Danfoss Performer SH184, Performer SH120, Performer SH105, Performer SH180, Performer SH240 Selection & Application Manuallines

...Page 1

MAKING MODERN LIVING POSSIBLE

Performer® scroll compressors

Single - SH090 to SH380

50 Hz - 60 Hz - R410A

Selection &

Application guidelines

Page 2

APPLICATION GUIDELINES

CONTENT

SCROLL COMPRESSION PRINCIPLE .................................................................................................. 4

F

EATURES ...............................................................................................................................5

OMPRESSOR MODEL DESIGNATION ............................................................................................... 6

C

Nomenclature ..................................................................................................................................................................6

TECHNICAL SPECIFICATIONS ......................................................................................................... 7

50-60 Hz data ...................................................................................................................................................................7

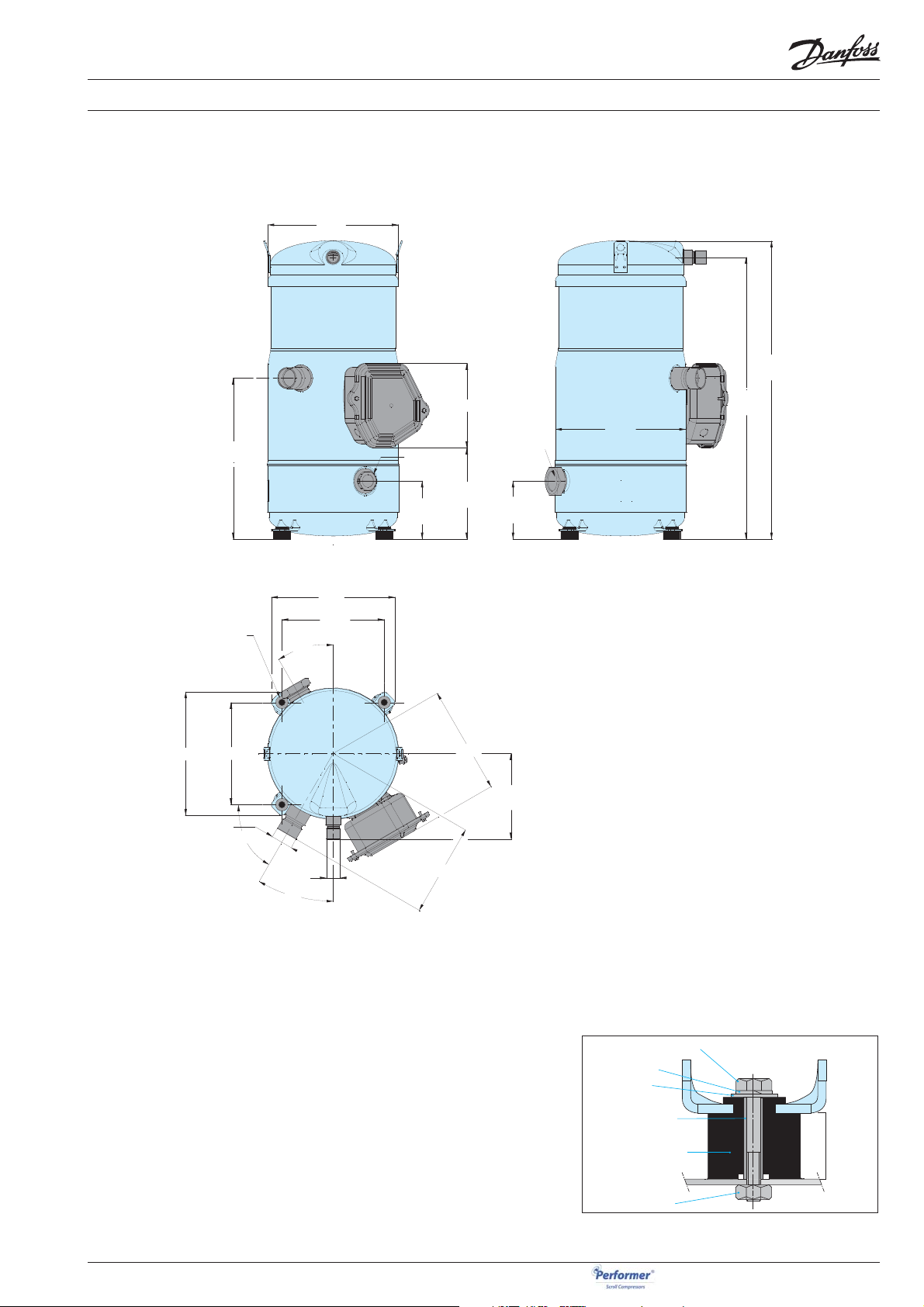

DIMENSIONS ........................................................................................................................... 8

SH090-105-120-140* & 161* ......................................................................................................................................8

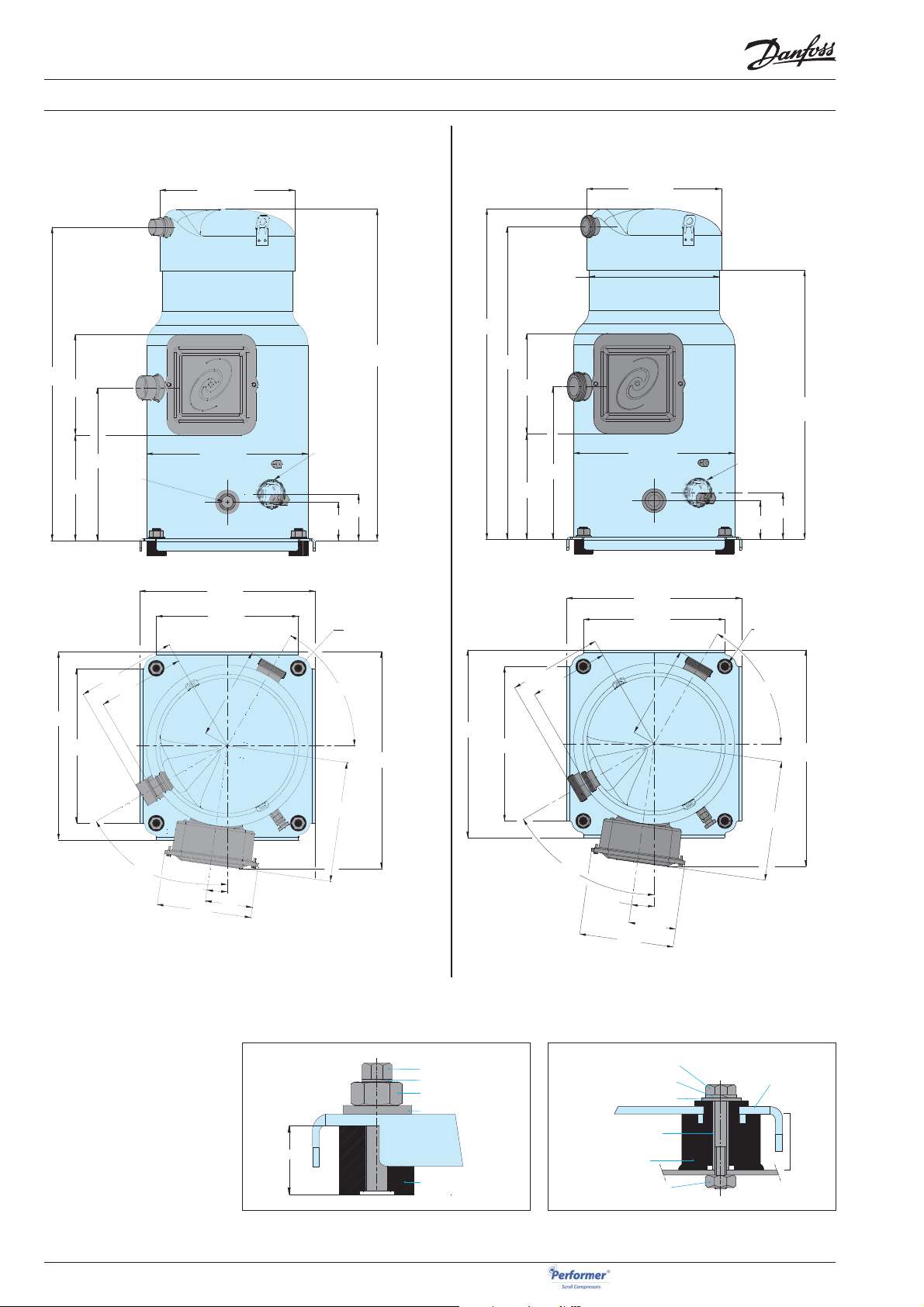

SH 140 & 161 code 3 & SH184 ....................................................................................................................................9

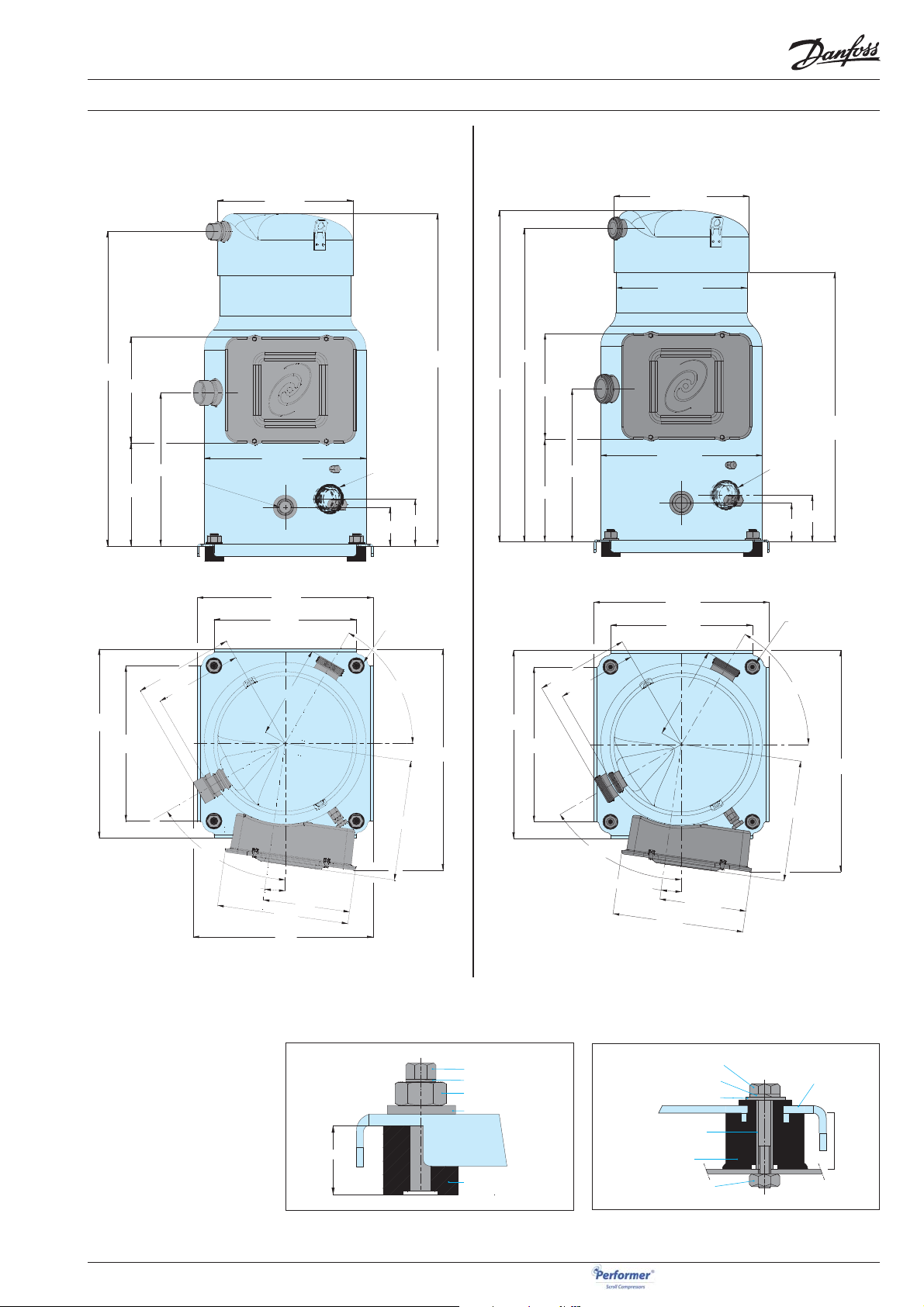

SH180 brazed version...................................................................................................................................................10

SH180 rotolock version ................................................................................................................................................10

