Page 1

Data sheet

Multifunctional Thermostatic Circulation Valve

MTCV - Lead free brass

Introduction

Fig. 1

Basic version - A

The MTCV is a multifunctional thermostatic

balancing valve used in domestic hot water

installations with circulation.

The MTCV provides a thermal balance in hot

water installations by keeping a constant

temperature in the system, thus limiting the flow

in the circulation pipes to the minimum required

level.

To meet the increasing demands placed on the

quality of drinking water, Danfoss MTCV valves

are made from corrosion resistant and Lead Free

materials:

Main functions of the MTCV • Thermostatic balancing of hot water systems

within the temperature range of 35 - 60 °C version A.

• Automatic (self-acting) thermal disinfection

at temperatures above 68°C with safety

protection of the installation to prevent the

temperature rising above 75 °C (automatically

shuts-off circulation flow) - version “B”.

• Automatic disinfection process, electronically

controlled, with the possibility of

programming the disinfection temperature

and duration - version “C”.

•

Automatic flushing of the system by temporarily

lowering the temperature setting to fully open

the MTCV valve for a maximum flow.

• Temperature measurement possibility.

Fig. 2 *

Self-acting version with automatic

disinfection function - “B”

* thermomete r is an accessory

Fig. 3

Version with electronically

controlled disinfection process - “C”

• Valve body made from rg5 bronze material

• Components made from no Lead Brass

• Main cone made from advanced engineering

polymere POM-C.

Simultaneously, the MTCV can realize a

disinfection process by means of 2 features:

• An automatic (self-acting) disinfection

module - thermo-element (fig.2).

• An electronic controller with thermal actuator

TWA and temperature sensors PT1000 (fig.3).

• Preventing of unwanted tampering.

• Constant temperature measurement and

monitoring - version “C”.

• Shut-off function of the circulation riser by

means of optional fittings with a built-in ball

valve.

• Modular upgrading of the MTCV valve during

operation, under pressurized conditions.

• Servicing - when necessary the calibrated

thermo-element can be replaced.

© Danfoss | 2019.04

VD.D3.L2.02 | 1

Page 2

Data sheet MTCV - Lead free brass

Function

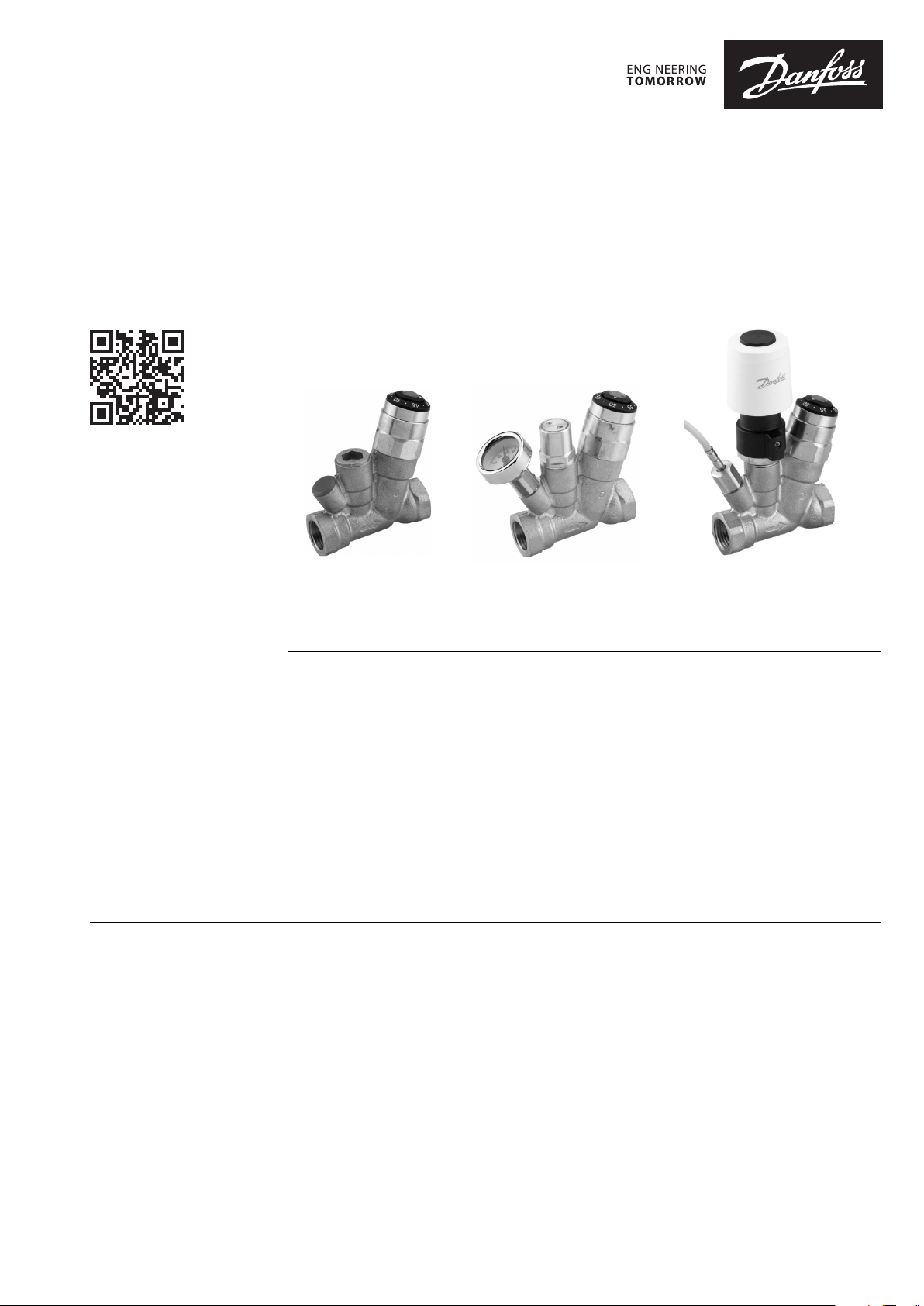

Fig. 4 MTCV basic version - A

The MTCV - is a thermostatic self-acting,

proportional valve. A thermo-element (fig. 6

elem. 4) is placed in the valve cone (fig. 6 elem. 3)

to react to temperature changes.

