Data sheet

NovoCon® S, M, L and XL

Digital actuators

Novo Con® M Novo Con® LNovo Con® S Novo Con® XL

Table of contents

Description .................................................................................................2

Ordering ......................................................................................................4

Cross reference table AB-QM – Flow sens or - NovoCon® ...6

Technical data ...........................................................................................7

Design ...........................................................................................................9

Installation and orientation .............................................................10

Dip switches ...............................................................................................11

DIP Switch Settings ......................................................................11

DIP Switch Settings - Manual Addressing ........................... 12

Wiring ............................................................................................................13

Wiring considerations.................................................................14

Daisy ch ain & Power booster ............................................................ 18

LED Display ............................................................................................... 22

Application principle ........................................................................... 28

NovoCon® S I/O ............................................................................. 28

NovoCon® I/O and Multiplexers/Relays .............................. 28

Central Plant Changeover – 2 pipe system ....................... 28

ChangeOver6 - 4 pipe system ................................................. 29

ChangeOver6 Energy .................................................................. 29

Analog CO6 mode ....................................................................... 29

ChangeOver6 ................................................................................. 31

No mixing and shut off ....................................................................... 32

Application mode .................................................................................. 32

BACnet objects and Modbus registers usage ......................... 33

Design flow rate set ting ...........................................................33

Advanced configuration and features ................................ 34

Optimize BACnet network speed ..................................................35

Energy management ...........................................................................35

Power Manager ............................................................................ 35

Delta T Manager ........................................................................... 36

Commissioning/connection of flow sensor to: ...................... 38

NovoCon® S .................................................................................... 38

NovoCon® M .................................................................................. 39

NovoCon® L, XL ............................................................................. 40

Auto baud rate ......................................................................................... 41

Auto MAC Addressing - BACnet only ...........................................41

BACnet Obje cts - Analog Value ...................................................... 42

BACnet Obje cts - Multi Stat e Value .............................................. 43

BACnet Objects - Binary Value ........................................................ 45

BACnet Objects- Device Object ...................................................... 45

BACnet Obje cts - Analog Input ....................................................... 46

BACnet Obje cts - Analog Out put ...................................................46

BACnet Objects - Notification class.............................................. 46

BACnet Objects - Averaging ............................................................. 46

BACnet BIBBs serv ices ......................................................................... 46

Modbus registers - Configuration ................................................ 47

Modbus registers - Operating ......................................................... 50

Modbus registers - Information .....................................................51

Alarms & warning ..................................................................................52

Firmware update .................................................................................... 52

Valve Type Selection ............................................................................ 53

Temperature sensors ...........................................................................54

Tender text ................................................................................................54

Trouble shooting ....................................................................................56

Firmware update ......................................................................... 56

BACnet data ................................................................................... 56

Modbus RTU data ........................................................................ 56

Manual operation .................................................................................. 57

Dimensions ............................................................................................... 58

© Danfoss | 2022.01 AI368140926963en-010102 | 1

Data sheet NovoCon® S, M, L and XL Digital actuators

Description

NovoCon® S

NovoCon® S is a high accuracy multi-functional

field bus actuator, specifically designed for use

in combination with the Pressure Independent

Control Valve type AB-QM in sizes from DN 10-32.

The flow is modulated by the AB-QM pressure

independent control valve to avoid overflow and

reduced boiler and/or chiller efficiency.

The actuator with AB-QM is used to control water

supply to fan coil units, chilled beams, induction

units, small re-heaters, re-coolers, AHU’s and other

terminal units for zone control, in which heating/

chilled water is the controlled medium. Due to its

accuracy, remote functionality and flow indication

features, this product facilitates an accelerated

commissioning process, allows easy maintenance,

improves indoor comfort, increases energy savings

and allows for fair cost allocation of heat/cool

energy.

The high position accuracy of the actuator,

together with the pressure independent and linear

characteristic of the AB-QM valve, allow NovoCon®

S to be used as a flow indicator.

Setup of the actuator and valve parameters are

made via fieldbus. Control is achieved via field bus

or via analog inputs to NovoCon® S.

Typical applications are:

• Radiant ceiling panels, supplied by 4 pipes

(Heating supply and return and cooling supply

and return).

• Fan coil units, with single coils supplied by 4

pipes (Heating supply and return and cooling

supply and return).

General features:

• Remote commissioning/Pre-set/Flush features

• Flow, power emission and energy indication

• High position resolution and accuracy

• Energy management algorithms

• 4/2-pipe changeover applications

• I/O applications

• LED bar displaying status and alarms

• No tools required for mounting

• Maintenance-free lifetime

• Self-positioning process

• Low-noise operation

• Plug-in halogen free cables

• Auto MAC addressing for BACnet

• Auto baud rate detection

• Intrinsic alarm reporting for BACnet

• Valve blockage alarm

• Broken wire detection on analog control and

ground signal

• Choice of BACnet MS/TP or Modbus RTU in the

same product

• Mis-wiring protection on any wire up to 30 V

Combined with the Actuator NovoCon®

ChangeOver6, NovoCon® S offers a unique solution

in controlling both the AB-QM valve and a 6-port

motorised ball valve that performs a diverting

function between two water circuits in 4-pipe

changeover systems.

This diverting function, primarily used for radiant

panels, also allows the cooling and heating capacity

of a fan coil unit to be increased for the same

compact size compared to a double coil model

where the heating and cooling water circuits each

have their own coil.

The 6-port diverting valve and actuator work in

combination with an AB-QM PIBCV valve and

NovoCon® S bus actuator. The AB-QM balances the

flow and the NovoCon® S bus actuator controls

the flow. NovoCon® S also controls the 6-port

diverting valve actuator which switches between

heating and cooling. This unique functionality is

characterized by the following:

• There is only one single field bus and power

supply connection cable to the NovoCon® S

actuator. This powers both the NovoCon® S

and controls the 6-port actuator. Furthermore,

there is feedback from the 6-port actuator to

NovoCon® S.

• The NovoCon® S actuator automatically faultdetects, by means of comparing 0-10V control

& feedback signals, if the 6-port actuator is in

manual operation mode, removed from the

valve or if the 6-port valve is blocked.

• The NovoCon® S actuator has two Design Flow

Rate pre-settings: one for heating and another

for cooling.

• The NovoCon® S actuator indicates power

emission and logs energy consumption

for heating and cooling energy based on

flow, supply and return pipe temperature

measurement.

• While in maintenance mode, the 6-port actuator

is able to fully close the valve and prevent any

leakage, thereby saving on stop valves.

• Logic contained within the NovoCon® S actuator,

ensures that only one actuator in each pair

(NovoCon® S and 6-port valve actuator) drives.

This ensures that 2 actuators in the pair never

drive at the same time. This reduces voltage

booster demands in daisy chains.

• The NovoCon® S actuator detects if the 6-port

actuator cable is disconnected. If this is the case

an alarm is initiated.

Features CO6:

• NovoCon® S + ChangeOver6 actuator represents

only ONE device on the fieldbus network

needing no physical I/O

• No cross-flow between heating and cooling

• Simple connection and control

• Feedback for position status and alarms

• Quiet and reliable operation

• Maintenance free

• Teflon seal and polished chrome valve ball to

prevent valve sticking

• Blocked valve alarm

• Manual override

2 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Red

AI:2 / 33220

Read / writeable via fieldbus

Read / writeable via fieldbus

AI:2 / 33220

Description (continued)

NovoCon® S (continued)

NovoCon® M

Features Energy:

•

Supply and return temperature measurement

• Power emission indication reading

• Energy management functionality for both

heating and cooling e.g. minimum delta T

management

• Energy logging of both heating and cooling

Features I/O:

• Connect to other devices and present them

on the field bus, e.g. room thermostat,

window contact, CO2 sensor, humidity

sensors, fan control, 0-10V actuator etc.

• Select temperature units, Ohms or use as

BACnet object / Modbus register

Black

Blue

Grey

White

0-20mA

AI:0 / 33216

0-10V

AO:0 / 33286

Yellow

Orange

NovoCon® M is a high accuracy multi-functional

fieldbus actuator, specifically designed for use

in combination with the Pressure Independent

Control Valve type AB-QM NovoCon® in sizes

from DN 40-100 used in air handling units AHU,

chillers and distribution station applications.

The high position accuracy of the actuator,

together with the pressure independent and

linear characteristic of the AB-QM valve, allow

NovoCon® M to be used as a flow indicator.

Setup of the actuator and valve parameters

are made via fieldbus. Control is achieved via

fieldbus or via analog inputs to NovoCon® M.

potential free contacts. Closed circuit <900Ω,

open circuit 100kΩ.

• Available connections: 1 x analog output (V),

1 x analog input (V/mA) and 2 x resistance

based inputs (°C/°F/Ohms)

BACnet object / Modbus register

0-10V

0-10V

0-10V

AI:1 / 33218

10kΩ

10kΩ

0-20mA

AI:0 / 33216

0-10V

AO:0 / 33286

AI:1 / 33218

General features:

• Remote commissioning/Pre-set/Flush features

• Flow, power emission and energy indication

• High position resolution and accuracy

• Energy management algorithms

• Inputs/Outputs

- 3x Resistance Inputs (Pt1000, PT500, PT100,

NTC 10k Type 2 & 3)

- 1x Analog Input (0-10V or 0/4-20mA),

- 1x Analog Output (0-10V)

• LED displaying status and alarms

• No tools required for mounting on valve

• Maintenance-free lifetime

• Low-noise operation

• Auto MAC addressing for BACnet

• Auto baud rate detection

• Intrinsic alarm reporting for BACnet

• Valve blockage alarm

• Choice of BACnet MS/TP or Modbus RTU in

the same product

• Mis-wiring protection on any wire up to 30 V

NovoCon® L, XL NovoCon® L/XL is a high accuracy multi-

functional fieldbus actuator, specifically

designed for use in combination with the

Pressure Independent Control Valve type AB-QM

in sizes from DN 125-250 used in air handling

units AHU, chillers and distribution station

applications.

The high position accuracy of the actuator,

together with the pressure independent and

linear characteristic of the AB-QM valve, allow

NovoCon® L/XL to be used as a flow indicator.

Setup of the actuator and valve parameters

are made via fieldbus. Control is achieved via

fieldbus or via analog inputs to NovoCon® L/XL.

General features:

• Remote commissioning/Pre-set/Flush features

• Flow, power emission and energy indication

• High position resolution and accuracy

• Energy management algorithms

• Inputs/Outputs

- 3x Resistance Inputs (Pt1000, PT500, PT100,

NTC 10k Type 2 & 3)

- 1x Analog Input (0-10V or 0/4-20mA),

- 1x Analog Output (0-10V)

• LED displaying status and alarms

• Maintenance-free lifetime

• Low-noise operation

• Auto MAC addressing for BACnet

• Auto baud rate detection

• Intrinsic alarm reporting for BACnet

• Valve blockage alarm

• Choice of BACnet MS/TP or Modbus RTU in

the same product

• Mis-wiring protection on any wire up to 30 V

AI368140926963en-010102 | 3© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Ordering

NovoCon® S

Typ e Code No.

NovoCon® S 003Z8504

Accessories

Typ e Length Connections Cable material Code No.

Cable NovoCon® Digital 1.5 m bus / power Halogen free 003Z8600

Cable NovoCon® Digital 5 m bus / power Halogen free 003Z8601

Cable NovoCon® Digital 10 m bus / power Halogen free 003Z8602

Cable NovoCon® Digital, daisy chain

Cable NovoCon® Digital, daisy chain

Cable NovoCon® Digital, daisy chain

Cable NovoCon® Digital, daisy chain

Cable NovoCon® Analog 1.5 m 0-10 V / power / voltage booster Halogen free 003Z8606

Cable NovoCon® Analog 5 m 0-10 V / power / voltage booster Halogen free 003Z8607

Cable NovoCon® Analog 10 m 0-10 V / power / voltage booster Halogen free 003Z8608

Cable NovoCon® I/O 1.5 m actuator / free wires Halogen free 003Z8612

Note! Cables are not i ncluded with actuator and m ust be ordered separately.

Cable NovoCon®

Energy

Cable NovoCon®

Energy

Cable NovoCon®

Temperature I/O

Note! If se parate Pt1000 temperature sensors a re needed, Danfoss has an ar ray of Pt100 0 sensors that can be used with Novo Con® S.

See Danfoss P t1000 sensor s ESMT, ESM-10, ESM-11, ESMB-12, ESMC, ESMU and code n o. 187F3418.

1.5 m Plug-in cable with Pt1000 surface temperature sensors PVC 003Z8610

1.5 m

1 m / Temp.

sensor 1.5m

0.5 m actuator / actuator Halogen free 003Z8609

1.5 m actuator / actuator Halogen free 003Z8603

5 m actuator / actuator Halogen free 003Z8604

10 m actuator / actuator Halogen free 003Z8605

Plug-in cable with Pt1000 Immersed /universal

temperature sensors (Ø 5,8m m)

Plug-in cable with Pt1000 surface temperature sensors

and free wires for input, output and power

PVC 003Z8611

Halogen free.

Sensor cables PVC

003Z8613

ChangeOver6 actuators

Actuator NovoCon ChangeOver

Actuator NovoCon ChangeOver6 Energy

Actuator NovoCon ChangeOver6 Flexible

6

1 m Plug-in Halogen free 003Z 8520

1 m

Temp. sensor 1.5 m

1.5 m

Plug-in incl. Pt1000 sur face

temperature sensors

Actuator / open wires Halogen free 003Z8522

Halogen free

Sensor cables PVC

003 Z8521

Typ e DN Fire load class Code No.

