Page 1

Data Sheet

Data sheet

Plug & Spray unit

Plug and Spray Unit

NPS

hpp.danfoss.com

hpp.danfoss.com

Page 2

Data sheet | Plug & Spray unit NPS

Table of Contents

Contents

1. General information.....................................................................3

2. Component description.................................................................5

2.1 PAHT high-pressure pump ..............................................................5

2.2 Electric motor ..........................................................................5

2.2.1 Danfoss FCP 106 drive motor ............................................................5

2.3 Aluminium cast bell housing and exible coupling ......................................5

2.4 Galvanized steel frame .................................................................5

2.5 Connection block .......................................................................5

2.6 Water lter .............................................................................5

2.7 Electrical connection box, optional .....................................................5

2.8 Supply pressure gauge .................................................................5

2.9 Pressure relief valve VRH 5 (30) CA cartridge .............................................5

2.10 Filter bleed button .....................................................................5

2.11 High-pressure gauge ...................................................................5

2.12 Check valve - inlet 3/4” ..................................................................5

2.13 Ball valve G 3/8” female .................................................................5

2.14 Inlet G 3/4” female ......................................................................5

2.15 High-pressure outlet G 3/8” female, optional ............................................5

2.16 High-pressure hose .....................................................................6

2.17 High-temperature switch ...............................................................6

2.18 Low-pressure hose .....................................................................6

2.19 MBS 3050 pressure transmitter ..........................................................6

2.20 Low-pressure switch ....................................................................6

2.21 Check valve - outlet .....................................................................6

2.22 Swivel union 3/4” .......................................................................6

3. P&ID ....................................................................................6

4. Technical data ..........................................................................7

5. Dimensions [mm] .......................................................................8

6. Local control panel......................................................................9

7. Opt i o ns .................................................................................9

8. Electrical connection box ..............................................................10

2

AI309730711498en-0 00901 | 02.2021

Page 3

Data sheet | Plug & Spray unit NPS

1. General information

The Danfoss Plug & Spray unit is designed for

humidication and adiabatic cooling systems

based on the high-pressure principle. The units

are available in a constant speed version (CS)

with IEC electric motor, as well as in a version

with constant pressure control using a Danfoss

FCP 106 variable speed drive motor (VS).

The Plug & Spray unit is available with 6 dierent

pump sizes (see Technical data, sec. 4) to match

the required ow demand. The motor power is

dimensioned to provide design ow at

a system pressure of max. 100 barg or 1,450 psig.

The Danfoss high-pressure axial piston pumps

provide excellent pressure stability at high

energy eciency and low noise level. Pulsation

dampeners are superuous.

The Plug & Spray unit comprises all necessary

components to ensure the best possible

performance, maximum service life with

maximum protection of the pump. It is very

compact, requires very little space and is suitable

for both wall and oor mounting.

The Danfoss Plug & Spray unit can be operated

with ordinary tap water as well as with all kinds

of technical water (distilled, de-ionised and

demineralised water).

The Plug & Spray unit is suitable for a variety of

applications, such as:

• High-pressure hymidication and adia batic

cooling in HVAC systems (Air-handling

units) i.e. in oces, server rooms etc.

• Open space humidication system in

production halls, storages etc.

• Humidication and adiabatic cooling

in animal farms, greenhouses and composting, server rooms

• Electrostatic Discharge (ESD) control

• Adiabatic outdoor cooling i.e. in pools,

bars, restaurants etc.

• Dust suppression and dust binding in

manufacturing and clean rooms

• Gas turbine inlet cooling and NOx control

• Odour control and soil lters

• Water mist clouds in theme parks,

exhibitions etc.

2

1

Pumps: PAHT 2 to PAHT 12.5

2

Electric motor, standard IEC or VS units with

Danfoss FCP 106 Drive Motor

3

Aluminium cast bell housing and exible

coupling

5

3

1

4

4

Galvanized steel frame for oor mounting

5

Very compact and reliable connection block,

see details on page 5

AI309730711498en-0 00901 | 02.2021

3

Page 4

Data sheet | Plug & Spray unit NPS

6

Water lter 5” or 10”,

6

7

10 μm absolute,

β ≥ 5,000

Optional electrical

7

box.

CS or VS versions

available.