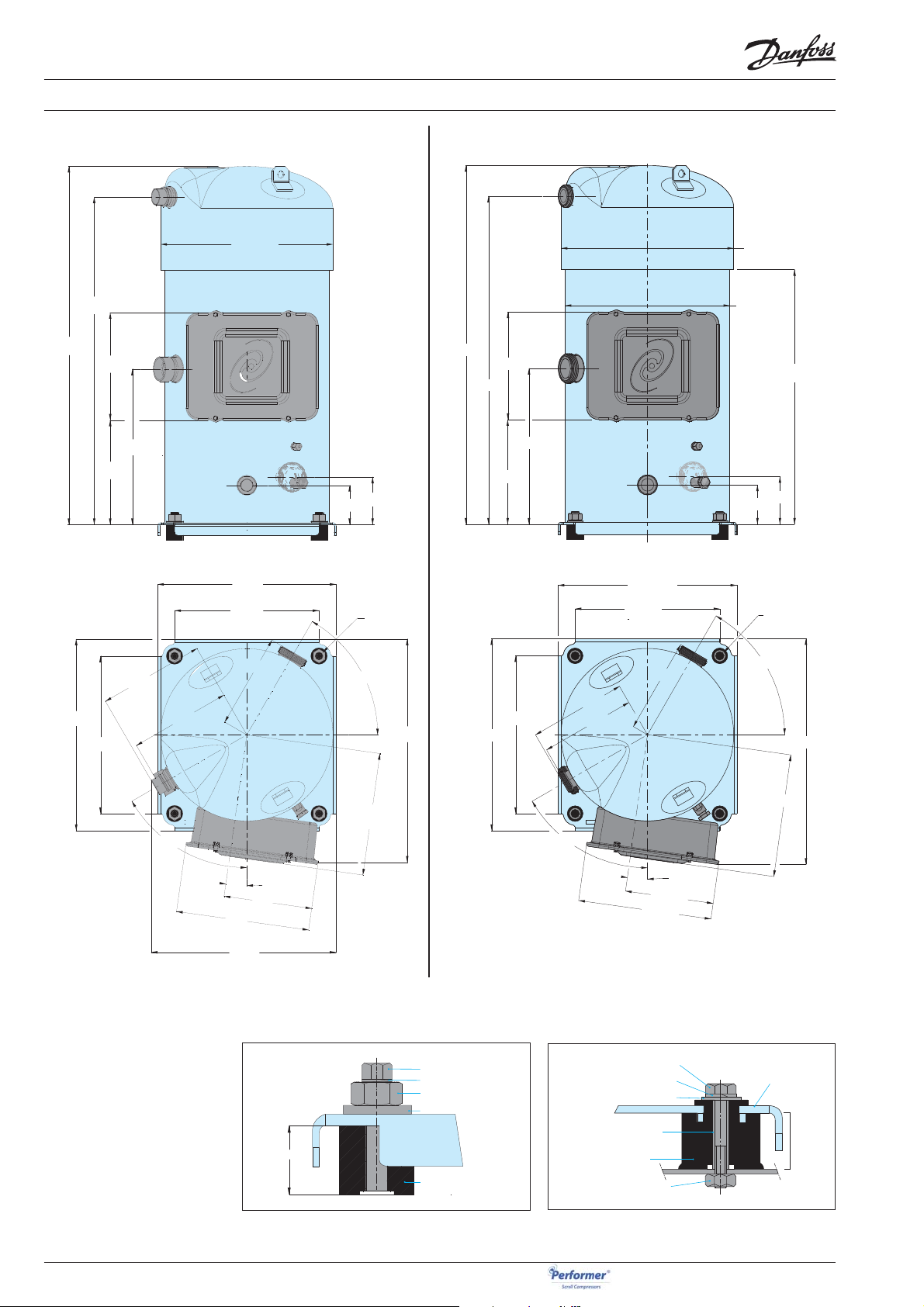

SH240 - brazed version ................................................................................................................................................ 11

SH240 - rotolock version .............................................................................................................................................11

SH300 - brazed version ................................................................................................................................................ 12

SH300 - rotolock version .............................................................................................................................................12

SH380 (except SH380 code 3) ...................................................................................................................................13

SH380 code 3 (available in 2010) .............................................................................................................................13

Connection details ........................................................................................................................................................14

ELECTRICAL DATA, CONNECTIONS AND WIRING ................................................................................ 15

Motor voltage .................................................................................................................................................................15

Wiring connections ....................................................................................................................................................... 15

IP rating .............................................................................................................................................................................17

Terminal box temperature ..........................................................................................................................................17

Three phase electrical characteristics.....................................................................................................................17

Danfoss MCI soft-start controller .............................................................................................................................18

General wiring information ........................................................................................................................................19

Motor protection ...........................................................................................................................................................21

Voltage imbalance .........................................................................................................................................................22

APPROVAL AND CERTIFICATIONS .................................................................................................. 23

Approvals and certifi cates ..........................................................................................................................................23

Pressure Equipment Directive ...................................................................................................................................23

Low voltage directive ...................................................................................................................................................23

Machines directive ........................................................................................................................................................23

Internal free volume .....................................................................................................................................................23

OPERATING CONDITIONS ........................................................................................................... 24

Refrigerant and lubricants ..........................................................................................................................................24

Motor supply ...................................................................................................................................................................25

Compressor ambient temperature ..........................................................................................................................25

Application envelope ................................................................................................................................................... 25

Discharge temperature protection ........................................................................................................................26

High and low pressure protection ...........................................................................................................................26

Cycle rate limit ................................................................................................................................................................27

2

FRCC.PC.007.B5.02

Page 3

APPLICATION GUIDELINES

CONTENT

SYSTEM DESIGN RECOMMENDATIONS ............................................................................................ 28

General ..............................................................................................................................................................................28

Essential piping design considerations .................................................................................................................28

Refrigerant charge limit ...............................................................................................................................................29

Off -cycle migration .......................................................................................................................................................30

Liquid fl ood back ...........................................................................................................................................................32

SPECIFIC APPLICATION RECOMMENDATIONS .................................................................................... 33

Low ambient application ............................................................................................................................................ 33

Low load operation ....................................................................................................................................................... 34

Brazed plate heat exchangers ................................................................................................................................... 34

Electronic expansion valve .........................................................................................................................................34

Reversible heat pump systems .................................................................................................................................34

Water utilizing systems ................................................................................................................................................36

SOUND AND VIBRATION MANAGEMENT .......................................................................................... 37

Starting sound level ...................................................................................................................................................... 37

Running sound level .....................................................................................................................................................37

Stopping sound level ...................................................................................................................................................37

Sound generation in a refrigeration or air conditioning system .................................................................. 37

INSTALLATION ........................................................................................................................ 39

Compressor handling and storage ..........................................................................................................................39

Compressor mounting .................................................................................................................................................39

Compressor holding charge ......................................................................................................................................40

System cleanliness.........................................................................................................................................................41

Tubing ................................................................................................................................................................................41

Brazing and soldering ..................................................................................................................................................41

System pressure test .....................................................................................................................................................42

Leak detection ................................................................................................................................................................43

Vacuum evacuation and moisture removal ......................................................................................................... 43

Filter driers........................................................................................................................................................................43

Refrigerant charging .....................................................................................................................................................44

Insulation resistance and dielectric strength ......................................................................................................44

Commissioning ...............................................................................................................................................................44

Oil level checking and top-up ...................................................................................................................................44

ORDERING INFORMATION AND PACKAGING ..................................................................................... 45

Packaging .........................................................................................................................................................................45

Ordering information ...................................................................................................................................................46

ACCESSORIES ......................................................................................................................... 48

FRCC.PC.007.B5.02

3

Page 4

APPLICATION GUIDELINES

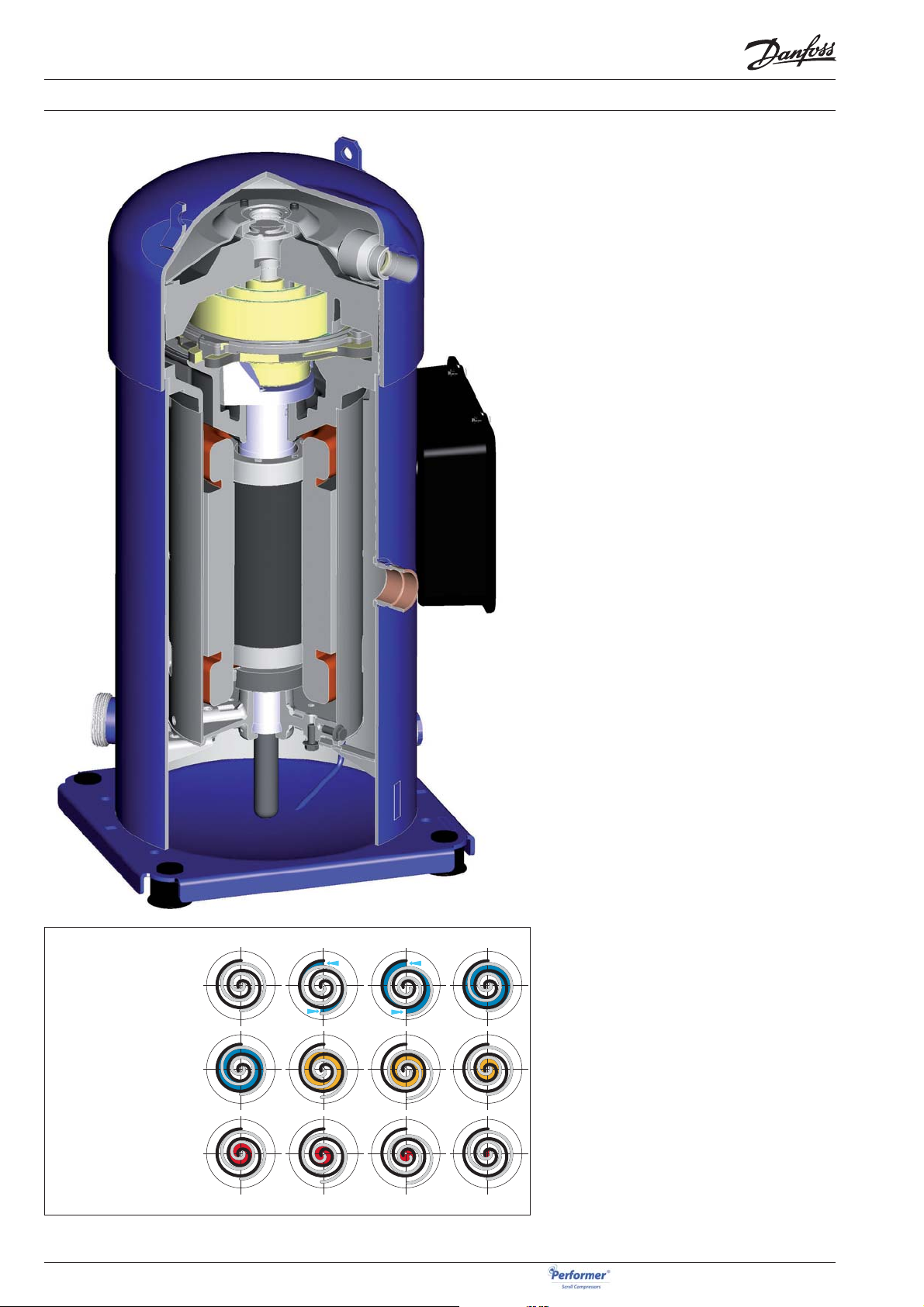

SCROLL COMPRESSION PRINCIPLE

In a Performer® SH scroll compressor, the compression is performed by two scroll elements located in the upper part of the compressor.

Suction gas enters the compressor at the suction connection. As all of the gas fl ows around

and through the electrical motor, thus ensuring

complete motor cooling in all applications, oil

droplets separate and fall into the oil sump. After

exiting the electrical motor, the gas enters the

scroll elements where compression takes place.

Ultimately, the discharge gas leaves the compressor at the discharge connection.

The fi gure below illustrates the entire compression process. The centre of the orbiting scroll (in

grey) traces a circular path around the centre of

the fi xed scroll (in black). This movement creates

symmetrical compression pockets between the

two scroll elements. Low-pressure suction gas is

trapped within each crescent-shaped pocket as it

gets formed; continuous motion of the orbiting

scroll serves to seal the pocket, which decreases

in volume as the pocket moves towards the centre of the scroll set increasing the gas pressure.

Maximum compression is achieved once a pocket

reaches the centre where the discharge port is

located; this stage occurs after three complete

orbits. Compression is a continuous process: the

scroll movement is suction, compression and discharge all at the same time.

SUCTION

COMPRESSION

DISCHARGE

4

FRCC.PC.007.B5.02

Page 5

APPLICATION GUIDELINES

FEATURES

SH range is composed of SH090-105-120-140-161

and 184 (light commercial platform) and SH180240-300 & 380 (large commercial platform).

Gas circulation, motor cooling and oil behav-•

iour are improved on light commercial platform

models by a new patented motor cap design.

Part protection and assembly reduces internal •

leaks and increases life durability.