When increases the water temperature above

the set point value, the thermo-element expands

and the valve’s cone moves towards the valve

seat, thus limiting circulation flow.

When decreases the water temperature below

the set point value, the thermo-element will

open the valve and allow more flow in the

circulation pipe. The valve is in equilibrium

(nominal flow = calculated flow) when the water

temperature has reached the value set on the

valve.

The MTCV regulating characteristic is shown in

fig. 13, version A.

When the water temperature is 5 °C higher than

the set point value, the flow through the valve

stops.

A special sealing of the thermo-element

protects it against direct contact with water,

which prolongs the durability of the thermoelement and at the same time secures a precise

regulation.

A safety spring (fig. 6 elem. 6) protects the

thermo-element from being damaged when the

water temperature exceeds the value on the set

point.

Design

1. Valve body

2. Spring

3. Cone

4. Thermo-element

5. O-ring

6. Safety spring

7. Setting ring

8. Setting knob

9. Plug for covering the setting

10. Cone for disinfection module

11. Safety spring

12. Plug for thermometer

13. Plug for disinfection module

2 | © Danfoss | 2019.04

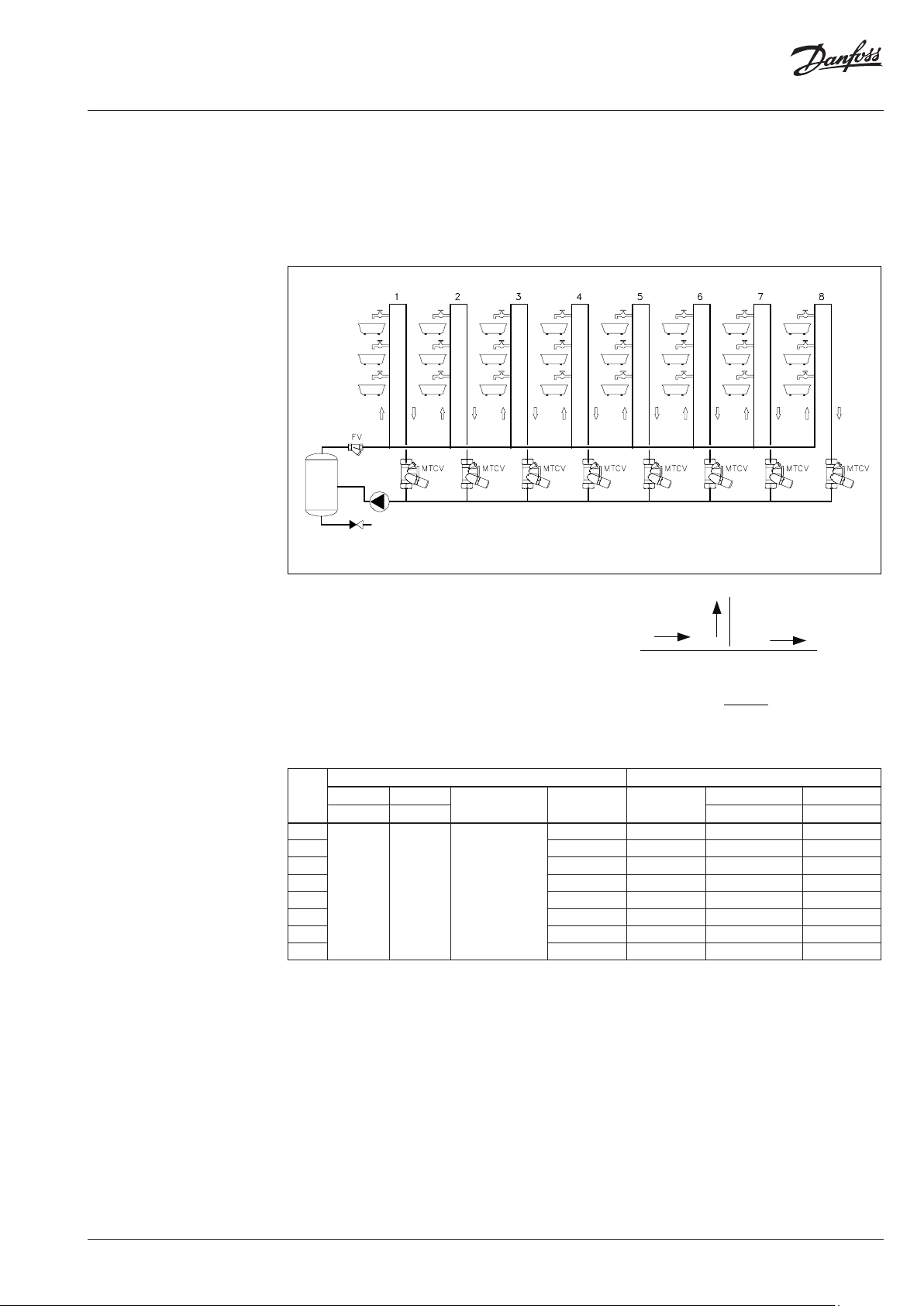

Fig. 5 Example of MTCV / basic version / placement in domestic hot water system

Fig. 6 Design - basic version - A

VD.D3.L2.02

Page 3

Data sheet MTCV - Lead free brass

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

TVM-W

FV

S

S

M

S

M

S

ECL...

