Page 1

System Description

Propel Controller Solutions

Automotive Control PC-AC

www.danfoss.com

Page 2

System Description

Propel Controller Solutions

Revision history Table of revisions

Date Changed Rev

July 2020 Added PC-AC SP content 0201

March 2019 First edition 0101

2 | © Danfoss | July 2020 AB298174786006en-000201

Page 3

System Description

Propel Controller Solutions

Contents

Basic information

Propel controller system overview.............................................................................................................................................4

Functional safety

Standards.............................................................................................................................................................................................5

PC-AC

Basic functions...................................................................................................................................................................................6

Advanced functions.........................................................................................................................................................................6

PC-AC SP

Basic functions...................................................................................................................................................................................7

Advanced functions.........................................................................................................................................................................7

System design....................................................................................................................................................................................9

PC-AC 2MT

Basic functions................................................................................................................................................................................ 10

Advanced functions......................................................................................................................................................................11

System design.................................................................................................................................................................................12

Functions

Function overview.........................................................................................................................................................................14

Propel functions............................................................................................................................................................................. 14

Protections

Engine control and protection..................................................................................................................................................18

Gearbox control and protection...............................................................................................................................................19

Auxiliary functions

Propel controller

Controller specification................................................................................................................................................................21

General dimensions...................................................................................................................................................................... 22

Pin assignments..............................................................................................................................................................................23

Mode Types.................................................................................................................................................................................14

Automotive Transport Mode................................................................................................................................................15

Non-Automotive Work Mode (FCMD)...............................................................................................................................15

ECO fuel saving mode.............................................................................................................................................................15

Mode transition control..........................................................................................................................................................15

Start Protection......................................................................................................................................................................... 15

Quick stop in automotive mode......................................................................................................................................... 16

State and direction change...................................................................................................................................................16

Hydromotor overspeed protection....................................................................................................................................16

Electronic Pressure Limiter (ePL).........................................................................................................................................16

Electronic pressure compensator over ride (ePCOR)...................................................................................................16

Load limiter.................................................................................................................................................................................16

Hydraulic-System overheat protection............................................................................................................................ 17

Vehicle constant-speed-drive (CSD).................................................................................................................................. 17

Cruise control.............................................................................................................................................................................17

Filter on drive pedal.................................................................................................................................................................17

Vehicle speed dependent ramps........................................................................................................................................17

Semi-Automatic calibration function................................................................................................................................17

1939-CAN engine interface...................................................................................................................................................18

CAN user interface....................................................................................................................................................................18

Engine speed control.............................................................................................................................................................. 18

Engine anti-stall protection.................................................................................................................................................. 18

All range engine overspeed..................................................................................................................................................18

All range engine overspeed with retarder.......................................................................................................................18

Cold start protection............................................................................................................................................................... 18

Gearbox control........................................................................................................................................................................ 19

Shift monitoring control........................................................................................................................................................ 19

