Page 1

Proportional Valves Technical Information

2

1

S2

S1

2

1

4

3

T

P

A

B

P

T

A

B

Quick Reference

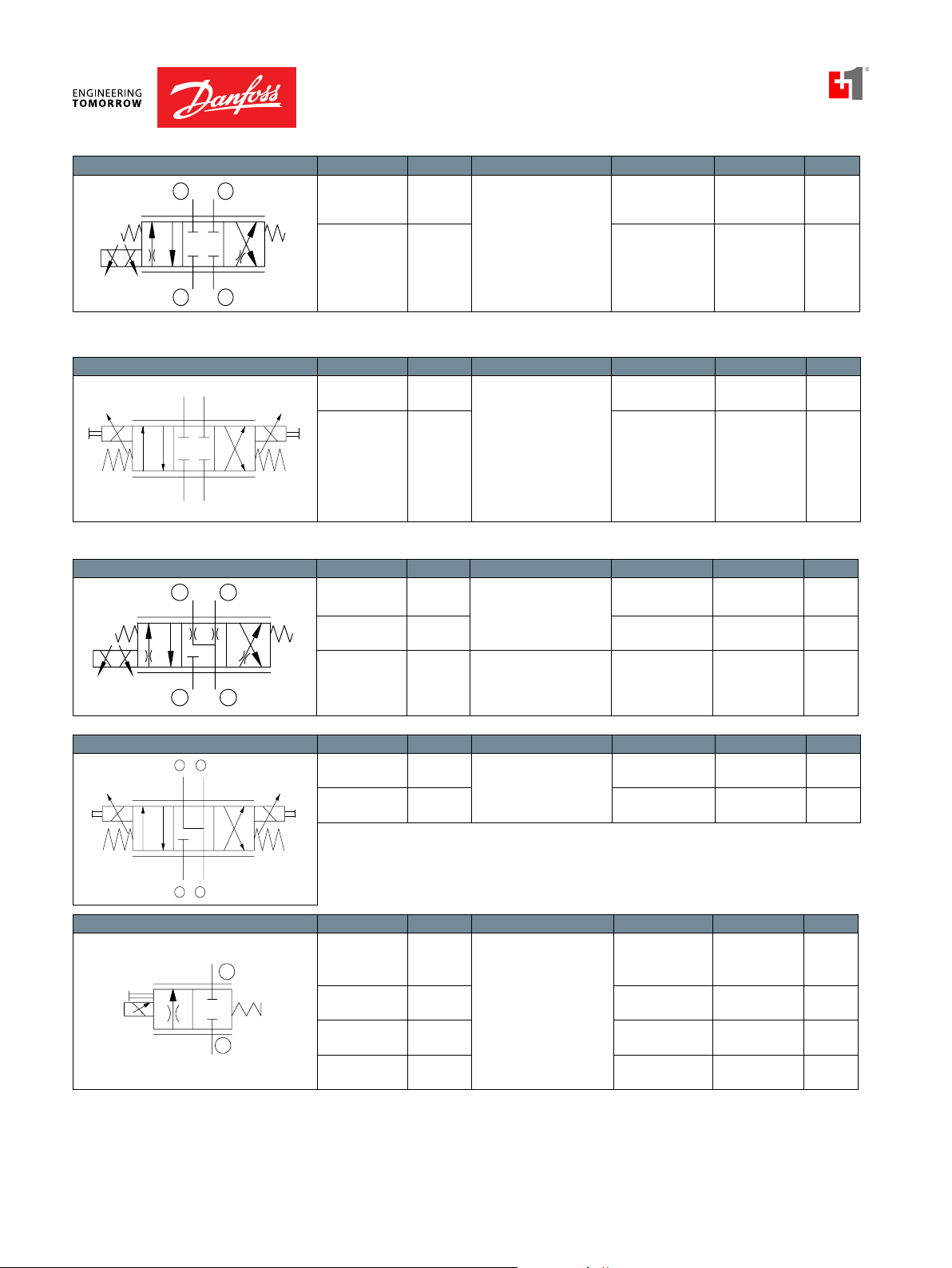

Proportional Directional Model No. Cavity Description Flow* Pressure Page

PSV10-34-02 SDC10-4 Proportional Directional

Valve

22 l/min

[6 US gal/min]

250 bar

[3600 psi]

PV - 13

PSV12-34-02 CP12-4 50 l/min

[13 US gal/min]

250 bar

[3600 psi]

PV - 15

Proportional Directional Model No. Cavity Description Flow* Pressure Page

PDCV03-3Z11 ISO D03 Proportional Directional

Valve

PDCV05-3Z11 ISO D05 60 l/min

Quick Reference

Proportional Directional Model No. Cavity Description Flow* Pressure Page

2

4

PSV08-34-05 SDC08-4 Proportional Directional

Valve

PSV10-34-05 SDC10-4 22 l/min

PSV12-34-05 CP12-4 60 l/min

S1

3

S2

1

30.3 l/min

[8 US gal/min]

[16 US gal/min]

12 l/min

[3.2 US gal/min]

[6 US gal/min]

[16 US gal/min]

350 bar

[5075 psi]

350 bar

[5075 psi]

241 bar

[3500 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

PV - 17

PV - 18

PV - 19

PV - 21

PV - 23

Proportional Directional Model No. Cavity Description Flow* Pressure Page

PDCV03-3Y11 ISO D03 Proportional Directional

Valve

PDCV05-3Y11 ISO D05 60 l/min

30.3 l/min

[8 US gal/min]

[16 US gal/min]

350 bar

[5075 psi]

350 bar

[5075 psi]

PV - 25

PV - 26

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

CP518-PNC SDC08-2 Proportional Flow

Control Valve, Non-

12 l/min

[3 US gal/min]

210 bar

[3000 psi]

PV - 27

Compensated, Normally

PSV10-NC SDC10-2 40 l/min

PSV12-NC SDC12-2 80 l/min

PSV16-NC SDC16-2 100 l/min

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

Closed

[11 US gal/min]

[21 US gal/min]

[26 US gal/min]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

PV - 28

PV - 29

PV - 30

purposes only.

BC332375973113en-000101 • February 2020

PV - 1

Page 2

Proportional Valves Technical Information

1

2

1

2

2

1

Quick Reference

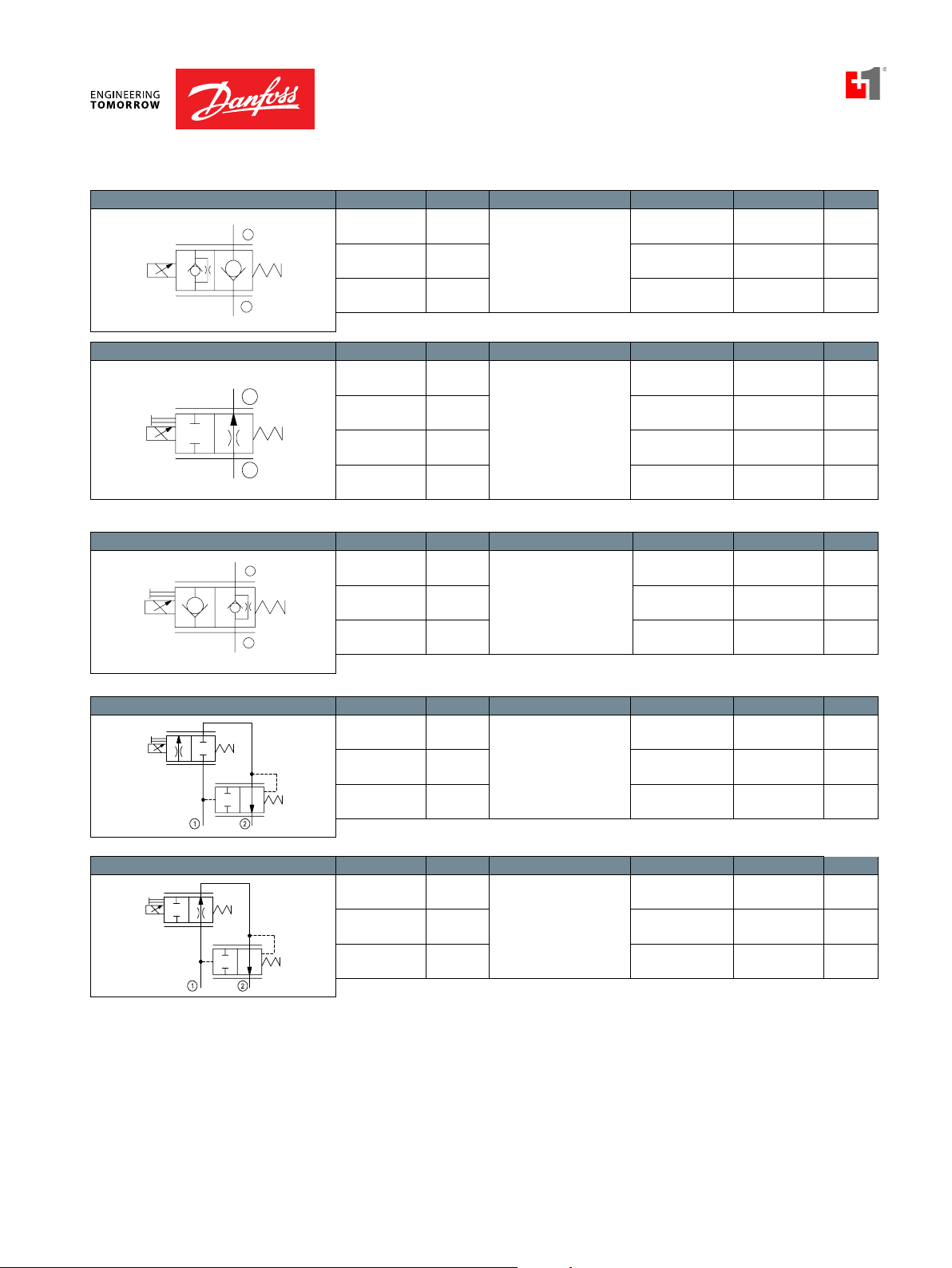

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PSVP10-NCR SDC10-2 Proportional Flow

Control Valve, Non-

PSVP12-NCR SDC12-2 70 l/min

PSVP16-NCR SDC16-2 90 l/min

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

CP518-PNO SDC08-2 Proportional Flow

PSV10-NO SDC10-2 45 l/min

PSV12-NO SDC12-2 100 l/min

PSV16-NO SDC12-2 110 l/min

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PSVP10-NOR SDC10-2 Proportional Flow

PSVP12-NOR SDC12-2 70 l/min

PSVP16-NOR SDC16-2 80 l/min

Compensated, Normally

Closed, Poppet Type

Control Valve, NonCompensated, Normally

Open

Control Valve, NonCompensated, Normally

Open, Poppet Type

55 l/min

[14 US gal/min]

[18 US gal/min]

[24 US gal/min]

12.1 l/min

[3.2 US gal/min]

[12 US gal/min]

[26 US gal/min]

[29 US gal/min]

45 l/min

[12 US gal/min]

[18 US gal/min]

[21 US gal/min]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

210 bar

[3000 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

PV - 31

PV - 32

PV - 33

PV - 34

PV - 35

PV - 36

PV - 37

PV - 38

PV - 39

PV - 40

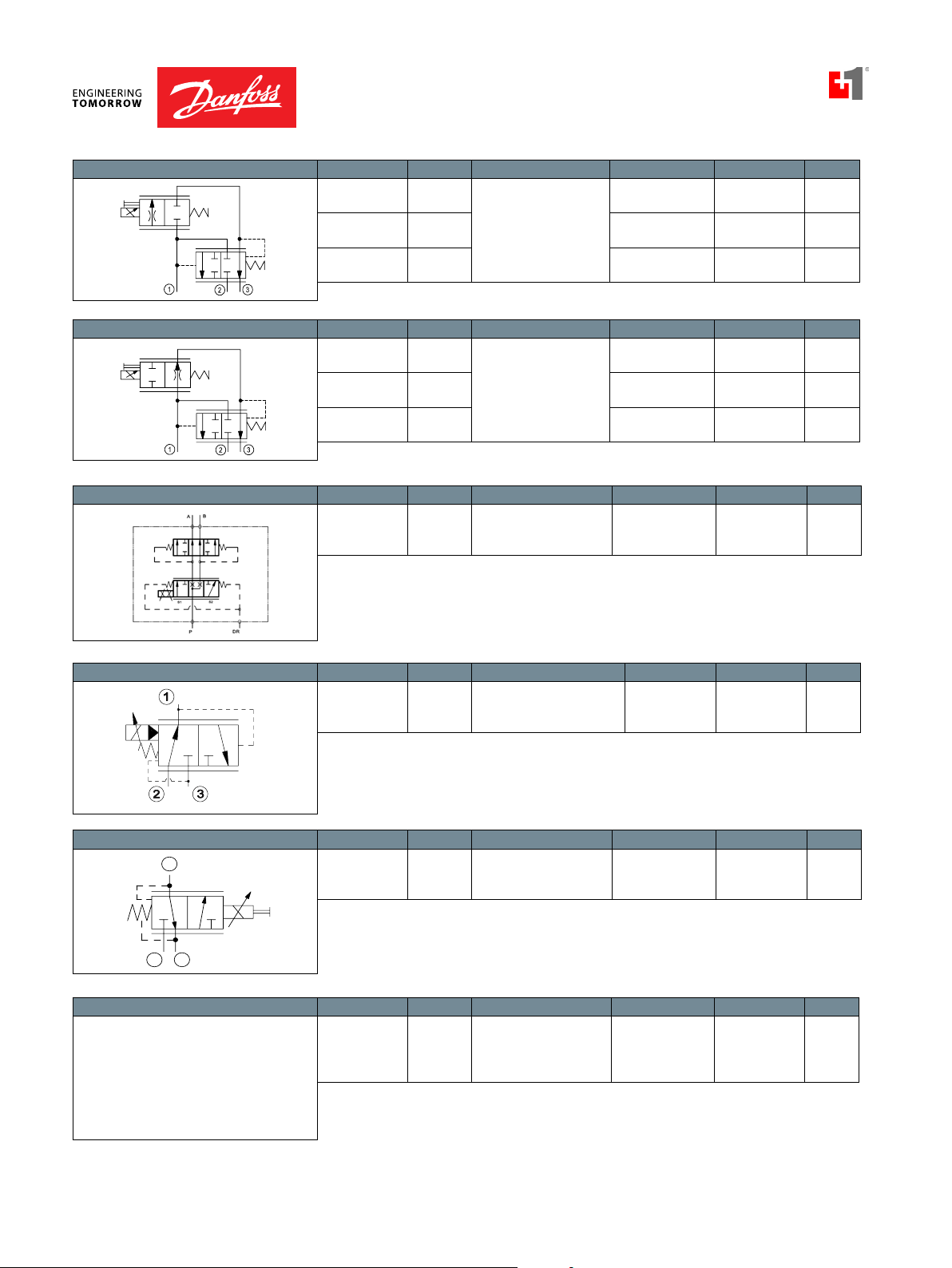

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PFC10-RC SDC10-2 Proportional Flow

Control Valve, Pressure

PFC12-RC SDC12-2 65 l/min

PFC16-RC SDC16-2 90 l/min

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PFC10-RO SDC10-2 Proportional Flow

PFC12-RO SDC12-2 60 l/min

PFC16-RO SDC16-2 85 l/min

Compensated,

Restrictive Type,

Normally Closed

Control Valve, Pressure

Compensated,

Restrictive Type,

Normally Open

30 l/min

[8 US gal/min]

[17 US gal/min]

[24 US gal/min]

30 l/min

[8 US gal/min]

[16 US gal/min]

[22 US gal/min]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

PV - 41

PV - 42

PV - 43

PV - 44

PV - 45

PV - 46

Quick Reference

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

purposes only.

