Page 1

MCF 106 A/B in C Option Adaptor Instruction Contents

Contents

1 How to Read these Operating Instructions

Available Literature for VLT AutomationDrive FC 300 3

Approvals 4

Symbols 4

Abbreviations 4

2 Safety and Conformity

Important notes 5

3 Introduction to MCF 106 A/ B in C Option Adaptor

Combinations 8

Elaboration of Combinations 9

4 How to Install

Mounting of A and B options in the MCF 106 11

Mounting of the MCF 106 in the Frequency Converter 12

Bookstyle (A2, A3 and B3) 12

Compact (A5 – F) 14

3

5

7

11

MI.38.F1.02 - VLT® is a registered Danfoss trademark

1

Page 2

1

1 How to Read these Operating Instructions MCF 106 A/B in C Option Adaptor Instruction

2

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 3

MCF 106 A/B in C Option Adaptor Instruction 1 How to Read these Operating Instructions

1 How to Read these Operating Instructions

1

1.1.1 How to Read these Operating Instructions

These Instructions will help you get started and mount your MCF 106 A/B in C Option Adaptor. Please read these instructions in full and, in order to be

able to work with the system safely and professionally, particularly observe the hints and cautionary remarks.

Chapter 1, How to Read these Operating Instructions, introduces the manual and informs you about the approvals, symbols, and abbreviations

used in this literature.

Chapter 2, Safety and Conformity, contains safety instructions and certificates for the MCF 106 A/B in C Option Adaptor option and the VLT AutomationDrive FC 302.

Chapter 3, Introduction to the MCB 112 VLT PT C Th e rmi stor Card, informs you about the general aspects of the option and its functions. It also

contains the technical data about the MCF 106 A/B in C Option Adaptor.

Chapter 4, How to Install, guides you through me c hanical and technical in s tallation.

1.1.2 Available Literature for VLT AutomationDrive FC 300

-

-

-

-

-

-

-

-

Danfoss Drives technical literature is also available online at www.danfoss.com/drives.

®

The VLT

The VLT

resolver and relay options.

The VLT

will find descriptions of the parameters and parameter lists, which give an overview of the parameters in each group.

The VLT

the drive via a Profibus fieldbus.

The VLT

ming the drive via a DeviceNet fieldbus.

The VLT

The VLT

The VLT

AutomationDrive FC 300 Operating Instructions provide the neccessary information for getting the drive up and running.

®

AutomationDrive FC 300 Design Guide entails all technical information about the drive design and applications including encoder,

®

AutomationDrive FC 300 Programming Guide contains information on how to programme the VLT AutomationDrive. Furthermore, you

®

AutomationDrive FC 300 Profibus Operating Instructions provide the information required for controlling, monitoring and programming

®

AutomationDrive FC 300 DeviceNet Operating Instructions provide the information required for controlling, monitoring and program-

®

AutomationDrive FC 300 MCT 10 Operating Instructions provide information for installation and use of the software on a PC.

®

AutomationDrive FC 300 IP21 / Type 1 Instruction provides information for installing the IP21 / Type 1 option.

®

AutomationDrive FC 300 24 V DC Backup Instruction provides information for installing the 24 V DC Backup option.

MI.38.F1.02 - VLT® is a registered Danfoss trademark

3

Page 4

1

1 How to Read these Operating Instructions MCF 106 A/B in C Option Adaptor Instruction

1.1.3 Approvals

1.1.4 Symbols

Symbols used in this Operating Instructions.

NB!

Indicates something to be noted by the reader.

Indicates a general warning.

Indicates a high-voltage warning.

∗

Indicates default setting

1.1.5 Abbreviations

Electro Magnetic Compatibility EMC

Drive FC

Local Control Panel LCP

Parameter par.

4

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 5

MCF 106 A/B in C Option Adaptor Instruction 2 Safety and Conformity

2 Safety and Conformity

2.1.1 Important notes

Proper, safe operation of a device requires that it be properly transported and stored, professionally installed and commissioned, and used as

intended. Only those personnel may work on the device who are familiar with its installation, commissioni n g , and op e ration and have appropriate

qualifications for their activities. They must observe the contents of the operating instructions, the notes attached to the device, and all applicable

safety regulations for the setup and operation of electrical installations. These devices are built and tested in compliance with EN 60947-8 and leave

our plant in perfect condition from a safety standpoint. To keep them in this state, you must observe the safety guidelines marked "Warning" in the

operating instructions. Failure to observe safety guidelines can result in death, bodily injury, or damage to the device itself and to other devices and

systems. If the information contained in the operating instructions is insufficient for a particular case, please contact us directly or the representative

responsible for you. Instead of the industry standards and regulations named in these operating instructions and valid in Europe, when operating

the device outside their area of applicability, you must follow the regulations applicable to the country of use.