MTCV MTCV

MTCV MTCV MTCV MTCV

Function

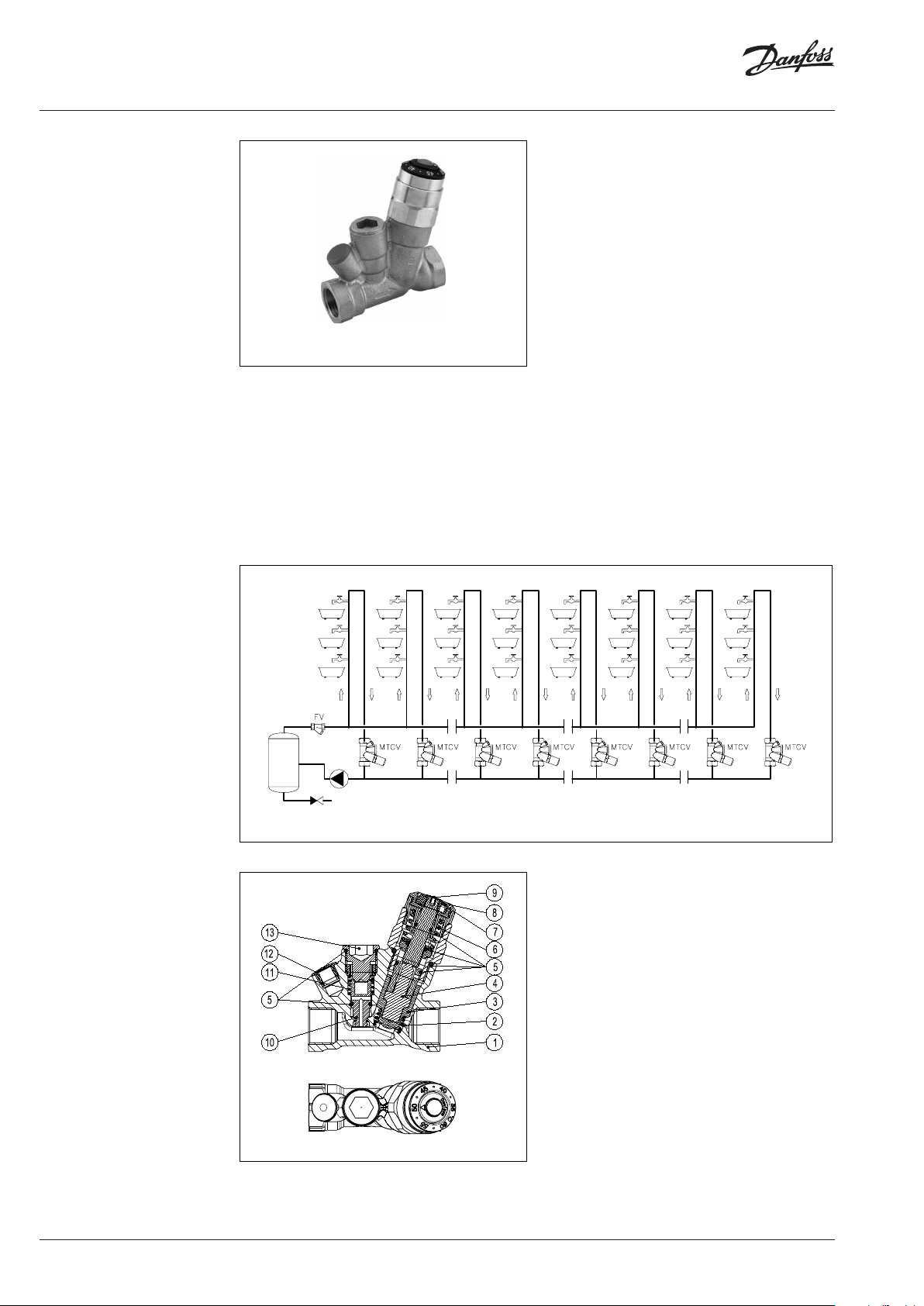

Fig.7 MTCV self-acting version with automatic thermal

disinfection function - B

* thermomete r is accessory

The MTCV standard version - A can easily and

quickly be upgraded to the thermal disinfection

function against the Legionella bacteria in hot

water systems.

After removing the plug from the disinfection

plug (fig. 6 elem. 13)-(this can be done during

working conditions, under pressure) the

thermostatic disinfection module can be

mounted (fig. 9 elem. 17).

The disinfection module will control the flow

according to its regulating characteristics,

(fig. 13, version B) thus performing a thermal

disinfection of the hot water installation.

The mounted disinfection module automatically

opens a by-pass of Kv min = 0.15 m3/h, which

allows flow for the disinfection. In the A version

of the MTCV this by-pass is always closed in

order to avoid sedimentation of dirt and calcium.

The MTCV can thus be upgraded with the

disinfection module even after a long period of

working in the A version without risking blocking

the bypass.

