Page 1

Technical Information

Propel Application Library (PAL)

Software Function Blocks

www.danfoss.com

Page 2

Technical Information

Propel Application Library (PAL) Software Function Blocks

Revision history Table of revisions

Date Changed Rev

June 2019 Correction, removed unreleased function block in PAL Basic and Advanced Function Block

Overview table

March 2019 Removed information regarding a Function block that needs further testing 0301

February 2019 Minor correction 0203

February 2019 Minor correction 0202

February 2019 Added new Function blocks descriptions and drawings 0201

December 2017 First version 0101

0302

2 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 3

Technical Information

Propel Application Library (PAL) Software Function Blocks

Contents

Introduction

What is PAL......................................................................................................................................................................................... 4

PAL Basic and Advanced Function Block Overview.............................................................................................................5

Basic Functions

Braking..................................................................................................................................................................................................6

Creeping Automotive..................................................................................................................................................................... 6

Creeping.............................................................................................................................................................................................. 7

Drive Modifier Basic.........................................................................................................................................................................7

Drive State machine with FNR + Hold.......................................................................................................................................8

Engine Control (basic).....................................................................................................................................................................9

Engine Control with Temperature Limitation........................................................................................................................9

FNR 2 Switch.......................................................................................................................................................................................9

FNR 3 Pushbuttons........................................................................................................................................................................10

FNR 3 Switch.................................................................................................................................................................................... 10

FNR 3 pin (LED) Output................................................................................................................................................................11

Hydrostatic Core Basic..................................................................................................................................................................11

Hydrostatic Core Drive State......................................................................................................................................................12

Hydrostatic Core (jump).............................................................................................................................................................. 13

Inching Function............................................................................................................................................................................ 14

Mode Transition Control............................................................................................................................................................. 14

Pedal................................................................................................................................................................................................... 15

Redundant Pedal............................................................................................................................................................................15

Rocker Pedal.................................................................................................................................................................................... 16

Vehicle Speed..................................................................................................................................................................................16

Advanced Functions

Antistall..............................................................................................................................................................................................17

Command Modifier....................................................................................................................................................................... 18

Command Modifier Multiply......................................................................................................................................................19

Cruise Control (basic)....................................................................................................................................................................19

Cruise Control with Jog Up / Down.........................................................................................................................................20

Electronic Pressure Control Override ePCOR.......................................................................................................................20

Electronic Pressure Limiter ePL.................................................................................................................................................21

Engine Control ECO.......................................................................................................................................................................21

Engine Overspeed EOS................................................................................................................................................................ 22

Hydromotor Overspeed Protection.........................................................................................................................................22

Max Hydromotor Torque Control............................................................................................................................................ 23

Stop to Shift..................................................................................................................................................................................... 23

Stop to Shift Driver........................................................................................................................................................................ 24

Temperature Derate......................................................................................................................................................................24

Vehicle Speed Limitation............................................................................................................................................................ 25

Service Tool and Documentation

Braking Function Example..........................................................................................................................................................26

System Builder Sales Tool

PAL Function Blocks Deck of Cards......................................................................................................................................... 28

PAL Function Blocks Card Game.............................................................................................................................................. 29

System Control Visualizer Tool

Graphical Elements Drag and Drop Function......................................................................................................................30

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 3

Page 4

Technical Information

Propel Application Library (PAL) Software Function Blocks

Introduction

What is PAL

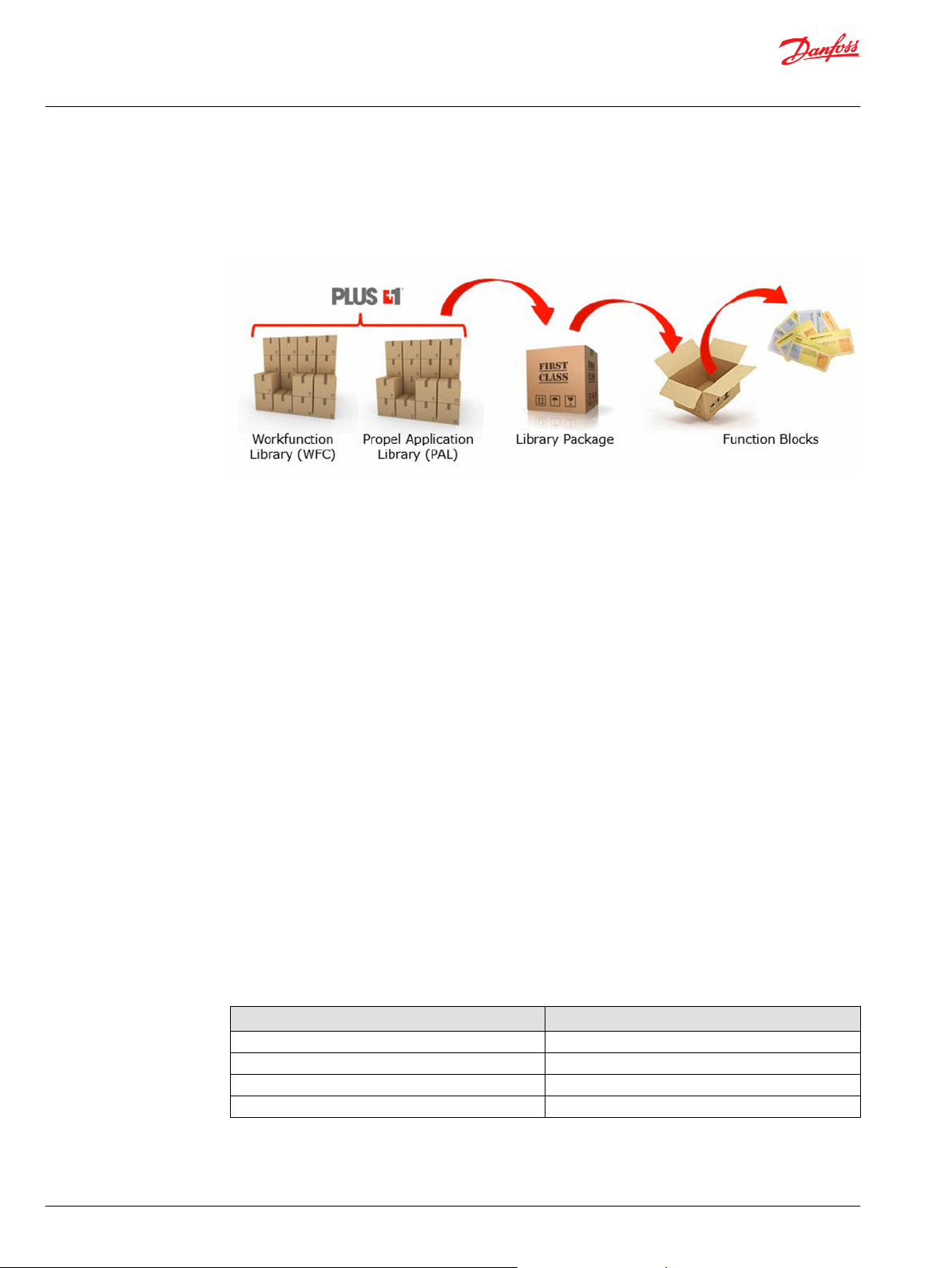

PLUS+1® GUIDE allows to implement different software libraries, such as Work Functions Control (WFC)

and Propel Application Library (PAL). Each library consists of one or more packages which includes

different function blocks.

Use Danfoss PLUS+1® and the library PAL to develop complete propel systems for mobile machinery or

easily integrate any PAL function block into an existing propel system regardless of the system

configuration or hardware in use.

PAL provides a competitive advantage by allowing for superior machine performance, it also dramatically

reduces development time therefore, getting to market faster. The reason for this is that PAL supports the

entire propel software development process, and is aligned with other PLUS+1® compliance blocks.

PAL offers two different library packages. The PAL Basic library package and the PAL Advanced library

package.

