Data sheet

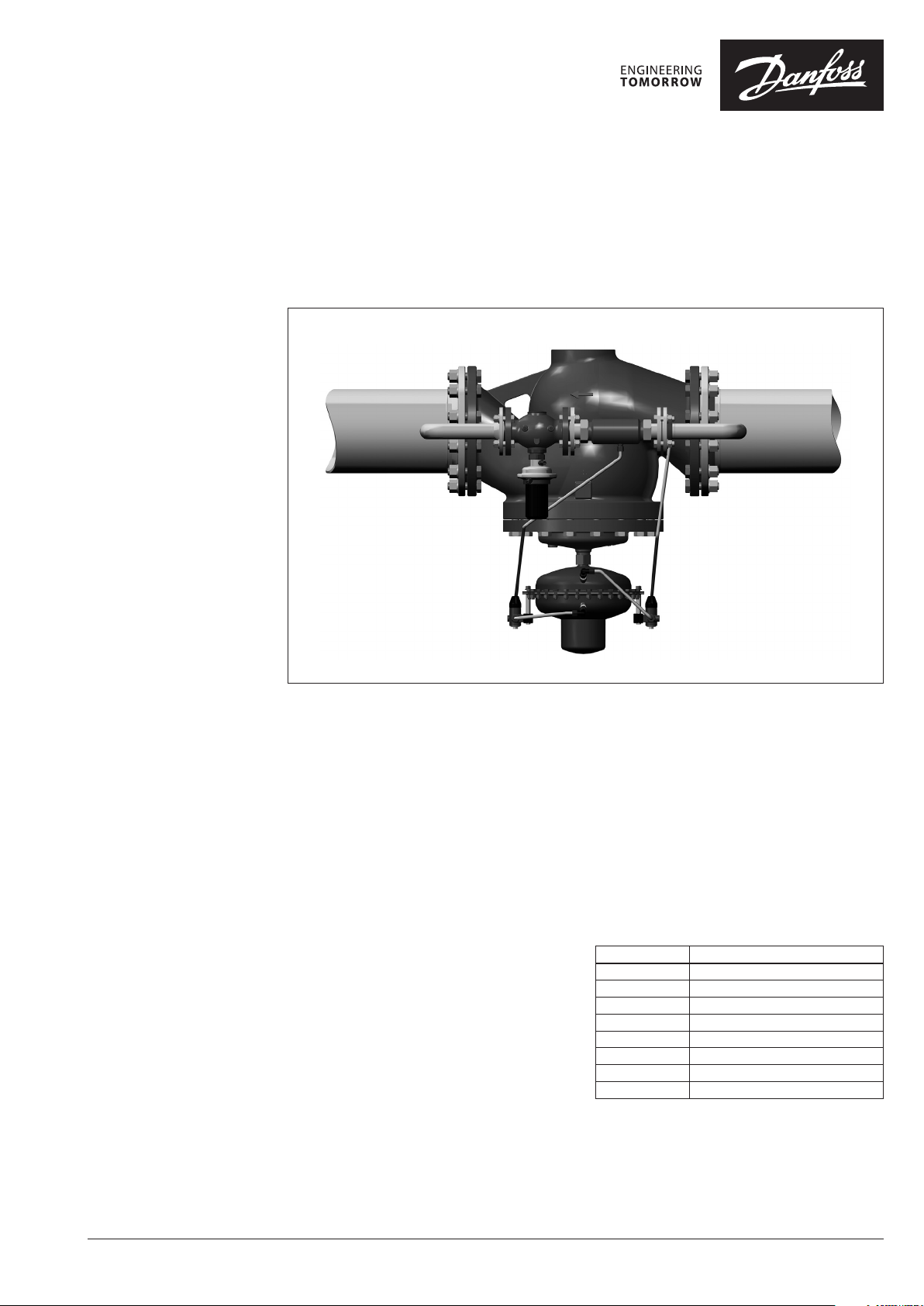

Pilot-controlled differential pressure controller (PN 16, 25, 40)

PCVP - flow and return mounting, adjustable setting

Description

Pilot-controlled differential pressure controller is

a self-acting differential pressure

controller primarily for use in district heating,

district cooling or in industrial systems as well. It

can be flow and return mounted in applications

with and without heat exchanger like large

substations and distribution stations.