ChangeOver6 insulation

According to D/N 4102

Typ e DN

ChangeOver6 valve

15 B2 003Z3159

k

VS

Connection

(m3/h)

15 2.4 Rp ½ 003 Z3150

20 4.0 Rp ¾ 0 03Z3151

Code No.

NovoCon® Configuration Tool

Typ e

NovoCon® Configuration Tool cable 5 m

Length

Connections Cable material Code No.

USB /

actuator

Software available on www.novocon.com

Temperature sensors

Typ e

Immersed Pt 1000 / f 5.2 mm / 1.5 m cable,

pair, MID

Code No.

187F3 418

Service kit - combination with old AB-QM

Typ e Code No.

NovoCon® adapter for AB-QM, DN 10-32 (5 pcs.) 003Z0239

Accessories (Cable NovoCon® Energy)

Typ e Designation Code No.

Immersion brass pockets,

40 mm, Ø 6.0 pair.

Pockets for Cable

NovoCon® Energy

(003Z8611)

Halogen free. USB Conver ter, PVC 003Z8620

For pipes DN25/32.

Immersion brasspockets, 35 mm, Ø 5.2

pair, MID. For pipes

DN15 -32

087G6061

087G6053

4 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Ordering (continued) Actuator

NovoCon® M

Typ e Supply voltage Code No.

NovoCon® M 24V ac /dc 003Z8540

Temperature sensors

Typ e Code No.

Immersed Pt 1000 / Ø 5.2 mm / 1.5 m cable,

pair, MID

Immersed Pt 1000 / Ø 5.2 mm / 3.0 m cable,

pair, MID

Accessories

Designation Code No.

Immersion brass-pockets, 52 mm, Ø 5.2 pair,

MID. For pipes DN40-65

Immersion brass-pockets, 85 mm, Ø 5.2 pair,

MID. For pipes DN80-125

NovoCon® Configuration Tool

Typ e Length Connections Cable material Code No.

NovoCon® Configuration Tool cable 5 m USB / actuator Halogen free. USB Converter, PVC

Software available on www.novocon.com

NovoCon® L, XL

Actuators

Picture Ty pe

Temperature sensors

Typ e

Immersed Pt 1000 / Ø 5.2 mm / 3.0 m cable,

pair, MID

Valve t ype

NovoCon® L AB -QM D N125-150

NovoCon® L SU AB -QM D N125-150

NovoCon® L SD AB -QM D N125-150

NovoCon® XL AB- QM DN2 00-250

187F3 418

187F3419

087G6054

087G6055

Code No.

003Z8560

003Z8 561

003Z8562

003Z8563

Code No.

187F3419

Valves

Typ e Co de No.

AB-QM NovoCon DN40 PN16 3TP 0 03Z17 70

AB-QM NovoCon DN50 PN16 3TP 00 3Z1771

AB-QM NovoCon DN50 PN16 - Flange 3TP 00 3Z177 2

AB-QM NovoCon DN65 PN16 3TP 0 03Z17 73

AB-QM NovoCon DN65 PN16 3TP HF 00 3Z179 3

AB-QM NovoCon DN80 PN16 3TP 0 03Z17 74

AB-QM NovoCon DN80 PN16 3TP HF 00 3Z179 4

AB-QM NovoCon DN100 PN16 3TP 003 Z1775

AB-QM NovoCon DN100 PN16 3TP HF 00 3Z179 5

Note: The abo ve AB-QM NovoCo n valves must be used with N ovoCon® M.

003Z8620

Accessories

Designation Co de No.

Immersion brass-pockets, 85 mm, Ø 5.2 pair,

MID. For pipes DN80-125

Immersion brass-pockets, 120 mm, Ø 5.2 pair,

MID. For pipes DN150-200

Immersion stainless steel-pockets, 155mm,

Ø

5.2 pair, MID. For pipes DN250

087G6055

087G6056

087G6059

NovoCon® Configuration Tool

Typ e Length Connections Cable material Code No.

NovoCon®

Configuration Tool cable

Software available on www.novocon.com

5 m USB / actuator Halogen free. USB Converter, PVC 003Z8620

AI368140926963en-010102 | 5© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

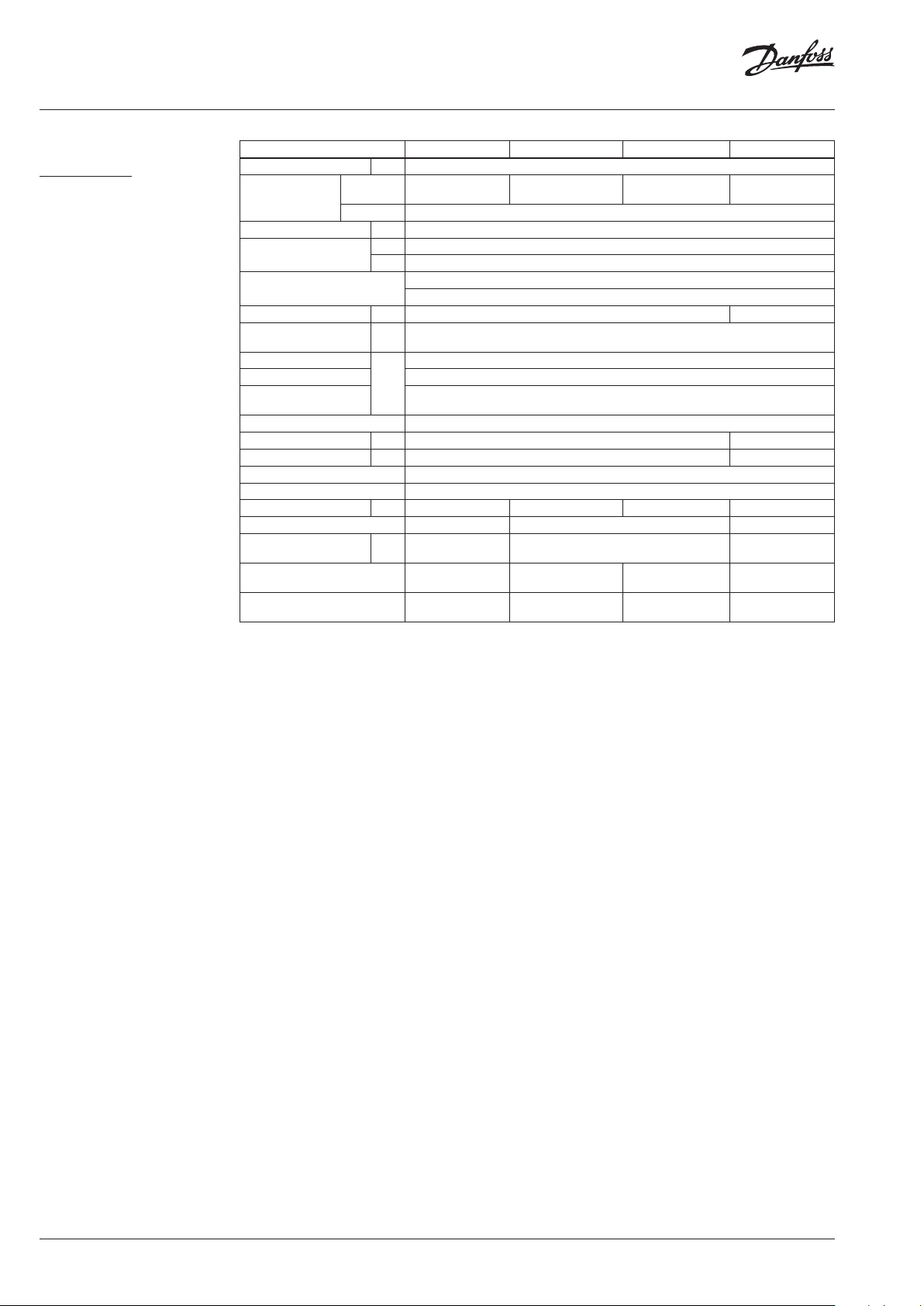

Cross reference table AB-QM – Flow sensor - NovoCon®:

Valve

code

003Z8220

003Z 8221

003Z8222

003Z8223

003Z8224

003Z8320

003Z8321

003Z8322

003Z8323

003Z8324

003 Z1204

003 Z1224

003 Z1205

003 Z1225

00 3Z1770

00 3Z1771

003Z1773

00 3Z1793

00 3Z1774

00 3Z179 4

00 3Z1775

003Z1795

003Z0705

003 Z0715

003Z0706

003 Z0716

003Z0707

00 3Z0717

003Z0708

003 Z0718

Valve name

AB-Q M4 DN15 LF 0. 2 m3/h

AB-Q M4 DN15 0.65 m3/h

AB-Q M4 DN15 HF 1.2 m3/h

AB-Q M4 DN20 1.1 m3/h

AB-Q M4 DN20 HF 1.9 m3/h

AB-Q M4 DN15 LF 0. 2 m3/h

AB-Q M4 DN15 0.65 m3/h

AB-Q M4 DN15 HF 1.2 m3/h

AB-Q M4 DN20 1.1 m3/h

AB-Q M4 DN20 HF 1.9 m3/h

AB-Q M DN25 1.7 m3/h

AB-Q M DN25 HF 2.7 m3/h

AB-Q M DN32 3.2 m3/h

AB-Q M DN32 HF 4.0 m3/h

AB-Q M NovoCon DN40

7. 5 m3/h

AB-Q M NovoCon DN50

12. 5 m3/h

AB-Q M NovoCon DN65

20.0 m3/h

AB-Q M NovoCon DN65 HF

25.0 m3/h

AB-Q M NovoCon DN80

28.0 m3/h

AB-Q M NovoCon DN80 HF

40.0 m3/h

AB-Q M NovoCon DN100

38.0 m3/h

AB-Q M NovoCon DN100 HF

59.0 m3/h

AB-Q M DN125 90.0 m3/h

AB-Q M DN125 HF 110.0 m3/h

AB-Q M DN150 150.0 m3/h

AB-Q M DN150 HF 190.0 m3/h

AB-Q M DN200 220.0 m3/h

AB-Q M DN200 HF 285.0 m3/h

AB-Q M DN250 300.0 m3/h flange 003Z8563 NovoCo n XL 187F3532 SONO 3500 CT D N150 Qp 150.0 m3/h flange / 187F3419 087G6059

AB-Q M DN250 HF 370.0 m3/h flange 003Z8563 Novo Con XL 187F3532 SONO 3500 CT D N150 Qp 150.0 m3/h flange / 187F3419 087G6059

* IO cable with sur face sensor (Pt1000)

Valve

connection

thread 003Z850 4 NovoCon S 187F3771 Sono S30 DN15 Qp 0.6 m3/ h thread

thread 003Z850 4 NovoCon S 187F3771 Sono S30 DN15 Qp 0.6 m3/ h thread

thread 003Z850 4 NovoCon S 187F3772 Sono S30 D N15 Qp 1.5 m3/h thread

thread 003Z850 4 NovoCon S 187F3772 Sono S30 D N15 Qp 1.5 m3/h thread

thread 003Z850 4 NovoCon S

int. thread 003Z8504 Novo Con S 187F3771 Sono S30 DN15 Qp 0.6 m3/h thread

int. thread 003Z8504 Novo Con S 187F3771 Sono S30 DN15 Qp 0.6 m3/h thread

int. thread 003Z8504 Novo Con S 187F3772 Sono S30 DN15 Qp 1.5 m3/h thread

int. thread 003Z8504 Novo Con S 187F3772 Sono S30 DN15 Qp 1.5 m3/h thread

int. thread 003Z8504 Novo Con S 187F3772 Sono S30 DN15 Qp 1.5 m3/h thread

thread 003Z850 4 NovoCon S 187F3773 Sono S30 DN20 Qp 2. 5 m3/h thread

thread 003Z850 4 NovoCon S 187F3773 Sono S30 DN20 Qp 2. 5 m3/h thread

thread 003Z850 4 NovoCon S 187F3774 Sono S30 DN25 Qp 3. 5 m3/h thread

thread 003Z850 4 NovoCon S 187F3774 Sono S30 DN25 Qp 3. 5 m3/h thread

thread 003Z854 0 NovoCon M 187F3776 Sono S30 DN4 0 Qp 10.0 m3/h thread / 187 F3418 087G6054

thread 003Z854 0 NovoCon M 187F3776 Sono S30 DN4 0 Qp 10.0 m3/h thread / 187 F3418 087G6054

flange 0 03Z8540 Novo Con M 187F3777 Sono S 30 DN50 Qp 15.0 m3/h f lange / 187F3419 087G6054

flange 0 03Z8540 Novo Con M 187F3778 Sono S30 DN 65 Qp 25.0 m3/h f lange / 187F3419 087G6054

flange 0 03Z8540 Novo Con M 187F3778 Sono S30 DN 65 Qp 25.0 m3/h f lange / 187F3419 087G6055

flange 0 03Z8540 Novo Con M 187F3779 Sono S30 DN8 0 Qp 40.0 m3/h f lange / 187F3419 087G6055

flange 0 03Z8540 Novo Con M 187F3779 Sono S30 DN8 0 Qp 40.0 m3/h f lange / 187F3419 087G6055

flange 0 03Z8540 Novo Con M 187F3780 Sono S30 D N100 Qp 6 0.0 m3/h f lange / 187F3419 087G6055

flange 0 03Z8560 NovoCon L 187F3530 S ONO 3500 CT DN100 Qp 60.0 m 3/h flange / 187F3419 087G6055

flange 0 03Z8560 NovoCon L 187F3530 S ONO 3500 CT DN100 Qp 60.0 m 3/h flange / 187F3419 087G6055

flange 0 03Z8560 NovoCon L 187F3531 SONO 350 0 CT DN125 Qp 100.0 m3/h flange / 187F3419 087G6056

flange 0 03Z8560 NovoCon L 187F3531 SONO 350 0 CT DN125 Qp 100.0 m3/h flange / 187F3419 087G6056

flange 003Z8563 NovoCon XL 187F3531 SONO 3500 CT D N125 Qp 100.0 m3/ h f lange / 187F3419 087G6056

flange 003Z8563 NovoCon XL 187F3532 SONO 3500 C T DN150 Qp 150.0 m 3/h flange / 187F3419 087G6056

