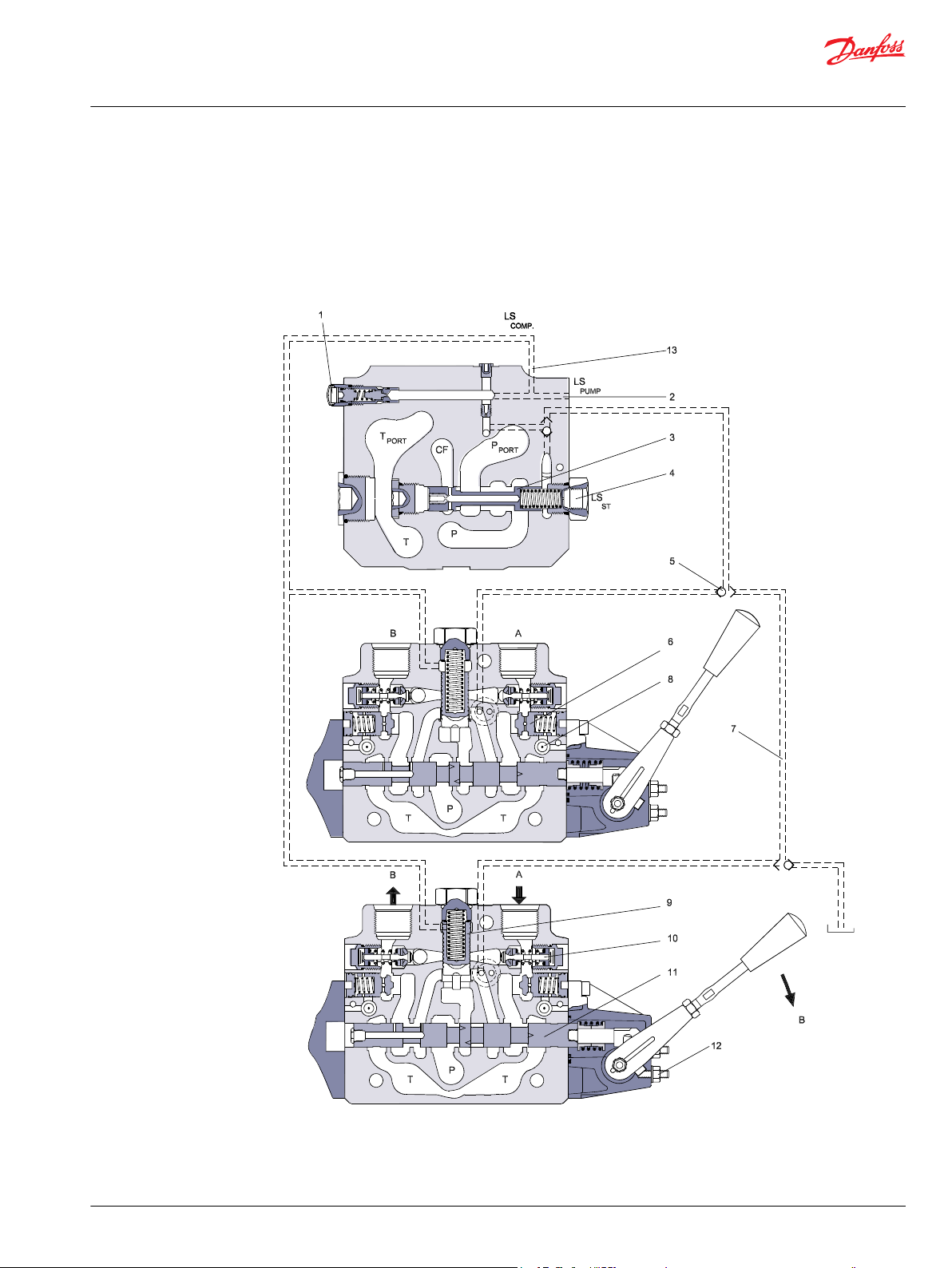

Load sensing controls

The LS control matches system requirements for both pressure and flow in the circuit regardless of the

working pressure. Used with a closed center control valve, the pump remains in low-pressure standby

mode with zero flow until the valve is opened. The LS setting determines standby pressure.

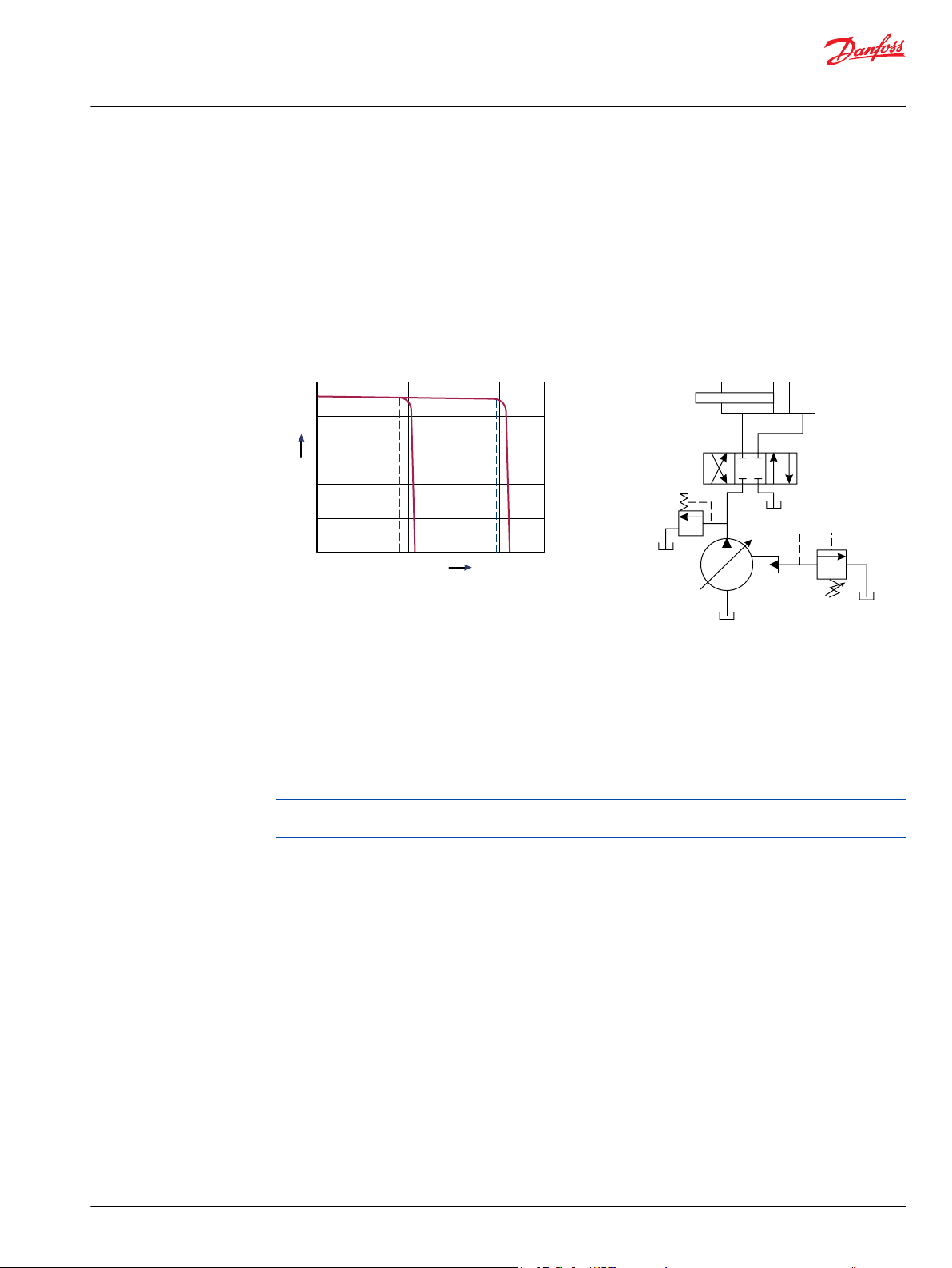

Typical operating curve

Load sensing circuit

Most load sensing systems use parallel, closed center, control valves with special porting that allows the

highest work function pressure (LS signal) to feed back to the LS control.