8

21

10

9

11

22

12

15

13

20

19

Supply pressure gauge 0-10 barg

8

Pressure relief valve VRH 5 (30) CA cartridge,

9

adjustable 20–100 barg / 363–1450 psig

(25–140 barg / 363–2031 psig)

10

Filter bleed button

11

High-pressure gauge

12

Check valve - inlet ¾”

13

Ball valve G 3/8” female

14

Inlet G 3/4” female

15

High-pressure outlet G 3/8” female, optional

17

18

High-pressure hose

16

17

High-temperature switch

18

Low-pressure hose

19

MBS 3050 pressure transmitter on VS-unit

20

Low-pressure switch

21

Check valve - outlet

22

Swivel union 3/4”

16

14

4

AI309730711498en-0 00901 | 02.2021

Page 5

Data sheet | Plug & Spray unit NPS

2. Component

description

The components described in this chapter refer

to the images on page 3 and 4.

2.1 PAHT high-pressure pump

1

The heart of the Plug & Spray unit is the Danfoss

axial piston high-pressure pump. The pump is

water lubricated and fulls the most stringent

hygiene requirements as no lubricants or

chemicals are involved at all.

Danfoss PAHT pumps are designed for long

periods of service-free operation to provide

customers with low maintenance and life cycle

costs. Provided that the pump is installed and

operated according to Danfoss specications,

Danfoss PAHT pumps typically run 8,000 hours

between service routines.

We recommend that you inspect your pump

after 8,000 hours of operation even if it is

running without any noticeable problems.

2.2 Electric motor

2

The electric motor is dimensioned to provide

sucient power for maximum ow at 100 barg/

1,450 psig system pressure. The motor is a

standard IEC 3-phase 400 V, 50 Hz asynchronous

motor.

2.2.1 Danfoss FCP 106 drive motor

The variable speed drive motor in connection

with a pressure transmitter allows adjusting the

pump capacity to the actual demand of the

application, keeping the system pressure

constant.

The FCP 106 has a built-in PID-controller and 24 V

DC transmitter power supply.

2.6 Water lter

6

The system comprises a 5” or 10” (10, 12,5 VS),

10-micron ne lter with a β-value ≥ 5,000 abs.

The lter protects the pump against rapid wear

caused by contamination of the supply water

and – as a second benet – prevents the nozzles

from clogging. The lter cartridge is easy to

replace.

2.7 Electrical connection box, optional

7

Both CS and VS units can be delivered with an

electrical connection box, please see sec. 8.

2.8 Supply pressure gauge

8

It allows monitoring the supply pressure under

operation and the condition of the lter. The

lter should be changed when the supply

pressure is below 2 barg (29 psig).

2.9 Pressure relief valve

VRH 5 (30) CA cartridge

9

The relief valve is integrated in the connection

block with internal recirculation loop back to the

lter. It works as a safety valve in case the

discharge is blocked and allows adjusting the

system pressure under normal operation. At 20

°C (68 °F) water temperature 90% of the water

can be run over the bypass loop (recirculation).

Pressure range: 20–100 barg / 363–1450 psig

(25–140 barg / 363–2031 psig).

2.10 Filter bleed button

10

It is important that there is no air in the system.

At commissioning air can be bled from the lter

by using the lter bleed button.

2.3 Aluminium cast bell housing and

exible coupling

3

The bell housing is made of cast aluminium. The

electric motor and the pump are directly coupled

with a exible coupling. The bell housing

requires minimum space and is lightweighted.

The transmission is maintenance free and cost

ecient compared to traditional belt drives.

2.4 Galvanized steel frame

4

The base frame is designed for oor mounting;

however it can be mounted on a wall with

suitable support bars. The base frame concept

allows adding numerous options.

2.5 Connection block

5

A central connection block with integrated

pressure relief valve provides a very compact and

reliable solution to connect all other necessary

components such as gauges, switches etc.

Service friendly gasket concept:

All HP components as well as the connections to

the pump are equipped with bonded seals,

which provide easy and reliable connections.

2.11 High-pressure gauge

11

It allows monitoring the discharge pressure

under operation and during adjusting the

pressure relief valve.

Pressure range: 0-160 barg (0-2,321 psig)

2.12 Check valve - inlet 3/4”

12

In order to make back-ow impossible, a check

valve at the water supply is mandatory when

connecting the system to the public utilities.

2.13 Ball valve G 3/8” female

13

The ball valve allows to interrupt the water

supply i.e. for lter change or pump service.

