Page 1

MCE102A

Phased Out Products

Automotive Controller

BLN-95-8993-3 Issued: May 1998

DESCRIPTION

The MCE102A automotive controller enables hydrostatically

powered vehicles to operate in a manner similar to a car’s

automatic transmission. The automotive control maintains a

definite relationship between the engine r.p.m. and the

swashplate angle (i.e, displacement) of the variable

displacement pump used in the hydrostatic transmission. The

transmission ratio (displacement of the pump/displacement of

the motor) increases with increasing engine r.p.m. Vehicle

speed is obtained by depressing the throttle pedal which

controls the vehicle engine r.p.m.

ORDERING INFORMATION

DEVICE

NUMBER

MCE102A1007 12 Vdc .14 amp 200 to 900 Hz Packard External Inch Pot

MCE102A1014 12 Vdc .14 amp 200 to 900 Hz Packard External Foot Break

MCE102A1022 12 Vdc .14 amp 50 to 225 Hz Terminal Strip External F/V Turn Down

MCE102A1030 24 Vdc .7 amp 4 to 20 mA Packard Reverse Acting

MCE102A1049 12 Vdc 1.0 amp 10 to 50 Hz Terminal Strip Lead/Lag Filter

MCE102A1055 12 Vdc .7 amp 90 to 500 Hz Packard Pressure Transducer Turn Down

MCE102A1063 12 Vdc 1.0 amp 200 to 650 Hz Terminal Strip Lead/Lag Filter, 2 Speed

MCE102A1071 24 Vdc .7 amp 4 to 20 mA Terminal Strip Reverse Acting

MCE102A1097 12 Vdc 1.0 amp 200 to 650 Hz Terminal Strip Lead/Lag Filter, 2 Speed

MCE102A1105 12 Vdc .14 amp 1000 to 3000 Hz Terminal Strip Lead/Lag Filter

MCE102A1113 12 Vdc .14 amp 200 to 650 Hz Terminal Strip Lead/Lag Filter

MCE102A1121 12 Vdc 1.0 amp 600 to 1950 Hz Terminal Strip Lead/Lag Filter, 2 Speed

MCE102A1139 24 Vdc .14 amp 1000 to 3000 Hz Terminal Strip Lead/Lag Filter

MCE102A1147 12 Vdc .14 amp 200 to 650 Hz Packard Lead/Lag Filter

SUPPLY

VOLTAGE

OUTPUT

CURRENT

INTERNAL

SETPOINT RANGE

CONNECTOR

TYPE

MISCELLANNEOUS

TECHNICAL DATA

ELECTRICAL

SUPPLY VOLTAGE

12 Vdc nominal (11 to 15 Vdc range)

24 Vdc nominal (22 to 30 Vdc range)

OUTPUT CURRENT

1.0 amps maximum in auto mode (12 Vdc models)

0.7 amps maximum in auto mode (24 Vdc models)

OUTPUT VOLTAGE

System supply voltage less 3 volts, maximum (limited by

a series resistor on some models).

REVERSE VOLTAGE PROTECTION

A series diode protects against reverse voltage up to

50 Vdc

SHORT CIRCUIT PROTECTION

1.4 to 2.0 amps (12 Vdc models)

0.8 to 1.2 amps (24 Vdc models)

Shorted load of more than 2 minutes may degrade

device at elevated temperature. Output limited by a

series resistor on some models.

© Danfoss, 2013-09 BLN-95-8993-3 1

.

.

Page 2

TECHNICAL DATA

Phased Out Products

(continued)

ENVIRONMENTAL

VIBRATION

Withstands a vibration test designed for mobile

equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes

2. Resonance dwell for one million cycles in each of

the three axes

Run from 1 to 10 Gs. Acceleration level varies with

frequency.

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 38° C (100° F) for 10 days, the controller will

perform within specification limits.

RAIN

After being showered from all directions by a high

pressure hose down, the controller will perform within

specification limits.

SHOCK

50 Gs for 11 milliseconds. Three shocks in both

directions of the three mutually perpendicular axes for a

total of 18 shocks.

OPERATING TEMPERATURE

-20 to 65° C (-4 to 149° F)

STORAGE TEMPERATURE

-30 to 65° C (-22 to 149° F)

PERFORMANCE

MAXIMUM OUTPUT VOLTAGE

The maximum output voltage to the load shall be the

supply voltage less three volts up to rated load current.

MAXIMUM OUTPUT CURRENT

With the output terminal shorted to ground, the

maximum output current shall be from 1.4 to 2.0 amps

(12 Vdc models) or 0.8 to 1.2 amps (24 Vdc models),

depending on temperature.

OPERATING SUPPLY VOLTAGE

11 to 15 Vdc, or 24 to 30 Vdc optional with added

components

SUPPLY CURRENT

1.1 amps maximum (except for shorted loads) (12 Vdc

models)

0.8 amps maximum (except for shorted loads) (24 Vdc

models)

VOLTAGE RANGE

The controlled voltage decreases from supply minus 3

volts down to zero.

