Page 1

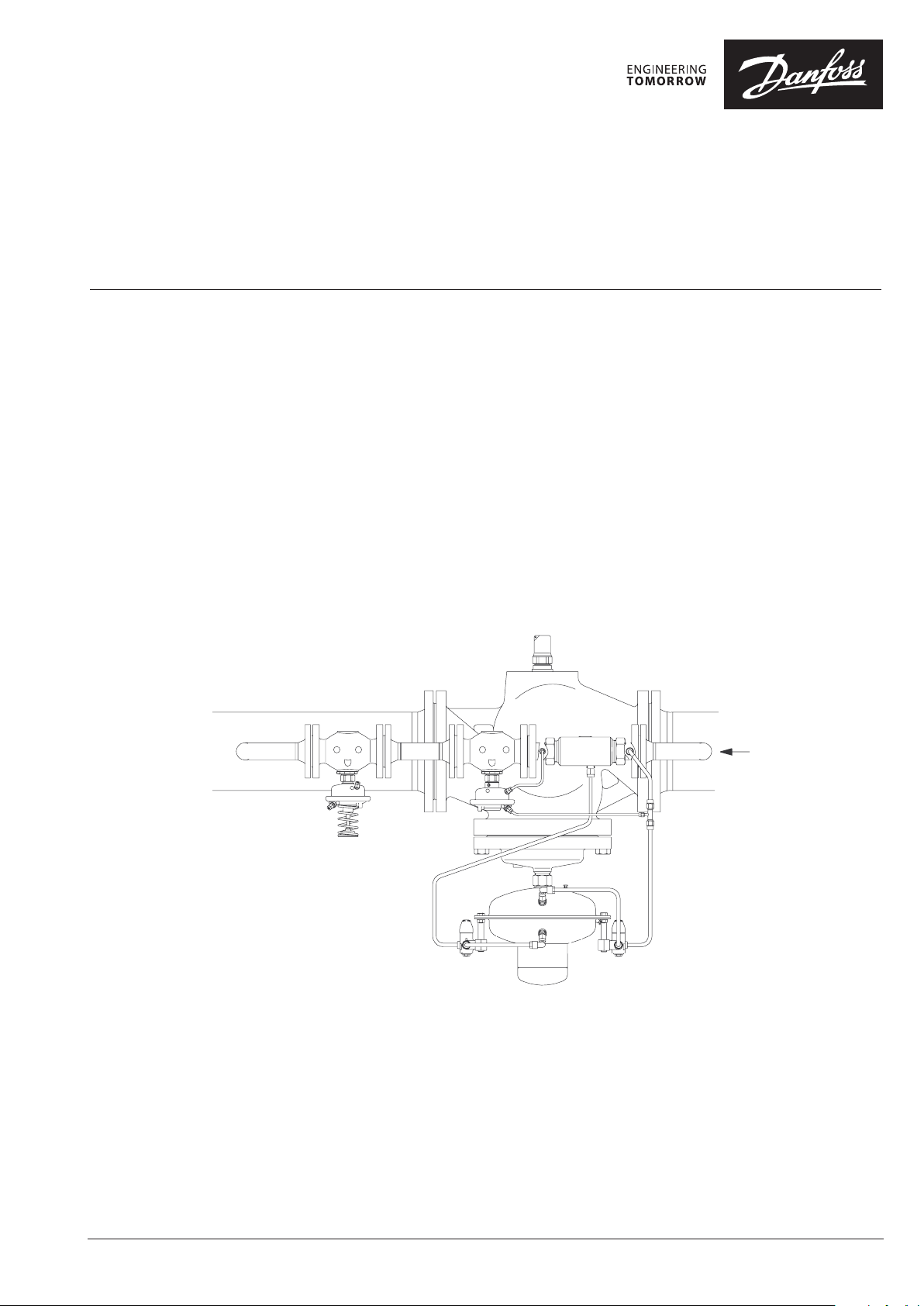

Instructions

Pilot-controlled Flow Rate and Differential Pressure

Controller PCVPQ

English Page 2

Instructions

Hilfsgesteuerter Volumenstrom-, Differenzdruckregler

PCVPQ

Deutsch Page 21

DN 100 - DN 250

PN 16 / PN 25

© Danfoss | 2016.05

VI.JA.H3.5B | 1

Page 2

Instructions PCVPQ

Table of Contents 1 Safety Notes ....................................................... 3

2 Definition of Application ............................. 3

3 Description ........................................................... 4

3.1 Construction ..........................................................4

3.2 Mode of Operation ............................................4

4 Technical Data ................................................... 4

5 Scope of Delivery .............................................. 5

6 Assembly .............................................................. 6

6.1 Prior to Assembly ................................................ 6

6.2 Installation Position,

Installation Place ................................................. 6

6.3 When Installaling observe ...............................6

6.4 Impulse Tube Installation ................................. 6

6.5 Insulation ............................................................... 6

6.6 Installation Scheme ............................................ 7

6.7 Assembly Drawings, Dimensions ................. 8

7 Start-up ................................................................10

7.1 Required static Pressure, Pressure

Difference ............................................................10

7.2 Leak and Pressure Test .....................................10

7.3 Filling the System ..............................................10

7.4 Start-up ..................................................................10

7.5 Putting out of Operation ................................10

7.6 Flow Rate Adjustment ......................................11

7.7 Flow Adjusting Curves .................................... 12

7.8 Adjustment of

the Differential Pressure ................................14

7.9 Sealing ..................................................................14

7.10 Adjustement of

the Throttle Valves ...........................................14

7.11 Funstion Test ......................................................15

8 Trouble Shooting ...........................................16

9 Replacement of Valve,

Actuator, Trims ................................................ 17

2 | © Danfoss | 2016.05

9.1 Dismounting and Mounting

Actuator Valve ....................................................17

9.2 Replacement of Trim Valve VFQ 21 ............19

9.3 Dismounting, Mounting

Actuator AVP, AVP-F .........................................20

9.4 Replacement of

Trim Valve AVP, AVP-F .......................................20

VI.JA.H3.5B

Page 3

Instructions PCVPQ

1 Safety Notes

observe these instructions.

Necessary assembly, start-up, and maintenance

work must be performed only by qualified,

trained and authorized personnel.

Prior to assembly and maintenance work on the

controller, the system must be:

depressurized,

cooled down,

emptied and

cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

MAINTENANCE

FREE

Prior to assembly and

commissioning to avoid injury

of persons and damages of the

devices, it is absolutely

necessary to carefully read and

2 Definition of

Application

The controller is used for flow rate limitation of

water for heating, district heating and cooling

systems.

The admissible medium temperatures depend

on the design and comprise 5-150 °C,

5-200 °C.

The technical data on the rating plates determine the use.