©

Danfoss | July 2020 AB298174786006en-000201 | 3

Page 4

System Description

Propel Controller Solutions

Basic information

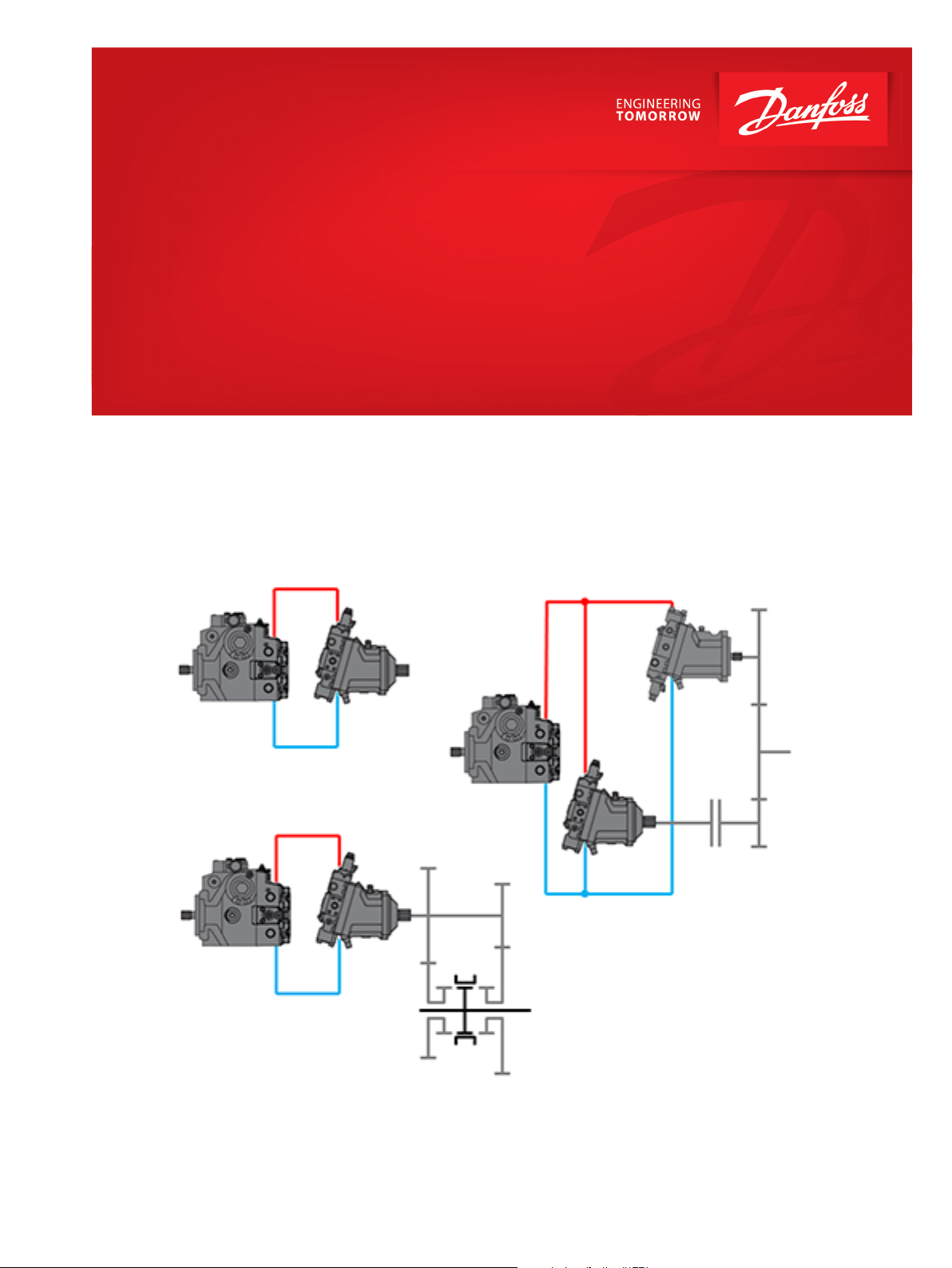

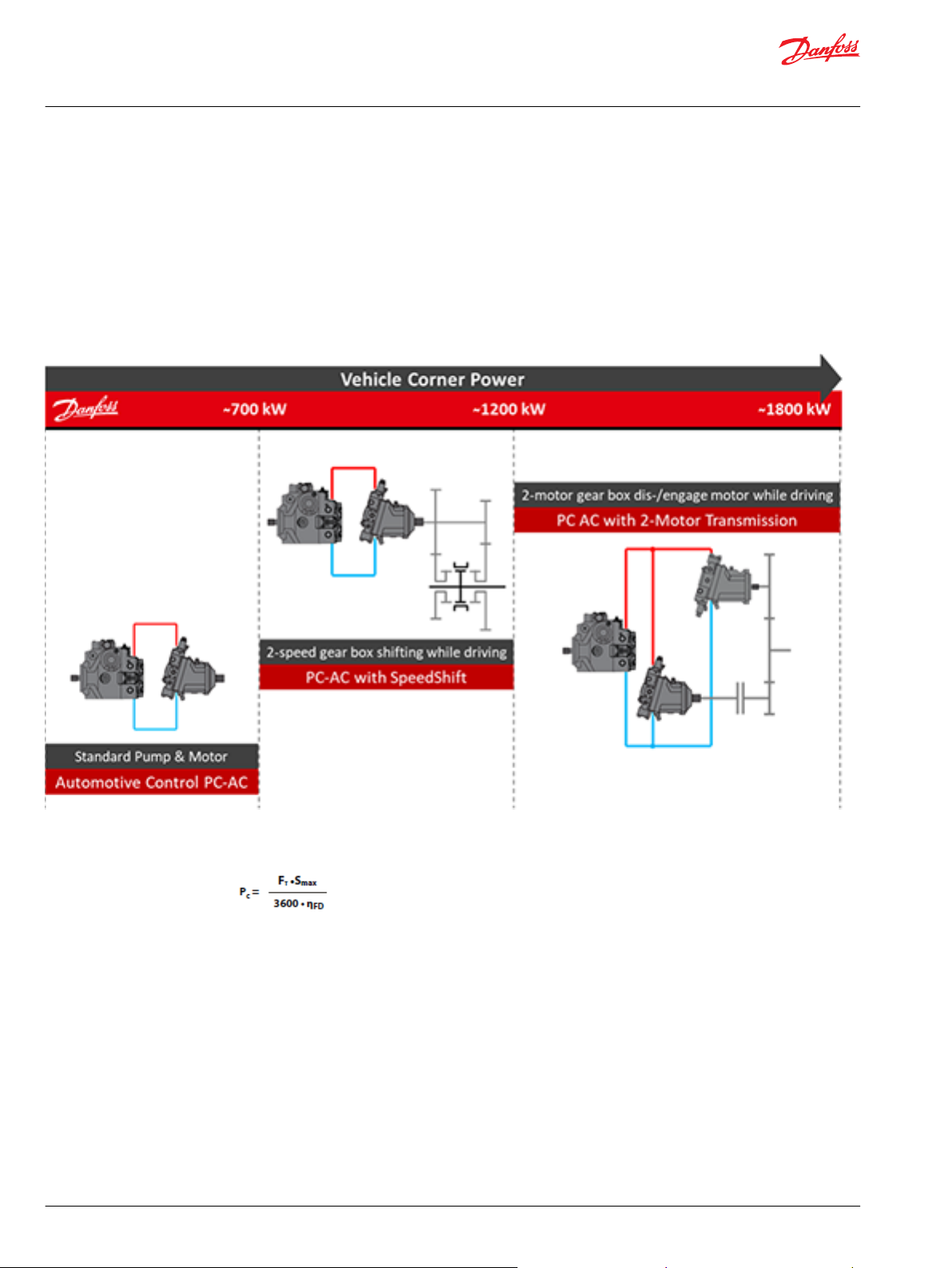

The Propel Controller Solutions are designed to support single path hydrostatic transmissions systems.