The controller consist of main controller, installed

in main pipe, and pilot controller and with a

throttling element, both installed in bypass.

Setting is done on pilot controler.

Throttle valve data can be found on page 10.

Main data1) :

• DN 50-250

• kVS 32-630 m3/h

• PN 16, 25, 40

2)

3)

• Temperature:

- Circulation water/glycolic water up to 30%:

2 … 200°C

• Connections:

- Pilot controller:

ext. thread (weld-on tailpieces) or flange

- Main valve: flange

1)

for details see Technica l data and Ordering sections

2)

smaller DN on re quest

3)

PN 40 on special re quest

Features:

- Differential pressure controller

- Extremely high control ratio (see Tab.1) as a

result of low pilot controller min. flow rate

(kVS value) and high flow rate (kVS) of the main

valve

- Small overall dimensions comparing to

standard design (especially height)

- Higher valve capacities for DN 150-250

comparing to standard design

- High control stability

- Smooth operation differential pressure

controller

Tab. 1

DN Min. control rat io

50 100 : 1

65 140 : 1

80 220 : 1

100 300 : 1

125 400 : 1

150 400 : 1

200 550 : 1

250 750 : 1

© Danfoss | 2018.04 VD.JA.N3.02 | 1

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

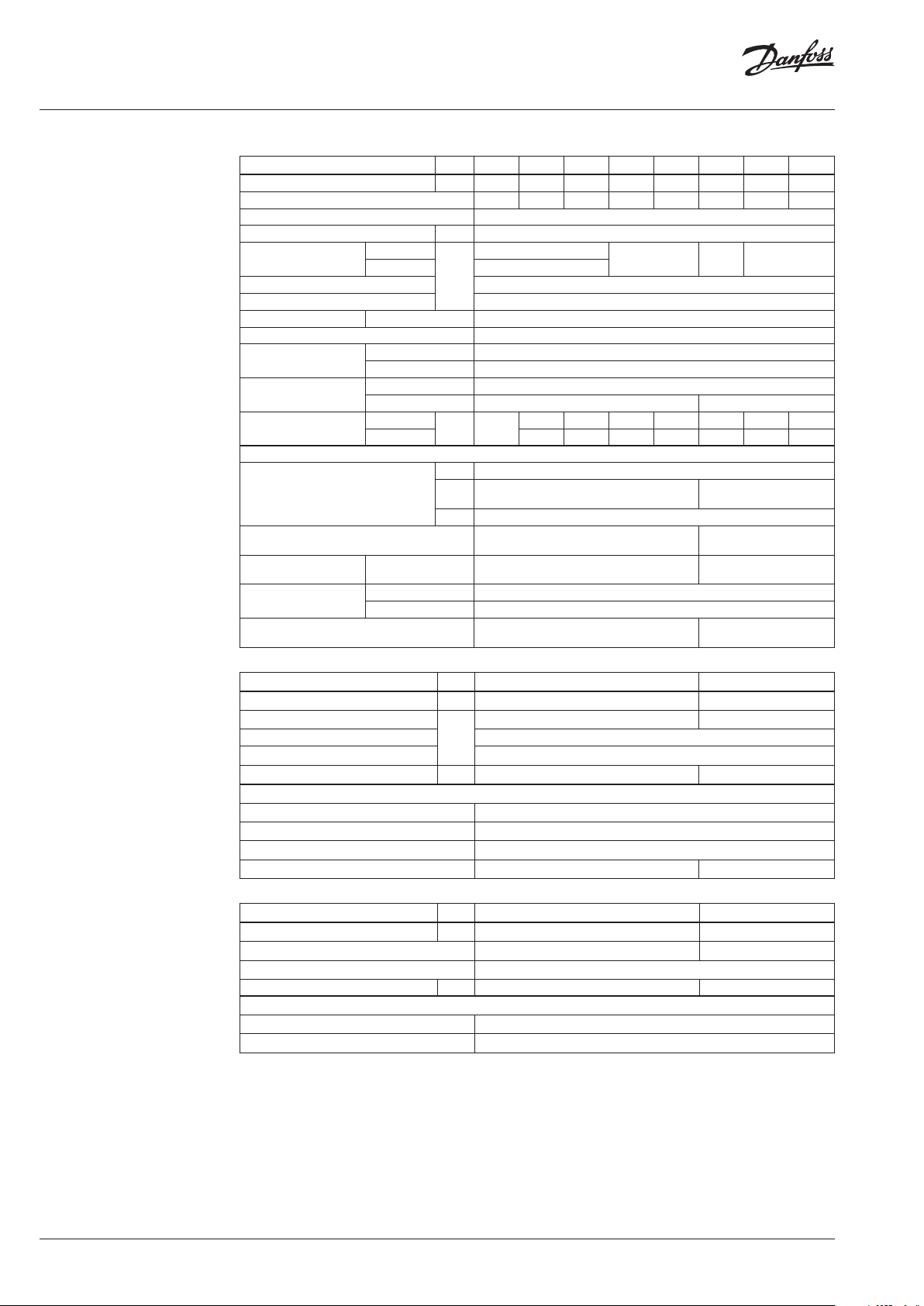

Technical Data Main valve

Nominal diameter DN 50 65 80 100 125 15 0 200 250

kVS value m3/h 32 50 80 125 160 320 450 630

Cavitation factor z 0.5 0.5 0.45 0.4 0.35 0.3 0.2 0.2

2)

On request

3)

Stainless steel M . No. 1.4571

4)

EPDM

1)

Defined by pilot controller

Leakage acc. to standard IEC 534 ≤ 0.05% of k

