Page 1

MCD DeviceNet Module Instructions Important User Information

CAUTION

Remove mains and control voltage from the soft starter before attaching or removing

accessories. Failure to do so may damage the equipment.

Remove the module using the following procedure:

1. Take the module off-line.

2. Remove the DeviceNet connector.

3. Remove control power and mains supply from the soft starter.

4. Fully pull out the top and bottom retaining clips on the module.

5. Pull the module away from the soft starter.

INSTALLATION INSTRUCTIONS: MCD DEVICENET MODULE

Order Code: 175G9002

1. Important User Information

Observe all necessary safety precautions when controlling the soft starter remotely. Alert

personnel that machinery may start without warning.

It is the installer's responsibility to follow all instructions in this manual and to follow correct

electrical practice.

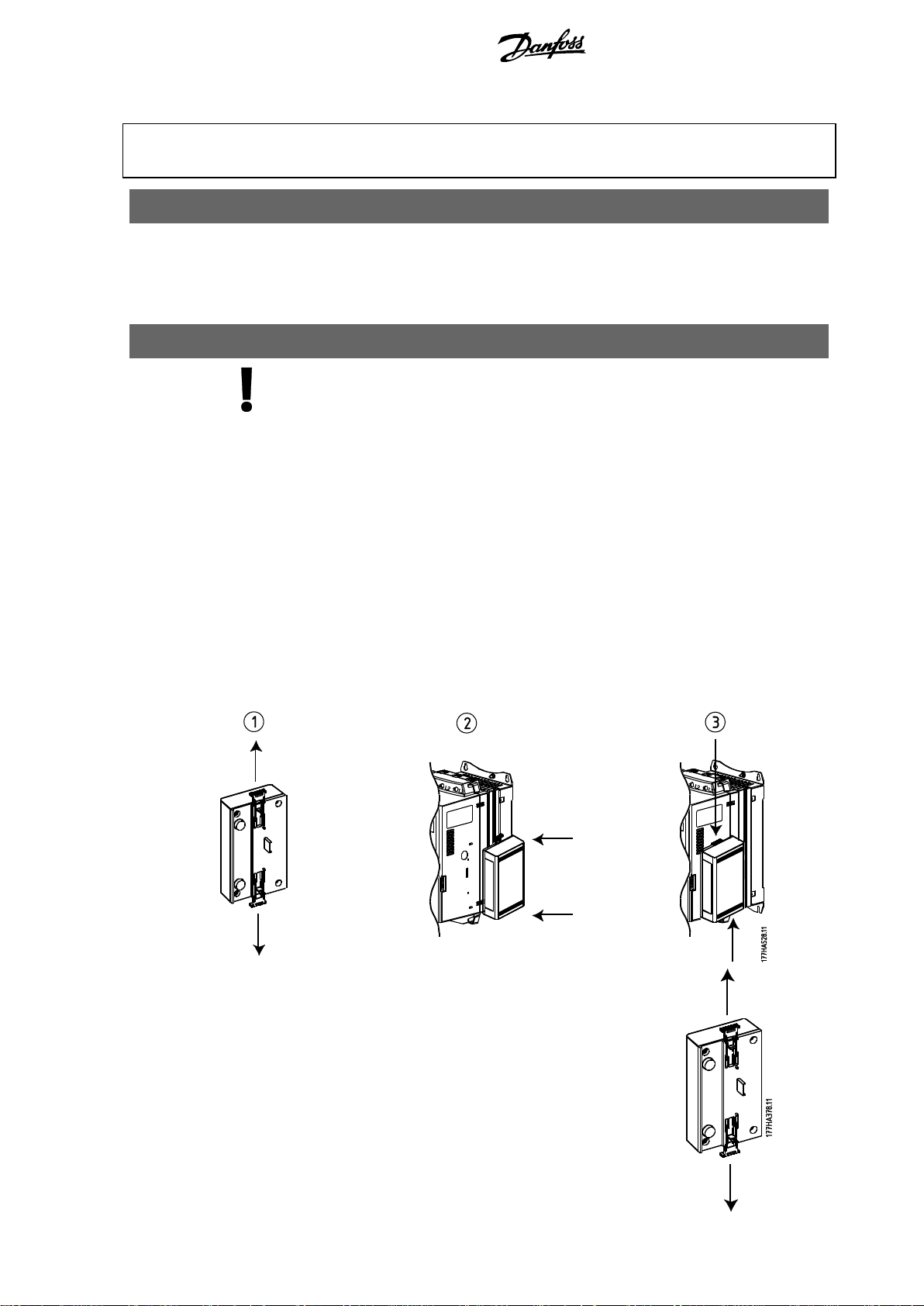

2. Installation

Install the DeviceNet Module using the following procedure:

1. Remove control power and mains supply from the soft starter.

2. Attach the module to the soft starter as illustrated.

3. Set the DeviceNet Module Node Address (MAC ID) and Data Rate.

4. Apply control power to the soft starter.

5. Insert the network connector into the module and power up the DeviceNet network.

2.1. Physical Installation

1. Fully pull out the top and bottom retaining clips on the module.

2. Line up the module with the comms port slot.

3. Push in the top and bottom retaining clips to secure the module to the starter.

MG17HA02 – VLT® is a registered Danfoss trademark 1

Page 2

Configuration MCD DeviceNet Module Instructions

CAUTION

Network designs must decrease the maximum allowable cumulative dropline length by

400 mm for every module installed on the network. Failure to do so may result in

network communication errors and decreased reliability.

Example: ODVA specifies a maximum cumulative dropline length of 156 m on a

network operating at 125 kb/s. If six modules were installed on this network, the total

cumulative dropline length would need to be decreased to 153.6 m.

N.B.!:

The Data Rate and Node Address (MAC ID) must be set locally on the module.

These cannot be set using DeviceNet management software.

When the Data Rate and MSD Node Address (MAC ID) rotary switches are set on

PGM position, the module uses the previously used valid on-line Data Rate and

Node Address (MAC ID).