The PAL Basic library package offers multiple function blocks to design simple propel solutions; for

instance, one pump and one motor.

The PAL Advanced library package offers function blocks cruise control to get better driving behavior or

Engine Control ECO for fuel saving, which means function blocks for advanced features of propel

solutions. More detail is provided, see Advanced Functions on page 17.

All function blocks of PAL work very well together with PLUS+1® Compliance blocks and other Danfoss

PLUS+1® libraries.

PAL function blocks can be used with all MCxx and SCxx Controllers. Using PAL on application hardware

is not required.

PLUS+1® GUIDE Professional Software (minimum version 8.1 or higher) is required, PAL will not work with

the PLUS+1® GUIDE Express license.

Both PAL library packages can have licenses. The PAL Basic has a free license. The non free licenses are

valid for a limited time and can be renewed by a yearly subscription for each library package.

Each function block of the PAL library package will have the following documents and software files as

part of their scope.

PAL library package

File name File format

PLUS+1® Compliant Software Function Block .scs - PLUS+1® GUIDE

Safety Manual and Programmers Guide .pdf - Adobe PDF

PLUS+1 Service Tool Page .pfx - PLUS+1® Service Tool

User Manual snippet .doc - MS Word

4 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 5

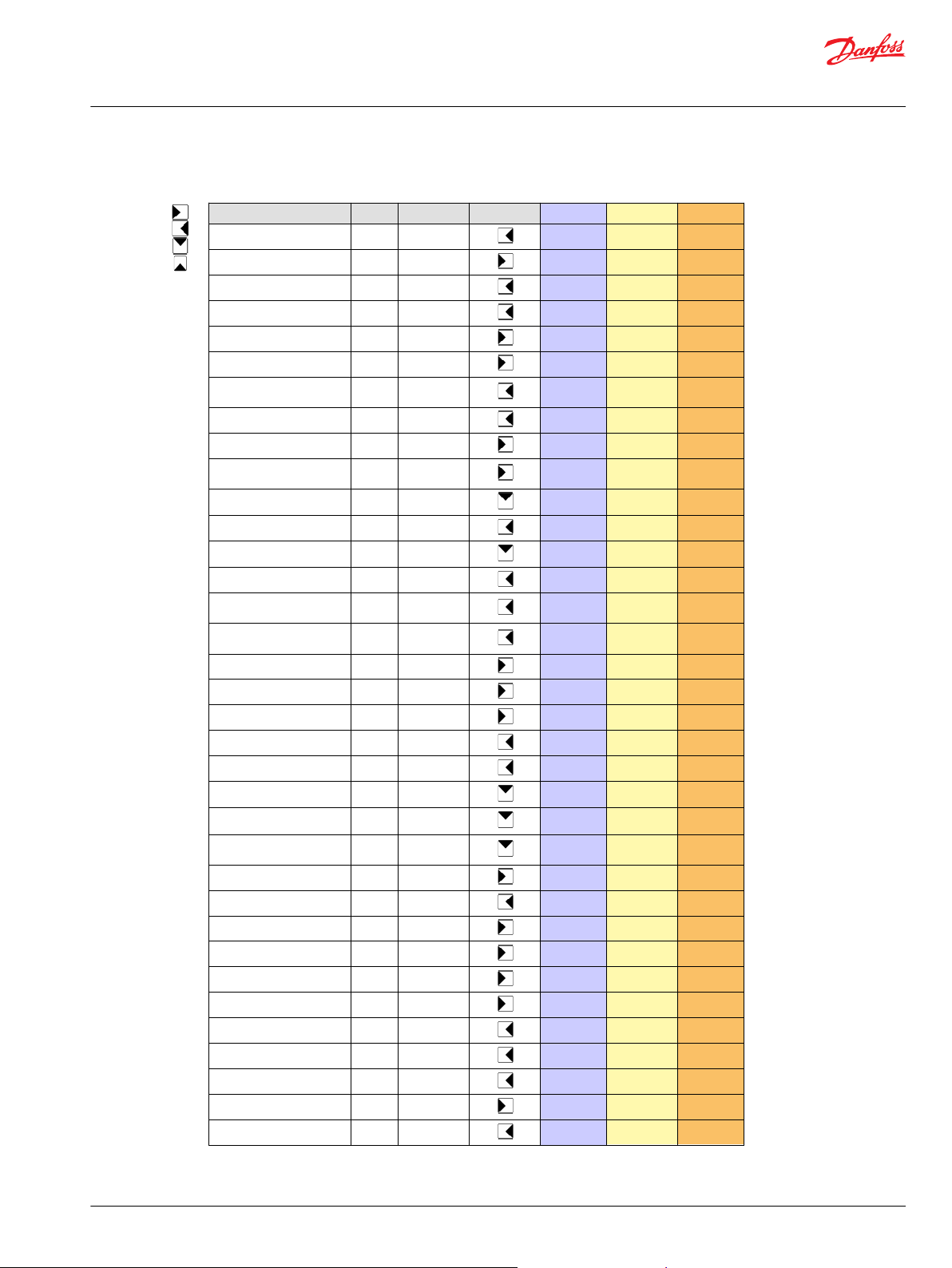

Function Block Basic Advanced FB-Group Input Function Output

Antistall X X

Braking X X

Command Modifier X X

Command Modifier Multiply X X

Creeping X X

Creeping Automotive X X

Cruise Control with jog up/

down

X X

Cruise Control Basic X X

Drive Modifier Basic X X

Drive Statemachine with FNR

+ Hold

X X

Engine Control Basic X X

Engine Control ECO X X

Engine Control Temp Limit X X

Engine Overspeed Protection X X

ePCOR (electronic pressure

control override)

X X

ePL (electronic pressure

limiter)