Danfoss offers several solutions for the propel system to cover vehicle corner power ranges up to 1800

kW. All of these propel system solutions combining proven hardware like PLUS+1® Safety Controller and

H1 hydraulic pumps and motors with reliable software developed according to current safety standards.

With the pre-installed application software and easily changeable control parameters, it is possible to

tailor the vehicle's driving behavior to the individual requirements of the customer.

Propel controller system overview

Definition of vehicle corner power

Where:

P

c

S

max

Corner Power (kW)

max Vehicle Speed (km/h)

ղFD Final drive efficiency (-)

4 | © Danfoss | July 2020 AB298174786006en-000201

Page 5

System Description

Propel Controller Solutions

Functional safety

The Propel Controller Software is designed to control a single-path transmission system consisting of one

pump and one (or two) hydrostatic motor(s). The propel controller and the application software needs to

fulfill the safety requirements according to machine directive (2006/42/EC).

PLUS+1® PC controllers are advanced elements of the PLUS+1® family of mobile machine management

products. The design of this general purpose safety controller includes features required for sophisticated

machine control strategies. It is equally suited for use in safety related or general machine control

applications.

These controllers have dual processors with the secondary processor having access to all controller

inputs and supervisory control of outputs. These controllers support smart digital inputs. Current

measurement capability has been added to some multifunction inputs. Device outputs can be

individually controlled by the secondary processor.

The Safety Manual of the propel controller solutions (available by request from your local Danfoss

representative) is intended to guide the system integrator concerning functional safety. The document

describes a possible implementation of the needed safety functions.

Standards

Type A Standards

Cover aspects applicable to all types of machines

•

IEC 61508 functional safety of electrical/electronic/programmable electronic safety-related systems

Type B Standards

Cover particular safety and ergonomic aspects of machinery

•

ISO 15998 Controller for earth moving machinery

•

EN ISO 13849-1:2015 Safety of machinery- Safety-related parts of control systems- Parts 1 & 2

•

ISO 25119 Agriculture machinery (former EN 16590)

Type C Standards

Machine safety standards dealing with detailed safety requirements for a particular machine or group of

machines

•

ISO 20474-2017, former DIN/EN 474 Earth moving machinery

•

EN 1459-1:2017 Rough-terrain trucks – Safety requirements and verification – Part 1: Variable-reach

trucks

•

EN 4254:2013 Agricultural machinery – Safety – Part 1: General requirements

•

EU 167/2013 Agricultural and Forestry vehicles (Tractor directive)

•

EU 1322/2014

‒

EU 68/2015

‒

EU 96/2015

‒

EU 208/2015

‒

EU 1788/2016

‒

©

Danfoss | July 2020 AB298174786006en-000201 | 5

Page 6

System Description

Propel Controller Solutions

PC-AC

The propel controller application PC-AC is designed to control a single-path hydrostatic transmission

system consisting of one pump and one motor. The hydrostatic pump is equipped with two proportional

valves.

In the PC-AC system the hydrostatic pump can be controlled in pressure dependent (NFPE) or pressure

independent (EDC) pump control mode.

The PC-AC system is optimized for use with a hydrostatic motor equipped with a proportional (PROP)

valve to control pressure or motor displacement.

The Danfoss patented Flow Controller Motor Displacement (FCMD) allows the software to change the

control command according to the system flow. Which brings advantages in controllability, engine

power utilization and system load dependency.

Parking brake valve, reverse motion buzzer, forward/reverse lamp indicator, a retarder valve and a

stabilizer valve can be controlled by additional digital outputs.

The PC-AC system can read several analog, digital, and frequency signals representing operator input,

system demands, and machine status inputs.

The CAN Communication Interface is used for diagnosis purposes and for information exchanging with

other controllers such as engines, other Danfoss power solutions or customer controllers.

Basic functions

Advanced functions

The PC-AC commands the basic vehicle driving behavior and performance (i.e. acceleration, deceleration,

and vehicle speed). The operator selects the driving mode, driving direction, and basic transmission set

point command via throttle or creep/drive pedal. An additional input, the inch pedal command, can be

used to override the basic transmission command.

A number of advanced features can be independently activated and configured depending on the

installed application software package. Below is a list of the primary advanced functions:

•

Engine and motor over-speed protection

•

Engine anti-stall

•

Constant speed control

•

ECO fuel saving mode

•

Vehicle speed limitation and flow limiter

•

Intelligent operator presence detection

•

Electronic swash plate control

•

Temperature compensation and overheat-protection

•

Maximum motor torque at vehicle start

•

Engine speed dependent retarder control

•

Cruise control

•

User defined I/Os

6 | © Danfoss | July 2020 AB298174786006en-000201

Page 7

System Description

Propel Controller Solutions

PC-AC SP

The PC-AC SP system is dedicated for use with one hydromotor which is mounted on a two speed

syncronizer gearbox. A syncroniser allows gear change while driving (SpeedShift).

The SpeedShift function will control and monitor the two speed gearbox. The hydrostatic components

are controlled according the requirements to perform a fast and smooth gear change.

A proportional controlled hydromotor with 0° and de-energized minimum displacement is required for

SpeedShift. The 0° position of the hydromotor is monitored with a MBS 1250 pressure sensor in port M4

(min. servo chamber).