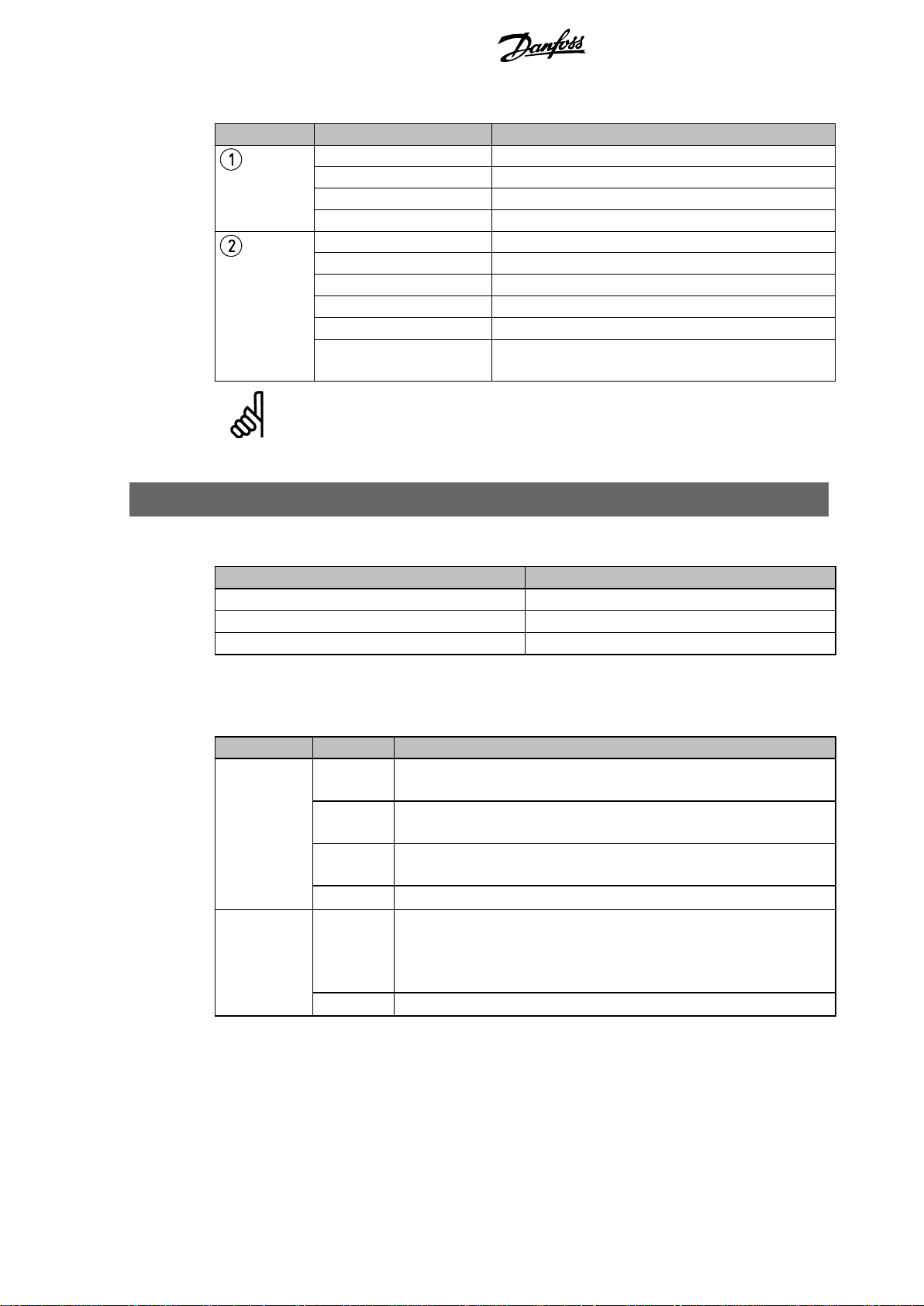

3. Configuration

The DeviceNet Module is a Group 2 slave device, using a predefined master/slave connection set.

I/O data is produced and consumed using polled I/O messaging.

The soft starter must be added to the DeviceNet manager project using the EDS file and

configuration/management software tool. This file is available from www.danfoss.com/drives. In

order to operate successfully, the correct EDS file must be used. An on-screen graphics bitmap

file (device.bmp) is also available.

4. Adjustment

The factory default settings for the rotary adjustment switches are:

Changes to the rotary switch settings take effect when the DeviceNet network is next powered

up.

MG17HA02 - VLT® is a registered Danfoss trademark 2

Page 3

MCD DeviceNet Module Instructions Connection

MCD 200

MCD 500

MCD 200

MCD 500 (Auto On mode)

17, 18: Stop

25, 18: Reset

MCD DeviceNet Module

MCD DeviceNet Module

Standard connection onto DeviceNet

network

Standard connection onto DeviceNet

network

N.B.!:

If MCD 500 parameter 3-2

Comms in Remote

is set to Disable Comms in Remote, the

starter will not accept start or stop commands from the serial network (the starter will

still accept reset commands and allow status monitoring).

5. Connection

MCD 200: For the MCD DeviceNet Module to accept serial commands, a link must be fitted across

terminals A1-N2 on the soft starter.

In order for the MCD 500 to accept commands from the serial network, the soft starter must be in

Auto On mode and links must be fitted to terminals 17, 18 and 25, 18.

In Hand On mode, the starter will not accept commands from the serial network but the starter's

status can still be monitored.

6. Module and Network LEDs

The Module LED indicates the condition of the power supply and module operation.

The Network LED indicates status of the communication link between the DeviceNet Module and

the network Master.

