Danfoss NRVA Installation guide

Installation Guide

Check valves

NRVA

027R9531

027R9531

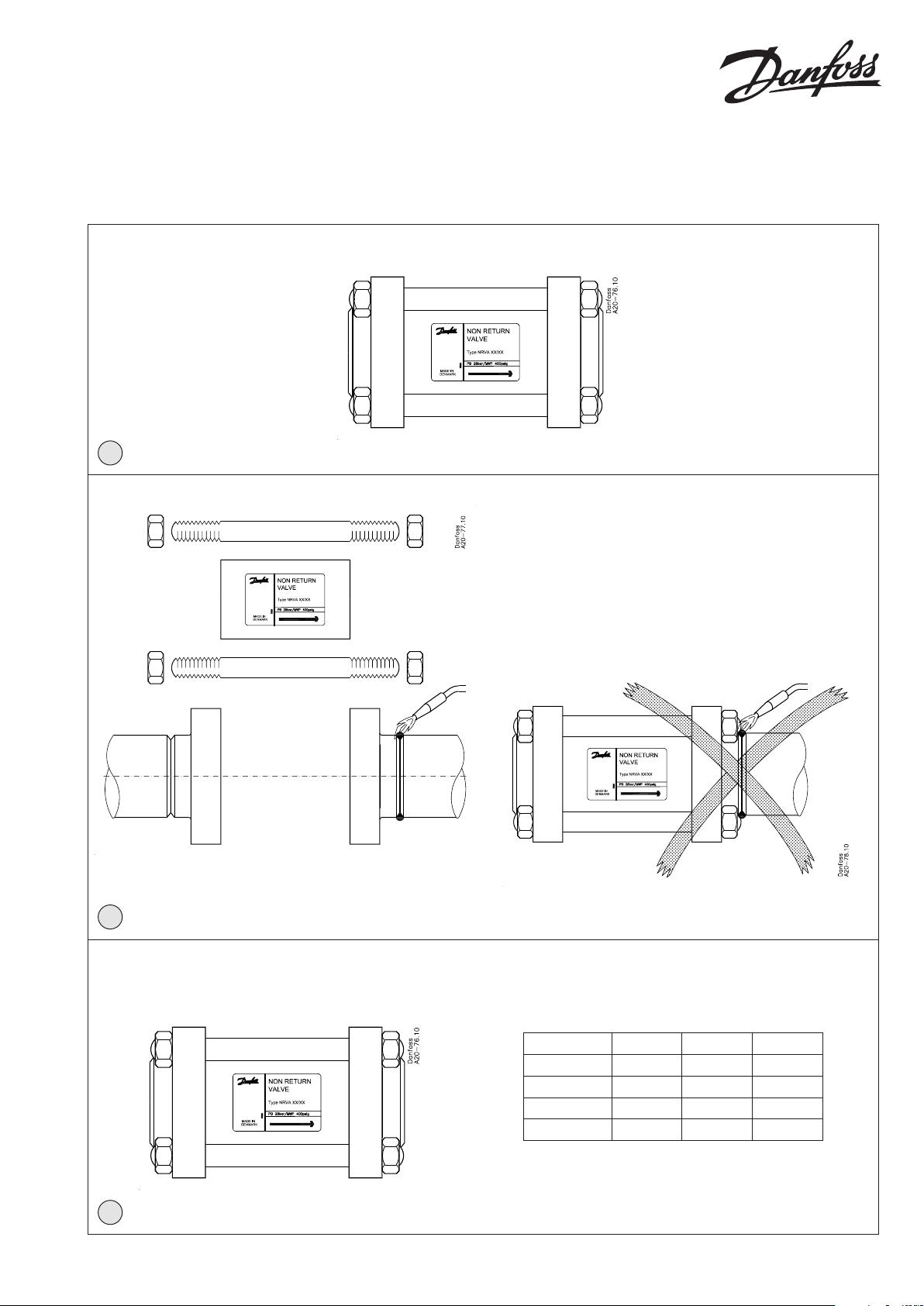

1

2

Type Bolt Nm LB-Feet

NRVA 15-20

NRVA 25-32

NRVA 40-50

NRVA 65

2 × M12

4 × M12

4 × M12

8 × M16

50 37

70 52

70 52

100 74

3

© Danfoss A/S (AC-MCI/MWA), 2013-10 DKRCI.PI.FK0.A2.02 / 520H4513 1

Installation

ENGLISH

Assembly

Remove welding debris and any dirt from

pipes and valve body before assembly.

Refrigerants

Applicable to HCFC, HFC and R717

(Ammonia).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use in closed circuits. For

further information please contact Danfoss.

Temperature range

NRVA: –50/+140°C (–58/+285°F)

Pressure range

NRVA: The valves are designed for a max.

working pressure of 40 bar g (580 psi g).

Installation

The valve must be installed in the flow

direction as indicated by the arrow on the

valve housing (fig. 1).

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Welding

The internal parts should be removed

before welding (fig. 2) to prevent damage

to the gaskets, as well as the teflon gasket

in the valve seat.

Only materials and welding methods,

compatible with the flange material, must

be welded to the flanges. The flanges

should be cleaned internally to remove

welding debris on completion of welding

and before the valve is reassembled.

Tightening

Thighten the staybolts and nut with a

torque wrench, to the values indicated in

the table (fig. 3).

Surface protection

The external surface of the flanges must be

prevented against corrosion with a suitable

protective coating after installation and

assembly.

Maintenance

Dismantling the valve

Do not remove the valve housing while the

valve is still under pressure.

- Check that the gasket has not been

damaged.

- Check that the cone is free of scratches

and impact marks.

- If the teflon cone ring has been

damaged, the whole cone assembly

must be replaced.

Assembly

Remove any dirt from the body before the

valve is assembled.

Tightening

Tighten the staybolts and nut with a torque

wrench, to the values indicated in the table

(fig. 3).

Use only original Danfoss parts, including

gaskets for replacement. Materials of

new parts are certified for the relevant

refrigerant.

Be careful not to damage the teflon on the

cone.

The valve inclusive flanges must be

free from stresses (external loads) after

installation.

The valves must not be mounted in

systems where the outlet side of the valve

is open to atmosphere. Both the inlet

and outlet side of the valve must always

be connected to the system or properly

capped off, for example with a welded-on

end plate.

2 DKRCI.PI.FK0.A2.02 / 520H4513 © Danfoss A/S (AC-MCI/MWA), 2013-10

In cases of doubt, please contact Danfoss.

Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

changes to products and specifications

without prior notice.

Loading...

Loading...