Heat shield that lowers the heat

transfer between discharge and

suction gas and the acoustic level

The SH090-105-120-140-161 & 184 compressors

benefi t from a further improved design to achieve

the highest effi ciency.

Improved part isolation reduces greatly acoustic •

levels.

Gas intake design induces higher resistance to •

liquid slugging.

SH090 - 105 - 120 - 140 - 161 - 184

New PTFE spring seal for even lower leaks

R410A optimised and dedicated

scroll profi le

Patented motor cap

Liquid slug protection per suction

fi tting in upper position

Patented motor centring spacer

Improved lower bearing centring

SH180 - 240 - 300 - 380

FRCC.PC.007.B5.02

5

Page 6

APPLICATION GUIDELINES

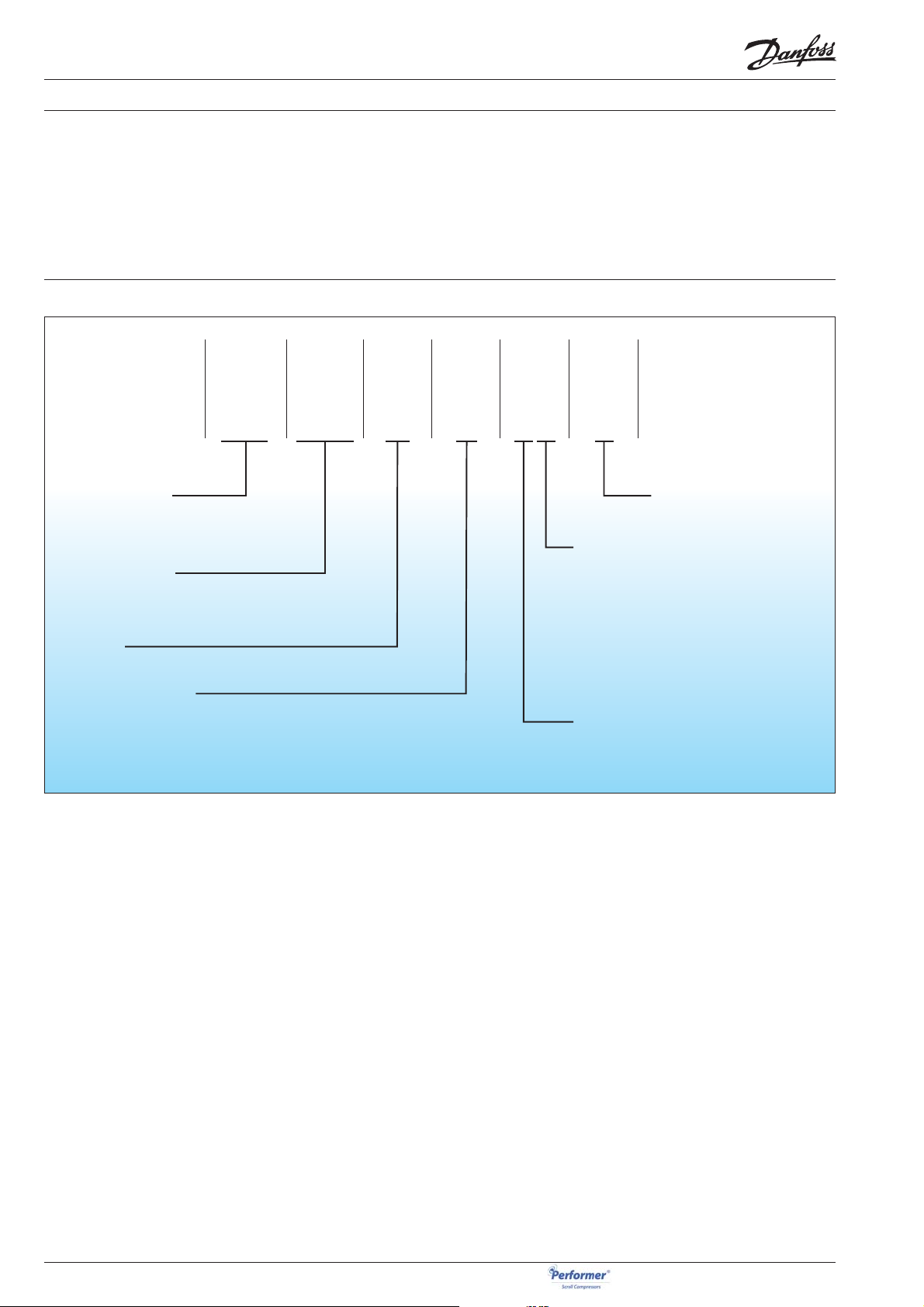

C

OMPRESSOR MODEL DESIGNATION

Nomenclature

Family,

lubricant

& refrigerant

Family, lubricant

& refrigerant

SH: Scroll, POE lubricant,

for R410A

Nominal capacity

in thousand Btu/h at 60 Hz, R410A,

ARI conditions

UL index

Motor voltage code

3: 200-230V/3~/60 Hz

4: 380-400V/3~/50 Hz - 460V/3~/60 Hz

6: 230V/3~/50 Hz

7: 500V/3~/50 Hz - 575V/3~/60 Hz

9: 380V/3~/60 Hz

Performer® SH scroll compressors for R410A are

available as single compressors. The example

below presents the compressor nomenclature

which equals the technical reference as shown on

the compressor nameplate.

Nominal

Approvals Voltage Version Evolution

capacity

Code numbers for ordering are listed section

"Ordering information and packaging".

For tandem and trio assemblies, please refer

to the Performer® SH scroll compressor Parallel

Application Guidelines, FRCC.EC.008.

index

A4SH A AB300

Evolution index

A~Z

Motor protection

L: Internal overload protector

A: Electronic, 24V AC

B: Electronic, SH180: 230V

SH240-300-380: 115/230V

C: Customized electrical box

D: Electronic SH180: 115 V

F: Electronic, 24V DC

Suction and discharge connections

A: Brazed connections

M: Rotolock connections

6

FRCC.PC.007.B5.02

Page 7

APPLICATION GUIDELINES

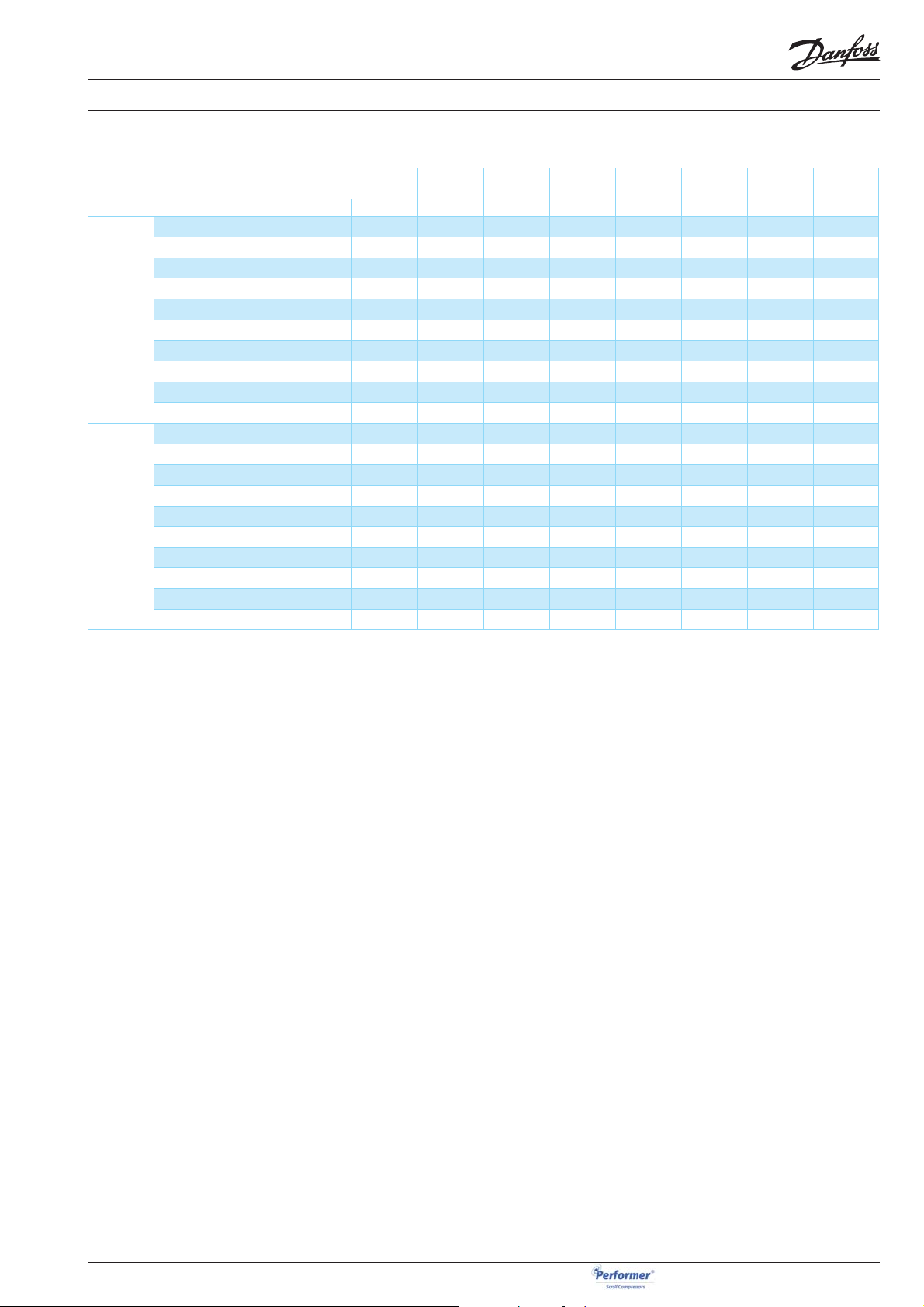

50-60 Hz data

ECHNICAL SPECIFICATIONS

T

Nominal

e

tons 60 Hz

TR W Btu/h kW W/W Btu/h/W cm

30 109 600 374 300 34.02 3.22 11.00 345.00 72.30 7.2 164.0

Model

SH090 7.5 22 300 76 100 7.19 3.10 10.59 88.40 15.40 3.0 58.0

SH105 9 26 850 91 600 8.47 3.17 10.80 103.50 18.00 3.3 64.0

SH120 10 30 000 102 200 9.46 3.17 10.80 116.90 20.30 3.3 64.0

SH140 12 34 700 118 400 10.86 3.19 10.90 133.00 23.12 3.3 67.0

50 Hz

60 Hz

c Displacement at nominal speed: 2900 rpm at 50 Hz, 3500 rpm at 60 Hz

d Net weight with oil charge

e Available in 2010

TR: Ton of Refrigeration, Standard rating conditions: ARI standard Evaporating temperature: 7.2 °C Superheat: 11.1 K

EER: Energy Effi ciency Ratio Refrigerant: R410A Condensing temperature: 54.4 °C Subcooling: 8.3 K

COP: Coeffi cient Of Performance,

Subject to modifi cation without prior notifi cation.

For full data details and capacity tables refer to Online Datasheet Generator: www.danfoss.com/odsg

SH161 13 38 800 132 400 12.15 3.19 10.90 151.70 26.40 3.3 69.0

SH184 15 44 650 152 500 13.73 3.25 11.10 170.30 29.60 3.6 71.5

SH180 15 44 000 150 300 13.73 3.21 10.95 170.20 29.60 6.7 106.0

SH240 20 60 400 206 300 18.77 3.22 11.00 227.60 39.60 6.7 108.0

SH300 25 77 300 264 000 24.01 3.22 11.00 285.50 49.70 6.7 153.0

SH380 30 90 400 308 700 28.19 3.21 10.95 345.00 60.00 7.2 164.0

SH090 7.5 27 100 92 500 8.57 3.16 10.79 88.40 18.60 3.0 58.0

SH105 9 32 100 109 500 9.96 3.22 11.00 103.50 21.80 3.3 64.0

SH120 10 36 800 125 400 11.25 3.27 11.15 116.90 24.60 3.3 64.0

SH140 12 42 300 144 300 12.94 3.27 11.15 133.00 27.90 3.3 67.0

SH161 13 47 200 160 900 14.43 3.27 11.15 151.70 31.90 3.3 69.0

SH184 15 54 000 184 400 16.45 3.28 11.20 170.30 35.80 3.6 71.5

SH180 15 53 700 183 400 16.45 3.27 11.15 170.20 35.70 6.7 106.0

SH240 20 73 500 251 000 22.48 3.27 11.15 227.60 47.80 6.7 108.0

SH300 25 93 000 317 600 28.71 3.24 11.05 285.50 60.00 6.7 153.0

SH380

Nominal cooling

capacity

Power

input

COP E.E.R.

