Page 1

Installation Instructions

PROFIBUS/PROFINET Decoupling Kit

®

VLT

AutomationDrive FC 360

PROFIBUS/PROFINET decoupling kit for mounting the control

cassette with PROFIBUS and control cassette with PROFINET.

Mount the control cassette on the frequency converter before

mounting the PROFIBUS/PROFINET decoupling kit.

Items Supplied

For each control cassette with PROFIBUS or control cassette

with PROFINET, 2 decoupling kits are supplied in the package.

Install the correct kit based on the enclosure size of the

frequency converter.

Code number Items supplied

132B0274 PROFIBUS/PROFINET decoupling kit for enclosure

sizes J1–J5, containing the following items:

Decoupling plate.

•

2 M3x6 screws.

•

132B0286 PROFIBUS/PROFINET decoupling kit for enclosure

sizes J6 and J7, containing the following items:

Decoupling plate.

•

2 M3x6 screws.

•

Table 1.1 Items Supplied

Voltage [V] Minimum waiting time (minutes)

415

380–480 0.37–7.5 kW 11–75 kW

High voltage may be present even when the warning LEDs are o!

Tab le 1. 2 D isc har ge Tim e

Refer to the quick guide for detailed information about safe

installation of the frequency converter.

Mounting

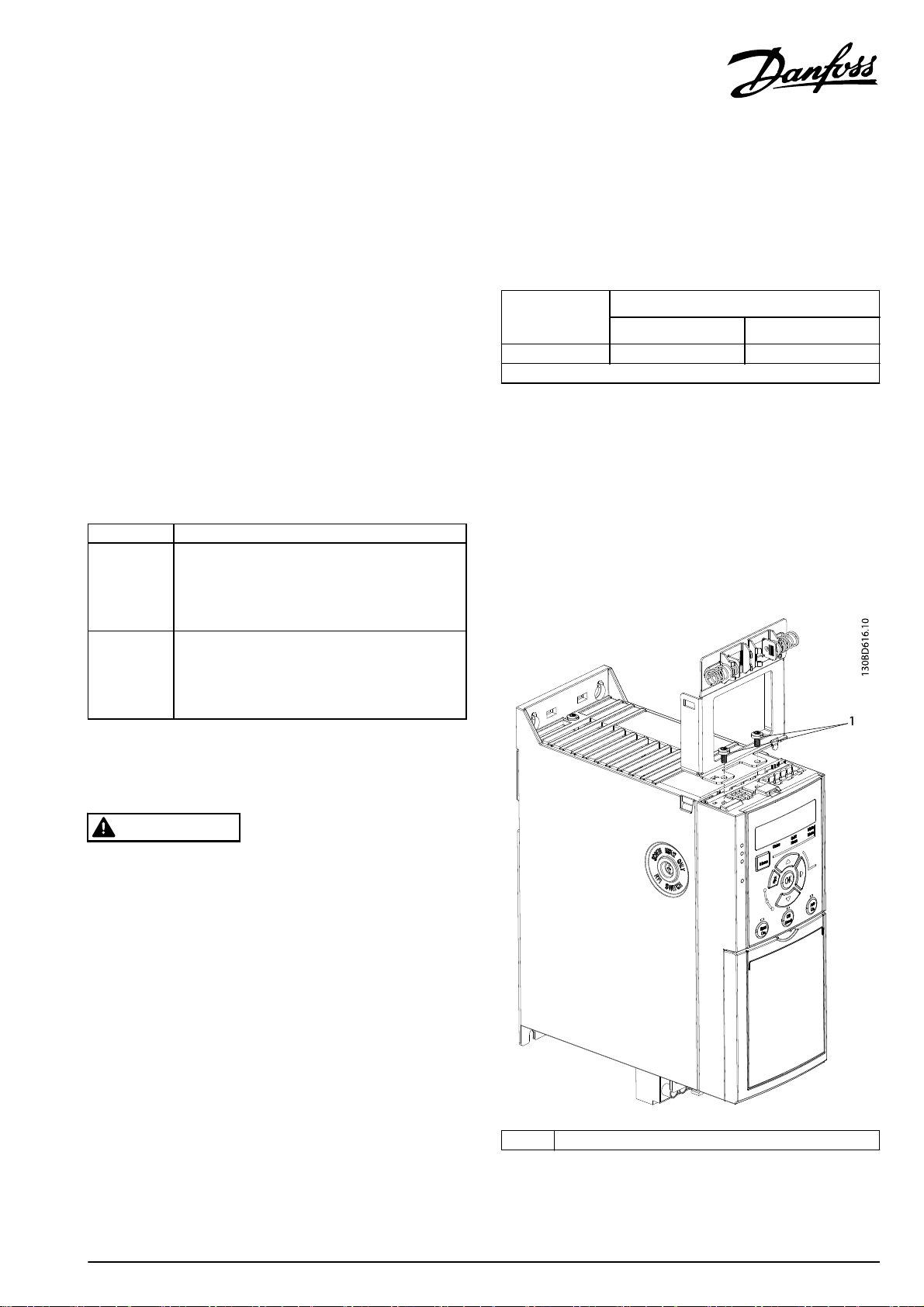

1. Place the decoupling plate on the control cassette

that is mounted on the frequency converter, and

fasten the plate using 2 screws (supplied). Tightening

torque 0.7–1.0 Nm.

