Page 1

DESCRIPTION

The MCHXXX Control Handle is intended for use in openloop systems controlling Danfoss hydrostatic pumps with

an Electrical Displacement Control (EDC).

These Control Handles may also be used with an MCE101

Proportional Transmission Controller in pressure or

horsepower limiting applications.

The Control Handle is designed to provide a remote manmachine interface. In addition to proportional operation of

electrically controlled hydrostatics, switches may be incorporated to operate backup, alarm, brake, and neutral interlock circuits.

FEATURES

MCH Control Handle/EDC

Control Handles For

Electrical Displacement Controls (EDC)

BLN

95-9007-0101

Issued

July 2017

• Choice of three mounting styles with or without water

resistant case.

• Mechanical options include center lock, spring return,

friction held, and center detents.

• High torque handle actuation gives a realistic force feel.

• Easy installation.

• Shock and vibration resistant.

• Environmental hardened components designed for off-

road construction equipment.

• Optional switches in knobs.

• Optional cam operated switches.

• Optional electrical cable and connectors.

ORDERING INFORMATION

The following tabulation is the list of current standard production Control Handle models for EDCs. Behind each circuit (as

described in the Electrical Characteristics section of this bulletin) is the mounting, knob, and actuation which are available as

production models. For example, for the B1039 circuit there is MCH12AB1039, MCH41AB1039, and MCH51AB1039 in

production. Other combinations may be possible. Consult factory for availability.

CIRCUIT

NUMBER MOUNTING, KNOB AND ACTUATION

B1032 11A 11B 12A 12B 13B 21A 21B 21C 22A

22B 23A 26A 26B 29A 29B 31A 32B 40A

41A 41B 42A 42B 47A 48B 51A 51B 58A

B1035 11C 21C 29C 31C 41C 43C 51C 59C

CIRCUIT

NUMBER MOUNTING, KNOB AND ACTUATION

C1065 22B

C1067 11A 12B 21A 22A 22B 32A 41B 42B

C5168 11A 22B 32A 42B

B1039 11A 12A 41A 51A

B1042 11A 11B 12A 12B 21A 22A 22B 23A 25A

29B 41A 41B 42A 43B 48A

B3069 12A 22B 32B 41A 42A

B5087 11B 22B 41B 42B

B5093 11A 12B 22A 22B 41A 51B

C1033 11A 11B 12A 12B 13A 21A 21B 22A 22B

23A 29A 32B 41A 41B 42A 42B 43A 51A

51B 52A 52B 53A

D1029 11B 22B 29B

D1040 19A 21A 22B 31B 42B

D1043 11A 11B 12B 13A 13B 16B 21A 22B 23A

26B 29A 29B 32A 41A 41B 42B 51B 52B

D1058 11A 11B 12A 12B 21B 22A 22B 23A 41B

42B 45B 48A 52B

D1064 11A 11B 12A 12B 22A 22B 29B 41A 41B

42B 48A

1

© Copyright 2017, Danfoss (US) Company.

All rights reserved. Contents subject to

change.

Page 2

ORDERING INFORMATION

(continued)