Nominal pressure PN 16, 25, 40

Max. differential pressure

Min. differential pressure 0.5

PN 16

PN 25, 40 20

bar

16

Min. static pressure 1.5

Medium VF G 2(1) Circulation water/glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature

Connections

Weight

VFG 21 PN 16, 25, 40 2 … 150 °C

VFG 2 PN 16, 25, 40 2 … 200 °C

Main controller Flange

Pilot controller Ext. thread (weld- on tailpieces) or flange Flange

PN 16 /25

PN 40 30 32.5 60.5 69 141 253 333

kg 18

27. 5 30 58 68 115 185 323

Materials

PN 16 Grey cast iron EN-GJL-250 (GG-25)

Valve body

PN 25

Ductile cast iron EN-GJS -400-18-LT

(GGG-40.3)

PN 40 Cast steel EN-GP-240-GH (GS -C 25)

Valve seat Stainless steel M. No. 1.4021

Valve cone VF G 2(1) Stainless steel M. No. 1.4404

Sealing

Pressure relieve system Bellows

VFG 21 EPDM

VFG 2 Metal

3)

Main actuator

For main va lve DN 50 - 125 150 - 250

Actuator size cm

Max. operational pressure

Flow restrictor differential pressure p

Diff. pressure setting ranges

1)

Weight kg 11 24

Materials

Housing Stainless steel M. No. 1.0338

Control diaphragm EPDM

Impulse tube Stainless steel tube Ø10 × 0.8 mm

Nr. of throttle valves (mounted on impulse tubes) 1 2

2

250 630

25 16 , 25

1)

bar

b

0.2-1.0/0.3-2.0/1-5/3-12

Trottling element

For main va lve DN 50 - 125 150 - 250

Size of throttling element DN 25 40

Connections Welded end Flange

Max. operational pressure 25

Weight kg 3.2 6.6

Materials

Body material Red bronze, M. No. 2.1090

Impulse tube Stainless steel tube Ø10 × 0.8 mm

VS

15 12 10

2)

0.2/0.5

Cast steel EN-GP-240-GH

(GS-C 25)

2)

Stainless steel M. No.