The regulation module in basic version A works

within the temperature range 35-60 °C. When

the temperature of the hot water increases

above 65°C the disinfection process starts meaning the flow through the main seat of the

MTCV valve stops and the bypass opens for the

“disinfection flow”. The regulating function is

now performed by the disinfection module,

which opens the bypass when the temperature is

above 65 °C.

The disinfection process is performed until a

temperature of 70 °C is reached. When the hot

water temperature is increased further, the flow

through the disinfection bypass is reduced (the

process of thermal balancing of the installation

during disinfection) and when reaching 75 °C

the flow stops. This is to protect the hot water

installation against corrosion and sedimentation

of calcium as well as to lower the risk of scalding.

A thermometer can optionally be mounted in both

version A and B in order to measure and control

the temperature of the circulating hot water.

Design

1-13 As described in fig. 6

14 Bypass for disinfection

15 Thermometer

16 Gasket Cu

17 Disinfecting module

VD.D3.L2.02

Fig. 8 Scheme of hot water installation with circulation - self acting version.

Fig. 9 Design - self-acting version with automatic

thermal disinfection function - B

© Danfoss | 2019.04 | 3

Page 4

Data sheet MTCV - Lead free brass

Function

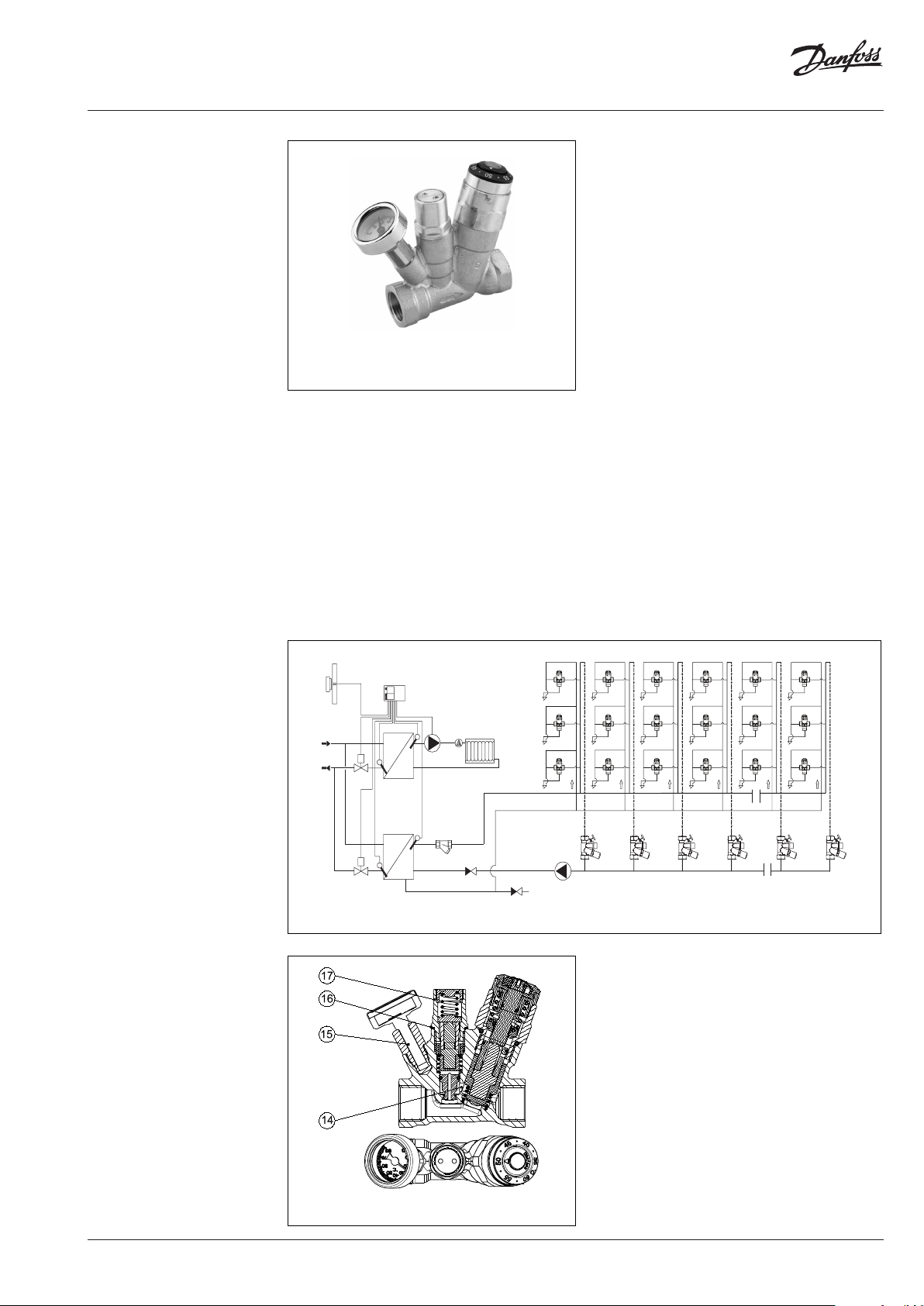

Fi g.10 Version with electronically controlled

disinfection process - C

The MTCV version “A” and “B” can be upgraded

to an electronic regulated disinfection process

(version C).

After removing the disinfection plug (fig. 6

elem. 13) the adapter can be mounted (fig. 12

elem. 21) and the thermo actuator TWA can be

mounted.

B

A temperature sensor PT 1000 has to be mounted

in the thermometer head (fig. 12 elem. 19).

