Optyma™ Plus

OP-LPQM, OP-MPXM

Name plate

A

OP-MPXM034MLP00G

114X4261

B

C

Application MBP

D

Refrigerant (1) R404A R507 R448A/R449A

R407A/R407F/R452A

E

M.W.P. HP (1) 28 bar

M.W.P. LP (1) 7 bar

F

Voltage 230 V ~ 1N ~ 50Hz

LRA 60 A MCC 19 A

OIL INSIDE POE 46

G

Serial No. 123456CG2816

EAN No.

xxxxxxxxxxxxxx

A: Model

B: Code number

C: Application, Protection

D: Refrigerant

E: Housing Service Pressure (Maximum

working pressure)

F: Supply voltage, Locked Rotor Ampere,

Maximum Current Consumption

G: Serial Number and bar code

MADE IN INDIA

IP 54

(2) R134a

R513A

(2) 23 bar

(2) 5 bar

Danfoss A/S, 6430 Nordborg, Denmark

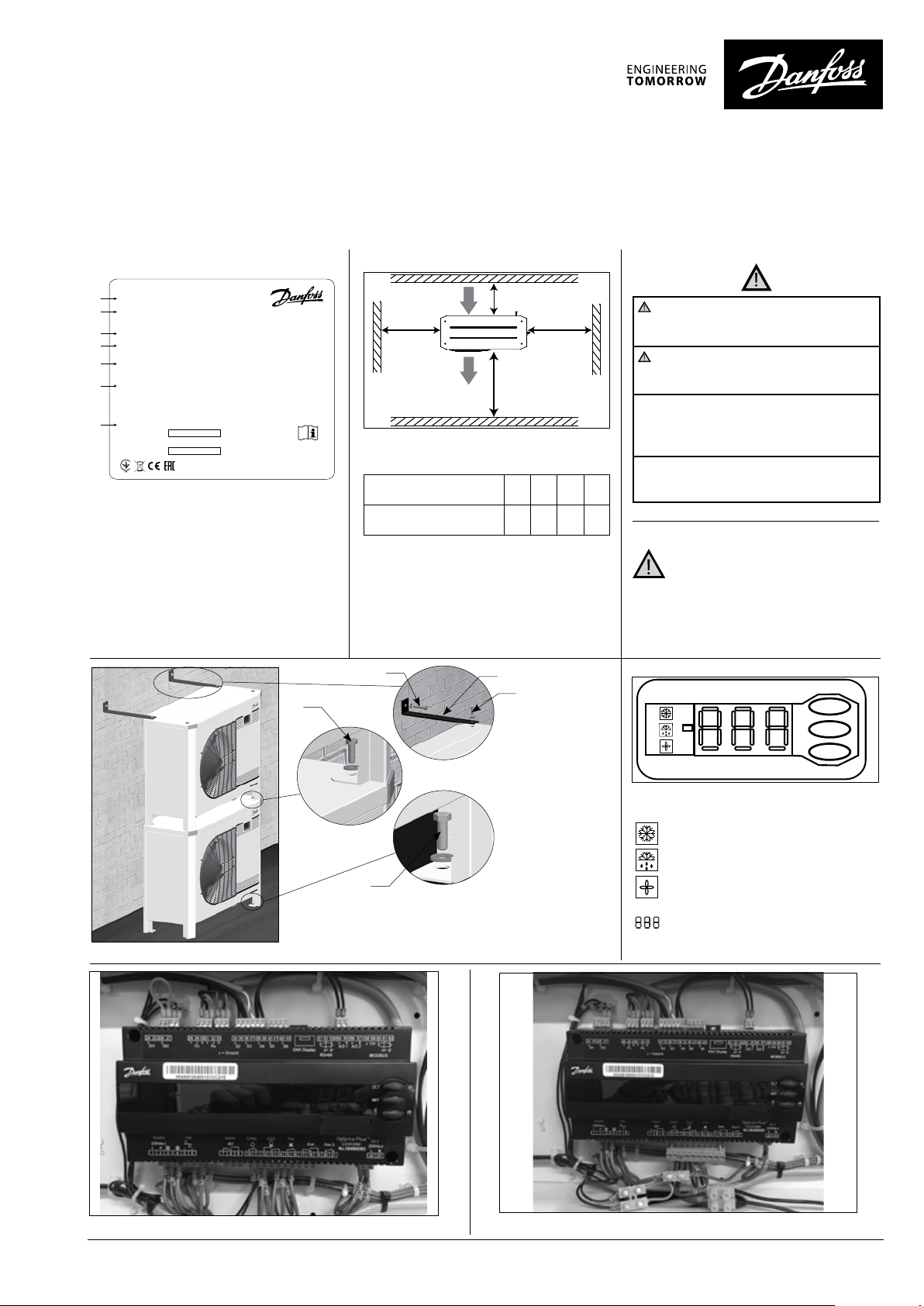

Picture 1 : Minimum mounting distances

Q: Air in R: Air out

118UXXXXXX

(Code n° 114X34-- or 114X44--)

Unit

Housing 4

Q

W

ZY

R

X

The condensing unit must only be used for

its designed purpose(s) and within its scope of

application.

Under all circumstances, the EN378 (or

other applicable local safety regulation)

requirements must be fulfilled.

The condensing unit is delivered under nitrogen gas pressure (1 bar) and hence it cannot

be connected as it is; refer to the «installation»

section for further details.

The condensing unit must be handled with cau-

W

[mm]X [mm]Y [mm]Z [mm]

250 900 700 700

tion in the vertical position (maximum offset

from the vertical : 15°)

Installation and servicing of the condensing

units by qualified personnel only.

Follow these instructions and sound

refrigeration engineering practice relating to

installation, commissioning, maintenance and

service.

