Installation Guide

Modbus TCP Card

VLT® Soft Starter MCD 600

vlt-drives.danfoss.com

Modbus TCP Card

Installation Guide

Contents

1

Safety 5

1.1

Disclaimer 5

Warnings 5

1.2

2

Introduction 6

2.1

Product Design 6

2.2

Compatibility 6

2.3

Network Connection 6

3

Installation 7

3.1

Installing the Expansion Card 7

3.2

Network Connections 7

Ethernet Ports 7

3.2.1

Cables 7

3.2.2

Contents

3.2.3

EMC Precautions 7

3.3

Network Establishment 7

3.4

Addressing 7

4

Device Configuration 8

4.1

Before Configuring the Device 8

4.2

Configuration Methods 8

4.3

Parameters for Configuring Network Settings 8

4.4

Enabling Network Control 8

4.5

On-board Web Server 9

4.5.1

Connect to the Device 9

4.5.2

Manage Users and Passwords 10

4.5.2.1

4.5.2.2

4.5.3

Configuring the IP Address 11

4.5.4

Configure IoT Settings 11

4.5.4.1

Adding a User 10

Deleting a User 10

Configuring MQTT Settings 12

4.5.4.2

4.6

Scanning the Network 13

4.6.1

Identifying the Device with Ethernet Device Configuration Tool 13

5

PLC Configuration 15

5.1

Configuration Requirements for PLC 15

Configuring OPC UA Settings 13

AN353424224484en-000101/130R0946 | 3Danfoss A/S © 2020.12

Modbus TCP Card

Installation Guide

6

Operation 16

Requirements for Successful Operation 16

6.1

6.2

Device Classification 16

Ensuring Safe and Successful Control 16

6.3

6.4

Feedback LEDs 16

7

Modbus Registers 17

7.1

Important Information 17

7.2

Command and Configuration Registers (Read/Write) 17

7.3

Parameter Management 17

7.3.1

Writing Parameters to the Soft Starter 18

7.4

Status Reporting Registers (Read Only) 18

7.5

Legacy Mode 20

7.5.1

Initializing Legacy Mode 20

7.5.2

Registers 20

Contents

7.6

Trip Codes 24

8

Network Design 26

8.1

Star Topology 26

8.2

Line Topology 26

8.3

Ring Topology 27

8.4

Combined Topologies 27

9

Specifications 29

9.1

Connections 29

9.2

Settings 29

9.3

Network 29

9.4

Power 29

9.5

Certification 29

AN353424224484en-000101/130R09464 | Danfoss A/S © 2020.12

Modbus TCP Card

Installation Guide

Safety

1 Safety

1.1 Disclaimer

The examples and diagrams in this manual are included solely for illustrative purposes. The information contained in this manual is

subject to change at any time and without prior notice. Responsibility or liability is never accepted for direct, indirect, or consequential damage resulting from the use or application of this equipment.

1.2 Warnings

W A R N I N G

SHOCK HAZARD

Attaching or removing accessories while the soft starter is connected to mains voltage may cause personal injury.

Before attaching or removing accessories, isolate the soft starter from mains voltage.

-

W A R N I N G

RISK OF PERSONAL INJURY AND EQUIPMENT DAMAGE

Inserting foreign objects or touching the inside of the soft starter while the expansion port cover is open may endanger person-

nel and can damage the soft starter.

Do not insert foreign objects in the soft starter with the port cover open.

-

Do not touch the inside of the soft starter with the port cover open.