Swept

volume

Displace-

3

ment c

/rev m3/h dm

Oil charge

3

Net weight

d

kg

FRCC.PC.007.B5.02

7

Page 8

APPLICATION GUIDELINES

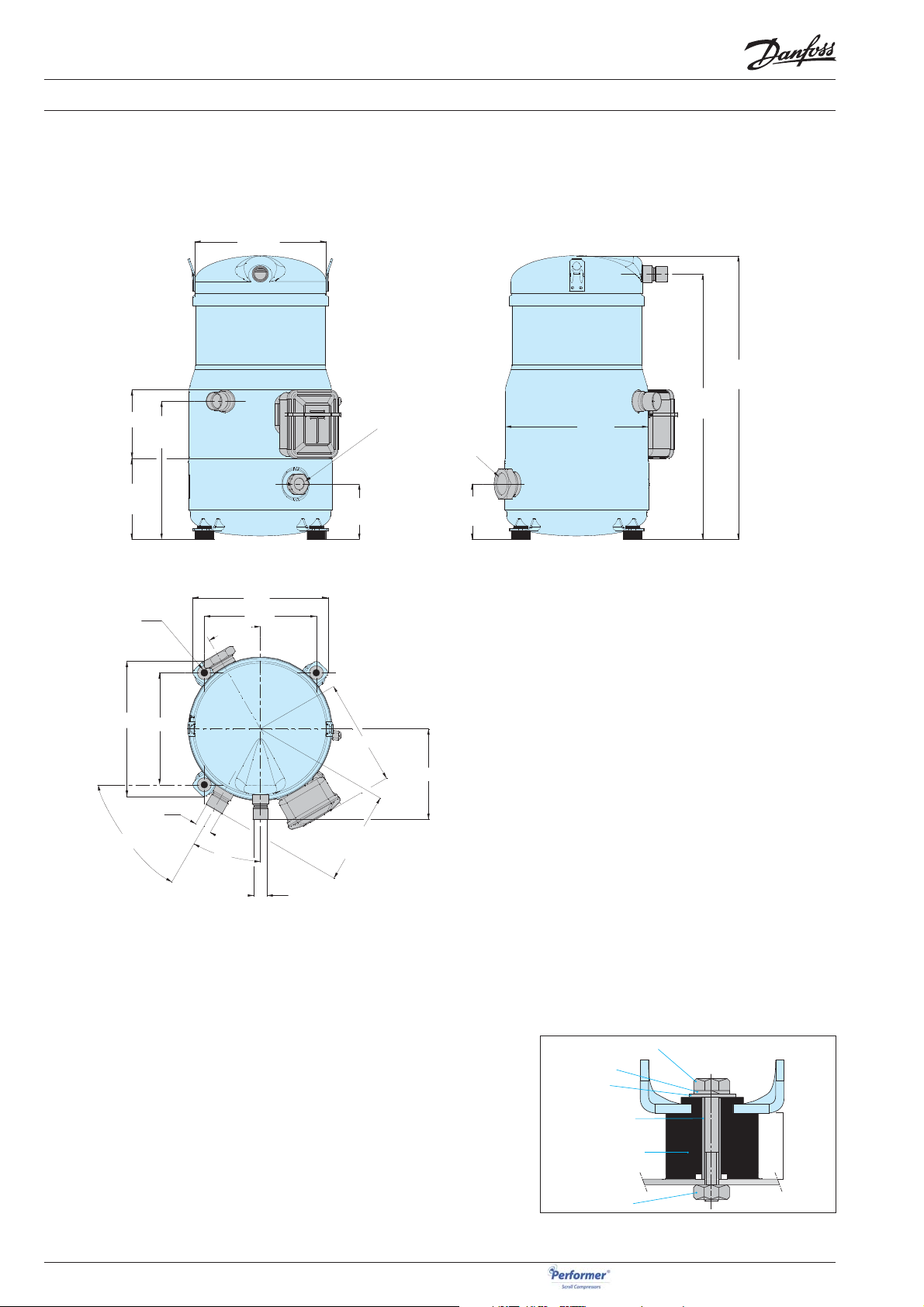

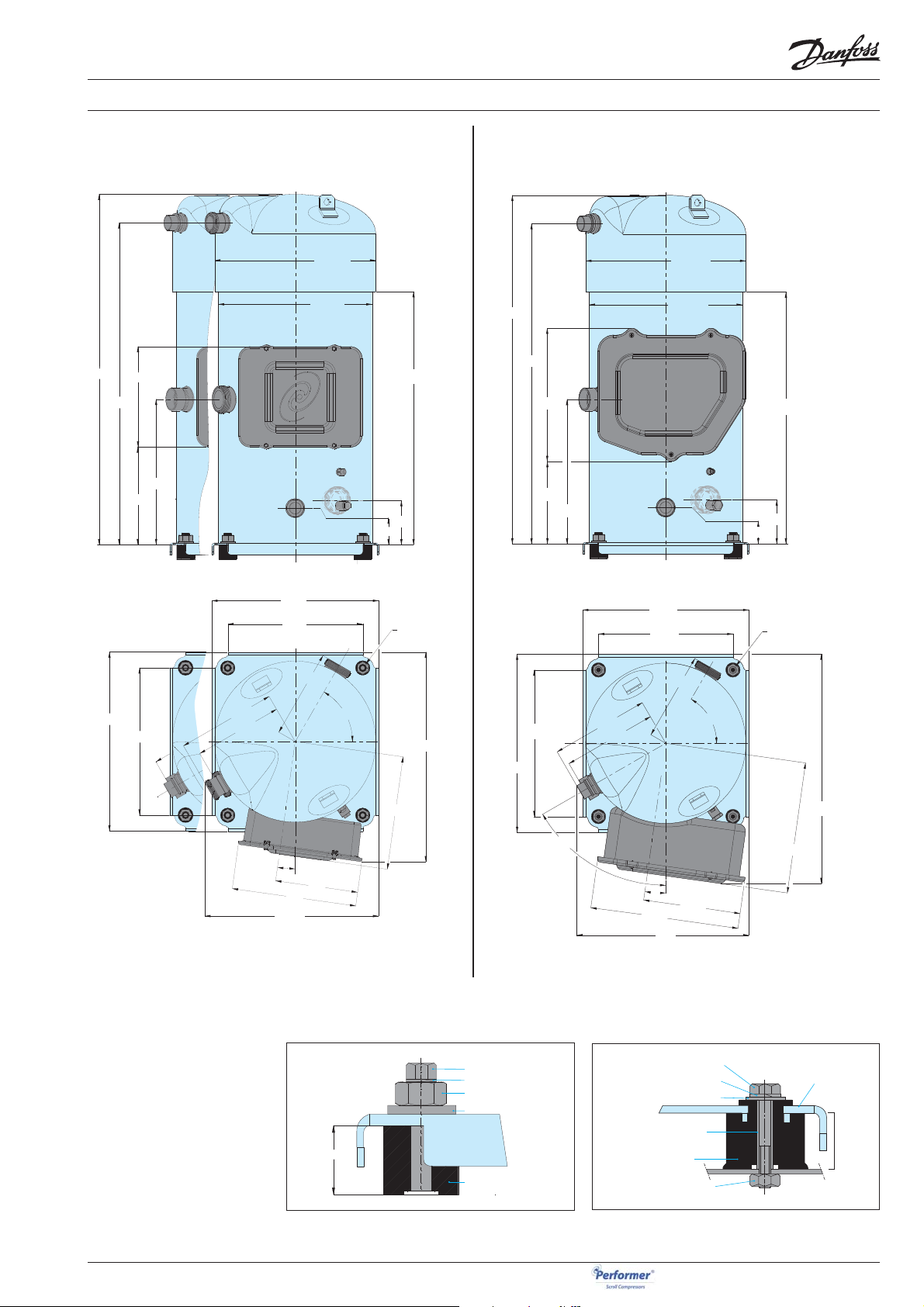

SH090-105-120-140* & 161*

(* except code 3)

117

(1)

235

(2)

278

(1)

137

(2)

189

DIMENSIONS

Ø 224

Oil sight glass

(1)

94

(2)

101

Equalisation line

(1)

482

(2)

540

(1)

451

(2)

509

Ø 243

(1)

94

(2)

101

4 x hole

Ø 19.05

230

(1)

(2)

60°

Ø 29

Ø 35

190.5

30°

30°

230

190.5

Ø 22

180

154

(1)

SH090

(1)

158

(2)

173

(2)

SH105 - 120 - 140* & 161*

* except code 3

All dimensions in mm

Flexible grommet

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

15 mm

Nut

8

FRCC.PC.007.B5.02

Page 9

APPLICATION GUIDELINES

SH 140 & 161 code 3 & SH184

(1) 278

(2) 300

IMENSIONS

D

Ø 243

Oil sight

glass

(1) 101

(2) 108

157

(1) 155

(2) 170

Equalisation

line

(1) 101

(2) 108

Ø 243

(1) 509

(2) 525

(1) 540

(2) 555

230

4 x holes

Ø19.05

190.5

Ø 35

60°

Ø 22

30°

30°

230

190.5

173

200

(1) 154

(2) 159

(1) SH140 & 161 code 3

(2) SH184

All dimensions in mm

Flexible grommet

Lock washer

Flat washer

HM 8 bolt

FRCC.PC.007.B5.02

Steel mounting

sleeve

Rubber grommet

Nut

15 mm

9

9

Page 10

APPLICATION GUIDELINES

IMENSIONS

D

SH180 brazed version SH180 rotolock version

617

198

208.2

301

Oil sight

glass

Ø 265.9

Ø 317.8

345.4

279.4

Equalisation

line

92

76.1

4 x holes Ø 19

652.5

652.5

617

198

208.2

Ø 257.5

301

Ø 265.9

Ø 317.8

345.4

279.4

Equalisation

line

92

76.1

4 x holes

Ø 19

531

370.8

304.8

195

171

60°

8°

186

183

93

All dimensions in mm

29.5 mm

236

60°

427

370.8

HM 8 bolt

Lock washer

Nut

Flat washer

Rigid spacer

304.8

183

156

60°

Flexible grommetRigid spacer

Steel mounting sleeve

Rubber grommet

183

8°

186

HM 8 bolt

Lock washer

Flat washer

93

Nut

60°

236

All dimensions in mm

Compressor

base plate

427

28 mm

10

FRCC.PC.007.B5.02

Page 11

APPLICATION GUIDELINES

IMENSIONS

D

SH240 - brazed version SH240 - rotolock version

617

208

202.2

301

Oil sight

glass

Ø 265.9

Ø 317.8

345.4

279.4

Equalisation

line

92

76.1

4 x holes Ø 19

652.5

652.5

617

208

202.2

301

Ø 265.9

Ø 257.5

Ø 317.8

345.4

279.4

Equalisation

line

92

76.1

4 x holes Ø19

531

370.8

304.8

195

171

60°

183

8°

258

353

171

Rigid spacer

29.5 mm

60°

236

All dimensions in mm

436

370.8

HM 8 bolt

Lock washer

Nut

Flat washer

Rigid spacer

304.8

183

156

60°

Flexible grommet

Steel mounting sleeve

Rubber grommet

8°

258

HM 8 bolt

Lock washer

Flat washer

183

171

Nut

60°

436

238

All dimensions in mm

Compressor

base plate

28 mm

FRCC.PC.007.B5.02

11

Page 12

APPLICATION GUIDELINES

DIMENSIONS

SH300 - brazed version SH300 - rotolock version

693

370.8

634

202.2

304.8

208

301

204

195

Ø 333.2

345.4

279.4

183

76.1

92

4 x holes

Ø 19.43

60°

434

693

634

370.8

208

202.2

304.8

301

187

183

345.4

279.4

183

Ø 333.2

Ø 318.1

76.1

4 x holes

Ø 19.43

60°

492

92

434

60°

8°

171

258

358

All dimensions in mm

Rigid spacer

29.5 mm

237

HM 8 bolt

Lock washer

Nut

Flat washer

Rigid spacer

60°

All dimensions in mm

Flexible grommet

Steel mounting sleeve

Rubber grommet

171

258

HM 8 bolt

Lock washer

Flat washer

Nut

235

8°

Compressor

base plate

28 mm

12

FRCC.PC.007.B5.02

Page 13

APPLICATION GUIDELINES

IMENSIONS

D

SH380 (except SH380 code 3) SH380 code 3 (available in 2010)