X X

FNR 2 Switch X X

FNR 3 Pushbutton X X

FNR 3 Switch X X

FNR LED Output X X

Hydro Motor Overspeed X X

Hydrostatic Core Basic X X

Hydrostatic Core Drive State X X

Hydrostatic Core Drive State

with Jump Command

X X

Inching X X

Maximum Motor Torque X X

Mode Transition Control X X

Pedal X X

Pedal Redundant X X

Rocker Pedal X X

Stop to Shift X X

Stop to Shift Driver

X

Temperature Derate X X

X

Vehicle Speed X X

Vehicle Speed Limitation X X

Front Add-on

Rear Add-on

Engine Core

Hydrostatic Core

Technical Information

Propel Application Library (PAL) Software Function Blocks

Introduction

PAL Basic and Advanced Function Block Overview

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 5

Page 6

Brake Command

Drive Command in

Subtract

& Limit

Drive Command out

Override

Stop Request

Braking

Creeping Automotive

Scale &

Limit

Activation

Engine Speed out

Parameter

Creep Command

Engine Speed in

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

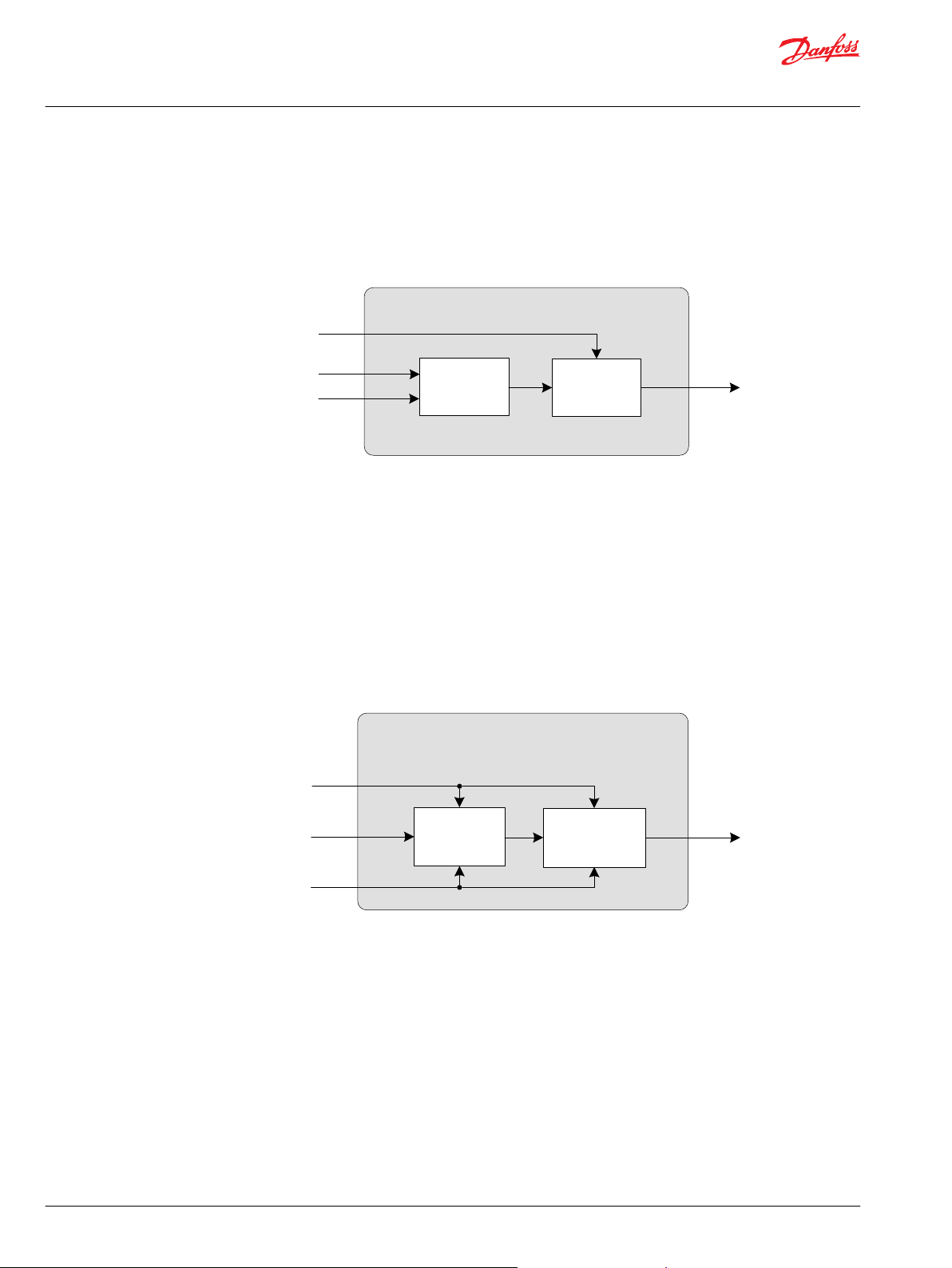

Braking

The Braking function has the purpose of reducing a Drive Command by a Brake Command. Both signals

can be read from a lever, potentiometer or pedal. The function can reduce the Drive Command down to

complete Stop.

The following diagram illustrates in a simplified way how the function block works:

Creeping Automotive

An Automotive drive Mode uses the engine rpm as the setpoint signal for the drive curves. The engine

rpm is measured with a PPU or received via CAN message. This engine rpm signal is virtually reduced by

the Creeping Command, the setpoint for the drive curves is reduced as well.

With a Creeping Command = 100% the Engine Speed In is directly sent to the Engine Speed Out signal.

By parameter a minimum Engine Speed out can be defined. A Creeping Command = 0% will reduce the

Engine Speed in to the minimum Engine Speed out.

This function requires a creeping pedal or potentiometer being installed on the machine. The creeping

signal needs to be prepared as a percentage value (for instance, by using Pedal function block).

The following diagram illustrates in a simplified way how the function block works.

6 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 7

Creeping

Multiply

& Limit

Activation

Drv_Cmd_Out

Parameter

Creep_Cmd

Drv_Cmd_In

6-point Profile

Time Ramp

Drv_Cmd_Out

Parameter

Drv_Cmd_In

Drv_Factor

Stop_Rqst

Drive Modifier Basic

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

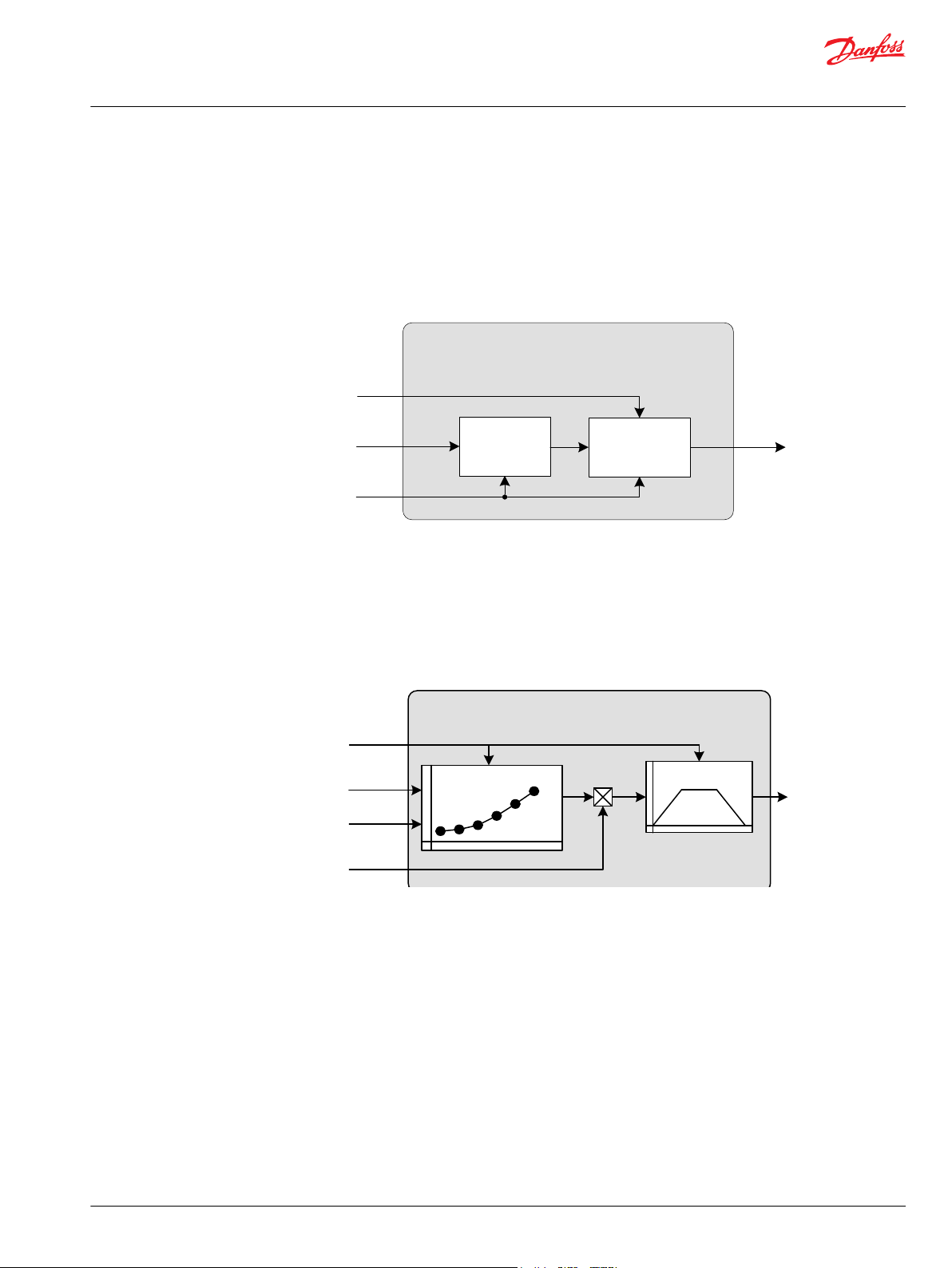

Creeping

Creeping is a function to scale (reduce) the Drive Command In proportionally.