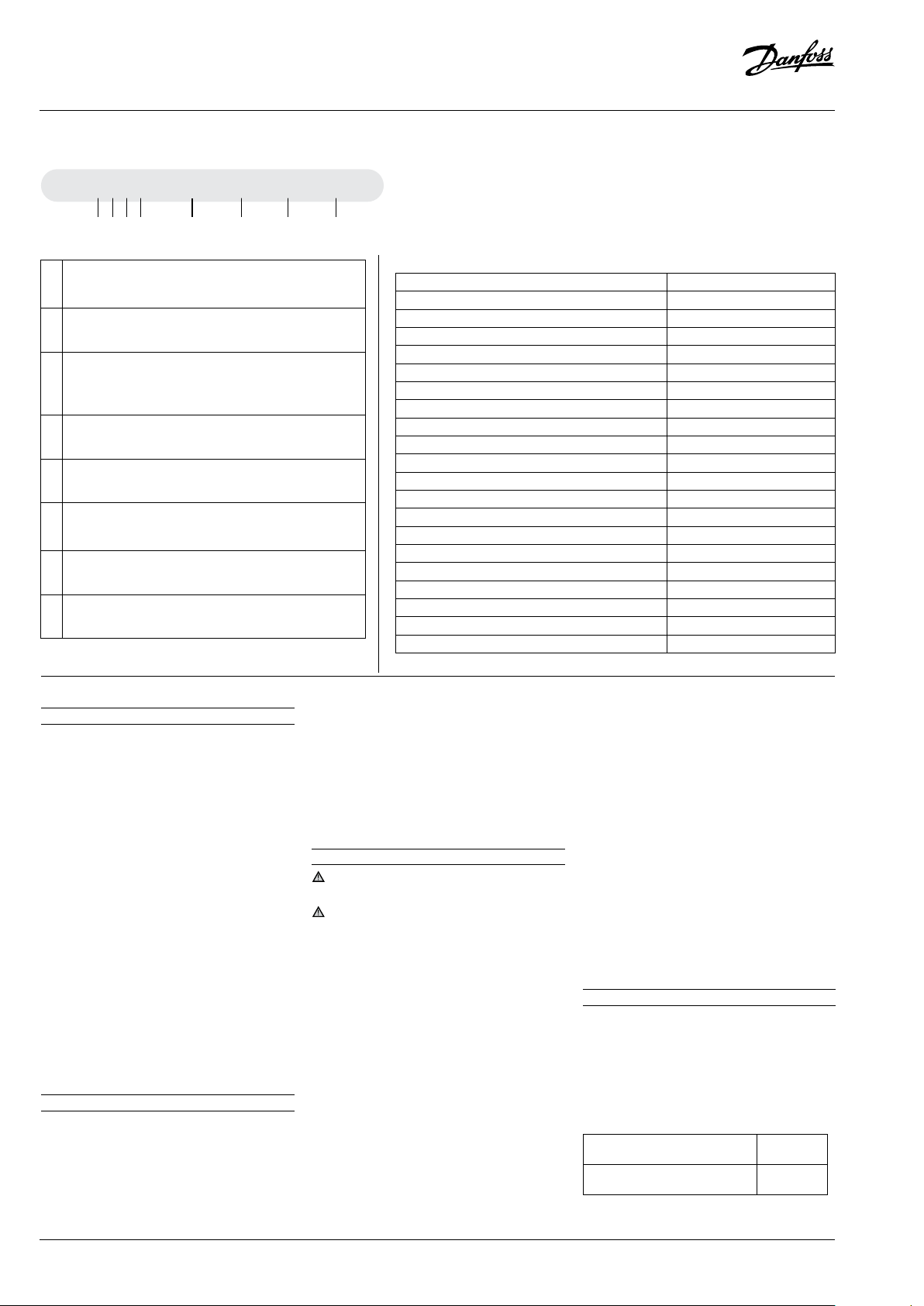

Picture 2 : Stacked mounting

V

T

U

U

V

T: Mounting brackets for stacked mounting (not supplied)

U: M8 bolts for stacked mounting (supplied)

V: Mounting bolts (not supplied)

Picture 3 : Electronic controller display

Compressor running

Crankcase heater on

Fan running

Temperature value for suction pressure.

Push lower button to switch to temperature value for condensing pressure

Picture 4 : Normal wiring Picture 5 : Temporary wiring

118A2221B - AN363632996019en-ZA0102 | 1© Danfoss | Climate Solutions | 2021.10

Instructions

Designation system for the Optyma™ Plus range

OP - MPXM 034 ML P06 G

1 2 3 4 5 6 7 8

1 Application

M = MBP

L = LBP

2 Package

Condensing unit family: P = Optyma™ Plus

3 Refrigerant

Q = R452A, R404A/R507

X = R404A/R507, R134a, R407A, R407F, R448A, R513A

R449A,R452A

4 Condenser

M = Microchannel heat condenser

5 Swept volume

Displacement in cm

3:

Example 034 = 34 cm

3

6 Compressor platform

ML = Fixed speed scroll MLZ

LL = Fixed speed scroll LLZ

7 Version

P06: Optyma™ Plus with PRV

8 Voltage code

E = 400V/3-phase/50Hz compressor & 230V/1-phase fan

Version control

Optyma™ Plus (P06)

IP level IP54

Compressor technology Scroll/ Reciprocating

Control box (pre-wired E-panel) yes

Microchannel condenser yes

Fan speed controller* yes

Main switch (circuit breaker) yes

Supply monitoring relay Filter drier (flare connections) yes

Sight glass yes

Crankcase heater yes

HP/LP adjustable pressostat Electronic

Fail safe mini-pressostat Mechanical

Access door(s) yes

Acoustic insulation yes

Condensing unit electronic controller yes

Network connectivity yes

Stack mounting yes

Discharge gas thermostat yes

HP/LP Alarm yes

Pressure relief valve yes

* Inbuilt function within Condensing unit electronic controller

1 – Introduction

These instructions pertain to Optyma

™

Plus

condensing units OP-LPOM, & OP-MPXM used

for refrigeration systems. They provide necessary

information regarding safety and proper usage of

this product.

The condensing unit includes following:

• Microchannel heat exchanger

• Reciprocating or scroll compressor

• Receiver with stop valve

• Ball valves

• Sight glass

• High & low pressure switches

• Replaceable filter drier

• Electronic controller

• Main circuit breaker (Main switch with overload

protection)

• Fan and compressor capacitors

• Compressor contactor

• Robust weather proof housing

2 – Handling and storage

• It is recommended not to open the packaging

before the unit is at the final place for

installation.

• Handle the unit with care. The packaging

allows for the use of a forklift or pallet jack. Use

appropriate and safe lifting equipment..

• Store and transport the unit in an upright

position.

• Store the unit between -35°C and 50°C.

• Don’t expose the packaging to rain or corrosive

atmosphere.

• After unpacking, check that the unit is complete

and undamaged.

3 – Installation precautions

Never place the unit in a flammable

atmosphere.

Place the unit in such a way that it is not

blocking or hindering walking areas, doors,

windows or similar.

• Ensure adequate space around the unit for air

circulation and to open doors. Refer to picture

1 for minimal values of distance to walls.