MG17HA02 – VLT® is a registered Danfoss trademark 3

Page 4

DeviceNet Polled I/O Structure MCD DeviceNet Module Instructions

LED

State

Description

(Module)

Off

Network power off

Green

Normal operation

Red

Unrecoverable fault

Red/Green flashing

Self Test mode

(Network)

Off

Duplicate MAC ID test has not been completed

Green flashing

Online but no connection with Master

Green

Online and allocated to a Master

Red flashing

One or more timed out I/O connections

Red

Failed communication between module and Master

Red/Green flashing

Communication faulted and received an Identity

communication faulted request

N.B.!:

When a communications failure occurs, the soft starter may trip if the Communication

Timeout parameter for the network is set greater than zero. When communication is

restored, the soft starter must be reset.

Parameter

Value

I/O connection type

Polled

Poll receive size

14 bytes

Poll transmit size

2 bytes

Byte

Bit

Function

0 0 0 = Stop command

1 = Start command

1

0 = Enable Start or Stop command

1 = Quick Stop (i.e. coast to stop) and disable Start command

2

0 = Enable Start or Stop command

1 = Reset command and disable Start command

3 to 7

Reserved

1

0 to 1

0 = Use soft starter remote input to select motor set

1 = Use primary motor set when starting 1

2 = Use secondary motor set when starting 1

3 =

Reserved

2 to 7

Reserved

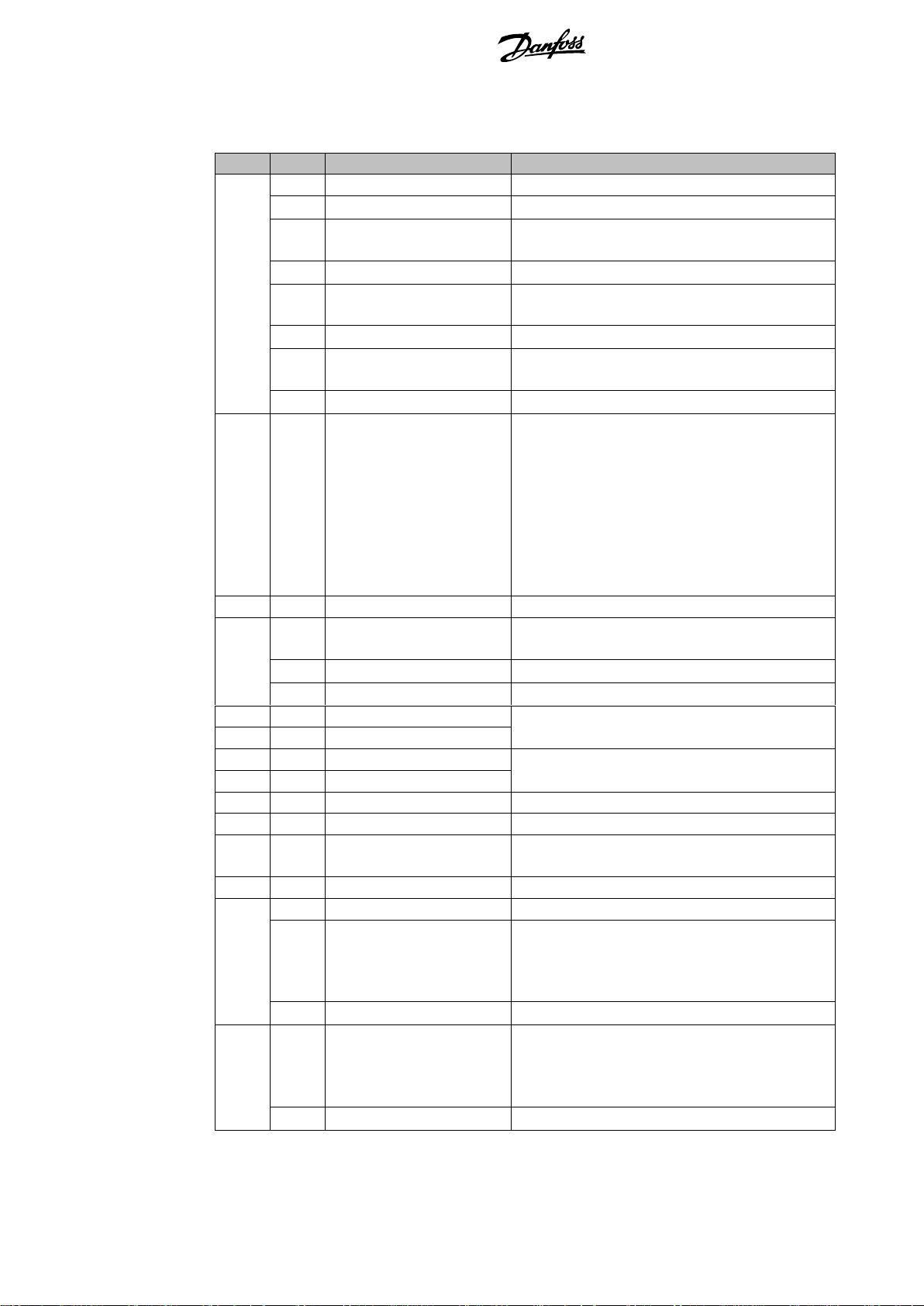

7. DeviceNet Polled I/O Structure

Once the EDS file has been loaded, the DeviceNet Module must be added to the scanner list with

parameters shown in the following table:

Once the soft starter, module and Master have been set up, configured and powered up, the

Master will transmit 2 bytes of data to the module and receive 14 bytes of data from the module.

Master > Slave polled I/O output data is as follows:

1

Ensure that the programmable input is not set to Motor Set Select before using this function.