725.3

666.3

208

202.2

301

345.4

279.4

183

Ø 333.2

Ø 318.1

76.1

524.3

92

4 x holes

Ø 19.43

725.3

666.3

277.4

171.6

301

345.4

279.4

Ø 333.2

Ø 318.1

524.3

92

76.1

4 x holes Ø 19.43

183

370.8

304.8

195

All dimensions in mm

204

183

60°

8°

171

258

359.8

Rigid spacer

29.5 mm

235

434

HM 8 bolt

Lock washer

Nut

Flat washer

Rigid spacer

370.8

304.8

204

195

60°

Flexible grommet

Steel mounting sleeve

Rubber grommet

8°

308.8

357

HM 8 bolt

Lock washer

Flat washer

202.3

Nut

60°

477

273

All dimensions in mm

Compressor

base plate

28 mm

FRCC.PC.007.B5.02

13

Page 14

APPLICATION GUIDELINES

DIMENSIONS

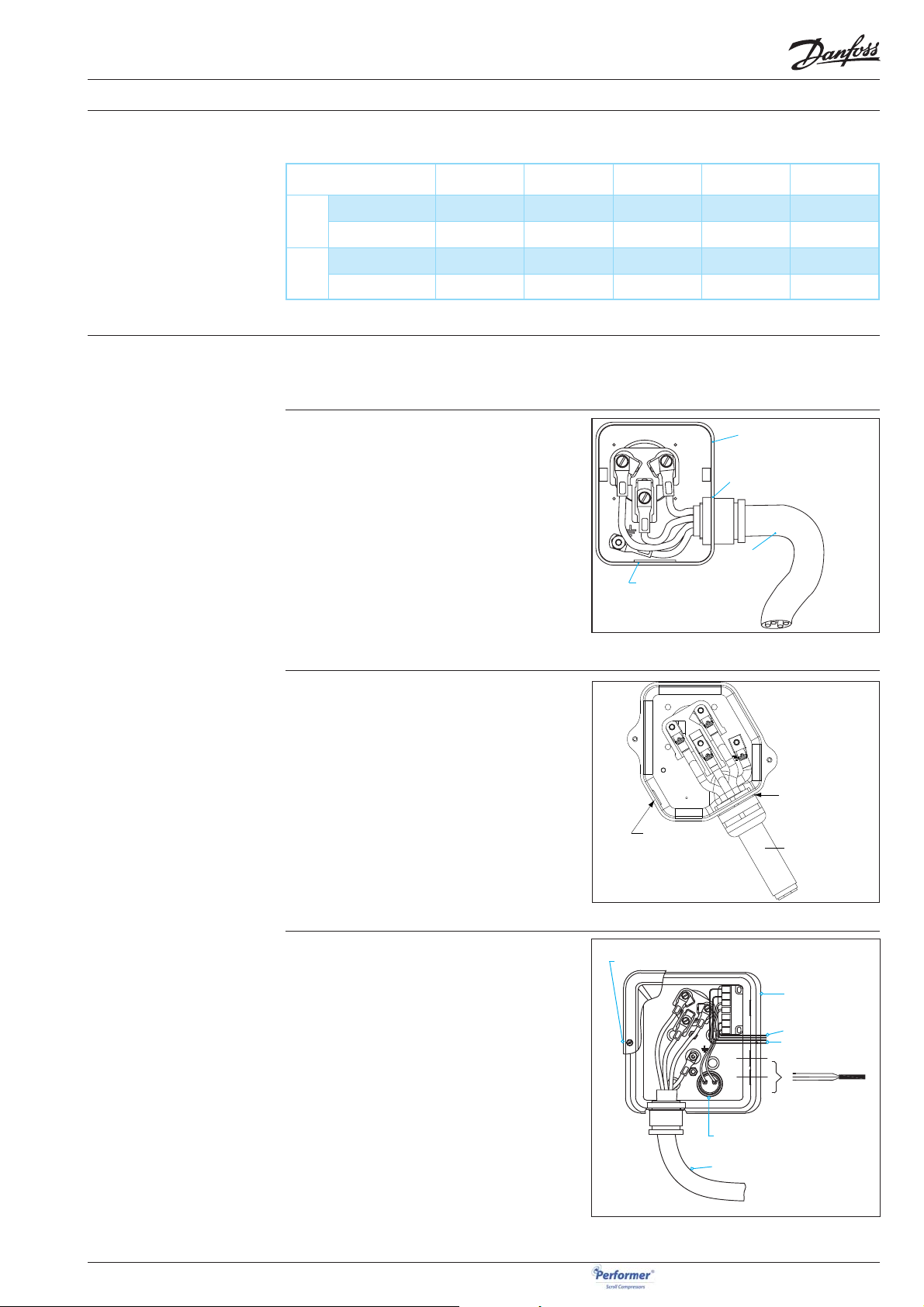

Connection details

Suction and discharge

connections

SH 090 - 105 - 120 -

140 - 161 - 184

Version AL AA - AB - AD - AF MA - MB - MD - MF

Suction and discharge connections Brazed Brazed Rotolock

Oil sight glass Threaded Threaded Threaded

Oil equalisation connection rotolock 1"3/4 rotolock 2"1/4 rotolock 2"1/4

Oil drain connection none 1/4’’ NPT 1/4’’ NPT

Low pressure gauge port (schrader) 1/4" fl are 1/4’’ fl are 1/4’’ fl are

Brazed version Rotolock version

Tube ODF Tube ODF

Brazed

SH090

SH105 -120-140-161-184

SH180-240-300-380

Suction

Discharge 7/8" - -

Suction 1"3/8 - -

Discharge 7/8" - -

Suction 1’’ 5/8 2’’ 1/4 1’’ 5/8

Discharge 1’’ 1/8 1’’ 3/4 1’’ 1/8

1"1/8 - -

SH 180 - 240 - 300 - 380

1

Rotolock c Adaptor d

2

Oil sight glass All Performer® SH scroll compressors come

equipped with a sight glass (1"1/8 - 18 UNF) which

may be used to determine the amount and condition of the oil contained within the sump.

Oil equalisation connection

SH090-105-120-140-161-184: 1"3/4 rotolock connector allowing use of 1”3/4 - 7/8" or 1”3/4 - 1”1/8

sleeve.

SH180-240-300-380: 2”1/4 rotolock connector

allowing the use of 2”1/4 - 1”3/8 or 2”1/4 - 1”5/8

sleeve.

This connection must be used to mount an oil

equalisation line when two or more compressors

are mounted in parallel (pl ease refer to Performer®

SH Parallel Application Guide lines FRCC.EC.008.

for details).

Oil drain connection

The oil drain connection allows oil to be removed

from the sump for changing, testing, etc. The fi tting contains an extension tube into the oil sump

to more eff ectively remove the oil. The connection is a female 1/4" NPT fi tting and is mounted on

SH180 - 240 - 300 - 380 models only.

Schrader

The oil fi ll connection and gauge port is a 1/4"

male fl are connector incorporating a schrader

valve.

14

FRCC.PC.007.B5.02

Page 15

APPLICATION GUIDELINES

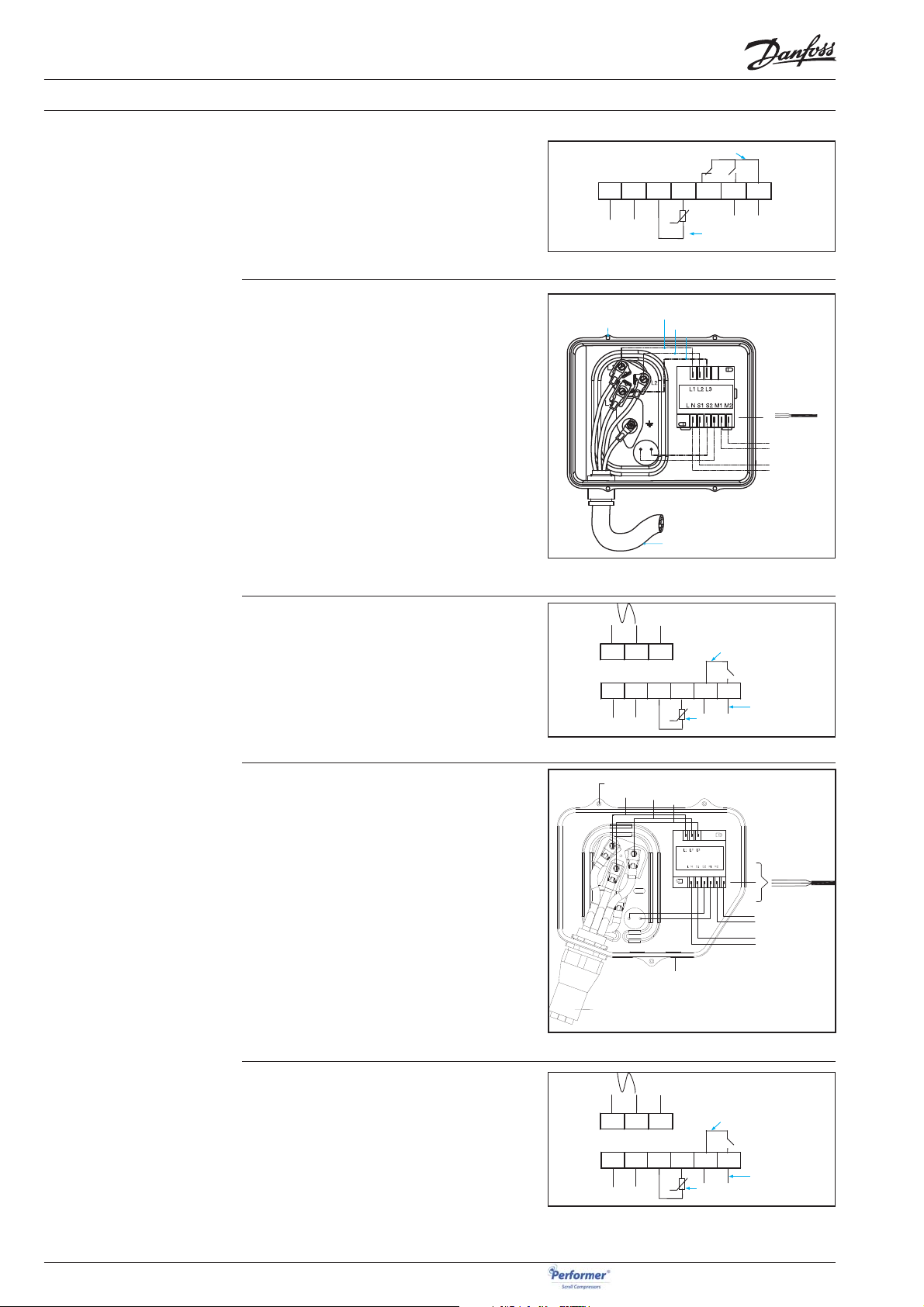

ELECTRICAL DATA, CONNECTIONS AND WIRING

Motor voltage

Wiring connections

SH090-105-120 - 140 & 161

Except SH140-161 code 3

Performer® SH scroll compressors are available in fi ve diff erent motor voltages as listed below.

Motor voltage code Code 3 Code 4 Code 6 Code 7 Code 9

Nominal voltage - 380-400V - 3 ph 230V - 3 ph 500V - 3 ph -

50 Hz

Voltage range - 340-440 V 207-253 V 450 - 550 V -

Nominal voltage 200-230V - 3 ph 460V - 3 ph - 575 V-3 ph 380V- 3 ph

60 Hz

Voltage range 180-253 V 414-506 V - 517-632 V 342-418 V

Electrical power is connected to the compressor

terminals by Ø 4.8 mm (3/16”) screws. The maxi-

The terminal box is provided with a Ø 25.5 mm

and a Ø 29 mm knockouts.

mum tightening torque is 3 Nm. Use a 1/4’’ ring

terminal on the power leads.

Terminal box

Ø 25.5 mm knockout

Power supply

Ø 29 mm knockout

SH140&161 code 3 & SH184

SH180

The terminal box is provided with a

Ø40.5 mm hole for power supply and a Ø16.5 mm

knockout.

The terminal box is provided with 2 double knockouts for the power supply and 3 knockouts for the

safety control circuit.

The 2 power supply knockouts accommodate the

following diameters:

Ø 44 mm / Ø 1”3/4 (for a 1”1/4 conduit) & Ø 34 mm

/ Ø 1”3/8 (for a 1” conduit),

Ø 32.1 mm / Ø 1.26” & Ø 25.4 mm / Ø 1”.

The 3 other knockouts are as follows:

Ø 20.5 mm / Ø 0.81”

Ø 22 mm / Ø 7/8” (for a 1/2” conduit)

Ø 16.5 mm / Ø 0.65”

Ø 16.5 mm

knockout

Cover holding screw (x2) - Torque: 2.2 Nm

L1

Motor Protection

N

Module

1

2

12

14

11

Faston 1/4" tabs

Power supply

Ø 40.5 mm hole

Power supply

Terminal box

Safety circuit

Protection module

power supply

Sump heater

FRCC.PC.007.B5.02

15

Page 16

APPLICATION GUIDELINES

T

ELECTRICAL DATA, CONNECTIONS AND WIRING

SH240 - 300 - 380 -

Except SH380 code 3

The motor protection module comes preinstalled

within the terminal box and has pre-wired thermistor connections. The module must be connected to a power supply of the appropriate

voltage. The module terminals are 6.3 mm size

Faston type except for 24V DC module (screw

connection).