CIRCUIT

NUMBER MOUNTING, KNOB AND ACTUATION

D1073 11B 12B 21A 21B 22B 23B 31B 41B 51B

52B

D1077 21A 21B 22B 41B 51A 51B

D1082 13A 21A 21B 22B 42B

D1089 42B 51B

D2155 48A

D3059 11B

D5129 11A 11B 22B 41A 41B

L2171 11A 11B 12A 12B 19A 21A 22B 42B

MCHXXX ORDERING SPECIFICATION CHART

M C H

X XXX X X X X

CIRCUIT

NUMBER MOUNTING, KNOB AND ACTUATION

M1068 11A 11B 12B 13A 21A 21B 22A 22B 28A

29B 41B 42A 42B 48A 51B 52A 58B 59A

M1083 11A 12B 19A 21A 22B 41A 51A 51B 52B

M1101 11B 12B 21A 22A 22B 41B 42B

M1112 22B 31B 41B 52B

M1122 21A 22B 41B 42B 48A

M1167 21A 32B 42B 51B

M1169 22B 41B 45B

TYPE OF

CONTROL KNOB

HANDLE

ACTUATION

MOUNTING

1 Base (surface) mount aluminum case

2 Top mount (drop-in) with plastic case

3 Top mount (drop-in) without plastic case

4 Panel mount with plastic case

5 Panel mount without plastic case

TYPE OF CONTROL KNOB

1 Non-locking

2 Center lock

3 Push button in knob

4 Tron maintained rocker switch (obsoleted)

5 Non-locking, no knob

6 3-position maintained rocker switch in knob

7 Tron momentary rocker switch (obsoleted)

8 Special (no handle or knob)

9 3-position momentary rocker switch in knob

C Maintained rocker and trigger switch

D Momentary rocker and lever switch

E Momentary rocker and trigger switch

HANDLE ACTUATION

A Spring-return, bi-directional

B Friction held, bi-directional

C Friction held, uni-directional

D Special (friction held, center detent only, no brake)

E Spring return, uni-directional (one direction

blocked, 30° movement)

ELECTRICAL

CHARACTERISTICS

CONNECTORMOUNTING SEE

ORDERING

INFORMATION

SECTION

ELECTRICAL CHARACTERISTICS

A Proportional, no switches

B Proportional, 12 Vdc center-off switch

C Proportional, 24 Vdc center-off switch

D Proportional, center-off and auxiliary switch

L Electronic PWM auxiliary switching

M 3-switches

N 4-switches

P 5-switches

R 2-switches

X Special

Y Special

Z Special

CONNECTOR

1 Terminal strip internal

2 Pigtail 60 inch with no connector

3 Pigtail with unsealed Packard connector

4 Pigtail with both halves of unsealed Packard

connector

5 Sealed Packard connector with mating half

6 Sealed Packard connector 4-pin male and female

7 Pigtail with sealed Packard connector

8 Pigtail sealed Deutsch connector

9 No connector / terminal strip

BLN 95-9007-0101

2

Page 3

TECHNICAL DATA

ELECTRICAL SPECIFICATIONS

OPERATING VOLTAGE RANGE

11-15 Vdc (12 Volt models)

10 Vdc (12 Volt proportional transmission controller

models)

22-30 Vdc (24 Volt models)

20 Vdc (24 Volt proportional transmission control-

ler models)

LOAD RESISTANCE

15-30 Ω

Danfoss single and dual-coil Electrical Displacement

Controls.

AUXILIARY SWITCH CURRENT CAPABILITY

V3L Microswitch (cam actuated)

3-amp, inductive at 28 Vdc

SM Microswitch (cam actuated)

2.5-amp, inductive at 28 Vdc

Rocker Switch (in knob)

2-amp, inductive at 28 Vdc

Push button Switch (in knob)

5-amp, inductive at 28 Vdc

MECHANICAL SPECIFICATIONS

HANDLE STROKE:

±30°

60° total travel

SPRING TORQUE

11 ± 4-in./lb. (1.2 ± 0.4-N-m) at center break away

18 ± 6-in./lb. (2.0 ± 0.7-N-m) at full stroke

DETENTE TORQUE (over & above friction drag):

10-in./lb. (1.1-N-m)

FRICTION DRAG:

13.5 ± 3-in./lb. (1.5 ± 0.3-N-m)

Friction is adjusted at brake assembly with a 5/32 English

Allen wrench and 3/8 open-ended wrench.

MOUNTING, TYPE OF KNOB, HANDLE ACTUATION

A wide range of options to the basic Control Handle allows it

be custom-tailored to each application. See Ordering Specification chart in Ordering Information.

MOUNTING (See Dimension Drawing)

1. BASE OR SURFACE MOUNT

Connection is via four screws to the flanges on the

bottom of the metal case.

2. TOP MOUNT WITH CASE

Connection is via two screws to an enlarged mounting

plate. Top mounting allows the entire handle to be

removed from above the panel. The case is made of

black nylon plastic.

3. TOP MOUNT WITHOUT CASE

Same as 2, but without case.

4. PANEL MOUNT WITH CASE

Connection is via four screws to the top plate that holds

the boot in place. The case is made of black nylon

plastic.

5. PANEL MOUNT WITHOUT CASE

Same as 4, but without case.