MG17HA02 - VLT® is a registered Danfoss trademark 4

Page 5

MCD DeviceNet Module Instructions DeviceNet Polled I/O Structure

Byte

Bit

Function

Value

0 0 Trip

1 = Tripped

1

Warning

1 = Warning

2

Running

0 = Unknown, not ready, ready to start or tripped

1 = Starting, running, stopping or jogging

3

Reserved

4

Ready

0 = Start or stop command not acceptable

1 = Start or stop command acceptable

5

Control from Net

1 = Always except in Program mode

6

Local/Remote

0 = Local control

1 = Remote control

7

At reference

1 = Running (full voltage at the motor)

1

0 to 7

Status

0 = Unknown (menu open)

2 = Starter not ready (restart delay, thermal delay

or run simulation)

3 = Ready to start (including warning state)

4 = Starting or running

5 = Soft stopping

7 = Trip

8 = Jog forward

9 = Jog reverse

2

0 to 7

Trip/Warning code

See trip code table.

3 0 Initialised

1 = Phase sequence bit is valid (bit 1) after 1st

start

1

Phase sequence

1 = Positive phase sequence detected

2 to 7

Reserved

4 1

0 to 7

Motor current (low byte)

Current (A)

5 1

0 to 7

Motor current (high byte)

6 0 to 7

Current %FLC (low byte)

Current as a percentage of soft starter FLC setting

(%)

7

0 to 7

Current %FLC (high byte)

8

0 to 7

% Motor 1 temperature

Motor 1 thermal model

9

0 to 7

% Motor 2 temperature

Motor 2 thermal model

10

0 to 7

% Power factor

Percentage power factor

(100 = power factor of 1)

11

0 to 7

Power (low byte)

Power low byte, scaled by power scale

12

0 to 3

Power (high nibble)

Power high nibble, scaled by power scale

4 to 5

Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

6 to 7

Reserved

13

0 to 3

Digital Input state

0 = Start (0 = open, 1 = closed)

1 = Stop

2 = Reset

3 = Input A

4 to 7

Reserved

Slave > Master polled I/O input data is as follows:

1

For models MCD5-0428C and smaller this value will be 10 times greater than the value displayed

on the LCP.