The terminal box is provided with 4 double knockouts and 4 single knockouts for power supply and

the safety control circuit.

The 4 power supply knockouts accommodate the

following diameters:

Ø 50 mm / 1”31/32

Ø 25.2 mm / 0.99”

Ø 43.7 mm / 1”23/32 & 34.5 mm / 1”23/64

Ø 40.5 mm / 1.59” & 32.2 mm / 1.27”

The 4 others knockouts are as follows:

Ø 20.5 mm / 0.81” (2x)

Ø 22 mm / 7/8” & 16.5 mm / 0.65” (2x)

LN1 2 1412 11

Module power

Cover holding screws (x4)

orque: 2.2 N.m.

Internal control contac t

Thermistor

connection

Black

Blue

Brown

Power supply

Safety

circuit

Sump heater

}

M1, M2

Control circuit

Power supply

SH380 code 3

The motor protection module comes preinstalled

within the terminal box. Phase sequence protection connections and thermistor connections are

pre-wired. The module must be connected to a

power supply of the appropriate voltage. The

module terminals are 6.3-mm size Faston type.

The terminal box is provided with Ø 43.7 mm

(1"23/32) h ole w ith p ossibl e Ø 50.8 mm (2") knockout for power supply and 2 x Ø 22.5 mm (7/8")

knockouts for safety control circuit.

Phase sequence in put

L1 L2 L3

Black Blue Brown

Internal control contac t

L N S1 S2 M1 M2

Thermistor

Blue

connection

Brown

Terminal box

Module power

Cover holding screws (x3)

Black

Power supply

Safety

circuit

Sump heater

M1, M2

Control circuit

Power supply

16

The motor protection module comes preinstalled

within the terminal box. Phase sequence protection connections and thermistor connections are

pre-wired. The module must be connected to a

power supply of the appropriate voltage. The

module terminals are 6.3-mm size Faston type.

FRCC.PC.007.B5.02

Phase sequence in put

L1 L2 L3

Black Blue Brown

Internal control contac t

L N S1 S2 M1 M2

Thermistor

Module power

connection

Safety

circuit

Page 17

APPLICATION GUIDELINES

ELECTRICAL DATA, CONNECTIONS AND WIRING

IP rating

Terminal box temperature

Three phase electrical

characteristics

The compressor terminal box according to IEC529 is IP54 for all models when correctly sized IP54 rated

cable glands are used.

First numeral, level of protection against contact and foreign objects•

5 - Dust protected

Second numeral, level of protection against water•

4 - Protection against water splashing

The temperature inside the terminal box may not

exceed 70°C. Consequently, if the compressor is

installed in an enclosure, precautions must be

taken to avoid that the temperature around the

compressor and in the terminal box would rise

too much. The installation of ventilation on the

enclosure panels may be necessary. If not, the

Compressor model

Motor voltage code 3

200-230V / 3ph / 60 Hz

Motor voltage code 4

380-400 V / 3ph / 50 Hz

50 Hz

code 6

230 V / 3ph /

Motor voltage

500 V / 3ph / 50 Hz

575 V / 3 ph / 60 Hz

Motor voltage code 7

380 V / 3ph / 60 Hz

Motor voltage code 9

SH090 203 43 38 0.39

SH105 267 46 45 0.27

SH120 267 61 48 0.27

SH140 304 64 56 0.24

SH161 315 69 64 0.22

SH184 351 75 71 0.22

SH180 320 78 71 0.19

SH240 485 105 103 0.12

SH300 560 132 125 0.10

SH380 680 150 147 0.08

SH090 98 20 19 1.47

SH105 142 23 22 1.05

SH120 142 29 24 1.05

SH140 147 30 28 0.92

SH161 158 33 31 0.83

SH184 197 38.6 36 0.83

SH180 180 38 36 0.76

SH240 215 51 49 0.55

SH300 260 65 62 0.43

SH380 320 79 72 0.36

SH090 157 40 32 0.5

SH105 223 43 38 0.35

SH120 223 51 41 0.35

SH140 236 53 49 0.31

SH161 236 57 53 0.31

SH184 236 57 56 0.31

SH090 84 18 14 2.34

SH105 103 22 17 1.57

SH120 103 24 19 1.57

SH140 122 26 22 1.38

SH161 136 29 24 1.32

SH184 135 35 28 1.32

SH180 135 30 28 1.20

SH240 175 41 38 0.88

SH300 210 53 48 0.67

SH380 235 60 55 0.56

SH090 124 26 23 1.05

SH105 160 30 26 0.72

SH120 160 35 29 0.72

SH140 168 37 33 0.62

SH161 177 41 37 0.57

SH184 239 51 44 0.57

SH180 210 46 41 0.52

SH240 260 60 58 0.36

SH300 310 85 72 0.29

SH380 360 90 85 0.24

LRA MCC

AAAΩ

electronic protection module may not operate

properly. Any compressor damage related to this

will not be covered by Danfoss warranty. In the

same manner, cables must be selected in a way

to insure that terminal box temperature does not

exceed 70°C.

Max. operating

current

Winding resistance

FRCC.PC.007.B5.02

17

Page 18

APPLICATION GUIDELINES

ELECTRICAL DATA, CONNECTIONS AND WIRING

LRA (Locked Rotor Amp)

MCC (Maximum Continuous

Current)

Max. operating Current

Winding resistance

Locked Rotor Amp value is the higher average

current as measured on mechanically blocked

compressor tested under nominal voltage. The

LRA value can be used as rough estimation for the

The MCC is the current at which the motor protection trips under maximum load and low voltage conditions. This MCC value is the maximum

at which the compressor can be operated in tran-

The max. operating current is the current when

the compressors operates at maximum load conditions and 10% below nominal voltage (+15°C

evaporating temperature and +68°C condensing

temperature).

Winding resistance is the resistance between

phases at 25°C (resistance value +/- 7%).

Winding resistance is generally low and it requires

adapted tools for precise measurement. Use a digital ohm-meter, a "4 wires" method and measure

under stabilised ambient temperature. Winding

resistance varies strongly with winding temperature ; if the compressor is stabilised at a diff erent

value than 25°C, the measured resistance must be

corrected with following formula:

starting current. However in most cases, the real

starting current will be lower. A soft starter can be

applied to reduce starting current.

sient conditions and out of the application envelope. Above this value, the internal motor protection or external electronic module will cut-out the

compressor to protect the motor.

Max Oper. A can be used to select cables and

contactors.

In normal operation, the compressor current

consumption is always less than the Max Oper. A.

value.

a + t

R

= R

tamb

_______

25°C

a + t

t

: reference temperature = 25°C

25°C

t

: temperature during measurement (°C)

amb

R

: winding resistance at 25°C

25°C

R

: winding resistance at t

amb

amb

25°C

amb

Coeffi cient a = 234.5

Danfoss MCI

soft-start controller

The inrush current for the Performer® SH scroll

compressors with motor code 4 (400V /3ph /

50Hz or 460V / 3ph / 60Hz) can be reduced using

the Danfoss digitally-controlled MCI compressor

soft starter. MCI soft starters are designed to reduce the starting current of 3-phase AC motors;

they can reduce the inrush current by up to 40%,

thereby eliminating the detrimental eff ects of

Compressor model

SH090 MCI15C MCI15C

SH105 MCI25C MCI25C

SH120 MCI25C MCI25C

SH140 MCI25C MCI25C *

SH161 MCI25C MCI25C *

SH184 MCI25C MCI25C *

SH180 MCI50CM MCI50CM

SH240 MCI50CM MCI50CM *

SH300 MCI50CM * MCI50CM *

SH380 MCI50CM * MCI50CM *

* by pass contactor K1 is required

Soft start reference

Ambient max. 40°C

high starting torque surges and costly demand

charges from the resultant current spike. Upon

starting, the controller gradually increases the

voltage supplied to the motor until full-line voltage has been reached. All settings, such as rampup time (less than 0.5 sec) and initial torque, are

preset and do not require modifi cation.

Soft start reference

Ambient max. 55°C

18

FRCC.PC.007.B5.02

Page 19

APPLICATION GUIDELINES

ELECTRICAL DATA, CONNECTIONS AND WIRING

Input controlled soft start

MCI with by pass contactor

General wiring

information

When the control voltage is applied to A1 - A2,

the MCI soft starter will start the motor, according to the settings of the ramp-up time and initial torque adjustments. When the control voltage is switched OFF, the motor will switch off

instantaneously.

By means of the built-in auxiliary contact (23-24)

the by pass function is easily achieved, see wiring

diagram beside.

No heat is generated from the MCI. As the contactor always switches in no-load condition it can

be selected on the basis of the thermal current

(AC-1).

13-14 contact not applicable with MCI 25C.

The wiring diagrams below are examples for a

safe and reliable compressor wiring. In case an alternative wiring logic is chosen, it is imperative to

respect the following rules:

system to build pressure. But it remains mandatory for compressor protection to apply an LP

safety switch. The LP safety switch must never be

bypassed.

When a safety switch trips, the compressor must

stop immediately and must not re-start until the

tripping condition is back to normal and the safety switch is closed again. This applies to the LP

safety switch, the HP safety switch, the discharge

gas thermostat and the motor safety thermostat.

In specifi c situations, such as winter start operation, an eventual LP control for pump-down cycles may be temporarily bypassed to allow the

Suggested wiring diagrams logic

Compressor model SH 090 - 105 - 120 - 140 - 161 - 184

CONTROL CIRCUIT

F1F1

KM

KA KA

KS

LP

KM

A1

A2

TH

KS

KA

LLSV KS

180 s

KA

KS

A3

L1 L3 L2

LPS

T1

HP

DGT

T3

Pressure settings for the LP and HP safety switch

and pump-down listed in table from section "Low

pressure".

When ever possible (ie. PLC control), it is recommended to limit the possibilities of compressor

auto restart to less than 3 to 5 times during a period of 12 hours when caused by motor protection

or LP safety switch tripping. This control must be

managed as a manual reset device.

CONTROL CIRCUIT

Q1

KM

T2

M

F1F1

KA KA

KS

KM KA

KA KS

A1

A3

180 s

A2

TH

KS

LPS

DGT

L1 L3 L2

Q1

KM

T1

HP

T2

T3

M

Wiring diagram with pump-down cycle

FRCC.PC.007.B5.02

Wiring diagram without pump-down cycle

85 52 019 - A

19

Page 20

APPLICATION GUIDELINES

Compressor models SH 180

ELECTRICAL DATA, CONNECTIONS AND WIRING

A1

LPS

A3

A2

Wiring diagram with pump-down cycle

Compressor model SH240-300-380

A1

A2

LP

LPS

A3

L1

MPM

Motor Protection

Module

1

N

A1

2

11

12

14

A2

A3

LPS

L1

MPM

1

N

2

11

12

14

Wiring diagram without pump-down cycle

A1

A3

LPS

MPM

A2

S

KS

S

Wiring diagram with pump-down cycle

Legend

20

Wiring diagram without pump-down cycle

Fuses ..................................................................................................F1

Compressor contactor .................................................................KM

Control relay ...................................................................................KA

Safety lock out relay .......................................................................KS

Optional short cycle timer (3 min) ........................................180 s

External overload protection .......................................................F2

Pump-down pressure switch .......................................................LP

High pressure safety switch.........................................................HP

Control device .................................................................................TH

FRCC.PC.007.B5.02

Liquid Line Solenoid valve ....................................................... LLSV

Discharge gas thermostat ........................................................ DGT

Fused disconnect ...........................................................................Q1

Motor safety thermostat ............................................................thM

Compressor motor ..........................................................................M

Motor Protection Module ........................................................MPM

Thermistor chain............................................................................... S

Safety pressure switch .................................................................LPS

Page 21

APPLICATION GUIDELINES

Motor protection

ELECTRICAL DATA, CONNECTIONS AND WIRING

Compressor model

SH 090 - 105 - 120 - 140-

161 - 184

SH 180 Electronic module located in terminal box Reverse vent valve

SH240 - 300 - 380 Electronic module located in terminal box

Overheating

protection

Internal motor protection Phase sequence detector recommended

9

9

9

Compressor models SH090-105-120-140-161

-18 4 have been provided with an internal over-

load motor protection to prevent against exces-

Over current

protection

Locked rotor

protection

9

While not compulsory, an additional external

overload is still advisable for either alarm or man-

ual reset.

sive current and temperature caused by overloading, low refrigerant fl ow or phase loss. The cutout

current is the MCC value listed in section "Three

phase electrical characteristics".

Then it must be set below MCC value (at max op-

erating current:

when the motor temperature is too high, •

then the internal protector will trip

The protector is located in the star point of the

motor and, should it be activated, will cut out all

three phases. It will be reset automatically.

when the current is too high the external •

overload protection will trip before the in-

ternal protection therefore off ering possibil-

ity of manual reset.