TYPE OF CONTROL KNOB (See Dimension Drawing)

1. NON-LOCKING

The non-locking handle has a standard ball knob. The

friction-held handle detents with a spring-loaded ball to

indicate null, while the spring-return handle has a springpreload indicating null.

2. CENTER-LOCK

The center-lock handle has a cylindrical knob and provides a positive center-lock that unlatches when the

operator pulls up on the knob.

3. NON-LOCKING, AUXILIARY SWITCH

This knob is teardrop shaped, with an auxiliary momentary push button switch on top. The switch is wired

through the handle shaft to the body with three wires

(common, normally open and normally closed).

5. NON-LOCKING, NO KNOB

The customer provides has own customized knob.

6. THREE POSITION MAINTAINED ROCKER SWITCH

IN KNOB

The cylindrical knob has a boot covering the three

position switch in the knob. The switch, wired through

the handle, is used for auxiliary functions.

9. THREE POSITION MOMENTARY ROCKER SWITCH

IN KNOB

This is the same as 6, but the switch returns to the center

position when released.

BLN 95-9007-0101

3

Page 4

HANDLE ACTUATION

HANDLE ACTUATION

(continued)

PERFORMANCE CURVE

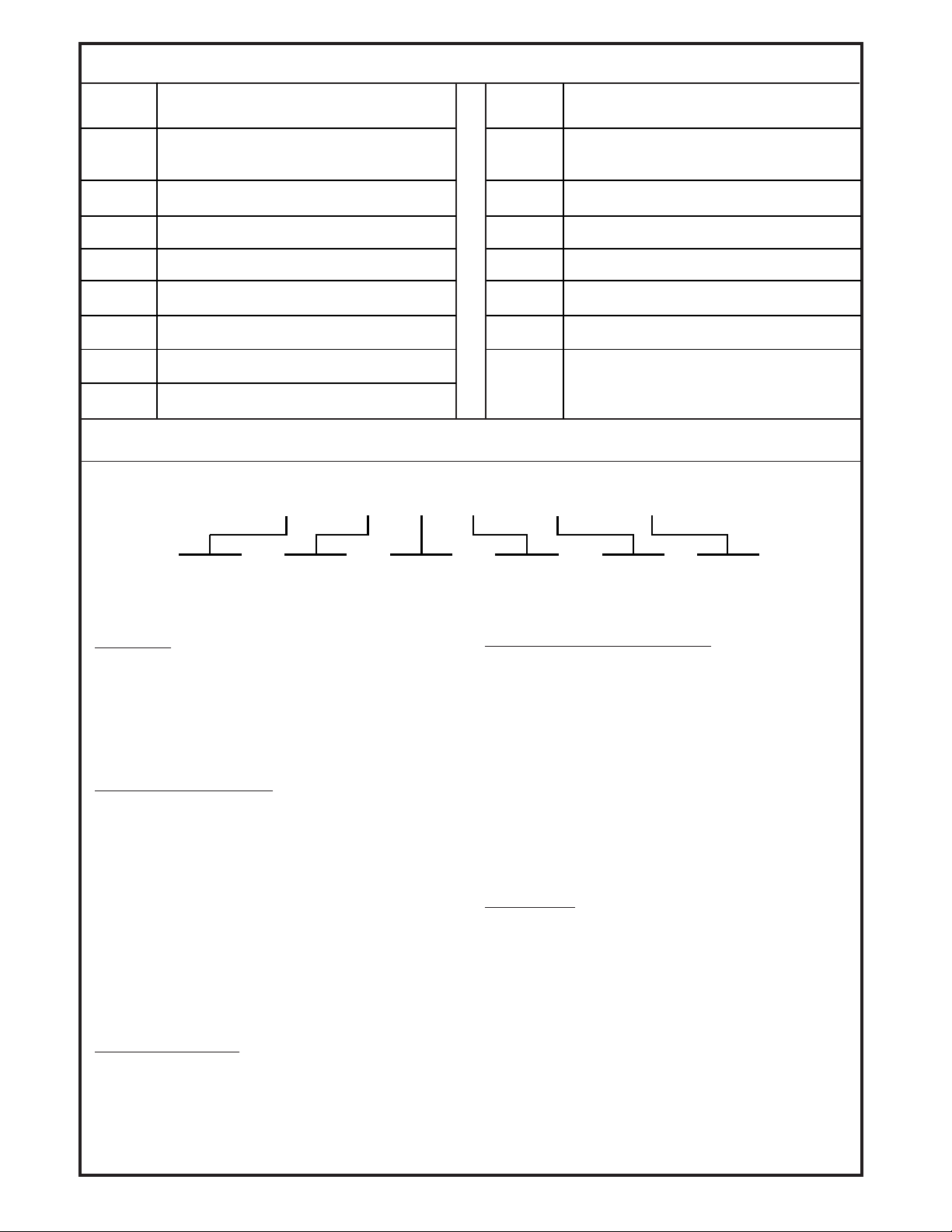

A. SPRING-RETURN, BI-DIRECTIONAL

This handle uses a torsion spring to return to the

mechanical center position, and has 30 degrees of

handle throw on either side of center.

B. FRICTION-HELD, BI-DIRECTIONAL

This handle has an adjustable drag set with a clamptype brake, that holds the handle at the set position, and