MG17HA02 – VLT® is a registered Danfoss trademark 5

Page 6

DeviceNet Polled I/O Structure MCD DeviceNet Module Instructions

Code

Trip Type

MCD 201

MCD 202

MCD 500

0

No trip

11

Input A trip

20

Motor overload (thermal model)

21

Heatsink overtemperature

23

L1 phase loss

24

L2 phase loss

25

L3 phase loss

26

Current imbalance

28

Instantaneous overcurrent

29

Undercurrent

50

Power loss/Power circuit

54

Phase sequence

55

Frequency (Mains supply)

60

Unsupported option (function not available in

inside delta)

61

FLC too high (FLC out of range)

62

Parameter out of Range

70

Miscellaneous

75

Motor thermistor

101

Excess start time

102

Motor connection

104

Internal fault x (where x is the fault code detailed

in the table below).

113

Starter communication (between module and soft

starter)

114

Network communication (between module and

network)

115

L1-T1 shorted

116

L2-T2 shorted

117

L3-T3 shorted

119

Time-overcurrent (Bypass overload)

121

Battery/clock

122

Thermistor circuit

Internal

fault

Message displayed on the LCP

70 ~ 72

Current Read Err Lx

73

Power On in Simulation mode

74 ~ 76

Motor connection Tx

77 ~ 79

Firing fail SCRx

80 ~ 82

VZC Fail Px

83

Low Control Volts

84 ~ 98

Internal fault X

Contact your local supplier with the fault code (X).