2.14 Inlet G 3/4” female

14

Connect your water supply to the inlet.

2.15 High-pressure outlet G 3/8” female,

optional

15

Not used by Danfoss.

AI309730711498en-0 00901 | 02.2021

5

Page 6

Data sheet | Plug & Spray unit NPS

2.16 High-pressure hose

To avoid vibrations in the system Danfoss always

use a exible high-pressure hose from the pump

outlet to the connection block.

2.17 High-temperature switch

The water temperature is monitored to prevent

overheating. The switch is set to 50 °C(122 °F).

regulation (only with VS units).

16

Pressure range: 0-160 barg (0-2,361 psig)/

4-20 mA.

2.20 Low-pressure switch

20

If insucient supply pressure occurs, the pump

17

can be damaged by cavitation or dry running.

A low-pressure switch set to 1.6 barg(23 psig) abs.

protects the pump.

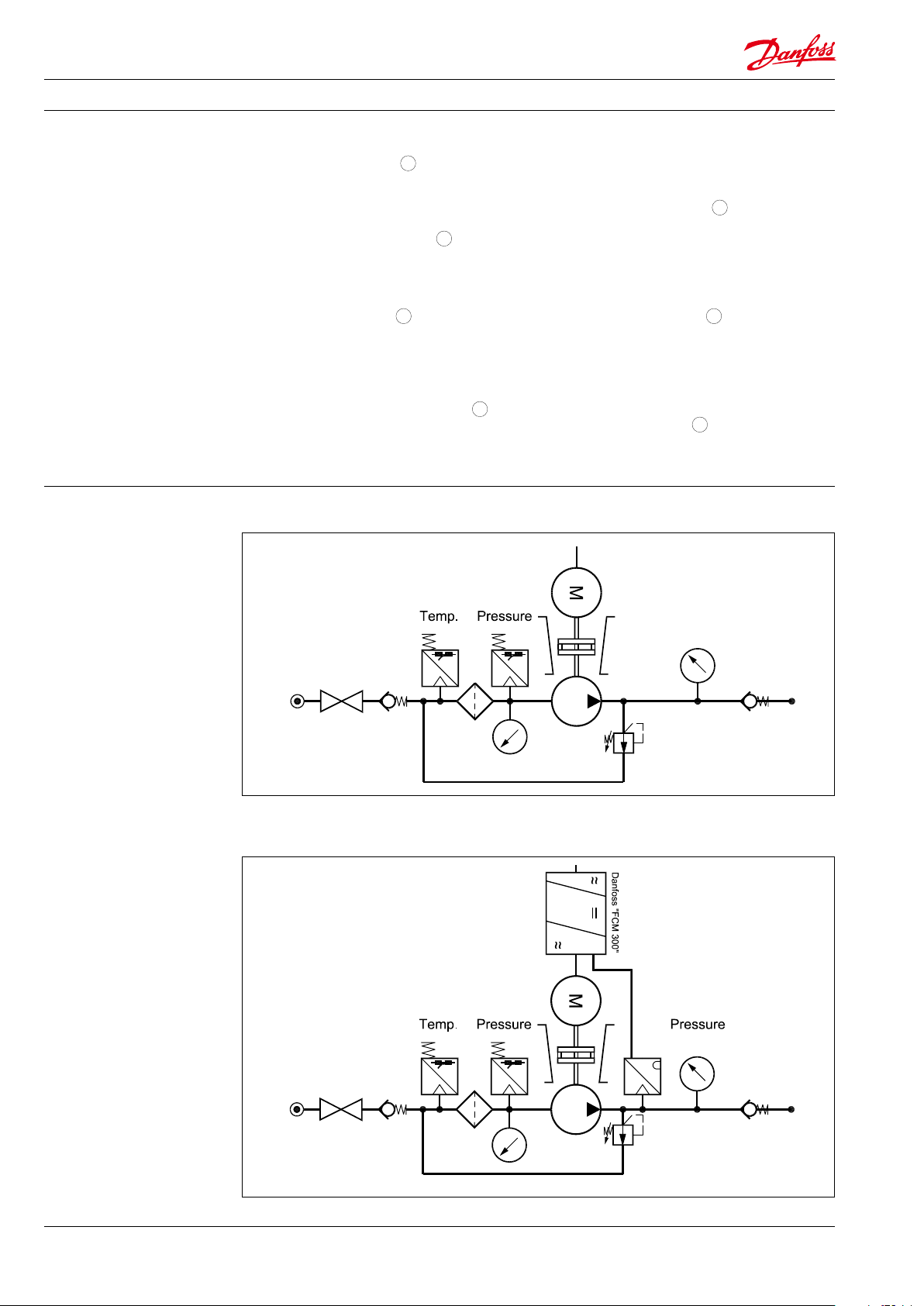

3. P&ID

2.18 Low-pressure hose

18

To avoid vibrations in the system Danfoss always

use a exible low-pressure hose from the

connection block to the pump inlet.

2.19 MBS 3050 pressure transmitter

19

The pressure transmitter is connected to the

internal PID controller of the FCP 106 Drive

Motor, which is set up for constant pressure

Constant speed versions:

2.21 Check valve - outlet

21

The connection block is mounted with a check

valve and a male connector for a 12 mm pipe. By

removing the male connector the outlet can be

changed to G 3/4” female.

2.22 Swivel union 3/4”

22

The swivel union allows establishing the water

supply from the top, back, front or bottom.

Variable speed versions:

6

AI309730711498en-0 00901 | 02.2021

Page 7

Data sheet | Plug & Spray unit NPS

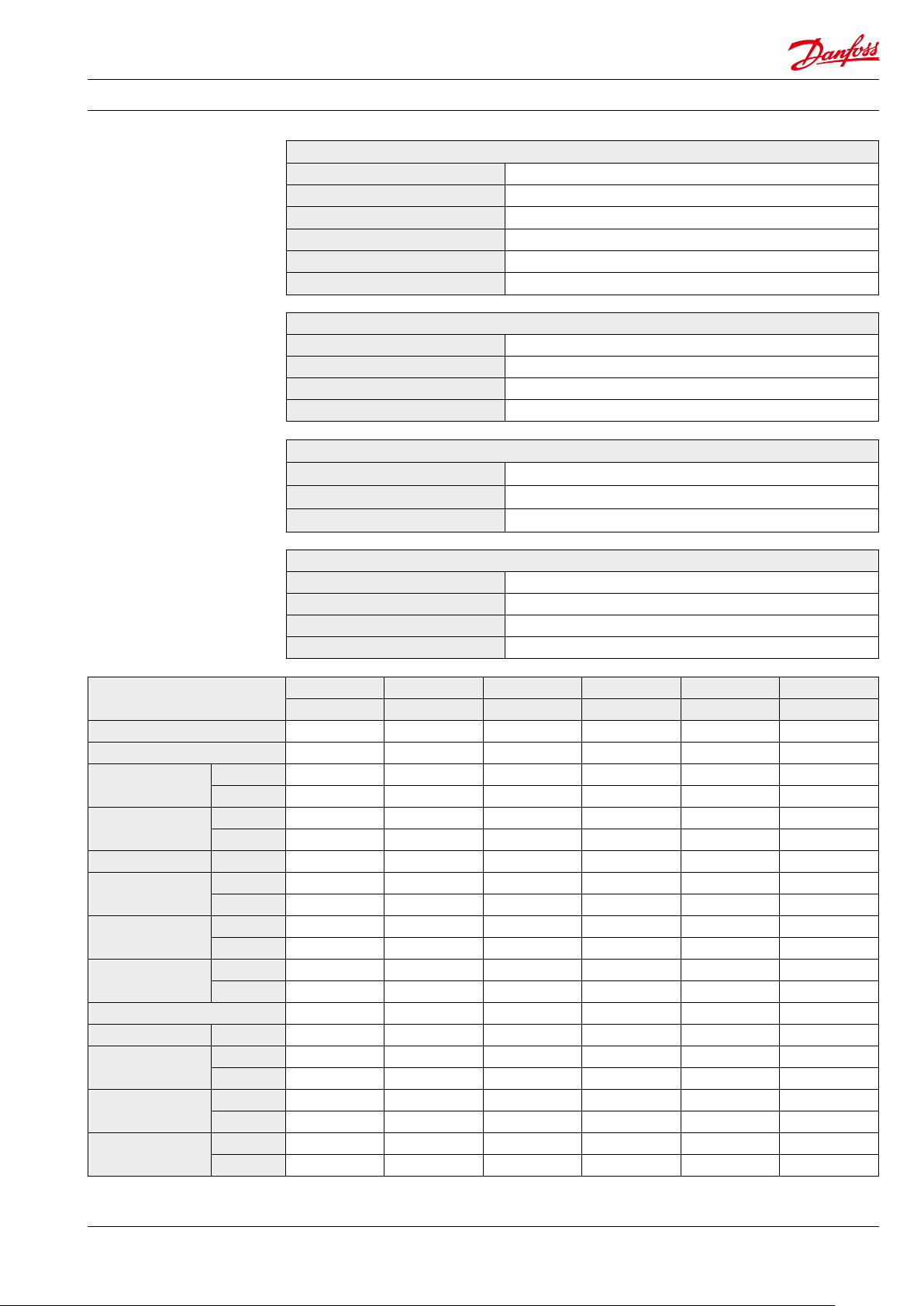

4. Technical data

Water supply

Connection ø19 mm hose tting or G 3/4” female thread

Pressure min. 2 barg (28 psig), max. 4 barg (56 psig)

Filter 10 μm absolute, β ≥ 5,000, 5” or 10” (10, 12.5 VS)

Pressure switch 1.6 barg (23 psig), 250 V AC/24 V DC, 0.5 A

Temperature switch 50 °C ± 5 °C, 250 V AC/24 V DC, 0.5 A

High pressure outlet 12 mm pipe

High-pressure pump

Max. discharge pressure 100 barg (1,450 psig), continuous

Min. pump speed 1,000 rpm

Max. pump speed 3,000 rpm, 2,400 rpm, NPS 10, 12.5 VS

Discharge connection G3/8“ female, 3/8“ NPT adaptor on request

Pressure relief valve

Typ e VRH 5 (30) CA Cartridge

Capacity max. 30 l/min / 1,800 l/h / 8 gpm

Adjustment range 25–100 barg / 363–1450 psig (25–140 barg / 363–2031 psig)

Environmental conditions

Water temperature supply +3 °C – +50 °C / 37 °F – 122 °F

Ambient temperature +3 °C – +50 °C / 37 °F – 122 °F, VS units max. 40 °C / 104 °F

Storage temperature -25 °C – +65 °C / 13 °F – 149 °F with frost protection!

Operation and storage humidity 5–95% rF, non condensing

Typ e