The gear stage is not linked to a system mode; a gear change is possible for all 4 system modes. It can be

automatically or manually triggered. The software will ensure a gear change is only applied if it is possible

and safe (dependent on vehicle speed, acceleration/deceleration, and temperature).

The CAN Communication Interface is used for diagnosis purposes and information exchanging with other

controllers such as engines and other Danfoss power solutions or customer controllers.

Basic functions

The PC-AC SP offers the same basic function like the PC-AC. It controls basic vehicle driving behavior and

performance (i.e. acceleration, deceleration, and vehicle speed). Additional it controls the two speed

gearbox. The operator selects the driving mode, driving direction, driving gear and the transmission set

point via throttle or creep/drive pedal.

•

•

•

•

•

•

•

•

Four system modes, selectable by the driver for different drive behavior

Independent pump/hydromotor profiling and ramping for each system mode

Independent pump/hydromotor profiles in first and second gear operation

Electric drive pedal

Electronic inching

Load dependent pump displacement control (automotive)

Proportional hydromotor displacement control by flow (FCMD)

User defined I/Os

Advanced functions

Protection and safety functions

•

Safety controlled vehicle start protection

•

Operator presence detection

•

Software based pressure protection

•

Hydraulic system overheat and low temperature protection

•

Hydromotor overspeed protection

•

SIL2 compliant

Performance functions

•

ECO fuel saving mode

•

Vehicle speed limitation

•

Dynamic brake light, automatic park brake, reverse buzzer and vehicle speed controlled output

functions

•

Advanced CAN J1939 interface

©

Danfoss | July 2020 AB298174786006en-000201 | 7

Page 8

System Description

Propel Controller Solutions

PC-AC SP

Engine control and protection

•

•

•

Gearbox control and protection

•

•

•

•

•

CAN J1939 engine interface

Engine speed control via drive pedal with safety controlled monitoring function

Engine over speed and cold start protection

Approved by gearbox manufacturer

Shift valve control (automatic or manual triggered)

Gear detection

Measure hydromotor M4 pressure for 0° detection (with start up and plausibility check)

Fault management

8 | © Danfoss | July 2020 AB298174786006en-000201

Page 9

System Description

Propel Controller Solutions

PC-AC SP

System design

System Overview of Danfoss Components

H1P Pump with load dependent NFPE control Electronic pressure limitation by

software (without hydraulic pressure limiter valve)

Optional: Control Cut Off (CCO), Swash angle sensor

Technical Information document number: BC152886483968.

Electric proportional control (M1/CA control without BPD)

Electronic load limitation by software (without hydraulic PCOR)

De-energized min. displacement

Without Speed Sensor

Technical Information document number: BC152886483576.

User manual Safety Controller PC AC SpeedShift

Technical Information document number: BC152986484387.

Pressure sensors MBS 1250

Data sheet document number: AI152886480966.

©

Danfoss | July 2020 AB298174786006en-000201 | 9

Page 10

System Description

Propel Controller Solutions

PC-AC 2MT

The propel controller application PC-AC 2MT is designed to control a single-path hydrostatic transmission

system consisting of one hydrostatic pump, two hydromotors and the gearbox control. The hydrostatic

pump is equipped with two proportional valves.

In the PC-AC 2MT application the hydrostatic pump can be controlled in pressure dependent (NFPE)

pump control mode.

The PC-AC 2MT system is optimized for use with two hydromotor which are mounted on a gearbox with

different ratios to the gearbox output shaft. At slow vehicle speeds (e.g. up to 14 kph) the machine is

operated with both hydromotors (high tractive force due to two motors engaged and high ratio of

hydromotor M2). At a certain vehicle speed the rated speed capacity of the gearbox and/or hydromotor

M2 are reached. At this condition the gearbox control allows the hydromotor M2 to be switched off

(jump from x%-displacement to ZERO displacement) and the hydromotor M2 is mechanically

disconnected from the gearbox. The disengagement and engagement of hydromotor M2 is actuated on

the fly without loss of tractive force while shifting. After the hydromotor M2 is disconnected the vehicle

operates up to final vehicle speed (e.g. 40 kph) just with hydromotor M1.

Proportional valves are used on the hydromotor controls. The Danfoss patented Flow Controller Motor

Displacement (FCMD) allows the software to change the control command according to the system flow

which brings advantages in controllability, engine power utilization and system load dependency.

Parking brake valve, reverse motion buzzer, forward/reverse lamp indicator can be controlled by

additional digital outputs.

The PC-AC system can read several analog, digital, and frequency signals representing operator input,

system demands, and machine status inputs.

The CAN Communication Interface is used for diagnosis purposes and for information exchanging with

other controllers such as engines, other Danfoss Power Solutions or customer controllers.

Basic functions

The PC-AC 2MT commands the basic vehicle driving behavior and performance (i.e. acceleration,

deceleration, and vehicle speed). The operator selects the driving mode, driving direction, and basic

transmission set point command via throttle or creep/drive pedal. An additional input, the inch pedal

command, can be used to override the basic transmission command.