BC332375973113en-000101 • February 2020

Page 3

Proportional Valves Technical Information

3

1

2

Quick Reference

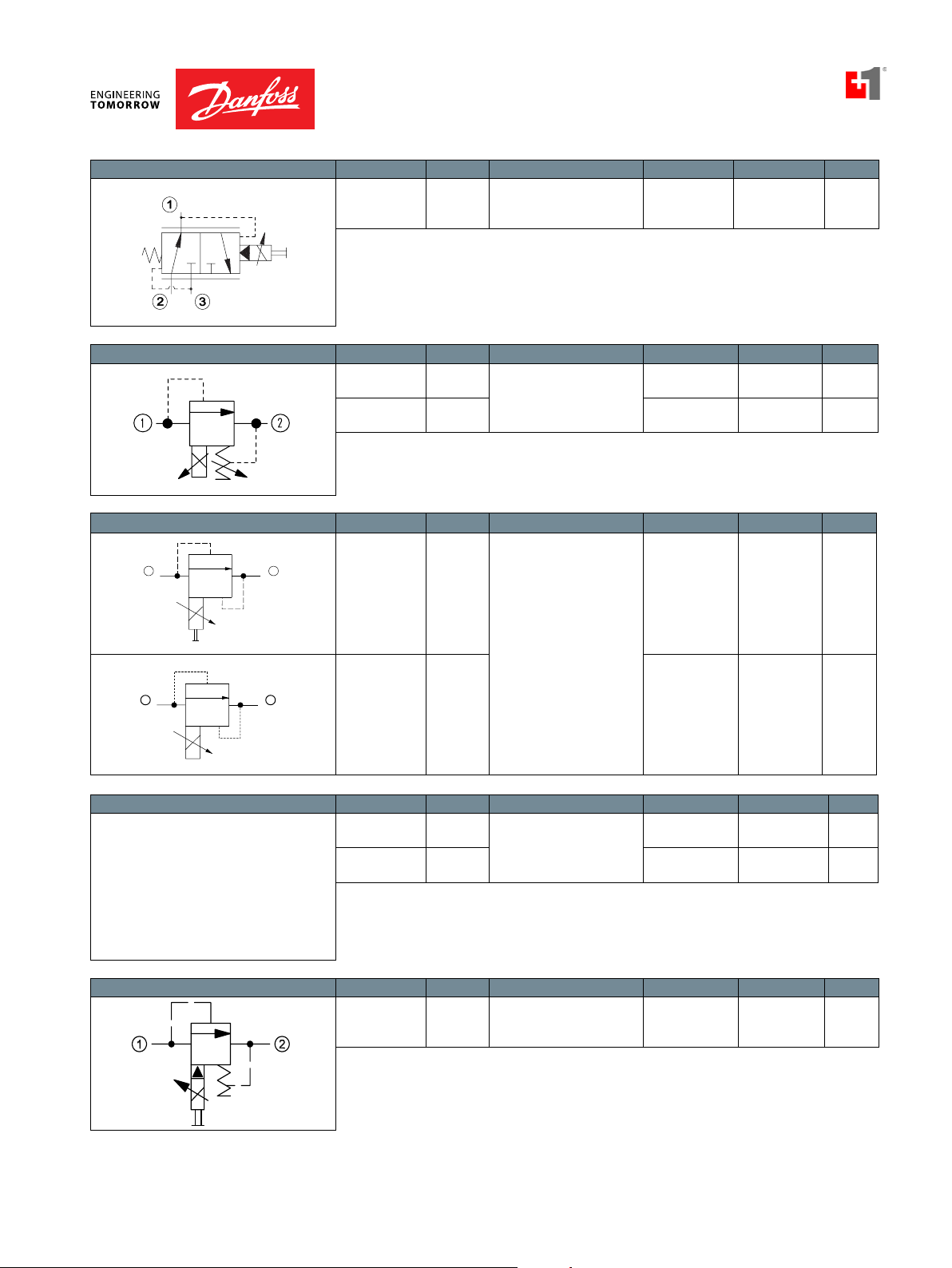

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PFC10-PC SDC10-3 Proportional Flow

Control Valve, Pressure

PFC12-PC SDC12-3 65 l/min

PFC16-PC SDC16-3 85 l/min

Proportional Flow Controls Model No. Cavity Description Flow* Pressure Page

PFC10-PO SDC10-3 Proportional Flow

PFC12-PO SDC12-2 70 l/min

PFC16-PO SDC16-3 90 l/min

Proportional Flow Divider Model No. Cavity Description Flow* Pressure Page

PFD10-OD CIB Proportional FLow

Compensated, Priority

Type, Normally Closed

Control Valve, Pressure

Compensated, Priority

Type, Normally Open

Divider, Compensated,

Catalog HIC

Quick Reference

40 l/min

[11 US gal/min]

[17 US gal/min]

[22 US gal/min]

35 l/min

[9 US gal/min]

[18 US gal/min]

[24 US gal/min]

40 l/min

[11 US gal/min]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

260 bar

[3770 psi]

230 bar

[3335 psi]

PV - 47

PV - 48

PV - 49

PV - 50

PV - 51

PV - 52

PV - 53

Proportional Pressure Reducing Model No. Cavity Description Flow* Pressure Page

PPR10-PAC SDC10-3 Proportional Pressure

Reducing/Relieving Valve,

Piloted

Proportional Pressure Reducing Model No. Cavity Description Flow* Pressure Page

CP558-24 SDC08-3 Proportional Pressure

Reducing Valve,

Direct Acting

Proportional Pressure Reducing Model No. Cavity Description Flow* Pressure Page

PPR09-POD SDC10-4 Proportional Pressure

Reducing/Relieving

Valve,

Piloted

18 l/min

[5 US gal/min]

4 l/min

[1 US gal/min]

25 l/min

[7 US gal/min]

250 bar

[3625 psi]

34 bar

[500 psi]

50 bar

[700 psi]

PV - 55

PV - 56

PV - 57

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

purposes only.

BC332375973113en-000101 • February 2020

PV - 3

Page 4

Proportional Valves Technical Information

1

2

12

Quick Reference

Proportional Pressure Reducing Model No. Cavity Description Flow* Pressure Page

XRP 06 NCS06/3 Proportional Pressure

Reducing/Relieving Valve,

Piloted

Proportional Pressure Relieving Model No. Cavity Description Flow* Pressure Page

PRV08-DAC SDC08-2 Proportional Pressure

Relief Valve,

HPRV08-DAC SDC08-2 1.89 l/min

Direct Acting,

Normally Closed

25 l/min

[7 US gal/min]

3.78 l/min

[1.0 US gal/min]

[0.5 US gal/min]

315 bar

[4500 psi]

215 bar

[3120 psi]

350 bar

[5075 psi]

PV - 59

PV - 60

PV - 61

Proportional Pressure Relieving

Proportional Pressure Relieving Model No. Cavity Description Flow* Pressure Page

Model No. Cavity Description Flow* Pressure Page

XMD 04 NCS04/2 Proportional Pressure

Relief Valve,

Direct Acting,

Normally Open

CP558-20 SDC08-2 8 l/min

PRV10-POC SDC10-2 Proportional Relief Valve,

Pilot Operated,

PRV12-POC SDC12-2 180 l/min

Normally Closed

5 l/min

[1.3 US gal/min]

[2 US gal/min]

76 l/min

[20 US gal/min]

[48 US gal/min]

250 bar

[3600 psi]

210 bar

[3000 psi]

250 bar

[3600 psi]

250 bar

[3600 psi]

PV - 62

PV - 63

PV - 64

PV - 65

Quick Reference

Proportional Pressure Relieving Model No. Cavity Description Flow* Pressure Page

* Flow ratings are based on a pressure drop of 7 bar [100 psi] unless otherwise noted. They are for comparison

purposes only.

BC332375973113en-000101 • February 2020

XMP 06 NCS06/2 Proportional Relief Valve,

Pilot Operated,

Normally Open

50 l/min

[13 US gal/min]

315 bar

[4500 psi]

PV - 66

Page 5

Proportional Valves Technical Information

Application Notes

Application Notes

PROPORTIONAL VALVES

Proportional, or electro-proportional valves, provide infinitely variable control of flow,

pressure, or direction, in response to a electric input signal.

There are four basic types of Danfoss ICS proportional valves:

• Flow control valves.

• Pressure reducing/relieving valves.

• Pressure relief valves.

• Directional control valves

Proportional valves

PLUS+1™ COMPLIANT Danfoss ICS solenoid valves are PLUS+1™ compliant. PLUS+1 compliance means our

valves are directly compatible with the PLUS+1 machine control architecture. Adding

solenoid valves to your application using PLUS+1 GUIDE software is as easy as drag-

and-drop. Software development that used to take months can now be done in just a

few hours. For more information on PLUS+1 GUIDE, visit http://powersolutions.danfoss.

com/Applications/PLUS1Compliance/index.htm. The table below details available GUIDE

function blocks for controlling Danfoss ICS solenoid valves.

GUIDE function blocks

Two-way proportional 10106103

Three-way proportional 10106104

BC332375973113en-000101 • February 2020

PV - 5

Page 6

Proportional Valves Technical Information

Restrictive-type circuit Priority-type circuit

Application Notes

PROPORTIONAL FLOW

CONTROL VALVES

Danfoss ICS proportional flow control valves are 2-way, spool-type valves that are

directly operated with a proportional electromagnetic solenoid actuator. By controlling

electric current, these valves create an infinitely variable orifice.

Proportional flow control valve

These valves are designed to be used with a logic element to provide pressure

compensation. Pressure compensation provides two advantages:

1. A constant pressure differential is maintained across the proportional valve (variable

orifice), which maintains constant flow regardless of changes in operating pressure

or load.

Typical flow versus pressure drop

2. A constant pressure differential

across the proportional valve limits

with compensation

without compensation

the flow forces acting on the valve

spool. At high flow and pressure,

Flow

the electromagnetic and spring

forces can be insufficient to maintain

valve operation without pressure

compensation.

Pressure drop

Application Notes

BC332375973113en-000101 • February 2020

Typical circuits use restrictive-type or priority-type pressure compensators with

proportional flow control valves to control speed of a hydraulic motor or cylinder.

Proportional flow control valves are available with a variety of flow capabilities (variable

orifice sizes). By matching this flow capability to various pressure compensator settings,

a wide range of flow vs. current control curves can be attained.

Typical circuit using a proportional valve

OutBypassOut

Flow

In In

Flow versus current

10.3 bar [150 psi]

6.9 bar [100 psi]

3.4 bar [50 psi]

Current

Effect of pressure compensator setting

Page 7

Proportional Valves Technical Information

AB

Application Notes

Application Notes

PROPORTIONAL

PRESSURE REDUCING/

RELIEVING VALVES

Proportional pressure reducing/relieving valves are 3-way valves that provide a

controlled output pressure as a function of electric current, regardless of system pressure

or flow (within the valve’s limits). Direct acting designs are available for low-flow

applications.

Direct-acting, proportional, pressure reducing valve

Proportional pressure reducing valves

Clutch pressure control

have a variety of applications including:

• Single acting cylinder position

control, e.g. combine header height

control.

• Clutch or brake pressure control.

• Pilot signal to a directional control

valve. By slowly ramping the current

P

to the proportional valve in this

example, a soft-start and soft-stop is

attained.

Single-acting cylinder piston control

Pilot signal to directional spool valve

W

High flow proportional pressure reducing valve functions can be created by using a

proportional valve to pilot a differential sensing valve; see differential sensing valve

application notes for more information.

BC332375973113en-000101 • February 2020

P

TP

PV - 7

Page 8

Proportional Valves Technical Information

Pressur

e

B

X

X

L1

S

L2

M2

Application Notes

PROPORTIONAL

PRESSURE RELIEF

VALVES

Proportional pressure relief valves

are 2-way valves that provide a relief

Normally closed versus normally open

proportional relief valves

pressure as a function of electric current.

Both normally-open (increasing pressure

with increasing current), and normallyclosed (decreasing pressure with

increasing current) are available.

The normally-open proportional relief

valve is a direct-acting design for low

flow applications. High flow normallyopen proportional relief valve functions

can be created by using a proportional

valve to pilot a differential sensing valve;

see differential sensing valve application notes for more information.

Normally-open proportional relief valve

P

T

Normally-Open

Normally-Closed

Current

Common applications for normally-open proportional relief valves are:

Application Notes

• Electro-proportional control of system relief pressure; see differential sensing valve

application notes for more information.

• Electro-proportional remote pressure compensator control for open circuit piston

pumps (for more information refer to BLN-10128 Series 45 Open Circuit Axial Piston

Pumps Technical Information).

Remote pressure compensator pump control

BC332375973113en-000101 • February 2020

Page 9

Proportional Valves Technical Information

Application Notes

Application Notes

PROPORTIONAL

PRESSURE RELIEF

VALVES

(continued)

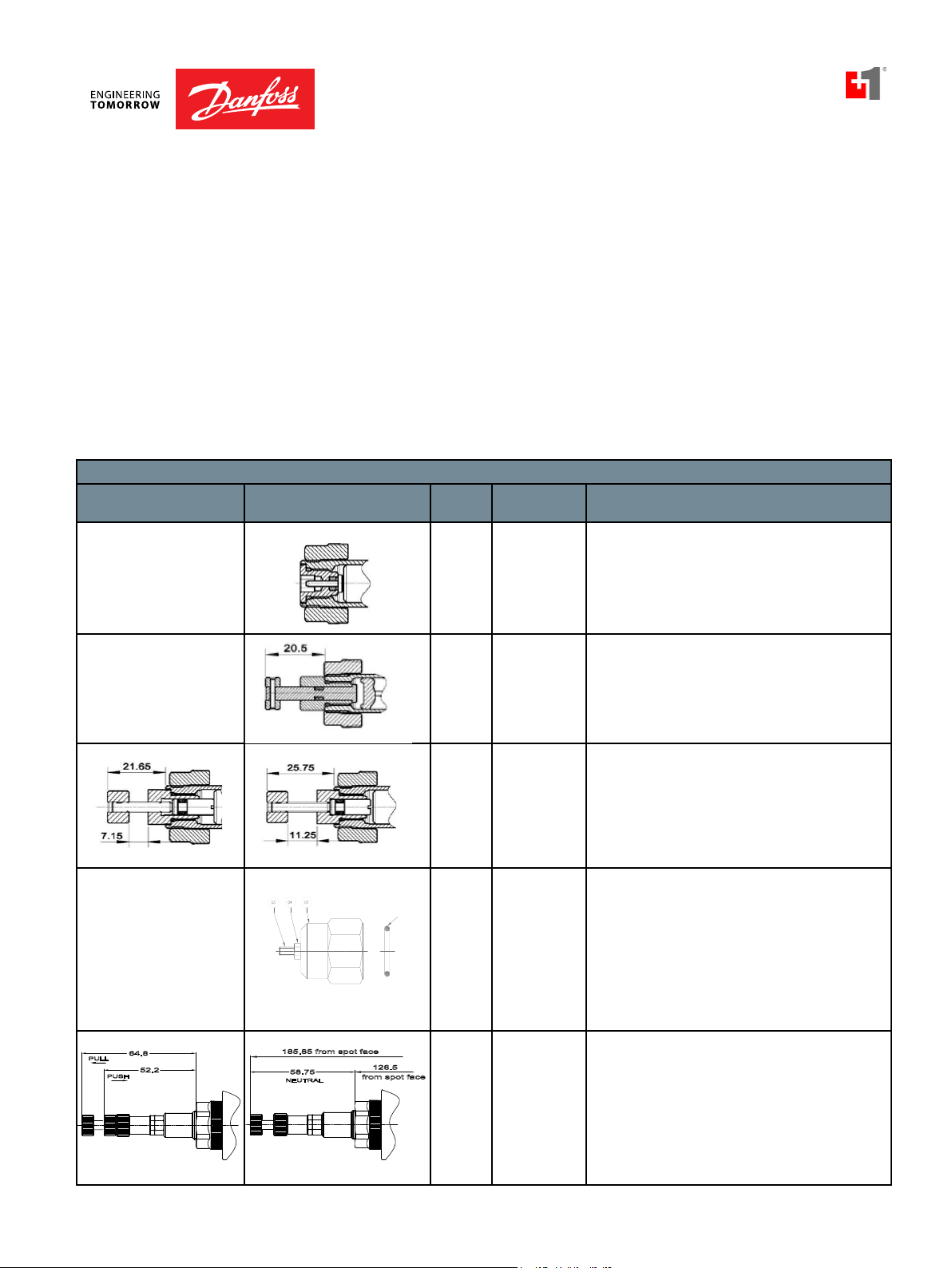

Normally-closed proportional relief valves are available in direct-acting and pilotoperated designs. A direct-acting, normally-closed proportional relief valve is used for

low flow applications. For high flow applications, internally pilot-operated cartridges are

available.

Internally pilot-operated cartridge for high flow applications

Common applications for normally-closed proportional relief valves are:

• Electro-proportional control of

Cooling fan speed control

system relief pressure or electroproportional remote pressure

compensator control for open circuit

piston pumps as above, but where

system requirements dictate full

pressure with no electrical signal.