Warning! EN60204-1 safety circuits. The devices may not be used alone for functions where an automatic restart must be prevented.

2.1.2 Safety Precautions

The voltage of the frequency converter is dangerous whenev er connected to mains. Incorrect inst allation of the motor, fr equency

converter or fieldbus may cause damage to the equipment, serious perso nal injury or death. Consequently, the instructions in this

manual, as well as national and local rules and safety regulations, must be complied with.

2

Safety Regulations

1. The mains supply to the frequency converter must be disconnected whenever repair work is to be carried out. Check that the mains supply has

been disconnected and that the necessary time has elapsed before removing motor and mains supply plugs.

2. The [OFF] button on the control panel of the frequency converterr does not disconnect the mains supply and consequently it must not be used

as a safety switch.

3. The equipment must be properly earthed, the user must be protected against supply voltage and the mo tor mus t be p rotecte d aga inst overload

in accordance with applicable nat ional and local regulations.

4. The earth leakage current exceeds 3.5 mA.

5. Protection against motor overload is not included in the factory setting. If this function is desired, set par. 1-90

data value ETR trip 1 [4] or data value ETR warning 1 [3].

6. Do not remove the plugs for the motor and mains supply while the frequency converter is connected to mains. Check that the mains supply has

been disconnected and that the necessary time has elapsed before removing motor and mains plugs.

7. Please note that the frequency converter h as more vo lta ge sources th an L1, L2 and L3, when lo ad sharing (linking of DC intermediate circuit)

or external 24 V DC are installed. Check that all vol tage sources have been disconnected and that t he necessary time has elapsed before

commencing repair work.

Warning against unintended start

1. The motor can be brought to a stop by mean s of digita l co mma nds, bus commands, references or a local stop, while the frequency converter

is connected to mains. If personal safety considerations (e.g. risk of personal injury caused by contact with moving machine parts following an

unintentional start) m ake it necess ary to e nsure that no unintended start occurs, these stop functions are not sufficient. In such cases the mains

Safe Stop

supply must be disconnected or the

2. The motor may start while setting the parameters. If this means that personal safety may be compromised (e.g. personal injury caused by

contact with moving machine parts), motor starting must be prevented, for instance by use of the

of the motor connection.

function must be activated.

Safe Stop

Motor Thermal Protection

function or secure disconnection

to

MI.38.F1.02 - VLT® is a registered Danfoss trademark

5

Page 6

2 Safety and Conformity MCF 106 A/B in C Option Adaptor Instruction

3. A motor that has been stopped with the mains supply connected, may start if faults occur in the electronics of the frequency converter, through

temporary overload or if a fault in the power supply grid or motor connection is remedied. If unintended start must be prevented for personal

safety reasons (e.g. risk of injury caused by contact with moving machine parts), the normal stop functions of the frequency converter are not

sufficient. In such cases the mains supply must be disconnected or the

Safe Stop

function must be activated.

2

NB!

When using the

4. Control signals from, or internally within, the frequency converter may in rare cases be activated in error, be delayed or fail to occur entirely.

When used in situations where safety is critical, e.g. when controlling t he electro magnetic brake function of a hoist application , these control

signals must not be relied on exclusively.

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as external 24 V DC, load sharing (linkage of DC intermediate circuit), as well as

the motor connection for kinetic back up.

Systems where frequency converters are installed must, if necessary, be equipp ed with additional monitoring and prot ective devices according to the

valid safety regulations, e.g law on mechanical tools, regulations for the prevention of accidents etc. Modifications on the frequency converters by means

of the operating software are allowed.

Hoisting applications:

The frequency converter functions for controlling mechanical brakes cannot be considered as a primary safety circuit. There must always be a redundancy

for controlling external brakes.

Protection Mode

Once a hardware limit on motor current or dc-link voltage is exceeded the drive will enter “Protection mode”. “Protection mode” means a change of the

PWM modulation strategy and a low switc hing freque ncy to minimi ze losses. This continues 10 sec after the last fault and increases the reliability and

the robustness of the drive while re-establishing full control of the motor.

In hoist applications “Protection mode” is not usable because the drive will usually not be able to leave this mode again and therefore it will extend the

time before activating the brake – which is not recommendable .