Margin pressure is the difference between system pressure and the LS signal pressure. The LS control

monitors margin pressure to read system demand. A drop in margin pressure means the system needs

more flow. A rise in margin pressure tells the LS control to decrease flow.

LS control with bleed orifice (do not use with PVG valves)

The load sense signal line requires a bleed orifice to prevent high-pressure lockup of the pump control.

Most load-sensing control valves include this orifice. An optional internal bleed orifice is available, for use

with control valves that do not internally bleed the LS signal to tank.

Integral PC function

The LS control also performs as a PC control, decreasing pump flow when system pressure reaches the PC

setting. The pressure compensating function has priority over the load sensing function.

For additional system protection, install a relief valve in the pump outlet line.

Load sensing system characteristics:

Variable pressure and flow

•

Low pressure standby mode when flow is not needed

•

System flow adjusted to meet system requirements

•

14 | © Danfoss | April 2021 BC152886483475en-000606

Page 15

0

0

Q max

Pressure

Fl

ow

P101 969E

PC setting

Remote PC setting

P101 966

Technical Information

PVG 100 Proportional Valve Group

Function

Lower torque requirements during engine start-up

•

Single pump can supply flow and regulate pressure for multiple circuits

•

Quick response to system flow and pressure requirements

•

Remote pressure compensated controls

The remote PC control is a two-stage control that allows multiple PC settings. Remote PC controls are

commonly used in applications requiring low and high pressure PC operation.

Typical operating curve

Closed center circuit with remote PC

The remote PC control uses a pilot line connected to an external hydraulic valve. The external valve

changes pressure in the pilot line, causing the PC control to operate at a lower pressure. When the pilot

line is vented to reservoir, the pump maintains pressure at the load sense setting.

When pilot flow is blocked, the pump maintains pressure at the PC setting. An on-off solenoid valve can

be used in the pilot line to create a low-pressure standby mode. A proportional solenoid valve, coupled

with a microprocessor control, can produce an infinite range of operating pressures between the low

pressure standby setting and the PC setting.

Size the external valve and plumbing for a pilot flow of 3.8 l/min [1 US gal/min]. For additional system

protection, install a relief valve in the pump outlet line.

Remote pressure compensated system characteristics:

Constant pressure and variable flow

•

High or low pressure standby mode when flow is not needed

•

System flow adjusts to meet system requirements

•

Single pump can provide flow to multiple work functions

•

Quick response to system flow and pressure requirements

•

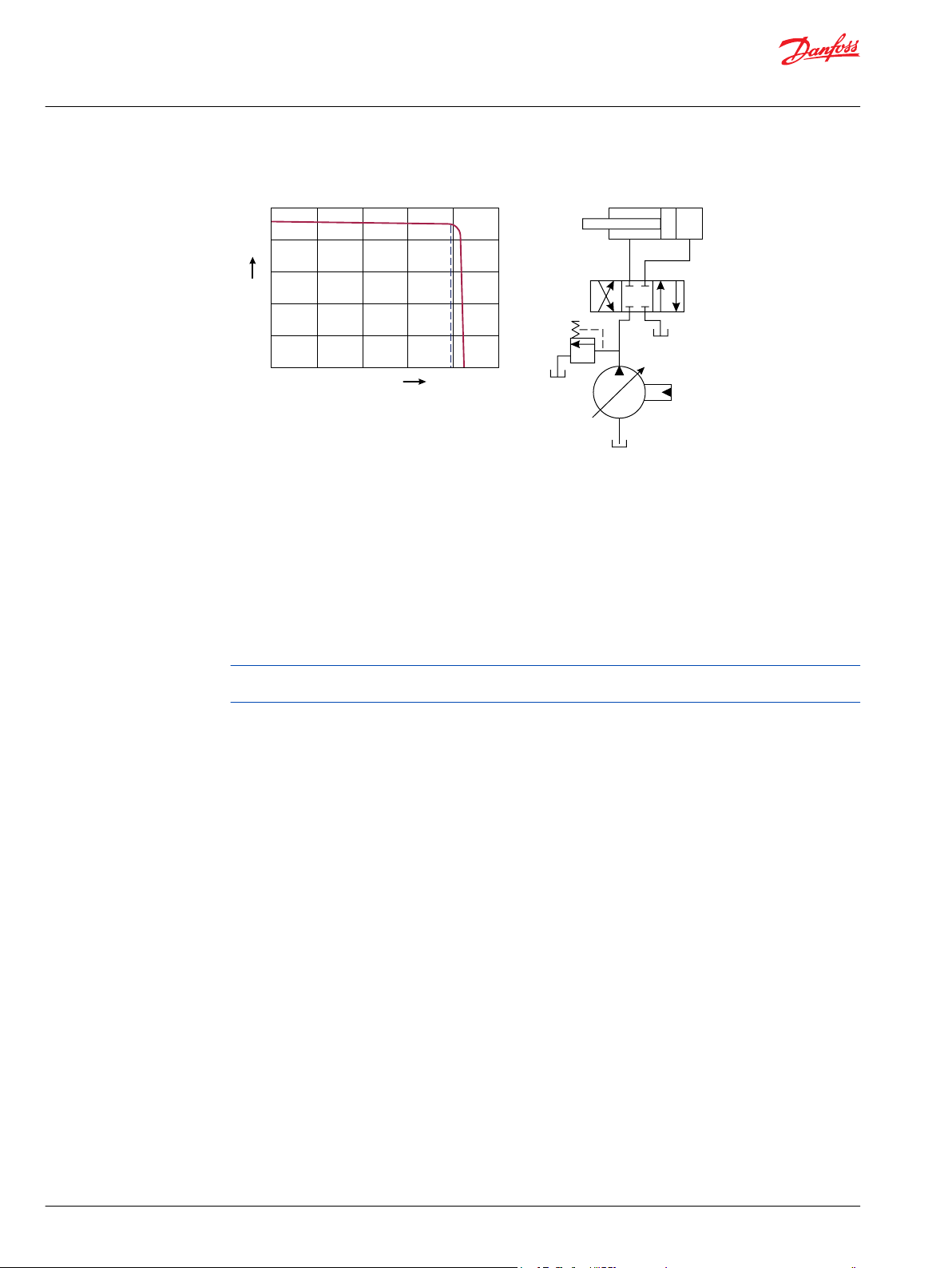

PVG 100 main spool with pressure compensated control

The PC control maintains constant system pressure in the hydraulic circuit by varying the output flow of

the pump. Used with a closed center control valve, the pump remains in high pressure standby mode at

the PC setting with zero flow until the function is actuated.

©

Danfoss | April 2021 BC152886483475en-000606 | 15

Page 16

0

0

Q max

Pressure

Fl

ow

P101 166E

PC setting

P101 965

Technical Information

PVG 100 Proportional Valve Group

Function

Typical operating curve

Once the closed center valve is opened, the PC control senses the immediate drop in system pressure

and increases pump flow by increasing the swashplate angle.

The pump continues to increase flow until system pressure reaches the PC setting. If system pressure

exceeds the PC setting, the PC control reduces the swashplate angle to maintain system pressure by

reducing flow.