ELECTRICAL

REQUIREMENTS

• Cooling fan speed control in

hydrostatic fan drive systems. (For

more information refer to BLN-10080

Fan Drives Systems and Components

Technical Information).

All proportional cartridge valves are

Proportional valve hysteresis

analog-type valves that control flow

or pressure as a function of electric

current. For this reason, proportional

valves should be driven with a current-

e

Direct current

PWM signal

controlled device that will maintain

constant output regardless of changes

in system voltage, line losses, or

ow or pressur

Fl

temperature. Typically available currentcontrolled valve drivers output a pulsewidth-modulated (PWM) square-wave

signal. An advantage of a PWM signal is

that the dither it provides significantly

Current

Typical performance

reduces hysteresis. Danfoss ICS recommends using a 100-200 Hz dither for best

performance.

BC332375973113en-000101 • February 2020

PV - 9

Page 10

Proportional Valves Technical Information

Current

Application Notes

TERMS AND

DEFINITIONS

Compensator is a hydraulic component that maintains a constant pressure drop across

a fixed or variable orifice.

Current is the flow of electricity through a conductor or coil, normally measured in amps

(A). Steady-state current flow in an electrical circuit can be calculated by Ohm’s Law, as

well as voltage and resistance.

Ohm’s Law I =

V

R

Current Control is a feature of almost all valve drivers. The output of analog

proportional valves is a direct function of current. If a valve is controlled with voltage,

higher solenoid temperatures, which increase solenoid resistance, will result in lower

valve output. To compensate for this, most valve drivers are designed with current

feedback circuitry. This means that as solenoid temperature rises or as supply voltage

and voltage losses change, the current

and corresponding valve output are

maintained.

Deadband is the range from zero to the

minimum current which causes the valve

Current feedback circuit

Input

sensing

resistor

Solenoid

to respond.

Digital Proportional Valves are

extremely fast responding valves that are controlled by a precise on-off signal to

produce an average output that is a function of duty cycle.

Application Notes

Dither is a “ripple” signal sent to a solenoid to reduce hysteresis. Dither can be a sine,

square, or saw-tooth wave superimposed on a PWM signal or it can be a wave on top of

a DC signal.

Duty Cycle is the % of time the valve is on divided by total time.

Hysteresis is the difference in output for a given input, depending on whether the

input is increasing or decreasing. It is normally expressed as a % of the maximum

rated output. For example, if a 160 l/min 42 US gal/min proportional flow control valve

provides 80 l/min 21 US gal/min with 1 amp-increasing and 88 l/min 23 US gal/min at 1

amp-decreasing, the hysteresis is:

(88-80)

= 5%

160

I

is the minimum current required for valve response (see deadband).

min

I

is the current required for maximum valve output.

max

Proportional Valves are analog devices controlled by electric current which may be

direct current (DC) or a PWM signal.

BC332375973113en-000101 • February 2020

Page 11

Proportional Valves Technical Information

Application Notes

Application Notes

TERMS AND

DEFINITIONS

(continued)

PWM is an acronym for Pulse-Width-Modulation. Most valve drivers use a current

controlled PWM which produces an average output that is a function of duty cycle in

order to reduce valve hysteresis and to allow current control without excessive heat

generation. A typical PWM output is a square wave from 80-500 Hz.

Ramping is the application of current to a solenoid with a linear or non-linear ramp,

rather than an instantaneous step. Ramping current on and off to a proportional valve

provides actuators with soft-starts and soft-stops. Ramps can generally be set or preprogrammed into valve drivers.

Resistance is a component’s opposition to the flow of electrical current, usually

measured in ohms (Ω). Resistance depends on the conductivity of the material, as well

as size, shape, and temperature. Solenoid resistance can vary greatly with temperature;

to compensate for this, current-controlled drivers are generally always used with

proportional valves.

Threshold is the minimum current required for valve response; see deadband.

Valve Driver is a generic term for any device that sends a signal to a proportional valve.

A valve driver may range from a simple electronic circuit attached to a knob or lever up

to a microcontroller with custom software and multiple inputs and outputs.

Voltage is the potential for current to flow in an electric circuit, usually measured in

volts (V).

BC332375973113en-000101 • February 2020

PV - 11

Page 12

Proportional Valves Technical Information

NEUTRAL

58.75

126.5

185.85 from spot face

from spot face

Application Notes

MANUAL OVERIDE

MANUAL OVERIDES

OPTIONS

Danfoss ICS proportional flow control valves, where noted in the individual

catalog pages, have optional manual overrides - “SPS” and “PB” (note

that it if the valve has a manual override option, it comes standard with

a push-pin style override). The manual overrides are “safety” features for

when power is lost and the proportional valve needs to be operated. If

using the “SPS” option, the screw-style manual override can be used to

proportionally adjust the flow setting when no power is supplied to the

coil. When using the “PB” option, the push-button manual override will

push to fully open or fully close the valve, which can send full flow, or

cut-off the flow to the system. So caution must be taken when applying

in a proportional system. The “SPS” proportional control is preferred. The

manual overrides, when activated, shift the valve to its energized position.

MANUAL OVERRIDE OPTIONS

Override Activated Normal Position Size Order Code Description

(mm) (mm)

10, 12,

16 Sizes

OMIT

(PN for HSV’s)

Standard for any valve with push-pin manual

override feature, where indicated in the catalog.

PB

10, 12,

Push Button

16 Sizes

SPS

10, 12,

16 Sizes

04 and

06 Sizes

Screw Style

(Push Type

Valves)

EN

Screw style

(metric)

64.8

PULL

PUSH

52.2

10 Size

PAP

(Push and Pull)

Optional feature for any valve with push-pin manual

override.

Optional feature for any valve with push-pin manual

override. Part number for SPS Manual Override Kit is

272601688.

Optional feature for screw adjustment for

proportional valves (XMD 04 and XMP 06)

Optional feature for push and pull functionality

on the 3 position, 4-way type proportional valves

(PSV10-34-XX)

Application Notes

BC332375973113en-000101 • February 2020

Page 13

Proportional Valves Technical Information

S2

S1

2

1

4

3

Proportional Directional

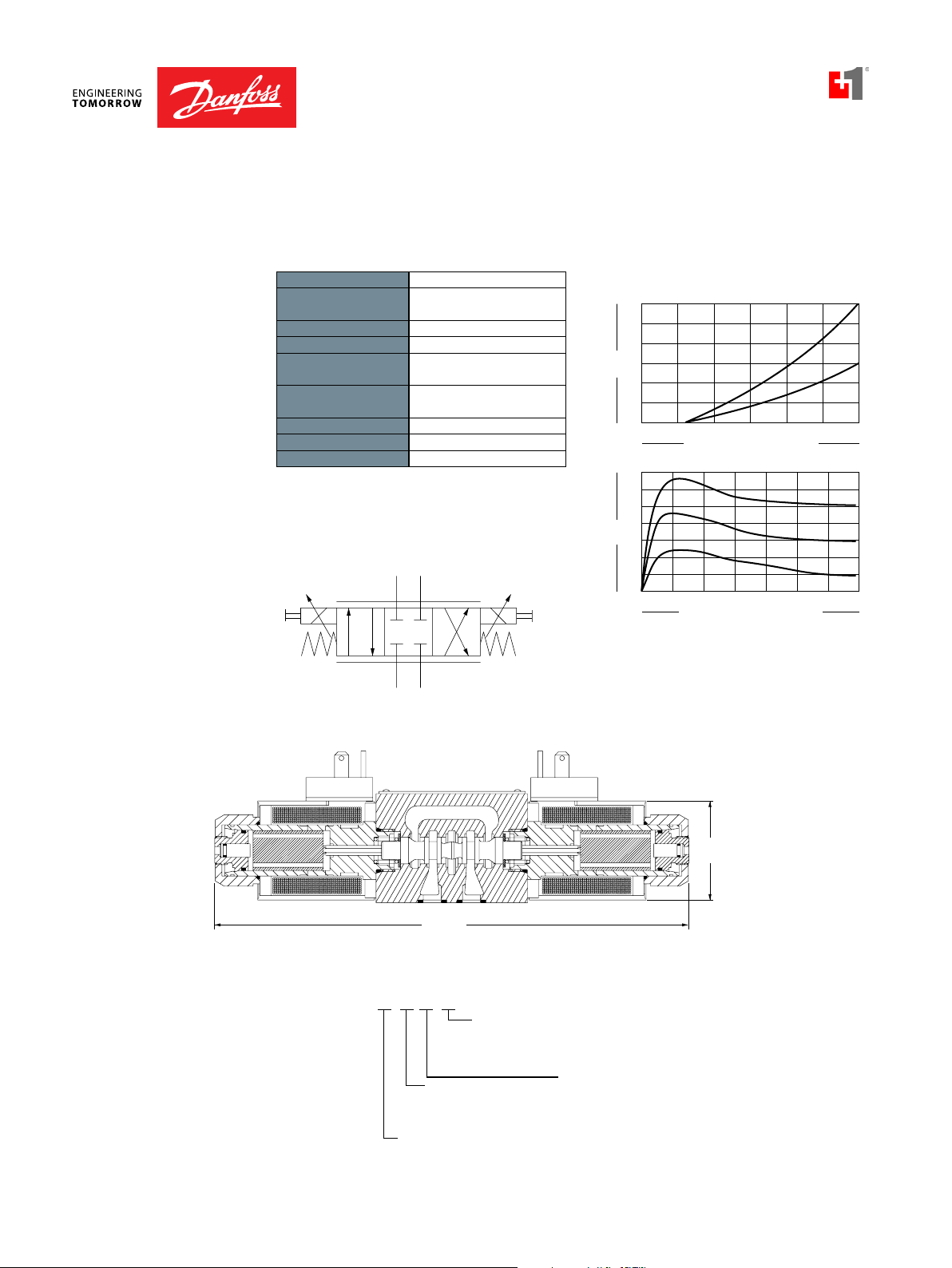

PSV10-34-02

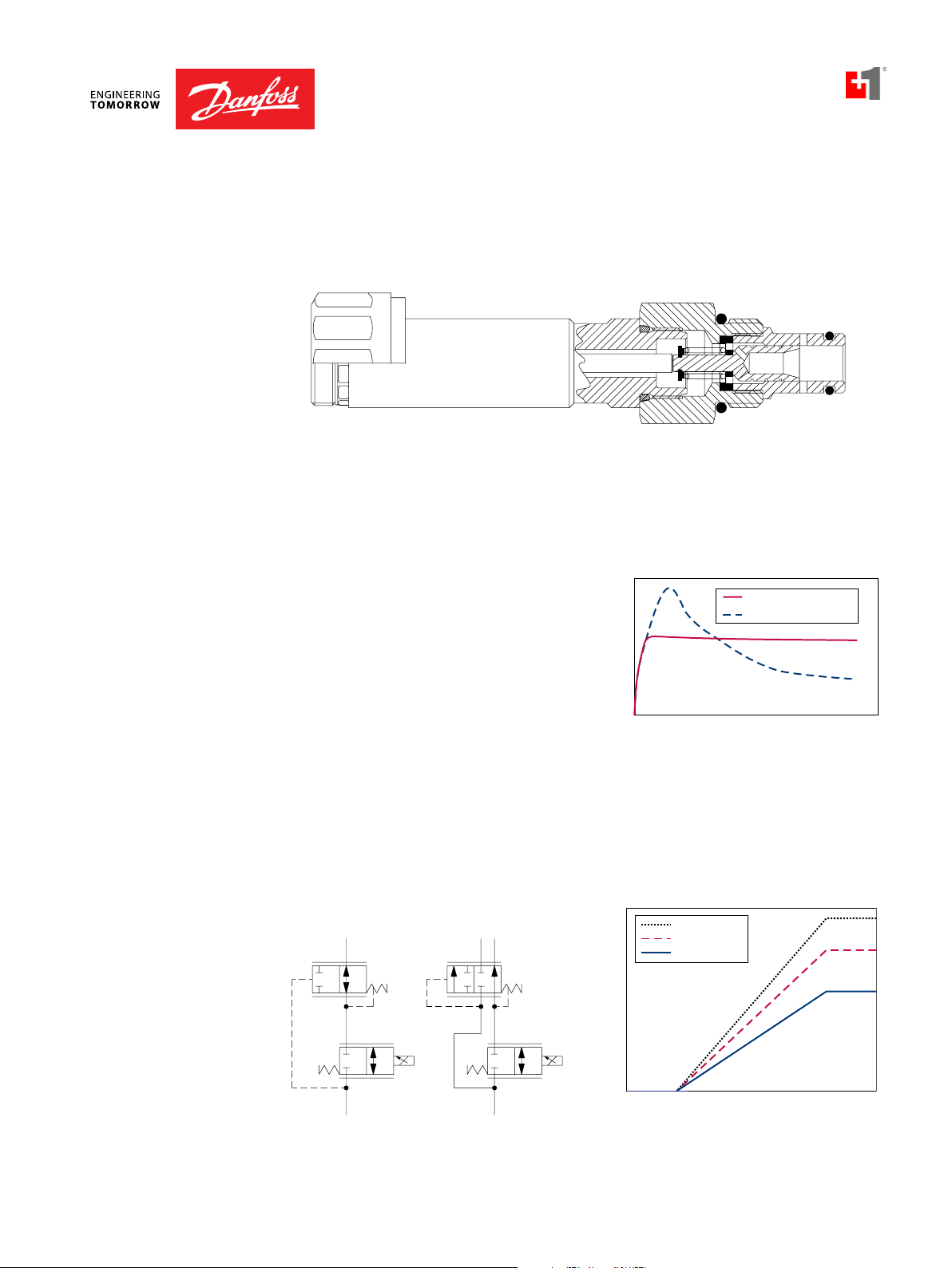

OPERATION

This is a proportional, non-compensated, 3 position 4 way,

directional flow control solenoid valve, with closed-center

spool.

APPLICATION NOTES

These cartridge valves are typically applied to provide bi-directional,

proportional control of hydraulic cylinders and motors where low

leakage is not required. For load-independent flow control, apply with

a pressure compensator, such as CP700-4 (see Example Circuit). Port 1

should be used as the tank port, with a maximum back-pressure of 150

bar. For applications with unequal flows, the highest flow should be

connected to Port 2.

Note: For optimal performance install with the solenoid valve below

the tank oil level in the horizontal position, reducing the chance for

trapped air in the valve.