Actuator

code

Actuator

name

Flow

sensor

code

187F3772 Sono S30 DN15 Qp 1.5 m3/h thread

Flow sensor name

Flow

sensor

connection

cable

Temperature

sensor code

(Pt1000)

Immersion

pockets code

NovoCon S

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

003Z8613* / /

003Z8612 187F3 418 087G6053

6 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

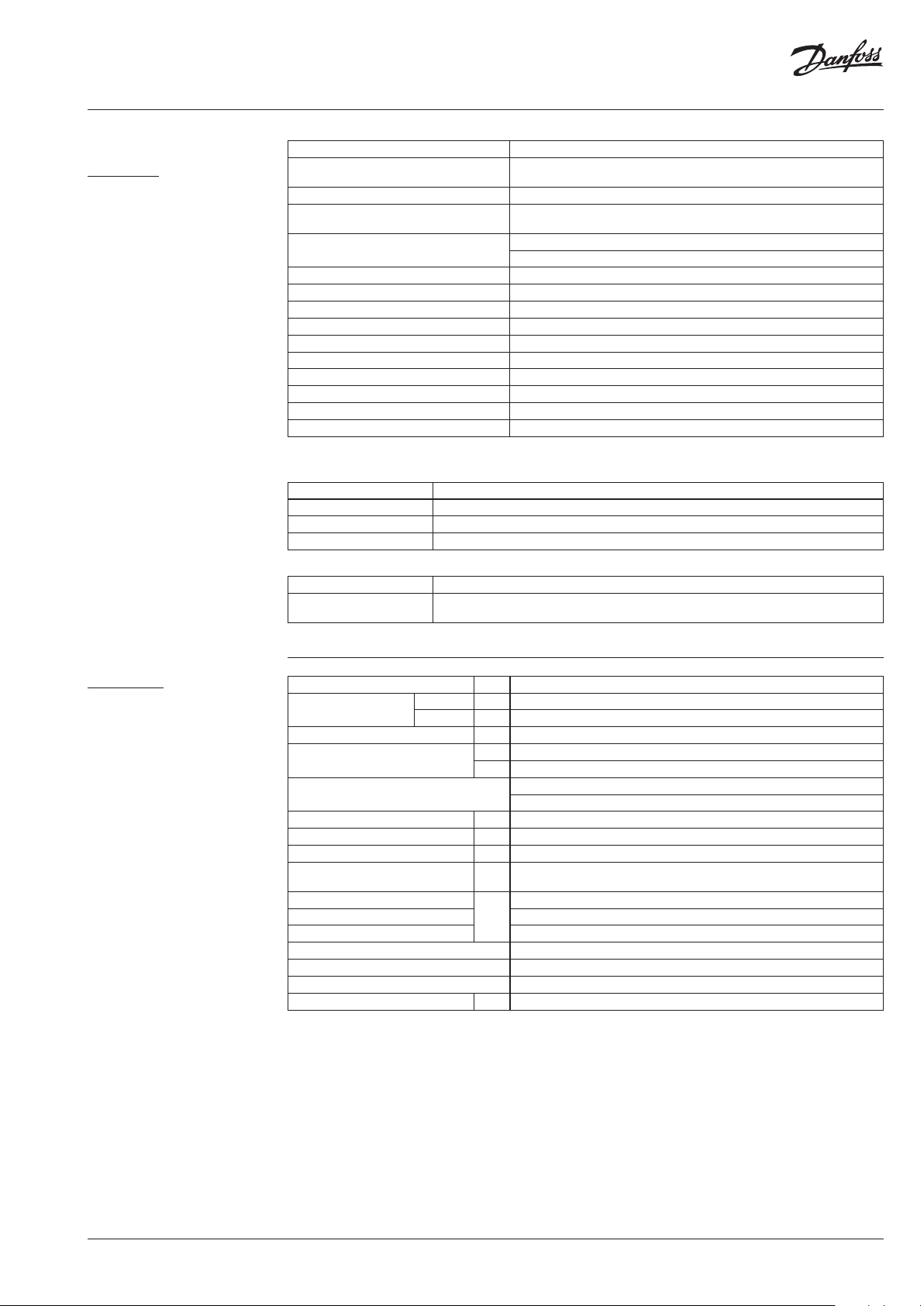

Technical data

NovoCon® S

Power supply range 24 V AC/DC, 50 / 60 Hz *

Power consumption

Protection class III safet y extra-low voltage

Control signal NovoCon® S

Impedance

Actuator sp eed selections (o pen to close)

Stroke 7 mm

Force 90 N

Position accuracy ± 0.05 mm

Ambient temp. range −10° C to 50° C

Ambient humidity 98% r.h., non-condensing (accordin g to EN 60730 -1)

Max. medium temp. 120 ° C

Storage temp. range –40 to 70 °C

Grade of enclosure IP 54 (IP 40 upside down)

Weight 0.4 kg

* NovoCon® S is designe d to operate at power deviatio ns up to ±25%.

0-10 VDC, 0-5 VDC, 2-10 VDC, 5-10 VDC, 2- 6 VDC, 6-10 VDC, 0-20 mA, 4 -20 mA

Operating: 2.7 VA@24VAC / 1.2 W@24VDC

Standby: 1.8 VA@24VAC / 0.7 W@24VDC

BACnet MS/TP, Modbus RTU

Rin AI:0 >100 kΩ (V); 500 Ω (mA)

Rout AO: 1500 Ω

3 sec/mm, 6 sec/mm, 12 sec/mm, 24 sec/mm, Constant Time

BACnet data

Typ e Description

BACnet device profile BACnet Application Specific Controller (B -ASC)

BACnet protocol BACnet Master Slave / Token Passing (MS/TP)

BACnet baud rates supported

Auto baud rate detection* / 9600 bps / 19200 bps / 38400 bps / 56700 bps / 76800 bps / 115200bps

Modbus RTU data

Supported baud rates

Supported transmission

modes

* Default

Auto baud rate detection* / 9600 bps / 19200 bps / 38400 bps / 56700 bps / 76800 bps / 115200bps

Parity: None (1-8-N -2) / Odd (1-8- O-1) / Even (1-8-E-1) / None (1-8-N-1) / Auto parity*

Data format: Parity (Start bit - Data bits - Parity - Stop bits)

NovoCon® M

Power supply V 24 ±25% ac/dc

Power consumption

Frequency Hz 50 /60±10 %

Control signal

Impedance

Closing force N 550

Max. stroke mm 20

Position accuracy mm ± 0.2

Actuator sp eed selections (open to

close)

Max. medium temperature

Ambient temperature –10 … 50

Storage and transport temperature –40 … 70

Ambient humidity 5-95% r.h., non-condensing (according to EN 60730-1)

Protection class III

Grade of enclosure IP 54

Weight kg 0.5

running VA <3.5@24Va c / <2.0@24Vdc

standby W 2.0 ac / 0.9 dc

VDC BACnet MS/TP, Modbus RTU, 0-10, 0-5, 2-10, 5-10, 2-6, 6-10

mA 0-20, 4 -20

Rin 90k Ω (V). 500 Ω (mA)

Rout 250Ω

s/mm 3, 6, 12, 24, Constant Time

120

°C

AI368140926963en-010102 | 7© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Technical data (continued)

NovoCon® L, XL

Actuator type NovoCon® L NovoCon® L SD NovoCon® L SU Novo Con® XL

Power supply V 24; +10 … 15 %; AC/DC

Power consumption

Frequency Hz 50/60

Control signal

Impedance

Position accuracy mm ± 1 ± 1.8

Actuator speed selections

(open to close)

Max. medium temperature

Ambient temperature –10 … 50

Storage and transport

temperature

Ambient humidity 5-95% r.h., non-condensing (according to EN 60730-1)

Closing force N 2000 4000

Max. stroke mm 50 80

Protection class III

Grade of enclosure IP 54

Weight kg 5.4 9.6 8.9 6.3

Safety function - Yes -

Safety function runtime /

32 mm stroke

Manual operation

Power failure response

Operating:

Standby: 1.7VA@24VAC / 0 .7W@24V DC

9.6VA@24VAC /

7.2W@24VDC

Vdc BACnet MS/TP, Modbus RTU, 0 -10, 0-5, 2-10, 5-10, 2-6, 6-10

mA 0-20, 4 -20

s/

mm

°C

s - 120 -

Electrical and

mechanical

Stem remains in last

position

14.4VA@24VAC /

12W@24VDC

Rin 90k Ω (V). 500 Ω (mA)

3, 6, 12, 24, Constant Time

–40 … 70 (above 50°C, less than 3 days)

Electrical and

mechanical

Safety function Down,

pushes stem down

14.4VA@24VAC /

12W@24VDC

Rout 250Ω

120

Electrical and

mechanical

Safety function

Open, pulls stem up

13.9VA @24VAC /

10.8W@24VD C

Electrical and

mechanical

Stem remains in last

position

8 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Design

NovoCon® S

NovoCon® M

⑦

⑥

⑤

①

②

③

④

1. Removable lid

2. Bus and power connections

3. Status LED

4. Locking ring

5. Manual override

6. Reset button

7. DIP switches

1. Communication LED

2. Manual operation knob

3. Buttons and status LED

4. Valve connector

5. Position indicator

6. DIP switches (under cover)

7. Service cover

8. Removable gland support

NovoCon® L, XL

1. Manual operation knob

2. Buttons and status LED

3. Service cover

4. Removable gland support

5. End position indication ring

6. Stem connector

7. Valve connector

AI368140926963en-010102 | 9© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

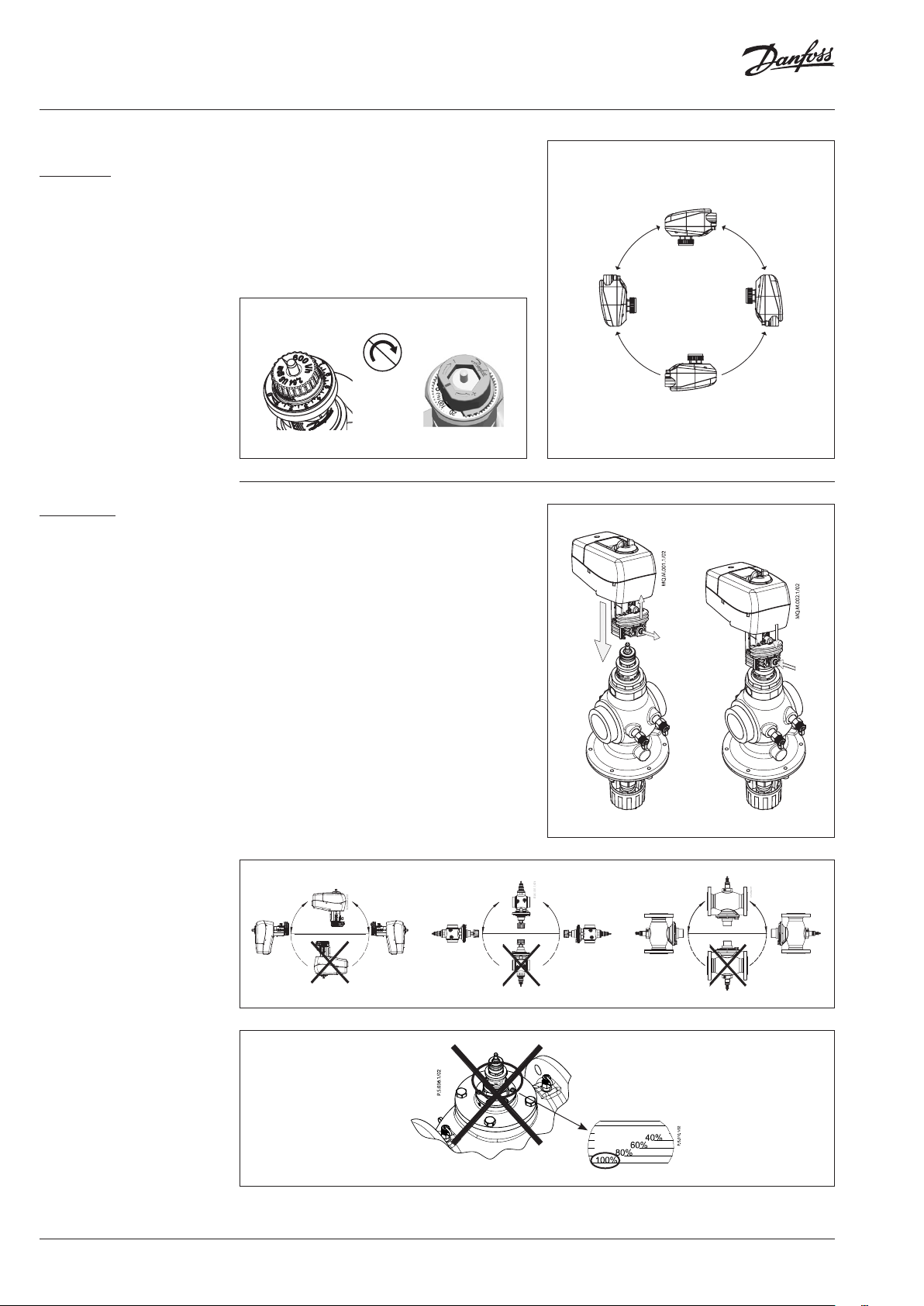

Installation and orientation NovoCon® S can be mounted in any position.