Ordering code 180U3300 180U3301 180U3302 180U3303 180U3304 180U3305

Pump type PAHT 2 PAHT 2 PAHT 3.2 PAHT 4 PAHT 6.3 PAHT 10

Min. ow at

100 barg / 1450

Max. ow at

100 barg / 1450

Motor type Pole 6 4 4 4 4 4

Rated power

Motor voltage

Motor current

FLA

Cos φ 0.72 0.77 0.79 0.79 0.82 0.83

Speed rpm 900 1,400 1,400 1, 400 1,420 1,420

Weight without

options

Shipping

Crate size

(H×W×D)

l/h 7.5 10.0 20.0 30.0 50.0 75.0

psig*

gal/h 2.0 2.6 5.3 7.9 13 .2 19. 8

l/h 75 100 200 300 500 750

psig*

gal/h 2.0 26.4 52.8 79.2 132.0 198 .0

kW @ 50 Hz 0.55 0.75 1. 50 1.50 2.20 3.00

kW @ 60 Hz 0.66 0.90 1.80 1.80 2.65 3.60

V @ 50 Hz 3×230/400 3×230/400 3×230/400 3×230/400 3×230/400 3×230/400

V @ 60 Hz 3x280/480 3x280/480 3x280/480 3x280/480 3x280/480 3x280/480

A 1.7 1.9 3.5 3.5 4.7 6.3

V 400 400 400 400 400 400

kg 55 55 58 58 67 73

lbs 121 121 12 8 128 148 161

kg 85 85 88 88 97 103

lbs 187 187 19 4 194 214 227

m 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8

inch 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5

NPS NPS NPS NPS NPS NPS

1CS 2CS 3.2CS 4CS 6.3CS 10CS

* Minimum and maximum ow increase with decreasing system pressure. Please observe technical data in pump data sheet.