• Avoid installing the unit in locations which are

daily exposed to direct sunshine for longer

periods.

• Avoid installing the unit in aggressive and

dusty environments.

• Ensure a foundation with horizontal surface

(less than 3° slope), strong and stable enough

to carry the entire unit weight and to eliminate

vibrations and interference.

• The unit ambient temperature may not exceed

50°C during off-cycle.

• Ensure that the power supply corresponds to

the unit characteristics (see nameplate).

• When installing units for HFC refrigerants,

use equipment specifically reserved for HFC

refrigerants which was never used for CFC or

HCFC refrigerants.

• Use clean and dehydrated refrigeration-grade

copper tubes and silver alloy brazing material.

• Use clean and dehydrated system components.

• The suction piping connected to the

compressor must be flexible in 3 dimensions

to dampen vibrations. Furthermore piping has

to be done in such a way that oil return for the

compressor is ensured and the risk of liquid

slug over in compressor is eliminated.

4 – Installation

• The installation in which the condensing unit is

installed must comply to pressure Equipment

Directive (PED) 2014/68/EU. The condensing unit

itself is not a ”unit” in the scope this directive.

• It is recommended to install the unit on rubber

grommets or vibration dampers (not supplied).

• It is possible to stack units on top of each other.

Unit

Housing 4

(Code no. 114X34-- or 114X44--)

Maximum

stacking

2

• When stacking, the topmost unit must be

2 | AN363632996019en-ZA0102 - 118A2221B

© Danfoss | Climate Solutions | 2021.10

Instructions

secured to the wall, as shown in picture 2.

• Slowly release the nitrogen holding charge

through the schrader port.

• Connect the unit to the system as soon as

possible to avoid oil contamination from

ambient moisture.

• Avoid material entering into the system while

cutting tubes. Never drill holes where burrs

cannot be removed.

• Braze with great care using state-of-the-art

technique and vent piping with nitrogen gas

flow.

• Connect the required safety and control

devices. When the schrader port is used for this,

remove the internal valve.

• It is recommended to insulate the suction pipe

up to the compressor inlet with 19 mm thick

insulation.

5 – Leak detection

Never pressurize the circuit with oxygen or dry

air. This could cause fire or explosion.

• Do not use dye for leak detection.

• Perform a leak detection test on the complete

system.

• The maximum test pressure is 31 bar.

• When a leak is discovered, repair the leak and

repeat the leak detection.

6 – Vacuum dehydration

• Never use the compressor to evacuate the

system.

• Connect a vacuum pump to both the LP & HP

sides.

• Pull down the system under a vacuum of 500

µm Hg (0.67 mbar) absolute.

• Do not use a megohmmeter nor apply power

to the compressor while it is under vacuum as

this may cause internal damage.

7 – Electrical connections

• Switch off and isolate the main power supply.

• Ensure that power supply can not be switched

on during installation.

• All electrical components must be selected as

per local standards and unit requirements.

• Refer to wiring diagram for electrical

connections details.

• Ensure that the power supply corresponds

to the unit characteristics and that the power

supply is stable (nominal voltage ±10% and

nominal frequency ±2,5 Hz).

• Dimension the power supply cables according

to unit data for voltage and current.

• Protect the power supply and ensure correct

earthing.

• Make the power supply according to local

standards and legal requirements.

• The unit is equipped with an electronic

controller. Refer to Manual 118U3808 for details.

• The unit is equipped with a main switch with

overload protection. The overload protection is

factory preset but it is recommended to check

the value before taking the unit in operation.

The value for the overload protection can be

found in the wiring diagram in the front door of

the unit.

• The unit is equipped with high and low

pressure switches, which directly cut the power

supply to the compressor in case of activation.

Parameters for high and low pressure cut outs

are preset in the controller, adapted to the

compressor installed in the unit.

• P05 models are also equipped with phase

sequence relay to protect the unit against

phase loss/sequence/ asymmetry and under-/

over-voltage.

For units with a 3-phase scroll compressor (OPMPXMxxxxxxxxE), correct phase sequence for

compressor rotation direction shall be observed.

• Determine the phase sequence by using a

phase meter in order to establish the phase

orders of line phases L1, L2 and L3.

• Connect line phases L1, L2 and L3 to main

switch terminals T1, T2 and T3 respectively.