1.4 313

Stainless steel M. No.

1.4021

Diaphragm4) (T

Bellows3) (T

max

max

150 °C )

300 °C)

2 | VD.JA.N3.02 © Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

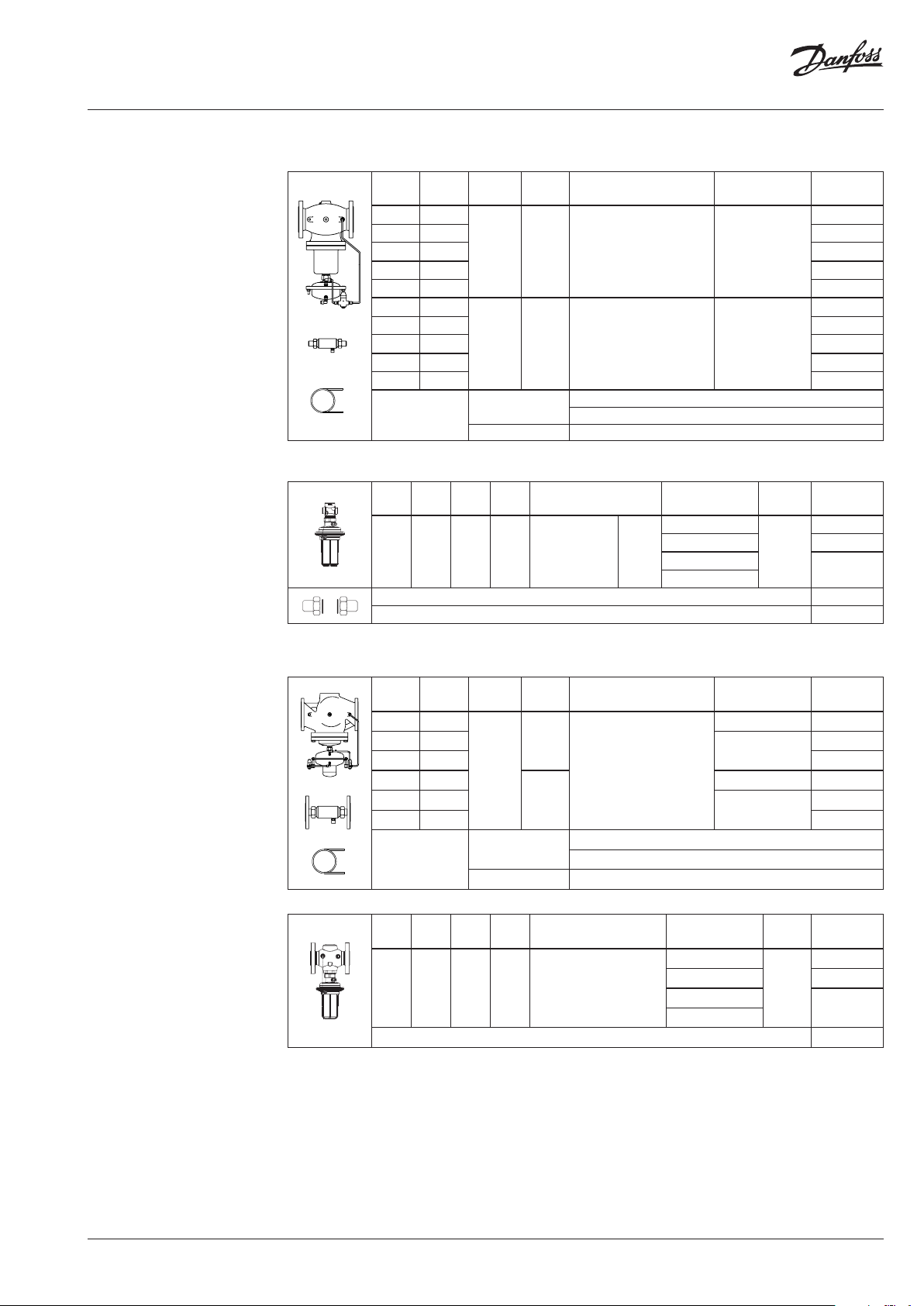

Ordering

Example 1:

Pilot-controlled differential pressure

controller; DN 100; kVS 125; PN 16;

setting range 0.2-1.0 bar; T

flange;

- 1× PCV-VFG 21 DN 100

Code No.: 0 03G157 3

- 1× AVP DN 25

Code No.: 0 03H 6319

- 1× Weld-on tailpieces DN 25

Code No.: 0 03H6910

- 1×

Mounting set for Impulse tube

Code No.: 0 03G159 9

1)

Contains accessories fo r remounting

the impulse tub e on the pilot controller

from internal co nnection (factory

delivered) to e xternal connectio n.

max

150 °C;

DN 50-125

PCV-VFG 21 - Main controller, throttling element, throttle valve, impulse tubes

DN 25

DN

(mm)

50 32

65 50 003G155 8

80 80 003G1559

100 125 003G1573

125 160 00 3G1574

50 32

65 50 003 G1568

80 80 003G15 69

100 125 0 03G152 3

125 160 003 G1524

Impulse tube

k

VS

(m3/h)

T

(°C)

max

PN Connection

150 16 Flange EN 1092-2 15

150 25 Flange EN 1092-2 15

Copper

Ø 6 × 1 × 3000 mm

Ø 10 × 1 × 1500 mm

Stainless steel Ø 10 × 0.8 × 1500 mm

Pilot controller AVP

DN

k

T

VS

max

(mm)

(m3/h)

PN Connection

(°C)

Cylindr. ext.

25 8.0 150 25

thread acc. to

DIN ISO 228/1

Weld-on tailpieces DN 25 003 H6910

Mounting set for impulse tube

1)

G 1¼ A

Δp setting range

(bar)

0. 2-1.0

0.3-2.0 003H6329

1-5

3-12

Δp

(bar)

max

Δp

(bar)

Code No.

003G1626

003G6707

max

Code No.

003 H6319

20

on request

003G1599

1) Contains accessories for remo unting

the impulse tub e on the pilot controller

from internal co nnection (factory

delivered) to e xternal connectio n.

DN 150-250

PCV-VFG 21 - Main controller, throttling element, throttle valves, impulse tubes

DN 40

DN

(mm)

150 320

200 450

250 630 003 G1507

150 320

200 450

250 630 003 G1527

Impulse tube

k

(m3/h)

T

VS

(°C)

max

PN Connection

16

150

25

Copper

Ø 6 × 1 × 3000 mm

Ø 10 × 1 × 1500 mm

Stainless steel Ø 10 × 0.8 × 1500 mm

Flange EN 1092-2

AVP

DN

k

T

VS

max

(mm)

(m3/h)

PN Connection

(°C)

40 20 150 25 Flange EN 1092-2

Mounting set for Impulse tube

1)

Δp setting range

(bar)

0. 2-1.0

0.3-2.0 003H6379

1-5

3-12

Δp

(bar)

max

Code No.

12 00 3G1505

10

003G1506

12 003G15 25

(bar)

max

003G152 6

Code No.