The PC control continues to monitor system pressure and changes swashplate angle to match the output

flow with the work function pressure requirements.

If the demand for flow exceeds the capacity of the pump, the PC control directs the pump to maximum

displacement. In this condition, actual system pressure depends on the actuator load.

Simple closed-center circuit

For additional system protection, install a relief valve in the pump outlet line. * Do not use the PVG 32

with bleed down load sense control.

Pressure compensated system characteristics

Constant pressure and variable flow

•

High pressure standby mode when flow is not needed

•

System flow adjusts to meet system requirements

•

Single pump can provide flow to multiple work functions

•

Quick response to system flow and pressure requirements

•

Typical applications for pressure compensated systems

Constant force cylinders (bailers, compactors, refuse trucks)

•

On/off fan drives

•

Drill rigs

•

Sweepers

•

Trenchers

•

Typical applications for remote pressure compensated systems:

Modulating fan drives

•

Anti-stall control with engine speed feedback

•

Front wheel assist

•

16 | © Danfoss | April 2021 BC152886483475en-000606

Page 17

Technical Information

PVG 100 Proportional Valve Group

Function

Road rollers

•

Combine harvesters

•

Wood chippers

•

PVMR, friction detent

The friction detent PVMR allows the directional spool to be held in any position, resulting in infinitely

variable, reversible, pressure compensated flow.

This can be sustained indefinitely without having to continue to hold the mechanical lever. Friction

detent spool position may be affected by high differential actuator flow forces and system vibration

resulting in work function flow reduction.

PVMR, friction detent

PVMF, mechanical float position lock

Allows the float spool to be held in the float position after release of the mechanical handle.

PVMF, standard mount only

P → A → F (Push-in)

PVBS, main mpools for flow control (standard)

With post-compensated valves, the A and B work port flow will depend on the pressure drop across the

main spool PVBS.

In open center systems, this pressure drop (standby-pressure) is determined by the volume of fixed pump

flow led to tank across the pressure adjusting spool in the inlet PVPF and the pressure adjusting spool

PVMF, optional mount only

P → A → F (Pull-out)

©

Danfoss | April 2021 BC152886483475en-000606 | 17

Page 18

Technical Information

PVG 100 Proportional Valve Group

Function

bias spring pressure. Since the pressure drop varies with pump flow volume led to tank, the A and B work

port flow will vary.

In closed center systems, the pressure drop across the main spool equals the standby setting of the

pump, measured at the P-port of the valve. The A and B work port flow will remain unchanged as long as

the standby is unchanged.

PVBS, main spools for flow control (with linear characteristic)

PVBS main spools with linear characteristic deliver a higher flow gain directly proportional to the linear

spool travel beyond the dead band.

18 | © Danfoss | April 2021 BC152886483475en-000606

Page 19

W

Technical Information

PVG 100 Proportional Valve Group

Safety

Building in safety

All makes and all types of control valves (including proportional valves) can fail. Thus the necessary

protection against the serious consequences of function failure should always be built into the system.

For each application an assessment should be made for the consequences of pressure failure and

uncontrolled or blocked movements.

To determine the degree of protection that is required to be built into the application, system tools such

an FMEA (Failure Mode and Effect Analysis) and Hazard and Risk Analysis can be used.

FMEA (Failure Mode and Effect Analysis) IEC EN 61508

FMEA is a tool used for analyzing potential risks. This analytical technique is utilized to define, identify,

and prioritize the elimination or reduction of known and/or potential failures from a given system before

it is released for production.

Please refer to IEC FMEA Standard 61508.

Hazard and risk analysis ISO 12100-1/14121

This analysis is a tool used in new applications as it will indicate whether there are special safety

considerations to be meet according to the machine directives EN 13849.

Dependent on the determined levels conformety this analysis will determine if any extra requirements

for the product design, development process, production process or maintenance, i.e. the complete

product life cycle.

Warning

All makes/brands and types of directional control valves – inclusive proportional valves – can fail and

cause serious damage. It is therefore important to analyze all aspects of the application.

Because the proportional valves are used in many different operation conditions and applications, the

manufacturer of the application is alone responsible for making the final selection of the products – and

assuring that all performance, safety and warning requirements of the application are met.

The process of choosing the control system – and safety levels – is governed by the machine directives

EN 13849 (Safety related requirements for control systems).

©

Danfoss | April 2021 BC152886483475en-000606 | 19

Page 20

W

Technical Information

PVG 100 Proportional Valve Group

Safety

Example of a control system for manlift

Example of a control system for man-lift

Example of a control system for man-lift using PVE Fault monitoring input signals and signals from

external sensors to ensure the PLUS+1® main controllers correct function of the man-lift.

Typical PVE wiring block diagram

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

20 | © Danfoss | April 2021 BC152886483475en-000606

Page 21

Fault detection output

high=on

low=off

Alarm

logic

2)

Memory3)

E1

E2

Output

AND

OR

U

DC2

Error

U

S

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

U

DC2

Error

U

S

PVEH

with AMP

connector

PVEH

with AMP

connector

Hydraulic

deactivation

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Emergency

stop

Man present

switch

C

C

D

B

B

A

P301 318

Technical Information

PVG 100 Proportional Valve Group

Safety

PVG 32 – used in system with fixed displacement pumps:

•

PVSK, commonly used in crane application - full flow dump

•

PVPX, LS dump to tank

PVG 100 – alternative LS dump/pilot supply disconnect:

•

PVPP, pilot oil supply shut off

•

External cartridge valve connecting LS pressure or main pressure to tank

PVG 120 – pump disconnect/block for variable pumps:

•

PVPE, full flow dump for the PVG 120

•

External cartridge valve connecting LS pressure to tank

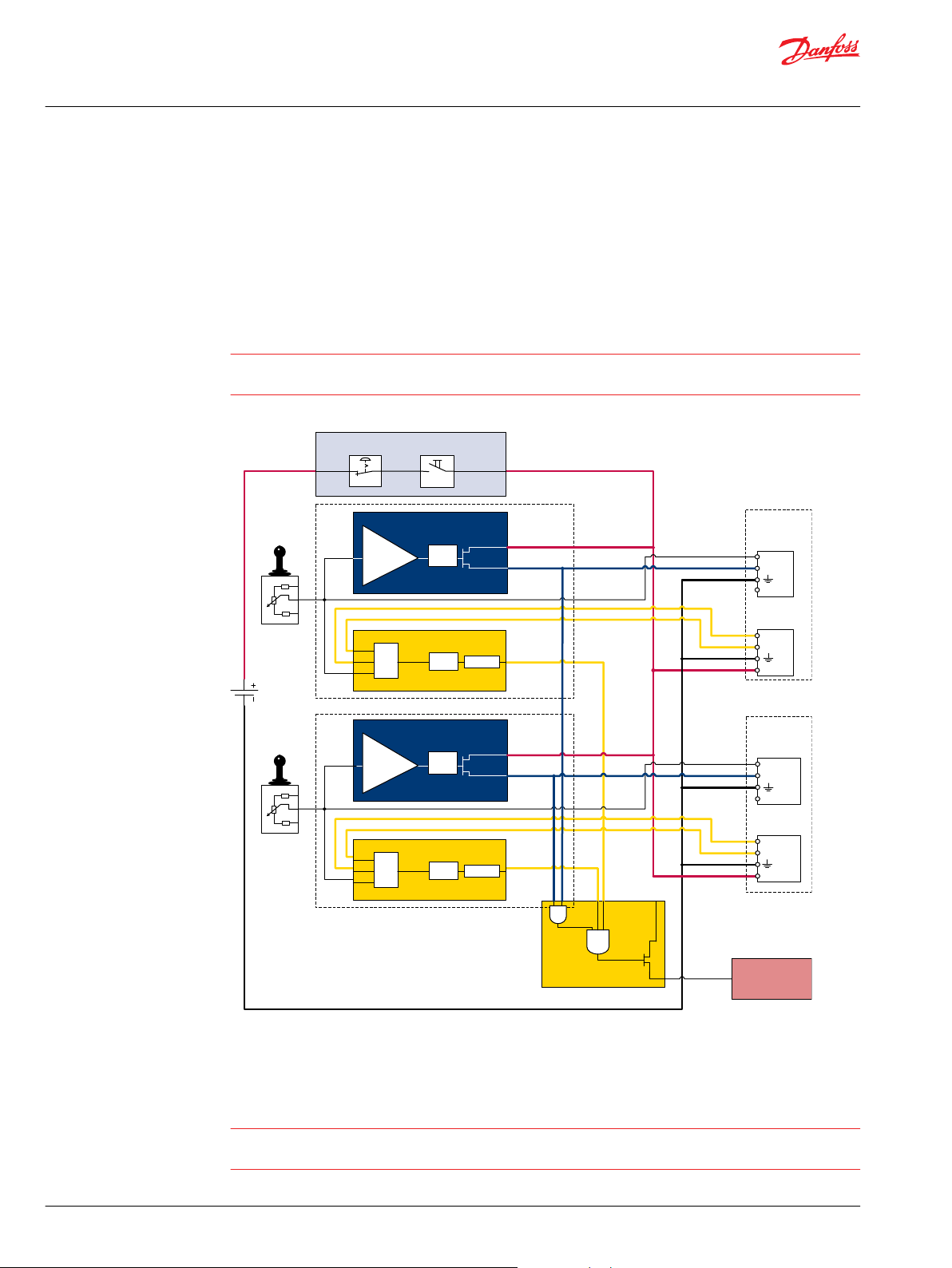

Examples of wiring block diagram

Example 1

Typical wiring block diagram using PVEH with neutral power off switch and fault monitoring output for

hydraulic deactivation.

©

Danfoss | April 2021 BC152886483475en-000606 | 21

Page 22

W

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

Fault detection output

PVEH-DI

AMP supply

connector

PVEH-DI

AMP supply

connector

PVEH-DI

AMP connector

PVEH-DI

AMP connector

AND

high=on

low=off

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

OR

Emergency

Stop

Man present

switch

P301 319

U

DC2

Error

U

S

DI-B

Error

DI-A

U

DC2

Error

U

S

Error

DI-A

Hydraulic

deactivation

W

Technical Information

PVG 100 Proportional Valve Group

Safety

A Emergency stop / man present switch

B PVE Fault monitoring signals

C Neutral signal detection

D Deactivation of the hydraulic system (System Control Logic, example: PLUS+1® for signal monitoring

and triggering signal)

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

Example 2

Fault monitoring for deactivation of the hydraulic system with extra fault inputs using the PVE’s with DI

(Direction Indication) function. System Control Logic, example PLUS+1® for signal monitoring and

triggering signal for deactivation of the hydraulic system.

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

22 | © Danfoss | April 2021 BC152886483475en-000606

Page 23

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

Fault detection output

PVEH-DI

AMP supply

connector

PVEH-DI

AMP supply

connector

PVEH-DI

AMP connector

PVEH-DI

AMP connector

AND

high=on

low=off

Neutral detection / Supply control

signal

≠

neutral

OFF

Delay

1)

PVE 1

PVE 2

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

Fault detection

Delay

DI

Logic

Memory

U

S

DI-A

DI-B

2)

4)

3)

Output

OR

Emergency

Stop

Man present

switch

P301 319

U

DC2

Error

U

S

DI-B

Error

DI-A

U

DC2

Error

U

S

Error

DI-A

Hydraulic

deactivation

W

Technical Information

PVG 100 Proportional Valve Group

Safety

Example of fault monitoring

Similar to previous example using fault monitoring for deactivation of the hydraulic system with extra

fault inputs using the PVE’s with DI (Direction Indication) function.

Example of fault monitoring for deactivation of the hydraulic system

System Control Logic e.g. PLUS+1® for signal monitoring and triggering signal for deactivation of the

hydraulic system.

Warning

It is the equipment manufacturers responsibility to ensure that the control system incorporated in the

©

Danfoss | April 2021 BC152886483475en-000606 | 23

machine is declared as being in conformity with the relevant machine directives.

Other non-electrical modules which can be used in connection with hydraulic deactivation at different

levels.