The “Protection mode” can be disabled by setting par. 14-26

of the hardware limits is exceeded.

Safe Stop

function, always follow the instructions in the

Trip Delay at Inverter Fault

Safe Stop

section of the Design Guide.

to zero which means that the dr ive will trip immediately if one

NB!

It is recommended to disable protection mode in hoisting applications (par. 14-26

6

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Trip Delay at Inverter Fault

= 0)

Page 7

3 Introduction to MCF 106 A/ B in C Option

MCF 106 A/B in C Option Adaptor Instruction

3 Introduction to MCF 106 A/ B in C Option Adaptor

The A/ B in C Option Adaptor makes it possible to combine a number of different options.

Adaptor

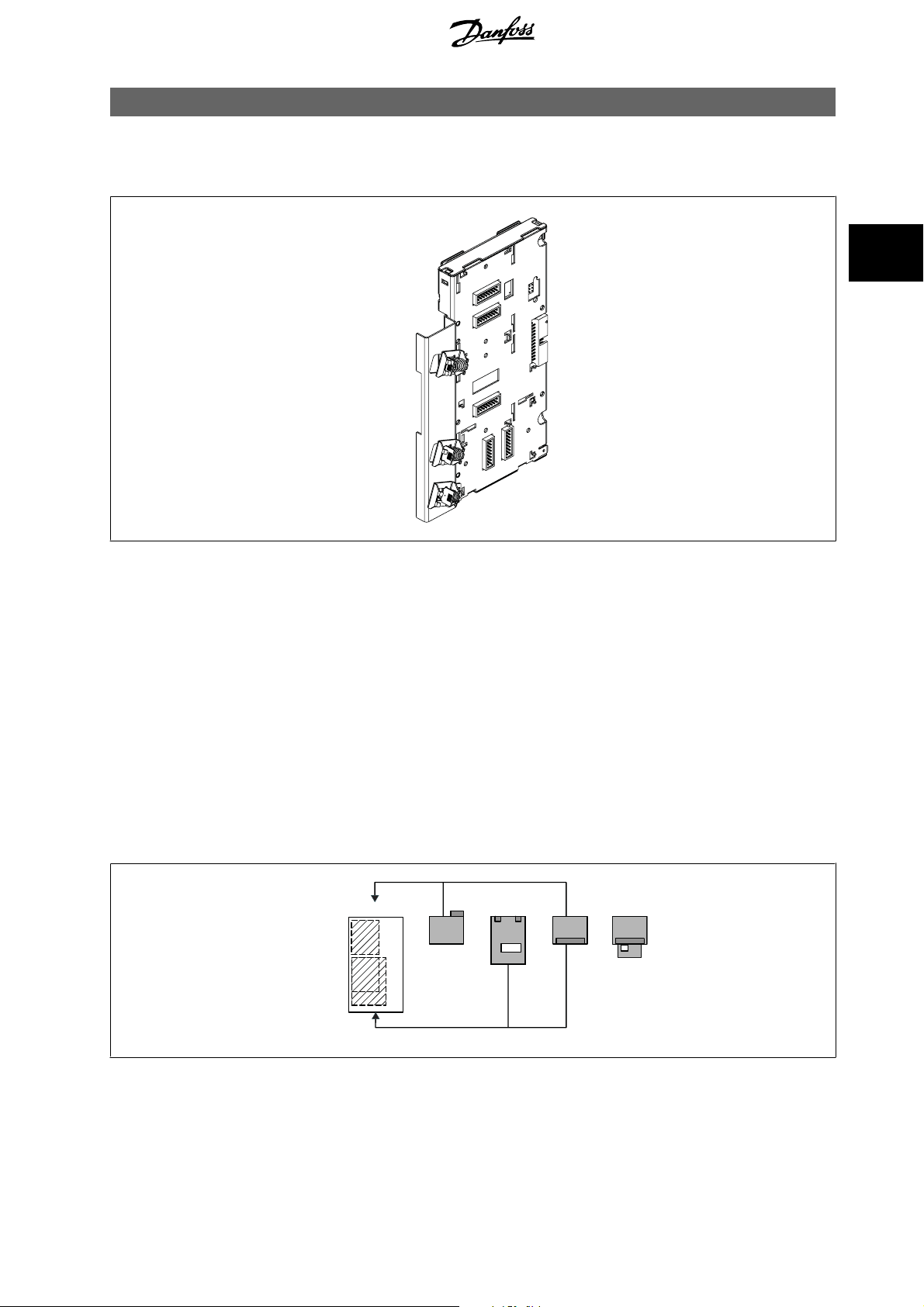

130BB093.10

Illustration 3.1: Drawing of MCF 106 A/B in C Option Adaptor.Two options can be installed in the MCF 106 at the same time. The upper slot is called E0

and the lower is called E1.