VI.JA.H3.5B

© Danfoss | 2016.05 | 3

Page 4

Instructions PCVPQ

P

(Diff

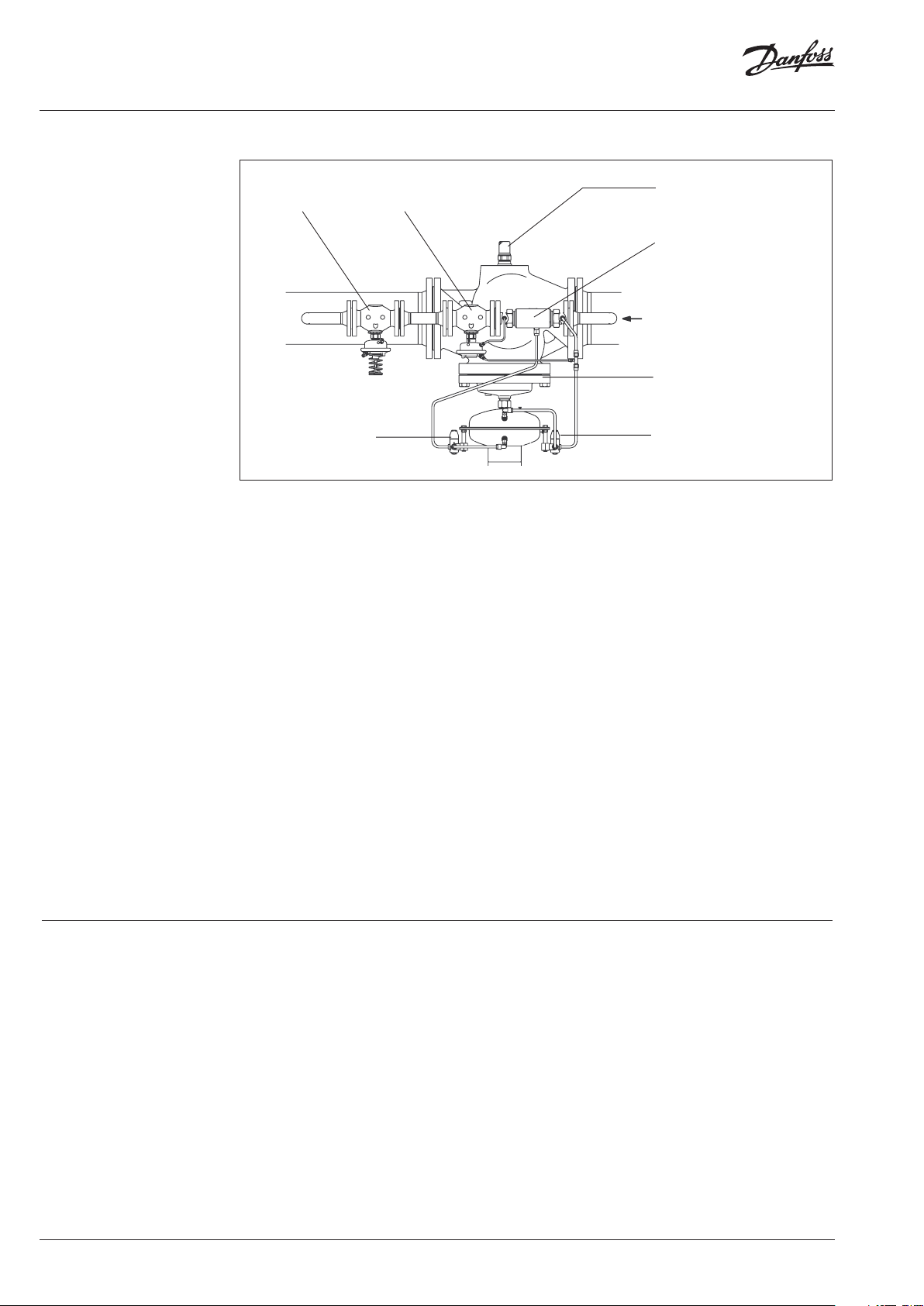

3 Description

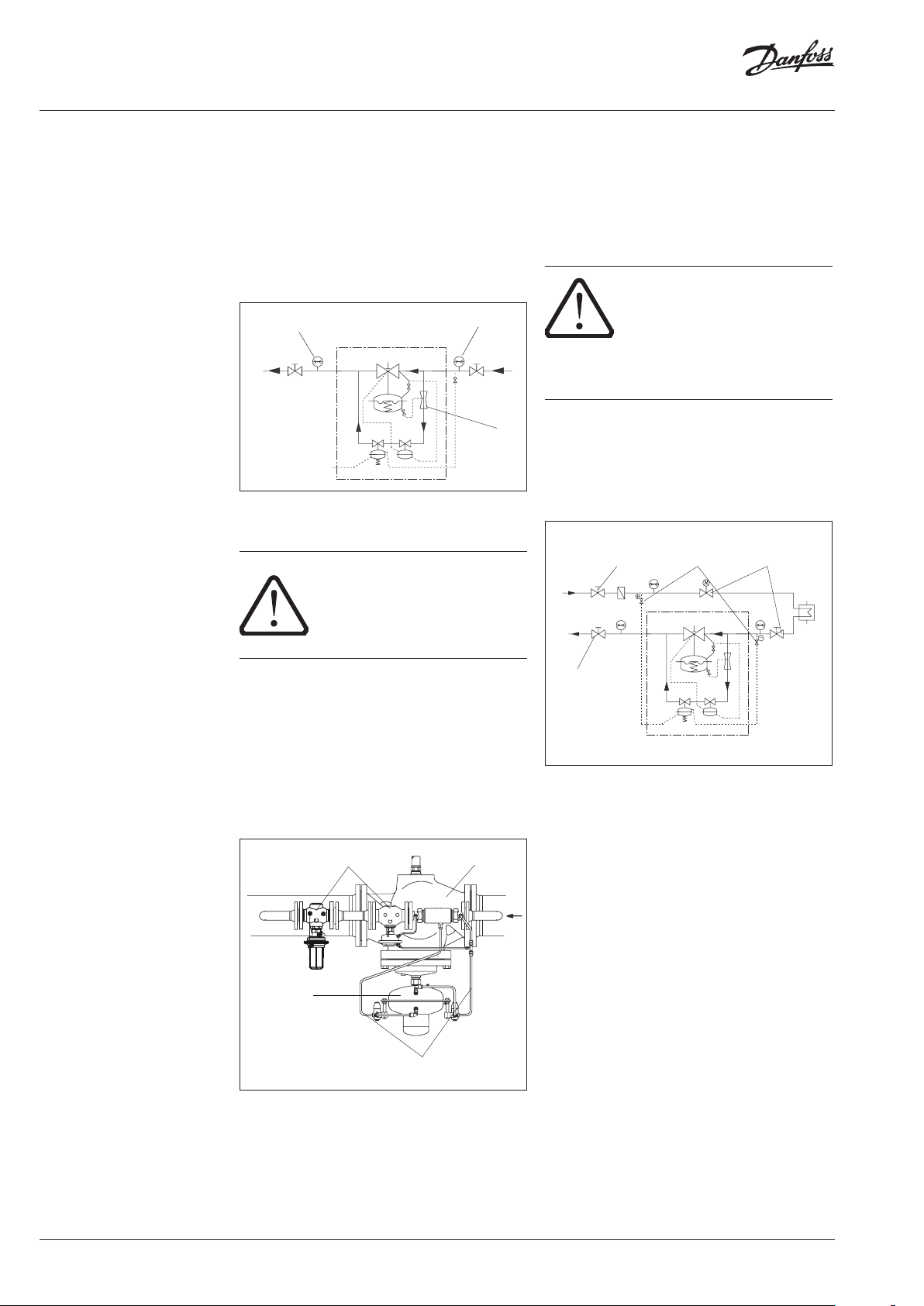

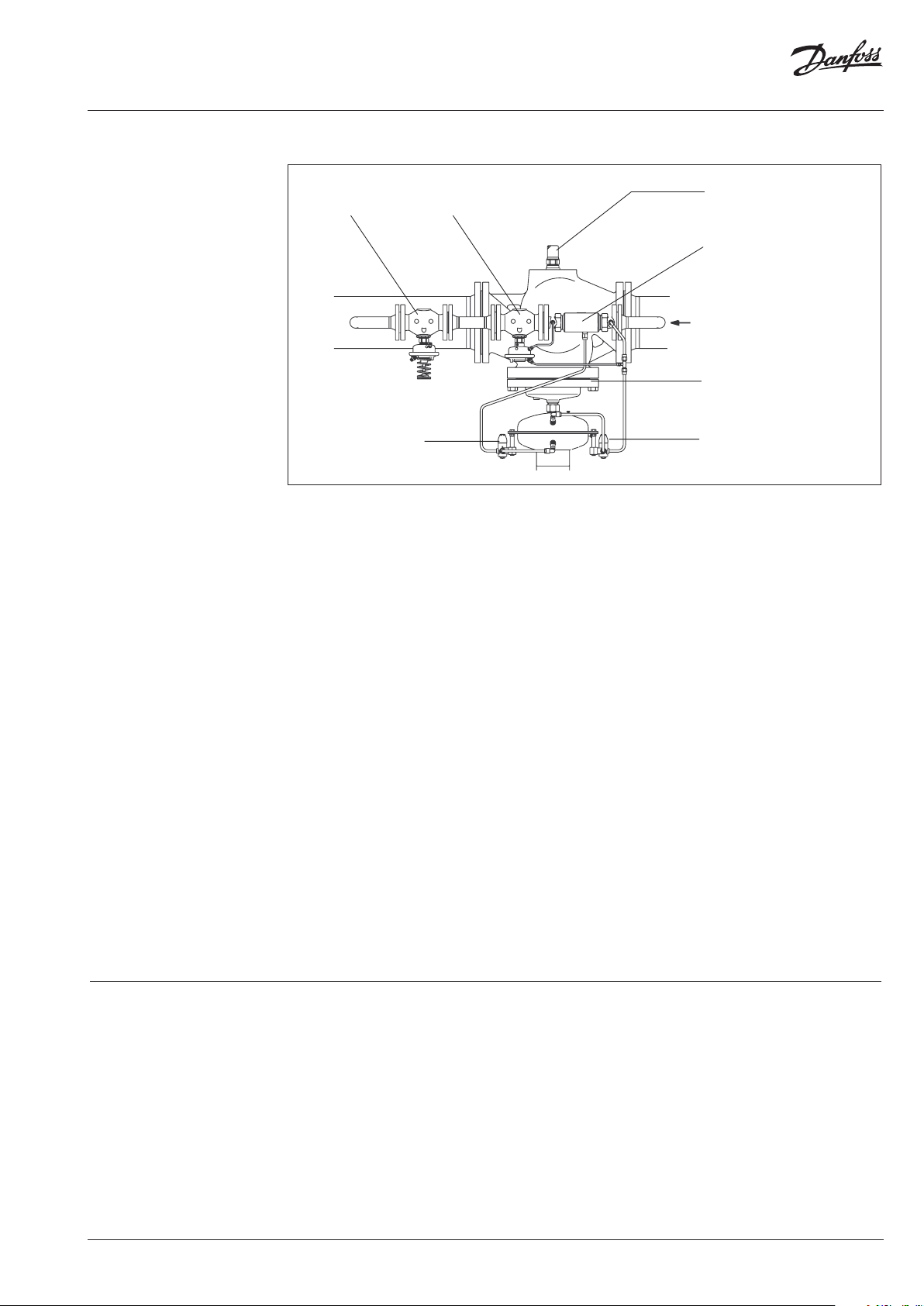

3.1 Construction

ilot controller AVP

erential Pressure)

Throttling valve

only by DN150-250

3.2 Mode of Operation

The control unit consists of the PCV-VFQ21

valve unit, installed in the main pipe, and the

differential pressure controllers AVP and AVP-F

installed as pilot controllers in the bypass. In the

bypass line, a throttle element is installed in front

of the pilot controllers.

The controller keeps the differential pressure

for the corresponding section on a constant

level and restricts the flow rate to the adjusted

setpoints.

The valve and the pilot valves are pressurebalanced.

The setpoint for the differential pressure is

adjusted by pre-stressing the setpoint spring

of the pilot controller AVP. The setpoint for the

flow rate limitation is adjusted at the adjusting

throttle of the valve unit.

The valve unit in the main pipe is opening on

rising pressure. The pilot controllers in the

bypass line are closing on rising pressure.

Differential Pressure Control

In case of small flow rates, the valve in the main

pipe remains closed through the pressure spring

Pilot controller AVP-F

(Flow Rate)

Adjusting throttle

Throttling element DE

Valve unit PCV-VFQ 21

Throttling valve

in the actuator of the valve unit. The pressure is

exclusively controlled by the pilot controller.

If the flow rate in the bypass is increased, the

pressure in the throttle element (Venturi nozzle)

decreases.

The reduced pressure acts through an impulse

tube upon the lower chamber of the actuator

of the valve unit. The main valve is thus opened

shock-free and continuously.

If the flow rate is reduced, the pressure in the

throttle element raises and the main valve closes.

This sequential switching guarantees an

operation free of vibrations and a small control

deviation over a wide positioning range.

Flow Rate Limitation

If the flow rate reaches the adjusted setpoint, the

differential pressure increases at the adjusting

throttle. This differential pressure acts on the

actuator AVP-F via the impulse tubes and the

valve AVP-F closes. Consequently, the valve of

the valve unit is throttled, too, and the flow rate

is restricted.

4 Technical Data Technical data, see rating plates and the PCV

data sheet.