With a Creeping Command = 100% the Drive Command in is equal to the Drive Command out. A

Creeping Command = 0% will reduce the Drive Command out to 0%. This function requires a creeping

pedal or potentiometer being installed on the machine. The creeping signal needs to be prepared as a

percentage value (for instance, by using Pedal function block).

The following diagram illustrates in a simplified way how the function block works.

Drive Modifier Basic

Drive Modifier Basic is a function that modifies an Input Drive Command with a 6-point profile. A

percentage factor is used to modify the output of the profile. If a stop request is received, the Output

Drive Command is pulled to zero. The final output is time-ramped at a rate settable by time rate

parameters.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 7

Page 8

Stop

Forward

Forward

Braking

Forward

Reversal

Reverse

Braking

Reverse

Reversal

Reverse

Hold Direction

Start Protection

Direction Request

Drive State

Direction State

Stop Request

Drive State Machine with FNR + Hold

Range

Check

Override

State

Machine

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

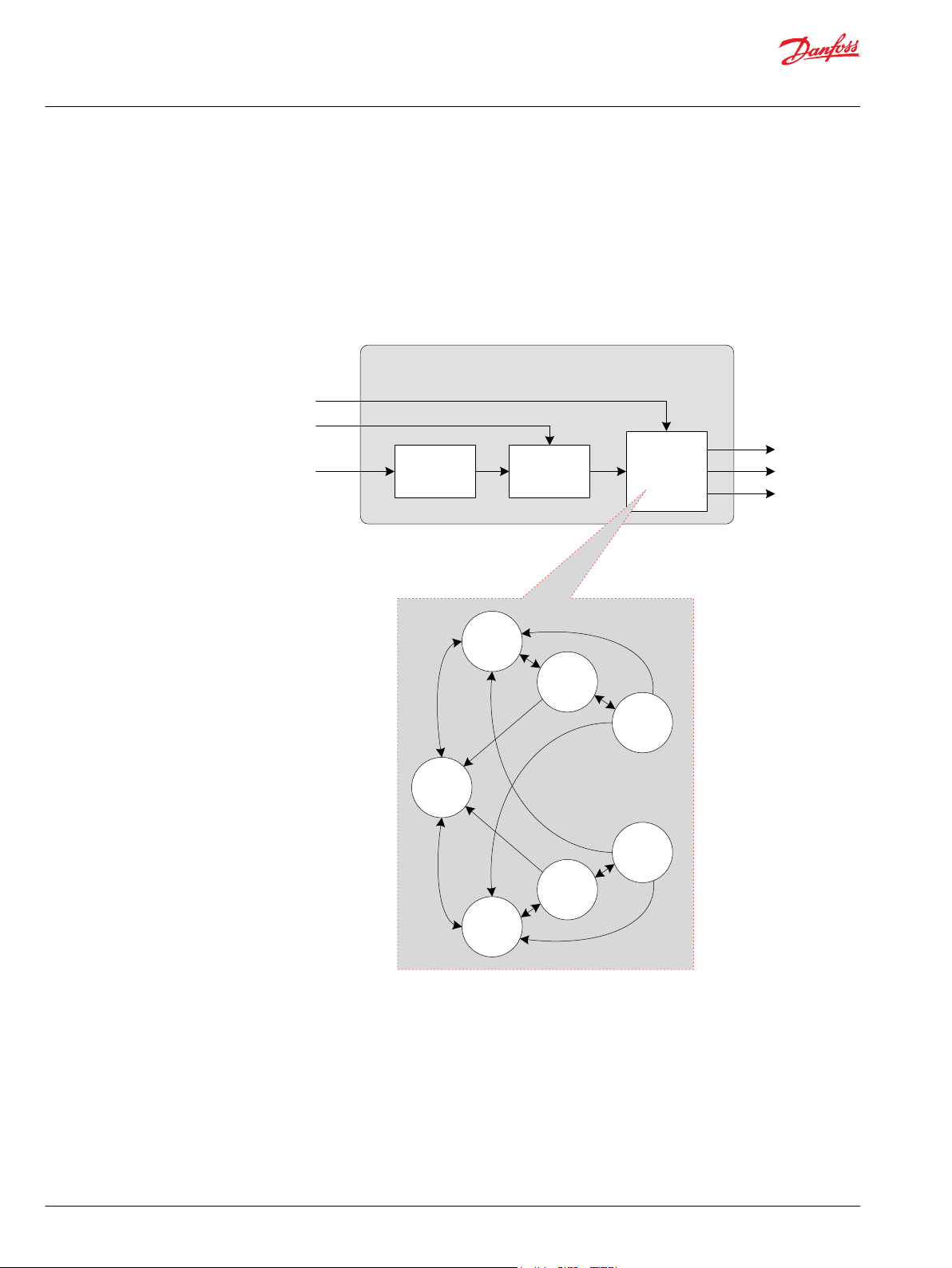

Drive State machine with FNR + Hold

The Drive State Machine is a function between a FNR to choose the driving direction and the hydraulic

power transmission for driving (pump + hydromotor). The Drive State Machine sets the Direction State

based on the request given via Direction Request (FNR). The Start Protection can block the Direction

Request e.g. if the engine rpm is too low.

The function Hold Direction can hold (store) the Direction Request if there is a reason not to change the

driving direction e.g. vehicle speed is too fast for a safe direction change.

The following diagram illustrates in a simplified way how the function block works.

8 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 9

Engine Speed Command

Drive Command

Engine Control (basic)

Scale Ramp

Parameter

Scale

Ramp

Parameter

Temperature

Limitation

Limited

Engine Control with

Temperature Limitation

Drive

Command

Temperature

Engine Speed

Command

FNR 2 Switch

Parameter

Forward Input

Reverse Input

Direction

Request

Fault

Detection

Override

FNR

Logic

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

Engine Control (basic)

The Engine Control Basic is a function that converts a Drive Command into an Engine Speed Command

and passes the output command through a time ramp. This requires an interface to the diesel engine

such as a CAN bus or throttle actuator.

The following diagram illustrates in a simplified way how the function block works.

Engine Control with Temperature Limitation

This function converts a Drive Command into an Engine Speed command and passes the output

command through a time ramp. If the measured Temperature is below a threshold value the engine

speed command will be limited to a parameter value and the output Limited will indicate that the engine

speed limitation is active. This function block shall be used for generating an engine speed setpoint. This

requires an interface to the diesel engine such as a CAN bus or throttle actuator.

The following diagram illustrates in a simplified way how the function block works.

FNR 2 Switch

The FNR switch for 2 pushbuttons function block generates a Driving Direction request (Forward, Neutral

or Reverse) based on Forward Switch and Reverse Switch. If Forward Switch is active exclusively, the

Direction Request will be Forward. If Reverse Switch is active exclusively, the Direction Request will be

Reverse. If no switch is active, the Direction Request will be Neutral. If both switches are active for more

than Error Delay Time, a fault will be declared and the Driving Direction request output is forced to