One A and one B option can be installed in the stan dard A an d B slots of the Control Ca rd – behind the LCP/ Blind cover. Wit h the addition of the MCF

106 the possibilities are increased.

• Up to three different B options – one in the standard B slot and two in the Adaptor

• One Fieldbus (A option) at any time – in the standard A slot or in the E0 slot of the adaptor.

• The MCB 121 Ethernet takes up both slot A and slot B when installed in the standard slot A of the Control Card. The only way to to install a B

option at the same time: Use the standard B slot of the Control Card and move the MCA 121 in the E1 slot of the Adapter.

• MCA 121 EthernetIP has bottom entry when installed in the Adaptor

• Two identical options can not be installed at the same time

• MCB 105 Relay Card and MCB 112 PTC Thermistor Card are not supported by the Adaptor and must thus only be installed in the standard slot

B of the Control Card. That also means that these two options can not be combined.

3

MCF 106

130BB094.11

Illustration 3.2: Generally, A- and B options can be installed in the MCF 106. The exceptions are the special B options (B*) MCB 105 Relay Card and MCB

112 PTC Thermistor Card that both have an extra large plastic part and are not supported by the MCF 106. Also the special A opt ion (A*) MCA 121

EthernetIP that takes up the size of almost two standard options is an exception as it can only be installed in the lower slot of MCF 106 and with bottom

entry.

A

A*

B

B*

MI.38.F1.02 - VLT® is a registered Danfoss trademark

7

Page 8

3

3 Introduction to MCF 106 A/ B in C Option

Adaptor

3.1.1 Combinations

The following table shows which combinations can be realized.

Mounting in the MCF 106 ID Name Possible combinations

Option

A

B Yes MCB 102 Encoder option

C0 No MCO 305 Programmable Motion Control None

C1 No MCA 103 ProfiSafe-Safe Stop None

D No MCB 107 24V External Supply

6)

Yes

6)

Yes

6)

Yes

6)

Yes

6)

Yes

7)

Yes

No MCB 105

Yes MCB 101 General Purpose I/O

Yes MCB 103 Resolver option

Yes MCB 108 PLC Safe Interfece

No MCB 112

No MCO 350 Synchronizing Control None

No MCO 351 Positioning Sontrol None

No MCO 352 Center Winder None

No MCB 113 Stt. Relay Card None

MCA 101 Profibus DP V1 + 3B + D + B + C + D

MCA 104 DeviceNet + 3B + D + B + C + D

MCA 105 CanOpen + 3B + D + B + C + D

MCA 108 LonWorks + 3B + D + B + C + D

MCA 113

MCA 121 EtherNetIP + 2B + D + C + D

Profibus Conv. (VLT®3000)

Relay option

PTC Thermistor Card

3)

3)

MCF 106 A/B in C Option Adaptor Instruction

with MCF 106 without MCF 106

+ 3B + D + B + C + D

+ A + 2B1) + D + A2) + C + D

+ A + 2B1) + D + A2) + C + D

+ A + 2B1) + D + A2) + C + D

+ A + 2B1) + D + A2) + C + D

+ A + 2B1) + D + A2) + C + D

+ A + 2B1) + D + A2) + C + D

+ A + B4) + C!5) + D

+ A + B4) + D

+ A + B4) + D

+ A + B4) + D

+ A + B4) + D

+ A + B4) + D

1)

+ A + 3B

+ A + B4) + C

Table 3.1: Overview of different possibilities for combinations. Look up one of the options in question and see which additional options this can be

combined with, if MCF 106 is used and if only the standard drive is used. A list of limitations and exceptions can be found to the right of the table.

1) One B less if MCA 121 EthernetIP is used

2) Does not incl. MCA 121 EthernetIP

3) MCB 105 and MCB 112 must always be installed in the standard B slot of the Control Card and can thus never be combined

4) Can only incl B if A is not MCA 121 EtherNetIP

5) One C1 option can be added on top of the MCO 305 in the bookstyle enclosures (A2, A3 and B3)

6) Only in E0slot

7) Only in E1 slot

NB!

Two identical options can n ot be installed at the same time

The table is elaborated in the following drawin gs.