4 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 5

Instructions PCVPQ

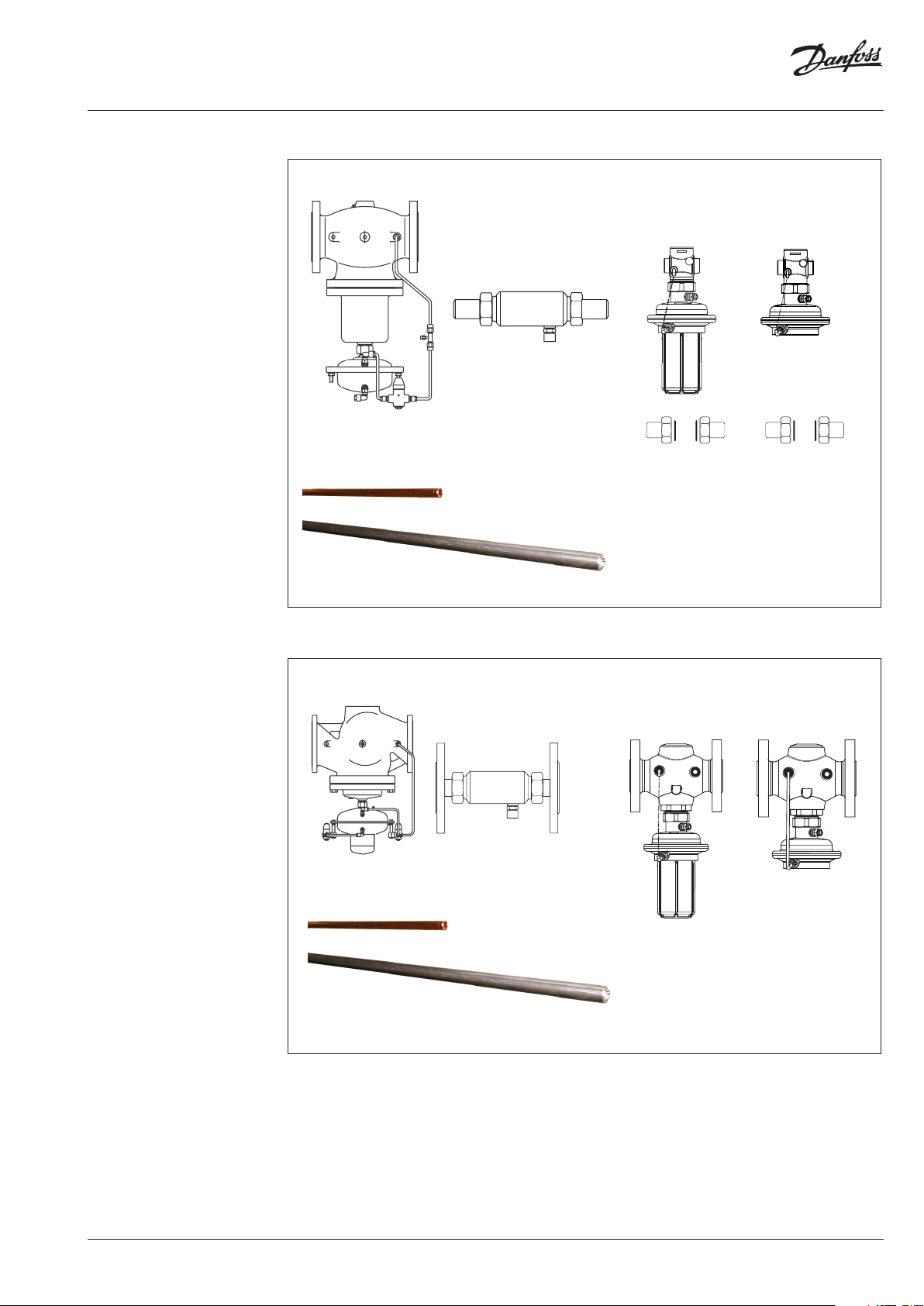

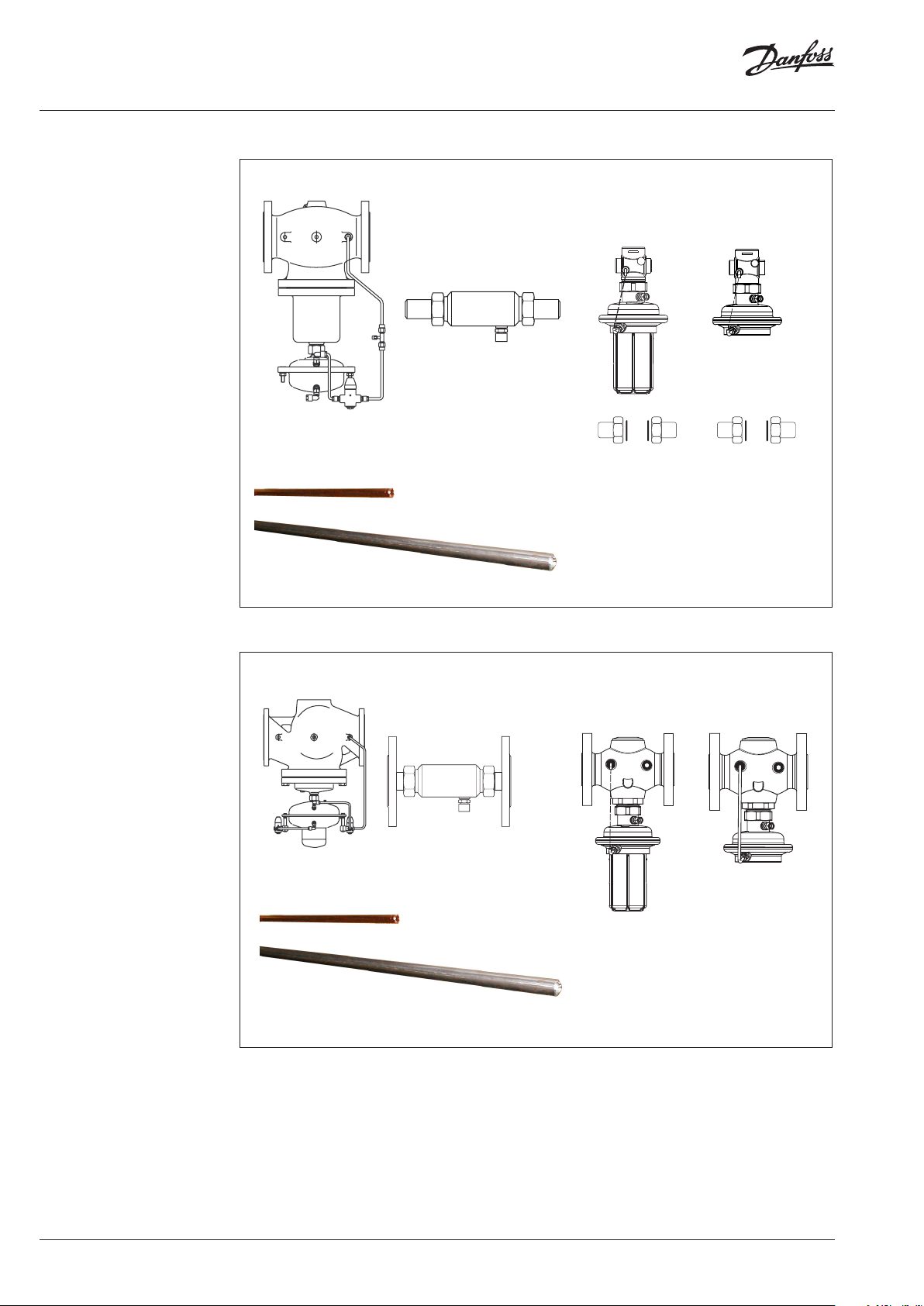

5 Scope of Delivery

DN 100-125

Assembly kit valve unit PCV-VFQ 21 Pilot controller DN 25

AVP

DN 25

Throttling element

Cu pipe Ø 6 × 1 × 1500 mm

Cu pipe Ø 10 × 1 × 3000 mm

AVP- F

DN 150-250

Assembly kit valve unit PCV-VFQ 21 Pilot controller DN 40

AVP

DN 40

Throttling element

Cu pipe Ø 6 × 1 × 1500 mm

Cu pipe Ø 10 × 1 × 3000 mm

AVP- F

VI.JA.H3.5B

© Danfoss | 2016.05 | 5

Page 6

Instructions PCVPQ

6 Assembly 6.1 Prior to Assembly:

Depressurized system before

any assembly work !

CAUTION!

• Clean pipeline system.

• Install strainer in front of the controller.

• Install shut-off units in front of and behind

the controller.

6.2 Installation Position, Installation Place

• Installation is only permitted in horizontal

pipelines with the actuators hanging in a

downward position.

• The controller may be installed in the supply

as well as in the return line.

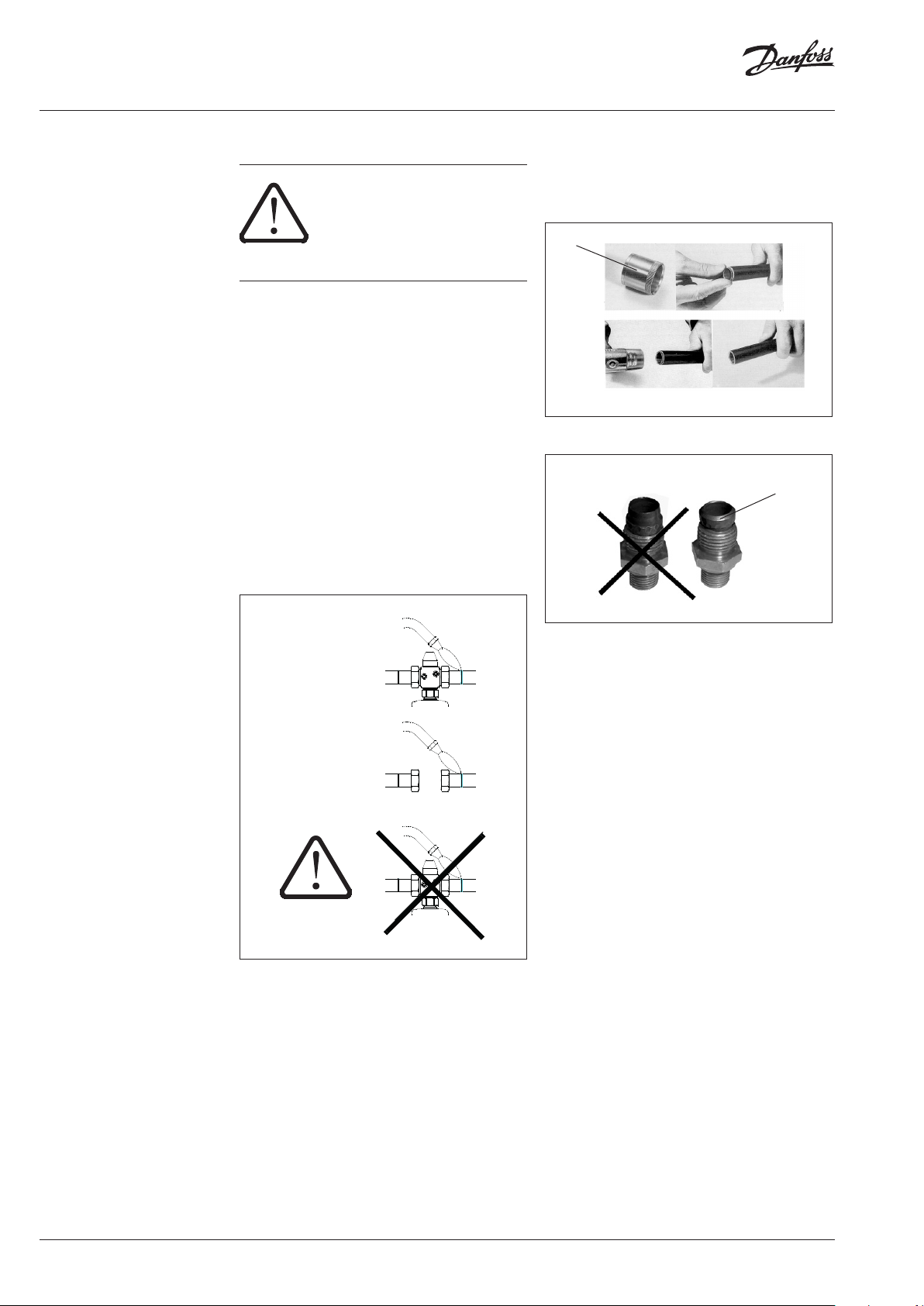

6.3 When installing:

• Observe direction of flow.

• Design with welded ends:

6.4 Impulse Tube Installation

See installation scheme, section 6.6.

For CU pipes Ø 10 × 1, insert sockets 1 on both

sides.

1

Care for correct position of the cutting rings 2.

2

pin only

weld

do NOT

weld

• Loads on the valve body and the throttle

element by the pipes are not permitted.

6.5 Insulation

The diaphragm actuators must not be insulated

when insulating system parts.

6 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 7

Instructions PCVPQ

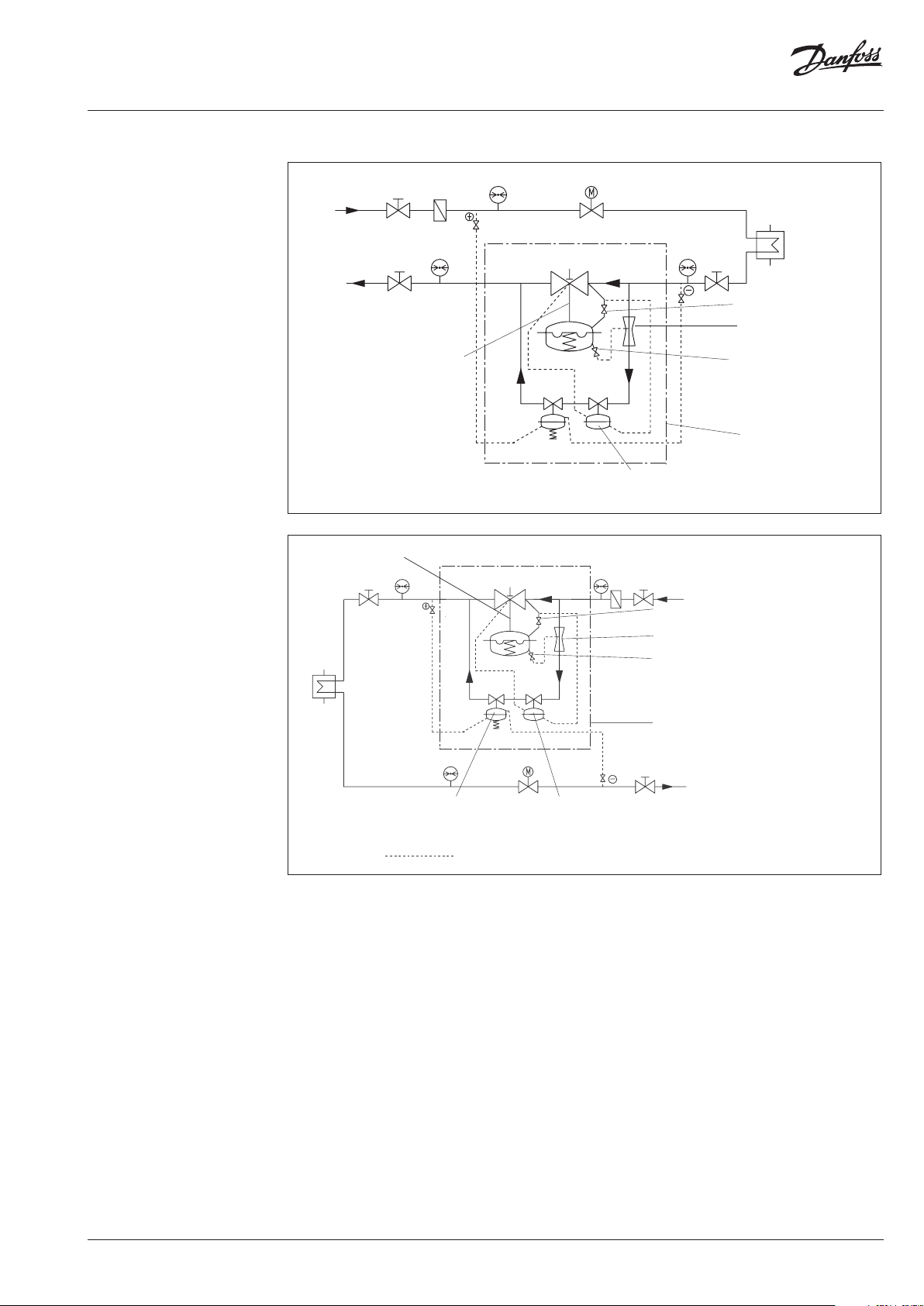

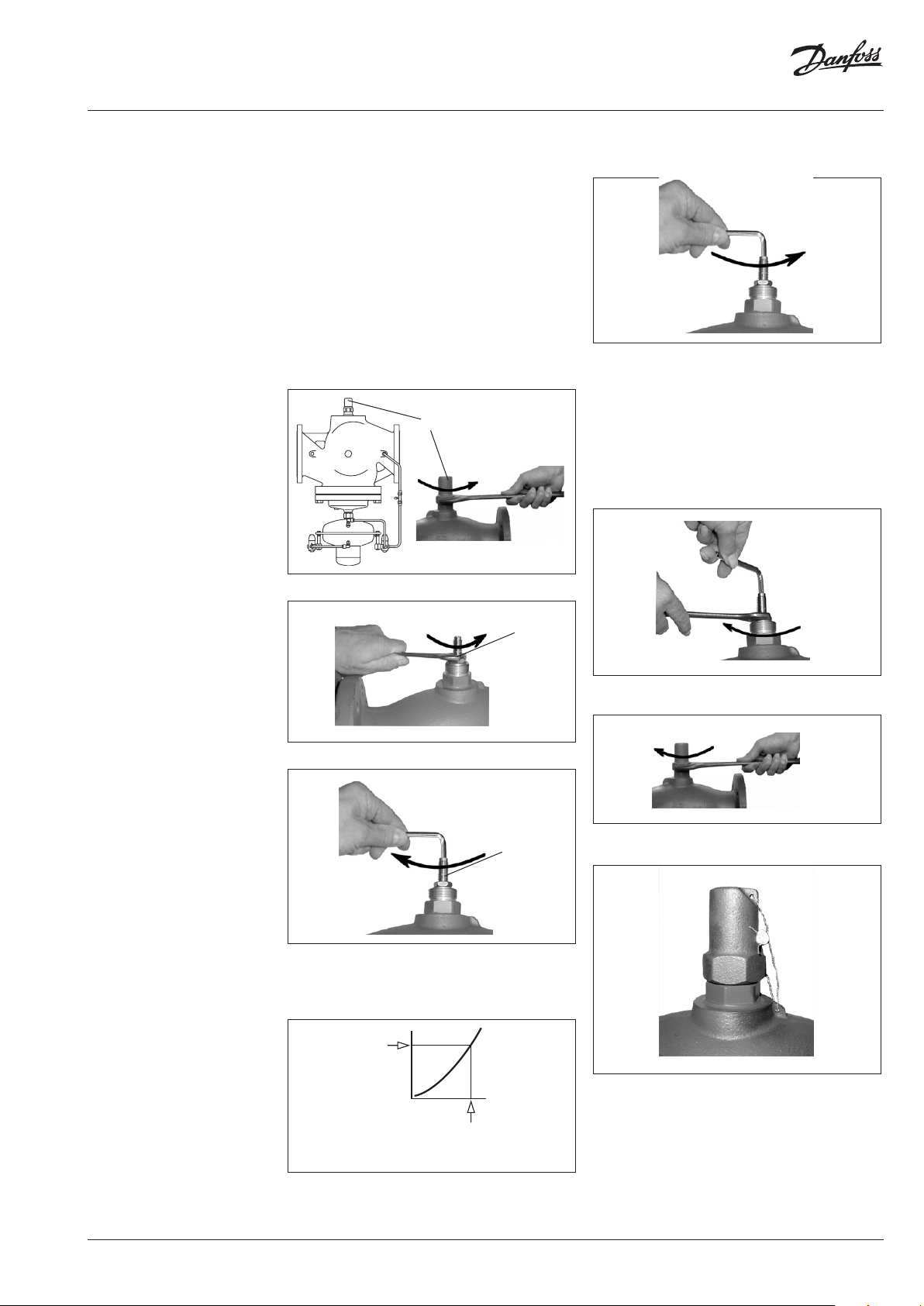

Valve unit PCV - VFQ 21

lay impulse tube during mounting

250)