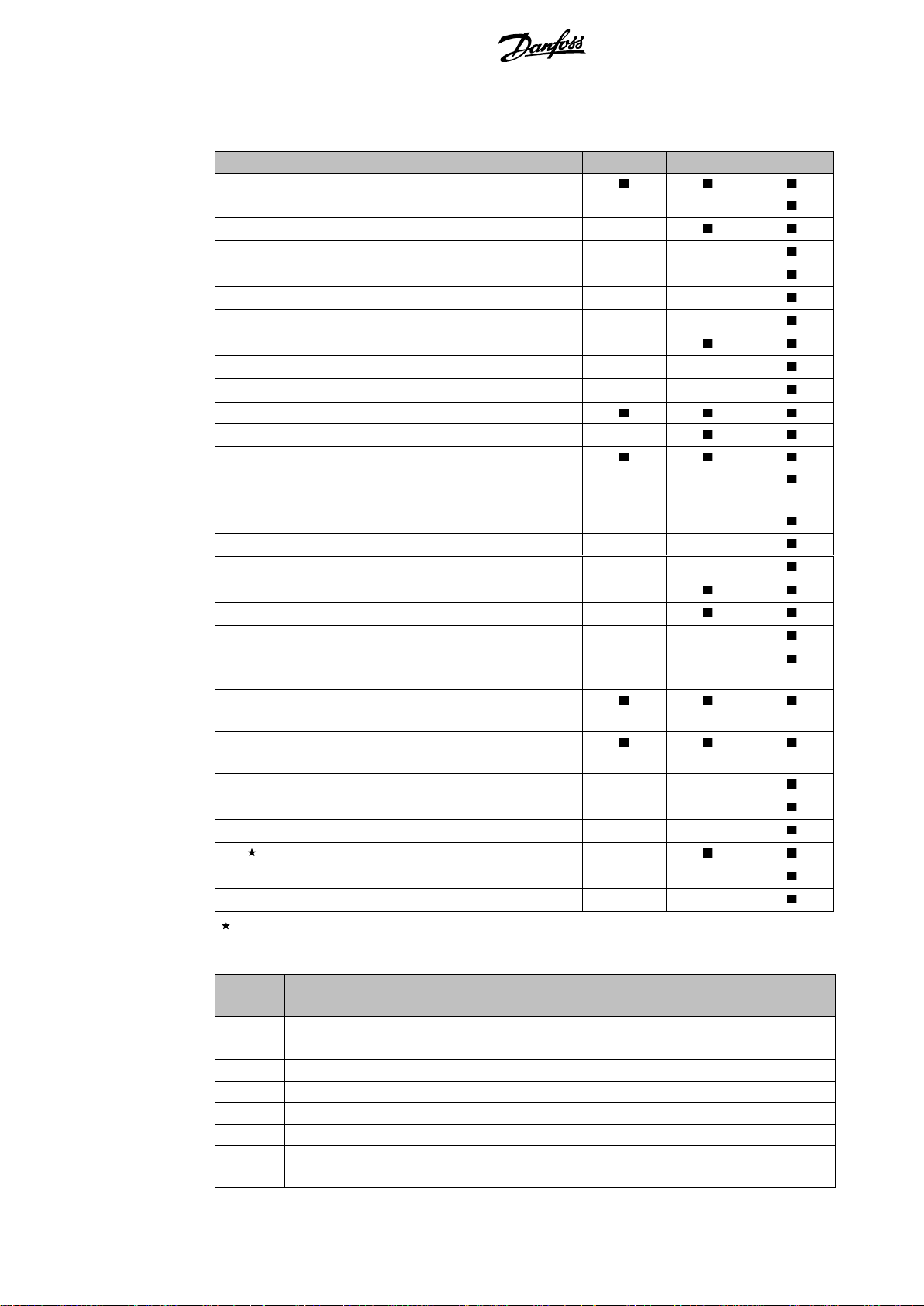

7.1.1. Trip Codes

For MCD 500, time-overcurrent protection is only available on internally bypassed models.

The table below details the internal fault code associated with trip code 104.

MG17HA02 - VLT® is a registered Danfoss trademark 6

Page 7

MCD DeviceNet Module Instructions Parameter Object

Detail

Value (Hex)

Comment

Class

0F

Parameter object address

Instance

1 ~ xxx

xxx = maximum soft starter parameter number

Attribute ID

01

Always 0x01

Get Service

0E

Read single soft starter parameter value

Set Service

10

Write single soft starter parameter value

N.B.!:

Only available on MCD 500 soft starters. For parameter details, see the soft starter

User Manual.

8. Parameter Object

The DeviceNet Module supports parameter objects through explicit messaging. Soft starter

parameters can be uploaded (written) and downloaded (read) using DeviceNet management

software. When the DeviceNet Module is powered up, it automatically obtains parameter

information from the soft starter.

MG17HA02 – VLT® is a registered Danfoss trademark 7

Page 8

Specifications MCD DeviceNet Module Instructions

È710-02937-00KrËÍ

9. Specifications

Enclosure

Dimensions ........................................................... 40 mm (W) x 166 mm (H) x 90 mm (D)

Weight .................................................................................................................. 250 g

Protection ............................................................................................................... IP20

Mounting

Spring-action plastic mounting clips (x 2)

Connections

Soft starter ....................................................................................... 6-way pin assembly

Network ..................................... 5-way male and unpluggable female connector (supplied)

Maximum cable size .......................................................................................... 2.5 mm2

Contacts ......................................................................................................... Gold flash

Settings

Node address (MAC ID)

Setting ............................................................................................. Rotary switches

Range ............................................................................. 0 to 63 (63, factory default)

Data rate

Setting ................................................................................................ Rotary switch

Options ............................................. 125 kB, 250 kB, 500 kB (125 kB, factory default)

Power

Consumption

steady state ................................................................................... 19 mA at 25 VDC

........................................................................................................ 31 mA at 11 VDC

in-rush (at 24 VDC) .............................................................. 1.8 A maximum for 2 ms

Galvanically isolated

Certification

CE ....................................................................................................... IEC 60947-4-2

MG17HA02 - VLT® is a registered Danfoss trademark 8

Loading...

Loading...