10

Δp

003H6373

16

on request

003G1599

VD.JA.N3.02 | 3© Danfoss | 2018.04

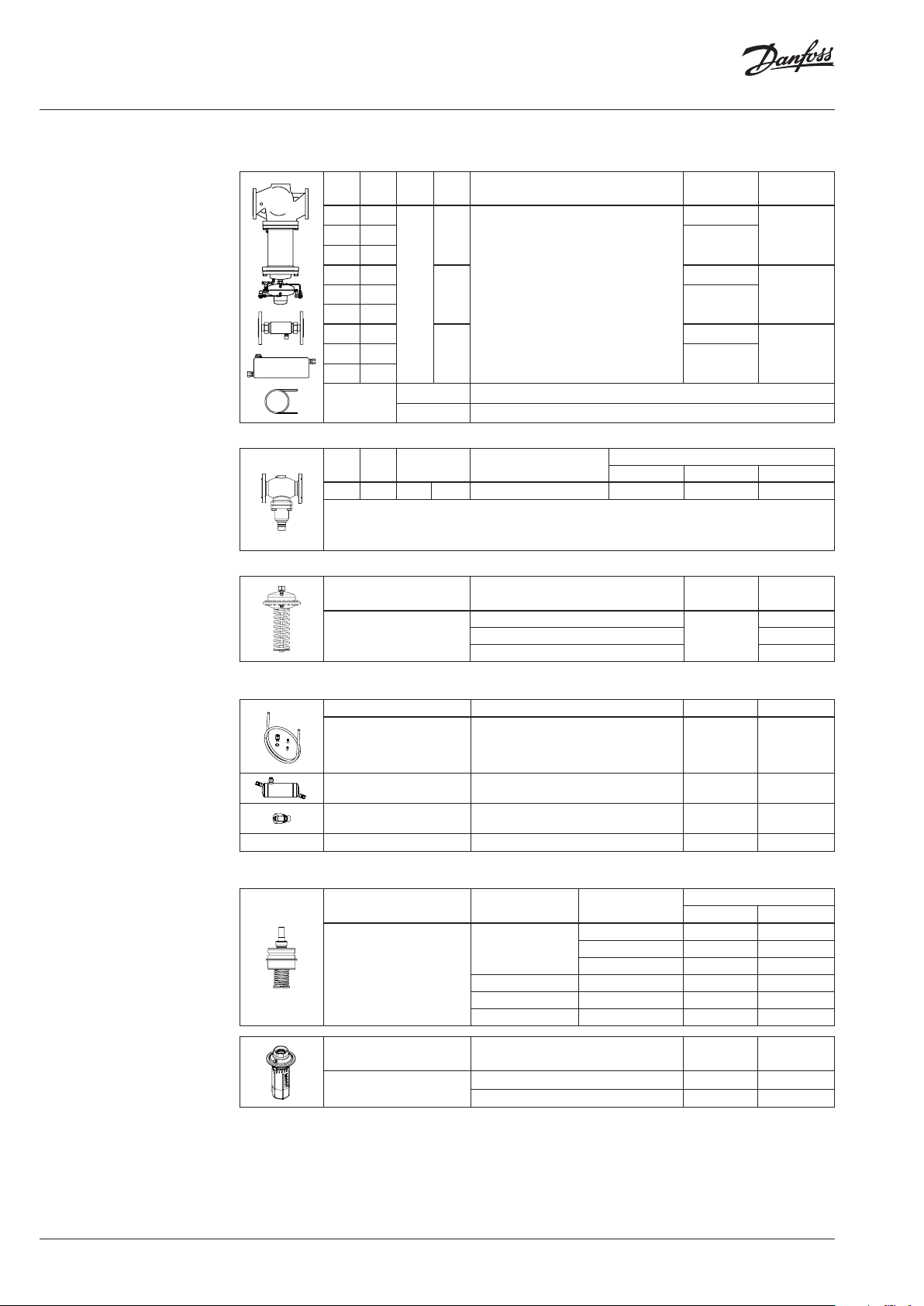

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Ordering (cont inuous)

Example 2:

Pilot-controlled differential pressure

controller; DN 150; kVS 320; PN 16;

setting range 0.2-1.0 bar; T

flange;

- 1× PCV-VFG 21 DN 150

Code No.: 003G15 05

- 1× AVP DN 40

Code No.: 0 03H6373

- 1×

Mounting set for impulse tube

Code No.: 0 03G159 9

1)