has 30 degrees of handle throw on either side of the

center detent.

C. FRICTION-HELD, UNI-DIRECTIONAL

This handle has a high-resolution 60 degrees of handle

throw, rotating on only one side of mechanical null,

which is at full stroke. It has no detent mechanism.

ELECTRICAL CHARACTERISTICS

A. PROPORTIONAL, NO SWITCHES, 12 Vdc,

BI-POLAR

Not recommended for Control Handles driving an Electrical Displacement Control. To be used only as setpoint.

See Performance Curve.

B. PROPORTIONAL, CENTER-OFF SWITCH, 12 Vdc,

BI-POLAR

These handles have a center-off switch wired to ensure

zero output when the handle is within ±3° of mechanical

center.

CIRCUIT NUMBERS FOR USE WITH A FIXED POWER

SUPPLY

B1032 - Single pot, terminal strip

B2095 - Single pot, pigtail no connector

B3069 - Single pot, unsealed Packard connector

B5093 - Single pot, sealed Packard connector

CIRCUIT NUMBERS FOR USE WITH THE MCE101 PROPORTIONAL TRANSMISSION CONTROLLER

B1042 - Dual pot, terminal strip

B3086 - Dual pot, unsealed Packard connector

B5087 - Dual pot, sealed Packard connector

CIRCUIT FOR OPERATING TWO EDCs IN SERIES

B1039 - Dual pot, terminal strip

C. PROPORTIONAL, CENTER-OFF SWITCH, 24 Vdc,

BI-POLAR

These handles have a center-off switch wired to ensure

zero output when the handle is within ±3° of mechanical

center.

OUTPUT

CURRENT

30°30°

HANDLE

STROKE

1139

Proportional Control Handle Output Current vs.

Control Handle Travel.