NovoCon® S

However, mounting orientation affects the IP

classification. Using NovoCon® S upside down in

cooling applications is not recommend due to

the risk condensation brings. See illustration.

Note!

IP classification is only valid when cable or plugs are

present in all connections.

IP 54

IP 54

No presetting should be done

on AB-QM valves. Valve must

be set to full open

(10 = AB-QM 4.0, 100% =

AB-QM)

NovoCon® M

DN 15 - 32

DN 15, 20

0 - 10

No tool is required to mount the actuator on the

valve. Installation of the valve with the actuator

is allowed in the horizontal position or upwards.

Installation downwards is not allowed.

The actuator must not be installed in an

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature higher

than 50 °C. It must not be subject to steam jets,

water jets or dripping liquid.

Note: The actuator may be rotated up to 360°

with respect to the valve stem by loosening the

retaining fixture. Once the actuator is in place,

retighten the retaining fixture.

Note: The cable and cable gland/grommet used,

must not compromise the actuator’s IP rating.

There must be no strain on the connectors.

The rubber cable grommet delivered from

factory do not compromise the IP rating but do

not provide full strain relief according to the LVD

directive.

Please observe local rules and regulations.

NO presetting!

DN 25, 32

0 - 100 %

③

IP 54

IP 40

①

②

⑤

④

DN 40 - 100

NO presetting!

100 %

10 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Installation (continued)

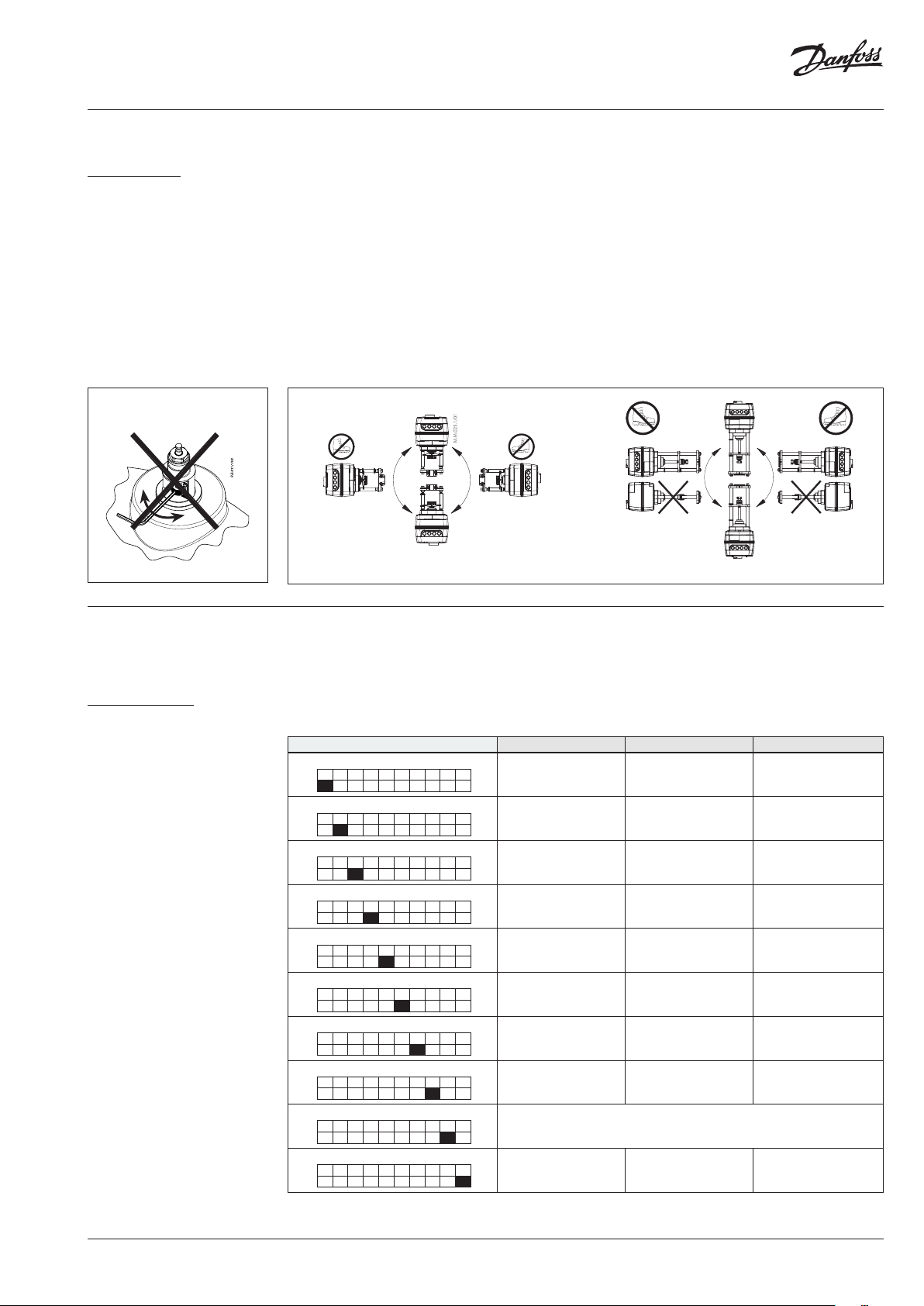

NovoCon® L, XL

DN 125 - 250

NO presetting!

–

+

100 %

Mechanical

Please check the allowed installation positions

for the valve and actuator. The actuator can be

installed in all positions (see below).

Installation of the actuator assembly is certified

for placement within the plenum airspace.

Use a M8/SW13 key (not supplied) to fit the

actuator to the valve body. Allow for necessary

clearance for maintenance purposes. To link

valve and actuator stems use a 4mm Allen

key (not supplied). The actuator has position

indication rings which should be pushed

together before el. connection; after calibration

cycle they indicate end positions of the stroke.

NovoCon® L NovoCon® XL

Electrical connection

Electrical connections can be accessed by

removing the service cover.

NovoCon® L/XL

Four cable entries are provided

- (1) M16x1.5

- (2) M20x1.5

- (1) 1/2”

Note in order to maintain the enclosure’s rating

appropriate electrical conduit connectors must

be installed.

Please observe local rules and regulations.

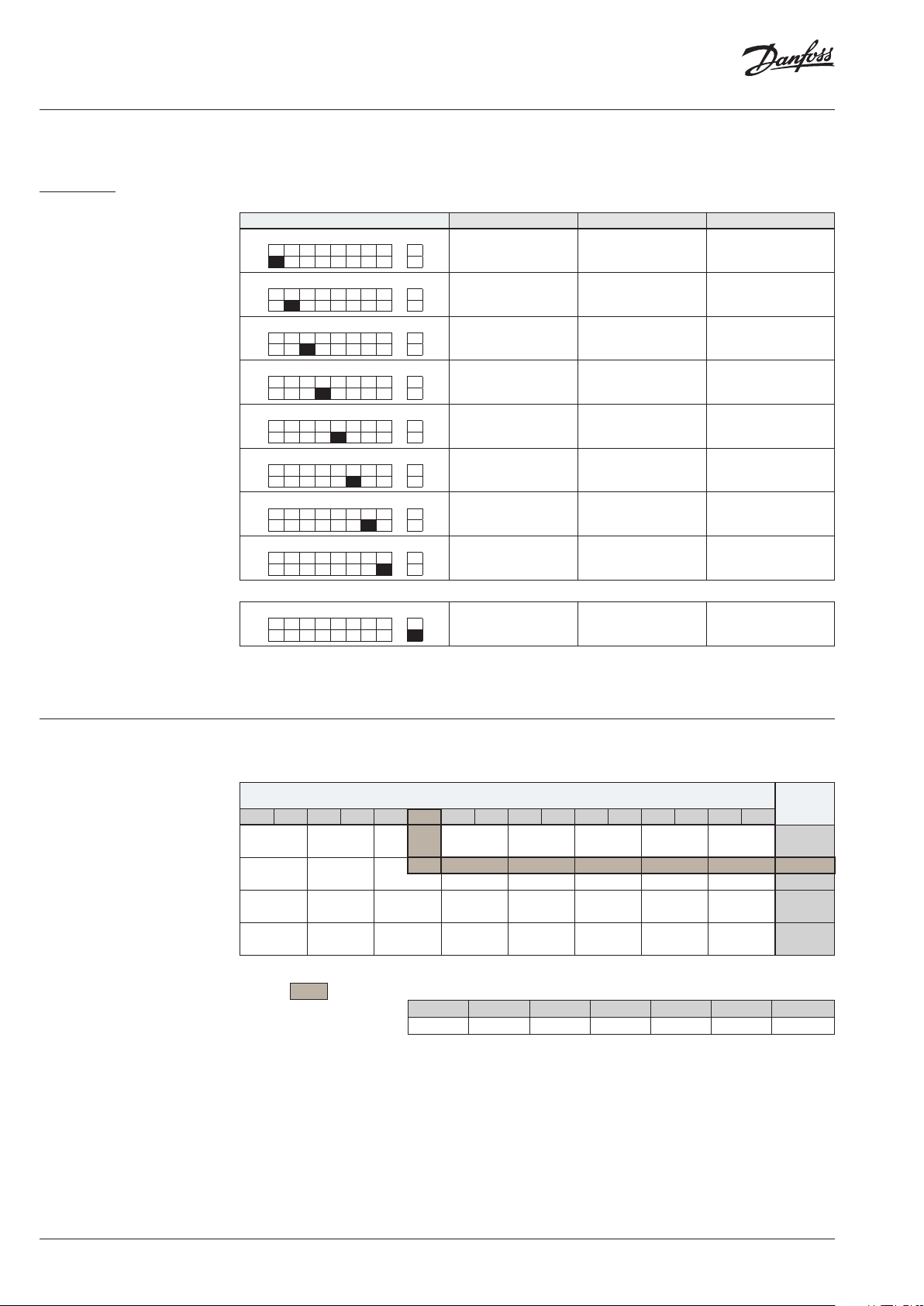

Dip switches

DIP Switch Settings

NovoCon® S, L, XL

The DIP switches located under the housing cover are for manual addressing.

The jumper next to the connectors is used for terminal resistor setting.

BACnet: Auto MAC addressing is default. For manual MAC addressing, use DIP Switches.

Modbus: Manual MAC addressing is default. Automatic addressing is not available for Modbus.

However, if an address has been assigned in BACnet before switching to Modbus, the

address will also be used in Modbus if the DIP switches are left in the default positions.

DIP Switch Configuration name OFF state (default) ON state

1 2 3 4 5 6 7 8 9 10

1.

1 2 3 4 5 6 7 8 9 10

2.

1 2 3 4 5 6 7 8 9 10

3.

1 2 3 4 5 6 7 8 9 10

4.

1 2 3 4 5 6 7 8 9 10

5.

1 2 3 4 5 6 7 8 9 10

6.

1 2 3 4 5 6 7 8 9 10

7.

1 2 3 4 5 6 7 8 9 10

8.

1 2 3 4 5 6 7 8 9 10

9.

1 2 3 4 5 6 7 8 9 10

10.

The actuato r possesses a resistor, DIP switch no. 8, th at can be activated in the last ac tuator on the bus for correct te rmination of the bus.

When the protocol is ch anged on DIP switch no. 10, a power c ycle is required to make the actu ator adopt the newly selec ted protocol.

BACnet addr ess / Modbus

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

unit ID bit 0

BACnet addr ess / Modbus

unit ID bit 1

BACnet addr ess / Modbus

unit ID bit 2

BACnet addr ess / Modbus

unit ID bit 3

BACnet addr ess / Modbus

unit ID bit 4

BACnet addr ess / Modbus

unit ID bit 5

BACnet addr ess / Modbus

unit ID bit 6

Termination r esistor (120Ω)

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

No

termination

Not used

- BACnet M S/TP Modbus R TU

Termination resistor enabled

AI368140926963en-010102 | 11© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

DIP Switch Settings

(continued)

NovoCon® M

BACnet: Auto MAC addressing is default. For manual MAC addressing, use DIP switches

Modbus: Manual MAC addressing is default. Automatic addressing is not available for Modbus.

However, if an address has been assigned in BACnet before switching to Modbus, the

address will also be used in Modbus if the DIP switches are left in the default positions.

DIP Switch Configuration name OFF state (default) O N state

1 2 3 4 5 6 7 8 R

1.

1 2 3 4 5 6 7 8 R

2.

1 2 3 4 5 6 7 8 R

3.

1 2 3 4 5 6 7 8 R

4.

1 2 3 4 5 6 7 8 R

5.

1 2 3 4 5 6 7 8 R

6.

1 2 3 4 5 6 7 8 R

7.

1 2 3 4 5 6 7 8 R

8.

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

BACnet addr ess / Modbus

ON

OFF

ON

OFF

unit ID bit 0

unit ID bit 1

unit ID bit 2

unit ID bit 3

unit ID bit 4

unit ID bit 5

unit ID bit 6

- BACn et MS/TP Modbus RT U

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

Logic ‘0’ Logic ‘1’

DIP Switch Settings

- Manual Addressing

1 2 3 4 5 6 7 8 R

R.

ON

Termination r esistor (120Ω) No termination

OFF

Termination r esistor enable d

The actuator p ossesses a resistor, located betwe en the connectors, DIP s witch no. 9 R on/off, that can be activate d in the last actuator

on the bus for corre ct termination of the bus .

When the protocol is ch anged on DIP switch no. 8, a po wer cycle is required to make th e actuator adopt the newl y selected protocol.

BACnet MAC address/Modbus Slave ID is set by DIP switch 1 to 7.