SPECIFICATIONS

Rated Pressure* 250 bar [3600 psi]

Maximum Rated Flow at 10 bar

[145 psi]

Weight including coil 0.77 kg [1.7 lbs]

Hysteresis 4% maximum

Threshold current 0.5 A (12 VDC coil)

Maximum control current 1.5 A (12 VDC coil)

DIMENSIONS

Cavity SDC10-4

Standard Coil M16 26 Watt

Robust Coil R16 20 Watt

22 l/min

[6 US gal/min]

0.25 A (24 VDC coil)

0.8 A (24 VDC coil)

Robust Nut P/N 173804910

(no coil O-rings needed)

Shown with standard coils,

DIN connectors

Shown with Robust Coil

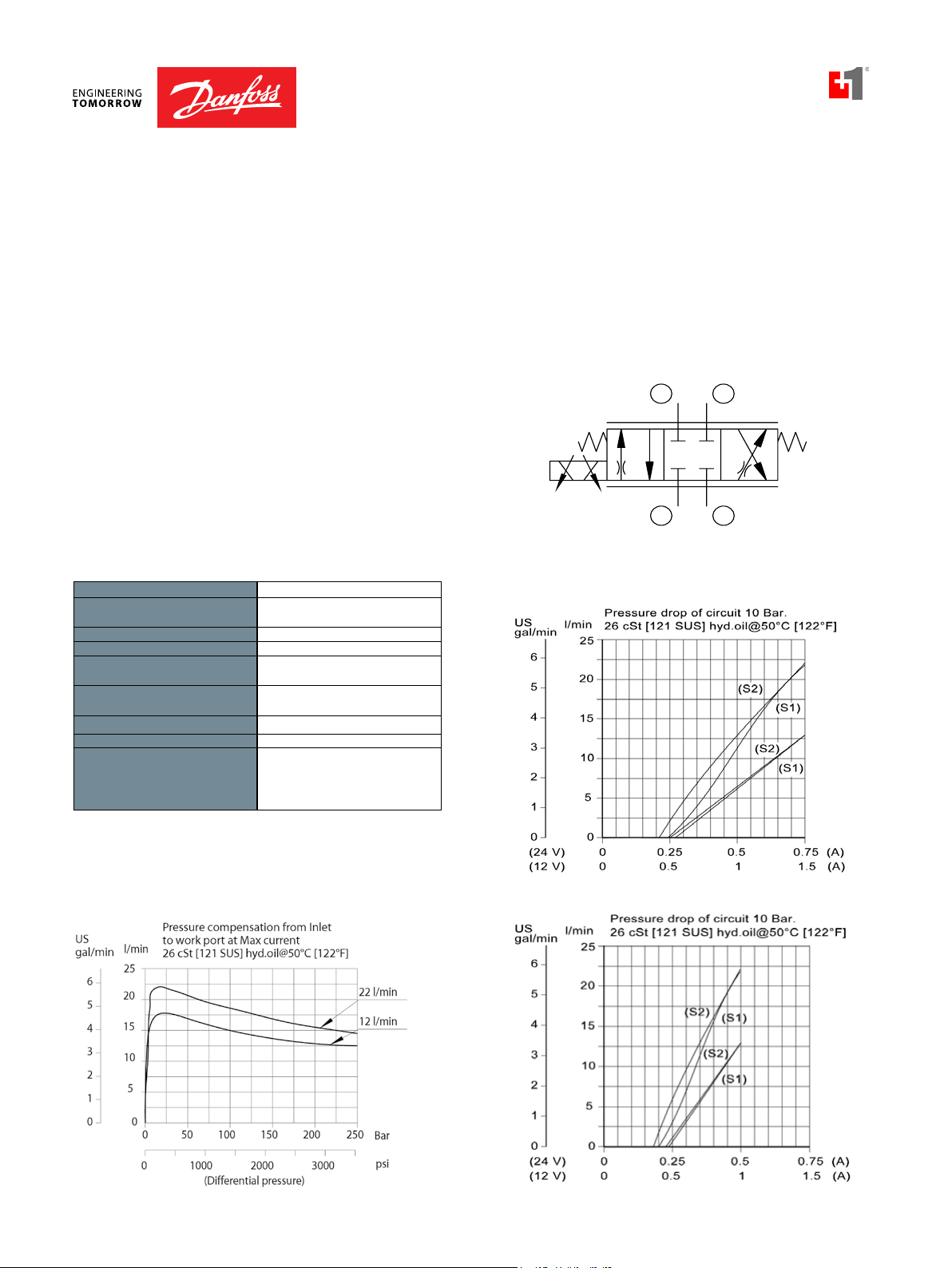

SCHEMATIC

THEORETICAL PERFORMANCE

Operating curves with M16 coil and plastic nut

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

BC332375973113en-000101 • February 2020

Operating curves with R16 coil and steel nut

PV - 13

Page 14

Proportional Valves Technical Information

Cavity Size:

Schematic:

Type

Max Regulated Flow:

Housing and Ports:

Housing P/N:

Seals: Seal Kit

Coil TerminationCoil Voltage:

10 = Size 10

34 = 3 Position, 4 Way

02 = Closed Center Spool

00 = No Coil

12D = 12 VDC

24D = 24 VDC

R12D = 12 VDC R-Coil

R24D = 24 VDC R-Coil

12 = 12 LPM (3 GPM)

22 = 22 LPM (6 GPM)

00 = No coil, with Nut

AJ = AMP Junior*

AS = AMP SuperSeal 1.5

DE = Deutsch

DN = DIN 46650*

FL = Flying Leads

*These terminations are not available

on robust coil (R12D, R24D)

B = Buna-N 354001919

V = Viton 354002019

00 = No Housing

L3B = AL 3/8 BSP

L4B = AL, 1/2 BSP

6S = AL #6 SAE

8S = AL, #8 SAE

Other housings available

PSV 10 - 34 - 02 - 12D

-

DE

-

22

-

PAP - B - 00

Proportional Solenoid

Valve, Non-compensated

Flow Control

No Housing

SDC10-4-L-3B

SDC10-4-L-4B

CP10-4-6S

CP10-4-8S

Manual Override:

Omit = No Override

PAP = Push and Pull Override**

**Consult Factory for Details

Proportional Directional

PSV10-34-02

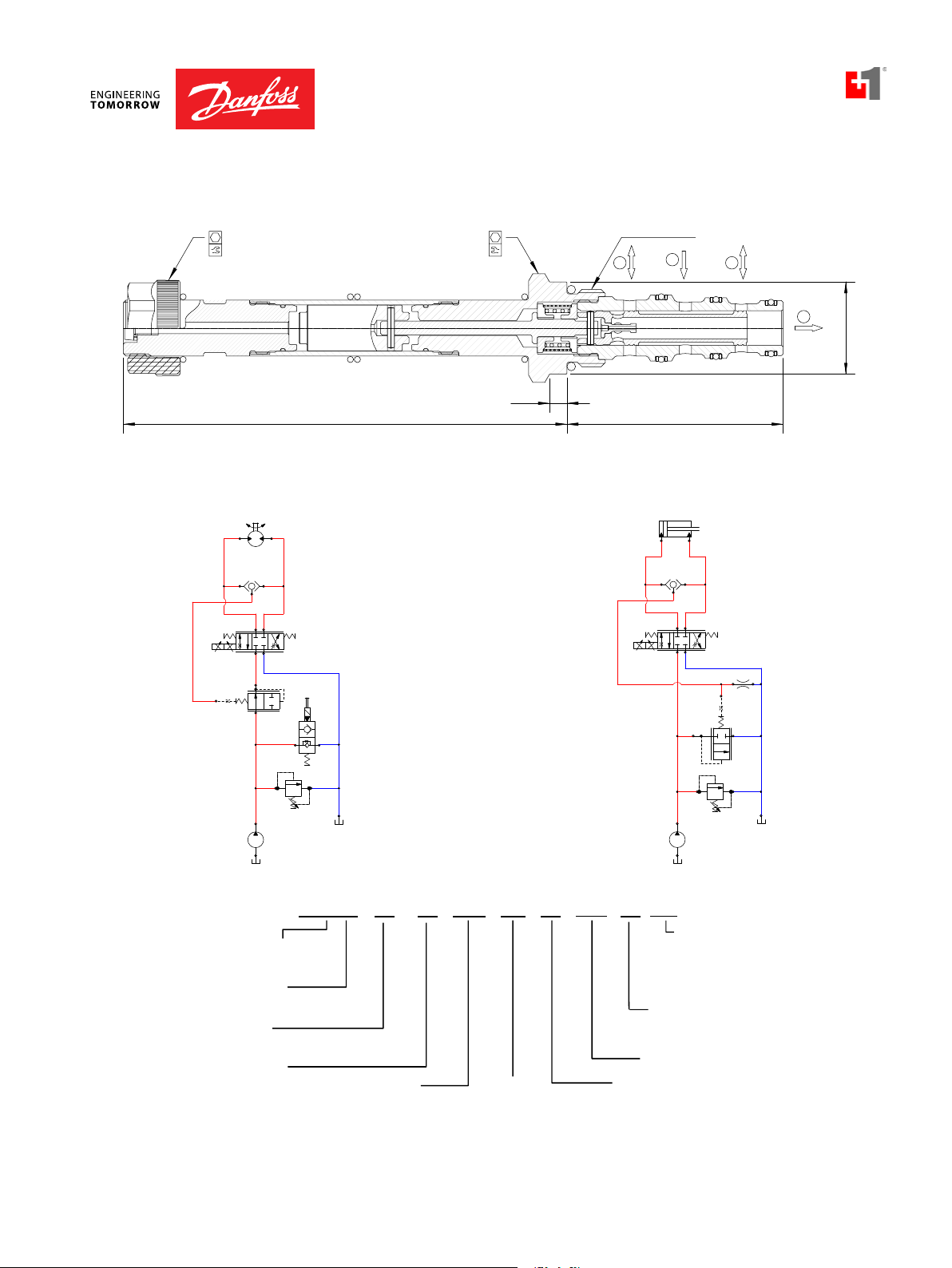

DIMENSIONS

mm [in]

24mm

9-11 Nm [6-8 lbf*ft]

EXAMPLE CIRCUITS

Pressure Compensated Bi-directional Proportional Motor Control Double Acting Cylinder with Proportional Speed Control

Cross-sectional view

45-50 Nm [33-37 lbf*ft]

Coil Nut KIT P/N 17400031

COILS NOT SHOWN FOR CLARITY

INSTALL O-RINGS (4) PLCS AS SHOWN

127.25

[5.01]

27mm

S1S2

[0.20]

7/8-14 UNF 2A

4

3

2

1

Ø26.5

5

62

[2.44]

[Ø1.04]

CP124-1

PSV10-34-02

CP700-4

SVP08-NO

RV08-DR

ORDERING INFORMATION

BC332375973113en-000101 • February 2020

CP124-1

PSV10-34-02

CP700-1

RV08-DR

Page 15

Proportional Valves Technical Information

S2

S1

2

1

4

3

)

)

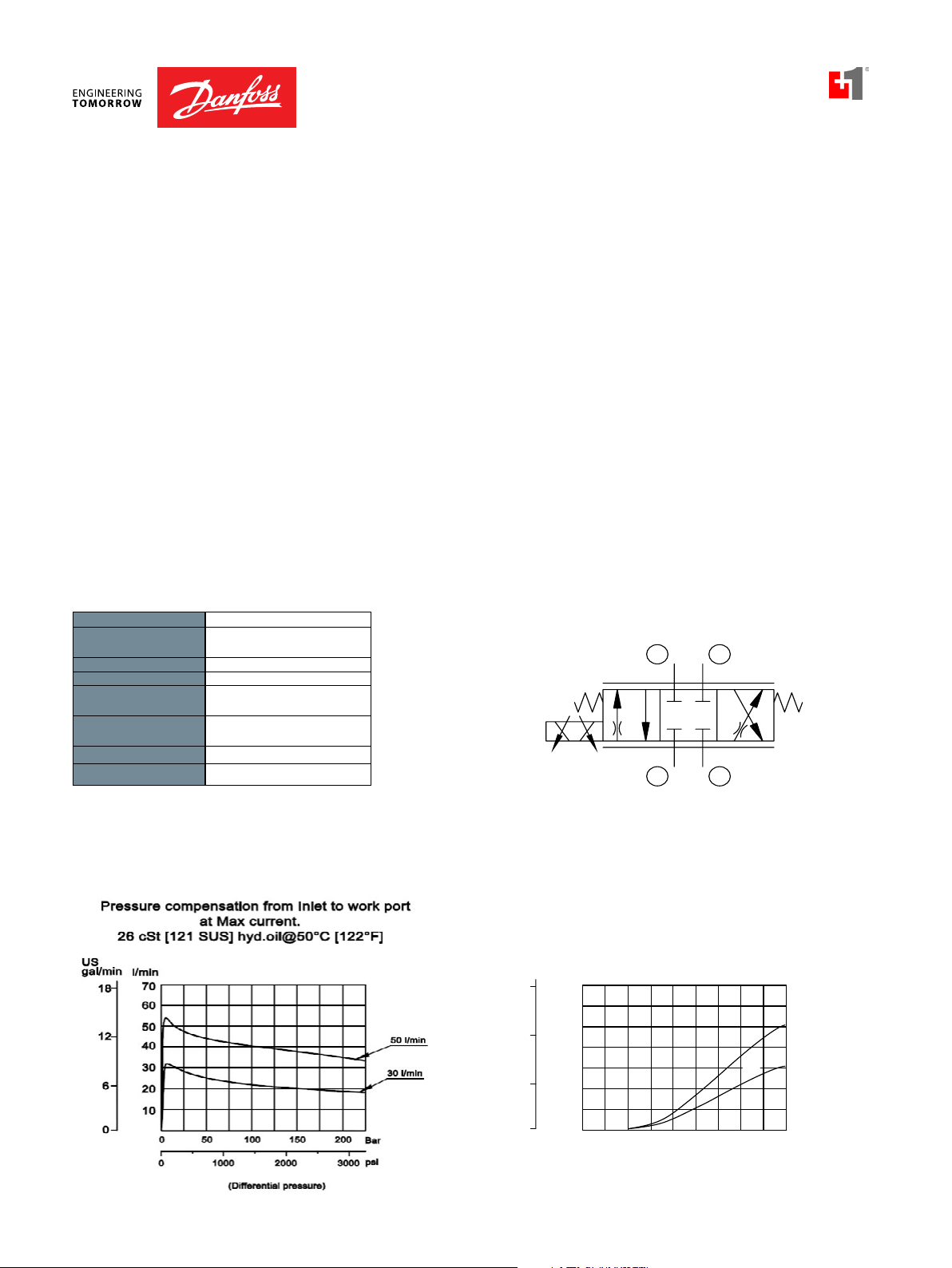

Operating curves with M19 coil and nut.

