Page 1

Data Sheet

Load Independent Proportional Valve

PVG 100

PVG 100 is a load independent proportional valve

with flow up to 180 l/min [48 gpm] and pressures up

to 350 bar [5076 psi]. It offers equitable flow sharing

for precise control of multiple machine functions

under varying load conditions and pressure

requirements.

Building on the modular, flexible, and proven Danfoss

load-sensing proportional valve concept, PVG 100

offers easy, fast configuration, thereby helping vehicle

designers meet tight time-to-market deadlines. The

new valve is positioned between the existing Danfoss

PVG 32 and PVG 120 with flows up to 130 l/min [34.4

gal/min] and 240 l/min [63.4 gal/min] respectively.

PVG 100 optimizes system design for engineers who

must incorporate new emissions restrictions by

providing a more efficient hydraulic system that

maximizes power and conserves energy. Typical

applications include backhoes, telehandlers, wheel

loaders, forklifts, and forestry equipment.

Features

•

Flow sharing for maximum

controllability and safety. All sections

will continue to function regardless of

load differences and pump flow.

•

Load-independent flow control for

smooth operation and improved

productivity.

•

Load-sensing technology for higher

efficiency, safety, reduced energy

consumption, and longer system

lifetime.

•

Configurable as advanced electrically

controlled proportional valve as well as

load-sensing directional control valve.

•

Modular design providing a wide range

of configuration possibilities.

•

Up to eight different sections per valve

group. Maximum flow per section: 180

l/min [48 gpm].

•

Can be configured in combination with

our range of HIC hybrid modules and/or

PVG 32 for maximum flexibility.

•

Mechanical, hydraulic, and electrical

actuation options.

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | Mar 2016 | AI00000082en-US0101 | 1

Page 2

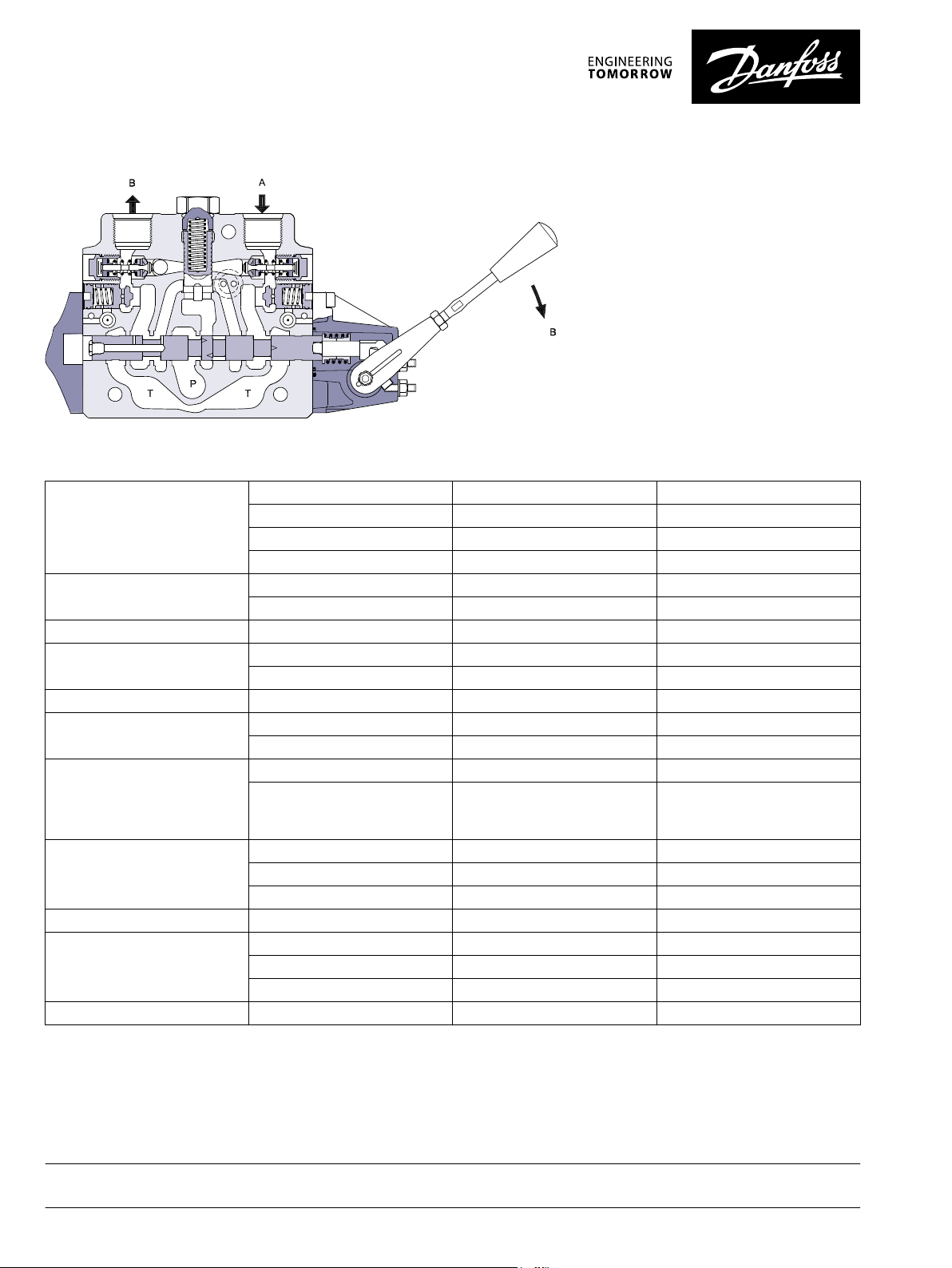

Sectional Drawing PVB

Technical Data PVG 100

Max. pressure Port P continuous 350 bar [5075 psi]

Port A/B 350 bar [5075 psi]

Port T, static / dynamic 25 bar/40 bar [365/580 psi]

Port T0, static / dynamic 5 bar/10 bar [75/145 psi]

Oil flow, rated (See characteristics, Port P 250 l/min [66 US gal/min]

Port A/B, with press. comp. 180 l/min [47.6 US gal/min]

Spool travel Standard ± 7 mm [±0.28 in]

Spool travel, float position spool

P→B→F

Dead band, flow control spools Standard ± 1.5 mm [±0.06 in]

Max. spool leakage at 100 bar [1450

psi] and 21 mm2/s [102 SUS]

Max. internal leakage shock valve

pilot operated check valve at 200

bar [2900 psi] and 21 mm2/s [102

SUS]

Oil temperature (inlet temperature) Recommended temperature 30 to 60°C 30 to 60°C

Ambient temperature -30 to +60°C [–22 to +140°F]

Oil viscosity Operating range 12 - 75 mm2/s [65 - 347 SUS]

Filtration Max. contamination (ISO 4406) 23/19/16 23/19/16

Proportional range 5.5 mm [±0.22 in]

Float position 8 mm [±0.32 in]

A/B to T, without shock valve 20 cm3/min [1.85 in3/min]

A/B to T, with shock valve 25 cm3/min [2.15 in3/min]

A/B to T, without shock valve 1 cm3/min [0.06 in3/min]

A/B to T, with shock valve 6 cm3/min [0.37 in3/min]

Min. temperature -30°C [–22°F]

Max. temperature +90°C [194°F]

Min. viscosity 4 mm2/s [39 SUS]

Max. viscosity 460 mm2/s [2128 SUS]

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | Mar 2016 | AI00000082en-US0101

Loading...

Loading...