Pilot controller AVP-F

6 Assembly 6.6 Installation Scheme

Valve unit PCV - VFQ 21

Installation in the Return Line

Throttling valve

Throttling

element

Throttling valve

(only by DN 150 -

Bypass controller

PCVPQ

Installation in the Supply Line

Pilotregler AVP-F

Pilotregler AVP-F

Throttling valve

Throttling

element

Throttling valve

(only by DN 150 - 250)

Bypass controller

PCVPQ

VI.JA.H3.5B

© Danfoss | 2016.05 | 7

Page 8

Instructions PCVPQ

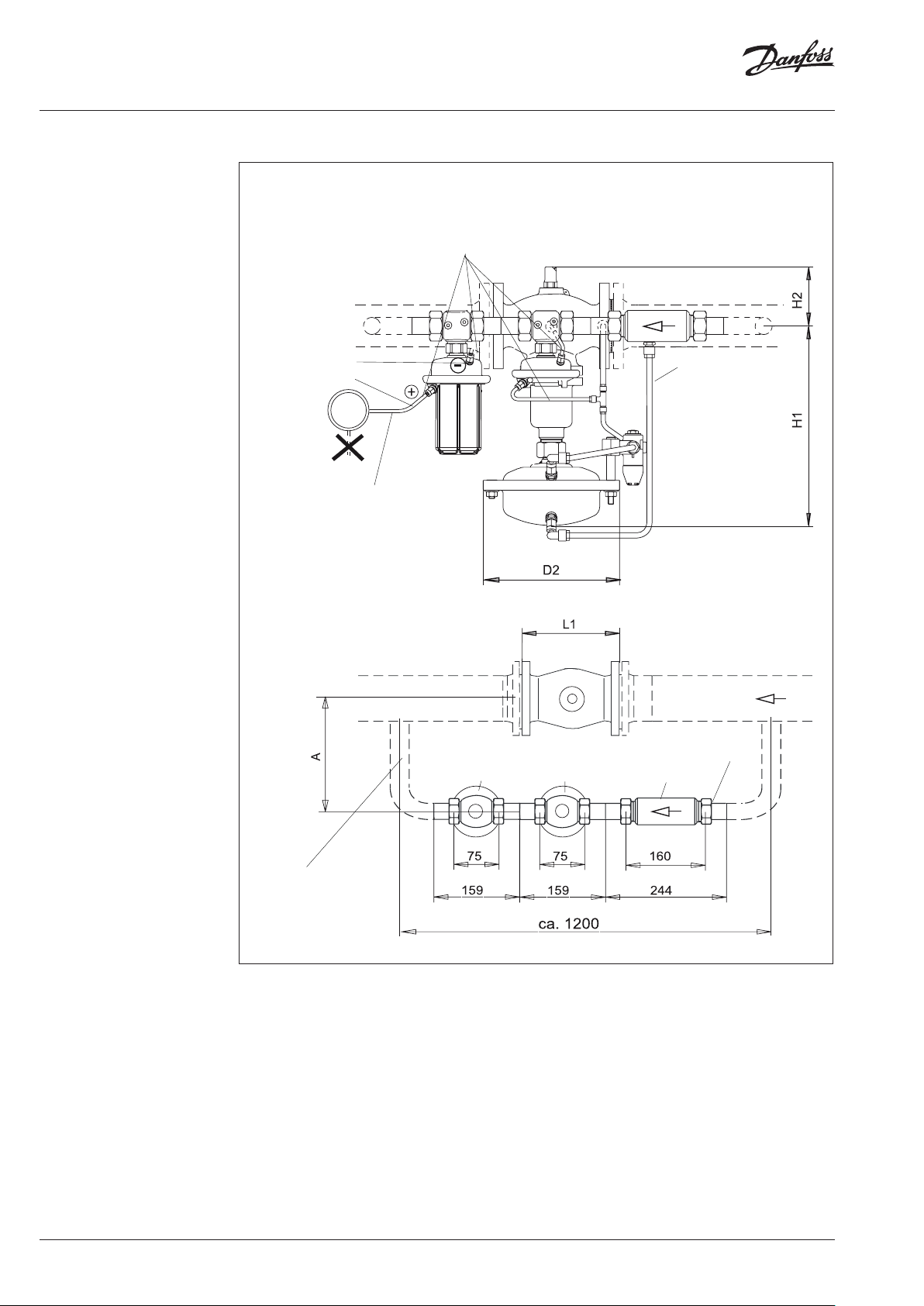

CU pipe Ø 6 x 1

DN 25: pipe

Mater

(not

6 Assembly

6.7 Assembly Drawings, Dimensions

Lay when assembling.

to the return flow

to the supply flow

Install impulse tubes

laterally because of dir t

Cu pipe

Ø 10 x 1

Lay when assembling.

DN 100-125

Ø 33.7 x 3.2

ial: ST 35.8

part of the delivery)

Pilot controller AVP

Pilot controller

AVP-F

Throttling

element

DN 25 SW 50

8 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 9

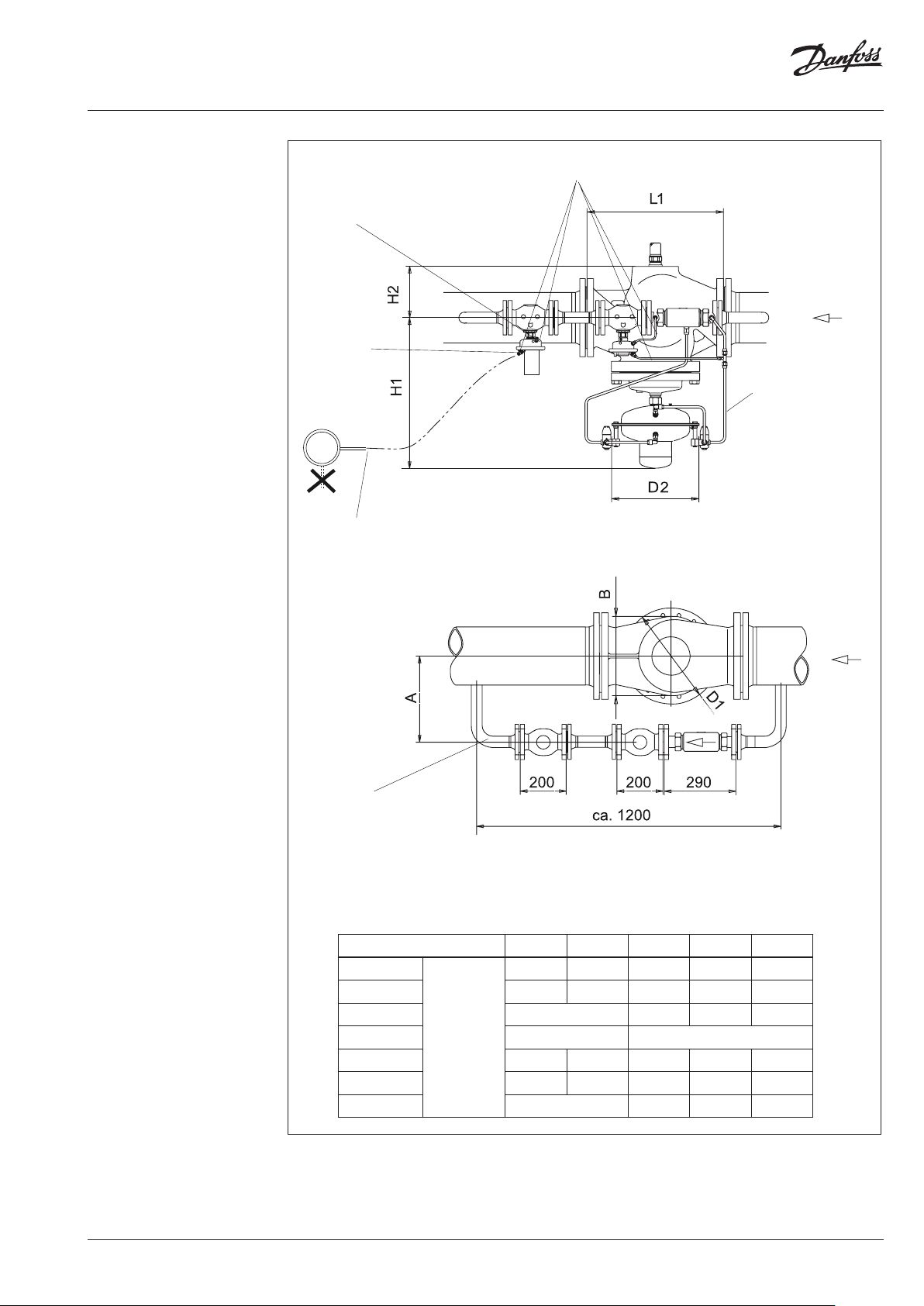

Instructions PCVPQ

laterally because of dirt

CU pipe Ø 6 x 1

DN 40: pipe

Mater

(not part of the delivery)

6 Assembly

to the return flow

to the supply flow

Install impulse tubes

Lay when assembling.

Cu pipe

Ø 10 x 1

Lay when assembling.

DN 150-250

Ø 48.3 x 3.2

ial: ST 35.8

Dimensions

Nominal diameter DN 100 125 150 200 250

L1

350 400 480 600 730

H1 530 530 619 647 697

H2 - 245 300 325

D2 263 380

mm

D1 150 250 320 385 500

B 200 210 310 336 412

A ≥ 290 320 350 410

VI.JA.H3.5B

© Danfoss | 2016.05 | 9

Page 10

Instructions PCVPQ

5

4

3

p2 p1

867

7 Start-up

7.1 Required Static Pressure, Pressure

Difference

For a proper functioning, a minimum pressure

difference of p1 - p2 ≥ 0.5 bar is required.

The static pressure p1 in front of the controller

must not fall below 1.5 bar (excess pressure).

Nonobservance may lead to cavitation and

damages in the throttling element 1.

1

7.2 Leak and Pressure Tests

To avoid too high pressures at

the diaphragm actuators, the

following should be observed

prior to any pressure tests:

7.3 Filling the System

Note:

The controller 4 is closed when no pressure is

applied and only opens with a defined flow in the

bypass.

The pilot controller 5 is closing on rising pressure.

To avoid too high pressure

differences on the controller,

observe the following sequence

when starting-up !

This procedure guarantees that there is no

overturn of the diaphragm in the valve and the

actuators.

1. Open shut-off valves 6 that possibly exist in

the impulse tubes.

2. Open units 7 of the system.

3. Slowly open shut-off units in the supply

flow 8 and the return flow 9.

Actuator of valve unit:

The admissible operating excess pressure in the

actuator 2 is 25 bar 1). For higher pressures, you

must:

• Remove the impulse tubes 3 at the actuator

and close the connections with a stopper.

• Prior to any leak or pressure test, the

instructions in section 7.3 must be complied

with.

2

1)

Pre-condi tion: Same pressure on both side s of the diaphragm.

If the pressure lo ad is one-sided, the (+)diaphragm cham ber

may have an excess p ressure of 1 bar in comparison to th e (-)

diaphragm chamber.

9

7.4 Start-up

During starting-up the filled system, open the

units in the same sequence as described in

section 7.3.