Page 24

Technical Information

PVG 100 Proportional Valve Group

Safety

PVG 32 – Mainly used in system with fixed displacement pumps

PVSK, commonly used in crane application - full flow dump

•

PVPX, LS dump to tank

•

PVG 100 – Alternative LS dump or pilot supply disconnect

PVPP, pilot oil supply shut off

•

External cartridge valve connecting LS Pressure to Tank

•

External cartridge valve connecting main Pressure to Tank

•

PVG 120 – Pump disconnect/block for variable pumps

PVPE, full flow dump for the PVG 120

24 | © Danfoss | April 2021 BC152886483475en-000606

Page 25

Technical Information

PVG 100 Proportional Valve Group

Technical data

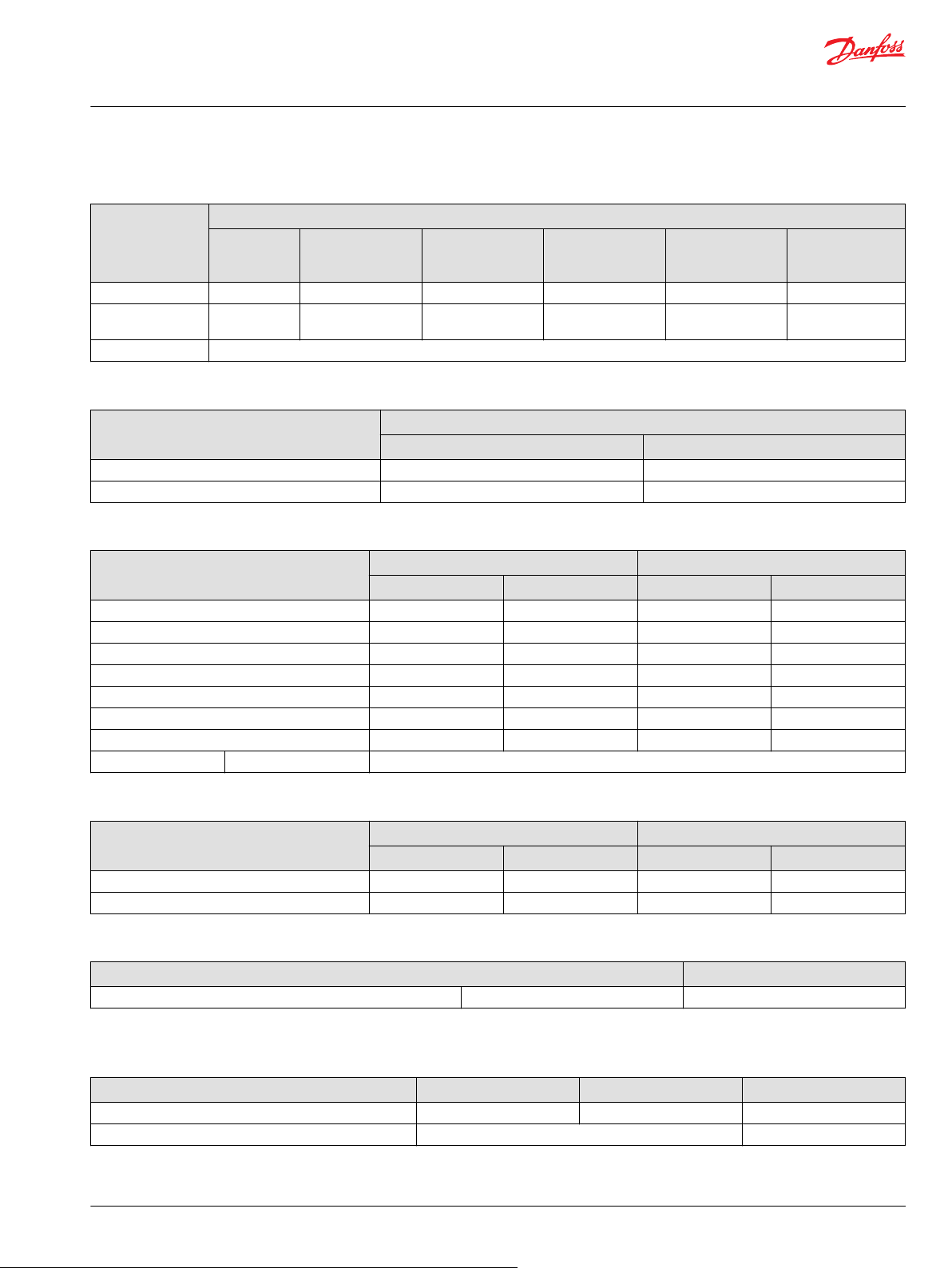

PVG 100 technical data

The technical data for PVG 100 are typical measured results. For the hydraulic system a mineral based

hydraulic oil with a viscosity of 21 mm2/s [102 SUS] and a temperature of 50 °C [122 °F] was used.

PVG 100 technical data

Max. pressure Port P continuous 350 bar [5075 psi]

Port P intermittent

2)

Port A/B

Port T, static / dynamic 25 bar/40 bar [365/580 psi]

Port T0, static / dynamic 5 bar/10 bar [75/145 psi]

Oil flow, rated

(See characteristics)

Port P (PVPV / PVPVM) 250/400 l/min [66/106 US gal/min]

Port A/B, with press. comp.

@15 bar [217psi]

Spool travel, standard ± 7 mm [±0.28 in]

Spool travel, float

Proportional range A: 5.5 mm

position spool P→A→F

Float position 8 mm [±0.32 in]

Dead band,

Standard ± 1.5 mm [±0.06 in]

flow control spools

Max. spool leakage

at 100 bar [1450 psi] and

21 mm2/s [102 SUS]

Max. internal leakage with pilot operated check

valve at 200 bar [2900 psi] and

21 mm2/s [102 SUS]

Oil temperature

(inlet temperature)

A/B→T, without shock valve

A/B→T, with shock valve

A/B→T, without shock valve 1 cm3/min [0.06 in3/min]

A/B→T, with shock valve 6 cm3/min [0.37 in3/min]

Recommended temperature 30 → 60°C [86 → 140°F]

Min. temperature -30°C [–22°F]

Max. temperature +90°C [194°F]

Oil viscosity Operating range 12 - 75 mm2/s [65 - 347 SUS]

Min. viscosity 4 mm2/s [39 SUS]

Max. viscosity 460 mm2/s [2128 SUS]

Ambient temperature -30 → +60°C [–22 → +140°F]

Filtration / Max. contamination (ISO 4406) 23/19/16

1)

Intermittent operation: the permissible values may occur for max. 10% of every minute.

2)

PVG 100-HF - 350 bar [5075 psi] rated for 250 000 cycles, max. continuous pressure 320 bar [4640 psi].

3)

PVG 100-HF - High Flow option work section.

1)

400 bar [5800 psi]

350 bar [5075 psi]

3)

180 l/min

240 l/min

[47.6 US gal/min]

[63.4 US gal/min]

A: [±0.22 in]

B: 7.0 mm

3)

3)

20/30 cm3/min [1.22/1.85 in3/min]

25/35 cm3/min [1.53/2.14 in3/min]

B: [±0.28 in]

PVH, hydraulic actuation

PVH, Hydraulic Actuation

PVH data Pressure, bar [psi]

Control range 5 to 15 [75 to 220]

Maximum pilot pressure, static 30 [435]

Maximum pressure on port T

(It is recommended that the tank connection from the hydraulic remote control unit

PVRH is taken directly to tank.)

©

Danfoss | April 2021 BC152886483475en-000606 | 25

10 [145]

Page 26

Technical Information

PVG 100 Proportional Valve Group

Technical data

PVG 100 PVM operating force

PVM operating force

Operating force PVM + PVMD, PVM + PVE

Proportional regulation range, control lever, standard spool ±19.5°

Proportional regulation range

Float position

Control lever positions No. 2 × 6

Actuation Neutral position Max. spool travel

22 ± 3 N

(PVE without voltage applied)

PVM + PVH 27 ± 3 N

PVM + PVMR Spool displacement from neutral position 34 N [7.6 lbf]

Spool displacement from any other position 12 N [2.7 lbf]

PVM + PVMF Spool displacement from neutral position 22 N [5.0 lbf]

Spool displacement into float position 60 N [13.5 lbf]

Spool displacement away from float position 28 N [6.3 lbf]

[5 ± 0.7 lbf]

[6 ± 0.7 lbf]

±15.3°

22.3°

28 ± 3 N

[6.3 ± 0.7 lbf]

83 ± 3 N

[18.7 ± 0.7 lbf]

PVG 100 PVE reaction time and oil consumption

PVE reaction time (s)

Voltage Reaction time function PVEO

Neutral

switch

Constant

voltage

Hysteresis

1)

For standard PVG 100 spools.

2)

Hysteresis is indicated at rated voltage and f = 0.02 Hz for one cycle. A cycle including N > full A > N > full B > N.

From neutral position to max.

spool travel

From maximum spool travel

to neutral position

From neutral position to

maximum spool travel

From maximum spool travel

to neutral position

2)

PVE oil consumption, l/min [US gal/min]

Voltage Function PVEO

Without voltage Pilot oil flow

With voltage

1)

For standard PVG 100 spools.

per PVE

1)

ON/OFF

Max. 0.235 0.500 0.230 0.230

Rated 0.180 0.320 0.150 0.150

Min. 0.120 0.250 0.120 0.120

Max. 0.175 0.550 0.175 0.175

Rated 0.090 0.400 0.090 0.090

Min. 0.065 0.300 0.065 0.065

Max.

–

Rated

–

Min.

–

Max.

–

Rated

–

Min.

–

Rated - 2% 4% <1%

ON/OFF

Neutral 0

Locked 0.1 [0.026] 0.5 [0.132] 0.1 [0.026] 0.2 [0.053]

1 actuation 0.2 [0.053]

Actuations 0.7 [0.185] 0.75 [0.2] 1.1 [0.29] 1.1 [0.29]

PVEA

Prop. fine

0.500

0.320

0.250

0.250

0.200

0.150

1)

PVEA

Prop. fine

PVEH

Prop. high

0.200

0.120

0.050

0.100

0.090

0.065

PVEH

Prop. high

PVES

Prop. super

0.200

0.120

0.050

0.100

0.090

0.065

PVES

Prop. super

26 | © Danfoss | April 2021 BC152886483475en-000606

Page 27

Technical Information

PVG 100 Proportional Valve Group

Technical data

PVEO power supply and consumption

Supply voltage U

DC

rated 12 V

DC

24 V

DC

range 11 V to 15 V 22 V to 30 V

max. ripple 5%

Current consumption at rated voltage 0.65 A @ 12 V 0.33 A @ 24 V

Input impedance in relation to 0.5 • U

DC

12 KΩ

Power consumption 8 W

PVEA, PVEH and PVES

Supply voltage U

DC

Current consumption at

rated voltage

Signal voltage neutral 0.5 • U

Signal current at rated voltage 0.25 mA to 0.70 mA

Input impedance in relation to 0.5 • U

Input capacitor 100 ηF

Power consumption PVEH/PVES (PVEA) 7 (3.5) W

rated 11 V to 32 V

range 11 V to 32 V

max. ripple 5%

PVEH/PVES (PVEA) 0.57 (0.28) A @ 12 V 0.3 (0.15) A @ 24 V

DC

A-port ↔ B-port 0.25 • UDC to 0.75 • U

DC

12 KΩ

DC

For detailed information, see PVE actuator catalog, BC152886484010.