8 – Safety

Fusible Plug is not installed in unit, it is replaced

with adapter blanking plug.

Unit has liquid receiver with an Adapter Plug with

3/8” NPT connection. installer/end user can select

various options as mentioned in EN378-2 : 2016

Article § 6.2.2.3

• Optyma Plus fitted with atmospheric pressure

relief valve. Don’t connect any tube at end of the

pressure relief valve.

• Once the pressure relief valve opens, don’t use

dry air or oxygen to evacuate the refrigerants.

• Optyma Plus (P06 version only) factory fitted

with pressure relief valve at 33 bar setting.

• Once pressure relief valve opens, Danfoss

recommended to replace new pressure relief

valve.

• The unit/installation into which the condensing

unit is mounted/integrated, must be in

accordance with the PED.

• Beware of extremely hot and cold components.

• Beware of moving components. Power supply

should be disconnected while servicing.

9 – Filling the system

• Never start the compressor under vacuum.

Keep the compressor switched off.

• Use only the refrigerant for which the unit is

designed for.

• Fill the refrigerant in liquid phase into the

condenser or liquid receiver. Ensure a slow

charging of the system to 4 – 5 bar for R404A/

R448A/R449A/R407A/R407F/R452A and

approx. 2 bar for R134a and R513A.

• The remaining charge is done until the

installation has reached a level of stable

nominal condition during operation.

• Never leave the filling cylinder connected to

the circuit.

10 – Setting the electronic controller

• The unit is equipped with an electronic controller

which is factory programmed with parameters

for use with the actual unit. Refer to Manual

118U3808 for details.

• By default, the electronic controller display

shows the temperature value for the suction

pressure in °C. To show the temperature value for

the condensing pressure, push the lower button

(picture 3).

The electronic controller is factory preset for R404A

or R449A or R452A or R134a depending on the

model of compressor mounted and application

(Refer Annexx in Optyma Controller installation

manual). If another refrigerant is used, the

refrigerant setting must be changed. Parameter

r12 must be set to 0 before (software main switch=

off).

• Push the upper button for a couple of seconds.

The column with parameter codes appears.

• Push the upper or lower button to find parameter

code o30.

• Push the middle button until the value for this

parameter is shown.

• Push the upper or lower button to select the new

value: 2 = R22, 3 = R134a, 36 = R513A, 17 = R507,

19 = R404A, 20 = R407C , 21 = R407A, 37 = R407F,

40 = R448A, 41 = R449A, 42 = R452A.

• Push the middle button to confirm the selected

value.

• Push the upper or lower button to find parameter code r84.

• Push the middle button until the value for this

parameter is shown as 125

• Push the upper button to select the new value:

130.

11 – Verification before commissioning

Use safety devices such as safety pressure

switch and mechanical relief valve in compliance

with both generally and locally applicable

regulations and safety standards. Ensure that

they are operational and properly set.

Check that the settings of high-pressure

switches and relief valves don’t exceed the

maximum service pressure of any system

component.

• Verify that all electrical connections inside the

condensing unit are properly fastened as they

could have worked loose during transportation.

• When a crankcase heater is required, the unit

© Danfoss | Climate Solutions | 2021.10

118A2221B - AN363632996019en-ZA0102 | 3

Instructions

must be energized at least 12 hours before

initial start-up and start-up after prolonged

shutdown for belt type crankcase heaters.

• The unit is equipped with a main switch with

overload protection. Overload protection is

preset from factory, but it is recommended

to check the value before taking the unit in

operation. The overload protection value can

be found in the wiring diagram in the unit front

door.

• Check if discharge temperature sensor is firm

and has proper contact with discharge pipe.

12 – Start-up

• Never start the unit when no refrigerant is

charged.

• All service valves must be in the open position.

• Rotalock valve on the receiver must be

turned 1 round to close direction to get the

right condensing pressure for the pressure

transmitter

• Check compliance between unit and power

supply.

• Check that the crankcase heater is working.

• Check that the fan can rotate freely.

• Check that the protection sheet has been

removed from the backside of condenser.

• Balance the HP/LP pressure.

• Energize the unit. It must start promptly. If

the compressor does not start, check wiring

conformity and voltage on terminals.