Thermo-actuator and sensor are connected to

the electronic regulator CCR2+ which allows

an efficient and effective disinfection process

in each circulation riser. The main regulation

module works within the temperature range

35-60 °C. When the disinfection process/thermalwater treatment starts CCR2+ controls the flow

through MTCV via thermo-actuators TWA.

Benefits of an electronic regulated disinfection

process with CCR2+ are:

• Providing full control over the disinfection

process in each individual riser.

• Optimisation of total disinfection time.

• Optional choice of temperature for the

disinfection.

• Optional choice of time for the disinfection.

• On-line measurement and monitoring of the

water temperature in each individual riser.

• Enabling the possibility of connecting to the

controller in the heat substation or boiler

room (i.e. Danfoss ECL) or to a BMS (Modbus).

Design

1-13 As described in fig. 6

18 Bypass; (position closed)

19 Temperature sensor PT 1000

20 Gasket Cu

21 Adapter to connect thermo-

actuator TWA

*

A

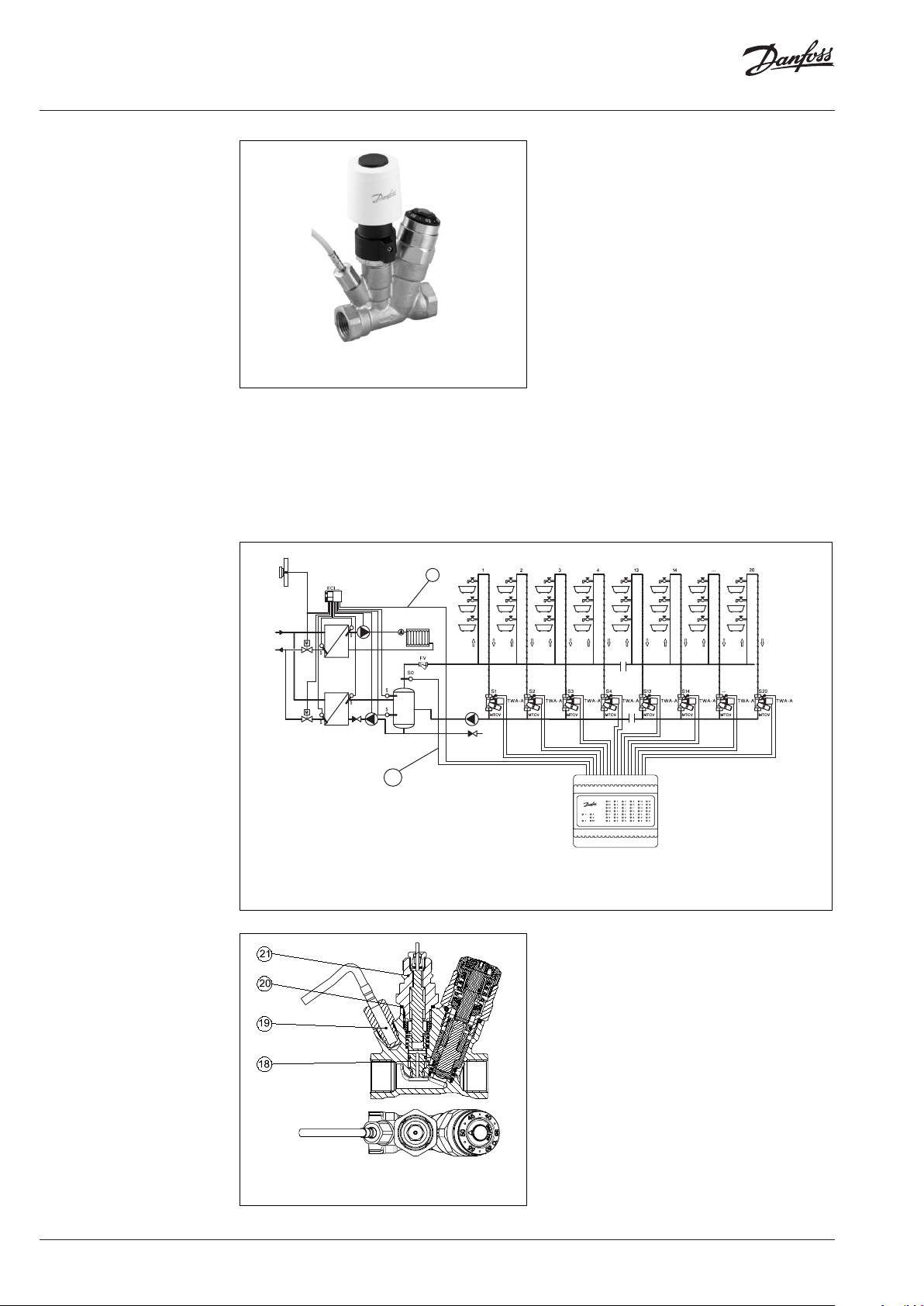

Fi g. 11 - scheme of installation for disinfection and registration temperature

A) in dependent system (only se nsor S0 needed)

B) depende nt system (sensor S0 and connectio n to weather or another control n eeded)

4 | © Danfoss | 2019.04

Fi g.12 Version with electronically controlled

disinfection process - C

VD.D3.L2.02

Page 5

Data sheet MTCV - Lead free brass

Technical data Max. working pressure ........................................ 10 bar

Test pressure ...........................................................16 bar

Max. flow temperature .......................................100 °C

kVS at 20 °C:

- DN20 ............................................................ 1.8 m3/h

- D N15 .............................................................1. 5 m3/h

Hysteresis .................................................................... 1.5 K

Ordering

Valve - basic ve rsion A Code No.