Compressor models SH180-240-300-380 are

delivered with a pre installed motor protection

module inside the terminal box. This device provides for effi cient and reliable protection against

overheating and overloading (as well as phase

has elapsed, the relay is once again pulled in – i.e.

contacts M1-M2 (11-14 for SH180) are closed. The

time delay may be cancelled by means of resetting the mains (L-N -disconnect) for approximately 5 sec.

loss/reversal on SH240-300-380).

When present, the LED on module will lighten as

The motor protector comprises a control module

follows in case of overheat:

and PTC sensors embedded in the motor winding.

The close contact between thermistors and windings ensures a very low level of thermal inertia.

Phase reversal protection

PTC overheat

Phase sequence and

reverse rotation protection

The motor temperature is being constantly

measured by a PTC thermistor loop connected

on S1-S2 (called 1-2 on SH180). If any thermistor

exceeds its response temperature, its resistance

increases above the trip level (4,500 Ω) and the

output relay then trips – i.e. contacts M1-M2 (or

11-14 for SH180) are open. After cooling to below

the response temperature (resistance < 2,750 Ω),

a 5-minute time delay is activated. After this delay

Use a phase meter to establish the phase orders

and connect line phases L1, L2 and L3 to terminals

T1, T2 and T3, respectively. The compressor will

Compressor models SH090-105-120-140-161184 have no internal reverse rotation protection.

If reverse rotation occurs it will be obvious as

soon as power is turned on. The compressor will

not build-up any pressure, the sound level will be

abnormally high and power consumption will be

minimal. In such case, shut down the compres-

FRCC.PC.007.B5.02

Appr. 1 second

Delay timer active (after PTC over temp.)

Appr. 1 second

only operate properly in a single direction, and

the motor is wound so that if the connections are

correct, the rotation will also be correct.

sor immediately and connect the phases to their

proper terminals. Prolonged reverse rotation will

damage the compressor.

Phase sequence detector is strongly

recommended.

21

Page 22

APPLICATION GUIDELINES

ELECTRICAL DATA, CONNECTIONS AND WIRING

Compressor model SH180 incorporates an inter-

nal reverse vent valve which will react in the presence of reverse rotation and will allow refrigerant

to circulate through a by-pass from the suction

to the discharge. Although reverse rotation is not

Compressor models SH 240 to 380 are delivered with an electronic module which provides

protection against phase reversal and phase loss

at start-up. Apply the recommended wiring diagrams from section "Suggested wiring diagram

logic". The circuit should be thoroughly checked

in order to determine the cause of the phase

problem before re energizing the control circuit.

The phase sequencing and phase loss monitoring functions are active during a 5-sec window 1

second after compressor start-up (power on L1L2-L3).

Compressor

start

Phase monitoring

0 1 s 6 s

Phase sequence module logic

destructive for the SH180, even over long periods

of time, it should b e corre cted as so on as possib le.

If reverse rotation is not halted, the SH180 will cycle off on the motor protection.

Should one of these parameters be incorrect, the

relay would lock out (contact M1-M2 open). When

present, the led on the module will show the following blink code:

In case of phase reverse error:

In case of phase loss error:

The lockout may be cancelled by resetting the

power mains (disconnect L-N) for approximately

5 seconds.

Voltage imbalance

The operating voltage limits are shown in the table section "Motor voltage". The voltage applied

to the motor terminals must lie within these table

limits during both start-up and normal operations. The maximum allowable voltage imbalance

% voltage

imbalance

Vavg = Mean voltage of phases 1, 2, 3.

V1-2 = Voltage between phases 1 & 2.

= x 100

| Vavg - V1-2 | + | Vavg - V1-3 | + | Vavg - V2-3 |

is 2%. Voltage imbalance causes high amperage

over one or several phases, which in turn leads to

overheating and possible motor damage. Voltage

imbalance is given by the formula:

2 x Vavg

V1-3 = Voltage between phases 1 & 3.

V2-3 = Voltage between phases 2 & 3.

22

FRCC.PC.007.B5.02

Page 23

APPLICATION GUIDELINES

APPROVAL AND CERTIFICATIONS

Approvals and certifi cates

Pressure Equipment

Directive 97/23/EC

Low voltage directive

2006/95/EC

SH scroll compressors comply with the following

approvals and certifi cates.

CE 0062 or CE 0038 or CE0871

(European Directive)

UL

(Underwriters Laboratories)

Other approvals / certifi cates Contact Danfoss

Products

Refrigerating fl uids Group 2 Group 2 Group 2

Category PED II II III

Evaluation module D1 D1 H

Service temperature - Ts -35°C < Ts < 55°C -35°C < Ts < 51°C -35°C < Ts < 51°C

Service pressure - Ps 33.3 bar(g) 30.2 bar(g) 30.2 bar(g)

Declaration of conformity contact Danfoss

Products SH090 to 380

Declaration of conformity

ref. Low voltage Directive 2006/95/EC

SH090-105-120-140-161-

184

Certifi cates are listed on the product datasheets:

http://www.danfoss.com/odsg

All SH models

All 60 Hz SH models

SH180-240-300 SH380

Contact Danfoss

Machines directive

2006/42/EC

Internal free volume

Products SH090 to 380

Manufacturer's declaration of incorporation

ref. Machines Directive 2006/42/EC

Products Internal free volume without oil (litre)

SH090 12.4

SH105-120-140-161 14.3

SH184 14.6

SH180 31.6

SH240 31.0

SH300 32.6

SH380 34.3

Contact Danfoss

FRCC.PC.007.B5.02

23

Page 24

APPLICATION GUIDELINES

OPERATING CONDITIONS

Refrigerant and lubricants

General information

The scroll compressor application range is infl uenced by several parameters which need to be

monitored for a safe and reliable operation.

These parameters and the main recommendations for good practice and safety devices are explained hereunder.

When choosing a refrigerant, diff erent aspects

must be taken into consideration:

• Legislation (now and in the future)

• Safety

• Application envelope in relation to expected

running conditions

• Compressor capacity and effi ciency

• Compressor manufacturer recommendations &

Guidelines

Danfoss Commercial Compressors, along with the

whole refrigeration and air conditioning industry,

shares today’s concern about the environmental

issues that are ozone depletion, global warming

and overall energy consumption. Usual HCFCs

refrigerant fl uids such as R22 are known to be implicated in these harmful phenomena, especially

ozone depletion due to their chlorinated content.

These substances are scheduled to be phasedout from production and use in coming years,

Refrigerant and lubricants•

Motor supply•

Compressor ambient temperature•

Application envelope• (evaporating tem-

perature, condensing temperature, return gas

temperature)

Additional points could infl uence the fi nal

choice:

• Environmental considerations

• Standardisation of refrigerants and lubricants

• Refrigerant cost

• Refrigerant availability

in accordance with the international Montreal

Protocol (1984).

As a result, new chlorine -free molecules have been

recently developed and are now ready to replace

former fl uids. Among those refrigerants, the HFC

blend R410A is admitted by a great majority of

manufacturers to be the most promising in terms

of environmental impact, stability and effi ciency,

and is already seen as the R22 replacement.

C

HEMICAL

PROPERTIES

ENVIRONMENTAL

IMPACT

THERMODYNAMIC

PROPERTIES

R410A

REFRIGERANT R22 R407C R410A

Chlorine content yes no no

Zeotropic pure refrigerant zeotropic mixture near azeotropic mixture

Composition R22 R32/R125/R134a R32/R125

ODP 0.05 0 0

GWP 1500 1526 1725

Vapour pressure (bar) at 25°C 10.4 11.9 16.5

Cooling capacity of liquid (kJ/kg.K) at 25°C 1.24 1.54 1.84

Cooling capacity of vapor (kJ/kg.K) at 1 atm, 25 °C 0.657 0.829 0.833

Temperature glide (°C) 0 7.4 <0.2

SH compressors are to be used with R410A refrigerant, with polyolester oil.

Because of the higher system effi ciency it al-•

lows to achieve, R410A is in this regard the best

refrigerant.

R410A’s superior thermodynamical properties •

compared to R22 and R407C refrigerants allow

for today’s massive – and necessary – switch to

high effi ciency systems.

Zero Ozone Depletion Potential (ODP): R410A •

doesn’t harm the ozone layer.

Global warming potential (GWP): R410A shows •

a relatively high warming potential. However,

the GWP index denotes direct warming eff ect,

which is relevant only in case of rele ase to th e atmosphere. A more accurate index is T.E.W.I., for

As a near-azeotropic mixture, refrigerant R410A •

behaves like an homogeneous substance,

whereas other zeotropic mixtures such as R407C

and other blends suff er a temperature glide

during phase change that lessens thermal effi -

ciency and makes them diffi cult to transfer from

a container to another.

Reduced refrigerant mass fl ow, permitted by a •

higher heat capacity, induce a lower sound level

of the installation as well as more compact and

lighter systems.

Total Equivalent Warming Impact, which takes

into account indirect contributions due to running energy costs.

24

FRCC.PC.007.B5.02

Page 25

APPLICATION GUIDELINES

OPERATING CONDITIONS

POE oil Polyolester oil (POE) is miscible with HFC's (while

mineral oil is not), but has to be evaluated regarding lubrication ability in compressors.

POE oil has better thermal stability than refrigerant mineral oil.

Motor supply SH scroll compressors can be operated at nomi-

nal voltages as indicated section "Motor voltage". Under-voltage and over-voltage operation

Compressor ambient

temperature

High ambient temperature

Low ambient temperature

SH compressors can be applied from -35°C to 55°C

ambient temperature for SH090-105-120-140-161184 and 51°C ambient temperature for SH180240-300-380. The compressors are designed as

In case of enclosed fi tting and high ambient temperature it’s recommend to check the temperature of power wires and conformity to their insulation specifi cation.

Although the compressor itself can withstand low

ambient temperature, the system may require

specifi c design features to ensure safe and reli-

POE is more hygroscopic and also holds moisture

more tight than mineral oil.

It also chemically reacts with water leading to acid

and alcohol formation.

is allowed within the indicated voltage ranges. In

case of risk of under-voltage operation, special

attention must be paid to current draw.

100 % suction gas cooled without need for additional fan cooling. Ambient temperature has very

little eff ect on the compressor performance.

In case of safe tripping by the internal compressor overload protection the compressor must

cool down to about 60°C before the overload will

reset. A high ambient temperature can strongly

delay this cool-down process.

able operation. See section ‘Specifi c application

recommendations’.

Application envelope

The operating envelope for SH scroll compressors

is given in the fi gure below, where the condensing and evaporating temperatures represent the

range for steady-state operation. Under transient

conditions, such as start-up and defrost, the compressor may operate outside this envelope for

short periods.

75

70

65

60

55

50

45

40

35

Condensing temperature (°C)

30

25

SH = 5 K

SH = 11.1 K

The operating limits serve to defi ne the envelope

within which reliable operations of the compressor are guaranteed:

• Maximum discharge gas temperature: +135°C,

• A suction superheat below 5 K is not recommended due to the risk of liquid fl ood back,

• Maximum superheat of 30 K,

• Minimum and maximum evaporating and condensing temperatures as per the operating

envelopes.

20

15

10

-35 - 30 -25 -20 - 15 -10 -5 0 5 10 15 20

FRCC.PC.007.B5.02

Evaporating temperature (°C)

25

Page 26

APPLICATION GUIDELINES

OPERATING CONDITIONS

Discharge temperature

protection

The discharge gas temperature must not exceed

135 °C .

The discharge gas thermostat accessory kit (code

7750009) includes all components required for installation as shown below. The thermostat must

be attached to the discharge line within 150 mm

from the compressor discharge port and must be

thermally insulated and tightly fi xed on the pipe.

DGT protection is required if the high and low

pressure switch settings do not protect the compressor against operations beyond its specifi c application envelope. Please refer to the examples

below, which illustrate where DGT protection is

required (Ex.1) and where it is not (Ex.2).

A discharge gas temperature protection device

must be installed on all heat pumps. In reversible air-to-air and air-to-water heat pumps the

discharge temperature must be monitored

70

65

Example 1 (R410A, SH = 11 K)

LP switch setting:

LP1 = 3.3 bar (g) (-15.5°C)

HP switch setting:

HP1 = 38 bar (g) (62°C)

Risk of operation beyond the application envelope.

DGT protection required.

Example 2 (R410A, SH = 11 K)

LP switch setting:

LP2 = 4.6 bar (g) (-10.5°C)

HP switch setting:

HP2 = 31 bar (g) (52°C)

No risk of operation beyond the application envelope.

No DGT protection required.

60

55

50

45

40

35

Cond. temp. (°C)

30

25

20

15

10

-30 -25 -20 -15

Thermostat

Discharge line

Bracket

Insulation

during development test by the equipment

manufacturer.

The DGT should be set to open at a discharge gas

temperature of 135°C.