8

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 9

3 Introduction to MCF 106 A/ B in C Option

MCF 106 A/B in C Option Adaptor Instruction

3.1.2 Elaboration of Combinations

The basics of Figure 3 is used to illustrate the combinations in a simple way.

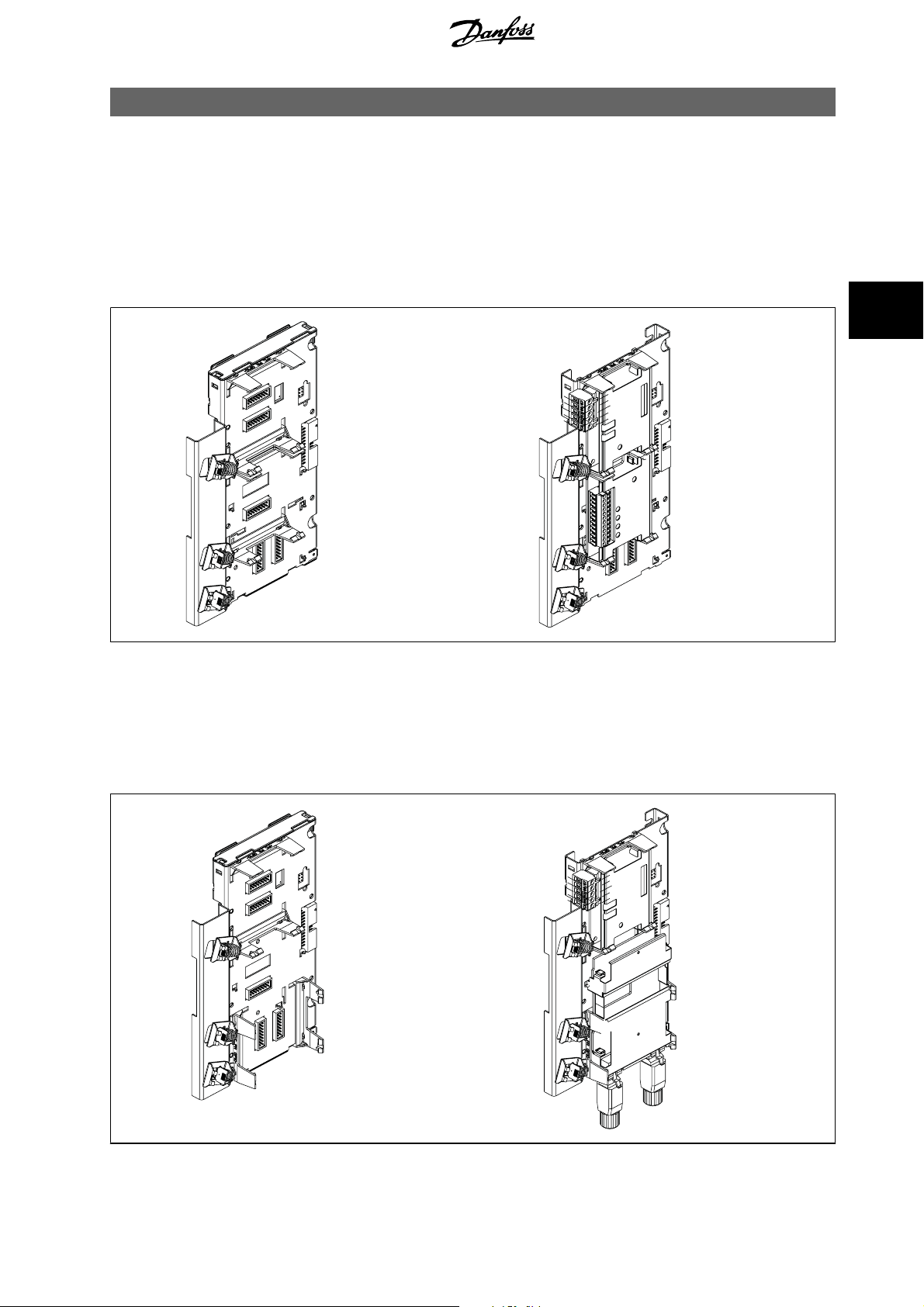

130BB095.10

Illustration 3.3: Rough illustration of the standard A- and B slot in the Control Card - behind the LCP/ blind cover (Left) and the MCF 106 (Right)

Adaptor

3

MCA

121

B

A

B

B

B

130BB097.10

A

B

130BB096.11

Illustration 3.4: A FieldBus option can be installed in the MCF 106 but only in the E0 slot (left), Normal ly, the Fi el dBus wi l l be installed in the standard Aslot of the Control Card which makes it possible to install a total of three B options (right).