Curves made with a logic element set at 10 Ba

26 cSt [121 SUS] hyd.oil@50C [122F

Proportional Directional

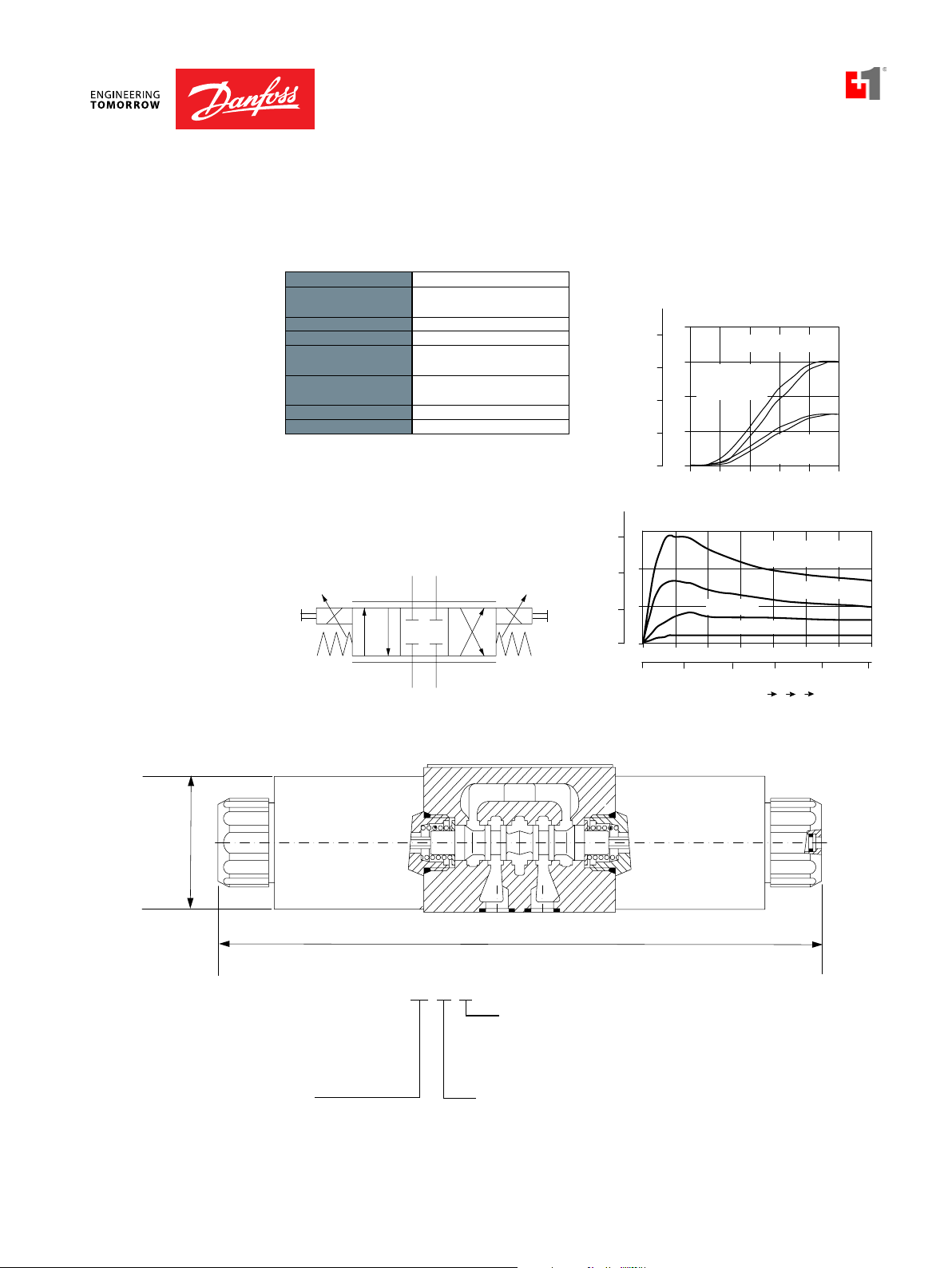

PSV12-34-02

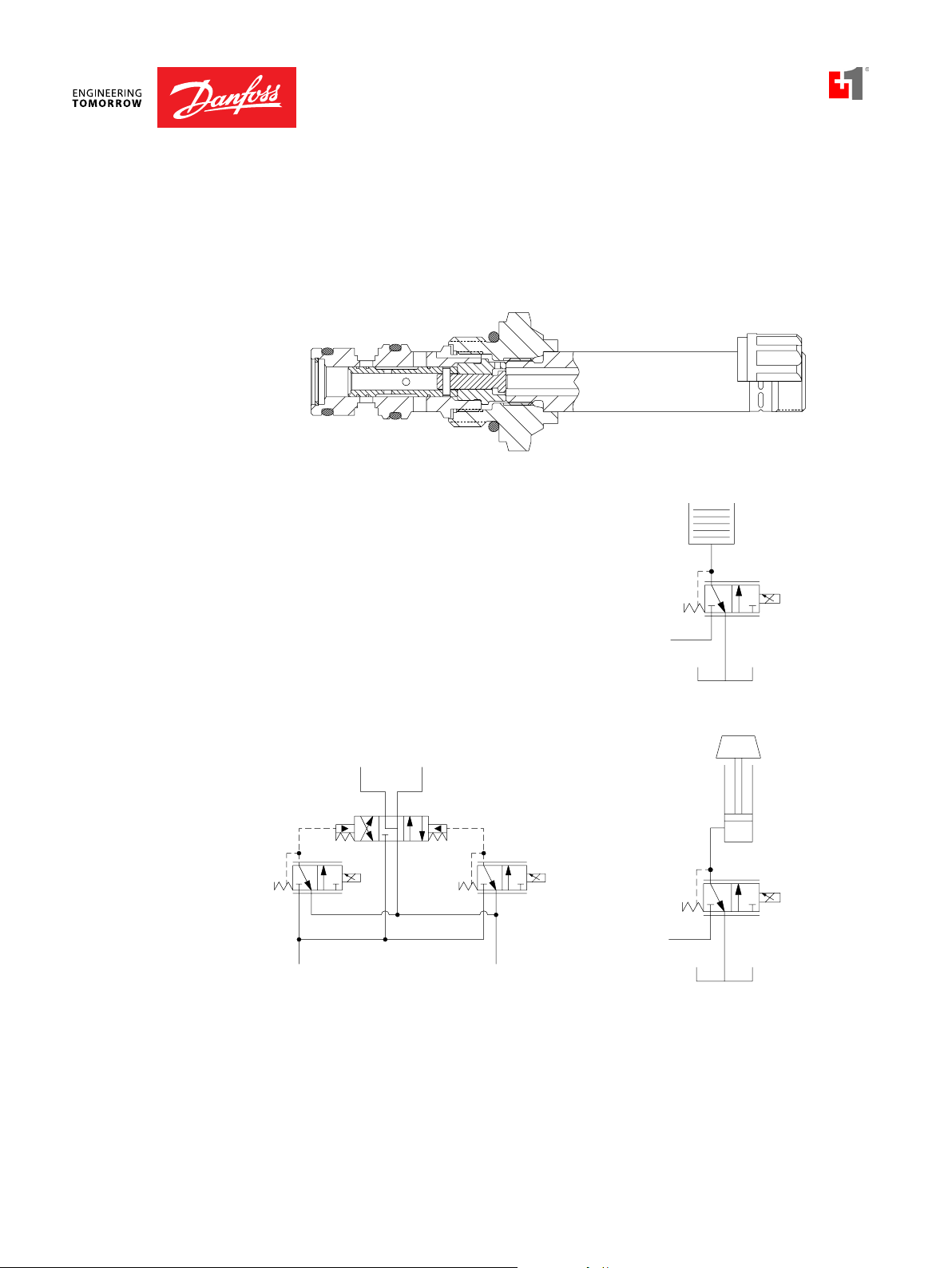

OPERATION

This is a proportional, non-compensated, 3 position 4 way, directional

Shown with Deutsch

connector

flow control solenoid valve, with closed-center spool.

APPLICATION NOTES

These cartridge valves are typically applied to provide bi-directional,

proportional control of hydraulic cylinders and motors where low

leakage is not required. For load-independent flow control, apply with

a pressure compensator, such as HLE10-OPO (see Example Circuit). Port

1 should be used as the tank port, with a maximum back-pressure of

150 bar. For applications with unequal flows, the highest flow should be

connected to Port 2.

Note: For optimal performance install with the solenoid valve below the

tank oil level in the horizontal position, reducing the chance for trapped

air in the valve.

SPECIFICATIONS SCHEMATIC

Rated Pressure* 260 bar [3770 psi]

Rated Flow at 10 bar

[145 psi]

Weight including coil 1.2 kg [2.64 lbs]

Hysteresis <4%

Threshold current 0.25 A (12 VDC coil)

DIMENSIONS

Maximum control

current

Cavity CP12-4

Standard Coil M19 33 Watt

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

50 l/min

[13 US gal/min]

0.50 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Shown with DIN

connector

THEORETICAL PERFORMANCE

BC332375973113en-000101 • February 2020

US

gal/min

18

12

6

0

l/min

(24 V)

(12 V)

60

40

20

r.

]

(50)

(30)

0.30

0.60

0.6

1.2

0.9 (A

1.8 (A

PV - 15

Page 16

Proportional Valves Technical Information

PSV12-34-02

CP124-1

HLE10-CPC

CP200-1

Proportional Directional

PSV12-34-02

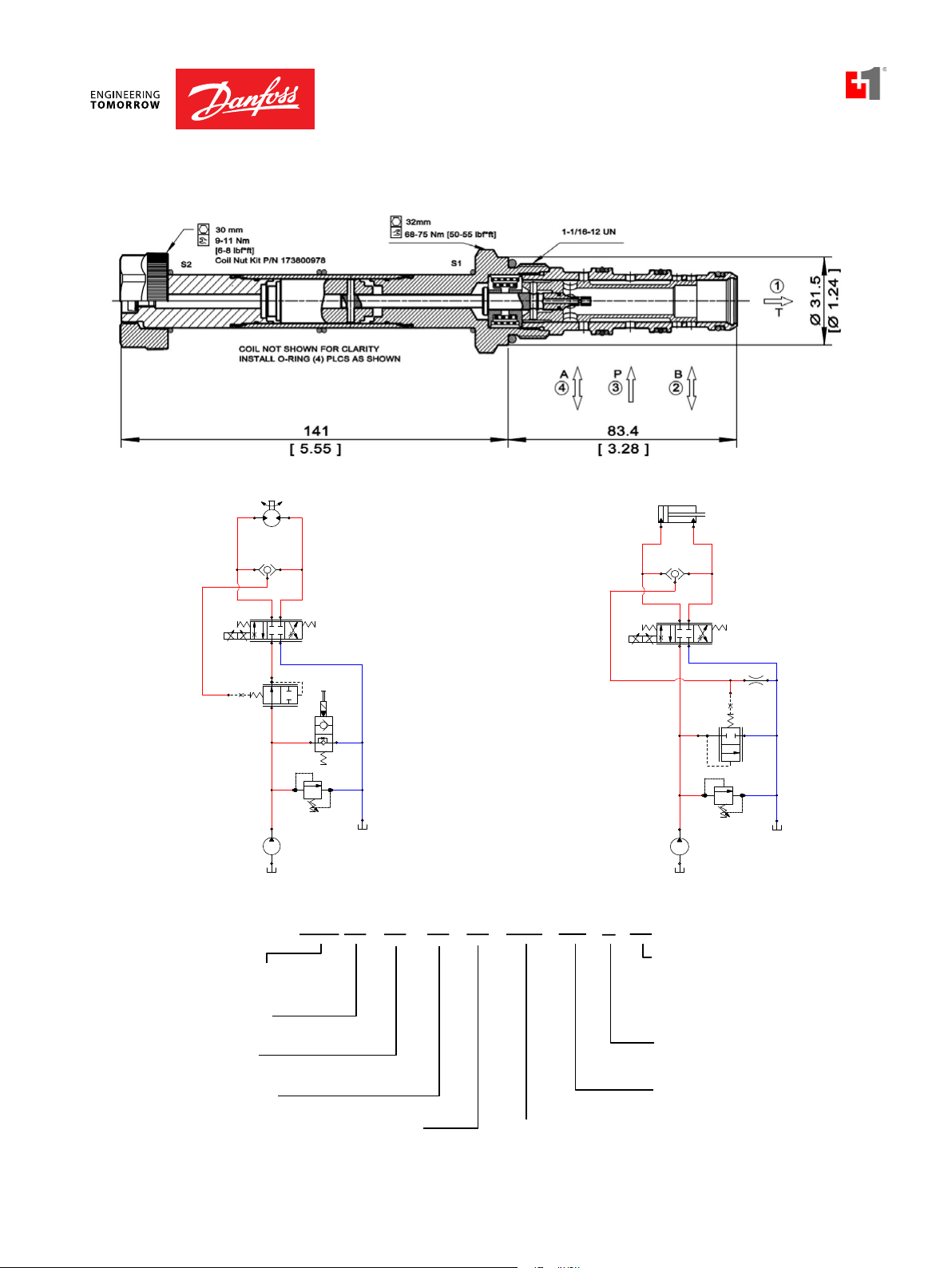

DIMENSIONS

mm [in]

EXAMPLE CIRCUITS

Pressure Compensated Bi-directional Proportional Motor Control Double Acting Cylinder with Proportional Speed Control

Cross-sectional view

ORDERING INFORMATION

CP124-1

PSV12-34-02

HLE10-OPO

CP200-1

Proportional Solenoid

Valve, Non-compensated,

Flow Control

Cavity Size:

12 = Size 12

Type :

34 = 3 Position, 4 W ay

Schematic:

02 = Closed Center Spool

SVP10-NO

12

PSV

Max Regulated Flow:

30 = 30 LPM (8 GPM)

50 = 50 LPM (13 GPM)

- 34

-

-

50

-

-

12D

Coil Voltage:

00 = No Coil

12D = 12 VDC

24D = 24 VDC

02

-

B

- 00DE

Housing and Ports: Housing P/N:

00 = No Housing

3B = AL, 3/8 BSP

4B = AL, 1/2 BSP

8S = AL, #8 SAE

10S = AL, #10 SAE

*Other housings available

Seals: Seal Kits:

B = Buna-N 11106420

V = Viton 11106444

Coil Termination:

00 = No coil, with Nut

AJ = AMP Junior

AS = AMP SuperSeal 1.5

DE = Deutsch

DN = DIN 46650

FL = Flying Leads

No Housing

CP12-4-3B

CP12-4-4B

CP12-4-8S

CP12-4-10S

BC332375973113en-000101 • February 2020

Page 17

Proportional Valves Technical Information

gpm

6

gpm

P

T

A

B

PDCV03-3Z11/15-12-E1-8S

ll internal seals are viton

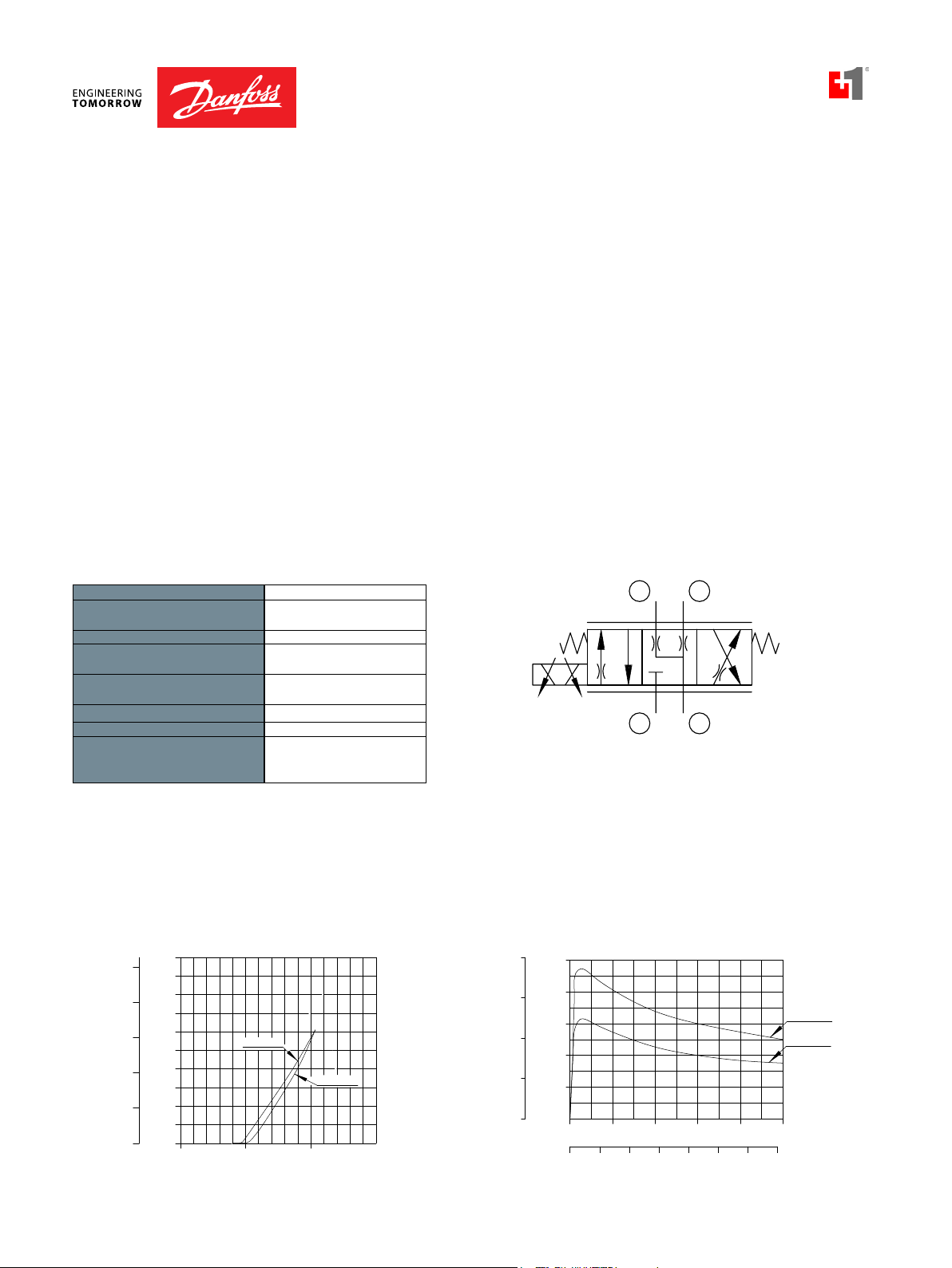

Proportional Directional

PDCV03-3Z11

OPERATION

SPECIFICATIONS

This valve is a proportional directional control.

Rated pressure 350 bar [5075 psi]

Rated flow at 10 bar

[145 psi]

30 l/min

[8 US gal/min]

Weight 2.40 kg [5.29 lb]

Hysteresis 6% maximum

Threshold current 0.5 A (12 VDC coil)

0.25 A (24 VDC coil)

Maximum control

current

2.4 A (12 VDC coil)

1.2 A (24 VDC coil)

Cavity ISO D03

Standard Coil PD03 40 Watt

Coil nut 158-8005

SCHEMATIC

THEORETICAL PERFORMANCE

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

L/min

30

8

25

7

20

5

15

4

Flow

10

3

51

0

L/min

35

9.2

30

7.9

25

6.6

20

5.3

Flow

15

4

10

2.6

51.3

0

at 10 bar [145 psi] pressure drop

e

d

o

C

C

0.4

0.8 1.2 1.622.4

Current, Amps (with 12VDC coil)

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

2

.

4

A

(

1

2

1

.

9

A

(

1

2

V

1

.