7.5 Putting out of operation

When putting the system out of operation, first

close the shut-off units in the supply flow and

then those of the return flow.

10 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 11

Instructions PCVPQ

Required

flo

for the adjusting throttle

7.6 Flow Rate Adjustment

The setting of the setpoint for the flow rate

limitation is made by means of flow adjusting

curves (see section 7.7) or a heat meter (see page

33).

Adjustment by means of flow adjusting

curves

Adjustment is to be made at a shut-down system.

Procedure

1. Unscrew cover 1.

1

2. Loosen the counter nut 2.

4. Turn the adjusting throttle by this number of

rotations to the left.

5. The adjusted flow rate can be verified by

means of a flow rate measuring device.

Perhaps you need to re-adjust the flow rate.

Care for an adequate differential pressure in

the system.

6. Tighten the counter nut without changing the

position of the adjusting throttle.

2

2. Screw in the adjusting throttle 3 to its stop.

3

3. Choose diagram,

(see section 7.7, Flow Adjusting Curves)

Observe effecitve pressure Δpb: 0.2 or 0.5 bar

see rating plate on the actuator AVP-F

w rate

7. Re-screw the cap nut 1.

8. The cap nut can be sealed.

VI.JA.H3.5B

The flow rate adjustment is completed.

Now, adjust the differential pressure,

see section 7.8.

Read rotations

© Danfoss | 2016.05 | 11

Page 12

Instructions PCVPQ

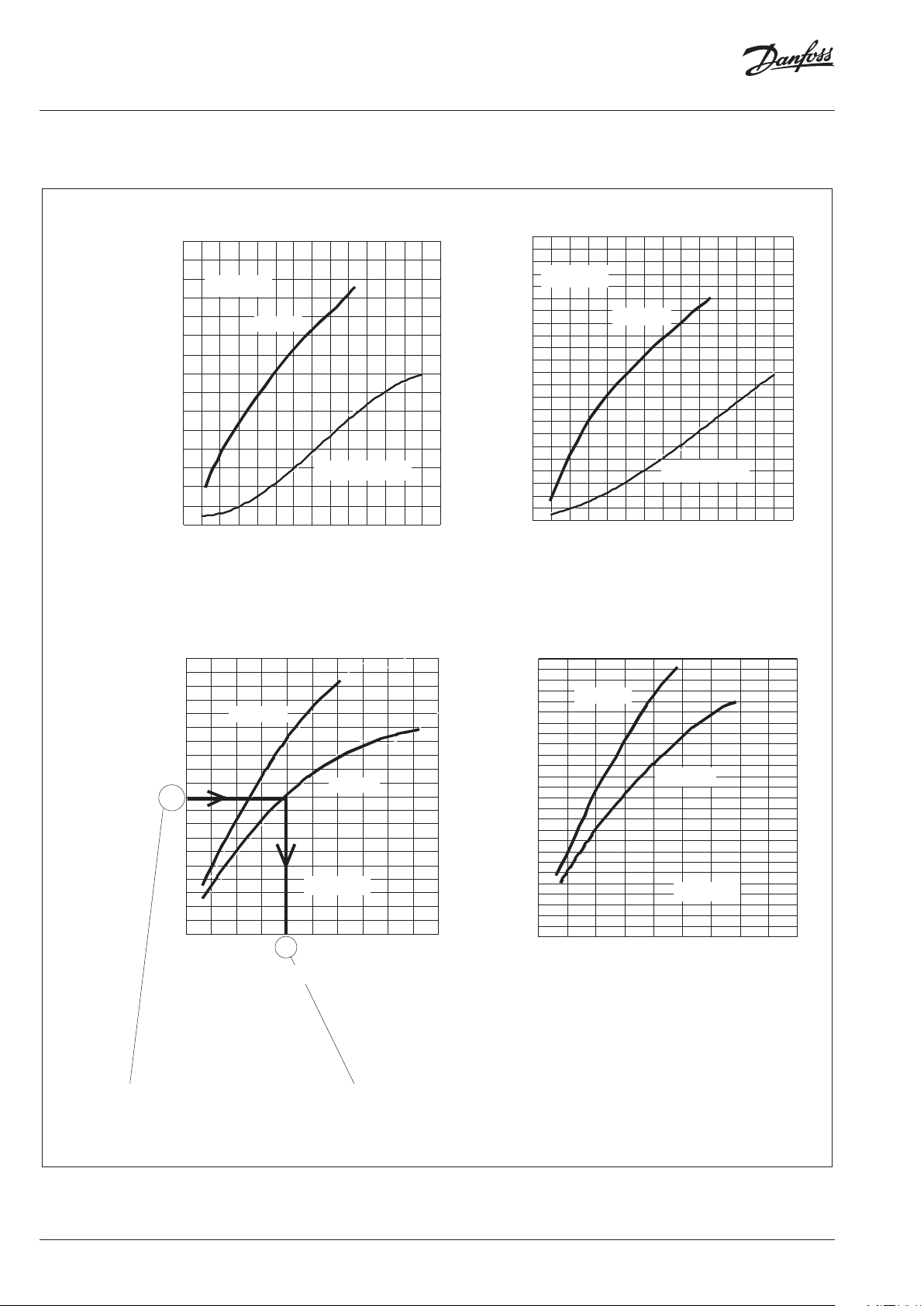

DN 100kvs 125/DN 125kvs 160/DN 150kvs 320

14

Rotations for the adjusting throttle

Flow rate (m

3

/h)

DN 100kvs 125/DN 125kvs 160/DN 150kvs 320

14

Rotations for the adjusting throttle

Flow rate (m

3

/h)

DN 200kvs 450/DN 250kvs 630

10

adjusting throttle: 4

required flow rate

limitation:

DN 200kvs 450/DN 250kvs 630

89

Rotations for the adjusting throttle

Flowrate (m

3

/h)

7 Start-up

7.7 Flow Adjusting Curves

140

p

=0,2

120

100

80

60

40

20

0

200

180

160

140

/h)

3

120

100

80

Flowrate (m

60

40

20

0

b

DN150

0123456789 10 11 12 13

DN 250

01234567 89

Rotations for the adjusting throttle

DN100/125

DN 200

p

=0,2

b

220

200

p

=0,5

b

180

DN 250

DN150

DN100/125

DN 200

p

=0,5

b

160

140

120

100

80

60

40

20

0

0123456789 10 11 12 13

260

240

220

200

180

160

140

120

100

80

60

40

20

0

012345 67

12 | © Danfoss | 2016.05

Example

Ventil DN 200

100 m³/h

necessary

rotations of the

VI.JA.H3.5B

Page 13

Instructions PCVPQ

P2

2

3

7 Start-up

Adjustment by means of a flow rate

measuring device:

Procedure

1. Prior to the adjustment of the flow rate,

start the system in accordance with the

instructions given in section 7.4.

2. The shut-off units 1 and the control units 2

must be completely opened so that the flow

rate is not restricted by a unit.

The adjustment can also be carried out via a

bypass 3.

P1

1

PCVPQ

5. Adjust the flow rate limitation by turning the

adjusting throttle 6:

Turning to the right 7, reduces the flow rate.

7

6

Turning to the left 8, increases the flow rate.

8

3. Unscrew cap nut 4.

4

4. Loosen the counter nut 5.

6. Observe the flow rate indicator.

7. After having completed the adjustment,

tighten the counter nut without changing the

position of the adjusting throttle.

8. Re-screw the cap nut.

5

9. The cap nut can be sealed.

VI.JA.H3.5B

The flow rate adjustment is completed.

© Danfoss | 2016.05 | 13

Page 14

Instructions PCVPQ

P1

4

max

5

right:

1

7 Start-up

7.8 Adjustment of the Differential Pressure

The setpoint of the differential pressure must

be adjusted at the pilot controller AVP 1. The

etpoint range is indicated on the rating plate of

the actuator.

1

Procedure

1. Prior to the differential pressure adjustment,

start the system as described in section 7.4.

The differential pressure can also be adjusted

while the bypass 2 is opened.

2. Adjust the flow rate at the unit by which the

differential pressure is controlled.

Adjustment, e.g. at unit 3 or 4 or via bypass 2

to approx. 50 % of the max. flow rate 5.

4. Observe pressure indicators 9.

5. After having completed the differential

pressure adjustment, check at the open

system whether the max. flow rate is reached.

If not, increase the differential pressure.

7.9 Sealing

The setpoint adjusters may be sealed.

7.10 Adjustment of the Throttle Valves

Number of throttle valves:

DN 100, 125: 1 ×

DN 150-250 : 2 ×

• Unscrew cover 1.

3

SW 5

Turning

9

PCVPQ

2

to the left:

reduces

damping

Turning

to the

increases

damping

P2

p

• Standard adjustment:

0 50% V

3. Turning to the right, increases the setpoint.

Turning to the left, reduces the setpoint.

Turn in the valve spindle by turning it to the

right by means of a wrench SW5 to its stop.

Then unscrew valve spindle by turning it to

the left by approx. 10 rotations.

• Increase of damping, e.g. necessary in case

of pressure vibrations.

Screw in the valve spindle by turning it to the

right.

• Reduction of damping, e.g. in case of a

control that is too slug.

Unscrew the valve spindle by turning it to the

left.

14 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 15

Instructions PCVPQ

7 Start-up

7.11 Fu nct ion Test

Differential pressure

Check the differential pressure on the pressure

indicators by opening and closing a unit in

the corresponding section of the system to be

controlled.

If the differential pressure is vibrating, slightly

close the throttle valves (see section 7.9).

If the differential pressure is exceeded in either

direction, adjust the differential pressure as

described in section 7.7.

Flow rate

The adjusted flow rate must not be exceeded if

the system is completely open.

If the setting is exceeded in either direction,

check the adjustment as described in section 7.5.

VI.JA.H3.5B

© Danfoss | 2016.05 | 15

Page 16

Instructions PCVPQ

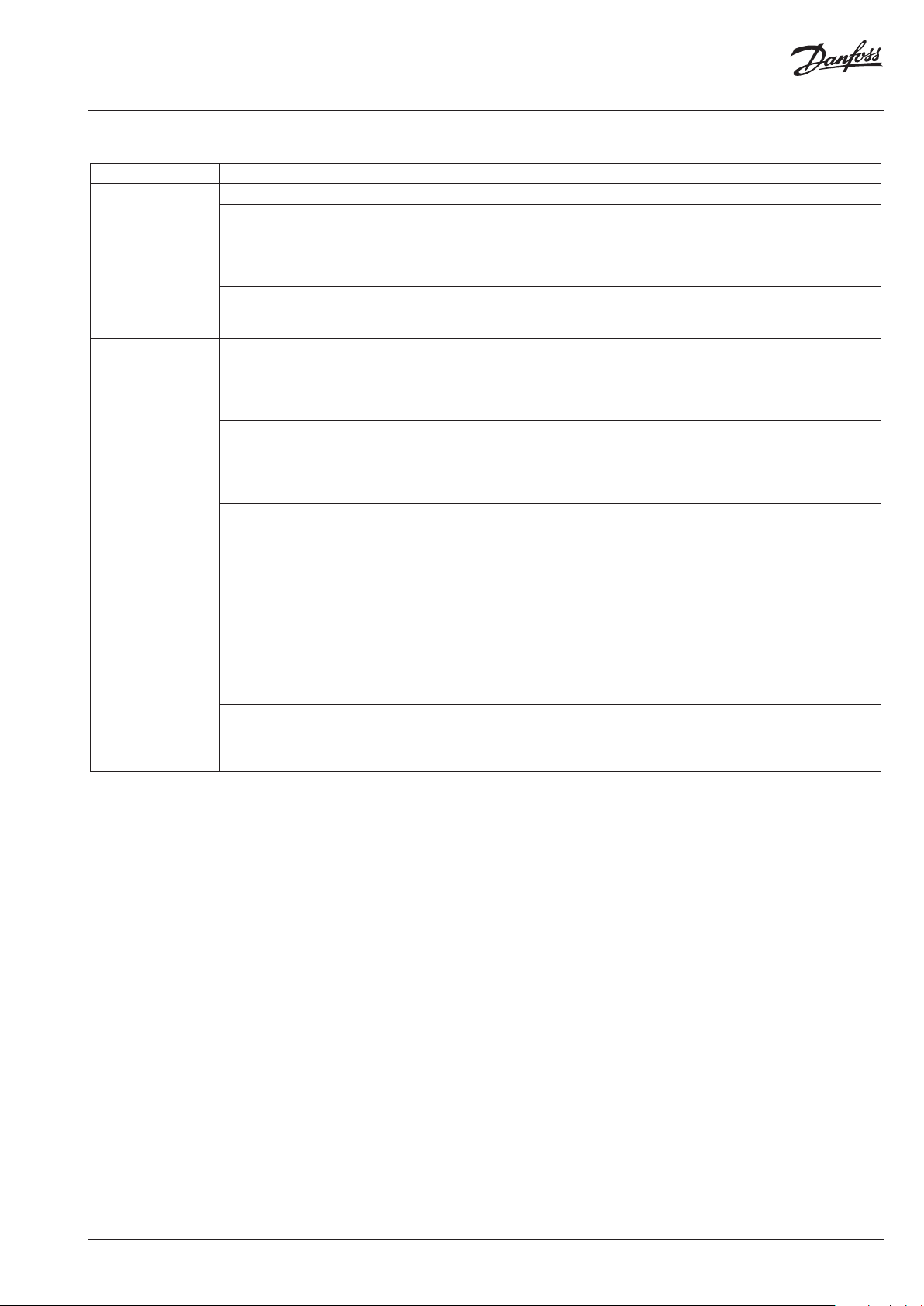

8 Trouble Shooting

Fault Possible cause Remedy

Throttle valve is open too widely. Slightly close the throt tle valve, see section 7.10.