0 = OFF, 1 = ON

DIP switch

1, 2, 3, 4

0000 1000 0100 110 0 0 010 1010 011 0 111 0 0001 1001 0101 11 01 0 011 1011 0111 1111

0* 1 2 3 4

16 17 18 19 20

32 33 34 35

48 49 50 51 52

64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 001

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 101

96 97 98 99 100 101 102 103 10 4 105 106 107 10 8 109 110 111 011

112 113 114 115 116 117 118 11 9 120 121 122 123 12 4 12 5 126 127 * 111

5

6 7 8 9 10 11 12 13 14 15 000

21

22 23 24 25 26 27 28 29 30

36 37 38 39 40 41

53

54 55 56 57 58 59 60 61 62

42 43 44 45 46

* Addresses no. 0 and 127 must not be used.

Example

Setting MAC address to 37:

DIP 1 D IP 2 D IP 3 D IP 4 DIP 5 DI P 6 DI P 7

ON OFF ON OFF OFF ON OFF

DIP switch

5,6,7

31 100

47 010

63 110

12 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Wiring

NovoCon® S

The wiring of BACnet MS/TP or Modbus RTU

(RS485) must be carried out in accordance with

applicable standard ANSI/TIA/EIA-485-A-1998.

Digital port

Galvanic separation shall be provided for

segments crossing buildings.

Common ground shall be used for all devices

Multifunctional

port

on the same network inclusive router,

gateways etc.

Digital port

All bus connections in the cables are made with

twisted wires.

The cable type used for NovoCon® analog, digital and I/O cables is AWG22/0.32mm2.

If other cables are used to extend the length, always use twisted pair wire for bus signal and include

ground for the bus signal. The recommended cable type is AWG22/0.32 mm2. If used for longer

distances please use a AWG20/0.5mm2 or AWG18/0.75mm2 cable. The cable’s impedance characteristic

shall be between 100-130Ω. The capacitance between conductors shall be less than 100 pf per meter.

The length of the cables influence on the communication speed. Longer cable lengths should result in

lower baud rates. The total maximum cable length allowed per network is 1200m.

Use a minimum 20 cm distance between 110V/230V/400V power line cables and bus cables.

NovoCon® S has mis-wiring protection on up to 30 V AC/DC on all wires, but be aware that if 30V AC

are connected to the Analog input, the external power supply will see this as a short circuit and blow

the fuse in the external power supply.

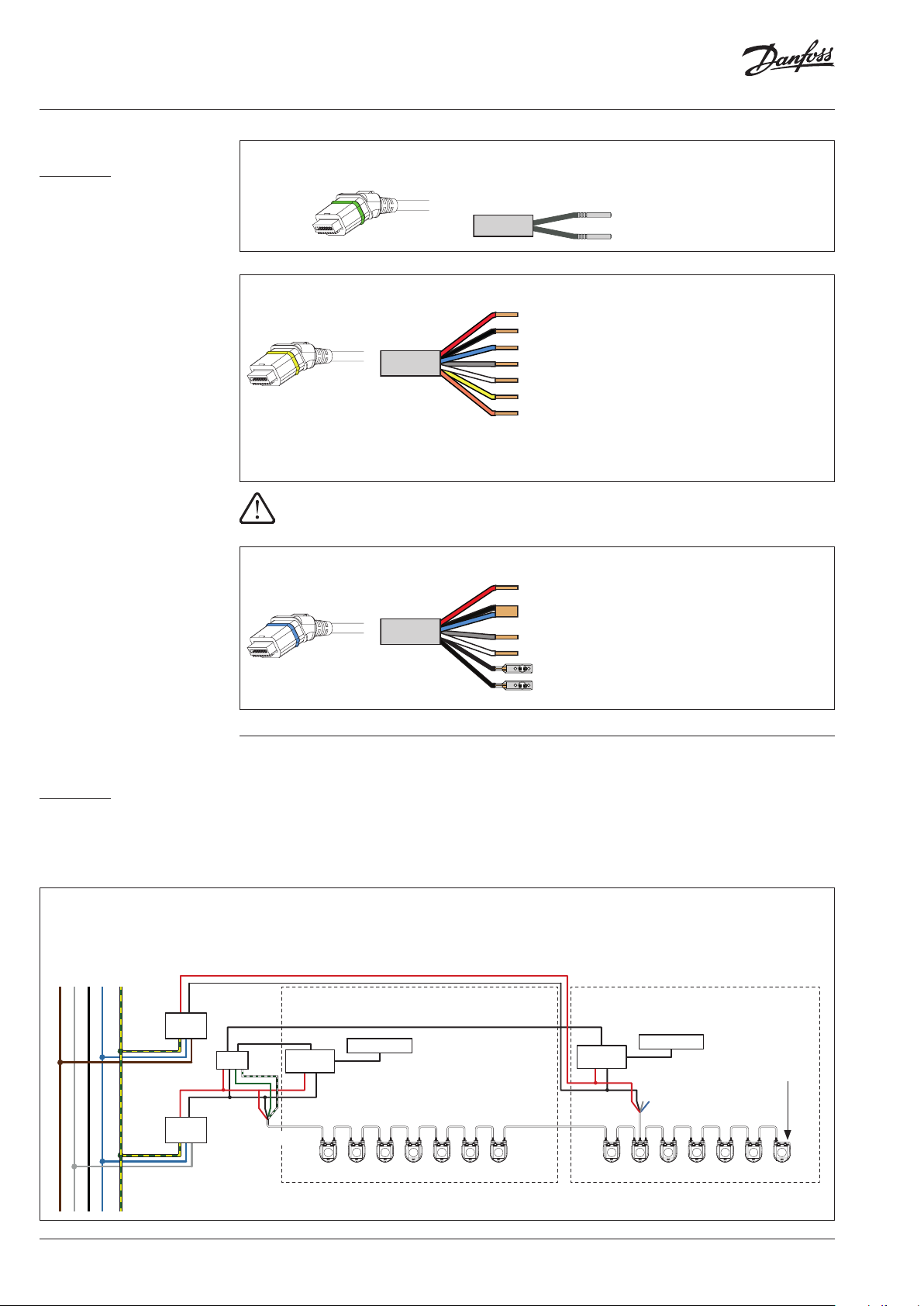

NovoCon® digital daisy chain cable

Black O-ring

Black O-ring

The digital daisy chain cable is used to connect power and BACnet/Modbus between two

NovoCon® S devices.

NovoCon® digital cable

Red: Power

White O-ring

Common ground for power

Black:

and bus signal wire

Green: ‘+’ non-inverting signal wire

Green/

‘-‘ inverting signal wire

White:

The digital cable is used to connect NovoCon® to other BACnet/Modbus devices. It is also used to

connect NovoCon to a longer length of power/communication cable other than standard sales codes.

NovoCon® analog cable

Red O-ring

The analog cable is used to connect power and analog control signal.

The analog cable can also be used as a voltage booster for NovoCon® S on the network.

Red: Power

Black: Power ground

Grey: Analog input

Blue: Analog input ground

Cable NovoCon® Energy with Pt1000 surface sensor

NovoCon® Energy cable - Pt1000 surface sensors

Green O-ring

AI368140926963en-010102 | 13© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Wiring (continued)

NovoCon® S (continued)

Cable NovoCon® Energy with universal Pt1000 temperature sensor

NovoCon® Energy cable - Pt1000 immersed sensors

Green O-ring

Cable NovoCon® I/O

Red Power 24V (in/out)

Black

Blue

Power ground (in/out)

Ground T1, T2, V/mA input & V output signal

Grey V/mA input signal

Yellow O-ring

White V output signal

Yellow T1 or resistance input

Orange T2 or resistance input

The red and black wires can be used to boost the power on the line. They may also be used to power

external devices, a separate calculation must be made for available power.

To avoid electrical short-circuiting, ensure that loose cable-ends have been connected or

isolated before inserting the plug-in connector to the NovoCon® S actuator.

Cable NovoCon® Temperature I/O

Red Power 24V (in/out)

Black

Power ground (in/out)

Blue

Ground T1, T2, V/mA input & V output signal

Grey V/mA input signal

Blue O-ring

White V output signal

T1

T2

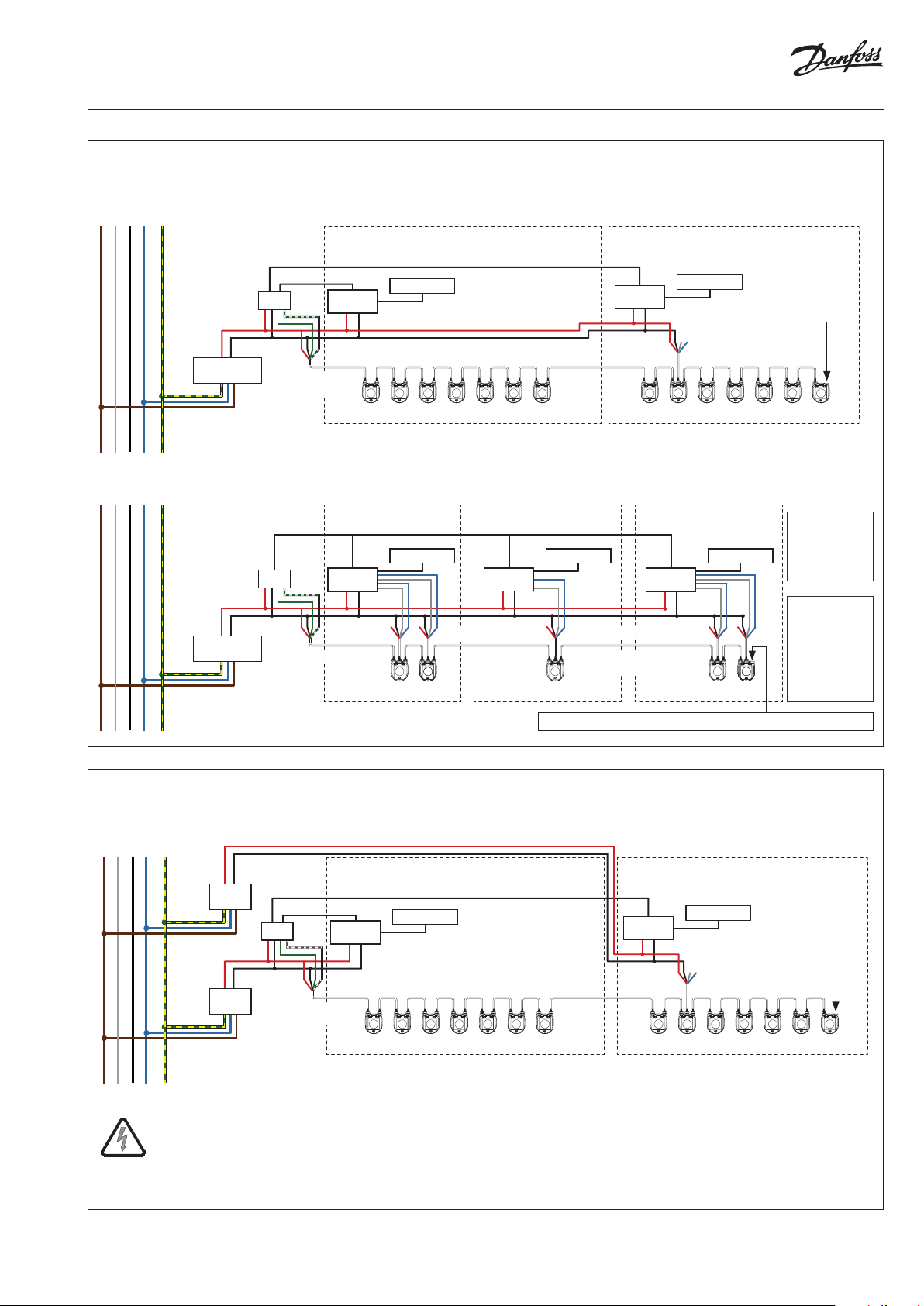

Wiring considerations

NovoCon® S

The important factors here are:

- Common ground

- 24VDC power supply is recommended

- In case more 24VAC power supplies are used

always separate the 24VAC power supplies if

different types of power supplies are used and /

or different phases are used.

Wiring with DC power supply: (recommended solution)

Digital application – 24V DC – PSU with power sharing capability, both on the same or different phases.

230/110V AC

L1 L2 L3

0

GND

24V DC

Ground

24V DC

PSU

DDC

24V DC

Ground

24V DC

PSU

Cable NovoCon® Digital

Bus

Room 1

Room

controller

Thermostat

Daisy chain cables between NovoCon® S

Room 2

Room

controller

Thermostat

X X

Cable NovoCon® Analog

Turn DIP switch

no. 8 ON for bus

termination of the

last unit on the bus.

14 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Wiring with DC or AC power supply:

230/110V AC

L1 L2 L3

0

230/110V AC

L1 L2 L3

0

GND

GND

24V DC / AC

Ground

24V DC / AC

PSU

24V DC / AC

Ground

24V DC / AC

PSU

Room 1 Room 2

Bus

DDC

Cable NovoCon®

Digital

Room

controller

Room 1 Room 2

Bus

DDC

Cable NovoCon® Digital

Room

controller

Digital application - One transformer

Thermostat

controller

Daisy chain cables between NovoCon® S

Analog Control Application - One transformer

Thermostat

Room

controller

X X X

Cable NovoCon® Analog

Thermostat

Cable NovoCon® Analog

Daisy chain cables between

NovoCon® S

Room

Room 3

Thermostat

XX

Cable NovoCon® Analog

Room

controller

X X

Thermostat

Turn DIP switch

no. 8 ON for bus

termination of the

last unit on the bus.

Connect Power

ground and

Analog input

ground on the

Controller.

24V power

can

also be

connected to

NovoCon® S

through the

analog cable,

but is not

required.