Neutral.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 9

Page 10

FNR 3 Pushbuttons

Forward Input

Reverse Input

Neutral Input

Direction

Request

Parameter

FNR Logic

Override

Fault Detection

FNR 3 Switch

Forward Input

Reverse Input

Neutral Input

Direction RequestFNR Logic Override

Fault Detection

Parameter

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

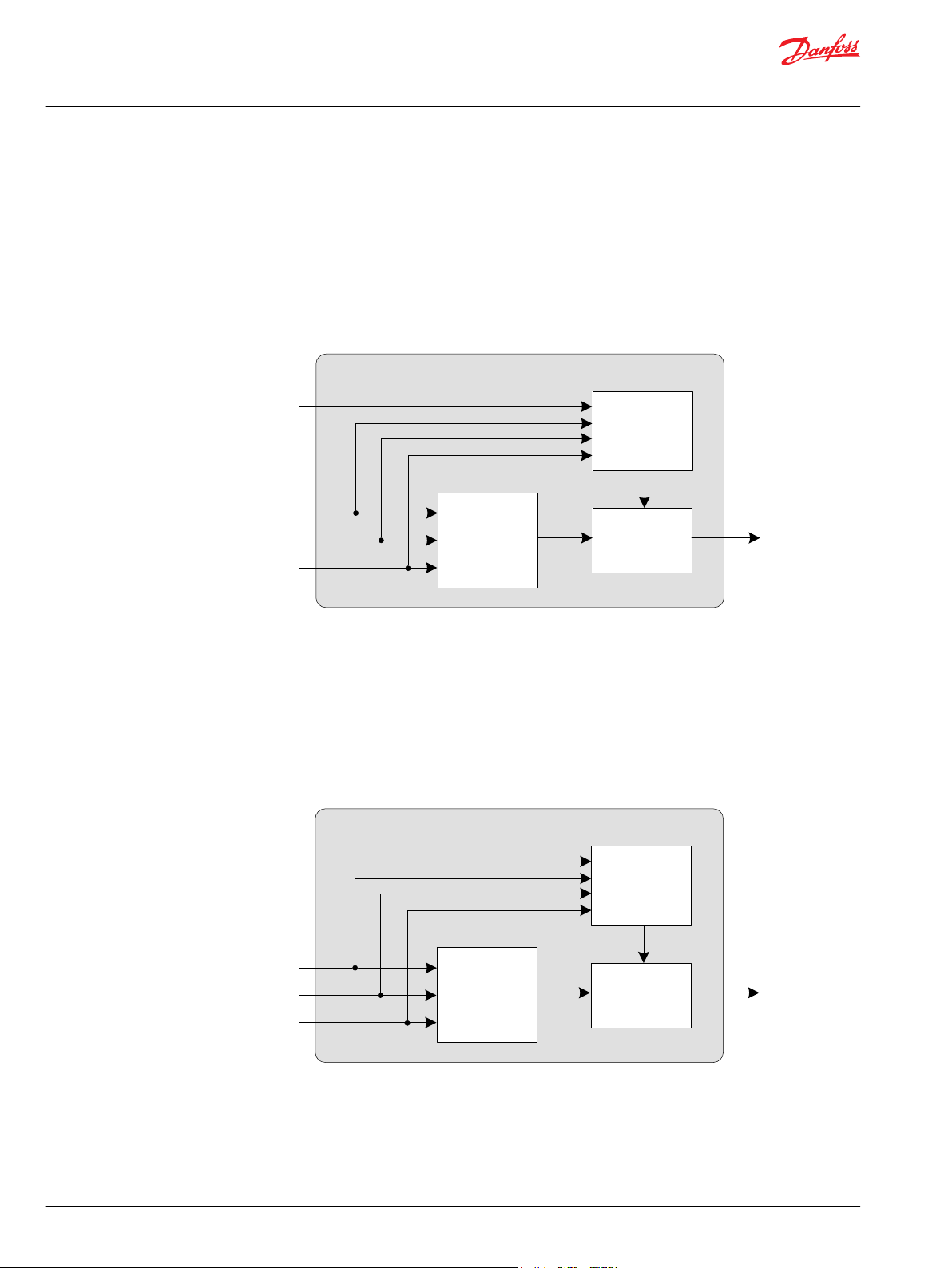

FNR 3 Pushbuttons

The FNR switch for 3 pushbuttons function block generates a Driving Direction request (Forward, Neutral

or Reverse) based on Forward Pushbutton, Reverse Pushbutton and Neutral Pushbutton. If Forward

Pushbutton is active exclusively, the Direction Request will be Forward. If Reverse Pushbutton is active

exclusively, the Direction Request will be Reverse. If Neutral Pushbutton is active exclusively, the

Direction Request will be Neutral. If no Pushbutton is active the last Direction Request will be kept. If

more than one pushbutton is active at the same time for more than Error Delay Time, a fault will be

declared and the Driving Direction request output is forced to Neutral.

The following diagram illustrates in a simplified way how the function block works.

FNR 3 Switch

The FNR switch for 3 state switch function block generates a Driving Direction request (Forward, Neutral

or Reverse) based on three input signals. The signal must be held (continuously). If Forward Switch is

active exclusively, the Direction Request will be Forward. If Reverse Switch is active exclusively, the

Direction Request will be Reverse. If Neutral Switch is active exclusively, the Direction Request will be

Neutral. If none or more than one switch is active for more than Error Delay Time, a fault will be declared

and the Driving Direction request output is forced to Neutral.

The following diagram illustrates in a simplified way how the function block works.

10 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 11

Limit

Decode

Direction

Request

Output Forward

Output Neutral

Output Reverse

FNR 3 pin (LED) Output

Parameter

Error

Drive Command

Hydrostatic

Command

Hydrostatic Core Basic

Profile Ramp

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

FNR 3 pin (LED) Output

This FNR LED Output block derives three output signals Forward, Reverse and Neutral from the input

Driving Direction. It can be used to control direction indication lamps.

The following diagram illustrates in a simplified way how the function block works.

Hydrostatic Core Basic

This function block takes an input Drive Command and converts it into a Hydrostatic Command. It allows

implementing different drive concepts for pump and motor such as Automotive Control and NonAutomotive Control. The Drive Command can be from various signals. For Automotive Control the drive

command will be the engine speed. For implementing a Non-Automotive Control the drive command

can be a pedal position or a hydrostatic ratio command. There’s no specific hardware for this function

block required. It is recommended that the engine goes to Low Idle instead of High Idle in case of an

error (such as, a lost connection).

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 11

Page 12

Parameter

Profile

Error

Ramp

Parameter

Selector

Force

To Zero

Drive State

Drive Command

Hydrostatic

Command

Hydrostatic Core Drive State

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

Hydrostatic Core Drive State

This function block takes an input Drive Command and converts it into a Hydrostatic Command. It allows

implementing different drive concepts for pump and motor such as Automotive Control and NonAutomotive Control. The drive command can be from various signals. For Automotive Control the drive

command will be the engine speed. For implementing a Non-Automotive Control the drive command

can be a pedal position or a hydrostatic ratio command.

Different sets of parameters are used for internal profile and time ramp depending on the actual drive

state. The input drive command is automatically forced to zero when the Drive State is at Braking,

Reversal, Stop, Parking or an undefined state. So only when drive state is Forward or Reverse the drive

command will be forwarded to the corresponding profile. There’s no specific hardware for this function

block required. It is recommended that the engine goes to Low Idle instead of High Idle in case of an

error (e.g. lost connection).

The following diagram illustrates in a simplified way how the function block works.

12 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 13

Parameter

Profile

Error

Ramp

Parameter

Selector

Jump

Function

Force

To Zero

Drive State

Drive Command

Hydrostatic

Command

Hydrostatic Core (jump)

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

Hydrostatic Core (jump)

This function block is intended to be used for controlling NFPE pumps.

This function block takes an input Drive Command and converts it into a hydrostatic command. It allows

implementing different drive concepts for pumps such as Automotive Control and Non-Automotive

Control. The drive command can be from various signals. For Automotive Control the drive command will

be the engine speed. For implementing a Non-Automotive Control the drive command can be a pedal

position or a hydrostatic ratio command.

Different sets of parameters are used for internal profile and time ramp depending on the actual drive

state. The input Drive Command is automatically forced to zero when the Drive State is at Braking,

Reversal, Stop, Parking or an undefined state. Only when drive state is Forward or Reverse the Drive

Command will be forwarded to the corresponding profile.

In this kind of hydrostatic core function block it is possible to perform a jump of the hydrostatic

command. The jump feature is useful when implementing an Automotive Control using a NFPE pump.

Typically the current controlling a NFPE pump is overdriven to ensure that the pump is at maximum

displacement. When triggering a Reversal, Braking or Stop state the pump current will ramp down, but

without any vehicle deceleration as long as the pump current is above a machine specific threshold. The

jump feature allows skipping this current range by jumping directly to this threshold. There’s no specific

hardware for this function block required. It is recommended that the engine goes to Low Idle instead of

High Idle in case of an error (e.g. lost connection).