• Eventual reverse rotation of a 3-phase

compressor can be detected by following

phenomena; the compressor doesn’t build up

pressure, it has abnormally high sound level

and abnormally low power consumption. P05

models are equipped with a phase-reversal

relay and compressor doesn’t start, the

compressor doesn’t build up pressure, in case

of wrong phase sequences. In such case, shut

down the unit immediately and connect the

phases to their proper terminals.

• If the rotation direction is correct the low pressure

indication on the controller (or low pressure

gauge) shall show a declining pressure and

the high pressure indication (or high pressure

gauge) shall show an increasing pressure.

13 – Check with running unit

• Check the fan rotation direction. Air must flow

from the condenser towards the fan.

• Check current draw and voltage.

• Check suction superheat to reduce risk of

slugging.

• When a sight glass is provided observe the oil

level at start and during operation to confirm

that the oil level remains visible.

• Respect the operating limits.

• Check all tubes for abnormal vibration.

Movements in excess of 1.5 mm require

corrective measures such as tube brackets.

• When needed, additional refrigerant in liquid

phase may be added in the low-pressure side

as far as possible from the compressor. The

compressor must be operating during this

process.

• Do not overcharge the system.

• Follow the local regulations for restoring the

refrigerant from unit.

• Never release refrigerant to atmosphere.

• Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

• Record type and amount of refrigerant charge

as well as operating conditions as a reference

for future inspections.