Four system modes, selectable by the driver for different drive behavior

•

Independent pump/motor profiling and ramping for each system mode

•

Independent motor profiles in one motor and two motor operation

•

Electric drive pedal

•

Electronic inching

•

Load dependent pump displacement control (automotive)

•

Proportional hydromotor displacement control by flow (FCMD)

•

User defined I/Os

•

10 | © Danfoss | July 2020 AB298174786006en-000201

Page 11

System Description

Propel Controller Solutions

PC-AC 2MT

Advanced functions

Protection and safety functions

•

•

•

•

•

•

Performance functions

•

•

•

•

Safety controlled vehicle start protection

Operator presence detection

Software based pressure protection

Hydraulic system overheat and low temperature protection

Hydromotor overspeed protection

SIL2 compliant

ECO fuel saving mode

Vehicle speed limitation

Dynamic brake light, automatic park brake, reverse buzzer and vehicle speed controlled output

functions

Advanced CAN J1939 interface

Engine control and protection

•

CAN J1939 engine interface

•

Engine speed control via drive pedal with safety controlled monitoring function

•

Engine over speed and cold start protection

Gearbox control and protection

•

Approved by gearbox manufacturer

•

Clutch control

•

Slip detection

•

Fault manager

©

Danfoss | July 2020 AB298174786006en-000201 | 11

Page 12

H1B Motor 1

H1B

Motor 2

Shift valve

CAN-Bus

Forward

Reverse

Diesel Engine

Two Motor

Transmission

Gearbox

Engine ECU

Safety

Controller

H1 Pump

MBS 1250

F/N/R Inch pedal Drive pedal

System Description

Propel Controller Solutions

PC-AC 2MT

System design

System Overview of Danfoss Components

H1P Pump with load dependent NFPE control Electronic pressure limitation by

software (without hydraulic pressure limiter valve)

Optional: Control Cut Off (CCO), Swash angle sensor

Technical Information document number: BC152886483968.

H1 Bent Axis Motor 1 (always engaged)

Electric proportional control (L1/L2 control)

De-energized max. displacement

Electronic pressure limitation by software (without hydraulic PCOR)

Technical Information document number: BC152886483576.

H1 Bent Axis Motor 2 (can be disconnected)

Electric proportional control (M1/M2 control)

De-energized min. displacement

Electronic pressure limitation by software (without hydraulic PCOR)

Technical Information document number: BC152886483576.

Safety Controller PC AC 2MT

Technical Information document number: BC152986484387.

12 | © Danfoss | July 2020 AB298174786006en-000201

Page 13

System Description

Propel Controller Solutions

PC-AC 2MT

Pressure sensors MBS 1250

Data sheet document number: AI152886480966.

©

Danfoss | July 2020 AB298174786006en-000201 | 13

Page 14

System Description

Propel Controller Solutions

Functions

The available functions for the individual software solution can be found in the table below. A more

detailed description of the individual function can be found on the following pages.

Function overview

Function PC-AC PC-AC SP PC-AC 2MT

Automotive Transport Mode (FCMD) x x x

Non-automotive Work Mode (FCMD) x x x

ECO fuel saving mode x x x

Mode Transition Control x x x

Start Protection x x x

Quick stop in Automotive Mode x x x

State and Direct Change x x x

Hydromotor Overspeed Protection x x x

Load limiter x x x

ePCOR - - x

ePL - - x

Hydraulic-System Overheat Protection x x x

Vehicle Constant-Speed-Drive (CSD) x x x

Vehicle-Speed-Limitation x x x

Cruise Control x x Filter for drive pedal x x x

Vehicle speed depending Ramps x x x

Semi-Auto Calibration Function x x x

J1939-CAN User Interface x x x

CAN User Interface (e.g. Error Messages,

calibration start)

Status and Error LED x x x

Engine Speed Control x x x

Engine Anti-stall Protection x x x

All range Engine Overspeed x x x

Engine Over Speed Protection with Retarder x x Optional

Cold Start Protection x x x

Brake light x x x

Automatic Park Brake Control x x x

Gearbox Control - x x

Shift Monitoring - x x

x x x

Propel functions

In the following the control functions are described. Not all of the functions are available for all software

solutions. The available functions for the individual software solution can be found in table on previous

page.

Mode Types

The application software provides different hydrostatic propel methods, defined as mode types, which

can be set individually by parameter.

14 | © Danfoss | July 2020 AB298174786006en-000201

Page 15

System Description

Propel Controller Solutions

Functions

Automotive Transport Mode

Proportional pump and hydromotor displacement control. The setpoint of the pump drive curves is given

by the engine rpm. The engine rpm is commanded by a drive pedal.

The hydromotor setpoint is calculated from the actual pump flow (FCMD - Flow Controlled Motor

Displacement). The pump flow is calculated from the displacement of the hydromotor (detected by the

control current) and the hydromotor rpm.

•

•

•

•

Non-Automotive Work Mode (FCMD)

Proportional pump and hydromotor displacement control. The setpoint of the drive curves is given by a

pedal command independent of the engine rpm. The engine rpm is commanded by a hand throttle to

mainly fulfill the requirements of the work hydraulic.

The hydromotor setpoint is calculated from the actual pump flow (FCMD - Flow Controlled Motor

Displacement). The pump flow is calculated from the displacement of the hydromotor (detected by the

control current) and the hydromotor rpm.