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 13

Page 14

Inching

Profile

Multiply

& Limit

Activation

Drive

command out

Drive Command in

Inch Command

Parameter

Encode

ModeIntlk_1

ModeIntlk_15

ModeIntlkMand

.

.

.

.

.

&&&&&&

Select

Parameter

Mode_Rqst

Init_Mode

Parameter

ModeIntlkMsk

Mode

Select

Init Mode

Mode_Actual

Mode_Pend

a

b

a = b

a

b

a = b

0

(bitwis e)

(U16)

Mode Transition Control

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

Inching Function

The Inching signal reduces the drive command. A 0% Inch Signal leaves the drive command unchanged

(Drive Command in = Drive Command out). A 100% Inch signal reduces the Drive Command out to 0. The

Inch Command can be profiled by an 8 point profile.

The following diagram illustrates in a simplified way how the function block works.

Mode Transition Control

The Mode Transition Control function block checks whether a requested mode change can be performed

or not. For each possible mode change, one parameter is available to select which of 15 Mode Interlock

condition inputs must be checked. Mode Interlock condition inputs must be 0 (False) for a mode change.

The Mode Interlock mandatory input will block any mode change as long as it is 1 (True), this mode

change is not de-selectable.

The following diagram illustrates in a simplified way how the function block works.

14 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 15

Pedal

Nominal Signal

Supply Voltage

Pedal

Command

Parameter

Pressed

Linear Scale Calibration Override

Pedal Status

Fault

Detection

Redundant Pedal

Parameter

Redundant

Signal

Nominal Signal

Supply Voltage

Redundancy

Check

Linear

Scale

Calibration Override

Fault

Detection

Pedal

Status

Pedal

Command

Pressed

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

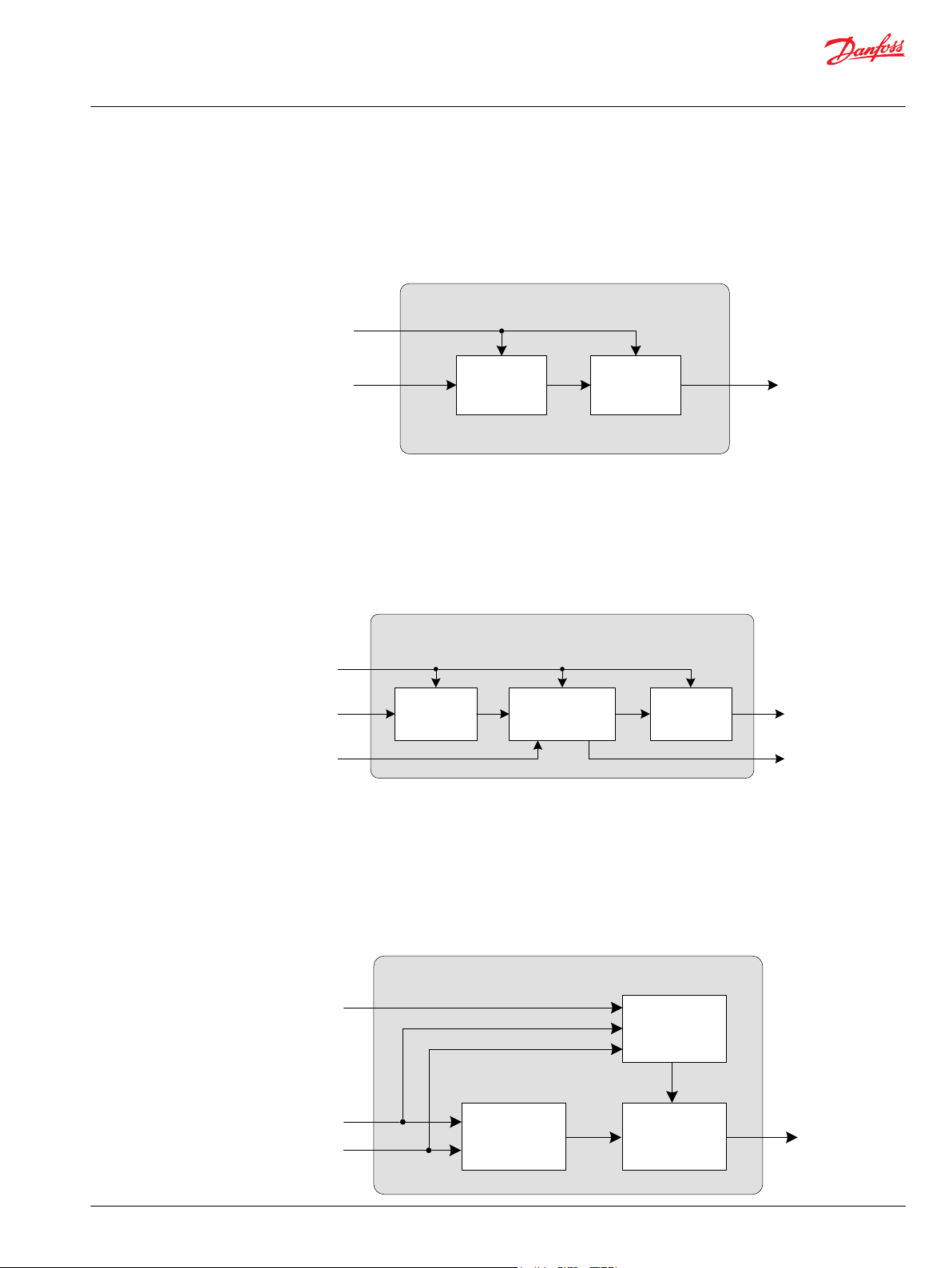

Pedal

The Pedal function block converts a voltage signal from a pedal into a percentage output. This

percentage output is based on the signal characteristics of the sensor. A built-in calibration routine can

capture the electric signal at each end of the sensors range. This function block scales its output between

0% and 100%.

The following diagram illustrates in a simplified way how the function block works.

Redundant Pedal

The Redundant Pedal function block converts a voltage signal from a pedal into a percentage output.

This percentage output is based on the signal characteristics of the sensor. A built-in calibration routine

can capture the electric signal at each end of the sensor’s range. This function block scales its output

between 0% and 100%. It also uses a redundant pedal signal input to monitor if the nominal signal works

well.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 15

Page 16

Nom_Signal

Supply

Linear

Scale

Fault

Detection

Override Pedal_Cmd

Parameter

Calibration

Safe_Cmd

Pedal

Status

Pressed

Redundancy

Check

Red_Signal

Direction

Detection

Dir_Rqst

Rocker Pedal

Vehicle Speed

Scaling Veh_SpdHydr_Motor_Spd

Parameter

Technical Information

Propel Application Library (PAL) Software Function Blocks

Basic Functions

Rocker Pedal

A Rocker Pedal is quite similar to an analog joystick with spring controlled center position. In the center

position the pedal voltage is at about 50% of supply voltage. In the max forward position, the pedal

voltage is at about 90% of supply voltage. In the max reverse position, the pedal voltage is at about 10%

of supply voltage.

The Rocker Pedal block converts a raw signal from the Rocker Pedal sensor into a percentage output. This

percentage output is based on the signal characteristics of the sensor. A built-in calibration routine can

capture the electrical signal at each end of the sensor’s range and at the center position. The block scales

its output between 0% and +100%. Additionally, the block outputs a direction request signal, like a FNR

(Forward, Neutral, Reverse), based on the pedal voltage signal. The block also uses a redundant pedal

signal to monitor if the nominal signal works well.

Vehicle Speed

The Vehicle Speed function block takes an input of Hydro Motor Speed and outputs the Vehicle Speed

per physical dimensions (wheel circumference, axle ratio and gearbox ratio).

The following diagram illustrates in a simplified way how the function block works.