CIRCUIT NUMBERS FOR USE WITH THE MCE101 PROPORTIONAL TRANSMISSION CONTROLLER

C1067 - Dual pot, terminal strip

CIRCUIT FOR OPERATING TWO EDCs IN SERIES

C1065 - Dual pot, terminal strip

D. PROPORTIONAL, CENTER-OFF SWITCH, UNWIRED

AUXILIARY SWITCH, 12 OR 24 Vdc, BI-POLAR

CIRCUIT NUMBERS FOR USE WITH FIXED 12 Vdc POWER

SUPPLY

D1043 - Single pot, reverse switch, terminal strip

D1058 - Single pot, neutral start switch, terminal strip

D2163 - Single pot, neutral start switch, 60" pigtail

D3059 - Single pot, reverse switch, unsealed Packard

connector

CIRCUIT NUMBERS FOR USE WITH FIXED 24 Vdc POWER

SUPPLY

D1040 - Single pot, reverse switch, terminal strip

D1082 - Single pot, neutral start switch, terminal strip

CIRCUIT NUMBERS FOR USE WITH 12 Vdc MCE101

PROPORTIONAL TRANSMISSION CONTROLLER

D1029 - Dual pot, reverse switch, terminal strip

D1064 - Dual pot, neutral start switch, terminal strip

D2155 - Dual pot, neutral start switch, 60" pigtail

D5129 - Dual pot, neutral start switch, sealed Packard

connector

CIRCUIT NUMBERS FOR USE WITH 24 Vdc MCE101

PROPORTIONAL TRANSMISSION CONTROLLER

D1077 - Dual pot, neutral start switch, terminal strip

CIRCUIT NUMBERS FOR USE WITH A FIXED POWER

SUPPLY

C1033 - Single pot, terminal strip

C3076 - Single pot, unsealed Packard connector

C5168 - Single pot, sealed Packard connector

BLN 95-9007-0101

CIRCUIT FOR OPERATING TWO EDCs IN SERIES

D1073 - 12 Vdc, dual pot, neutral start switch, terminal

strip

D1089 - 24 Vdc, dual pot, reverse switch, terminal strip

D1138 - 24 Vdc, dual pot, neutral start switch

4

Page 5

ELECTRICAL CHARACTERISTICS

(continued)

L.

ELECTRONIC, PULSE WIDTH MODULATED,

ADJUSTABLE OUTPUT, 12 Vdc, BI-POLAR

CIRCUIT NUMBERS FOR USE WITH AN ELECTRICAL

DISPLACEMENT CONTROL

L2171 - Center off and output phasing switch, suitable

for fixed or variable power supplies.

PROPORTIONAL, THREE SWITCHES, 12 OR

M.

24-VOLT

The three switches include a wired center-off switch and

two unwired auxiliary switches.

CIRCUIT NUMBERS FOR USE WITH 12 Vdc FIXED

POWER SUPPLY

M1068 - Single pot, forward & reverse switches, terminal strip

M1101 - Single pot, forward & neutral start switches,

terminal strip

CIRCUIT NUMBERS FOR USE WITH 24 Vdc FIXED

POWER SUPPLY

M1083 - Single pot, forward & reverse switches, terminal strip

CONNECTORS

CIRCUIT NUMBERS FOR USE WITH 12 Vdc MCE101

PROPORTIONAL TRANSMISSION CONTROLLER

M1122 - Dual pot, forward & neutral start switches,

terminal strip

M1167 - Dual pot, forward & reverse switches, terminal

strip

M2151 - Dual pot, forward & neutral start switches, 60"

pigtail

CIRCUIT NUMBERS FOR USE WITH 24 Vdc MCE101

PROPORTIONAL TRANSMISSION CONTROLLER

M1169 - Dual pot, forward & reverse switches, terminal

strip

CIRCUIT NUMBERS FOR OPERATING TWO EDCs IN

SERIES

M1091 - Dual pot, 12 Vdc, forward & reverse switches,

terminal strip

M1112 - Dual pot, 24 Vdc, forward & reverse switches,

terminal strip

TERMINAL STRIP

Electrical connectors are made to a set of four internal

screw terminals.

PIGTAIL WITHOUT A CONNECTOR

60 inch lead wire, total length.

PIGTAIL WITH UNSEALED PACKARD CONNECTOR

12 inch lead wire with unsealed Packard connector. Unsealed connectors are generally used inside a sealed

panel.

BLOCK DIAGRAM 1

R1

N/C

CENTER

OFF

SWITCH

COM.

200 Ω

PIGTAIL WITH UNSEALED PACKARD CONNECTOR

Halves of the connector are included.

SEALED PACKARD CONNECTOR WITH MATING HALF

A weather-sealed Packard connector and unassembled

mate.

SEALED PACKARD CONNECTORS

(4-pin male & female) These are two separate connectors,

each connected to a separate potentiometer bridge.

F

(A)(+) (B) (-)

R2 = 33 Ω

R3 = 33 Ω

CONTROL

HANDLE

+ VOLTS

EDC COIL GROUND

Single Potentiometer Control Handle Circuit (Bi-Directional Output).

5

1437

BLN 95-9007-0101

Page 6

BLOCK DIAGRAM 2

R1

N/O

CENTER

OFF

SWITCH

COM.

+ VOLTS

Dual Potentiometer Control Handle Circuit (Bi-Directional Output).

CONNECTION DIAGRAM

N/C

200 Ω

200 Ω

F

F

CONTROL

HANDLE

(A)(+) (B) (-)

EDC COIL

GROUND

1438

HYDROSTATIC

TRANSMISSION

BLN 95-9007-0101

NEUTRAL START

SWITCH

PV

EDC COIL

EDC COIL

NEUTRAL START COMMON

GND

NEUTRAL START NORMALLY OPEN

NEUTRAL START NORMALLY CLOSED

+12 Vdc

+24 Vdc

Typical Connection Diagram.