Safety Instructions

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. Failure to wait the specied time after power

has been removed before performing service or repair work,

could result in death or serious injury.

Disconnect AC mains, permanent magnet type

•

motors, and remote DC-link power supplies,

including battery back-ups, UPS, and DC-link

connections to other frequency converters.

Wait for the capacitors to discharge fully, before

•

performing any service or repair work. The duration

of waiting time is specied in Ta b l e 1 . 2 .

1Screws

Illustration 1.1 Fasten the Plate with Screws

Danfoss A/S © 05/2015 All rights reserved. MI06L302

Page 2

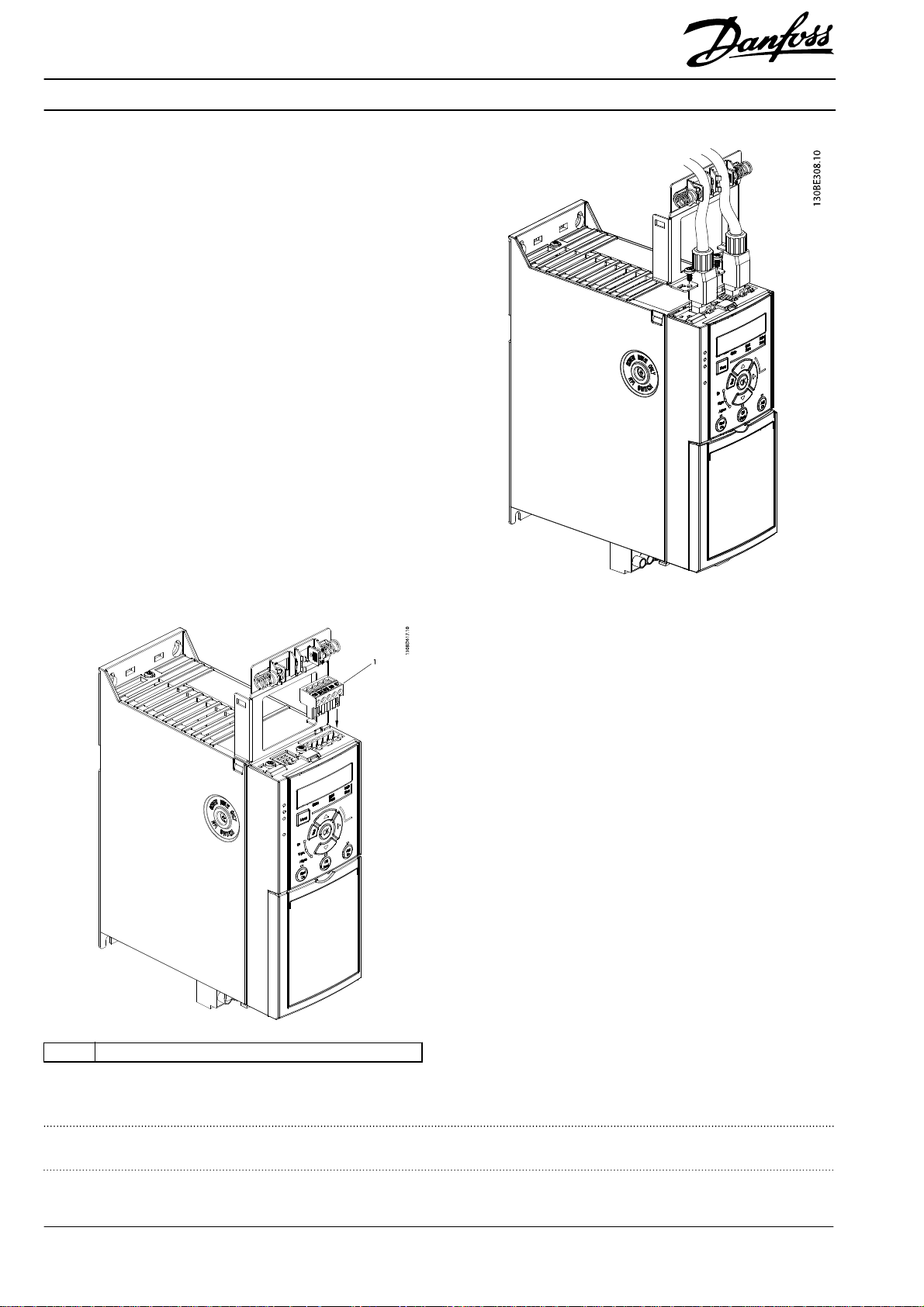

2. 2a PROFIBUS

a. Push PROFIBUS cables into the

b. Place the cables between the

c. Push the 5-pin connector into the

2b PROFINET

a. Push the Ethernet cable

b. Place Ethernet cables between the

slots of the 5-pin connector, and

tighten the screws. Tightening

torque 0.3–0.6 Nm.

spring-loaded metal clamps, to

establish contact and mechanical

xation between cable shielding

and the clamps.

control cassette, as shown in

Illustration 1.2.

connectors into the slots on the

control cassette.

spring loaded metal clamps, as

shown in Illustration 1.3, to

establish mechanical xation and

electrical contact between the

cable and ground.

Illustration 1.3 Place Ethernet Cables between Clamps

1 5-pin connector for PROFIBUS

Illustration 1.2 Push the Connector into Place

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI06L302132R0209 05/2015

*MI06L302*

Loading...

Loading...