©

Danfoss | April 2021 BC152886483475en-000606 | 27

Page 28

50 100

300 l/min

0

0

5

30

bar

Q

p

TP

20

25

15

10

150 250 200

20 bar spring

[290 psi spring]

12 bar spring

[174 psi spring]

PVPE

PVPH

psi

∆ p ∆ p

0

Q

p

0

155B390.11

80 US gal/min

400

300

100

200

10 20 30 40 706050

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

The characteristics in this catalog are typical measured results. During measuring a mineral based

hydraulic oil with a viscosity of 21 mm2/s [102 SUS] at a temperature of 50°C [122°F] was used.

PVPF, pump side module

Pressure relief valve characteristic in PVP

Neutral flow pressure in PVP, open center

The pressure relief valve is set at an oil flow of 15 l/min [4 US gal/min]. Setting range: 30 to 350 bar [435 to

5075 psi].

Open center flow rating

The flow rating of the different main spools will depend on the standby pressure available. In open center

systems, the standby pressure equals the pressure drop P–>T, see the diagram above. A pump flow of 150

l/min led to tank across the pressure adjusting spool, will generate a standby pressure of app. 15 bar (PVP

with 12 bar spring). The according main spool flow ratings will correspond to the curves.

For PVPs with a 20 bar spring, the standby pressure available will be 20 bar or higher. Hence the

Closed center flow rating

28 | © Danfoss | April 2021 BC152886483475en-000606

according main spool flow ratings will correspond.

The flow rating of a the different main spools, PVBS, is dependent upon the Load Sense margin (pump

margin pressure). The nominal flows specified for each PVBS is specified at 15 bar [218 psi] Ls margin

pressure. If LS margin is increased above 15 bar [218 psi], the PVBS will deliver more flow then the

nominal rating. The following curves show the relationship between LS margin and work port flow.

Page 29

0

50

100

150

200

250

300

350

l/min

5 10 15 20 25 bar

Work Port Flow

LS Margin

P301 788

"F" Spool

"E" Spool

"H" Spool*

"G" Spool*

"D" Spool

"C" Spool

"B" Spool

"A" Spool

90

75

60

45

30

15

0

US gal/min

50 100 150 200 250 300 350

[psi]

*With PVG100 High Flow body and spool

C

l/min

A/B

Q

V310 203.C

US gal/min

Q

A/B

psi

bar

0

pp

100

200

300

400

500

600

700

800

900

D

D

A/B T max spool travel

40 80 120 160 200 240 280 320 360 400 440

PVG 100

30

0

10

20

40

50

60

600 30 10545 7515 90

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A = 40

B = 65

C = 100

D = 130

E = 150

F = 180

G = 210

H = 240

A

B

C

E

D

F

G

H

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

Flow vs. LS margin @ maximum spool shift

Caution

Because of flow forces, cylinder differential areas, Danfoss recommends LS margins under 25 bar [360

psi].

As noted above, work port flow is dependent upon the LS margin set on the pump. PC pumps maintain a

constant discharge pressure which is equal to the PC setting on the pump. Hence the LS margin for PC

pumps can be thought of as the difference between the PC setting and the load pressure. Therefore work

port flow will change with load pressure, thus, pressure compensated flow will not be obtained.

PVG 100 pressure drop for PVB, basic module

Pressure drop PVB at max. main spool travel

©

Danfoss | April 2021 BC152886483475en-000606 | 29

Page 30

0

100

20

40

80

30

40

50

160

120

200

l/min

p p

psi

bar

0

500

1000

1500

2000

2500

3000

Q

A/B

US gal/min

86

4

2

0

14

10

12

Q

A/B

A/B T neutral open center spool

DD

V310204.A

250

40/65

100

130

150/180

3500

a

in

PVM

0.240.16 0.20 0.280.08 0.120 0.04

bar

p

PVH

s

U

DC

U

PVE

psi

13

11

0.700.65

160 218

0.75

15

157-689.11

9

5

7

0.600.50 0.55

130

100

73

p

PVH

PVM

P

US

0

25

50

75

100

125

150

175

200

225

0

2

3

4

5

6 7

mm

1

60

50

30

40

10

20

A/B

0

A

190

250

B

C

D

E

F

a

l/min

gal/min

Q

A/BQA/B

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

Pressure drop PVB for open spool in neutral position

PVB with pressure compensation, closed center PVP

Oil flow as a function of spool travel for spools A to F - 20 bar [290 psi]

30 | © Danfoss | April 2021 BC152886483475en-000606

Set pressure difference between pump pressure and LS signal = 20 bar [290 psi] measured at the P-port

of the valve.

Page 31

160

0.65

0.16

0.50

0.08

7

5

73

0.55

100

0.040

9

130

0.60

0.12

157-690.11

DC

s

0.24

11

13

0.70

0.20

15

bar

0.75

218

U

U

psi

p

0.28

a

in

p

PVE

PVH

PVM

PVH

US

225

0

10

20

30

40

50

50

0

0

25

1 2

3

4

75

125

100

175

150

200

60

P A/B

5

6 7

mm

PVM

A

190

B

C

D

E

F

gal/minQl/min

l/min

A/BQA/B

a

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

Oil flow as a function of spool travel for spools A to F - 15 bar [218 psi]

Set pressure difference between pump pressure and LS signal = 15 bar [218 psi] measured at the P-port

of the valve.

©

Danfoss | April 2021 BC152886483475en-000606 | 31

PVLP, shock and suction valve

Page 32

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

8 7 6 5 4 3 2 1 0 1 2 3 4 5 6 7

0.32 0.28 0.24 0.20 0.16 0.12 0.08 0.04 0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

45

40

35

30

25

20

15

10

5

U

S

U

DC

mm

in

PVM

PVM

PVE

P → A → F P → B

l/min US gal/min

Q

0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 0.650.65 0.70

P301 789

"F" Spool

"E" Spool

"D" Spool

"C" Spool

"B" Spool

"A" Spool

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

PVLP/PVLA, suction valve

The shock valve PVLP is designed to absorb shock effects. Consequently, it should not be used as a

pressure relief valve. PVLP is set at an oil flow of 10 l/min [2.6 US gal/min].