•

•

•

•

•

•

Drive pedal controls vehicle speed

Load dependent mode

Brake/inch signal reduce vehicle speed

Coast down when release the drive pedal

Drive pedal controls vehicle speed

Engine speed is set separately according requirement of work functions

Load independent mode

Brake/inch signal reduce vehicle speed

Vehicle speed limitation by the drive pedal (no roll down the hill)

Antistall protect the engine from overloading

ECO fuel saving mode

The ECO fuel saving mode is designed for the Automotive Transport Mode (FCMD). It needs a CAN

controlled Engine (TSC1 & EEC1), an electric drive pedal and a larger pump displacement. The ECO Mode

function reduces the engine rpm setpoint (TSC1) automatically when a vehicle speed is reached for a

defined time. This will reduce the fuel consumption and noise emission. The pump displacement will be

increased to keep the vehicle speed on the same level with a reduced engine rpm. The ECO mode is

automatically switched off, if the vehicle slows down or the driver releases the electric drive pedal. If the

engine is overloaded (EEC1) the “Engine Speed Command” will be increased.

The ECO Mode is available in all Automotive Transport Modes and can enabled individually in each ofthe

four Modes.

Mode transition control

This function allows configuration of an application specific System Mode transition. The System Mode

The propel controller can exchange information with the engine via the CAN J1939 protocol (TSC1

change condition can be dependent on multiple factors including actual FNR direction, drive pedal

message or Kubota protocol). All CAN messages can be individually activated and designated for usage.

Input, and ground speed. The following functions and standard messages are provided: The vehicle

driving direction change can be configured on vehicle speed.

When a momentary FNR switch logic is configured, the driving direction change request is rejected if the

vehicle speed is above a predefined speed.

Start Protection

The Safety Controlled Vehicle Start Protection prevents commanded, unexpected, or otherwise

dangerous machine propel movement after initial power on the engine. The Start Protection is

monitoring the following signals.

©

Danfoss | July 2020 AB298174786006en-000201 | 15

Page 16

System Description

Propel Controller Solutions

Functions

•

•

•

•

•

If all conditions are fulfilled the Start Protection will switch OFF and the vehicle can drive.

Quick stop in automotive mode

When operating the vehicle in Automotive Transport Mode the propel controller will use the engine rpm

as the setpoint. The electric drive pedal position (out of the deadband) is used as an enable signal. The

driver must press the drive pedal and the engine rpm must rise to move the vehicle. If the driver release

the drive pedal fully (drive pedal return into the deadband), the pump current will decrease with an

adjustable ramp to a defined value. The vehicle will decelerate much faster compared to the today’s

behavior.

If the driver release the drive pedal to a minimum value (drive pedal signal is over the deadband), the

pump current will follow the drive curve as today. The vehicle will decelerate “normal”.

State and direction change

After a direction change request by the FNR switch, the system state will wait until the vehicle speed is

lower than the “Vehicle Speed for State Change” before it will switch to Neutral or the other direction.

Engine rpm

Battery voltage

Error status

Inch calibration

FNR in Neutral

Hydromotor overspeed protection

The Hydromotor Overspeed Protection prevents the hydromotor(s) from over speeding by either

decreasing pump displacement or increasing hydromotor displacement. The hydromotor rpm speed

limit, is user defined and valid in all four System Modes when activated

Electronic Pressure Limiter (ePL)

The electronic pressure limitater prevents the pump from over pressure. When the system pressure

exceeds the ePL pressure setting (set by parameter) the pump is being stroked towards min

displacement to maintain the pressure in the system. The system pressure information is provided by

MBS1250 pressure sensor located in the system pressure lines.

Electronic pressure compensator over ride (ePCOR)

The electronic Pressure Compensator Over Ride prevents the motor from over pressure. When the system

pressure exceeds the ePCOR pressure setting (set by parameter) the motor is being stroked towards max

displacement to maintain the pressure in the system. The system pressure information is provided by

MBS1250 pressure sensor located in the system pressure lines. Dependent on the available engine power

different features might be required:

•

Engine power higher than hydrostatic system can utilize → ePCOR required

•

Engine power less than hydrostatic system can utilize → Load Limiter required

Load limiter

The Load Limiter allows the system to utilize maximum available engine power. The commanded engine

rpm (TSC1) is compared with the measured engine rpm (EEC1). If the engine is drooped, the engine Load

Limiter function will increase the hydrostatic motor displacement to maintain a certain engine droop

level set by parameter. It works with CAN controlled engines.

Dependent on the available engine power different features might be required:

16 | © Danfoss | July 2020 AB298174786006en-000201

Page 17

System Description

Propel Controller Solutions

Functions

•

•

Hydraulic-System overheat protection

An external temperature sensor, in the hydromotor PPU sensor, will measure the hydraulic oil

temperature. The function protects the complete hydrostatic system by reducing the pump flow (by

pump command) at extreme high temperatures according to user defined temperature curve.

Vehicle constant-speed-drive (CSD)

The CSD function will allows driving with a constant vehicle speed, independent of the load. If the actual

vehicle speed differs from the commanded speed, the CSD function will adjust the pump and

hydromotor command to compensate the speed difference. The speed set-point usually comes from an

electric drive pedal. For the feedback a hydromotor or vehicle speed sensor is required.

Cruise control

The Cruise Control will keep the vehicle speed constant during driving. The driver can release the drive

pedal if Cruise Control is enabled.

When the vehicle is driving the required speed, within the defined range, the driver press the “Set”

button, the vehicle speed is captured (frozen). The driver can release the drive pedal. A signal light will

show “Cruise Control switched on”. The software will keep the vehicle speed constant by adjusting the

setpoint.