At temperature s above 150 °C only with

seal pots (see Accesso ries)

max

150 °C;

DN 150-250

PCV-VFG 2 - Main controller, throttling element, throtlle valves, seal pots, impulse tubes

DN

k

T

VS

max

(mm)

(m3/h)

PN Connection

(°C)

150 320

200 450

16

250 630

150 320

25

200 450

DN 40

3.0 l (2 ×)

250 630

150 320

250 630

Impulse tube

200

40

Copper Ø 10 × 1 × 1500 mm

Stainless steel Ø 10 × 0.8 × 1500 mm

Flange EN 1092-2

VFG 2 Valves (metallic sealing cone)

DN

(mm)

k

(m3/h)

T

VS

(°C)

max.

Connections

PN 16 PN 25 PN 40

40 20 150 2001)Flanges acc. to EN 1092-1 065B2392 065B2405 06 5B2415

AFP / AFP-9 Actuators

Typ e

AFP

∆p setting range

(bar)

0.15 -1.5

0.1-0.7 00 3G1017

0.05-0.35 00 3G1018

Δp

(bar)

max

Code No.

12

10

on request

12

10

on request

12

10

on request200 450

Code No.

for DN Code No.

003 G1016

15-2 50

1)

Seal pot has to be us ed on impulse

tubes always w hen T

2)

Consist of a nipple , compression ring

and nut

3)

Impulse tube s on T>150 °C or PN> PN 16

≥ 150 °C

max

should be of stai nless steel

Accessories

Type designation Description Connections Code No.

Impulse tube set AF

Seal pot V1

Compression fitting

Throttle valve-PCV Regulating and shut-off device - 065Z1502

Service kits AVP

Type designation

Valve insert

Type designation

Actuator with adjustable

handle (AVP)

- 1× Copper tube Ø10 × 1 × 1500 mm

3)

- 1 × compression fitting for imp. tub e

connection to pipe (G ⁄)

- 003G1391

- 2 × socket

1)

2)

Capacit y 1 liter; with compression fittings

for imp. tube Ø10

For impulse tube Ø10 connections to

controller

DN

(mm)

k

VS

(m3/h)

- 003G1392

G ⁄ 003G1468

Code No.

AVP return AVP flow

1.6 003H6863 003H6871

15

2.5 003H6864 003H6872

4.0 003H6865 003H6873

20 6.3 003H6866 003 H6874

25 8 003H6867 003H6 875

32 / 40 / 50 12.5 / 20 / 25 003H6868 003H 6876

Δp setting range

(bar)

AVP return AVP flow

0. 2-1.0 003H6829 003H6834

0.3-2.0 003H6830 003H6835

4 | VD.JA.N3.02 © Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Ordering (cont inuous)

Function

Service kits AFP

Type designation

Valve insert

Stuffing cone (with EPDM O-rings) 003G1464

(mm)

100 125

125 160

150 280 065B2964 065B2966

250 400 065B2965 -

The pilot valve maintains the differential pressure

over selected part of system/application. By this

action also flow through a bypass changes and

therefore (-p) at the throttling element.

Pressure changes from inlet pipe (+p) and from

throttling element (-p) are being transferred

through the impulse tubes to the main actuator

chambers and act on control diaphragm

In case of small flow rates the main controller is

closed and control is taken by the pilot controller

only. With increasing the flow rate, a negative

pressure is built in the throttling element.

This partial vacuum acts on the main actuator

diaphragm and causes the main controller to

open.

DN

15 4.0 065B2796 065B2790

20 6.3 065B2797 065B2791

25 8

32 16

40 20

50 32

65 50

80 80

k

VS

(m3/h)

Code No.

for VFG 2 for VFG 21

065B2798 065B2792

065B2799 065B2793

065B2800 065B2794

065B2801 0 65B2795

Main valve

⊕ p

◯ p

−

Throttling

element

Throttle valve

Bypass

Pilot controller

Main controller

Main actuator

Installation positions

Both main and pilot controllers have to be

installed in horizontal pipes only, with a pressure

actuator oriented downwards.