4

A V

(

1

2

bar

psi

100 150 200 250 300 350

50

Loop pressure drop (P ABT)

725

1450 2176 2901 3626 4351 507

0

3

=

1

=

e

d

o

V

c

o

i

l

)

c

o

i

l

)

c

o

i

l

)

5

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

Nominal flow rate

215.9

[8.50]

Subplate option

OMIT= No subplate

8S = Aluminum, #8 SAE ports

S8S =Steel, #8 SAE ports

Voltage

12 = 12 VDC

24 = 24 VDC

15 = 15 L/min [4.0 gpm]

30 = 30 L/min [7.9 gpm]

Termination

E1 = DIN 43650

E3 = Amp Jr.

E8 = Lead wires

E12= Deutsch

E14= Dual spade

Ø 45.7

[1.80]

Seal Kit

B=Buna-N158-8007

V=Viton 158-8062

Note :A

Bolt Kit

#10-24 Thd. 158-8064

M5 Thd. 158-8026

Seal kit

BC332375973113en-000101 • February 2020

PV - 17

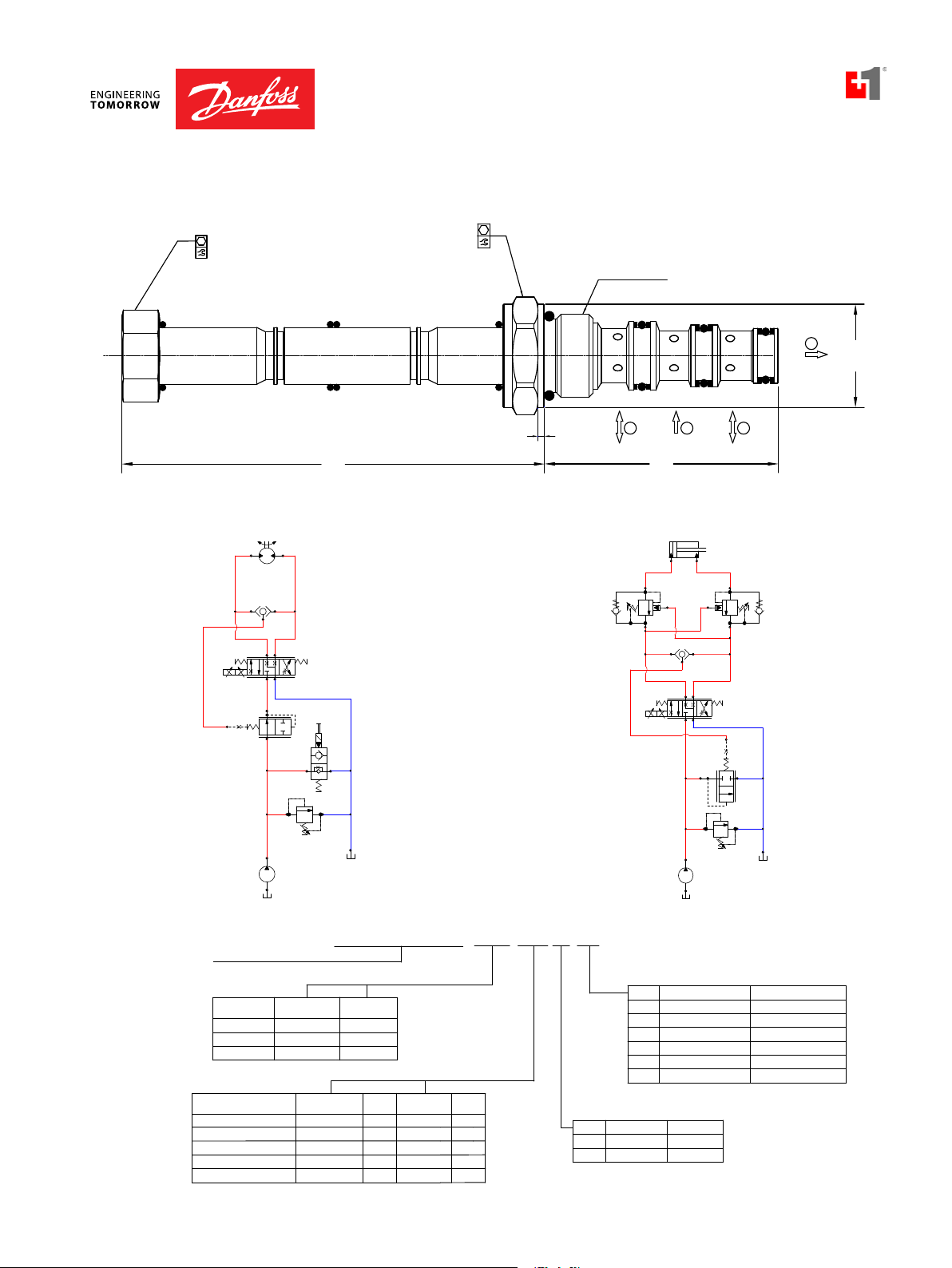

Page 18

Proportional Valves Technical Information

flow

P

T

A

B

318 mm

[12.52 in]

70 mm

[2.76 in]

Fl

n9

Proportional Directional

PDCV05-3Z11

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated proportional directional control valve.

THEORETICAL PERFORMANCE

Rated pressure 350 bar [5075 psi]

Rated Flow at 10 bar

[150 psi]

Weight 6.60 kg [14.60 lb]

Hysteresis 6% maximum

Threshold current 0.2 A (12 VDC coil)

Maximum control

current

60 l/min

[16 US gal/min]

0.1 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

US gal/min

20

15

10

flow

26 cSt [125 SUS] hyd.oil @ 20° C [68° F]

l/min

80

60

At 10 bar

(145 psi)

pressure drop

40

Cavity ISO D05

Standard Coil PD05 23 Watt

15

l/min

60

20

5

0

0

SCHEMATIC

40

10

20

5

0

0

psi

50

bar

0

100

1000

Loop Pressure Drop P A BT

Cross-sectional view

flow vs current

Nominal flow=60 l/min

Nominal flow

=30 l/min

2.0

0.96 Amps

150

1.51.00.50

Current = 2.40 Amps

1.92 Amps

250

200

3000

Current, Amps (12VDC coil)

pressure drop

1.44 Amps

2000

3500

300

2.5

350

5000

ORDERING

INFORMATION

30 = 30 l/min [7.9 US gal/min]

60 = 60 l/min [15.8 US gal/min]

PDCV05-3Z11/30-12-E1

ow rate

Connector

E1 =DIN 43650

E8 =Lead wires

E10 =Deutsch on leads

Voltage

12 =12 VDC

24 =24 VDC

Seal kit

B=Buna N 158-8023

V=Vito

158-80

All internal seals areViton

Bolt kit

1/4-20 Thd 158-8095

M6 Thd 158-8024

4

BC332375973113en-000101 • February 2020

Page 19

Proportional Valves Technical Information

3 TO 2

3 TO 4

1

2

3

4

5

gal/min

0

(12 V)

(24 V)

1.5 (A)10.50

l/min

20

16

12

8

4

0.75 (A)0.50.25

0

0

Flow vs. Current

26 cSt [121 SUS] hyd.oil@50°C [122°F]

10 bar pressure drop

Pressure Compensation from Inlet to Work Port

26 cSt [121 SUS] hyd.oil@50°C [122°F]

Bar

250

l/min

12

9

6

3

20015010050

0

0

Differential pressure

300020000 1000

psi

0

US

gal/min

4

3

2

1

15

0.8 A

1.0 A

3

4

1

2

S1

S2

Proportional Directional

PSV08-34-05

OPERATION

This is a proportional, non-compensated, 3 position 4 way,

directional flow control solenoid valve, with float-center spool.

APPLICATION NOTES

These cartridge valves are typically applied to provide

bi-directional, proportional control of hydraulic cylinders and

motors. In applications requiring load-holding, PO checks or

counterbalance valves can be added to provide a low leakage

solution. For load-independent flow control, apply with a

pressure compensator, such as CP700-4 (see Example Circuit).

Port 1 should be used as the tank port, with a maximum backpressure of 150 bar. For applications with unequal flows, the

highest flow should be connected to Port 2.

Note: For optimal performance install with the solenoid valve

below the tank oil level in the horizontal position, reducing the

chance for trapped air in the valve.

Shown with Standard Coils,

Deutsch connectors

SPECIFICATIONS SCHEMATIC

Rated Pressure* 240 bar [3500 psi]

Maximum Rated Flow at 10 bar

[145 psi]

Weight including coil 0.55 kg [1.21 lbs]

Threshold current 0.5 A (12 VDC coil)

Maximum control current 1.0 A (12 VDC coil)

DIMENSIONS

Cavity

Standard Coil M13 20 Watt

Robust Coil R13 16 Watt

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

THEORETICAL PERFORMANCE

BC332375973113en-000101 • February 2020

12 l/min

[3.2 US gal/min]

0.25 A (24 VDC coil)

0.5 A (24 VDC coil)

SDC08-4

Robust Nut P/N 173800539

(no coil O-rings needed)

Operating curves with M13 coil and steel nut

PV - 19

Page 20

PSV08-34-05-12D-DE-B-00

Coil Termination

DIMENSIONS

24 mm

RV08-DR

CP124-1

PSV08-34-05

CP700-1

CP448-1CP448-1

mm [in]

Proportional Valves Technical Information

Proportional Directional

PSV08-34-05

Cross-sectional view

19 mm

3-4 Nm [26-35 lbf*in]

Coil Nut Kit P/N 11193677

(coil o-rings included)

EXAMPLE CIRCUITS

S2

COIL NOT SHOWN FOR CALRITY

INSTALL O-RING (4) PLCS AS SHOWN

97.0

[3.82]

24-28 Nm [17-20 lbf*ft]

S1

1.5

[0.06]

PSV08-34-05

3/4-16 UNF-2A

4

53.7

[2.11]

1

3

2

Pressure Compensated Bi-directional Proportional Motor Control Double Acting Cylinder with Proportional Speed Control

CP124-1

PSV08-34-05

Ø 23.7

[Ø 0.93]

CP700-4

ORDERING INFORMATION

Proportional Solenoid Valve

08-Size, 3 position, 4 way

Coil Voltage

Description

No Coil

12 VDC

24 VDC

Description

No Coil

Flying Lead

Deutsch

AMP SuperSeal 1.5

DIN 43650

SVP08-NO

RV08-DR

Standard Coil

Code

00

12D

24D

Standard Coil

Code

00

FL

DE

AS

DN

Robust Coil

Code

R00

R12D

R24D

IP

Rating

-

IP65

IP69K

IP67

IP65

Robust Coil

Code

00

FL

DE

AS

-

IP

Rating

-

IP69K

IP69K

IP69K

-

Seals

Code

Housings

Code

Ports & Material

Cartridge only

00

4S6S#4 SAE, AL

#6 SAE, AL

S6S

#6 SAE, Steel

1/4 BSP, AL SDC08-4-L2B

L2B

S3B

3/8 BSP, Steel CP08-4-S3B

Material

B

BUNA

V

VITON

Seal kit

354003319

354003919

Body Nomenclature

No Body

CP08-4-4S

CP08-4-6S

CP08-4-S6S

BC332375973113en-000101 • February 2020

Page 21

Proportional Valves Technical Information

Proportional Directional

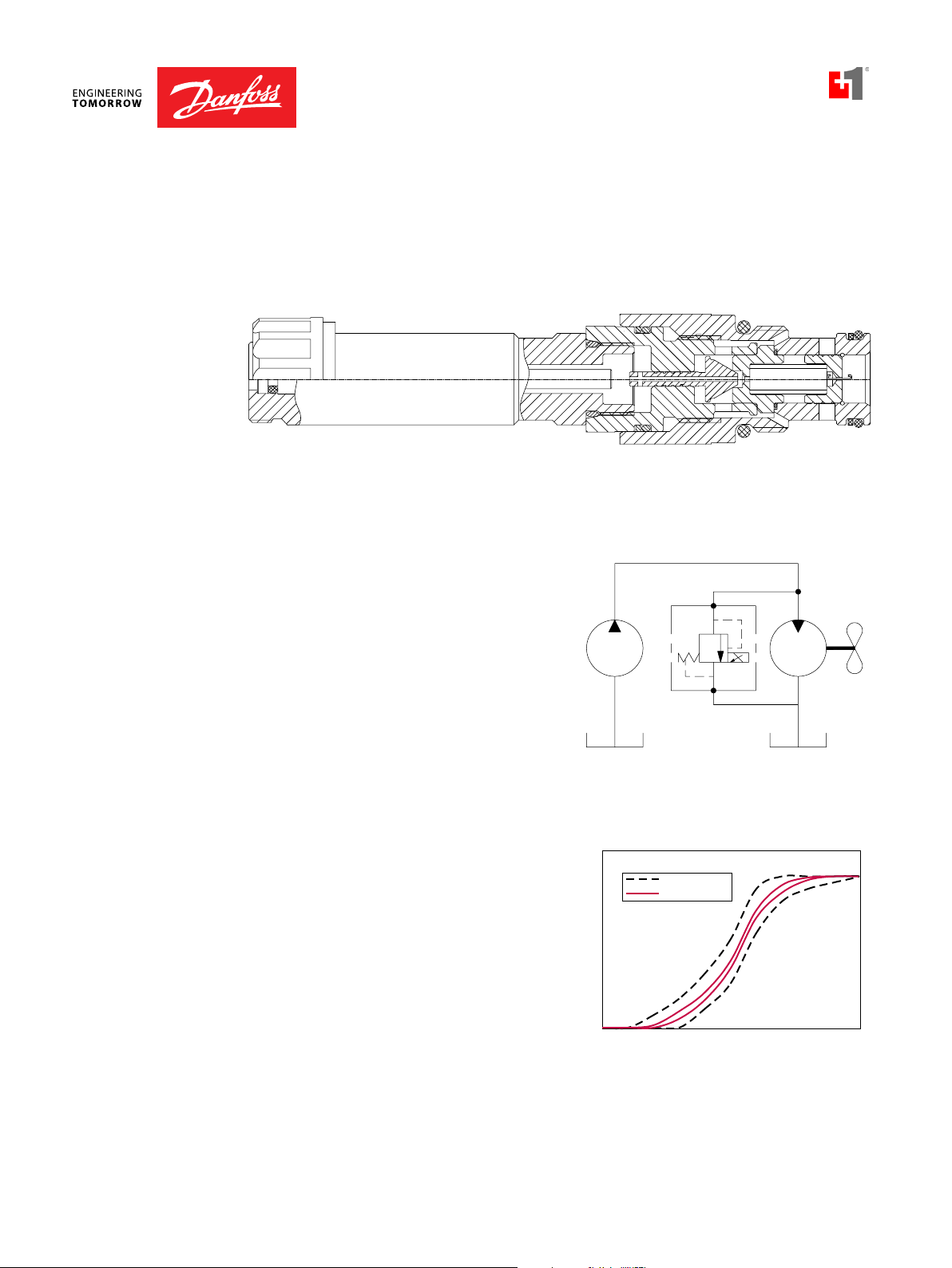

PSV10-34-05

OPERATION

This is a proportional, non-compensated, 3 position 4 way,

directional flow control solenoid valve, with float-center spool.

APPLICATION NOTES

These cartridge valves are typically applied to provide

bi-directional, proportional control of hydraulic cylinders and

motors. In applications requiring load-holding, PO checks or

counterbalance valves can be added to provide a low leakage

solution. For load-independent flow control, apply with a

pressure compensator, such as CP700-4 (see Example Circuit).

Port 1 should be used as the tank port, with a maximum backpressure of 150 bar. For applications with unequal flows, the

highest flow should be connected to Port 2.