The compressor must not be allowed to cycle

on the discharge gas thermostat. Continuous operations beyond the compressor’s operating range

will cause serious damage to the compressor!

Example 1

DGT - limit

LP1

LP2

-10

Evap. temp. (°C)

Example 2

R410A

-5 0 5 10 15 20

HP1

HP2

High and low

pressure protection

High pressure

Internal pressure relief valve

26

A high-pressure (HP) safety switch is required to

shut down the compressor should the discharge

pressure exceed the values shown in the table

section "System pressure test". The high-pressure

switch can be set to lower values depending on

the application and ambient conditions. The HP

The SH380 incorporate an internal relief valve set

to open between the internal high and low pressure sides of the compressor when the pressure

diff erential between the discharge and suction

pressures surpasses 31 to 38 bar.

This safety feature prevents the compressor from

developing dangerously high pressures should

the high pressure cut-out, for whatever reason,

fail to shut down the compressor.

FRCC.PC.007.B5.02

switch must either be placed in a lockout circuit

or consist of a manual reset device to prevent cycling around the high-pressure limit. If a discharge

valve is used, the HP switch must be connected to

the service valve gauge port, which must not be

isolated.

HP

LP

Relief valve

Page 27

APPLICATION GUIDELINES

T

OPERATING CONDITIONS

Low pressure

A low-pressure (LP) safety switch must be used.

Deep vacuum operations of a scroll compressor

can cause internal electrical arcing and scroll instability. Performer SH Scroll compressors exhibit

high volumetric effi ciency and may draw very low

vacuum levels, which could induce such a problem. The minimum low-pressure safety switch

(loss-of-charge safety switch) setting is given in

Pressure settings R410A

Working pressure range high side bar (g) 13.5 - 44.5

Working pressure range low side bar (g) 2.3 - 11.6

Maximum high pressure safety switch setting bar (g) 45

Minimum low pressure safety switch setting * bar (g) 1.5

Minimum low pressure pump-down switch setting ** bar (g) 2.3

* LP safety switch shall never be bypassed and shall have no time delay.

** Recommended pump-down switch settings: 1.5 bar below nominal evap. pressure with minimum of 2.3 bar(g)

Note that these two diff erent low pressure switches also require diff erent settings. The low pressure

pump down switch setting must always be within

the operating envelope, for example 2.3 bar for

R410A. The compressor can be operated full time

the following table. For systems without pumpdown, the LP safety switch must either be a manual lockout device or an automatic switch wired

into an electrical lockout circuit. The LP switch

tolerance must not allow for vacuum operations

of the compressor. LP switch settings for pump-

down cycles with automatic reset are also listed

in the table below.

under such condition. The minimum low pressure

safety switch setting may be outside the normal

operating envelope and should only be reached

in exceptional (emergency) situations, for example 1.5 bar for R410A.

Cycle rate limit

Danfoss recommends a restart delay timer to limit

compressor cycling. The timer prevents reverse

compressor rotation, which may occur during

brief power interruptions.

There must be no more than 12 starts per hour, a

number higher than 12 reduces the service life of

the motor-compressor unit. A three-minute (180sec) time out is recommended.

The system must be designed in a way that guarantees a minimum compressor running time of 2

minutes so as to provide for suffi cient motor cooling after start-up along with proper oil return.

Note that the oil return may vary since it depends

A1

H

T T

A2

upon system design.

Please contact Danfoss Technical Support for any deviation from this guidelines.

~

KA

TH

KA

~

A2 A3A1

180 s

FRCC.PC.007.B5.02

27

Page 28

APPLICATION GUIDELINES

SYSTEM DESIGN RECOMMENDATIONS

General

Essential piping design

considerations

Successful application of scroll compressors is

dependent on careful selection of the compressor for the application. If the compressor is not

The working pressure in systems with R410A is

about 60% higher than in systems with R22 or

R407C. Consequently, all system components and

piping must be designed for this higher pressure

level.

Proper piping practices should be employed to

ensure adequate oil return, even under minimum

load conditions with special consideration given

to the size and slope of the tubing coming from

the evaporator. Tubing returns from the evaporator should be designed so as not to trap oil and to

prevent oil and refrigerant migration back to the

compressor during off -cycles.

In systems with R410A, the refrigerant mass fl ow

will be lower compared to R22/R407C systems.

To maintain acceptable pressure drops and acceptable minimum gas velocities, the refrigerant

piping must be reduced in size compared to R22

correct for the system, it will operate beyond the

limits given in this manual. Poor performance, reduced reliability, or both may result.

/ R407C systems. Take care not to create too high

pressure drops or since in R410A systems the negative impact of high pressure drops on the system

effi ciency is stronger than in R22/R407C systems.

Piping should be designed with adequate threedimensional fl exibility. It should not be in contact

with the surrounding structure, unless a proper

tubing mount has been installed. This protection

proves necessary to avoid excess vibration, which

can ultimately result in connection or tube failure

due to fatigue or wear from abrasion. Aside from

tubing and connection damage, excess vibration

may be transmitted to the surrounding structure

and generate an unacceptable noise level within

that structure as well. For more information on

noise and vibration, see the section on: «Sound

and vibration management».

Suction lines

If the evaporator lies above the compressor, as

is often the case in split or remote condenser

systems, the addition of a pump-down cycle is

strongly recommended. If a pump-down cycle

were to be omitted, the suction line must have a

loop at the evaporator outlet to prevent refrigerant from draining into the compressor during off cycles.

If the evaporator were situated below the compressor, the suction riser must be trapped so as

to prevent liquid refrigerant from collecting at the

outlet of the evaporator while the system is idle,

which would mislead the expansion valve’s sensor (thermal bulb) at start-up.

max. 4 m

max. 4 m

To condenser

U-trap

0.5% slope

4 m/s or more

U-trap, as short as possible

8 to 12 m/s

Evaporator

0.5% slope

4m/s or more

U trap, as short as possible

HP

LP

28

FRCC.PC.007.B5.02

Page 29

APPLICATION GUIDELINES

SYSTEM DESIGN RECOMMENDATIONS

Discharge lines

Heat exchangers

When the condenser is mounted at a higher position than the compressor, a suitably sized «U»shaped trap close to the compressor is necessary

to prevent oil leaving the compressor from draining back to the discharge side of the compressor

during off cycle. The upper loop also helps avoid

condensed liquid refrigerant from draining back

to the compressor when stopped.

To obtain optimum effi ciency of the complete refrigerant system, optimised R410A heat exchangers must be used. R410A refrigerant has good

heat transfer properties: it is worthwhile designing specifi c heat exchangers to gain in size and

effi ciency.

Upper loop

HP

U Trap

LP

3D flexibility

Condenser

A sub-cooler circuit in the condenser that creates high sub cooling will increase effi ciency at

high condensing pressure. In R410A systems the

positive eff ect of sub cooling on system effi ciency will be signifi cantly larger than in R22/R407C

systems.

An evaporator with optimised R410A distributor

and circuit will give correct superheat at outlet

and optimal use of the exchange surface. This is

critical for plate evaporators that have generally

a shorter circuit and a lower volume than shell &

tubes and air cooled coils.

For all evaporator types a special care is required

for superheat control leaving the evaporator and

oil return.

Refrigerant charge limit Performer® SH compressors can tolerate liquid

refrigerant up to a certain extend without major

problems. However, excessive liquid refrigerant in

the compressor is always unfavourable for service

life. Besides, the installation cooling capacity may

be reduced because of the evaporation taking

place in the compressor and/or the suction line

instead of the evaporator. System design must be

such that the amount of liquid refrigerant in the

compressor is limited. In this respect, follow the

guidelines given in the section: “essential piping

design recommendations” in priority.

Furthermore, for good operation of the expansion device and to maintain good effi ciency in the

evaporator it is important to have a high degree

of liquid sub cooling. Without adequate sub cooling, fl ash gas will be formed at the expansion device resulting in a high degree of vapour at the

evaporator inlet leading to low effi ciency.

Use the tables below to quickly evaluate the required compressor protection in relation with the

system charge and the application.

Model

SH090 5.9

SH105-120-140-161-184 7.9

SH180-240-300 13.5

SH380 14.5

Refrigerant charge limit

(kg)

FRCC.PC.007.B5.02

29

Page 30

APPLICATION GUIDELINES

SYSTEM DESIGN RECOMMENDATIONS

BELOW charge limit ABOVE charge limit

Cooling only systems,

Packaged units

Cooling only systems

with remote condenser

and split system units

Reversible heat pump system

REC

Note: for special conditions such as low ambient temperature, low refrigerant load or brazed plate heat exchangers please refer to

corresponding sections.

No test or additional safeties required

9

Refrigerant migration & fl ood back test

REC

Sump heater

REC

REQ

Specifi c tests for repetitive fl ood back

Sump heater

REQ

Defrost test For more details, refer to section "Reversible heat pump system"

REQ

Recommended Required No test or additional safeties required

REQ

More detailed information can be found in the paragraphs hereafter.

Please contact Danfoss Technical Support for any deviation from these guidelines.

Off -cycle migration Off -cycle refrigerant migration is likely to occur

when the compressor is located at the coldest

part of the installation, when the system uses a

bleed-type expansion device, or if liquid is allowed to migrate from the evaporator into the

compressor sump by gravity. If too much liquid

refrigerant accumulates in the sump it will saturate the oil and lead to a fl ooded start: when the

compressor starts running again, the refrigerant

evaporates abruptly under the sudden decrease

of the bottom shell pressure, causing the oil to

foam. In extreme situations, this might result

in liquid slugging (liquid entering the scroll elements), which must be avoided as it causes irreversible damage to the compressor.

Performer® SH scroll compressors can tolerate occasional fl ooded starts as long as the total system

charge does not exceed the maximum compressor refrigerant charge.

Refrigerant migration & fl ood back test

REQ

Sump heater

REQ

Refrigerant migration & fl ood back test

REQ

Sump heater

REQ

Liquid receiver (in association with LLSV and

REC

pump down)

9

A suitable test to evaluate the risk of off -cycle migration is the following:

Stabilize the non running system at 5°C ambi-•

ent temperature,

Raise the ambient temperature to 20°C and •

keep it for 10 minutes,

Start the compressor and monitor sump tem-•

perature, sight glass indication and sound

level.

The presence of liquid in the crankcase can be easily detected by checking the sump level through

the oil sight glass. Foam in the oil sump indicates

a fl ooded start.

A noisy start, oil loss from the sump and sump cool

down are indications for migration. Depending

on the amount of migration graduate measures

shall be taken:

Sump heater•

Liquid line solenoid valve•

Pump down cycle•

30

FRCC.PC.007.B5.02

Page 31

APPLICATION GUIDELINES

SYSTEM DESIGN RECOMMENDATIONS

Sump heater The surface sump heaters are designed to protect

the compressor against off -cycle migration of

refrigerant.

When the compressor is idle, the oil temperature

in the sump of the compressor must be maintained at no lower than 10 K above the saturation temperature of the refrigerant on the lowpressure side. This requirement ensures that

the liquid refrigerant is not accumulating in the

sump. A sump heater is only eff ective if capable

of sustaining this level of temperature diff erence.

Tests must be conducted to ensure that the appropriate oil temperature is maintained under

all ambient conditions (temperature and wind).

Note that below –5°C ambient temperature and a

wind speed of above 5m/second, we recommend

that the heaters be thermally insulated in order to

limit the surrounding energy losses.

Since the total system charge may be undefi ned,

a sump heater is recommended on all standalone compressors and split systems. In addition, any system containing a refrigerant charge

in excess of the maximum recommended system

charge for compressors requires a sump heater. A

sump heater is also required on all reversible cycle

applications.

SH180-240-300-380 initial start-up: For large

commercial platform initial start-up, it is not recommended to energize the crankcase heater in

advance, but quick starts may be needed to evacuate refrigerant in the system.

Then the heater must be energized whenever the

compressor is off to avoid liquid refrigerant entering the compressor.

Provide separate electrical supply for the heaters

so that they remain energized even when the machine is out of service (eg. Seasonal shutdown).

Surface sump heater accessories are available

from Danfoss (see section "Accessories").

SH090-105-120-140-161-184 initial start-up: Due

to light commercial platform compact design, it

is recommended to energize surface sump heater

in advance to remove refrigerant at initial start-up

only 6 hours in advance.

Liquid line solenoid valve

(LLSV)

A LLSV may be used to isolate the liquid charge

on the condenser side, thereby preventing

against charge transfer or excessive migration to

the compressor during off -cycles. The quantity of

Pump-down cycle A pump-down cycle represents one of the most

eff ective ways to protect against the off -cycle migration of liquid refrigerant. Once the system has

reached its set point and is about to shut off , the

LLSV on the condenser outlet closes. The compressor then pumps the majority of the refrigerant charge into the condenser and receiver before