Turn DIP switch no. 8 ON for bus termination of the last unit on the bus.

Wiring with AC power supplies:

230/110V AC

L1 L2 L3

The power b oosters must be p rotected against over load, otherwise the power booster may be damag e if one of the othe r power boosters in the network is

disconnected.

GND

0

If the NovoCon® S network is supplied with two or more AC power boosters, c aution must be observe d when disconne cting one of the

transformers from the high voltage power line. A s the NovoCons are co nnected in a dai sy chain, there may be high voltage on the primary s ide

of the disconne cted power supp ly.

24V AC

PSU

24V AC

24V AC

PSU

24V AC

Ground

DDC

Ground

Digital application - Identical transformers, same phase

Room 1

Bus

Room

controller

Cable NovoCon®

Digital

Disconnect always both the primary and secondary side of the transformer.

Thermostat

Daisy chain cables between NovoCon® S

Room 2

Room

controller

Thermostat

Turn DIP switch

no. 8 ON for bus

termination of the

last unit on the bus.

XX

Cable NovoCon® Analog

Wires that ends in an "X" must be properly terminated.

AI368140926963en-010102 | 15© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

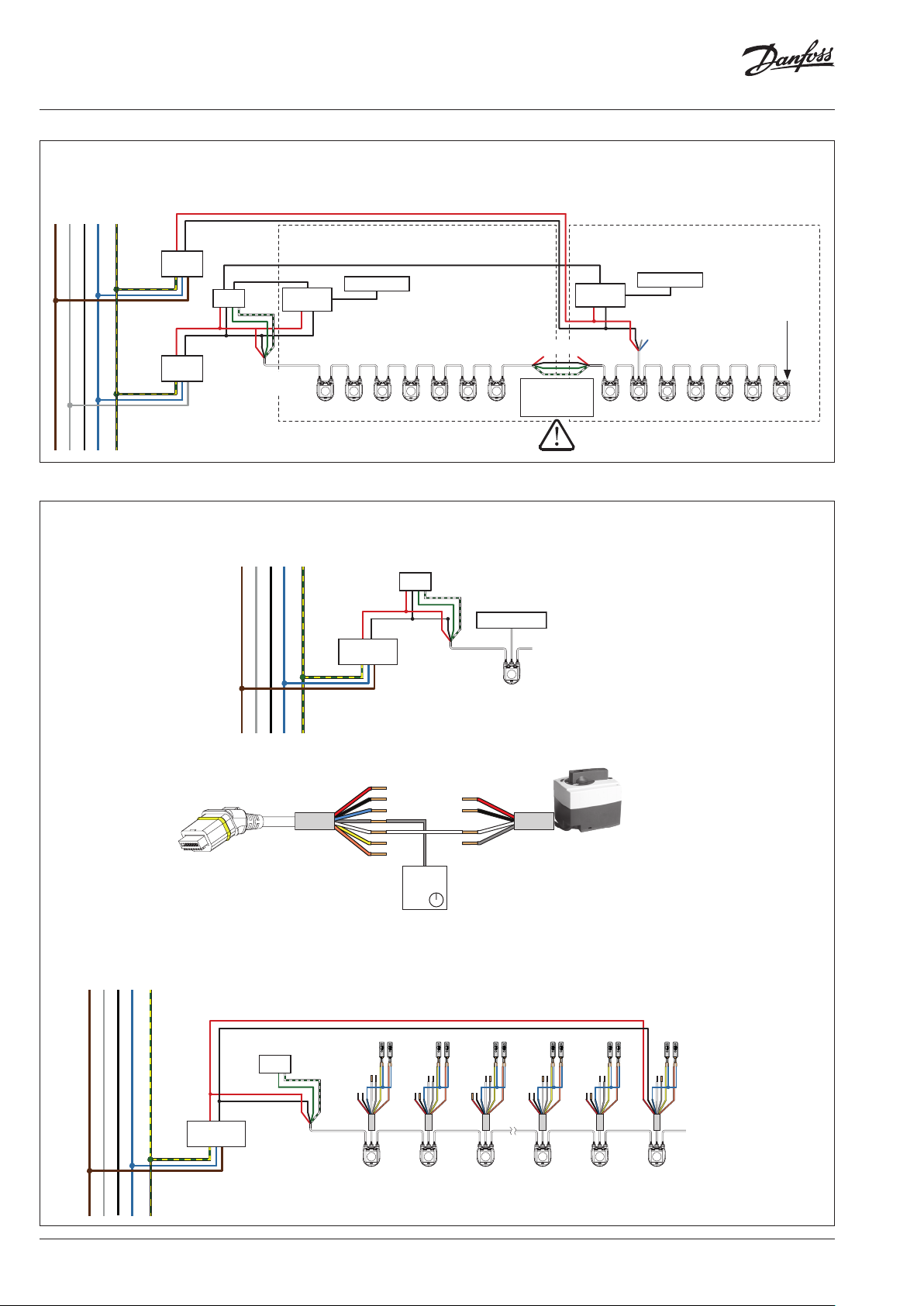

Wiring with AC power supply: (continued)

230/110V AC

L1 L2 L3

0

GND

24V AC

PSU

24V AC

24V AC

PSU

24V AC

Ground

Ground

Digital application - Identical or different transformers with different phases, but same ground

Room 1

Bus

DDC

Cable NovoCon®

Digital

Room

controller

Wires that ends in an "X" must be properly terminated.

NovoCon® S ChangeOver6 application

230/110V AC

0

GND

L1 L2 L3

Thermostat

Daisy chain cables between NovoCon® S

NovoCon® S ChangeOver6 application

DDC

24V AC/DC

Ground

24V AC/DC

PSU

Cable NovoCon®

Digital

ChangeOver

Room 2

Room

controller

Cable NovoCon® Digital

X X

Disconnect

Power 24V, but

NOT ground

6

Additional products in

daisy chain if needed

Thermostat

XX

Cable NovoCon® Analog

Turn DIP switch

no. 8 ON for bus

termination of the

last unit on the bus.

Wiring Analog CO6 mode

Cable NovoCon® I/O

Wiring I/O application

230/110V AC

0

GND

24V D C/AC

L1 L2 L3

Yellow O-ring

Power

24V AC/DC

X

X

X

X

Actuator NovoCon®

ChangeOver6 Flexible

Room controller

Example using voltage booster and temperature sensors on the same NovoCon® S

24V D C/AC

Ground

PSU

DDC

Bus

Cable NovoCon®

Digital

T1 T2 T1 T2 T1 T2 T1 T2 T1 T2

XX

X

X

Cable NovoCon I/O

XX

X

X

XX

X

X

XX

X

X

T1 T2

XX

XXXX

Additional products in

daisy chain if needed

16 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Wiring (continued)

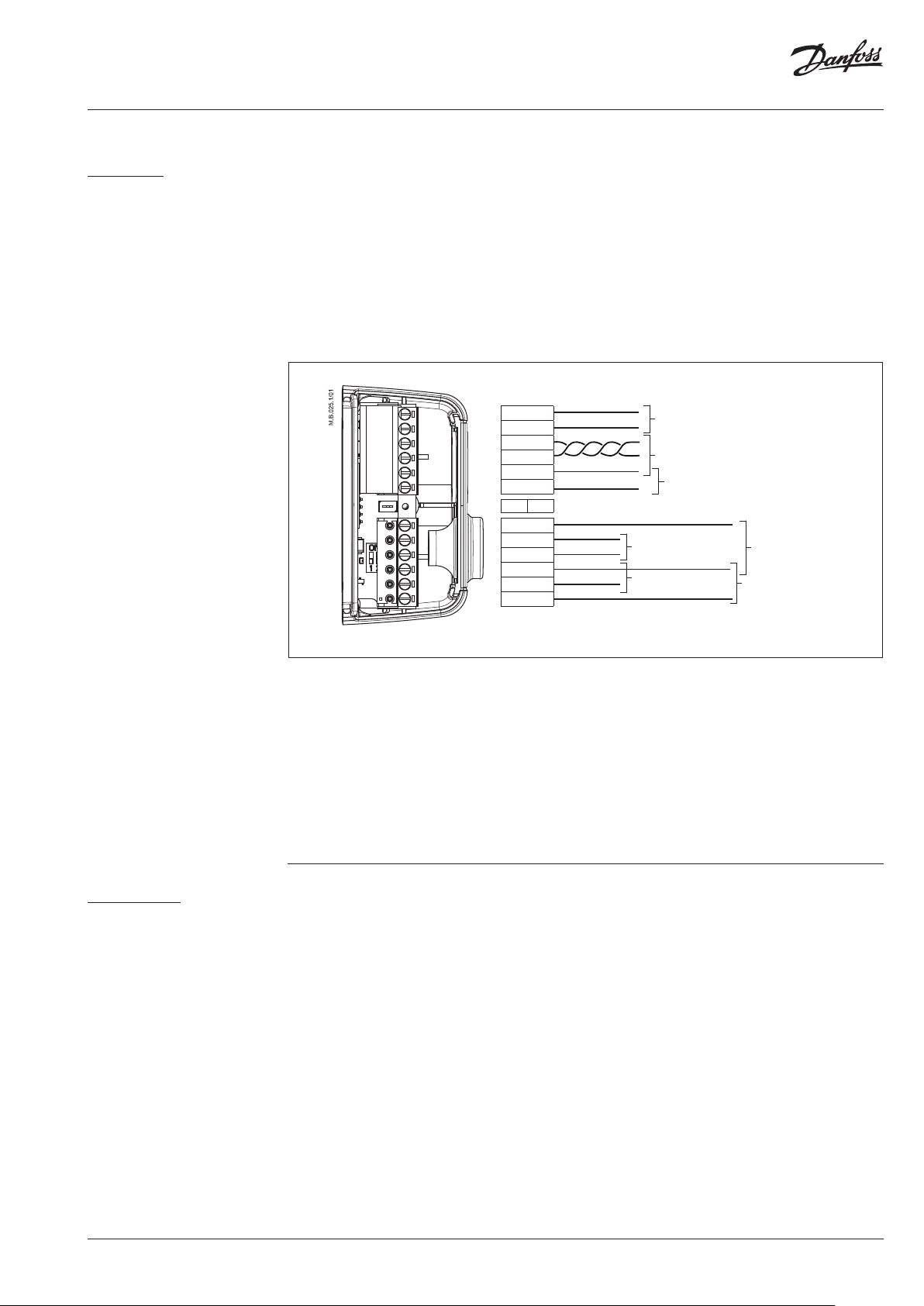

NovoCon® M

The wiring of BACnet MS/TP or Modbus RTU (RS485) must be carried out in accordance with applicable

standard ANSI/TIA/EIA-485-A-1998. Galvanic separation shall be provided for segments crossing

buildings. The bus connection ‘A+’ is the non-inverting signal and ‘B-‘ is the inverting signal wire.

Common ground shall be used for all devices on the same network including routers gateways etc.

The recommended cable type is AWG22/0.32 mm2 twisted pair. If used for longer distances, please use a

AWG20/0.5mm2 or AWG18/0.75 mm2 cable. The cable’s impedance characteristic shall be between

100-130 Ω. The capacitance between conductors shall be less than 100 pf per meter. The length of the

cables influence the communication speed. Longer cable lengths should result in lower baud rates. The

total maximum cable length allowed per network is 1200 m.

Use a minimum 20 cm separation distance between 110V/230V/400V power line cables and bus

cables. NovoCon® M has mis-wiring protection up to 30V AC/DC on all wires but be aware that if 30V

AC are connected to the Analog input, the external power supply will see this as a short circuit and

blow the fuse in the external power supply.