6

CENTER OFF

SWITCH

FROM

POTENTIOMETER

FROM

TERMINAL

1439

Page 7

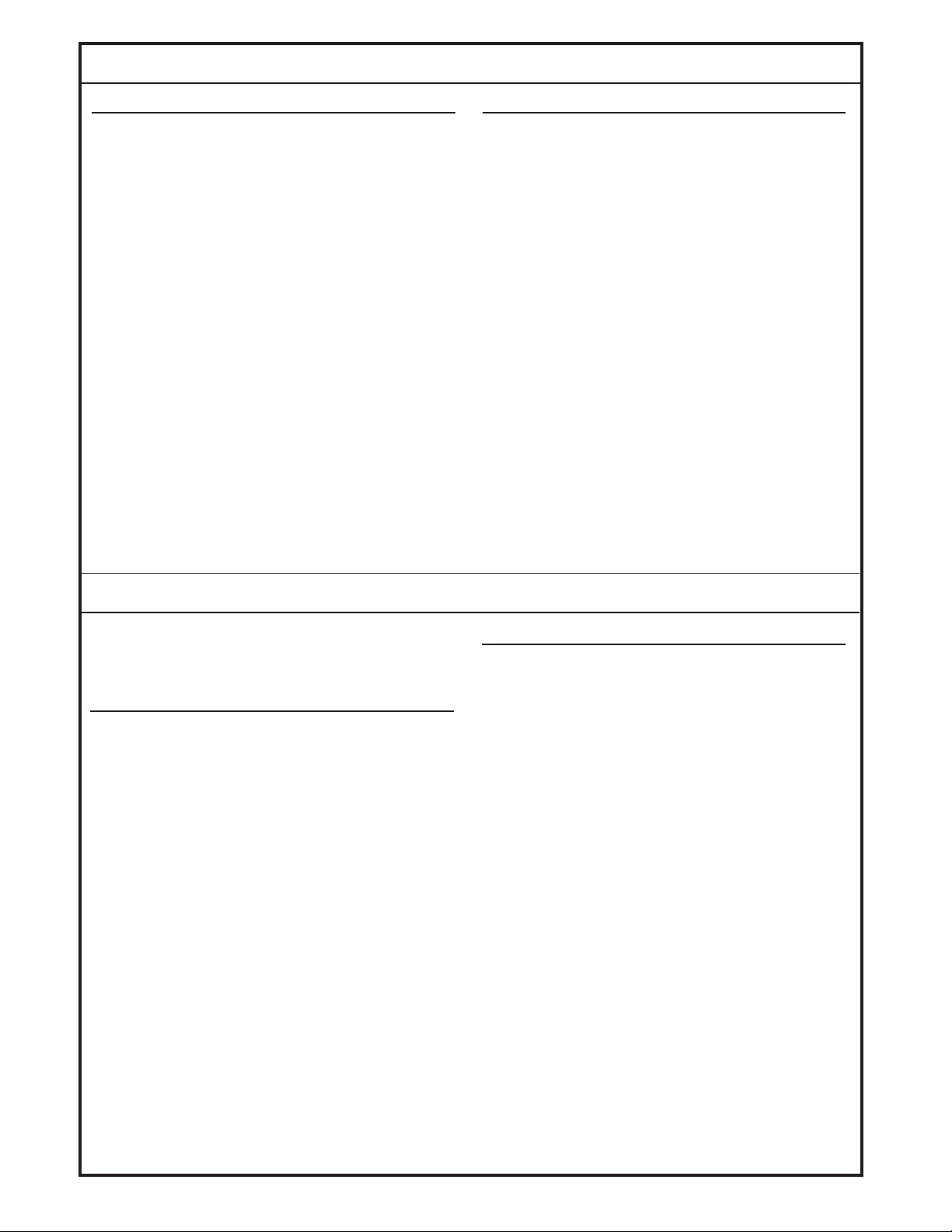

DIMENSIONS

149,1 MAX (5.87)

136,4 ±0,4 (5.37)

31,75

(1.25)

50,8 ±0,4

(2.0)