DN 15 003Z4 515

DN 20 003Z4520

Accessories and spare parts

Accessory Comments

Thermostatic disinfection module - B DN 15/DN 20

Fittings with shut-of f ball valve

(for allen key 5 mm), DN 15

Thermometer with adapter DN 15/DN 20

Socket for ESMB PT1000 DN 15/DN 20

Adapter for thermo-actuator DN 15/DN 20

Material of parts in contact with water:

Valve body ...................................................................Rg5

Spring housing, etc. ............Cuphin alloy (CW724R)

O-rings ...................................................................... EPDM

Spring, bypass cones ........................... Stainless steel

Cone .......................... POM-C (Acetal Homopolymer)

Code No.

003 Z2021

G ½ × Rp ½

G ¾ × Rp ¾ 003 Z1028

003 Z1027

003 Z1023

003 Z1024

003 Z1022

CCR2+ Controller also see enclosure VD.D3.K1.02 003 Z3851

CCR+ Slave Unit also see enclosure VD.D3.K1.02 003Z38 52

Temperature sensor ESMB Universal

Temperature sensor ESMC contact 08 7N 0011

Fittings for soldering Cu 15 mm

Fittings for soldering Cu 18 mm

Fittings for soldering Cu 22 mm

Fittings for soldering Cu 28 mm

Thermoactuator TWA-A/NC, 24V also see enclosure VD.57.U4.02 088H3110

also see enclosure VD.D3.K1.02

DN 15

int. R 1/2”

DN 20

int. R 3/4”

08 7B11 84

003Z1034

003Z1035

003Z1039

003 Z1040

VD.D3.L2.02

© Danfoss | 2019.04 | 5

Page 6

Data sheet MTCV - Lead free brass

25 35 45 55 65 75 85

K

vs

K

vmin

K

vdis

basic

disinfection

version B

version

C

vri

n A

temperature ˚C

presetting 50 ˚C

flow

Regulating characteristics

Fig.13 The MTCV regulating characteristics

Kv

min

Main function setting

• Basic version A

• Version B:

Kv

= 0.15 m3/h - min. flow through the

min

bypass when main regulation module

is closed.

*Kv

*Kv

= 0.60 m3/h for DN 20,

dis

= 0.50 m3/h for DN 15 - max. flow of the

dis

disinfection process by a temperature

of 70 °C.

Setting ring

1

Ring with a reference point

2

Plastic cover - unwanted

3

tampering protection

Hole for screwdriver

4

Temperature setting screw -

5

Allen-key 2.5 mm

References temperature

6

setting point

4

Fig.14 MTCV setting of the temperature

Temperature range: 35-60 °C

MTCV´s factory pre-setting 50 °C

The temperature setting can be made after

removing the plastic cover (3), by lifting it with a

screwdriver using the hole (4). The temperature

setting screw (5) must be turned with an allenkey to match the wanted temperature on the

scale with the reference point. The plastic cover

(3) must be pressed back into place after the

setting has been made.

• Version C:

* Kv

= 0.60 m3/h for DN 20 and DN 15 -

dis

flow through the MTCV when the

disinfection module is fully opened

(regulation at thermo-actuator TWA-NC).

* Kv

- Kv during disinfection process

dis

3

1

5

2

6

It is recommended to control the set temperature

with a thermometer. The temperature of the hot

water from the last tapping point on the riser

must be measured*. The difference between the

measured temperature at the last tapping point

and the temperature set on the MTCV is due to

heat losses in the circulation pipe between the

MTCV and the tapping point.

* where T VM valves (thermostatic mixing val ves) are installed t he

temperature mu st be measured before the T VM valve.

6 | © Danfoss | 2019.04

VD.D3.L2.02

Page 7

Data sheet MTCV - Lead free brass

0

10

20

30

40

50

60

70

0 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60

Flow temperature ˚C

setting

at 60 ˚C

setting at 50 ˚C

setting

at 35 ˚C

Kv (m

3

/h)

55

60

65

70

75

80

0 0.10 0.20 0.30 0.40 0.500 0.60

Flow temperature ˚C

Kv (m3/h)

version B

version C

Setting procedure

Pressure and flow chart

MTCV - DN 15

The required temperature setting of the MTCV

depends on the required temperature at the last

tap and the heat losses from the tap to MTCV in

the same riser.

Example:

Required temperature at the last tap: 48 °C

Heat losses from the last tap to the MTCV: 3 K

Differential pressure 1 bar, DN 15

Required:

correct setting of MTCV

Solution:

Correct setting of MTCV: 48 - 3 = 45 °C

Note:

After new setting use the thermometer to check if

the required temperature at the tap is reached and

correct the MTCV setting accordingly.