AI309730711498en-0 00901 | 02.2021

7

Page 8

Data sheet | Plug & Spray unit NPS

Mounted with with Danfoss FCP 106 Drive Motor

Typ e

Ordering code 180U330 6 180U3307 180U3308 180U3309 18 0U3310 18 0U3311 18 0U3312

Pump type PAH T 12. 5 PAHT 2 PAHT 3.2 PAHT 4 PAHT 6.3 PAHT 10 PAHT 12 .5

Min. ow at

100 barg*

Max. ow at

100 barg*

Motor type Pole 4 2 2 2 2 4 4

Rated power

Motor voltage

Motor current

FLA

Cos φ 0.83 1 1 1 1 1 1

Speed rpm 1, 440

Weight without

options

Shipping

Crate size

(H×W×D)

l/h 100 10 20 30 50 75 100

gph 26.4 2.64 5.3 7.92 13.2 19.8 26.4

l/h 1,000 300 450 600 1,000 1,350 1,650

gph 264.0 79.2 119. 0 158.0 264.0 356.0 443.0

kW @ 50 Hz 4.00 1. 50 2.20 2.20 4.00 7. 50 7.50

kW @ 60 Hz 4.80 1. 80 2.65 2.65 4.80 9.00 9.00

V @ 50 Hz 3×400/690 3×230/400 3×230/40 0 3×230/4 00 3×400/690 3×400/690 3×400/690

V @ 60 Hz 3x480/830 3x280/480 3x280/480 3x280/480 3x480/830 3x480/830 3x480/830

A 8.2 3.3/2.6 4.7/3.7 4.7/3.7 7.9/6 .4 11/ 8 .7 11/8.7

V 400 380/480 380/480 380/480 380/480 380/480 380/480

kg 76 64 70 70 81 10 4 104

lbs 168 141 15 4 154 179 229 229

kg 106 94 10 0 100 111 134 134

lbs 234 207 220 220 245 295 295

m 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8 0.8 x 0.6 x 0.8

inch

NPS NPS NPS NPS NPS NPS NPS

12. 5CS 2VS 3.2VS 4VS 6.3VS 10VS * * 12. 5VS **

1,000–3,000

31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5 31.5 x 23.6 x 31.5

1,000–3,000 1,000–3,000 1,000–3,000 1,000–2,400 1,000–2,400

* Minimum and maximum ow increase with decreasing system pressure. Please observe technical data in pump data sheet.