63,76 MAX

(2.51)

6,35

(0.25)

6,35

(0.25)

7,1 (4)

(0.279)

PANEL CUTOUT AND

MOUNTING PLATE

138

(5.43)

7

(0.275)

33,3

(1.31)

66,6

(2.62)

124 (4.88)

150,5 MAX (5.93)

85,5 MAX

(3.37)

4,5 ± 0.008 (2)

MOUNTING PLATE

MOUNTING PLATE

50,8

(2.0)

50,8

(2.0)

25,4

(1.0)

25,4

(1.0)

54,0

(2.12)

REMOVE BURRS

FROM BOTH SIDES OF PANEL

TO AVOID DAMAGING BOOT

6,2 (4 HOLES)

(0.245)

CUSTOMER

PANEL

CUSTOMER

PANEL

30° REF30° REF

251,5 MAX

(9.9)

113 MAX

(4.45)

29,5 (1.16)

60,4

(2.38)

121,3 MAX (4.78)

TOP (DROP IN)

MOUNT

CUSTOMER

PANEL

TAPPING

SCREWS

(2)

30° REF

30° REF

302 MAX

(11.88)

121 MAX (4.76)

30° REF30° REF

121 MAX (4.76)

CUSTOMER

PANEL

120 MAX

(4.72)

14,2

(0.56)

2 PLACES

27

(1.06)

269,2 MAX

(10.6)

29,5 MAX

(1.16)

SURFACE MOUNT

96 MAX

(3.78)

120 MAX

(4.72)

2

30° REF30° REF

149,9 MAX

(5.9)

114,6

MAX

(4.51)

29,5 (1.16)

60,4

(2.38)

121,3 MAX (4.78)

44,4

(1.75)

64,1 MAX

2.52

PANEL MOUNT SIDE VIEW

OF ALL

PANEL MOUNT

REMOVE COLLAR

THAT RETAINS BOOT

AND DISCARD

Dimensions of the MCHXXX Control Handle in Millimeters (Inches).

7

1135C

BLN 95-9007-0101

Page 8

THEORY OF OPERATION (Single Potentiometer)

The single potentiometer Control Handles are generally used

with a fixed output power supply. The power supply may be

either an automotive type battery for mobile equipment or an

AC to DC convertor for industrial applications. There are

Control Handle models designed for both 12 and 24 Volt

power supply.

The single pot Control Handles have two advantages: simplified electrical circuit and lower cost. The only disadvantage is the limited output power makes it unsuitable for

applications with the MCE101 or driving more than one EDC

simultaneously.

A single coil or one coil of a dual coil EDC is connected as

shown in the Block Diagram 1. The coil terminal connected

to the common point of R2 and R3 (“B” terminal) will all remain

at or near half the supply (with R1 = 0-Ω) voltage as measured

with respect to ground. The other side of the valve coil is

connected to the potentiometer wiper (“A” terminal), with the

handle centered it will also be at or near half the supply

voltage.

With the Control Handle centered, the voltage on each EDC

terminal is the same and there is no current flow through the

valve coil. Since it is current flow which causes the pump

output flow to change, the pump will be at zero stroke.

When the Control Handle is moved forward (as indicated by

the forward arrow in Block Diagram 1), the voltage at the “A”

terminal increases proportionally with distance travelled.

The Control Handle is moved, at full handle stroke, the

voltage at terminal “A” will be approximately 8.6 Volts with

respect to ground. The “B” terminal remains at half supply,

thus a 2.6 Volt differential will result (for 12 Volt system and

single coil valves). This differential voltage is sufficient to fully

stroke any Danfoss pump.

When the Control Handle is moved in the reverse

direction, the voltage at the “A” terminal decreases to

approximately 3.4 Volts, the “B” termi-nal becomes more

positive so current flows through the coil in the opposite

direction resulting in flow out the other pump port.

Although useful for understanding how the single potentiometer Control Handle functions, it is not normally necessary to

measure the voltages with respect to ground. The voltage

measured across the “A” and “B” terminals is more useful

since this is the actual differential voltage applied to the valve

coil. The difference between 12 and 24 Volt version is a

resistor (R1) installed to limit the current through the bridge

circuit. The value for R1 used in most 24 Vdc Control Handles

is 40 Ω, 25 W.