Fig. 15

Table 1

preset preset preset preset preset preset

60 °C 55 °C 50 °C 45 °C 40 °C 35 °C

65 60 55 50 45 40 0

62.5 57. 5 52.5 47. 5 42. 5 37. 5 0.238

60 55 50 45 40 35 0.427

57. 5 52.5 47. 5 42. 5 37. 5 32.5 0.632

55 50 45 40 35 30 0.795

52.5 47. 5 42. 5 37. 5 32.5 0.963

50 45 40 35 30 1.087

47. 5 42.5 37.5 32.5 1.202

45 40 35 30 1.28 3

42.5 37. 5 32.5 1.351

Flow temperature °C

40 35 30 1.394

37. 5 32.5 1.437

35 30 1.469

32.5 1.500

30 1.500

Differential pressure 1 bar, DN 15 - disinfection process

Fig. 16

kv

(m3/h)

VD.D3.L2.02

© Danfoss | 2019.04 | 7

Page 8

Data sheet MTCV - Lead free brass

70

2.00

Flow temperature ˚C

80

0.70

Flow temperature ˚C

Differential pressure 1 bar, DN 20Pressure and flow chart

MTCV - DN 20

60

Fi g. 17

Tab le 2

Flow temperature °C

50

40

30

20

10

0

0 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80

preset preset preset preset preset preset

60 °C 55 °C 50 °C 45 °C 40 °C 35 °C

65 60 55 50 45 40 0

62.5 57. 5 52.5 47. 5 42. 5 37. 5 0. 251

60 55 50 45 40 35 0. 442

57. 5 52.5 47. 5 42. 5 37. 5 32.5 0.645

55 50 45 40 35 30 0.828

52.5 47. 5 42. 5 37. 5 32.5 1.000

50 45 40 35 30 1.164

47. 5 42.5 37.5 32.5 1.32 2

45 40 35 30 1.46 2

42.5 37. 5 32.5 1.577

40 35 30 1.667

37. 5 32.5 1.733

35 30 1.753

32.5 1.761

30 1.761

Ex. 1

0.366

setting at 50 ˚C

setting

at 35 ˚C

Kv (m

3

/h)

setting

at 60 ˚C

kv

(m3/h)

Differential pressure 1 bar, DN 20 - disinfection process

75

70

65

60

55

0 0.10 0.20 0.30 0.40 0.50 0.60

Fig . 18

Kv m3/h

version B

version C

8 | © Danfoss | 2019.04

VD.D3.L2.02

Page 9

Data sheet MTCV - Lead free brass

p

.

Example of calculation

Example:

The calculation is done for a

3-storey building with 8 risers.

The following assumptions were

used in order to simplif y

calculation:

• Heat losses per meter of the

pipe,

q1 =10 W/m *

* during calcula tion it is required to

calculate heat lo sses according to the

country-specific standards.

Usually the calculated heat loses are dependent

on :

- The dimension of the pipe

- The materials used in insulations

- The ambient temperature where the pipe is

located

- The efficiency and condition of insulation

Fig. 19 Scheme of installation

• Inlet of hot water temperature, T

• Temperature drop through the system,

= 55 °C

sup

∆T= 5 K

• Distance between risers, L = 10 m

• Height of the risers, l = 10 m

• Installation scheme as shown below:

I Basic operation

o

˙

V

Calculation:

• calculation of heat losses in each riser

(Qr) and header (Qh)

Qr = l riser x q = ( 10 + 10 ) x 10 = 200 W

Qh = l horiz. x q = 10 x 10= 100 W

• The table 3 shows the results of the

calculations:

˙

V

c

&

V+=

c

˙

V

p

V

o

.o.

VV

Tab le 3

heat losses

riser

In risers In header

Qr (W) Qh (W ) Vo (l/h) Vc (l /h)

1

2 2100 0.09 38 376

3 1800 0.1 40 339

4 150 0 0 .12 43 299

200 100 300

5 120 0 0 .14 47 256

6 900 0.18 52 210

7 600 0.25 63 157

8 300 0.4 94 94

Total in each part

(W)

ΣQ total

(W)

2400 - 36 412

Factor risers

Flow in each part Total f low

VD.D3.L2.02

© Danfoss | 2019.04 | 9

Page 10

Data sheet MTCV - Lead free brass

V

&

V

&

Example of calculation

(continuous)

• The total flow in the hot water circulation

system is calculated using formula:

&

Q

&

V

∑

=

Δ

tcr

hww

ΣQ - total heat loses in installation, (kW)

thus:

total

&

V

C

4.2

=

518.41

××

= 0.114 l/s = 412 l/h

The total flow in hot water circulation system

is: 412 l/h - the circulation pump shall be sized

for this flow.

• The flow in each riser is calculated using

formula:

Flow in the riser number 1:

Q

&&

VV

o

×=

co

QQ

+

po

thus:

1

&

412V

0

200

×=

2100200

+

= 35.84 l/h ≅36 l/h

Flow in remaining risers should be calculated

in the same way.

• The pressure drop in the system

Following assumptions were made to simplify

calculation:

- Linear pressure drop, p

(Linear pressure is the same for all pipes)

= 60 Pa/m

l

- Local pressure drop is equal to 33 % of

total linear pressure drop, pr = 0.33 p

thus:

pr = 0.33 × 60 = 19.8 Pa/m ≅ 20 Pa/m

l

- For the calculation used

p

= pr + pl = 60 + 20 = 80 Pa/m

basic

- Local pressure drop across the MTCV is

calculated on the basis of:

⎛

⎜

=

Δp

MTCV

⎜

⎝

Kv

⎞

×

V01.0

0

⎟

⎟

⎠

2

&

where:

Kv - according to fig. 19 page 10

in this case

Kv = 0.366 m3/h for preset 50 °C

- flow through the MTCV at the flow

0

temperature 50 °C (l/h)

• When designed flow have been calculated,

use the fig. 17 on page 9.

Please note:

during pressure drop calculation across the valve

the temperature of circulation water has to be

observed. MTCV - Multifunction Thermostatic

Circulation Valve has variable Kv value which is

dependent on two values: the preset temperature

and the temperature of the flow temperature.