An actuation of the drive pedal above the captured value (higher wins) will accelerate the vehicle. If the

drive pedal is released again, the vehicle speed will return to the captured value.

The cruise control signal light is still on.

The cruise control is switched off, if the inch pedal is pressed (more to a defined level), the FNR is

switched to neutral, the seat switch (door switch) is operated, the “Stop” button is pressed or the mode is

changed. The cruise control signal light is switched off.

To resume the stored vehicle speed again, the driver has to press the drive pedal and the “Resume”

button.

If cruise control is switched on, the driver can increase the vehicle speed by pressing the “Set” button. The

speed step and trigger time can be set by parameter. To decrease the vehicle speed, the driver can press

the button “Resume”.

Engine power higher than hydrostatic system can utilize → ePCOR required

Engine power less than hydrostatic system can utilize → Load Limiter required

Filter on drive pedal

When driving over a field or other rough terrain, the vehicle is shaking and the driver has no chance to

keep the electric drive pedal constant in one position. The filter function for the drive pedal is able to

filter this short movement. The Filter can configure individually in each Mode.

Vehicle speed dependent ramps

The time ramps for the pump and hydromotor must different depending on the vehicle speed. A vehicle

speed dependent multiplier will adjust the ramp times.

Semi-Automatic calibration function

All hydraulic components like hydromotors having tolerances. Even during lifetime they will change their

control behavior. The semi automatic calibration routine for the hydrostatic motors can be started by

service tool or CAN message. A pump calibration is due to NFPE pump not required.

©

Danfoss | July 2020 AB298174786006en-000201 | 17

Page 18

System Description

Propel Controller Solutions

Protections

Engine control and protection

1939-CAN engine interface

The propel controller can exchange information with the engine via the CAN J1939 protocol (TSC1

message . All CAN messages can be individually activated and designated for usage. The following

functions and standard messages are provided:

•

•

•

•

•

CAN user interface

The propel controller can exchange information with external divices via DM1 and DM2 CAN messages. A

easy realisation to display error messages or the start of calibration routines is possible.

Engine speed control

An electric drive pedal with redundant input can be connected to the AC Control. The Engine Speed

setpoint is transmitted via CAN TSC1 to the engine controller.

Engine speed control (TSC1) via redundant drive pedal

Engine Anti-Stall protection

Engine Overspeed protection during inching

Engine Overspeed protection with Retarder function

Cold start protection

Engine anti-stall protection

The Engine Antistall protection prevents the engine from being stalled due to overload. The commanded

engine rpm (TSC1) is compared with the measured engine rpm (EEC1). If the engine is drooped, the

engine Antistall function will reduce the hydrostatic propel command to reduce the engine load and the

vehicle speed.

The engine Antistall function can be individually enabled for each system mode and is configurable. It

works with CAN controlled engines.

All range engine overspeed

The engine rpm is monitored in all driving situations, independent of the FNR position, seat switch

(enable), SAFE or LIMITED state. If the engine is in overspeed, a system mode change is blocked. The

overspeed protection is only active if the vehicle is moving.

When the system detects an overspeed situation, the pump will swivel out. That will limit the

deceleration of the vehicle. The driver must use the service brake to reduce the vehicle speed.

The rpm range for the overspeed detection can define by parameter. Time ramps for activation and

deactivation of the function are available.

Optional the Hydromotor (only proportional Control) is commanded to a smaller displacement. With a

larger pump and smaller Hydromotor displacement the deceleration of the vehicle will be lower. The

driver has to use the service brake.

All range engine overspeed with retarder

The engine rpm dependent Retarder Control toggles a digital output when the actual engine rpm

exceeds a user defined level. The Retarder can activate a valve of the work hydraulic to give load to

engine and prevent an over speeding.

Cold start protection

A temperature sensor measures the system temperature. If the temperature is lower than a user defined

level, the engine rpm command (TSC1) is limited until the system is warmed up to protect the engine and

the hydraulic system.

18 | © Danfoss | July 2020 AB298174786006en-000201

Page 19

System Description

Propel Controller Solutions

Protections

Gearbox control and protection

Gearbox control

The gearbox control provides the function to actuate the shift gearbox. It actuates the shift valve and

controls the hydrostatic components according to the individual gearbox supplier specification.

Shift monitoring control

The shift monitoring control monitors the shifting process based on sensor information. It also continues

to monitor operation condition outside the shifting process.

©

Danfoss | July 2020 AB298174786006en-000201 | 19

Page 20

System Description

Propel Controller Solutions

Auxiliary functions

Automatic park brake control

The park brake logic supports "negative brakes".

Brake applied = output is switched on

Brake released = output switched off

The conditions for the automatic park brake control are:

•

•

•

•

Delay times for park brake application and release are individually configurable.

The park brake is connected in closed loop, that means a short circuit or broken connection will detected

and lead into a SAFE state error.

Brake light

The digital brake light output is switched on if the inch/brake pedal command exceeds a user defined

value or the calculated deceleration is too high (measured by the hydromotor rpm sensor). This even

applies the brake light if the vehicle decelerates by the hydrostatic system. There will be an on/off delay

to avoid flickering of the brake lights.

Software machine state in STOP mode

Actual pump valve current below user defined value

Actual inch pedal command exceeds user defined value.

Actual vehicle speed is lower than an user defined value

Reverse buzzer

The reverse buzzer is switched on if the FNR is set to reverse.