A center-off switch is recommended for all single potentiometer type Control Handles. If one of the wires between the

Control Handle and the pump control becomes shorted to

ground (i.e., worn insulation or broken wire), there would be

sufficient electrical signal to fully stroke the pump. The

center-off switch cuts the electrical power to the bridge circuit

when the handle is in mechanical center of travel.

THEORY OF OPERATION (Dual Potentiometer)

The operation of the dual potentiometer circuit is similar to

single potentiometer circuit. When the Control Handle is in

mechanical center both of the terminals are at half the supply

voltage with respect to ground. As the handle is moved in the

forward direction (as indicated by arrow in Block Diagram 2).

The voltage on terminal “A” will increase (to approximately 9

Volts with a 12 Volt supply), as the pot wiper moves toward

the plus terminal. The voltage on terminal “B” will decrease

(to approximately 3 Volts with a 12 Volt supply), as the pot

wiper moves toward the ground terminal. This results in a 6

Volt differential across the load. This differential voltage is

large enough to drive two pumps with an EDC coil connected

in series to full stroke, or operate a variable pump, variable

motor combination.

The dual potentiometer Control Handle circuit can be operated with an MCE101 Proportional Transmission Controller.

It is necessary to utilize the larger available voltage differential in the dual pot circuit, because the MCE101A acts as a

variable power supply starting at approximately 3 Volts less

than the battery terminal voltage.

PERFORMANCE

NULL CURRENT

±5 mA maximum if Control Handle is centered and centeroff switch is closed (12 Vdc models).

±8 mA maximum if Control Handle is centered and centeroff switch is closed (24 Vdc models).

CENTER DEAD ZONE

±3° nominal. Handle travel required to actuate center-off

switch.

FULL STROKE OUTPUT CURRENT

STEP CURRENT

120 mA into 22 Ω load (factory test current) other full stroke

current optional.

Generally not applicable to Control Handles for EDCs but

may be custom designed for special applications.

BLN 95-9007-0101

8

Page 9

ENVIRONMENTAL

TEMPERATURE

-40°F to 170°F (-40°C to 77°C) operating

-30°F to 150°F (-34°C to 66°C) storage

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 100°F (38°C) for 10 days, the Control Handle

will perform within specification limits.

RAIN

NEMA 4 for units with aluminum case only. After being

showered from all directions by a high-pressure hosedown, the Control Handle will perform within specification

limits.

WIRING

For most Control Handles, access to power, ground, and the

output is gained through the barrier terminal strip inside the

handle case (see Connection diagram). A cable should run

from the terminal strip through the connector/strain relief on

the side or bottom of the case. For most applications, #18

AWG wire should be used.

Auxiliary switches are not factory wired. The switch terminals are 3/16" quick-connected for Control Handles with one

VIBRATION

Withstands a vibration test designed for mobile equipment

control consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the 3 axes.

2. Resonance dwell for one million cycles for each resonance point in each of the 3 axes.

SHOCK

50 g’s for 11 milliseconds. Three shocks in both directions

of the 3 mutually perpendicular axes for a total of 18

shocks.

LIFE

Greater than 1,000,000 cycles.

DIMENSIONS AND MOUNTING

See Dimension drawing.

or two switches. For Control Handles with three switches, the

terminals are 1/4 quick-connected. Generally a clockwise

handle movement causes a current flow from terminal “B” to

“A” when the terminal strip is facing you. Consult the factory

for units with pigtail or connectors.

In order to avoid damaging the Control Handle, a 1-amp fuse

wired in series with the power wire is recommended.

ACCESSORIES

ELECTRICAL DISPLACEMENT CONTROL MATING CONNECTORS

K03383 Single-coil Packard 2-wire

K03384 Dual-coil Packard 4-wire

K08106 MS connector

9

BLN 95-9007-0101

Page 10

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (612) 509-2084

Fax: (612) 559-0108

DEVICE REPAIR

For devices in need of repair, include a description of the

problem, a copy of the purchase order and your name,

address and telephone number.

RETURN TO

Danfoss (US) Company Return

Goods Department 3500

Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co. Order

Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: +49 4321 871-0

Fax: +49 4321 871-284

BLN 95-9007-0101

10

Loading...

Loading...