Oil flow as a function of spool travel for float spools A-F - 15 bar [218 psi] margin

32 | © Danfoss | April 2021 BC152886483475en-000606

Page 33

0

400

200

600

1

2

1200

800

1000

1400

Current in mA

3

4

5

6

Spool stroke, mm

7

1600

400

200

600

1200

800

1000

1400

1600

200

100

300

600

400

500

700

800

200

100

300

600

400

500

700

800

@ 12V

@ 24V

V310 000.A

Ideal curve

Hysteresis

280/560 mA 500/1000 mA280/560 mA500/1000 mA

Technical Information

PVG 100 Proportional Valve Group

Technical characteristics

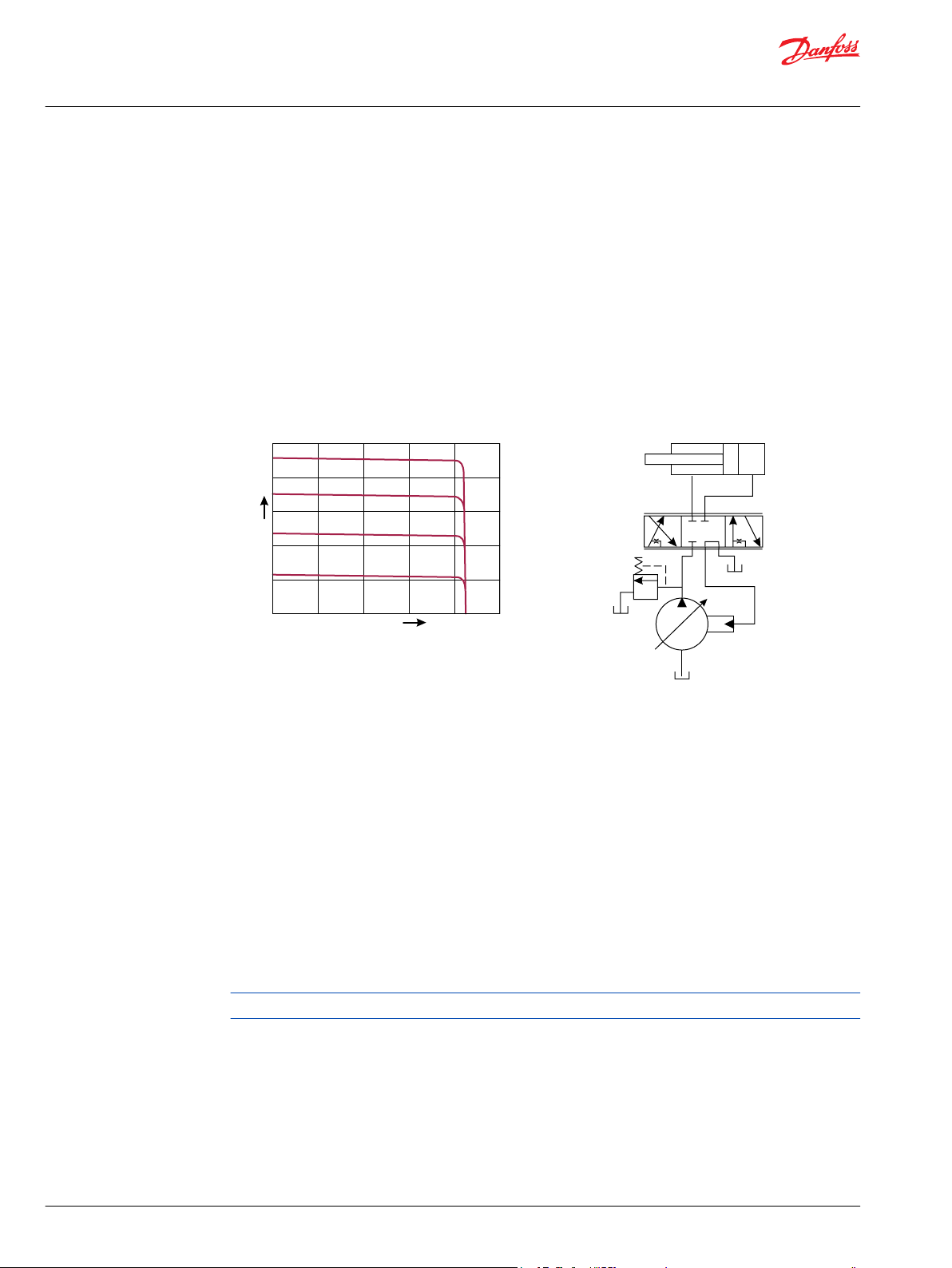

PVHC characteristic - Spool stroke vs current

PVHC current response and hysteresis @ 25 bar Pp, 21 ctS, 25 °C. The ideal curve is determined by the

main spool neutral spring. The PVHC has high hysteresis. The hysteresis is affected by viscosity, friction,

flow forces, dither frequency and modulation frequency. The spool position will shift when conditions are

changed e.g. temperature change.

©

Danfoss | April 2021 BC152886483475en-000606 | 33

Page 34

PVLP setting

in PVT should

be a minimum

of 30 bar above

setting on the

pump or external

relief valve

Inlet LS

Relief setting

should be set

below the PC

setting of the

pump by the

LS margin"

300

250

T0

P

PpPgage

A B B B B

T

A A A

240

240

160

270 bar PC setting

with 20 bar LS margin

P301 790

P301 232

A AB B

A AB B

Technical Information

PVG 100 Proportional Valve Group

Hydraulic systems

PVG 100 with variable displacement pump schematic example

Electrically actuated PVG 100, variable displacement pump, PVB 100 with integrated pilot operated check valves

34 | © Danfoss | April 2021 BC152886483475en-000606

Page 35

Technical Information

PVG 100 Proportional Valve Group

Hydraulic systems

Electrically actuated PVG 100/32, fixed displ. pump, PVB 100/32 with integrated pilot operated check valves

©

Danfoss | April 2021 BC152886483475en-000606 | 35

Page 36

Technical Information

PVG 100 Proportional Valve Group

Other operating conditions

Oil

The main duty of the oil in a hydraulic system is to transfer energy; but it must also lubricate the moving

parts in hydraulic components, protect them against corrosion, and transport dirt particles and heat out

of the system. It is therefore important to choose the correct oil with the correct additives. This gives

normal operation and long working life.

Mineral oil

For systems with this valve Danfoss recommends the use of mineral-based hydraulic oil containing

additives: Type HLP (DIN 51524) or HM (ISO 6743/4).

Non-flammable fluids

Phosphate-esters (HFDR fluids) can be used without special precautions. However, dynamic seals must be

replaced with FPM (Viton) seals. Please contact the Danfoss Sales Organization, if the PVG 100 valve is to

be used with phosphate-esters.

The following fluids should only be used according to agreement with the Sales Organization for

Danfoss:

Water-glycol mixtures (HFC fluids)

•

Water-oil emulsions (HFB fluids)

•

Oil-water emulsions (HFAE fluids)

•

Biodegradable oils

PVG 100 valves can be used in systems with rapeseed oil.

The use of rapeseed oil is conditioned by:

complying with the demands on viscosity, water content, temperature and filtering etc. (see chapters

•

below and technical data page 7).

adapting the operating conditions to the directions of the oil supplier.

•

Before using other biodegradable fluids, please consult the Danfoss Organization.

Particle Content, Degree of Contamination

Oil filtration must prevent the particle content from exceeding an acceptable level, i.e. an acceptable

degree of contamination.

Maximum contamination for is 23/19/16 (see ISO 4406).

Calibration in accordance with the ACFTD method.

A degree of contamination of 23/19/16 can be maintained by using a filter fineness as described in the

next section.

Filtration

Effective filtration is the most important precondition in ensuring that a hydraulic system performs

reliably and has a long working life. Filter manufacturers issue instructions and recommendations. It is

advisable to follow these.