16 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 17

Parameter

Antistall

Scaling

PI

Controller

Active

AS_Adj

Eng_Spd_Cmd

Eng_Spd/Load

Eng_Scale

PI_Scale

Enable_B

Hold

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Antistall

The Antistall detects engine stalling conditions and generates an appropriate signal to manage power

use by vehicle functions so the engine can recover without stalling while keeping machines functions

operational at a reduced capacity.

Dependent on the setting of the parameter Detect Mode the Antistall function is based on one of two

strategies:

Speed Drop Error calculation

•

Engine Load Error calculation

•

The error signal is used as a loop back signal of the PI controller. The resulting Antistall Adjust signal can

be utilized by Command Modifier block.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 17

Page 18

Ran ge

Che ck and

Limi tation

Apply

Adju st

Valu es

Prio rity

Command Modifier

Priority 1 adjustment

Priority 3 adjustment

Priority 2 adjustment

Priority 4 adjustment

Priority 5 adjustment

Priority 6 adjustment

Priority 7 adjustment

Priority 8 adjustment

Command in

Priority 2 hold

Priority 3 hold

Priority 4 hold

Priority 5 hold

Priority 6 hold

Priority 7 hold

Priority 8 hold

Command adjust

Command out

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Command Modifier

The Command Modifier function block is used to modify a command signal by adding adjust value. This

could be a different control functions (e.g. Motor Overspeed Protection, Engine Overspeed Protection,

Speed Limiter, Antistall, etc.).

Furthermore the Command Modifier function block calculates a hold signal for each of the control

functions. The hold signals allow to hold the adjust value of a control function with a lower priority at its

momentary value if another control function with a higher priority becomes active (adjust value no

longer zero).

The following diagram illustrates in a simplified way how the function block works.

18 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 19

Command Modifier Multiply

Command_In

Prio8_Adjust

Prio7_Adjust

Prio6_Adjust

Prio5_Adjust

Prio4_Adjust

Prio3_Adjust

Prio2_Adjust

Prio1_Adjust

Prio1_LimitMask

Priority

Prio2_Hold

Prio3_Hold

Prio4_Hold

Prio5_Hold

Prio6_Hold

Prio7_Hold

Prio8_Hold

Command_Out

Prio3_LimitMask

Prio2_LimitMask

Prio5_LimitMask

Prio4_LimitMask

Prio7_LimitMask

Prio6_LimitMask

Prio8_LimitMask

Value to

Factor

Calculation

Range is

limited

Apply

Adjust

Factors,

limit to

Command

Range

a

b

a > b

Error

Resume

Enable

Activate

Deactivate

Drive Command In

Control

Logic

Mem

Override

Logic

Drive Command Out

Cruise Control (basic)

Only ramping

the transitions

at deactivation

and resume

Update

Active

Time Ramp

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Command Modifier Multiply

There may be more than one functions (such as, motor overspeed protection, engine overspeed

protection, ePCOR, …) that need to modify a hydro motor command signal (in terms of displacement) by

applying their adjust values to it. The control functions may have different priority. Therefore, the adjust

value of a control function with a lower priority must be held at its momentary value if another control

function with a higher priority becomes active (adjust value no longer zero). The Prio’n’_Hold outputs

(n=2..8) serve this purpose. The Command Modifier Multiply first converts the adjust values provided by

up to eight control functions into adjust factors which are then applied sequentially onto a hydro motor

command signal, beginning with the lowest priority adjust factor. The Prio’n’_LimitMask outputs (n=1..8)

indicate that by applying Prio’n’_Adjust_Factor the modified hydro motor command signal has reached

the upper or the lower limit (can be used to avoid winding up of the corresponding control function).

The following diagram illustrates in a simplified way how the function block works.

Cruise Control (basic)

The Cruise Control function stores (freeze) the Drive Command value (vehicle speed) when activated. The

cruise operation can be deactivated and resumed.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 19

Page 20

Activation

Logic

Mem

Active

Update

a

b

a > b

Override

Logic

Active

Inc/Dec

Logic

Update

Error

Cruise Control with Jog Up / Down

Drive Command in

Drive Command out

Increase

Decrease

Enable

Activate

Deactivate

Resume

Time Ramp

ePCOR

Scaling

PI

Controller

Parameter

Drive_Pressure

Pressure_Limit

Enable_B

Hold

Active

ePCOR_Adj

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Cruise Control with Jog Up / Down

The Cruise Control function stores (freeze) the Drive Command value (vehicle speed) when activated. The

cruise operation can be deactivated and resumed. The stored value can be increased or decreased in

steps.

The following diagram illustrates in a simplified way how the function block works.

Electronic Pressure Control Override ePCOR

The Electronic Pressure Control OverRide (ePCOR) compares the actual Drive_Pressure with the

Pressure_Limit. Based on this deviation the PI Controller calculates an ePCOR Adjust. This value is

intended to be applied to the motor command for reducing the Drive_Pressure.

The following diagram illustrates in a simplified way how the function block works.

20 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 21

ePL

Deviation

Scaling

PI

Controller

Selector

and

Factor

Parameters

FWD_Press

Press_Lim_Drv

REV_Press

Press_Lim_Brk

Dir_State

Enable_B

Hold

Braking

Active

ePL_Adj

Factor

Scale

Ramp

Parameter

Modifier

PI

Controller

ECO

Activation

ECO Mode Hold

Vehicle Speed

Enable ECO

Drive Command

Engine Speed

Command

Engine Control ECO

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Electronic Pressure Limiter ePL

The Electronic Pressure Limiter (ePL) function utilizes pressure sensors to monitor forward and reverse

pressures. As they approach or exceed pressure limits, an adjustment value is calculated and is later

applied to another command (such as, pump command). This adjustment reduces system pressure thus

preventing overpressure situations without dissipating energy.

The following diagram illustrates in a simplified way how the function block works.

Engine Control ECO

An Engine Control (ECO) is used to drive the vehicle with reduced engine rpm at the maximum vehicle

speed. The hydrostatic driveline needs to be oversized (faster) to be able to reduce the engine rpm.

The Drive Command (for instance, from the drive pedal) creates the Engine Speed Command. If the ECO

is enabled but not active, then PI controller of the ECO function serves as a speed limiter. When a certain

vehicle speed is reached and maintained for a defined time, the ECO will be activated and reduces the

engine speed automatically. Then the PI controller works as a constant speed drive (CSD). The pump

displacement must in turn be increased to keep the vehicle speed on the same level with a reduced

engine speed.

If the vehicle slows down the ECO is automatically switched off (inactive) and the Drive Command (pedal)

drops or the Drive State is changed.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 21

Page 22

Parameter

Parameter

Parameter

Engine Speed

EOS_Active

EOS_Adj

Overspd Calc

Time Ramp

Profile

EOS_Calc

EOS_Calc_Ramp

EOS

Parameter

Hydromotor Speed

Hold

Active

Overspeed

Adjust

Hydromotor

Overspeed Protection

PI

Controller

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Engine Overspeed EOS

The Engine Overspeed (EOS) is a function which provides engine protection by changing the setpoint of

the Pump, Motor1 or Motor2. The block compares the Actual Engine speed with the maximum speed and

calculates the Engine overspeed adjust value to modify the setpoint of the Pump, Motor1 or Motor2. The

block is intended to be used exclusively for the Pump, Motor1 or Motor2 for better performance.

The following diagram illustrates in a simplified way how the function block works.

Hydromotor Overspeed Protection

The function block compares the actual hydro motor speed with the parameter value for maximum

allowed speed. If actual speed is below maximum speed the hydro motor Overspeed Adjust will be zero.

If actual speed is above maximum speed the function calculates a negative overspeed adjust value. This

value is later applied to another command, (such as pump or hydro motor command depending on the

used components) to reduce the hydro motor speed.

The following diagram illustrates in a simplified way how the function block works.