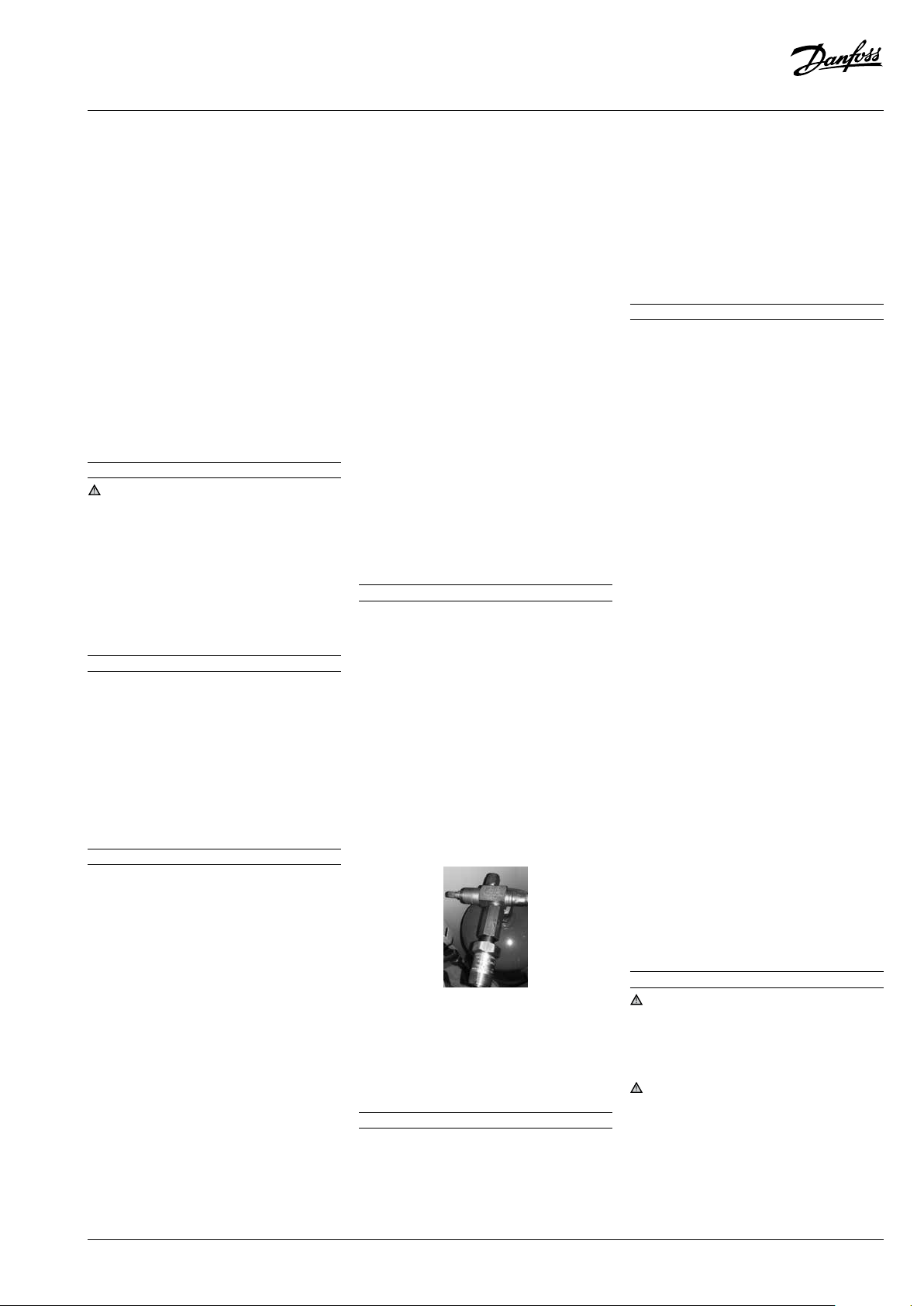

14 – Emergency running without controller

In case of controller failure, the condensing unit

can still be operated when the controller standard

wiring (picture 4) is modified into a temporary

wiring (picture 5) as described below.

This modification may be done by authorized

electricians only. Country legislations have to be

followed.

Disconnect the condensing unit from power

supply (turn hardware main switch off)

• Contact of Room Thermostat must be possible

to switch 250VAC.

• Remove wire 22 (safety input DI3) and wire 24

(room thermostat DI1) and put them together

with an insulated 250 Vac 10mm² terminal

bridge.

• Remove wire 25 (room thermostat DI1) and

wire 11 (compressor supply) and put them

together with an insulated 250VAC 10mm²

terminal bridge.

• Remove wire 6 and connect it with terminal

bridge for wire 11 and 25. A fan pressure switch

or fan speed controller can be connected in

series to wire 6.

• Remove wire 14 (crankcase heater) and connect

it to the compressor contactor terminal 22.

• Remove wire 12 (supply crankcase heater),

extend this wire by using an 250 Vac 10mm²

terminal bridge and 1,0mm² brown cable and

connect it to compressor contactor terminal 21

• Remove the large terminal block from the

controller terminals 10 to 19.

• Connect the condensing unit to power supply

(turn hardware main switch on).

15 – Maintenance

Always switch off the unit at main switch

before opening the fan door (s).

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related problems, following

periodic maintenance is recommended:

• Verify that safety devices are operational and

properly set.

• Ensure that the system is leak tight.

• Check the compressor current draw.

• Confirm that the system is operating in a way

consistent with previous maintenance records

and ambient conditions.

• Check that all electrical connections are still

adequately fastened.