B

B

A

B

A

MCA

121

B

Illustration 3.5: The Control Card has an A- and a B slot which makes it possible to install an A option at the same time as a B option (left). The MCA 121

EtherNet A option takes up more space than the other FieldBusses but can still be installed in the A slot as long as the B slot is left empty (middle). It is

not possible to install both MCA 121 and a B option on the Control Card (right).

(1) One B less if MCA 121 EthernetIP is used

(2) Does not incl. MCA 121 EtherNetIP

(4) Can only incl. B if A is not MCA 121 EtherNet

MI.38.F1.02 - VLT® is a registered Danfoss trademark

9

Page 10

3

3 Introduction to MCF 106 A/ B in C Option

Adaptor

B

B

MCA

121

130BB098.10

Illustration 3.6: 121 EthernetIP can be installed with bottom entry in the lower slot of the MCF 106.

MCB 105/

MCB 112

MCF 106 A/B in C Option Adaptor Instruction

B

MCA

121

B

MCB 105/

MCB 112

130BB99.10

Illustration 3.7: MCB 105 and MCB 112 are different from the other B options as these two have an extended plastic cover for protection. They can be

installed in the standard B slot of the Control Card but never in the MCF 106.

(3) MCB 105 and MCB 112 must always be installed in the standard B slot of the Control Card and can thus never be combined

MCB 105/

MCB 112

10

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 11

MCF 106 A/B in C Option Adaptor Instruction 4 How to Install

4How to Install

The MCF 106 is installed in the C slot. Please refer to t he

for more information.

FC 300 Design Guide

, chapter

Options and Accessories

, section

4.1.1 Mounting of A and B options in the MCF 106

The A and B options are mounted in the MCF 106 via the standard option connector and two plastic holders per option.