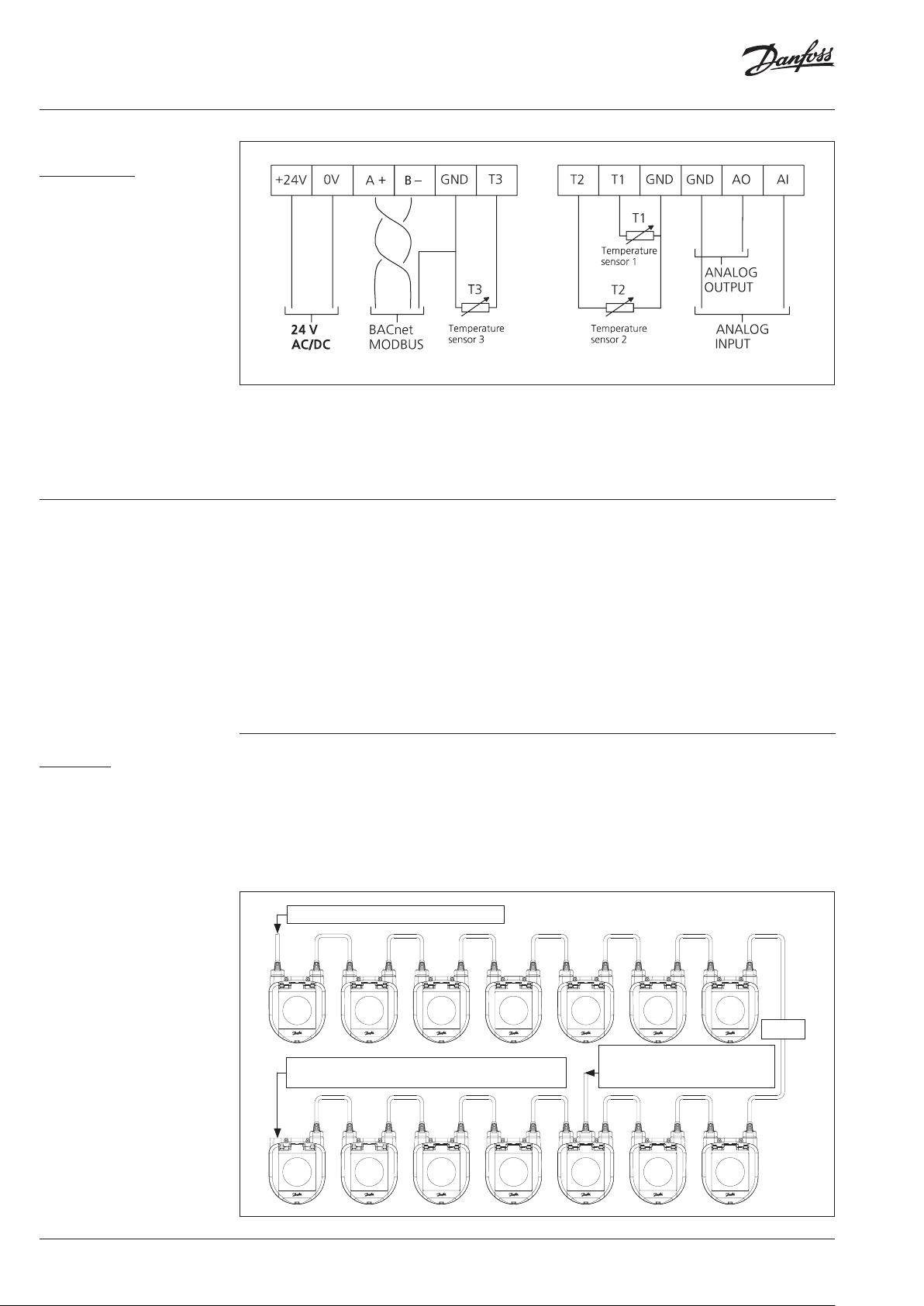

+24V

0V

A+

B−

GND

T3

R on R off

T2

T1

GND

GND

AO

AI

24V AC/DC

BACnet MS/TP or

Modbus RTU

Temperature

sensor 3

Temperature

sensor 1

Analog

output

Temperature

sensor 2

Analog input

NovoCon® L, XL

GND is common for a ll signals

Danfoss recommends that NovoCon® M should be used on its own sub-network for optimal

performance.

General requirements and recommendations:

• Use the termination resistor (between the 2 connectors) at the end of each daisy chain.

• Generally, one power supply is preferred.

• If two power supplies are used, they must have the same polarity and the same common ground.

• A common ground must be used for all devices on the same sub-network, including routers and

gateways.

• Galvanic separation shall be provided for segments crossing buildings.

• Total maximum sub-network cable length is 1200m.

The wiring of BACnet MS/TP or Modbus RTU (RS485) must be carried out in accordance with applicable

standard ANSI/TIA/EIA-485-A-1998. The bus connection ‘A+’ is the non-inverting signal and ‘B-‘ is the

inverting signal wire.

NovoCon® L/XL has a galvanic separated power supply, but common ground is recommended to use

for all devices on the same network including routers gateways etc.

The cable’s impedance characteristic for communication shall be between 100-130 Ω. The capacitance

between conductors shall be less than 100 pf per meter. The length of the cables influence the

communication speed. Longer cable lengths should result in lower baud rates. The total maximum

cable length allowed per network is 1200 m.

Use a minimum 20 cm separation distance between 110V/230V/400V power line cables and bus

cables. NovoCon® L/XL has mis-wiring protection up to 30V ac/dc on all wires but be aware that if 30V

ac are connected to the Analog input, the external power supply will see this as a short circuit and

blow the fuse in the external power supply.

AI368140926963en-010102 | 17© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Wiring (continued)

NovoCon® L, XL (continued)

GND is common for a ll signals

Danfoss recommends that NovoCon® L/XL should be used on its own sub-network for optimal

performance.

General requirements and recommendations:

• Use the termination resistor (DIP switch 8) at the end of each daisy chain.

• Total maximum sub-network cable length is 1200m.

Daisy chain & Power booster

NovoCon® S

T-junctions

T-junction connections (stub lines) are not recommended.

In the event of T-Junction connections being used the following limitations must be adhered to:

- max T-junction cable length 1.5m (shortest standard digital cable)

- total length of Network max 640m (+ 100m stub length)

- max baud rate 76 kb/s 1)

- max number of devices on network 64 1)

- main cable should be standard RS485 bus, twisted pair, min thickness AWG22 / 0.32mm2.

1)

When using less than 32 devices you may attempt to raise the speed to 115 kb/s.

Star topology

Star topology is not according to the RS485 standard and should not be used with NovoCon® S, M

and L/XL.

DC Power supply (recommended)

When daisy chaining with 10m NovoCon® cables

and using a 24V DC power supply, additional

voltage boosters/power supply is needed when

12 NovoCons in series is exceeded. See table

below.

AC Power supply

When daisy chaining with 10m NovoCon® cables

and using a 24V AC power supply, additional

voltage boosters/power supply is needed when

7 NovoCons in series is exceeded. See table below.

Important: The power supply used must be able

to deliver 60% more power than the nominal

rating of NovoCon® S.

Controller and 24 Volt AC or DC Power supply

U=24V

Remember to enable DIP switch 8 for bus termination on the

last NovoCon

® S in the daisy chain

Voltage booster/power supply,

temperature sensors added directly

or through the Cable NovoCon® I/O

18 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

T-junction

Daisy chain & Power booster

(continued)

NovoCon® S (continued)

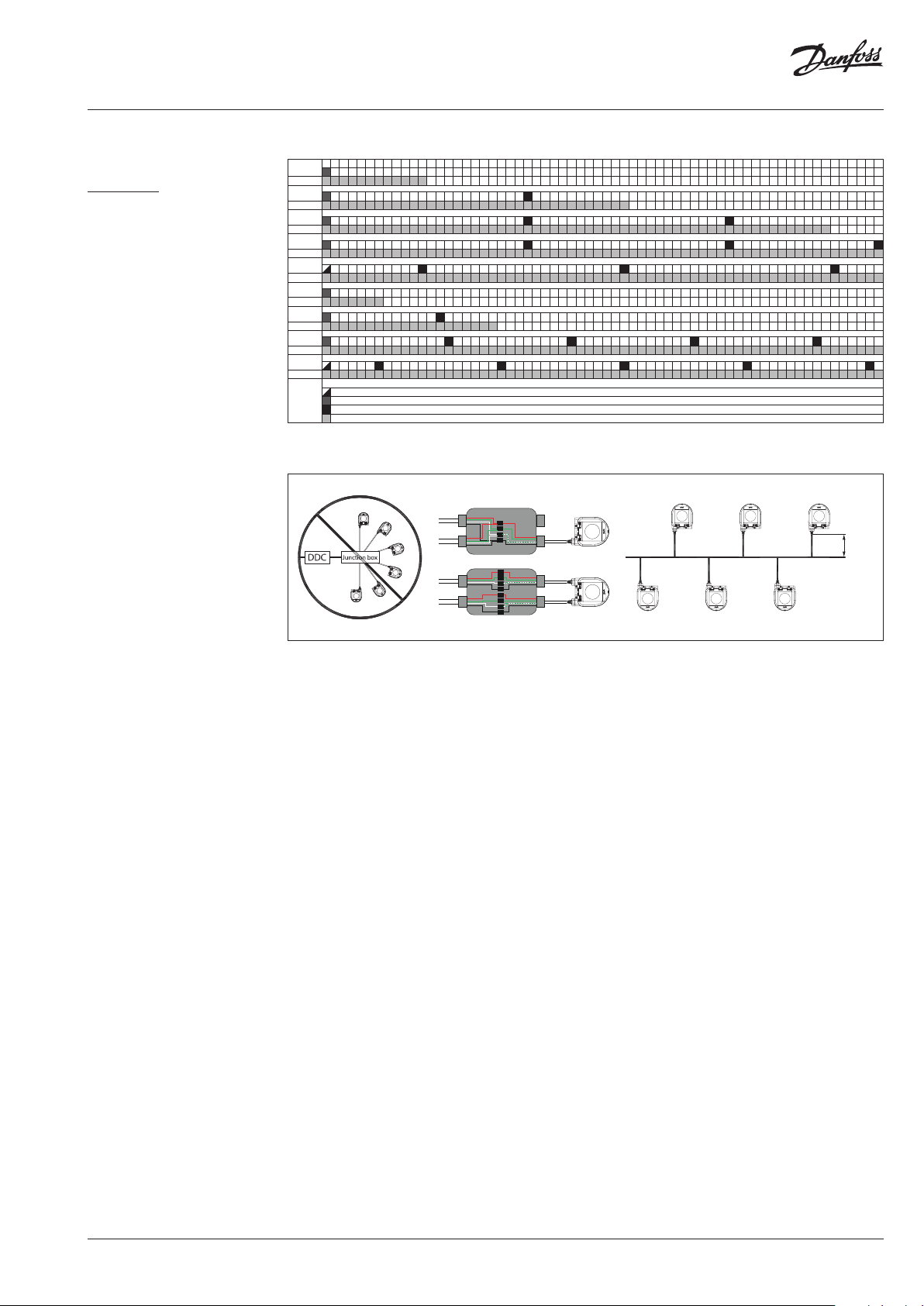

When all devices on the sub-network are NovoCon® S, refer to the examples below for guidance.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 2324 25 2627 28 2930 31 32 33 3435 36 3738 39 4041 42 43 4445 4647 48 4950 51 52 53 5455 56 5758 59 6061 62 63 64

24 Volt DC

24 Volt DC

24 Volt DC

24 Volt DC

24 Volt DC

24 Volt AC

24 Volt AC

24 Volt AC

24 Volt AC

Bus communication from the controller

Power supply w ith daisy chain fr om controller

Usage of anal og cable as volta ge booster

NovoCo n® S

If NovoCon® S is used to power external devices, a separate calculation must be made for power booster amount and

location.

max

Daisy chain

1.5m

If the supply voltage to the first device in the daisy chain is lower than 24V AC/DC, or long thin cables

other than NovoCon® cables are used, then the quantity of devices in the daisy chain may have to be

reduced.

The recommended maximum quantities of NovoCon® S are 64 pcs in one daisy chain connection.

If other BACnet devices are added with NovoCon® S in the same daisy chain connection, Danfoss

recommends a maximum of 32 pcs. to ensure sufficient network speed.

Danfoss recommends that NovoCon® S should be used on its own sub-network for optimal

performance.

General requirements and recommendations:

• Use Danfoss daisy chain cable to connect two NovoCon® S devices.

• Use Danfoss digital cable to connect NovoCon® S with another BACnet device.

• The current in cables should not exceed 3Arms at 30°C.

• Use the termination resistor (DIP switch 8) at the end of daisy chain.

• Voltage boosting may be achieved via any port.

• Generally, one power supply is preferred.

• If two power supplies are used, they must have the same polarity and the same common ground.

• A common ground must be used for all devices on the same sub-network, including routers and

gateways.

• Galvanic separation shall be provided for segments crossing buildings.

• Total maximum sub-network cable length is 1200m.

AI368140926963en-010102 | 19© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Daisy chain & Power booster

(continued)

NovoCon® M

DC Power supply (recommended)

When daisy chaining with 10m AWG20/0,5 mm2

twisted pair cable and using a 24V DC power

supply, additional voltage boosters/power

supply is needed when 12 NovoCons in series is

exceeded.

AC Power supply

Please secure:

• Common ground

• 24VDC power supply is recommended

• In case more 24VAC power supplies are used

always separate the 24VAC power supplies if

different types of power supplies are used and /

or different phases are used.

When daisy chaining with AWG20/0,5 mm2

twisted pair cable and using a 24V AC power

supply, additional voltage boosters/power

supply is needed when 7 NovoCons in series is

exceeded.

Important: The power supply used must be able

to deliver 60% more power than the nominal

rating of NovoCon® M.

NovoCon® M in daisy chain NovoCon® M in daisy chain with NovoCon® S

NovoCon® S

+24V

0V

A+

B−

GND

T3

R on R off

T2

T1

GND

GND

AO

AI

NovoCon® S

GND is common for a ll signals

+24V

0V

A+

B−

GND

T3

R on R off

T2

T1

GND

GND

AO

AI

BACnet

MS/TP or

Modbus

RTU

If the Novo Con® M network is su pplied with t wo or more AC power bo osters, cau tion must be obs erved when

disco nnecting one o f the transfor mers from the hi gh voltage power l ine. As the Novo Cons are connec ted in a daisy

chain , there may be hig h voltage on the pr imary side of t he disconne cted power sup ply. Disconne ct always both

the prim ary and secon dary side of t he transforme r.

The powe r boosters mus t be protected ag ainst overloa d, otherwi se the power boos ter may be damag e if one of the

other po wer boosters i n the network is d isconnect ed.

BACnet MS/ TP or

+24V

0V

A+

B−

GND

T3

R on R off

T2

T1

GND

GND

AO

AI

GND is common for a ll signals

24V AC/DC

Max. 1.5 m

BACnet MS/ TP or

Modbus R TU

Modbus R TU

Modbus R TU

24V AC/DC

Junction box

BACnet MS/ TP or

24V AC/DC

20 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Daisy chain & Power booster

(continued)

NovoCon® L, XL

AC Power supply

Important: The power supply used must be able

to deliver 60% more power than the nominal

rating of NovoCon® L/XL.

NovoCon® L/XL in daisy chain

B−

A+

GND

GND is common for a ll signals

If the Novo Con® L/XL netw ork is supplie d with two or more AC p ower booster s, caution mus t be observed w hen

disco nnecting one o f the transfor mers from the hi gh voltage power l ine. As the Novo Cons are connec ted in a daisy

chain , there may be hig h voltage on the pr imary side of t he disconne cted power sup ply. Disconne ct always both

the prim ary and secon dary side of t he transforme r.