When the

across MTCV is calculated using the following

and Kv are known, the pressure drop

0

formula:

⎛

⎜

=

Δp

MTCV

⎜

⎝

Kv

⎞

×

V01.0

0

⎟

⎟

⎠

2

&

thus:

2

9401.0

×

Δp

∆p

⎛

=

⎜

MTCV

⎝

MTCV

⎞

⎟

366.0

⎠

kPa 6.59

=

= (0.01 x 94 / 0.366 )2 = 6.59 kPa

• Differential pressure across the pump:

Where:

∆p

*p

*p

pump

= ∆p

circuit

+ ∆p

MTCV

= 14.4 + 6.59 = 21 kPa

- pressure drop in critical circuit

circuit

(table 4)

- includes pressure drop across all

pump

devices in circulation installation like:

boiler, strainer etc.

10 | © Danfoss | 2019.04

Tab le 4

riser

In risers

(kPa)

1

2 12. 8 38 1. 07

3 11. 2 40 1.19

4 9.6 43 1.38

5 8.0 47 1.64

6 6.4 52 2.01

7 4.8 63 2.96

8 3.2 94 6.59

1.6 1.6

pressure drop across the MTCV

In heade r

(kPa)

p

circuit

(kPa)

14.4 36 0.97

V0-flow

(l/h)

∆mMTCV pressure drop

(kPa)

Total pressure

pump

(kPa)

21

VD.D3.L2.02

Page 11

Data sheet MTCV - Lead free brass

V

&

V

&

Example of calculation

(continuous)

II Disinfection

The heat losses and pressure drop should be

calculated according to new conditions.

- inlet hot water temperature during

disinfection T

- ambient temperature *T

(*T

- according to standard and norm

amb

obligatory)

= 70 °C

dis

amb

= 20 °C

thus:

Δp

MTCV

Due to lower flow comparing to basic

condition (412 l/h), pressure drop in the

installation, p

Δp

where :

1. The heat losses are calculated from the

formula:

q1 = Kj x l x ∆T1 → Kj x l = q1/∆T1

for basic process

q2 = Kj x l x ∆T2 → Kj x l = q2 /∆T2

for disinfection process

Thus :

⎛

Δ

T

2

⎜

=

=

qq

q

12

1

⎜

Δ

T

1

⎝

⎞

−

TT

ambdis

⎟

⎟

−

TT

ambsup

⎠

for given case:

C 20C 70

°−°

=

2

⎜

⎝

⎛

(W/m) 10q

⎞

W/m 14.3

=

⎟

C 20C 55

°−°

⎠

In this case during disinfection process heat

losses increase for around 43 %.

w - velocity of the water (m/s)

By comparing conditions during basic

operation and disinfection one can estimate:

pp ×=

where :

V

- disinfection flow (l/h)

dis

VC - basic flow (l/h)

Thus:

- for first part of installation

1

80p

dis

This calculation should be done for all

critical circuit. The table 5 shows the result of

calculation.

2. Required flow

Due to sequence disinfection process (step by

step) only critical circuit should be calculated.

For given case:

Q

= Qr + Qh

dis

Q

= ((10+10) + (8 × 10)) × 14.3 W/m =

dis

1430 W = 1.43 kW

The flow:

1.43

&

V

=

dis

54.18

×

==

l/h 246l/s 0.0684

3. The required pressure

The required pressure during the disinfection

For the critical circuit:

p

dis(circuit)

+ 2.20 + 3.93 + 21.92 = 32.70 kPa

p

= 32.70 + 16.81 = 49.51 kPa

dispump

= p

The pump should be chosen to cover both

requirements:

• basic operation,

= 412 l/h and p

0

• disinfection operation

= 246 l/h and P

0

process should be checked

p

dispump

where:

Δp

MTCV

= p

=

dis(circuit)

⎛

⎜

⎜

⎝

Kv

×

+ ∆p

&

V01.0

0

MTCV

2

⎞

⎟

⎟

⎠

Tab le 5

pressure drop the circuit during disinfection process

flow (l/h)

basic disinfection

412 246 29

376 246 34 0.68

339 246 42 0.84

299 246 54 1.08

256 246 74 1.4 8

210 246 110 2.20

157 246 196 3.93

94 246 548 40 21.92

new pressure drop

(Pa/m)

length

(m)

20

2

×

2460.01

0.6

⎞

⎟

⎠

kPa 16.81

=

should be recalculated.

2

V

dis

2

V

c

2

⎞

Pa/m 29

=

⎟

⎠

⎛

=

⎜

⎝

circuit

2

w

2

basicdis

246

⎛

×=

⎜

412

⎝

= 0.57 + 0.68 + 0.84 + 1.08 + 1.48

+ ∆p

dis(circuit)

pressure drop

(kPa)

0.57

∑ 32.70

MTCV

= 21 kPa

pump

= 49.51 kPa

pump

Total pressure drop

in critical circuit

32.70

VD.D3.L2.02

© Danfoss | 2019.04 | 11

Page 12

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet MTCV - Lead free brass

Dimensions

Internal thread

DN 15

DN 20

Fig. 20

A a H H1 L L1

IS O 7/1 mm

Rp ⁄ Rp ⁄ 79 129 75 215 0.56

Rp ⁄ Rp ⁄ 92 12 9 80 230 0.63

Weight

(kg)

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all D anfoss logotypes are trademarks of Danfoss A/S. All rights reser ved.

12 | © Danfoss | DHS-SRMT/SI | 2019.04

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

VD.D3.L2.02

Loading...

Loading...