Note: For optimal performance install with the solenoid valve

below the tank oil level in the horizontal position, reducing the

chance for trapped air in the valve.

standard coil

SCHEMATIC

S1

Shown with Robust CoilShown with DIN connector,

2

3

4

S2

1

SPECIFICATIONS

Rated Pressure* 250 bar [3600 psi]

Maximum Rated Flow at 10 bar

[145 psi]

Weight including coil 0.77 kg [1.7 lbs]

Hysteresis 4% maximum

Threshold current 0.5 A (12 VDC coil)

Maximum control current 1.5 A (12 VDC coil)

DIMENSIONS

Cavity SDC10-4

Standard Coil M16 26 Watt

Robust Coil R16 20 Watt

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

22 l/min

[6 US gal/min]

0.25 A (24 VDC coil)

0.8 A (24 VDC coil)

Robust Nut P/N 173804910

(no coil O-rings needed)

THEORETICAL PERFORMANCE

Operating curves with M16 coil and plastic nut

Operating curves with R16 coil and steel nut

BC332375973113en-000101 • February 2020

PV - 21

Page 22

Cavity Size:

Type

Housing and Ports:

Housing P/N:

Seals: Seal Kit

Coil Termination

Coil Voltage:

10 = Size 10

34 = 3 Position, 4 Way

Schematic:

05 = Float Center Spool

00 = No Coil

12D = 12 VDC

24D = 24 VDC

R12D = 12 VDC R-Coil

R24D = 24 VDC R-Coil

Max Regulated Flow:

3 = 3 LPM (0.8 GPM)

12 = 12 LPM(3 GPM)

22 = 22 LPM (6 GPM)

00 = No coil, with Nut

AJ = AMP Junior*

AS = AMP SuperSeal 1.5

DE = Deutsch

DN = DIN 46650*

FL = Flying Leads

B = Buna-N 354001919

V = Viton 354002019

00 = No Housing

L3B = AL 3/8 BSP

L4B = AL, 1/2 BSP

6S = AL #6 SAE

8S = AL, #8 SAE

Other housings available

PSV 10 - 34- 05 - 12D

-

DE

-

22

-

PAP - B - 00

Proportional Solenoid

Valve, Non-compensated

Flow Control

No Housing

SDC10-4-L-3B

SDC10-4-L-4B

CP10-4-6S

CP10-4-8S

**Consult Factory for Details

Manual Override:

Omit = No Override

PAP = Push and Pull Override**

DIMENSIONS

RV08-DR

CP124-1

PSV10-34-05

CP700-1

CB10-HVCB10-HV

mm [in]

Proportional Valves Technical Information

Proportional Directional

PSV10-34-05

Cross-sectional view

24mm

9-11 Nm [6-8 lbf*ft]

45-50 Nm [33-37 lbf*ft]

Coil Nut KIT P/N 17400031

27mm

S1S2

7/8-14 UNF 2A

4

3

2

1

COILS NOT SHOWN FOR CLARITY

INSTALL O-RINGS (4) PLCS AS SHOWN

127.25

[5.01]

[0.20]

5

62

[2.44]

EXAMPLE CIRCUITS

Pressure Compensated Bi-directional Proportional Motor Control Double Acting Cylinder with Proportional Speed Control

CP124-1

PSV10-34-05

CP700-4

SVP08-NO

Ø26.5

[Ø1.04]

ORDERING INFORMATION

BC332375973113en-000101 • February 2020

RV08-DR

Page 23

Proportional Valves Technical Information

Proportional Directional

PSV12-34-05

OPERATION

This is a proportional, non-compensated, 3 position 4 way,

directional flow control solenoid valve, with float-center spool.

APPLICATIONS

These cartridge valves are typically applied to provide bi-directional,

proportional control of hydraulic cylinders and motors. In

applications requiring load-holding, PO checks or counterbalance

valves can be added to provide a low leakage solution. For loadindependent flow control, apply with a pressure compensator, such

as HLE10-OPO (see Example Circuit). Port 1 should be used as the

tank port, with a maximum back-pressure of 150 bar. For applications

with unequal flows, the highest flow should be connected to Port 2.

Shown with Deutsch

connector

Note: For optimal performance install with the solenoid valve below

the tank oil level in the horizontal position, reducing the chance for

trapped air in the valve.

SPECIFICATIONS SCHEMATIC

Rated Pressure* 260 bar [3770 psi]

Maximum Rated Flow at 10

bar [145 psi]

Weight including coil 1.2 kg [2.64 lbs]

Hysteresis 4% maximum

Threshold current 0.5 A (12 VDC coil)

Maximum control current 1.8 A (12 VDC coil)

DIMENSIONS

Cavity CP12-4

Standard Coil M19 33 Watt

* Rated Pressure based on NFPA fatigue test standards (at 1 Million Cycles).

60 l/min

[16 US gal/min]

0.25 A (24 VDC coil)

0.9 A (24 VDC coil)

THEORETICAL PERFORMANCE

S1

Shown with DIN

connector

2

4

S2

3

1

BC332375973113en-000101 • February 2020

PV - 23

Page 24

Proportional Valves Technical Information

Cavity Size:

Schematic:

Type:

Max Regulated Flow:

Housing and Ports: Housing P/N:

Seals: Seal Kits:

Coil Termination:

Coil Voltage:

12

12 = Size 12

34 = 3 Position, 4 Way

05 = Float Center Spool

00 = No Coil

12D = 12 VDC

24D = 24 VDC

30 = 30 LPM (8 GPM)

60 = 60 LPM (16 GPM)

00 = No coil, with Nut

AJ = AMP Junior

AS = AMP SuperSeal 1.5

DE = Deutsch

DN = DIN 46650

FL = Flying Leads

B = Buna-N 11106420

V = Viton 11106444

00 = No Housing

3B = AL, 3/8 BSP

4B = AL, 1/2 BSP

8S = AL, #8 SAE

10S = AL, #10 SAE

*Other housings available

- 34

-

05

60

-

12D

-

-

B

- 00DE

-

PSV

Proportional Solenoid

Valve, Non-compensated

Flow Control

No Housing

CP12-4-3B

CP12-4-4B

CP12-4-8S

CP12-4-10S

Proportional Directional

PSV12-34-05

DIMENSIONS

mm [in]

SPECIFICATIONS

EXAMPLE CIRCUITS

Pressure Compensated Bi-directional Proportional Motor Control Double Acting Cylinder with Proportional Speed Control

Cross-sectional view

CP124-1

PSV12-34-05

HLE10-OPO

ORDERING INFORMATION

CP200-1

SVP10-NO

CB10-HVCB10-HV

CP124-1

PSV12-34-05

HLE10-CPC

CP200-1

BC332375973113en-000101 • February 2020

Page 25

Proportional Valves Technical Information

gpm

6

gpm

T

P

Ø 45.7

[1.80]

215.9

[8.50]

PDCV03-3Y11/15-12-E1-8S

Proportional Directional

PDCV03-3Y11

OPERATION

SPECIFICATIONS

This valve is a proportional directional control.

Rated pressure 350 bar [5075 psi]

Rated Flow at 10 bar

[145 psi]

30 l/min

[8 US gal/min]

Weight 2.40 kg [5.29 lb]

Hysteresis 6% maximum

Threshold current 0.5 A (12 VDC coil)

0.25 A (24 VDC coil)

Maximum control

current

2.4 A (12 VDC coil)

1.2 A (24 VDC coil)

Cavity ISO D03

Standard Coil PD03 40 Watt

Coil nut 158-8005

SCHEMATIC

A

B

THEORETICAL PERFORMANCE

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

L/min

30

8

25

7

20

5

15

4

Flow

10

3

51

0

L/min

35

9.2

30

7.9

25

6.6

20

5.3

Flow

15

4

10

2.6

51.3

0

at 10 bar [145 psi] pressure drop

e

d

o

C

0.4

0.8 1.2 1.622.4

Current, Amps (with 12VDC coil)

154 SUS (33 cSt) hyd. oil @ 100° F (38° C)

2

.

4

A

(

1

2

1

.

9

A

(

1

2

V

1

.

4

A V

(

1

2

bar

psi

100 150 200 250 300 350

50

Loop pressure drop (P ABT)

725

1450 2176 2901 3626 4351 507

0

3

=

5

1

=

e

d

o

C

V

c

o

i

l

)

c

o

i

l

)

c

o

i

l

)

DIMENSIONS

mm [in]

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

Cross-sectional view

Voltage

12 = 12 VDC

24 = 24 VDC

Nominal flow rate

15 = 15 L/min [4.0 gpm]

30 = 30 L/min [7.9 gpm]

Subplate option

OMIT= No subplate

8S = Aluminum, #8 SAE ports

S8S =Steel, #8 SAE ports

Termination

E12= Deutsch

E14= Dual spade

E1 = DIN 43650

E3 = Amp Jr.

E8 = Lead wires

Seal Kit

Seal kit

B=Buna-N158-8007

V=Viton 158-80062

Note :All internal seals are viton

Bolt Kit

#10-24 Thd. 158-8064

M5 Thd. 158-8026

PV - 25

Page 26

Proportional Valves Technical Information

0

flow

350

T

P

A

B

318 mm

[12.52 in]

70 mm

[2.76 in]

Nominal flow rate

n9

Proportional Directional

PDCV05-3Y11

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated proportional directional control valve.

THEORETICAL PERFORMANCE

Rated pressure 350 bar [5075 psi]

Rated Flow at 10 bar

[150 psi]

Weight 6.60 kg [14.60 lb]

60 l/min

[16 US gal/min]

US gal/min

20

26 cSt [125 SUS] hyd.oil @ 20° C [68° F]

l/min

80

Hysteresis 6% maximum

Threshold current 0.2 A (12 VDC coil)

0.1 A (24 VDC coil)

Maximum control

current

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Cavity ISO D05

60

15

10

flow

5

40

20

At 10 bar

(145 psi)

pressure drop

Standard Coil PD05 23 Watt

0

0

SCHEMATIC

US gal/min

15

10

20

5

0

psi

l/min

60

40

0

50

bar

0

loop pressure drop P A BT

100

1000

Cross-sectional view

flow vs current

Nominal flow=60 l/min

Nominal flow

=30 l/min

2.0

0.96 Amps

150

1.51.00.50

Current = 2.40 Amps

1.92 Amps

250

200

3000

Current, Amps (12VDC coil)

pressure drop

1.44 Amps

2000

3500

2.5

300

500

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

P-DCV05-3Y11/30-12-E1

Connector

E1 =DIN 43650

E8 =Lead wires

E10 =Deutsch on leads

30 = 30 l/min [7.9 US gal/min]

60 = 60 l/min [15.8 US gal/min]

Voltage

12 =12 VDC

24 =24 VDC

Seal kit

B=Buna N 158-8023

V=Vito

158-80

All internal seals areViton

Bolt kit

1/4-20 Thd 158-8093

M6 Thd 158-8024

4

Page 27

Proportional Valves Technical Information

61

US

2

1

CP518-PNC-U-6S-2H-24-DE

3B = AL, 3/8 BSP SDC08-2-DG-3B

Flow Controls, Non-Compensated, Normally Closed

CP518-PNC

OPERATION

SPECIFICATIONS

CP518-PNC

DIMENSIONS

mm [in]

This valve is a non-compensated, normally-closed, proportional flow control.

Rated pressure 210 bar [3000 psi]

Rated flow at 6 bar

[80 psi]

12 l/min

[3 US gal/min]

Weight 0.36 kg [0.80 lb]

Hysteresis 10% maximum

Threshold current 0.8 A (12 VDC coil)

0.4 A (24 VDC coil)

Maximum control

current

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Pressure differential 21 bar [300 psi] maximum

Cavity SDC08-2

Standard Coil M19P 22 Watt

Coil nut 173802114

SCHEMATIC

Cross-sectional view

THEORETICAL PERFORMANCE

Flow vs. Current

at 5.5 bar [80psi] pressure drop

gal/min l/min

174

145

L/min

gal/min

33 cSt[154 SUS] hyd.oil@38°C [100°F]

14

3.7

3.2

12

2.6

10

2.1

8

1.6

6

1.1

4

0.5

2

0.0

11 6

87

58

29

0

0

barpsi

12

10

8

6

4

2

0

0.4

0.00.2 2.0

33 cSt[154 SUS] hyd.oil@38°C [100°F]

024681012141

0.6 0.8 1.21.0 1.4 1.81.6

Current, Amps (with 12 VDCcoil)

Pressure Drop vs. Flow

At MaximumControlCurrent

4H

6H

8H

6H

4H

2H

8H

8

4.84.23.73.22.62.11.61.00.50

5N·m MAX.

[44lbf·in]

COIL NOT SHOWN FOR CLARITY

INSTALL O-RING AS SHOWN

ORDERING

INFORMATION

Seals

Housing and portsHousing P/N

0=Cartridge only No Housing

4S = AL, #4 SAE CP08-2-4S

6S = AL, #6 SAE CP08-2-6S

2B = AL,1/4 BSP SDC08-2-DG-2B

U= Urethane 120591

BC332375973113en-000101 • February 2020

86.1[3.39]

7/8 HEX

27-34N·m

[20-25 lbf·ft]

Seal kits

3/4-16 UNF

2

Termination

00 = No connector

DE = Deutsch

Voltage

00 = No coil

12 = 12 VDC

24 = 24 VDC

Flow code

2H = 5 l/min [1.3 US gal/min] at 5.5 bar [80 psi]

4H = 9 l/min [2.4 US gal/min]

6H = 11 l/min [2.9 US gal/min]

8H = 13 l/min [3.4 US gal/min]

DN = DIN 43650

FL = Lead wires

AJ = AMP Jr

PV - 27

Page 28

Proportional Valves Technical Information

2

1

Flow Control, Non-Compensated, Normally Closed

PSV10-NC

OPERATION

SPECIFICATIONS

This is a normally-closed, direct-acting, spool-type, non-compensated, proportional

flow-control. Controlled flow is from port 1 to 2.

Rated pressure 260 bar [3770 psi]

Maximum flow at 10 bar

[145 psi pressure drop]

Leakage 420 cm³/min [25.6 in³/min] @

Weight 0.51 kg [1.12 lb]

Hysteresis 5% maximum

Threshold current 0.5 A (12 VDC coil)

Maximum control

current

Cavity SDC10-2

Standard Coil M19P 22 Watt

PSV10-NC-10: 10 l/min

[2.64 US gal/min]

PSV10-NC-25: 25 l/min

[6.6 US gal/min]

PSV10-NC-40: 40 l/min

[10.6 US gal/min]

rated pressure

0.25 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

THEORETICAL PERFORMANCE

SCHEMATIC

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

26mm

3-5 Nm [2.2-3.7bf•ft]

COIL NUTKIT P/N 173802188

COIL NOTSHOWN FORCLARITY

86.80

[3.42]

27

45-50Nm[33-37lbf•ft]

2

32.00

[1.26]

1

354004019

354003419

7/8-14 UNF2A

[Ø1.04]

Ø26.50

BC332375973113en-000101 • February 2020

* PB (Push-Button)

available upon request

Page 29

Proportional Valves Technical Information

Operating Curves

01

2

1

Flow Control, Non-Compensated, Normally Closed

PSV12-NC

OPERATION

SPECIFICATIONS

PSV12-NC

This is a normally-closed, direct-acting, spool-type, non-compensated, proportional

flow-control. Controlled flow is from port 1 to 2.

Rated pressure 260 bar {3770 psi]

Maximum flow at 10 bar

[145 psi]

PSV12-NC-60: 60 l/min

[15.85 US gal/min]

PSV12-NC-80: 80 l/min

[21.13 US gal/min]

Leakage 420 cm³/min [25.6 in³/min] @

rated pressure

Weight 0.76 kg [1.68 lb]

Hysteresis 5% maximum

Threshold current 0.5 A (12 VDC coil)

0.25 A (24 VDC coil)

Maximum control

current

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Cavity SDC12-2

Standard Coil D14E(35W) 35 Watt

SCHEMATIC

THEORETICAL PERFORMANCE

US

gal/min

(using a circuit with a pressure drop of 10 Bar)

26 cSt [121 SUS] hyd.oil@50°C [122°F]

l/min

24

80

14

60

12

40

6

20

0

0 0.3 0.9 (A)

(24 V)

(12 V)

0 0.6

Pressure drop (from port 1 to 2)

psi

217

145

72

0

26 cSt [121 SUS] hyd.oil@50°C [122°F]

Bar

15

10

5

0

3020100

40

80

0.6

1.2

60

60

1.8 (A)

80

70

6050

8612

l/min

90

80

US

gal/min

24

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

9-11 Nm [6-8 lbf*ft]

Coil NutP/N 17380531

COIL NOTSHOWN FORCLARITY

94.50

[3.72]

32mm27mm

68-75Nm[50-55lbf*ft]

1-1/16-12 UN

2

45.00

[1.77]

1

[Ø1.24]

Ø31.50

BC332375973113en-000101 • February 2020

PV - 29

Page 30

Proportional Valves Technical Information

12

l/min.

2

1

Flow Control, Non-Compensated, Normally Closed

PSV16-NC

OPERATION

SPECIFICATIONS

This is a normally-closed, direct-acting, spool-type, non-compensated, proportional

flow-control. Controlled flow is from port 1 to 2.