SENSITIVITY

The sensitivity control changes the proportioning band

from 4% (turned clockwise) to 75% (turned counter

clockwise) of calibrated r.p.m. The proportioning band is

defined as the change necessary to reduce output

voltage from 100% to 20% of rated output. Sensitivity

control may be removed and replaced with a fixed

resistance in some models.

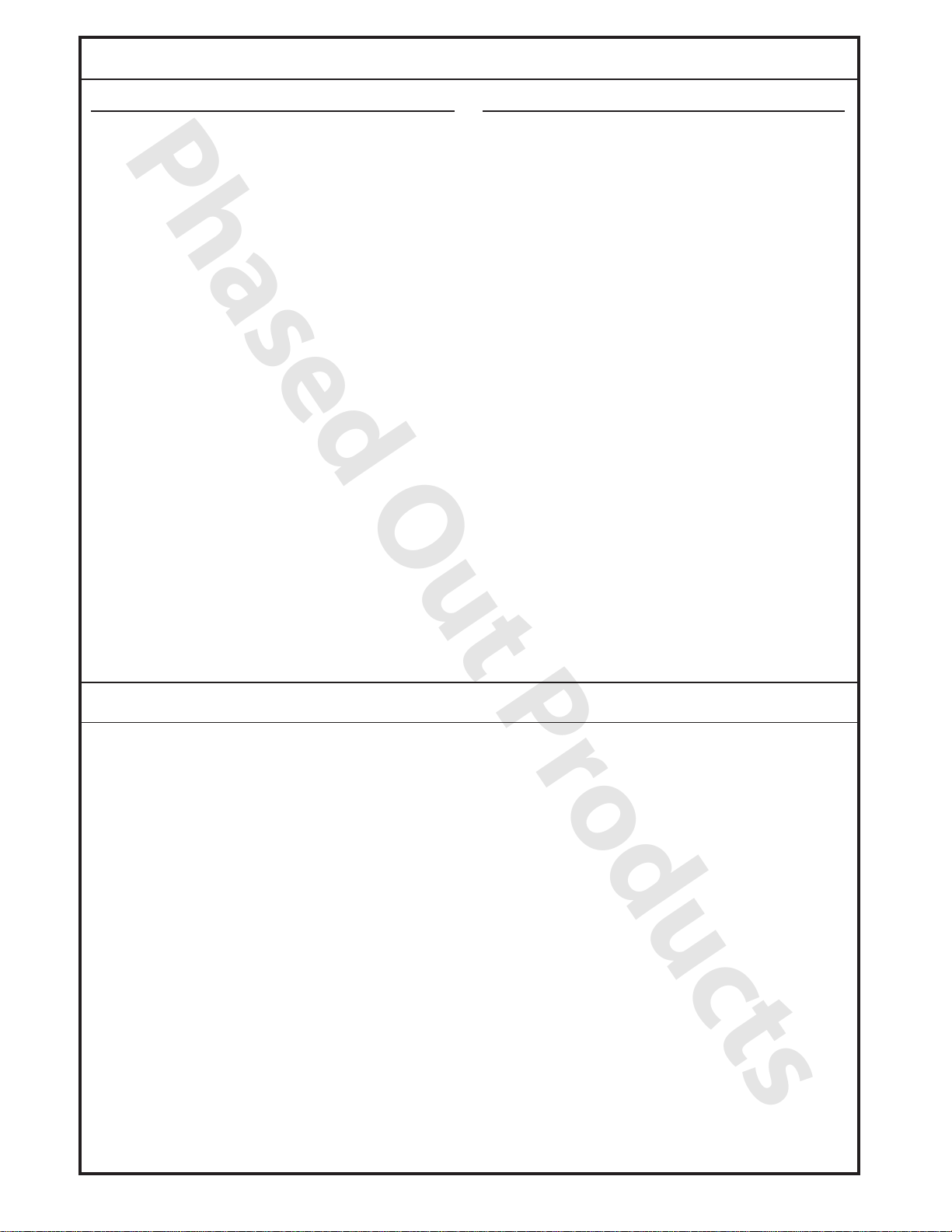

THEORY OF OPERATION

The automotive controller monitors engine r.p.m. as a

variable frequency through the alternator or pulse pickup.

The controller’s calibration (point of maximum displacement)

is at or near the r.p.m. at which the engine is capable of

maximum horsepower. The output is directed to the pump

displacement control through a double-pole double-throw

center off switch. For vehicle forward, neutral and reverse,

see Automotive Control System Diagram.

Between low idle and low r.p.m., the engine is well below

setpoint (see Controller Output Vs. Engine RP M and Reverse

Acting Controller), which the controller interprets as a lugged

condition; consequently there is no propel. As engine r.p.m.

increases, the controller output increases, the rate of

increase being determined by the gain setting of the

controller. The engine r.p.m. that corresponds to maximum

ratio is determined by the engine r.p.m. calibration

potentiometer. Vehicle speed will continue to increase with

increasing engine r.p.m. even though the transmission ratio

remains unchanged above the high r.p.m. calibration point.