1. Loosen impulse tube connections at the

Controller does not

hold the flow rate o r

differential pressure

on a constant level

Differential pressure

is too high

Differential pressure

or flow rate is too low

1)

The trim can be re placed by qualified pe rsonnel up to DN 125.

From DN 150 replacement should b e carried out by the Danfoss se rvice personnel.

Air in the actuators

Impulse tubes or impulse tube connections are

dirty or damaged.

Pilot valve AVP, AVP-F does not close:

Valve seat or plug is dirty or damaged.

Valve VFQ 2 does not close:

Valve seat or plug is dirty or damaged.

Rolling diaphragm in the actuator AVP, AVP-F

(pilot controller) is defective, i.e. valve AVP does

not close.

Valve plug of the pilot valve AVP does not open:

Valve seat or plug is dirty or damaged, trim is

dir ty.

Valve plug of the pilot valve VFQ 21 does not

open:

Valve seat or plug is dirty or damaged, trim is

dir ty.

Rolling diaphragm in the actuator of the valve

unit is defective, i.e. valve VFQ 21 does not open.

actuators by approx. 1 rotation.

2. Deaerate, Caution hot water !

(move impulse tube until medium

penetrates).

3. Tighten impulse tube connections.

1. Remove impulse tube.

2. Clean impulse tubes and impulse tube

connections and check for free passage.

1. Remove impulse tube.

2. Dismount actutor and trim.

Procedure see section 9.4.

3. Clean seat and plug.

4. If damaged, replace trim or valve.

1. Remove impulse tube.

2. Dismount actutor and trim 1).

Procedure, see section 9.2.

3. Clean seat and plug.

4. If damaged, replace trim or valve.

1. Remove impulse tube.

2. Replace actuator, see sec tion 9.3.

1. Remove impulse tube.

2. Dismount actuator and trim.

Procedure, see section 9.4.

3. Clean seat and plug.

4. If damaged, replace trim or valve.

1. Remove impulse tube.

2. Dismount actutor and trim 1).

Procedure, see sections 9.1 and 9.2.

3. Clean seat and plug.

4. If damaged, replace trim or valve.

1. Remove impulse tube.

2. Loosen union nut SW 46 and remove

actuator, see also section 9.1.

3. Replace actuator.

16 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 17

Instructions PCVPQ

grease

Cone

9 Replacement of Valve,

Actuator, Trims

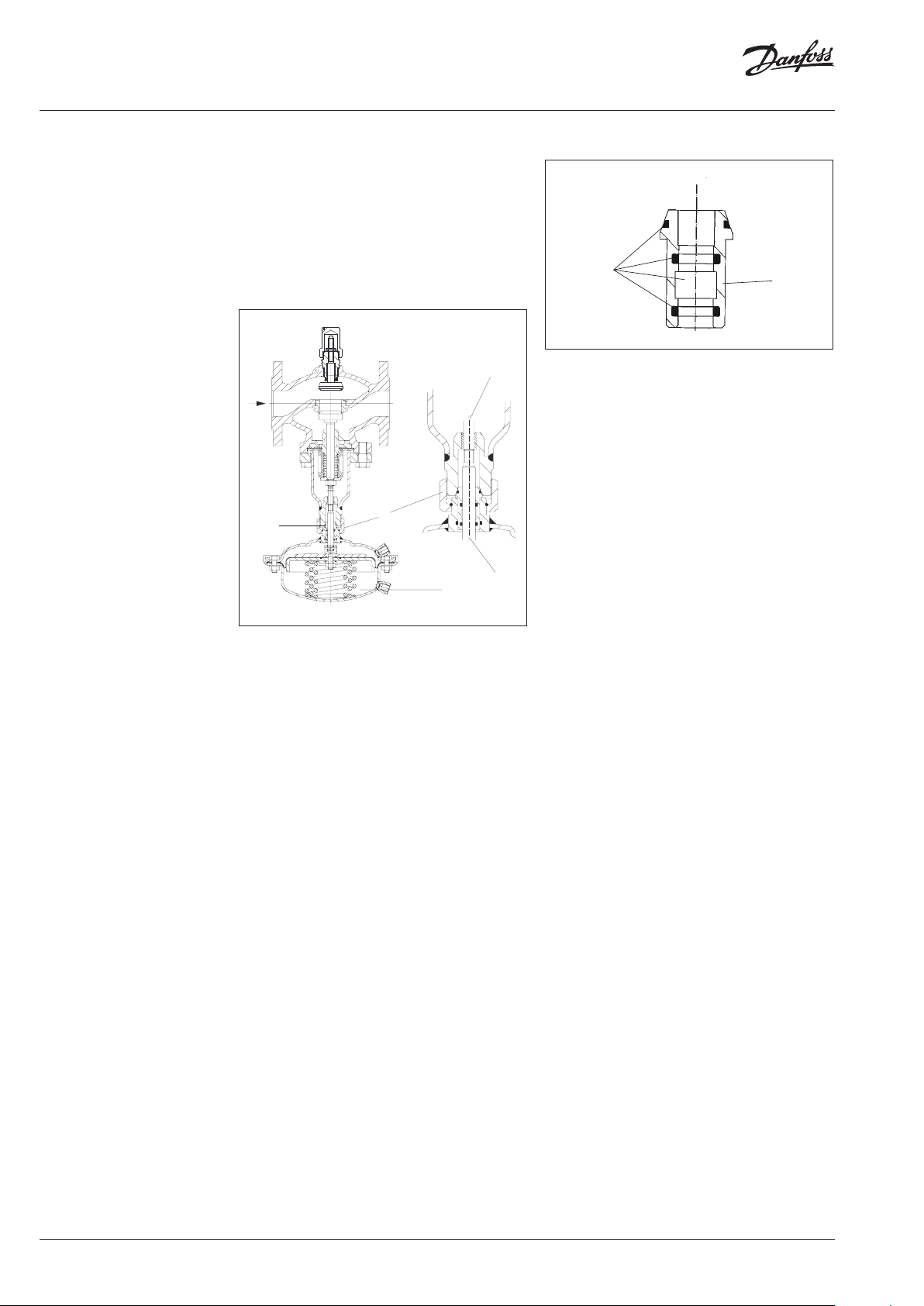

9.1 Dismounting and Mounting Actuator and

Valve

Note:

The springs 1 in the actuator are pre-stressed.

Therefore, the actuator must be pushed upwards

to be dismounted. You need a second person to

do this.

Valve unit DN 100–125

3

SW 46

5

2

1

4

Prior to assembly check cone 5 !

5

1. Clean cone prior to mounting.

2. Check O rings for damages, in case of

damages, replace cone (see Spare Parts).

3. Grease cone with high-performance fitting

component: BARRIERTA L55/3 HV (see Spare

Parts).

Mounting

1. Place actuator at the valve and push upwards.

2. Screw on union nut 2.

3. Align actuator, observe position of impulse

tube connections.

4. Tighten union nut 1, max. torque 100 Nm.

Valve stem 3 and the stem of the actuator 4 are

not screwed to eachother.

Dismounting

1. Dismount impulse tubes.

2. Support actuator below or by a second

person as the springs 1 are pre-stressed.

3. Loosen union nut 2.

4. Remove actuator.

VI.JA.H3.5B

© Danfoss | 2016.05 | 17

Page 18

Instructions PCVPQ

to the left

9 Replacement of Valve,

Actuator, Trims

Valve unit DN 150–250

3

SW 46

1

4

Tu rn

actuator

The stem of the actuator 4 is screwed into the

valve stem 3.

Dismounting

1. Dismount impulse tubes.

2. Completely loosen union nut 1.

The actuator hangs on the screwed-in stem 4.

The actuator weights approx.

20 kg. In addition, an internal

spring package is pre-stressed.

Secure against dropping down

before unscrewing.

3. Screw the stem of the actuators 4 out of the

valve stem 3 by turning the actuator to the

left.

Mounting

1. Place actuator at the valve and push upward

to press the spring package in the actuator

together (second person necessary).

2. Carefully turn actuator to the right.

By this, carefully screw in the stem of the

actuator into the valve stem to its stop.

Then, return the actuator by

approx. 1 rotation (to the left)

3. Align actuator, observe position of the control

lines connections.

4. Tighten union nut 1, torque 100 Nm.

18 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 19

Instructions PCVPQ

2

3

1

5

6

9 Replacement of Valve,

Actuator, Trims

9.2 Replacement of Trim Valve VFQ 21

The trim can be replaced by qualified personnel

up to DN 125. From DN 150 replacement should

be carried out by the Danfoss service personnel.

Removing the trim:

Valves DN 100–125

4

1. Dismount actuator 1

(see section 9.1).

2. Unscrew hexagon head cap screw 2.

3. Remove bonnet 3.

4. Take out trim 4.

Prior to installation:

Clean sealing surfaces 5 and socket 6, grease

sealing surfaces with antiseize graphite

petroleum.

Installing the trim:

Mounitng is carried out in reverse order.

Torque hexagon head cap screws 2:

DN Torque Wrench

100 -125 180 Nm SW 30

VI.JA.H3.5B

© Danfoss | 2016.05 | 19

Page 20

Instructions PCVPQ

2

9 Replacement of Valve,

Actuator, Trims

9.3 Dismounting, Mounting

Actuator AVP, AVP-F

1

Dismounting

1. Dismount impulse tubes.

2. Loosen union nut 1.

3. Remove actuator.

Mounting

1. Place actuator at the valve and align, observe

position of the impulse tube connections.

2. Screw on union nut 1 and tighten,

torque 100 Nm.

9.4 Replacement of Trim Valve AVP, AVP-F

AVP DN 25

2

AVP DN 40

Dismounting

1. Unscrew actuator (see above).

2. Unscrew trim 2.

DN 25: with pipe tongs, wrap gum strips

around the trim DN 40: with wrench SW 55

3. Pull out trim.

Mounting

Mounting is carried out in reverse order. Only

tighten with low torque, sealing is made with O

rings.

20 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 21

Instructions PCVPQ

Inhaltsverzeichnis 1 Sicherheitshinweise ......................................22

2 Bestimmungsgemäße Verwendung .....22

3 Beschreibung ....................................................23

3.1 Auf bau ...................................................................23

3.2 Wirkungsweise ...................................................23

4 Technische Daten ............................................23

5 Lieferumfang ....................................................24

6 Montage ..............................................................25

6.1 Vor der Montage beachten ............................25

6.2 Einbaulage, Einbauort .....................................25

6.3 Beim Einbau beachten .....................................25

6.4 Einbau Steuerleitung ........................................25

6.5 Isolierung ..............................................................25

6.6 Einbauschema.....................................................26

6.7 Montagezeichnungen, Abmessungen ......27

7 Inbetriebnahme...............................................29

7.1 Erforderliche(r) statischer Druck,

Druckdifferenz ....................................................29

7.2 Dichtheitsprüfung / Druckprüfung ............29

7.3 Füllung der Anlage ............................................29

7.4 Inbetriebnahme .................................................29

7.5 Ausserbetriebnahme ........................................29

7.6 Volumenstromeinstellung .............................30

7.7 Einstellkennlinien ..............................................31

7.8 Differenzdruckeinstellung .............................33

7.9 Plombierung ........................................................33

7.10 Einstellung Drosselventil ................................33

7.11 Funktionsprüfung ............................................ 34

8 Störungshinweise ...........................................35

9 Austausch von Ventil, Antrieb,

Innengarnituren ..............................................36

9.1 Demontage,

Montage Antrieb Stellgerät ...........................36

VI.JA.H3.5B

9.2 Austausch der Innengarnitur

Ventil VFQ 21 .......................................................38

9.3 Demontage, Montage Antrieb

AVP, AVP-F.............................................................39

9.4 Austausch der Innengarnitur

Ventil AVP, AVP-F ................................................39

© Danfoss | 2016.05 | 21

Page 22

Instructions PCVPQ

1 Sicherheitshinweise

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Vor Montage und Wartungsarbeiten am Regler

die Anlage:

drucklos machen,

abkühlen,

entleeren und

reinigen.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

MAINTENANCE

FREE

Um Verletzungen an Personen

und Schäden am Gerät zu

vermeiden, ist diese Anleitung

vor der Montage unbedingt zu

beachten.