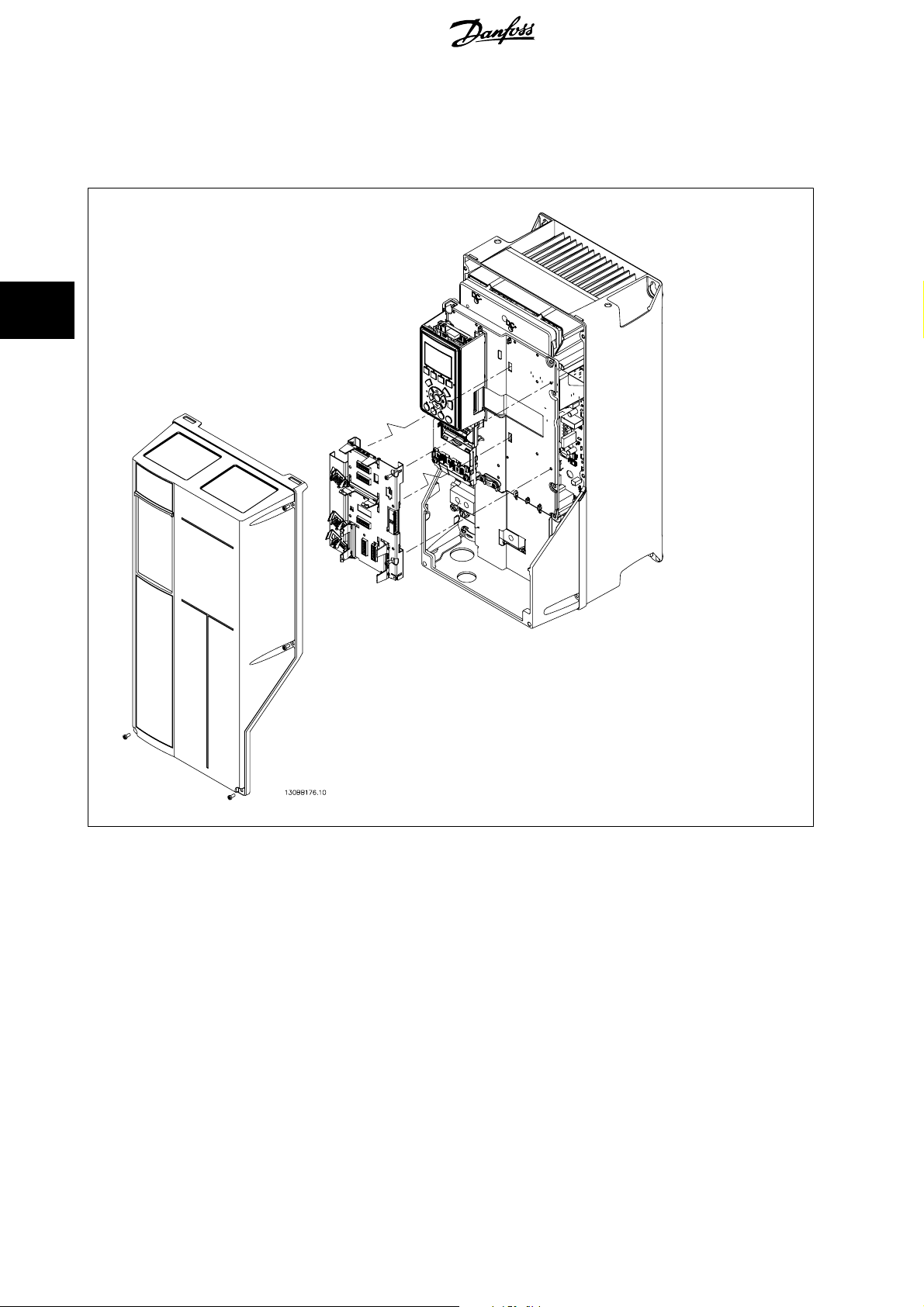

130BB104.10

130BB101.10

Mounting of Options in Slot C

4

Illustration 4.1: Mounting of A and B options in the MCF 106. Plastic holders placed for side entry (left) and installed options (right).

The connectors are facing the left side where the support plate for the cable connections is placed.

All options that are mounted in the MCF 106 are installed with side entry except the MCA 121 EthernetIP option that can only be installed in slot E1 with

bottom entry. The plastic holders are moved to another position when installing the MCA 121 which is illustrated in the following figures

130BB102.10

130BB103.10

Illustration 4.2: 9 Mounting of A and B options in the MCF 106. Plastic holders placed for MCA 121 EthernetIP (left) and installed options (right).

MI.38.F1.02 - VLT® is a registered Danfoss trademark

11

Page 12

4 How to Install MCF 106 A/B in C Option Adaptor Instruction

4.2 Mounting of the MCF 106 in the Frequency Converter

4.2.1 Bookstyle (A2, A3 and B3)

NB!

For installation in the bookstyle frames, the manual describes how to use guides to install the MCF 106 to the backplate of the option

box.

The existing backplate does not have these guides yet. Therefore, the MCF 106 must be installed as a standard C0 option on the

backplate.