• Keep the unit clean and verify the absence of

rust and oxidation on the unit components,

tubes and electrical connections.

The condenser must be checked at least once

a year for clogging and be cleaned if deemed

necessary. Access to the internal side of the

condenser takes place through the fan door.

Microchannel coils tend to accumulate dirt on

the surface rather than inside, which makes them

easier to clean than fin-&-tube coils.

• Switch off the unit at main switch before

opening the fan door.

• Remove surface dirt, leaves, fibres, etc. with

a vacuum cleaner, equipped with a brush or

other soft attachment. Alternatively, blow

compressed air through the coil from the inside

out, and brush with a soft bristle. Do not use

a wire brush. Do not impact or scrape the coil

with the vacuum tube or air nozzle.

• Before closing the fan door, turn the fan blade

in a safe position, to avoid that the door hits the

fan.

If the refrigerant system has been opened, the

system has to be flushed with dry air or nitrogen

to remove moisture and a new filter drier has to

be installed. If evacuation of refrigerant has to

be done, it shall be done in such a way that no

refrigerant can escape to the environment.

16 – Declaration of incorporation

• Pressure Equipment Directive 2014/68/EU

EN 378-2:2016 - Refrigerating systems and Heat

Pumps - Safety and environmental requirementsParts 2: Design, construction, testing, marking

and documentation.

Low Voltage Directive 2014/35/EU EN

60335-1:2012 + A11:2014- Household and

similar electrical appliances-Safety-Part 1:

General requirements-for all above mentioned

condensing units Eco-design DIRECTIVE

2009/125/ EC, establishing a framework for the

setting of Eco-design requirements for energyrelated products.

REGULATION (EU) 2015/1095, implementing Ecodesign Directive 2009/125/EC with regard to Ecodesign requirements for professional refrigerated

storage cabinets, blast cabinets, condensing units

and process Chiller.