2 Bestimmungsgemäße

Verwendung

Der Regler dient der Volumenstrombegrenzung

und Differenzdruckregelung von Wasser für

Heizung, Fernwärmeheizung und Kühlsysteme.

Die zulässigen Mediumstemperaturen sind je

nach Ausführung 5 - 150 °C, 5 - 200 °C.

Die technischen Daten auf den Typenschildern

sind für die Verwendung maßgebend.

22 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 23

Instructions PCVPQ

P

(Diff

3 Beschreibung 3.1 Aufbau

ilotregler AVP

erenzdruck)

Drosselventil

nur bei DN150-250

3.2 Wirkungsweise

Die Regeleinheit besteht aus dem in der

Hauptleitung eingebauten Stellgerät PCV-VFQ21

und dem im Bypass als Pilotregler angeordneten

Differenzdruckreglern AVP und AVP-F. In der

Bypassleitung ist vor den Pilotreglern ein

Drosselement eingebaut.

Der Regler hält den Differenzdruck über der

Anlagestrecke konstant und er begrenzt den

Volumenstrom entsprechend den eingestellten

Sollwerten.

Das Stellventil und die Pilotventile sind

druckentlastet.

Die Sollwerteinstellung des Differenzdruckes

erfolgt über die Vorspannung der Sollwertfeder

des Pilotreglers AVP. Der Sollwert für die

Volumenstrombegrenzung wird an der

Einstelldrossel des Stellgerätes eingestellt.

Das Stellgerät in der Hauptleitung ist drucklos

geschlossen. Die Pilotregler in der Bypassleitung

sind drucklos geöffnet.

Pilotregler AVP-F

(Durchfluss)

Einstelldrossel

Drosselelement DE

Stellgerät PCV-VFQ 21

Drosselventil

Differenzdruckregelung

Bei geringen Volumenströmen bleibt das Ventil

in der Hauptleitung durch die Druckfeder

im Antrieb des Stellgerätes geschlossen. Die

Differenzdruckregelung erfolgt ausschließlich

über das Pilotventil.

Erhöht sich der Volumenstrom in der

Bypassleitung, so sinkt der Druck im

Drosselelement (Venturidüse).

Dieser abgesenkte Druck wirkt über eine

Steuerleitung auf die Unterkammer des Antriebs

des Stellgerätes. Das Hauptventil wird dadurch

stoßfrei und stetig geöffnet. Reduziert sich

der Volumenstrom, so steigt der Druck im

Drosselelement an und das Hauptventil schließt.

Diese Folgeschaltung gewährleistet eine

schwingungsfreie Betriebsweise und eine

geringe Regelabweichung über einen großen

Stellbereich.

Volumenstrombegrenzung

Erreicht der Volumenstrom den eingestellten

Sollwert, so steigt der Differenzdruck an der

Einstelldrossel an. Dieser Differenzdruck wirkt

über die Steuerleitungen auf den Antrieb

AVP-F und das Ventil AVP-F schließt. In Folge

drosselt auch das Ventil des Stellgerätes und der

Volumenstrom wird begrenzt.

4 Technische Daten Technische Daten siehe Typenschilder und

Datenblatt PCV.

VI.JA.H3.5B

© Danfoss | 2016.05 | 23

Page 24

Instructions PCVPQ

5 Lieferumfang

DN 100-125

Bausatz Stellgerät PCV-VFQ 21 Pilotregler DN 25

AVP

DN 25

Drosselelement

Cu-Rohr Ø 6 × 1 × 1500 mm

Cu-Rohr Ø 10 x 1 × 3000 mm

AVP- F

DN 150-250

Bausatz Stellgerät PCV-VFQ 21 Pilotregler DN 40

AVP

DN 40

Drosselelement

Cu-Rohr Ø 6 × 1 × 1500 mm

Cu-Rohr Ø 10 × 1 × 3000 mm

AVP- F

24 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 25

Instructions PCVPQ

6 Montage 6.1 Vor der Montage beachten

Anlage vor der Montage

drucklos machen!

Achtung!

• Rohrleitungssystem reinigen

• Schmutzfänger vor dem Regler einbauen

• Absperrarmaturen vor und nach dem Regler

einbauen

6.2 Einbaulage, Einbauort

• Der Einbau ist nur in waagrechte

Rohrleitung mit nach unten hängenden

Antrieben zulässig.

• Der Regler kann im Vorlauf oder Rücklauf

der Anlage eingebaut werden 6.3 Beim

Einbau beachten

• Durchflussrichtung beachten

• Ausführung mit Anschweißenden

6.3 Beim Einbau beachten

6.4 Einbau Steuerleitung

Siehe Einbauschema Abschnitt 6.6

Bei den CU-Leitungen Ø 10 × 1 beidseitig

Einsteckhülsen 1 einfügen.

1

Richtige Lage der Schneidringe 2 beachten

2

• Durchflussrichtung beachten

• Ausführung mit Anschweißenden

nur Heften

Schweißen

nicht

Schweißen

• Belastung der Ventilgehäuse und des

Drosselelementes durch die Rohrleitungen

sind nicht zulässig.

6.5 Isolierung

Bei Isoliermaßnahmen dürfen die

Membranantriebe nicht isoliert werden.

VI.JA.H3.5B

© Danfoss | 2016.05 | 25

Page 26

Instructions PCVPQ

r

Stellgerät PCV - VFQ 21

Steuerleitungen bei Montage verlegen

r

Pilotregler AVP-FPilotregler AVP-F

6 Montage

6.6 Einbauschema

Stellgerät PCV - VFQ 21

Einbau im Rücklauf

Drosselventil

Drosselelement

Drosselventil

(nur bei DN 150 - 250)

Hilfsgesteuerter Regle

PCVPQ

Einbau im Vorlauf

Pilotregler AVP

Drosselventil

Drosselelement

Drosselventil

(nur bei DN 150 - 250)

Hilfsgesteuerter Regle

PCVPQ

Pilotregler AVP

26 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 27

Instructions PCVPQ

CU-Rohr Ø 6 × 1

DN 25: Rohr Ø 33,7 × 3,2

Werkstoff:

(kein Lieferbestandteil)

6 Montage

6.7 Montagezeichnung, Abmessungen

Bei Montage verlegen.

zum Rücklauf

zum Vorlauf

Steuerleitungen wegen

Verschmutzung seitlich

anbringen

Cu - Rohr

Ø 10 × 1

Bei Montage verlegen.

DN 100-125

ST 35.8

Pilotregler AVP

Pilotregler AVP-F

DN 25 SW 50

Drosselelement

VI.JA.H3.5B

© Danfoss | 2016.05 | 27

Page 28

Instructions PCVPQ

CU-Rohr Ø 6 × 1

anbringen

DN 40: Rohr

Werkstoff:

(kein Lieferbestandteil)

zum Rücklauf

zum Vorlauf

Steuerleitungen wegen

Verschmutzung seitlich

Bei Montage verlegen.

Cu - Rohr

Ø 10 × 1

Bei Montage verlegen.

ST 35.8

DN 150-250

Abmessungen

Ø 48.3 x 3.2

Nennweite DN 100 125 150 200 250

L1

350 400 480 600 730

H1 530 530 619 647 697

H2 - 245 300 325

D2 263 380

mm

D1 150 250 320 385 500

B 200 210 310 336 412

A ≥ 290 320 350 410

28 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 29

Instructions PCVPQ

p2 p1

5

4

3

867

7 Inbetriebnahme

7.1 E rforderliche(r) statischer Druck,

Druckdifferenz

Für die Funktion ist eine Mindestdruckdifferenz

erforderlich: p1 - p2 ≥ 0,5 bar

Der statische Druck p1 vor dem Regler darf

1, 5 bar (Überdruck) nicht unterschreiten.

Nichtbeachtung kann zu Kavitation und Schäden

im Drosselement 1 führen.

1

7.2 Dichtheits-, Druckprüfung

Um unzulässig hohe Drücke

an den Membranantrieben

zu vermeiden muß vor

Druckprüfungen folgendes

beachtet werden:

Antrieb Stellgerät:

Der zulässige Betriebsüberdruck im Antrieb 2

beträgt 25 bar 1). Bei höherem Prüfdruck müssen:

• Die Steuerleitungen 3 am Antrieb entfernt

und die Anschlüsse mit einem Stopfen

verschlossen werden.

• Vor einer Dichtheitsprüfung bzw.

Druckprüfung nach Abschnitt 7.3 vorgehen

7.3 Füllung der Anlage

Hinweis:

Der Stellgerät 4 ist drucklos geschlossen und öffnet

erst bei definiertem Durchfluss im Bypass.

Die Pilotregler 5 sind drucklos geöffnet.

Vorgehensweise

1. Eventuell in den Steuerleitungen vorhandene

Absperrventile 6 öffnen.

2. Armaturen 7 in der Anlage öffnen.

3. Die Absperrarmaturen im Vorlauf 8 und im

Rücklauf 9 langsam öffnen.

9

7.4 Inbetriebnahme

Bei der Inbetriebnahme der gefüllten Anlage

ist die gleiche Reihenfolge beim Öffnen

der Armaturen zu beachten wie unter 7.3

beschrieben.

7.5 Ausserbetriebnahme

Bei der Ausserbetriebnahme zuerst die

Absperrarmaturen im Vorlauf und dann im

Rücklauf schließen.

VI.JA.H3.5B

2

1)

Voraussetzung: gleicher Druck auf beiden Seiten der

Membrane. B ei einseitiger Druckbe lastung ist in der

(+)-Membrankammer ei n max. Überdruck gege nüber der

(-)-Membrankam mer von 1 bar zulässig.

© Danfoss | 2016.05 | 29

Page 30

Instructions PCVPQ

erforderlicher

Volumenstrom

Umdrehungen Einstelldrossel

ablesen

7 Inbetriebnahme

7.6 Volumenstromeinstellung

Die Einstellung des Sollwertes für die

Volumenstrombegrenzung kann mit Hilfe von

Einstellkennlinien (s. Abschnitt 7.7) oder mittels

eines Wärmezählers erfolgen (siehe Seite 13).

Einstellungen mit Einstellkennlinien

Die Einstellung bei außer Betrieb genommener

Anlage durchführen.

Vorgehensweise

1. Die Abdeckhaube 1 abschrauben.

2

2. Die Kontermutter 2 lösen.

4. Die Einstelldrossel um diese Anzahl

Umdrehungen nach links drehen.

5. Über ein Volumenstrommeßgerät kann der

eingestellte Volumenstrom überprüft werden,

ggf. die Einstellung nachjustieren.

Auf ausreichenden Differenzdruck in der

Anlage achten.

6. Die Kontermutter anziehen. Die Stellung der

Einstelldrossel hierbei nicht verändern.

3

2. Die Einstelldrossel 3 bis zum Anschlag

eindrehen.

3

3. Diagramm auswählen, (siehe Abschnitt 7.7

Einstellkennlinien)

Wirkdruck Δpb beachten: 0,2 oder 0,5 bar

siehe Typenschild auf dem Antrieb AVP-F

7. Die Hutmutter 1 aufschrauben.

8. Die Hutmutter kann plombiert werden.

30 | © Danfoss | 2016.05

Die Volumenstromeinstellung ist abgeschlossen,

jetzt die Einstellung des Differenzdruckes

durchführen, siehe Abschnitt 7.8.

VI.JA.H3.5B

Page 31

Instructions PCVPQ

DN 100kvs 125/DN 125kvs 160/DN 150kvs 320

14

Umdrehungen Einstelldrossel

Volumenstrom (m

3

/h)

DN 100kvs 125/DN 125kvs 160/DN 150kvs 320

14

Volumenstrom (m

3

/h)

DN 200kvs 450/DN 250kvs 630

geforderte Volumenstrom

DN 200kvs 450/DN 250kvs 630

89

Umdrehungen Einstelldrossel

Volumenstrom (m

3

/h)

7 Inbetriebnahme

140

120

100

7.7 Einstellkennlinien

p

=0,2

b

DN150

80

60

40

DN100/125

20

0

0123456789 10 11 12 13

220

200

p

=0,5

b

180

160

140

120

100

80

60

40

20

0

0123456789 10 11 12 13

DN150

DN100/125

Umdrehungen Einstelldrossel

200

180

160

140

/h)

3

120

100

Volumenstrom (m

begrenzung 100 m³/h

DN 250

DN 200

80

60

40

20

0

01234567 8910

p

=0,2

b

Umdrehungen Einstelldrossel

Beispiel

Ventil DN 200

erforderliche

Umdrehungen

Einstelldrossel: 4

260

240

220

200

180

160

140

120

100

80

60

40

20

0

DN 250

DN 200

p

=0,5

b

012345 67

VI.JA.H3.5B

© Danfoss | 2016.05 | 31

Page 32

Instructions PCVPQ

P2

2

3

7 Inbetriebnahme

Einstellungen mit Volumenstrommessgerät

In diesem Fall ist es sinnvoll zuerst den

Differenzdruck (siehe Abschnitt 7.8) einzustellen.