Vehicle speed dependent outpost speed

The retarder control (Engine-Speed-Dependent Output) is switched on if the actual engine rpm exceeds a

user defined level. It can be used to enable a retarder to increase the braking capability of the system. It

can also be used to provide a signal to the boom damping system or the all wheel steering.

Error handling

The control system can detect failures which leads to different type of error modes. The safe state will

stop the machine. A limited state will reduce the machine performance and will provide information to

the driver. This can be done directly by acoustical signal, or indirectly via display by visual indication

triggered by a CAN DM1 or DM2 message.

20 | © Danfoss | July 2020 AB298174786006en-000201

Page 21

System Description

Propel Controller Solutions

Propel controller

Controller specification

Dual Processor Primary Flash: 1 MB; RAM: 128 kB

Rated supply voltage 12 V system 9-16 V

Rated supply voltage 24 V system 18-36 V

Digital and PWM outputs 3000 mA

Sensor supply (internal) 5 V / 500 mA

Ambient temperature -40 to 85°C

IP rating with attached connectors IP69k

EMC immunity 150 V/m

Vibration and shock tested IEC60068

Input (24 user defined inputs)

Input Function

7 x digital FNR (direction selection), temperature switch gearbox, park brake switch, park brake

10 x analog Inch pedal, drive pedal, hydrostatic oil temperature, operator presence, engine speed

4 x frequency Hydro-motor rpm

3 x frequency For customized function (option dependent)

Secondary Flash: 512 kB; RAM: 64 kB

feedback, clutch pressure feedback, pin not used

setpoint, pressure sensors, system mode switches

Output (14 user defined outputs)

Output Function

4 x PWM Pump and hydro-motor displacement control

2 x PWM For customized function (option dependent)

8 x digital Dynamic brake light, park brake, reverse buzzer, retarder control (optional), status LED,

clutch valve, low side switches pump and motor

©

Danfoss | July 2020 AB298174786006en-000201 | 21

Page 22

114.4 [4.50]

159.7 [6.29]

25.2 [1.0]

143.3 [5.64]

97.0

[3.82]

35.0 [1.38]

144.5 [5.69]

ysa1473441044006

C

C

System Description

Propel Controller Solutions

Propel controller

General dimensions

Dimensions in mm [in]

Caution

PCB damage may occur. All device power supply + pins must be connected to battery +.

Caution

This device is not field serviceable. Opening the device housing will void the warranty.

* The Propel Controller is suitable as a safety-related part of a control system up to SIL 2 when used per

Danfoss requirements and the machine is so certified by an appropriate notified body or certifying

authority.

Use care when wiring mating connector. Pinouts listed are for device pins.

22 | © Danfoss | July 2020 AB298174786006en-000201

Page 23

2198B

1 2 3 4 5

11 12 13 14 15

2524232221

3534333231

4544434241

6 7 8 9 10

16 17 18 19 20

3029282726

4039383736

5049484746

System Description

Propel Controller Solutions

Propel controller

Pin assignments

Pin connector

Pin Controller function Pin Controller function

C1-P1 Power ground - C1-P26 DIN/AIN/FreqIN

C1-P2 Power supply + C1-P27 DIN/AIN/FreqIN

C1-P3 CAN0 + C1-P28 DIN/AIN/FreqIN

C1-P4 CAN0 - C1-P29 DIN/AIN/FreqIN

C1-P5 DIN/AIN/CAN shield C1-P30 DIN/AIN/FreqIN

C1-P6 DIN/AIN/SnsrPwr1.6Vdc C1-P31 DIN/AIN/ResIN/CrntIN

C1-P7 DIN/AIN/SnsrPwr3.3Vdc C1-P32 DIN/AIN/ResIN/CrntIN

C1-P8 3-12Vdc SnsrPwr + C1-P33 DOUT

C1-P9 SnsrPwr - (sensor ground) C1-P34 DOUT

C1-P10 DIN/AIN C1-P35 DOUT

C1-P11 DIN/AIN C1-P36 DOUT

C1-P12 DIN/AIN C1-P37 DOUT

C1-P13 DIN/AIN C1-P38 DOUT

C1-P14 DIN/AIN C1-P39 PWMOUT/CrntOUT/DOUT

C1-P15 DIN/AIN C1-P40 PWMOUT/CrntOUT/DOUT

C1-P16 DIN/AIN C1-P41 PWMOUT/CrntOUT/DOUT

C1-P17 DIN/AIN C1-P42 PWMOUT/CrntOUT/DOUT

C1-P18 DIN/AIN/ResIN/CrntIN C1-P43 PWMOUT/CrntOUT/DOUT

C1-P19 DIN/AIN/ResIN/CrntIN C1-P44 PWMOUT/CrntOUT/DOUT

C1-P20 CAN1 + C1-P45 PWMOUT/CrntOUT/DOUT

C1-P21 CAN1 - C1-P46 PWMOUT/CrntOUT/DOUT

C1-P22 DIN/AIN/CAN shield C1-P47 Power supply +

C1-P23 DIN/AIN/ResIN/CrntIN C1-P48 Power supply +

C1-P24 DIN/AIN/ResIN/CrntIN C1-P49 Power supply +

C1-P25 DIN/AIN/FreqIN C1-P50 Power supply +

©

Danfoss | July 2020 AB298174786006en-000201 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | July 2020 AB298174786006en-000201

Loading...

Loading...