• Condensing unit measurements are made

according to standard “EN 13771-2:2017”

4 | AN363632996019en-ZA0102 - 118A2221B

© Danfoss | Climate Solutions | 2021.10

Instructions

– Compressor and condensing units for

refrigeration-performance testing and test

methods- part 2: Condensing units.

17 - Warranty

Always transmit the model number and serial

number with any claim filed regarding this

product.

The product warranty may be void in following

cases:

• Absence of nameplate.

• External modifications, in particular, drilling,

welding, broken feet and shock marks.

• Compressor opened or returned unsealed.

• Rust, water or leak detection dye inside the

compressor.

• Use of a refrigerant or lubricant not approved

by Danfoss.

• Any deviation from recommended instructions

pertaining to installation, application or

maintenance.

• Use in mobile applications.

• Use in explosive atmospheric environment.

• No model and serial number transmitted with

the warranty claim.

18 – Disposal

Danfoss recommends that condensing

units and oil should be recycled by a

suitable company at its site.

© Danfoss | Climate Solutions | 2021.10

118A2221B - AN363632996019en-ZA0102 | 5

Instructions

OP-LPQM215-271 & OP-MPXM125-162

C

English Legend

A Ø12 Hole for Mounting

B Sight Glass

C Controller Display

E

B

A

D Air in

E Air out

F Suction Port

G Liquid Port

H

D

F

G

H4

H Nameplate

Electrical Cables

Note: all dimension are in mm

6 | AN363632996019en-ZA0102 - 118A2221B

© Danfoss | Climate Solutions | 2021.10

Instructions

3

P06 Models: OP-LPQM215-271 & OP-MPXM125-162

T1

R2

1

B4

B2

1 Compressor

2 Electric Expansion Valve

3 Micro Channel Heat Exchanger with axial fan

4 Refrigerant receiver with rotalock valve

5 Filter Drier

6 Sight Glass

7 Liquid Ball Valve

T3

R3

P2

T4

R1

78

8 Suction Ball Valve

B1 Condensing Pressure Transducer (P1)

B2 Suction Pressure Transducer (P2)

B3

High Pressure cartridge Switch (auto-reset)(PSH)

B4

Low Pressure cartridge Switch (auto-reset) (PSL)

D1

Pressure relief valve (PRV)

R1 Ambient Temperature sensor (T4)

B3

B1

R1

P1

PRV

4

R2 Discharge Temperature Sensor (T2)

R3 Suction Temperature Sensor (T3)

S1 Pressure Relief Valve

R8 Discharge Temperature Sensor (T1)

Insulation

5

6

© Danfoss | Climate Solutions | 2021.10

118A2221B - AN363632996019en-ZA0102 | 7

Code E: OP-LPQM215-271 & OP-MPXM125-162

English Legend

A1 : Optyma

A2 : EMI Filter

A3 : Liquid Injection Controller

B1,B5 : Condensing Pressure Transducer

B2 : Suction Pressure Transducer

B3 : High Pressure Switch (OFF = 31bar(g),

B4 : Low Pressure Switch (OFF = -0,3bar(g),

C1 : Start Capacitor (Compressor)

™

Plus Controller

ON = 24bar(g))

ON = 0,5bar(g))

C2 : Run Capacitor (Compressor)

C3 : Run Capacitor (Fan 1)

C4 : Run Capacitor (Fan 2)

F1 : Fuse (Control Circuit)

F2,F3 : Motor protector

K1 : Contactor

K2 : Start Relay

M1 : Compressor

M2 : Fan Motor 1

M3 : Fan Motor 2

M4 : Electronic Expansion Valve

Q1 : Main Switch

R1 : Ambient Temp. Sensor

R2,R8 : Discharge Temp. Sensor

R3 : Suction Temp. Sensor

R4,R5 : Auxiliary Temp. Sensor (optional)

R6 : Crankcase Heater

R7 : NTC Resistor

S1 : Room Thermostat (optional)

S2 : Door Limit Switch

X1 : Terminal

WD1

Supply : Supply

Fan : Fan

Alarm : Alarm

Comp. : Compressor

CCH : Crankcase Heater

Aux : Auxiliary

8 | AN363632996019en-ZA0102 - 118A2221B

© Danfoss | Climate Solutions | 2021.10

Loading...

Loading...