22 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 23

Hydromotor

Command Out

Max Hydromotor

Torque Control

Selector

Parameter

Hydromotor

Command In

Vehicle Speed

Enable

Active

Memorize

Parameter

Allow

Shifting

Enable

Vehicle Speed

Gear Command In

Gear Command Out

Stop to Shift

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Max Hydromotor Torque Control

The Max Hydromotor Torque block will command the Hydromotor to max displacement until a defined

vehicle speed is reached. This will provide the max torque/tractive force when starting from stop. The

Hydromotor command for the drive profile will be overwritten as long as the function is active.

The following diagram illustrates in a simplified way how the function block works.

Stop to Shift

The Stop to Shift function block prevents gear shifting if vehicle speed is too high. It holds the last gear

command at the output as long as the vehicle speed is above the parameter Allow Shift Speed. If the

vehicle speed is below the parameter value and Enable input is true then the requested gear command is

forwarded.

When starting the microcontroller the gear command at the output is set to a default value, defined by

parameter.

This function requires a gearbox which can only shift in standstill.

A fault of the PPU used for measuring the vehicle speed can cause shifting at too high speeds. If the PPU

has a fault detection then this could be used to suppress the shifting.

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 23

Page 24

State

Machine

NudgeNudge

ToggleToggle

Gear Command

Gear Feedback

Pump Command In

Direction State In

Gear Timeout

Gear 1 Command

Gear 2 Command

Gear 3 Command

Gear 4 Command

Pump Command Out

Direction State Out

Shift State

Stop to Shift Driver

Temp Derate

Parameters

Cmd_Out

Temp

6-point Profile

Cmd_In

Time Ramp

Temp_Factor

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Stop to Shift Driver

The Stop to Shift Driver gets a gear command and tries to engage the requested gear. If engaging does

not succeed, then assisting functions (Nudge, Toggle) can be executed. Nudging works on pump valves

and toggling works on gearbox valves.

The following diagram illustrates in a simplified way how the function block works.

Temperature Derate

The Temperature Derate block modifies an input command by multiplying it by a percentage

temperature factor. This factor is derived from a temperature input feeding into a 6-point profile. A Time

Ramp is used directly on the profile output to smoothen the result of any steep-sloped profiles. If the

function becomes inactive, the input command is passed straight through by multiplying by 100%. The

purpose of this function is to protect your system when it is too hot or too cold.

24 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 25

Vehicle Speed Limitation

PI

Controller

Parameter

Direction State

Drive Command

Enable

Hold

Active

Speed Limitation

Adjustment

Technical Information

Propel Application Library (PAL) Software Function Blocks

Advanced Functions

Vehicle Speed Limitation

The Vehicle Speed Limitation compares actual Vehicle Speed with Max Vehicle Speed in Forward and

Reverse direction. Depending on the selected driving direction one of the limits is used. If the Limit is

reached a correction signal (Speed Limit adjust) is modified. This value is intended to limit the vehicle

speed by applying it to another command (e.g. drive command).

The following diagram illustrates in a simplified way how the function block works.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 25

Page 26

Technical Information

Propel Application Library (PAL) Software Function Blocks

Service Tool and Documentation

Braking Function Example

Braking function purpose is described in Braking on page 6, with a simplified diagram of how the

function block works. The following screen is an overview of adjusting the Braking function.

Specific start-up procedure is not needed for this function.

Adjusting the Braking function

The Braking function can reduce the drive setpoint down to zero if a Stop Request is set by another

function.

Braking commands

Description

Drive Command In Drive command for driving comes from a foot pedal, lever or potentiometer.

Brake Command Brake command for decreasing driving speed comes from a foot pedal, lever or

potentiometer.

Stop Request Digital (Boolean) input signal.

Stop Request command.

1 (True): Performs braking regardless of the Brake Command input

0 (False): Performs normal action

Limit Input Signal after subtraction and switch input to limitation.

Drive Command Out Modified Drive Command.

Fault Signal that indicates if an input fault is declared.

It is a bitwise code, so multiple items can be reported at a time.

Fault codes provided:

0x0000: No fault

0x8002: Drive Command In/Brake Command value is/are too high

Material Number Material/identification number of the overall software application.

Software Version Software version number of the overall software application.

Fault Analysis

If Drive Command In or Brake Command is greater than 100.00% then Fault displays 0x8002 and Drive

Command In or Brake Command is clamped to 100.00%.

26 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 27

Technical Information

Propel Application Library (PAL) Software Function Blocks

System Builder Sales Tool

The PAL System Builder Sales Tool is like a card game to support the visualization of propel software

solutions with PAL function blocks during the design phase of the propel software development process.

PAL deck of cards

PAL System Builder Sales Tool is a deck of 60 cards plus 1 instruction card:

37 software function blocks of the PAL Basic and PAL APM library package

•

12 blank cards for customized functions (4 of each color)

•

11 compliance block cards (4 motor driver, 4 pump driver, speed and pressure sensors)

•

Design phase of the propel software development process

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 27

Page 28

4 different card types

4 different

library packages

4 different

function block groups

Name of function block

Library package symbol

Group symbol

Inputs, Functions, Outputs of the function block

Technical Information

Propel Application Library (PAL) Software Function Blocks

System Builder Sales Tool

PAL Function Blocks Deck of Cards

4 different card types

(1x compliance 3x function blocks)

4 different library packages

4 different function block groups

Name of function block

(1 card = 1 function block)

Library package symbol

Group symbol

Inputs, Functions, Outputs of the

function block

GREY = Compliance blocks

BLUE = Input function blocks

YELLOW = Function blocks

ORANGE = Output function blocks

Available::

Basic (Basic) and Advanced (APM) function block library packages

Unavailable::

No release defined for Multi-Motor (MM) and Dual Path (DuPa) function block library packages

Function block groups are Front Add-on, Engine Core, Rear Add-on or Hydrostatic Core.

The name in this example is Hydrostatic Core function block, followed by the name of the sub-function.

Some function blocks sub-functions are Drive State (shown in this example), Basic, or DS with Jump.

In the example, the symbol stands for the Basic library package. These symbols are included for the software

developer to easily find the library package needed for a propel software solution.

In the example, the symbol stands for the Hydrostatic Core group. These symbols are included for the

software developer to easily find a function block group in the library.

BLUE area = Inputs signals necessary for the function block

YELLOW area = Functions of the function block, short description

ORANGE area = Outputs signals delivered by the function block

28 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 29

Technical Information

Propel Application Library (PAL) Software Function Blocks

System Builder Sales Tool

PAL Function Blocks Card Game

Using a white sheet of paper or white board is the best way to layout function block cards.

It makes sense to start with motor, pump or sensor, as well as the remaining sensors, such as FNR switch

or braking lights with compliance function blocks within the controller, followed by the necessary PAL

function blocks cards. Controller memory and connections to the PAL function blocks and compliance

blocks are drawn lines. If a function block is not available in the deck of cards of the PAL System Builder

Sales Tool, there are blank function block cards, that are for writing a specific name with a nonpermanent writing utensil, and can be added to the layout.

Example on paper

This very fast process supplies a visual of a software design to photograph. The next step of the software

development starts in PLUS+1® GUIDE with PAL.

Example of digital software development

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 29

Page 30

Technical Information

Propel Application Library (PAL) Software Function Blocks

System Control Visualizer Tool

The System Control Visualizer is a simple tool to visualize PLUS+1® software based on compliance blocks

and function blocks of different libraries like PAL or WFC.

This tool also supports the actual design phase of the software development process.

This tool is only available as an online version at: http://experttoolsonline.com/danfoss/cards/

Graphical Elements Drag and Drop Function

The System Control Visualizer has a drag and drop function to place graphical elements that provide a

PLUS+1® software visual to demonstrate benefits and how to use PAL and PAL Systems Builder Sales Tool.

30 | © Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Page 31

Technical Information

Propel Application Library (PAL) Software Function Blocks

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302 | 31

Page 32

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | June 2019 BC00000396 | BC262271566298en-000302

Loading...

Loading...