Ein zu niedriger Differenzdruck kann dazu

führen, dass der erforderliche Volumenstrom

nicht erreicht wird.

Vorgehensweise

1. Vor der Volumenstromeinstellung

Inbetriebnahme der Anlage nach Abschnitt

7.4 durchführen.

2. Absperrarmaturen 1 und Regelarmaturen

2 müssen ganz geöffnet sein, so dass keine

Volumenstrombegrenzung über eine Armatur

erfolgt.

Die Einstellung kann auch über einen Bypass

3 erfolgen.

P1

1

5. Einstellung der Volumenstrombegrenzung

durch drehen der Einstelldrossel 6:

Rechtsdrehen 7: Volumenstrom reduzieren

7

6

Linksdrehen 8: Volumenstrom erhöhen

8

PCVPQ

3. Die Abdeckhaube 4 abschrauben.

4

4. Die Kontermutter 5 lösen.

6. Die Volumenstromanzeige beachten.

7. Nach der Einstellung. Die Kontermutter

anziehen. Die Stellung der Einstelldrossel

hierbei nicht verändern.

8. Die Hutmutter aufschrauben.

9. Die Hutmutter klann plombiert werden.

5

32 | © Danfoss | 2016.05

Die Volumenstromeinstellung ist abgeschlossen.

VI.JA.H3.5B

Page 33

Instructions PCVPQ

P1

4

max

5

n

1

7 Inbetriebnahme

7.8 Differenzdruckeinstellung

Der Sollwert des Differenzdrucks ist an

dem Pilotregler AVP 1 einzustellen. Der

Sollwertbereich ist auf dem Typschild des

Antriebes angegeben.

1

Vorgehensweise

1. Vor der Differenzdruckeinstellung

Inbetriebnahme der Anlage nach Abschnitt

7.4 durchführen. Die Einstellung des

Differenzdruckes kann auch erfolgen, wenn

ein Bypass 2 geöffnet ist.

2. Den Volumenstrom an einer Armatur, über

welche der Differenzdruck zu regeln ist,

einstellen.

Einstellung z.B. an der Armatur 3 oder 4 oder

über einen Bypass 2 auf ca. 50 % des max.

Volumenstroms 5.

4. Die Druckanzeigen sind zu beachten.

5. Nach der Differenzdruckeinstellung ist bei

offener Anlage zu überprüfen, ob der max.

Volumenstrom erreicht wird. ggf. ist der

Differenzdruck zu erhöhen.

7.9 Plombierung

Die Sollwertsteller können plombiert werden.

7.10 Einstellung Drosselventil

Anzahl der Drosselventile:

DN100, 125: 1

DN150-250: 2 x

• Die Abdeckhaube 1 abschrauben.

3

Linksdrehen

Dämpfung

reduzieren

SW 5

Rechtsdrehe

Dämpfung

erhöhen

9

PCVPQ

2

P2

p

0 50% V

3. Rechtsdrehung:Sollwerterhöhen

• Standardeinstellung:

Die Ventilspindel durch Rechtsdrehung

mit Sechskantschlüssel SW5 bis zum

Anschlag eindrehen. Dann Ventilspindel

durch Linksdrehung ca. 10 Umdrehungen

herausschrauben.

• Erhöhung der Dämpfung z. B. erforderlich bei

Druckschwingungen. Die Ventilspindel durch

Rechtsdrehung hineinschrauben.

• Reduzierung der Dämpfung z.B. bei zu

träger Regelung. Die Ventilspindel durch

Linksdrehung herausschrauben.

Linksdrehung: Sollwert reduzieren

VI.JA.H3.5B

© Danfoss | 2016.05 | 33

Page 34

Instructions PCVPQ

7 Inbetriebnahme

7.11 Funktionsprüfung

Differenzdruck

Durch Öffnen und Schließen einer Armatur

in der zu regelnden Anlagenstrecke ist der

Differenzdruck über die Druckanzeigen zu

überprüfen.

Schwingt der zu regelnde Differenzdruck, so

sind die Drosselventile etwas zu schließen (s.

Abschnitt 7.9).

Bei Über- oder Unterschreitung den

Differenzdruck nach Abschnitt 7.7 nachstellen.

Volumenstrom

Bei vollständig geöffneter Anlage darf der

eingestellte Volumenstrom nicht überschritten

werden.

Bei Über- oder Unterschreitung die Einstellung

nach Abschnitt 7.5 überprüfen.

34 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 35

Instructions PCVPQ

8 Störungshinweise

Störung Mögliche Ursache Maßnahme

Drosselventile zu weit geöffnet Drosselventil etwas schließen siehe Abschnitt 7.10

1. Steuerleitungsanschlüsse an den Antrieben ca. 1 Umdrehung

Regler hält den

Volumenstrom bzw.

Differenzdruck nicht

konstant

Differenzdruck zu hoch

Volumenstrom zu

niedrig

1)

Austausch de r Innengarnitur bis DN 125 ist durch sachku ndige Personen möglic h. Ab DN 150 sollte der

Austausch durch de n Danfoss-Kundendienst e rfolgen.

Luft in den Antrieben

Steuerleitungen bzw.

Steuerleitungsanschlüsse verschmutzt oder verstopft

Pilotventil AVP, AVP-F schließt nicht:

Ventilsitz bz w. Kegel verschmutzt oder beschädigt

Stellventil VFQ 2 schließt nicht:

Ventilsitz bz w. Kegel verschmutzt oder beschädigt

Rollmembrane im Antrieb AVP, AVP-F (Pilotregler) defekt, d. h. Ventil

AVP schließt nicht

Ventilkegel des Pilotventils AVP öffnet nicht:

Ventilsitz bz w. Kegel verschmutzt oder beschädigt, Innengarnitur

verschmutzt

Ventilkegel des Stellventils VFQ 21 öffnet nicht:

Ventilsitz bz w. Kegel verschmutzt oder beschädigt, Innengarnitur

verschmutzt

Rollmembrane im Antrieb des Stellgerätes defekt, d. h. Ventil VFQ 21

öffnet nicht

lösen

2. Entlüften, Achtung Heisswaser!

(Steuerleitung bewegen bis Medium austritt)

3. Steuerleitungsanschlüsse wieder anziehen

1. Steuerleitungen demontieren

2. Steuerleitungen und Anschlüsse reinigen und Durchgang

überprüfen

1. Steuerleitungen abbauen

2. Antrieb und Innengarnitur demontieren Vorgehensweise siehe

Abschnitt 9.4

3. Sitz und Kegel reinigen

4. Bei Beschädigung Innengarnitur bzw. Ventil austauschen

1. Steuerleitungen abbauen

2. Antrieb und Innengarnitur demontieren 1)

Vorgehensweise siehe Abschnitt 9.2

3. Sitz und Kegel reinigen

4. Bei Beschädigung Innengarnitur bzw. Ventil austauschen

1. Steuerleitungen abbauen

2. Antrieb austauschen, siehe Abschnitt 9.3

1. Steuerleitungen abbauen

2. Antrieb und Innengarnitur demontieren Vorgehensweise siehe

Abschnitt 9.4

3. Sitz und Kegel reinigen

4. Bei Beschädigung Innengarnitur bzw. Ventil austauschen

1. Steuerleitungen abbauen

2. Antrieb und Innengarnitur demontieren 1)

Vorgehensweise siehe Abschnitt 9.1 und 9.2

3. Sitz und Kegel reinigen

4. Bei Beschädigung Innengarnitur bzw. Ventil austauschen

1. Steuerleitungen abbauen

2. Überwur fmutter SW 46 lösen und Antrieb abnehmen siehe auch

Abschnitt 9.1

3. Antrieb austauschen

VI.JA.H3.5B

© Danfoss | 2016.05 | 35

Page 36

Instructions PCVPQ

fetten

s

9 Austausch von

Ventil, Antrieb,

Innengarnituren

9.1 Demontage, Montage Antrieb Stellgerät

Hinweis:

Die Federn 1 im Antrieb sind vorgespannt.

Deshalb muss der Antrieb zur Demontage,

Montage hochgedrückt werden. Hierzu ist eine

2. Person erforderlich.

Stellgerät DN 100–125

3

SW 46

5

2

1

4

Vor der Montage Konus 5 überprüfen

5

Konu

1. Konus vor der Montage reinigen

2. O-Ringe auf Beschädigung überprüfen, bei

Beschädigung Konus austauschen (siehe

Ersatzteile)

3. Konus fetten mit HochleistungsArmaturenfett: z. B. BARRIERTA L55/3 HV

Montage

1. Antrieb am Ventil ansetzen und hochdrücken

2. Überwurfmutter 2 aufschrauben

3. Antrieb ausrichten, Position der

Steuerleitungsanschlüsse beachten

4. Überwurfmutter 1 anziehen, max.

Anzugsmoment 100 Nm

Ventilstange 3 und die Stange des Antriebs 4

sind nicht miteinander verschraubt.

Demontage

1. Steuerleitungen demontieren

2. Antrieb unten abstützen oder durch 2. Person

gegenhalten, da Federn 1 vorgespannt sind

3. Überwurfmutter 2 lösen

4. Antrieb abnehmen

36 | © Danfoss | 2016.05

VI.JA.H3.5B

Page 37

Instructions PCVPQ

9 Austausch von

Ventil, Antrieb,

Innengarnituren

Stellgerät DN 150–250

3

SW 46

1

4

Antrieb

nach links

drehen

die Stange des Antriebs 4 ist in die Ventilstange 3

eingeschraubt

Demontage

1. Steuerleitungen demontieren

2. Überwurfmutter 1 ganz lösen

Antrieb bleibt an der eingeschraubten

tange 4 hängen

Der Antrieb wiegt ca. 20

kg, zusätzlich ist internes

Federpaket vorgespannt. Vor

dem Herausschrauben gegen

herunterfallen sichern.

3. Durch drehen des Antriebs nach links die

Stange des Antriebs 4 aus der Ventilstange 3

herausschrauben

Montage

1. Antrieb am Ventil ansetzen und

hochdrücken um Federpaket im Antrieb

zusammenzudrücken (2. Person erforderlich)

2. Antrieb vorsichtig nach rechts drehen.

Dadurch die Stange des Antriebes in die

Ventilstange vorsichtig bis zum Anschlag

eindrehen.

danach unbedingt den

Antrieb um ca. 1 Umdrehung

zurückdrehen (nach links)

3. Antrieb ausrichten, Position der

Steuerleitungsanschlüsse beachten

4. Überwurfmutter 1 anziehen, Anzugsmoment

100 Nm SW

VI.JA.H3.5B

© Danfoss | 2016.05 | 37

Page 38

Instructions PCVPQ

2

3

1

5

6

9 Austausch von

Ventil, Antrieb,

Innengarnituren

9.2 Austausch der Innengarnitur

Ventil VFQ 21

Der Austausch der Innengarnitur bis DN 125 ist

durch sachkundige Personen möglich. Ab DN

150 sollte der Austausch durch den DanfossKundendienst erfolgen.

Innengarnitur ausbauen

Ventile DN 100–125

4

1. Antrieb 1 demontieren

(siehe Abschnitt 9.1)

2. Sechskantschrauben 2 herausschrauben

3. Ventilunterteil 3 abnehmen

4. Innengarnitur 4 herausnehmen

Vor dem Einbau

Dichtflächen 5 und Buchse 6 reinigen,

Dichtflächen mit Graphitfett fetten

Innengarnitur einbauen

Die Montage erfolgt in umgekehrter

Reihenfolge. Anzugsmoment der

Sechskantschrauben 2 :

38 | © Danfoss | 2016.05

DN Anzugsmoment Schlüsselweite

100 -125 180 Nm SW 30

VI.JA.H3.5B

Page 39

Instructions PCVPQ

2

9 Austausch von

Ventil, Antrieb,

Innengarnituren

9.3 Demontage, Montage Antrieb AVP, AVP-F

1

Demontage

1. Steuerleitungen demontieren

2. Überwurfmutter 1 lösen

3. Antrieb abnehmen

Montage

1. Antrieb am Ventil aufsetzen und ausrichten,

osition der Steuerleitungsanschlüsse

beachten

2. Überwurmutter 1 aufschrauben und

anziehen, Anzugsmoment 100 Nm

9.4 Austausch der Innengarnitur

Ventil AVP, AVP-F

AVP DN 25

2

Demontage

1. Antrieb abschrauben (siehe oben)

2. Innengarnitur 2 herausschrauben DN 25: mit

Rohrzange, Gummistreifen um Innengarnitur

wickeln DN 40: mit Schlüssel SW 55

3. Innengarnitur herausziehen

Montage

Die Montage erfolgt in umgekehrter

Reihenfolge. Nur mit niedrigem Anzugsmoment

anziehen, Abdichtung erfolgt mit O-Ringen.

VI.JA.H3.5B

© Danfoss | 2016.05 | 39

Page 40

Danf

already on order pro

All trademarks in this material are property of the respec

Instructions PCVPQ

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

40 | © Danfoss | DHS-SRMT/SI | 2016.05

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

73696690/VI.JA.H3.5B

Loading...

Loading...