** Mounted with VRH 30 CA (180G0032)

8

AI309730711498en-0 00901 | 02.2021

Page 9

Data sheet | Plug & Spray unit NPS

5. Dimensions [mm]

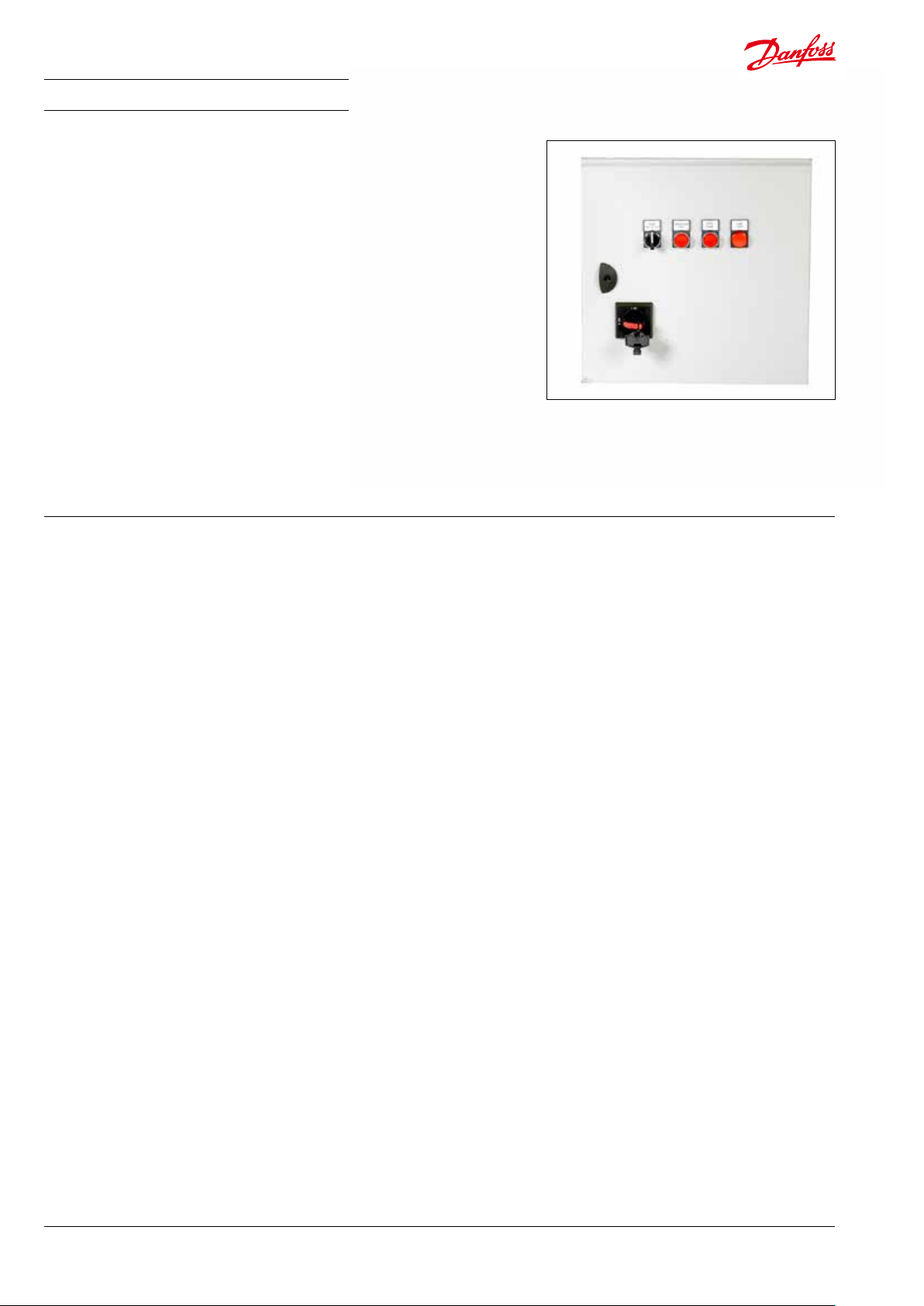

6. Local control panel

7. Options

The Plug & Spray VS units with the Danfoss

FCP 106 Drive Motor are pre-programmed from

the factory. However some parameters must be

adjusted during commissioning (i.e. for the PID

loop).

Danfoss recommends ordering at least one Local

Control Panel (LCP 102) per installation.

For xed installation of the LCP in a cabinet,

Danfoss oers a remote mounting kit with 3 m

cable.

Ordering codes:

VLT® Control Panel LCP 102

(Graphical LCP only): 130B1107

Remote Mounting Kit (LCP 102)

3 m cable, panel mounting bracket,

gasket and fastners: 134B0564

The Plug & Spray product program oers

numerous options and possibilities for customization.

Examples of options:

• Water supply solenoid valve

• Pressure reduction valve (supply)

• Zone or step control valves (please refer to

Danfoss’ wide program of high-pressure

solenoid valves).

For details, please contact your nearest Danfoss

representative.

Multiple valve block solution installed on base frame

AI309730711498en-0 00901 | 02.2021

9

Page 10

Data sheet | Plug & Spray unit NPS

8. Electrical connection

box

The electrical connection box can be directly

connected to a 3×400 V, 50 Hz power supply and

provides a simple, pre-wired “plug and play”

solution for integrating the Plug & Spray unit in a

humidication or adiabatic cooling system. The

electrical connection box is available for CS and

VS units.

The electrical connection box comprises

following basic components:

• Mains disconnect with fuses

• Hand-O-Auto switch (CS only)

• Motor overload protection (CS only)

• Operation hour counter (CS only)

• Inlet pressure monitoring with reset button

• Water temperature monitoring with reset

button

• Terminals for external start signal

(potential free contact)

• Contacts for fault relay

• LCP 102 in front door (VS units only, allows

monitoring operation hours and Hand-OAuto functionality)

10

AI309730711498en-0 00901 | 02.2021

Page 11

Data sheet | Plug & Spray unit NPS

The electrical connection box can be ordered from factory in two versions:

Wall

With 2 metres cable

Free standing

On supports

Ordering codes for any customized units are available on request, please contact your nearest

Danfoss representative.

AI309730711498en-0 00901 | 02.2021

11

Page 12

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2021.02

AI309730711498en-000901 | 12

Loading...

Loading...