System filters

Where demands on safety and reliability are very high a pressure filter with bypass and indicator is

recommended. Experience shows that a 10 µm nominal filter (or finer) or a 20 µm absolute filter (or finer)

is suitable. It is our experience that a return filter is adequate in a purely mechanically operated valve

system. The fineness of a pressure filter must be selected as described by the filter manufacturer so that a

particle level of 23/19/16 is not exceeded. The filter must be fitted with pressure gauge or dirt indicator to

make it possible to check the condition of the filter. In systems with differential cylinders or accumulators

36 | © Danfoss | April 2021 BC152886483475en-000606

Page 37

Technical Information

PVG 100 Proportional Valve Group

Other operating conditions

the return filter must be sized to suit the max. return oil flow. Pressure filters must be fitted to suit max.

pump oil flow.

Internal filters

The filters built into PVG 32 are not intended to filter the system but to protect important components

against large particles. Such particles can appear in the system as a result of pump damage, hose fracture,

use of quick-couplings, filter damage, starting up, contamination, etc. The filter in the electrical actuator

PVE protecting the solenoid valves has a mesh of 150 µm. Bursting pressure drop for internal filters is 25

bar [360 psi].

©

Danfoss | April 2021 BC152886483475en-000606 | 37

Page 38

B

A

Standard Mounted Work Section

LS holes

P301 065

B A

LS holes

P301 066

LS holes

Technical Information

PVG 100 Proportional Valve Group

Mounting

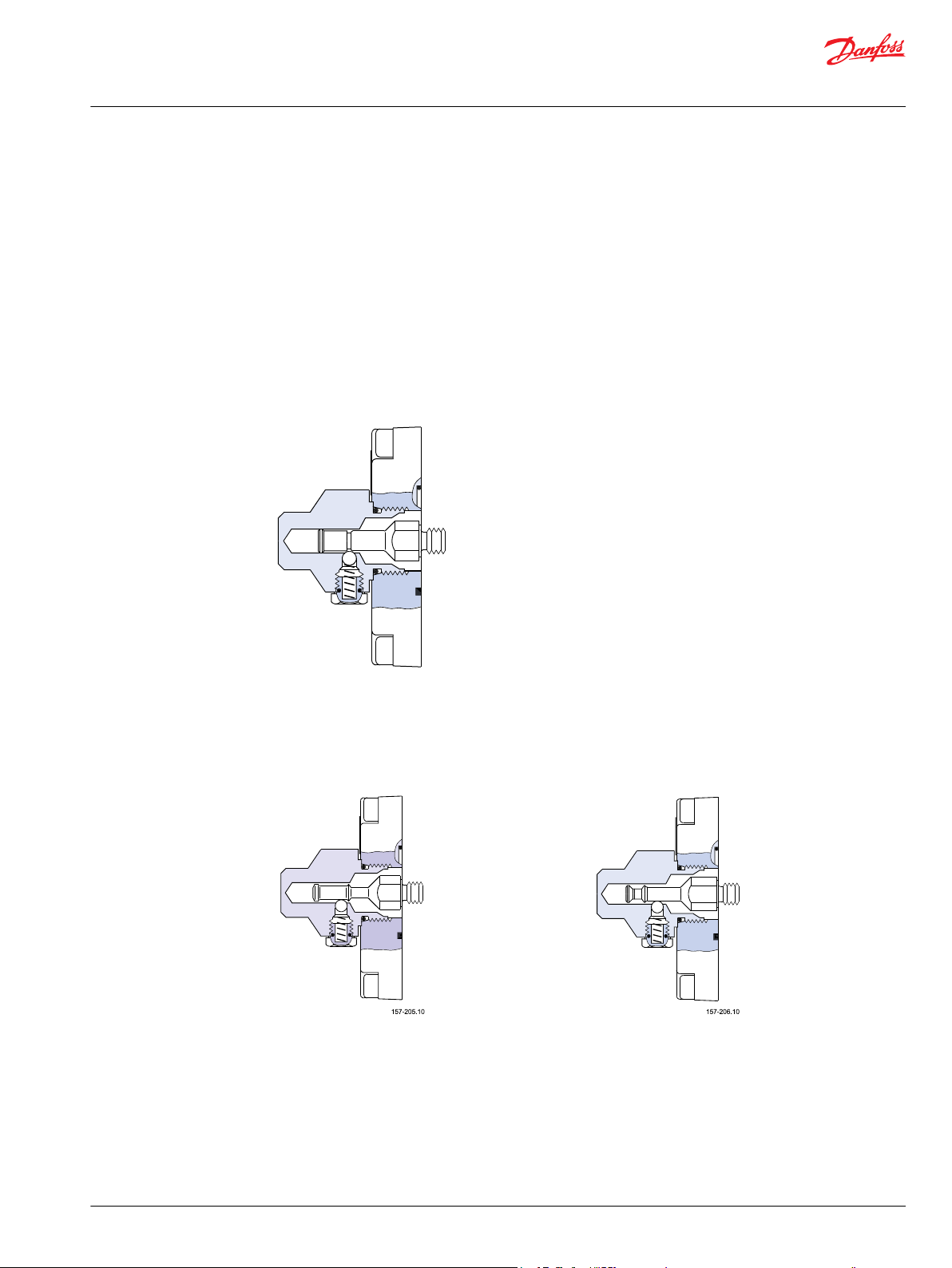

Standard mounting vs. option mounting

Standard mounting – the PVM on the “A” port side of the PVB

Standard mounting is defined as installing the PVM on the “A” port side of the PVB. Because of this, the

PVE or PV cover (PVH, PVMD, PVMR, PVMF or PVHC) would be on the “B” port side of the valve.

Option mounting – the PVM on the “B” port side of the PVB

Option mounting is defined as installing the PVM on the “B” port side of the PVB. Because of this, the PVE

or PV cover (PVH, PVMD, PVMR, PVMF or PVHC) would be on the “A” port side of the valve.

The PVBS in PVG 100 are not symmetric. Because of this the “Load Sense” (Ls) holes in the PVBS main

spool must be installed so that they are on the “B” port side of the PVB.

Standard mounting spool (upper PVBS) vs. Option mounting spool (below PVBS)

Before determining spool part numbers, determine whether the section will be standard or option

mounted. Standard and Option mounting only applies to a work section. Standard and option mounted

section can be used together in the same stack.

38 | © Danfoss | April 2021 BC152886483475en-000606

Page 39

T0

P

T0LSLST P

LS

Refer to PVPE and Dummy

Spool in PVPF Acessories

P301 051

P

gage

P

P

P

P

P301 052

T0

P

P

gage

P

P

P

P

T0LSLST P

Refer to PVPP in PVP Accessory Section

LS

Refer to PVPE and Dummy

Spool in PVPF Acessories

P301 053

T0

P

T0LSLS

T P

PVPE

LS

P

gage

P

P

P

P

P301 797

T0

P

P

gage

P

P

Ls

Technical Information

PVG 100 Proportional Valve Group

Modules and code numbers

PVPF (Open Center) Inlet Modules - for Pumps with Fixed Displacement

Symbol Description BSP port

G1

Open center pump side module for pumps with fixed

displacement.

Max pump flow 250 l/min [66 US gal/min].

With pilot supply for PVE actuation.

With pilot gauge port.

Open center pump side module for pumps with fixed

displacement.

Max pump flow 250 l/min [66 US gal/min].

With pilot supply for PVH/PVHC actuation.

With pilot gauge port.

Open center pump side module for pumps with fixed

displacement.

Max pump flow 250 l/min [66 US gal/min].

With pilot supply for PVE actuation.

Accumulator port and facility for pilot shut-off valve

12 bar

spring

20 bar

spring

12 bar

spring

20 bar

spring

12 bar

spring

20 bar

spring

161B5110 161B5510

*

161B5112 161B5512

*

11013065 11013066

*

11013067 11013068

*

161B5140 161B5540