VD.JA.N3.02 | 5© Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Installation positions

(cont inuous)

Installation in the return pipe T

Main controller

Trottling

element

Pilot controller

Installation in the supply pipe

Main controller

Trottling

element

Pilot controller

max

T

max

= 150 °C

= 200 °C

Pressure temperature

diagram

Working area is below P-T line

and it ends at T

for each valve

max

PN 25

PN 16

EN-GJS- 400

(GGG-40.3)

EN -GJL-2 50

(GG -25)

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-1)

6 | VD.JA.N3.02 © Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Dimensions Impulse tubes (pos.1, 2, 3) are part of the delivery.

Their shape depends on the controller type. In

case of high temperatures (T

have to be installed. For details see relevant

> 150) seal pots

max

Instructions.

T

150 DN 50-250

max

⑤

Location of conn ection

depends of con troller type

①

②

The components shown with dashed lines are

NOT part of the delivery. The pipes (pos. 5) must

be welded during mounting.

L

2

H

1

H

③

D

DN 50 65 80 10 0 125 15 0 200 250

L

H

1

H

2

D 263 263 263 263 263 380 380 380

230 290 310 350 400 480 600 730

390 42 5 425 530 530 619 647 697

mm

82 95 95 12 5 125 17 9 237 257

VD.JA.N3.02 | 7© Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Dimensions (cont inuous)

T

200 DN 150-250

max

Location of conn ection

depends of con troller type

⑤

④

①

②

L

2

H

1

H

③

DN 15 0 200 250

L

H

2

H

4

D 380 380 380

480 600 730

169 234 254

mm

916 1162 14 94

D

Impulse

tubes

①

②

③

④

T

max

(200 °C)

Cu Ø 6 × 1

SS Ø 10 × 0.8

Cu Ø 10 × 1

SS Ø 6 × 1

8 | VD.JA.N3.02 © Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

Dimensions (cont inuous)

T

150 °C DN 50-125

max

T

150°C DN 150-250

max

①

160

244

ca. 1200

DN 50 65 80 10 0 12 5

A

mm

290 290 290 290 290

1

D

A

75

159

B

A

Pipes Pos. 1:

DN 25: Pipes Ø 33.7 × 2.6

DN 40: Pipes 48.3 × 3.2

min 300

①

290

DN 150 200 250

D

1

A 320 350 410

B 310 336 412

320 385 500

mm

200

ca. 1200

min 300

VD.JA.N3.02 | 9© Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

6

20

(1 revolution of spindle equals to 1 mm stroke)

Flow [l/min]

Throttle valve

Flow diagram

Throttle valve is regulating and shut-off device,

which is / are installed on the impulse tubes

connected to main PCV actuator. Number of

used throttle valves can be seen in table for Main

actuator in Technical Data section.

Function of throttle valve is to control flow

speed through impulse tube and consequently

influence on PCV’s reaction time. Influence

on reaction time is not completly defined and

strongly depends on application conditions

and could significantly vary from application to

application.

In general:

- by opening of the valve (clockwise) PCV’s

reaction time increases

- by valve closing (counterclockwise) PCV’s

reaction time decreases

In case valve is completly closed it has function

as shut-off valve.

Throttle valve is delivered from factory in

completly open position.

Main data:

• DN 4

• used for Ø10 mm impulse tube

5

4

3

2

1

0

0 2 4 6 8 10 12 14 16 18

Stroke [mm] = no. of revolution

10 | VD.JA.N3.02 © Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

VD.JA.N3.02 | 11© Danfoss | 2018.04

Data sheet PCVP - Pilot-controlled differential pressure controller (PN 16, 25, 40)

© Danfoss | DHS-SRMT/SI | 2018.0412 | VD.JA.N3.02

Loading...

Loading...