The transmission ratio is proportional to engine r.p.m., an d

overhauling loads resulting in high engine r.p.m. will keep the

pump at full angle, resulting in dynamic braking limited by the

engine horsepower absorption. Therefore, to guarantee

adequate braking, the vehicle mechanical brake must be

applied.

The automotive controller is adaptable to applications with

either medium or heavy duty transmissions. Additional

features such as HI/LOW range, reverse acting, pressure

transducer turn down, lead/lag and inching may also be

incorporated into the system.

The feedback circuit may be modified to accept a dc signal.

4 to 20 mA from a pressure transducer or 0 to 6 Vdc from a

tachometer are two types of dc signals acceptable for

feedback.

The unit may be modified to provide decreasing output for

increasing r.p.m. (reverse acting).

BLN-95-8993-3

2

Page 3

AUTOMOTIVE CONTROL SYSTEM DIAGRAM

Phased Out Products

ENGINE

B A D C

+12 V

+

-

GRD

EDC

RED

C

3

BLACK

A

D

WHITE

+12 V

FORWARD

NEUTRAL

REVERSE

GREEN

F/V

B

+2 VOLT REF

PROPORTIONAL TRANSMISSION

CONTROL BOARD

1

+

-

2

ENGINE CALIBRATION POTENTIOMETER

1

SLOPE ADJUST POTENTIOMETER

2

SERIES RESISTOR IN SOME MODELS TO LIMIT CURRENT IF

3

DIRECT DRIVING AN ELECTRICAL DISPLACEMENT CONTROL (EDC).

STARTER

RELAY

CONTROLLER OUTPUT Vs. ENGINE RPM REVERSE ACTING CONTROLLER

AUTOMOTIVE CONTROL BOARD

% OF FULL DRIVE

CONTROLLER OUTPUT VOLTAGE

LOW

LOW

RPM

IDLE

HIGH RPM

CALIBRATION

GAIN

ENGINE RPM

HIGH

IDLE

100

% OF FULL DRIVE

CONTROLLER OUTPUT

CALIBRATE

POINT

1417

GAIN

PRESSURE

0-6 Vdc

or CURRENT

(4-20 mA)

14191418

3

BLN-95-8993-3

Page 4

MCE102A1007 (1014) (1147*) AUTOMOTIVE

Phased Out Products

+12 V

0 - 2.5 V

200 - 900 Hz

R

NEUT

START

BRAKE

SWITCH

(1014)

F

R

F

N

D

C

A

B

INCH

ALT.

(200 - 650 Hz*)

1K

N.C

A - WHT

B - GRN

C - RED

D - BLK

A - N/C

B - YEL

C - ORG

D - BLK

A - 10

60 W

B - 3

C - 1

D - 2

B - 6

C - 5

D - 4

MCE102A1022 SLAVE RATIO

50 - 225 Hz ALT

2063

MCE102A

EDC

B

A

0 - 2.5 V

10

9

60 W

8

7

6

5

SLAVE

RATIO

1K

4

3

2

BLN-95-8993-3

+12 V

1

TERM

STRIP

4

1421

Page 5

MCE102A1113 LEAD/LAG FILTER

Phased Out Products

MCE102A

EDC

B

A

0 - 2.5 V

10

9

60 W

8

7

6

5

4

200 - 650 Hz ALT

3

2

+12 V

1

TERM

STRIP

2064

MCE102A1105 (1139) LEAD/LAG FILTER

MCE102A

60 W

EDC

B

A

0 - 2.5 V

(120 W)

10

9

KPP

1600 - 3000 Hz

+12 V

(+24 V)

8

7

8.2 V

6

5

4

3

2

1

TERM

STRIP

2065

5

BLN-95-8993-3

Page 6

MCE102A1030 REVERSE ACTING, 24 VOLT, 4 - 20 mA INPUT

Phased Out Products

CONTROL

HANDLE

20 V

ZERO

EDC

+24 V

A

B

+

-

4 - 20 mA

A - WHT

B - GRN

C - RED

D - BLK

A - 10

B - 3

C - 1

D - 2

1422A

MCE102A1097 (1121) WITH LEAD/LAG FILTER

EDC

200 - 650 HZ

(600 - 1950 Hz)

IGNITION

CONTROL

HANDLE

+12V

SLOW

0 - 10 V

NORM

MCE102A

10

9

8

7

6

5

4

3

2

1

BLN-95-8993-3

TERMINAL

STRIP

6

1423

Page 7

MCE102A1071 REVERSE ACTING, 24 VOLT, 4 - 20 mA INPUT (TERMINALS)

Phased Out Products

Control

Handle

20 V

A

EDC

B

+

-

ZERO

10

9

8

7

6

5

4

3

4 - 20 mA

2

1

+24 VOLTS

TERMINAL

STRIP

1424

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871355

7

BLN-95-8993-3

Loading...

Loading...