The powe r boosters mus t be protected ag ainst overloa d, otherwi se the power boos ter may be damag e if one of the

other po wer boosters i n the network is d isconnect ed.

BACnet

MS/TP or

Modbus RTU

Please secure:

• In case more 24V ac power supplies are used

always separate the 24V ac power supplies if

different types of power supplies are used and /

or different phases are used.

GND

A+

B−

24V AC/DC

BACnet MS/TP or

Modbus RTU

GND is common for a ll signals

Junction box

24V AC/DC

24V AC/DC

BACnet MS/TP or

Modbus RTU

Max. 1. 5m

BACnet MS/TP or

Modbus RTU

AI368140926963en-010102 | 21© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display

NovoCon® S

BACnet/Modbus (RS485) activity

BACnet/Modbus (RS485) activity

No light from LED: Actuator sees no activit y on the network.

LED turn on and off quickly, 10x/second:

Normal operation on the network communication is OK.

LED turn on and off slowly with green light, 3x /second: Normal operation on the

network - communication over longer time directly with this actuator.

BACnet/Modbus (RS485) activity with ERRORS

LED turns on and off slowly, 3x/second, with RED color: Actuator sees activit y,

but with errors.

LED turn on and off quickly, 10x/second, with RED color: Communication is OK, EXCEPT

that another device may be using the same MAC address.

Position of valve/actuator

AB-QM valve is fully closed.

AB-QM is open 1-24% of Design Flow.

AB-QM is open 25-49% of Design Flow.

AB-QM is open 50-74% of Design Flow.

AB-QM is open 75-99% of Design Flow.

AB-QM valve is open 100% of Design Flow.

Flush is active

All LEDs turns on/off with specific period.

22 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display (continued)

NovoCon® S (continued)

Movement of valve/actuator

Information from actuator

NovoCon® S is closing the valve

All green LEDs are turned ON, then turned OFF one at the time (repeatedly).

NovoCon® S is opening the valve

All green LEDs are turned OFF, then turned ON one at the time (repeatedly).

NovoCon® S is calibrating

Green light moves forward and backwards, one by one.

De-air is active

Yellow LEDs are turned ON one by one, then turned OFF one by one (repeatedly).

Blinking function, all green LEDs turns on/off. Used to physically identif y individual

actuator on the bus.

Error during closing

Debris might be trapped under the AB-QM valve cone. Flushing may solve the problem.

Temperature inside NovoCon® S is out of the recommended range

LEDs change between showing the alarms and showing normal operation. Ambient

temperature has likely exceeded 60°C.

Internal NovoCon® S error

LEDs change between showing the alarms and showing normal bet ween operation. Try:

A: Re-calibrate.

B: Turn power off and on.

C: If the error does not disappear actuator replacement can be necessary.

Error during NovoCon® S calibration

LEDs change between showing the alarms and showing normal operation. Verify if the

NovoCon® S is correctly at tached to the valve and recalibrate.

Power supply is outside limits

LEDs change between showing the alarms and showing normal operation. Use analog

cables as voltage booster.

No Control Signal

In analog control the broken control wire is detec ted.

In CO6 mode or Inverted CO6 mode the ChangeOver6 actuator is not connected or damaged.

ChangeOver6 actuator

The ChangeOver6 actuator is in manual override or unable to reach position.

LEDs change between showing the alarms and showing normal operation.

AI368140926963en-010102 | 23© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display (continued)

NovoCon® S (continued)

NovoCon® M

Pressing the mode button during normal operation

Calibration/Reset/Flush

Press reset button. All LED's are turned off.

Keep pressing the reset button for

1 second: 1 LED ON

2 seconds: 2 LEDs ON = Start calibration (Reset).

3 seconds: 3 LEDs ON

4 seconds: 4 LEDs ON = Start flushing.

5 seconds or more = Return to normal operation.

Factory reset - reset to default settings

Press and hold the reset button and then power up the actuator, all LED's are initially

turned off.

Keep pressing the reset button until 4 LED's are turned on = Reset to default settings.

When fac tory reset is per formed it is shown by:

1 short f lash with all yellow position LED’s.

Note that af ter factory reset a calibration will be automatically be performed and all

settings are reverted to factory settings.

BACnet/Modbus (RS485) activity

BACnet/Modbus (RS485) activity

No light from LED: Actuator sees no activit y on the network.

LED turn on and off quickly, 10x/second:

Normal operation on the network communication is OK.

LED turn on and off slowly with green light, 3x /second: Normal operation on the

network - communication over longer time directly with this actuator.

Position of valve/actuator

Movement of valve/actuator

BACnet/Modbus (RS485) activity with ERRORS

LED turns on and off slowly, 3x/second, with RED color: Actuator sees activit y,

but with errors.

LED turn on and off quickly, 10x/second, with RED color: Communication is OK, EXCEPT

that another device may be using the same MAC address.

AB-QM valve is fully closed.

AB-QM is open 1-24% of Design Flow.

AB-QM is open 25-49% of Design Flow.

AB-QM is open 50-74% of Design Flow.

AB-QM is open 75-99% of Design Flow.

AB-QM valve is open 100% of Design Flow.

Flush is active

All LEDs turns on/off with specific period.

NovoCon® is closing the valve

All green LEDs are turned ON, then turned OFF one at the time (repeatedly).

NovoCon® is opening the valve

All green LEDs are turned OFF, then turned ON one at the time (repeatedly).

NovoCon® is calibrating

Green light moves forward and backwards, one by one.

De-air is active

Yellow LEDs are turned ON one by one, then turned OFF one by one (repeatedly).

24 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display (continued)

NovoCon® M (continued)

Information from actuator

Blinking function, all green LEDs turns on/off. Used to physically identif y individual

actuator on the bus.

Error during closing

Debris might be trapp ed under the AB-QM valve cone. Flushing may solve the

Temperature inside NovoCon® is out of the recommended range

LEDs change between showing the alarms and showing normal operation. Ambient

temperature has likely exceeded 60°C.

Internal NovoCon® error

LEDs change between showing the alarms and showing normal bet ween operation. Try:

A: Re-calibrate.

B: Turn power off and on.

C: If the error does not disappear actuator replacement can be necessary.

Error during NovoCon® calibration

LEDs change between showing the alarms and showing normal operation. Verify if the

NovoCon® M is correctly at tached to the valve and recalibrate.

Power supply is outside limits

LEDs change between showing the alarms and showing normal operation.

No Control Signal

In analog control mode a broken control wire is detected.

LEDs change between showing the alarms and showing normal operation.

problem.

Pressing the mode button during normal operation

Calibration/Reset/Flush

Press reset button. All LED's are turned off.

Keep pressing the reset button for

1 second: 1 LED ON

2 seconds: 2 LEDs ON = Start calibration (Reset).

3 seconds: 3 LEDs ON

4 seconds: 4 LEDs ON = Start flushing.

5 seconds or more = Return to normal operation.

Factory reset - reset to default settings

Press and hold the reset button and then power up the actuator, all LED's are initially

turned off.

Keep pressing the reset button until 4 LED's are turned on = Reset to default settings.

When fac tory reset is per formed it is shown by:

1 short f lash with all yellow position LED’s.

Note that af ter factory reset a calibration will be automatically be performed and all

settings are reverted to factory settings.

AI368140926963en-010102 | 25© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display (continued)

NovoCon® L, XL

BACnet/Modbus (RS485) activity

BACnet/Modbus (RS485) activity

No light from LED: Actuator sees no activit y on the network.

LED turn on and off quickly, 10x/second:

Normal operation on the network communication is OK.

LED turn on and off slowly with green light, 3x /second: Normal operation on the

network - communication over longer time directly with this actuator.

BACnet/Modbus (RS485) activity with ERRORS

LED turns on and off slowly, 3x/second, with RED color: Actuator sees activit y,

but with errors.

LED turn on and off quickly, 10x/second, with RED color: Communication is OK, EXCEPT that another

device may be using the same MAC address.

Position of valve/actuator

AB-QM valve is fully closed.

AB-QM is open 1-49% of Design Flow.

AB-QM is open 50-99% of Design Flow.

AB-QM valve is open 100% of Design Flow.

Flush is active

All LEDs turns on/off with specific period.

Movement of valve/actuator

NovoCon® is closing the valve

All green LEDs are turned ON, then turned OFF one at the time (repeatedly).

NovoCon® is opening the valve

All green LEDs are turned OFF, then turned ON one at the time (repeatedly).

NovoCon® is calibrating

Green light blink alternately.

De-air is active

Yellow LEDs blink alternately.

Stand-by mode

Information from actuator

Blinking function, all green LEDs turns on/off. Used to physically identif y individual actuator on the

bus.

26 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

LED Display (continued)

NovoCon® L, XL (co ntinued)

Information from actuator (continued)

Error during closing

Debris might be trapp ed under the AB-QM valve cone. Flushing may solve the

Error during NovoCon® calibration

LEDs change between showing the alarms and showing normal operation. Verify if the NovoCon® L/

XL is correctly attached to the valve and recalibrate.

Temperature inside NovoCon® is out of the recommended range

LEDs change between showing the alarms and showing normal operation. Ambient temperature

has likely exceeded 60°C.

Internal NovoCon® error

LEDs change between showing the alarms and showing normal bet ween operation. Try:

A: Re-calibrate.

B: Turn power off and on.

C: If the error does not disappear actuator replacement can be necessary.

Power supply is outside limits

LEDs change between showing the alarms and showing normal operation.

No Control Signal

In analog control mode a broken control wire is detected.

LEDs change between showing the alarms and showing normal operation.

Pressing the mode button during normal operation

Calibration/Reset/Flush

Press MODE button. All LED's are turned off.

Keep pressing the reset button for

1 second: 1 LED ON = Standby mode

2 seconds: 2 LEDs ON = Start calibration (Reset).

3 seconds: 1 LEDs ON

4 seconds: Start flushing. If f lushing should be stopped before the default timeout on 1 hour, press

again for 1 sec.

Factory reset - reset to default settings

Press and hold the MODE button and then power up the actuator, all LED's are initially turned off.

Keep pressing the MODE button for 4 seconds = Reset to default set tings.

When fac tory reset is per formed it is shown by:

1 short f lash with all yellow position LED’s.

Note that af ter factory reset a calibration will be automatically be performed and all settings are

reverted to factory settings.

problem.

AI368140926963en-010102 | 27© Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Door ContactDamper

Multiplex

Application principle

NovoCon® S I/O

Application principle

NovoCon® I/O and

Multiplexers/Relays

When combining the NovoCon® S and the Cable NovoCon® I/O, many options are possible

Operation example (DDC command)

NovoC on® S

Resistance input s can also be used

as galvanic insula ted digital inputs

for detecti on of window contact,

condensation s witch etc.

Connected: <90 0 Ohm.

Disconnecte d 100 kO hm.

Object /Register

AV:1 / 33280 85 DDC write s % opening value of t he AB-QM valve

AO:0 / 33286 5.5

Read on the BMS example

Object /Register

AO:0 / 33286 5.5 Voltage outpu t from NovoCon® S to remo te device

AI:0 / 33216 6.5

AI:1 / 33218 11 60 Resis tance value (Ohm) rec eived from remote d evice 1

AI:2 / 33220 12 63 Resistan ce value (Ohm) receive d from remote devi ce 2

Write value Description

DDC writ es level of voltage o n NovoCon® S analog o utput,

which is se nt to the connecte d remote device

Read value Description

Voltage le vel on the analog con trol input measur ed by

the actu ator

(may also be mA)

Multiplexers and relays (analog-digital-analog convertors) in combination with NovoCon® S, may be

used to gather information on, or control on/off devices.

Using NovoCon’s 0-10V output signal (AO:0 / 33286), multiplexer relays convert this signal in order

to switch devices on or off e.g. 7V signal from NovoCon® S is converted inside the multiplexer so

device1=on, device 2=on, device3=off. E.g. 4V signal from NovoCon® S is converted inside the

multiplexer so the device1=on, device 2=off, device3=off.

Using NovoCon’s 0-10V input signal (AI:0 / 33216) received from the multiplexers, the DDC can

decipher the meaning of the voltage signal e.g. 7V signal to NovoCon® S from the multiplexer is

deciphered by the DDC as meaning device1=on, device 2=on, device3=off. 4V signal to NovoCon® S

from the multiplexer is deciphered by the DDC as meaning device1=on, device 2=off, device3=off.

Application principle:

Central Plant Changeover –

2 pipe system

Fieldbus

Heating/

Cooling Coil

er/Multiplexer relays

Boiler

Temp.

Alarms

Fan Speed

Chiller

Digital Outputs

Fan coil unit

NovoC on® S

Actuator

Objec t /

Register

MSV:9 /

32810

MSV:3 /

32802

AV:30 /

32796

AV:31 /

32798

MSV:10 /

32 811

Window Contact

Digital Inputs

D/AA/DA/DD/A

Multiplexer/Multiplexer relays

Temp.

Condensation

Write/

read value

Selected

Val ve Typ e

Description

Digital /

The Heati ng and Cooling Des ign flow

Analog

values b elow may be used.

ISO valve se lected = l/h, ° C , kW and kg/m3.

ANSI valve s elected = GPM, ° F, kBTU a nd lb/ft

250 D esign flow set ting of Heating e. g. 250 l/h

400 Des ign flow setti ng of Cooling e.g. 4 00 l/h

When the s ystem is changed f rom central

Heating to c entral Cooling th e affected

Cooling

NovoCons m ay be written to so th e correct

Design flow will be adopted.

PIR

3

28 | AI368140926963en-010102 © Danfoss | 2022.01

Data sheet NovoCon® S, M, L and XL Digital actuators

Radiant Panels

Q

400 l/

0V 10V5V