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[145 psi]

100 l/min

[26 US gal/min]

Leakage 420 cm³/min [25.6 in³/min] @

rated pressure

Weight 0.87 kg [1.92 lb]

Hysteresis 5% maximum

Threshold current 0.5 A (12 VDC coil)

0.25 A (24 VDC coil)

Maximum control

current

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Cavity SDC16-2

Standard Coil D14E(35W) 35 Watt

SCHEMATIC

THEORETICAL PERFORMANCE

US

gal/min

24

20

16

12

8

4

0

(24 V)

(12 V)

0

80

40

Operatingcurve smad ewithcircuit

having apressure drop of 10 bar.

l/min

26 cSt[121SUS]hyd.oil@50°C[122°F]

100

80

60

40

20

0

0

barpsi

26 cSt [121SUS]hyd.oil at 50°C [122°F]

9

6

3

0.60

Pre ssure drop

1.2

0.9(A)0.60.3

1.8 (A)

0

0

DIMENSIONS

mm [in]

27mm

9-11 Nm [6-8 lbf*ft]

Cross-sectional view

38mm

122-136Nm[90-100 lbf*ft]

Coil NutP/N 17380531

COIL NOTSHOWN FORCLARITY

97.30

[3.83]

3.60

[0.14]

15/16-12UN

2

47.10

[1.85]

0

0

4020

1

[Ø1.49]

Ø37.80

100

8060

2010US gal/min

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

Page 31

Proportional Valves Technical Information

30

20

40

80

60

1

2

Flow Control, Non-Compensated, Normally Closed, Poppet

PSVP10-NCR

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated, normally-closed, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[150 psi]

55 l/min

[14 US gal/min]

Leakage 6 drops/min @

rated pressure

Weight 0.54 kg [1.19 lb]

Hysteresis 8% maximum

Threshold current 0.8 A (12 VDC coil)

0.4 A (24 VDC coil)

Maximum control

current

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

Cavity SDC10-2

Standard Coil M19P 22 Watt

US

gal/min

30

25

20

15

10

5

0

(24 V)

(12 V)

0

l/min

125

100

75

50

25

0

barpsi

26 cSt[121SUS]hyd.oil at 50°C [122 °F]

60

OperatingC

26 cSt[121SUS]hyd.oil@50°C[122°F]

0

00.6 1.8(A)

Pressuredrop

ur

ves

0.

1.2

0.6

.9 (A)

50 bar

35 bar

20 bar

SCHEMATIC

40

0

0

20

0

0

0

0

0

40

5

10

8060

15

20

100

25

12020

l/min.

US gal/min

Cross-sectional view

26mm

3-5 Nm [2.2-3.7bf*ft]

COIL NUTKIT P/N 173802188

COIL NOTSHOWN FORCLARITY

107.12

[4.22]

27

45-50Nm[33-37lbf*ft]

2

31.90

[1.26]

1

7/8-14 UNF2A

[Ø1.04]

Ø26.50

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

PV - 31

Page 32

Proportional Valves Technical Information

l/min.

60

80

40

20

1

2

Flow Control, Non-Compensated, Normally Closed,

PSVP12-NCR

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated, normally-closed, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[150 psi]

70 l/min

[18 US gal/min]

Leakage 6 drops/min @

rated pressure

Weight 0.60 kg [1.32 lb]

Hysteresis 8% maximum

Cavity SDC12-2

Standard Coil M19P 22 Watt

SCHEMATIC

US

gal/min

36

30

24

18

12

6

0

(24 V)

(12 V)

psibar

0

0

0

0

0

l/min

150

120

90

60

30

0

0

26 cSt[121SUS]hyd.oil at 50°C [122°F]

60

40

20

0

0

Operating Curves

26 cSt[121SUS]hyd.oil@50°C[122°F]

125

0.9(A)0.3

1.8(A)0.60

US gal/min

0.6

1.2

Pressuredrop

25 150

50

75 100

15 300

50 bar

35 bar

20 bar

Cross-sectional view

PSVP12-NCR

26mm

3-5Nm[2.2-3.7bf*ft]

COIL NUT KITP/N 173802188

COIL NOT SHOWN FOR CLARITY

105.52

[4.15]

32 mm

68-75Nm[50-55lbf*ft]

45

[1.77]

1-1/16-12 UN

1

Ø31.5

[ 1.24]Ø

2

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

Page 33

Proportional Valves Technical Information

US

gal/min

Operating

Curve s

20

40

80

60

1

2

Flow Control, Non-Compensated, Normally Closed, Poppet Type

PSVP16-NCR

OPERATION

SPECIFICATIONS

PSVP16-NCR

DIMENSIONS

mm [in]

This is a non-compensated, normally-closed, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[150 psi]

90 l/min

[24 US gal/min]

Leakage 6 drops/min @

rated pressure

Weight 0.85 kg [1.87 lb]

Hysteresis 8% maximum

Cavity SDC16-2

Standard Coil M19P 22 Watt

52

40

32

24

16

(24 V)

(12 V)

0

l/min

26 cSt[121SUS]hyd.oil@50°C[122°F]

200

160

120

80

40

8

0

0

0

0.3 0.9(A)

00.6 1.8(A)

barpsi

60

Pressure drop

26 cSt[121SUS]hyd.oil at 50°C [122 °F]

0.6

1.2

50 bar

35 bar

20 bar

SCHEMATIC

40

0

0

20

0

0

0

20040

160

120

0

0

80

20

40

l/min.

US gal/min

Cross-sectional view

26mm

3-5 Nm [2.2-3.7bf*ft]

COIL NUTKIT P/N 173802188

COIL NOTSHOWN FORCLARITY

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

38mm

122-136Nm[90-100 lbf*ft]

98.51

[3.88]

15/16-12UN

44.7

[1.76]

1

Ø37.8

[Ø1.49]

2

PV - 33

Page 34

Proportional Valves Technical Information

21

gal/mi

Flow vs. Current

2

1

CP518-PNO-U-6S-2H-24-DE

Flow Control, Non-Compensated, Normally Open

CP518-PNO

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This valve is a non-compensated, normally-open, proportional flow control.

THEORETICAL PERFORMANCE

Rated pressure 210 bar [3000 psi]

Rated flow at 7 bar

[100 psi]

Weight 0.36 kg [0.80 lb]

Hysteresis 4% maximum

Threshold current 0.2 A (12 VDC coil)

Maximum control

current

Pressure

differential

Cavity SDC08-2

Standard Coil M19P 22 Watt

Coil nut 173802114

SCHEMATIC

12.1 l/min

[3.2 US gal/min]

0.1 A (24 VDC coil)

1.2 A (12 VDC coil)

0.6 A (24 VDC coil)

21 bar [300 psi] maximum

nl/min

3.7

3.2

2.6

2.1

1.6

1.1

0.5

0.0

174

145

11 6

87

58

29

0

L/min

US gal/min

at 5.5 bar [80psi] pressure drop

33 cSt[154 SUS] hyd.oil @ 38°C[100° F]

14

12

8H

10

8

6

2H

4

2

0

0.0 0.

0.40.6 0.8 1.01.41.2

Current, Amps(with12VDC coil)

Pressure Drop vs. Flow

barpsi

33 cSt[154 SUS] hyd.oil@38°C[100° F]

12

10

8

6

4

2

0

0 24681012141618

CoilDe-Energized

2H

Cross-sectional view

.6

8H

CP518-PNO

4.84.23.73.22.62.11.61.00.50

5N·m MAX.

[44 lbf·in]

COIL NOT SHOWN FOR CLARITY

INSTALL O-RING AS SHOWN

ORDERING

INFORMATION

Housing and portsHousing P/N

0=Cartridge only No Housing

4S = AL,#4 SAE CP08-2-4S

6S = AL,#6 SAE CP08-2-6S

2B = AL,1/4 BSP SDC08-2-DG-2B

3B = AL, 3/8 BSP SDC08-2-DG-3B

BC332375973113en-000101 • February 2020

7/8 HEX

27-41N·m

[20-30 lbf·ft]

Seals

U= Urethane 120591

Seal kits

27.7 [1.09]86.1[3.39]

Voltage

00 = No coil

12 = 12 VDC

24 = 24 VDC

Flow code

3/4-16 UNF-2A

2

2H

8H

Termination

00 = No connector

DE = Deutsch

DN = DIN 43650

FL = Lead wires

AJ = AMP Jr

Page 35

Proportional Valves Technical Information

Flow Control, Non-Compensated, Normally Open

PSV10-NO

OPERATION

SPECIFICATIONS

This is a normally-open, direct-acting, spool-type, non-compensated, proportional flowcontrol. Controlled flow is from port 1 to 2.

Rated pressure 260 bar [3770 psi]

Maximum flow at 10 bar

[145 psi]

Leakage 420 cm³/min [25.6 in³/min] @

Weight 0.51 kg [1.12 lb]

Hysteresis 5% maximum

Threshold current 0.1 A (12 VDC coil)

Maximum control

current

Cavity SDC10-2

Standard Coil M19P 22 Watt

PSV10-NO-10: 10 l/min

[2.64 US gal/min]

PSV10-NO-25: 25 l/min

[6.6 US gal/min]

PSV10-NO-40: 40 l/min

[10.6 US gal/min]

rated pressure

0.05 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

THEORETICAL PERFORMANCE

SCHEMATIC

2

1

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

26mm

3-5 Nm [2.2-3.7bf*ft]

COIL NUTKIT P/N 173802188

COIL NOTSHOWN FORCLARITY

86.80

[3.42]

27

45-50Nm[33-37lbf*ft]

2

32.00

[1.26]

1

7/8-14 UNF2A

[1.04]

26.50

BC332375973113en-000101 • February 2020

PV - 35

Page 36

Proportional Valves Technical Information

Flow Control, Non-Compensated, Normally Open

PSV12-NO

OPERATION

SPECIFICATIONS

This is a normally-open, direct-acting, spool-type, non-compensated, proportional flowcontrol. Controlled flow is from port 1 to 2.

Rated pressure 260 bar [3770 psi]

Maximum flow at 10 bar

[145 psi]

Leakage 420 cm³/min [25.6 in³/min] @

Weight 0.76 kg [1.68 lb]

Hysteresis 5% maximum

Threshold current 0.3 A (12 VDC coil)

Maximum control

current

Cavity SDC12-2

Standard Coil D14E(35W) 35 Watt

PSV12-NO-60: 60 l/min

[15.85 US gal/min]

PSV12-NO-80: 80 l/min

[31.13 US gal/min]

PSV12-NO-100: 100 l/min

[26.41 US gal/min]

rated pressure

0.15 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

THEORETICAL PERFORMANCE

SCHEMATIC

2

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

27mm

9-11 Nm [6-8 lbf*ft]

Coil NutP/N 17380531

COIL NOTSHOWN FORCLARITY

94.50

[3.72]

1

32mm

68-75Nm[50-55lbf*ft]

4.00

[0.16]

1-1/16-12 UN

2

45.50

[1.79]

1

[Ø1.24]

Ø31.50

BC332375973113en-000101 • February 2020

Page 37

Proportional Valves Technical Information

Operating curvesmade with circuit

l/min.

US gal/min

10 200

2

1

Flow Control, Non-Compensated, Normally Open

PSV16-NO

OPERATION

SPECIFICATIONS

This is a normally-open, direct-acting, spool-type, non-compensated, proportional flowcontrol. Controlled flow is from port 1 to 2.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[145 psi]

Leakage 420 cm³/min [25.6 in³/min]]

Weight 0.87 kg [1.92 lb]

Hysteresis 5% maximum

Threshold current 0.3 A (12 VDC coil)

Maximum control

current

Cavity SDC16-2

Standard Coil D14E(35W) 35 Watt

SCHEMATIC

110 l/min

[29 US gal/min]

@ Rated pressure

0.15 A (24 VDC coil)

1.8 A (12 VDC coil)

0.9 A (24 VDC coil)

US

gal/min

30

25

20

15

10

5

0

(24 V)

(12 V)

psibar

120

80

40

havingapressure drop of 10 bar.

l/min

26 cSt[121SUS]hyd.oil@50°C[122°F]

125

100

75

50

25

0

0

0

26 cSt [121SUS]hyd.oil at 50°C [122°F]

9

6

3

0.3

0.6

Pressure drop

0.60.9 (A)

1.2

1.8(A)

DIMENSIONS

mm [in]

ORDERING

INFORMATION

Cross-sectional view

27mm

9-11 Nm [6-8 lbf*ft] 122-136 Nm [90-100 lbf*ft]

COIL NOTSHOWN FORCLARIT Y

38mm

Coil NutP/N 17380531

97.3

[3.83]

3.6

[0.14]

0

0

15/16-12UN

2

47.1

[1.85]

0

20 40

1

37.8

[1.49]

60 80

100

BC332375973113en-000101 • February 2020

PV - 37

Page 38

Proportional Valves Technical Information

20

40

80

60

Operating Curves

02

1

2

Flow Control, Non-Compensated, Normally Open, Poppet Type

PSVP10-NOR

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated, normally-open, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[145 psi]

45 l/min

[12 US gal/min]

Leakage 6 drops/min @

Rated pressure

Weight 0.54 kg [1.19 lb]

Hysteresis 8% maximum

Cavity SDC10-2

Standard Coil M19P 22 Watt

SCHEMATIC

US

gal/min

30

25

20

15

10

5

0

(24 V)

(12 V)

0

0

0

0

0

l/min

26 cSt[121SUS]hyd.oil@50°C[122°F]

125

50 bar

100

75

50

25

0

barpsi

60

40

20

0

0

35 bar

20 bar

0

0.3 0.9(A)

00.6 1.8(A)

Pressure drop

26 cSt[121SUS]hyd.oil at 50°C [122 °F]

40

52015

0.6

1.2

12020

100

8060

510

l/min.

US gal/min

Cross-sectional view

26mm

3-5Nm[2.2-3.7bf*ft]

COIL NUTKIT P/N 173802188

COIL NOTSHOWN FORCLARITY

86.8

[3.42]

27

45-50Nm[33-37lbf*ft]

2

31.9

[1.26]

7/8-14 UNF2A

1

Ø26.5

[Ø1.04]

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

Page 39

Proportional Valves Technical Information

n.

60

80

40

20

1

2

86.34

[3.4]

44.91

[1.77]

Ø31.44

[Ø1.24]

COIL NOT SHOWN FOR CLARITY

2

1

1-1/16-12 UN

COIL NUT KITP/N 173802188

3-5Nm[2.2-3.7bf*ft]

26mm

68-75Nm[50-55lbf*ft]

32 mm

Flow Control, Non-Compensated, Normally Open, Poppet Type

PSVP12-NOR

OPERATION

SPECIFICATIONS

This is a non-compensated, normally-open, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[150 psi]

70 l/min

[18 US gal/min]

Leakage 6 drops/min @

Rated pressure

Weight 0.60 kg [1.32 lb]

Hysteresis 8% maximum

Cavity SDC12-2

Standard Coil M19P 22 Watt

SCHEMATIC

US

gal/min

36

30

24

18

12

6

0

(24V)

(12V)

psibar

0

0

0

0

l/min

150

120

35 bar

90

20 bar

60

30

0

0

26 cSt[121SUS]hyd.oil at 50°C [122 °F]

60

40

20

Operating Curves

26 cSt[121SUS]hyd.oil@50°C [122°F]

50 bar

0.6

1.2

Pressure drop

0.9(A)0.3

1.8(A)0.60

0

0

DIMENSIONS

mm [in]

Cross-sectional view

0

50

25 150

75 100

15 300

125

l/mi

US gal/min

ORDERING

INFORMATION

BC332375973113en-000101 • February 2020

PV - 39

Page 40

Proportional Valves Technical Information

30

20

40

80

60

1

2

Flow Control, Non-Compensated, Normally Open, Poppet Type

PSVP16-NOR

OPERATION

SPECIFICATIONS

DIMENSIONS

mm [in]

This is a non-compensated, normally-open, pilot-operated, poppet-type, proportional

flow-control. Controlled flow is from port 2 to 1.

THEORETICAL PERFORMANCE

Rated pressure 260 bar [3770 psi]

Rated flow at 10 bar

[150 psi]

80 l/min

[21 US gal/min]

Leakage 6 drops/min @

Rated pressure

Weight 0.85 kg [1.87 lb]

Hysteresis 8% maximum

Cavity SDC16-2

Standard Coil M19P 22 Watt

SCHEMATIC

US

gal/min

52

40