4

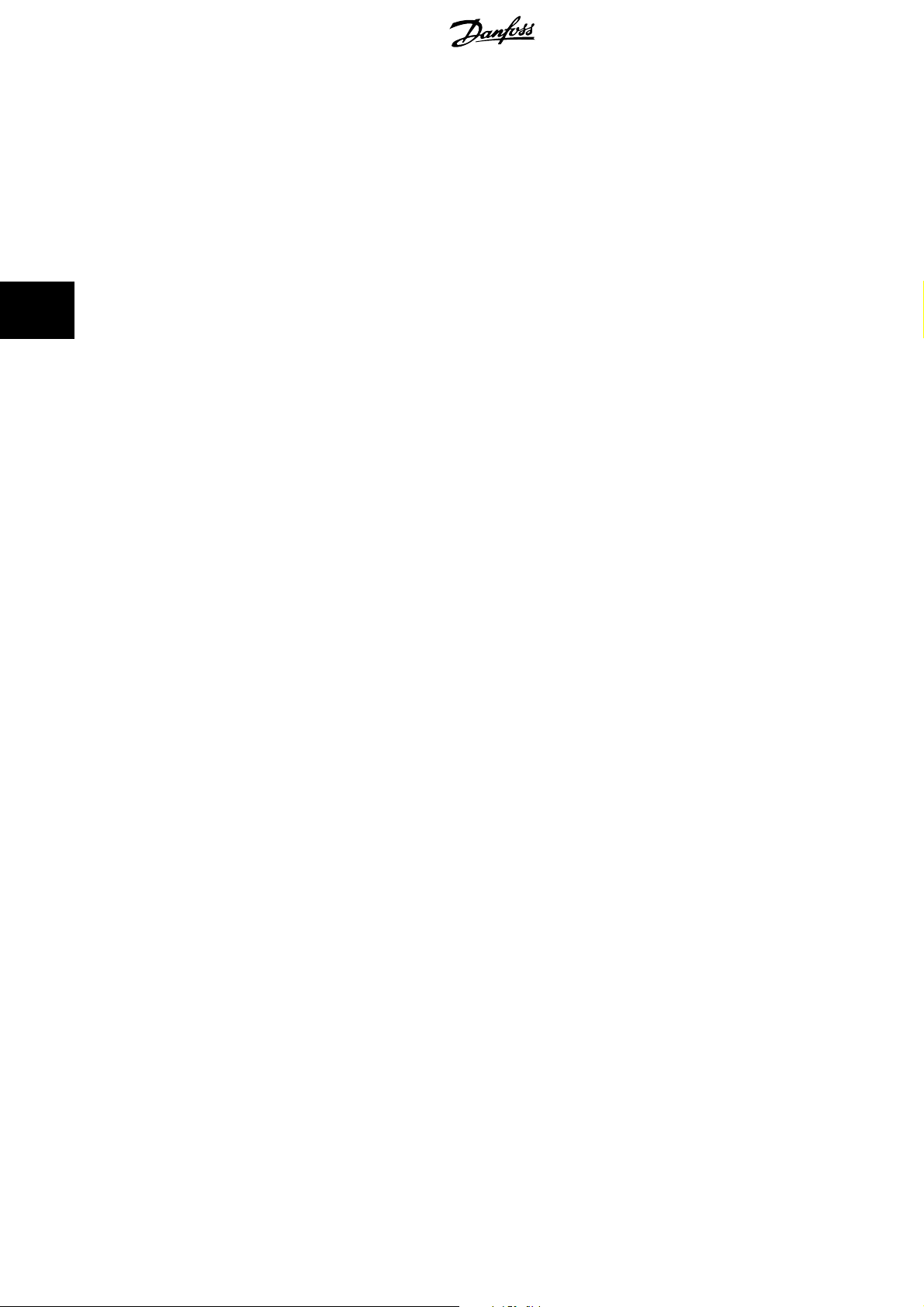

A special mounting system is used for the bookstyle enclosures. The MCF 106 is mounted in the 60 mm extended op tion box on the side of the frequency

converter via a guide. This makes it possibl e to do c ommissionin g on the mounted options in an easy way even if a series of frequency converters are

mounted side-by-side. When the MCF 106 is in place it is fixed to the extended option bo x with a hook and two screws. The following figures illustrates

the principle.

130BB105.10

130BB106.10

130BB107.10

Illustration 4.3: Installation of MCF 106 in the extended op tion box on the side of the bookstyle frames. The MCF 106 and the e xtended option box where

the guide principle can be seen (left) and the MCF 106 installed in the extended option box via the guide (center).The support plate for the cable

connections has been removed from the last drawing (right) to give view to the hook system that fixes the MCF 106 to the extended option box.

NB!

Connect the earth wire from the MCF 106 to the metal plate of the option box (only relevant for the bookstyle).

12

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 13

MCF 106 A/B in C Option Adaptor Instruction 4 How to Install

The bottom plate can be mounted before or after sliding in the MCF 106. Whe n the MCA 121 is instal led (bottom e ntry) eith er the bottom plate or the

the fieldbus cables must be disconnected during commissioning in order to make it possible to use the guide. This is illustrated in the following figure.

130BB100.10

4

Illustration 4.4: Installation with MCA 121 EthernetIP. When the EthernetIP cables are disconnected the guide can be used to slide the MCF 106 into

place or out for commissioning.Another possibility is to remove the bottom plate during commissioning.

MI.38.F1.02 - VLT® is a registered Danfoss trademark

13

Page 14

4

4 How to Install MCF 106 A/B in C Option Adaptor Instruction

4.2.2 Compact (A5 – F)

For the compact frequency converters the installation is similar to that of a C option where screws are used. Please refer to the Design Guide section

10.1.3 Mounting of Options in Slot C for an elaboration.

Illustration 4.5: Frame sizes: A5. B1. B2. B4. C1. C2. C3 and C4

14

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 15

MCF 106 A/B in C Option Adaptor Instruction 4 How to Install

4

MI.38.F1.02 - VLT® is a registered Danfoss trademark

15

Page 16

4

4 How to Install MCF 106 A/B in C Option Adaptor Instruction

16

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Page 17

MCF 106 A/B in C Option Adaptor Instruction 4 How to Install

4

MI.38.F1.02 - VLT® is a registered Danfoss trademark

17

Page 18

4

4 How to Install MCF 106 A/B in C Option Adaptor Instruction

18

MI.38.F1.02 - VLT® is a registered Danfoss trademark

Loading...

Loading...