-

AN353424224484en-000101 / 130R0946 | 5Danfoss A/S © 2020.12

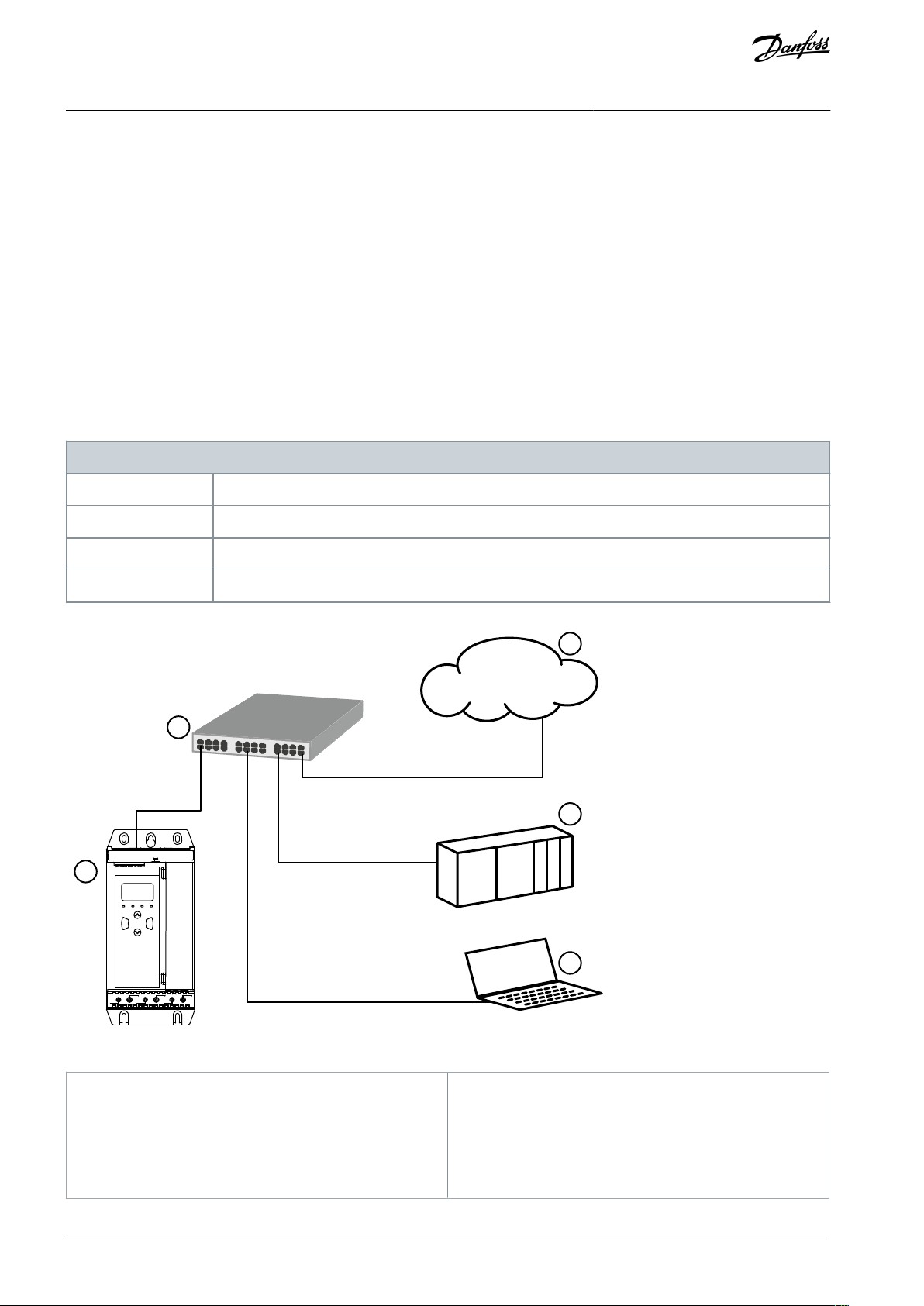

Protocols

Modbus TCP

Industrial Ethernet via Modbus TCP

TCP

Transmission control protocol to connect to port 4000 of a PC

MQTT

Message queue telemetry transport

OPC UA

Open platform communications unified architecture

4/T2

READY RUN TRIP LOCAL

Exit

Reset

Menu

Store

2/T1 6/T3

1/L1 3/L2

5/L3

VLT

®

Soft Starter

1

2

4

3

5

e77ha805.10

1

Soft starter

2

Network switch

3

IoT connection (MQTT/OPC UA)

4

Industrial Ethernet connection to programmable

logic controller

5

TCP connection to VLT® Motion Control Tool MCT

10. Refer to the VLT® Motion Control Tool MCT 10

Operating Guide for connection details.

Modbus TCP Card

Installation Guide

Introduction

2 Introduction

2.1 Product Design

The Modbus TCP Card allows the soft starter to connect to an Ethernet network and be controlled or monitored using an Ethernet

communication model.

Familiarity with Ethernet protocols and networks is required to operate the device successfully. For difficulties arising from using

this device with 3rd-party products, including PLCs, scanners, and commissioning tools, contact the relevant supplier.

2.2 Compatibility

This communication expansion card is suitable for use with VLT® Soft Starter MCD 600.

This Installation Guide is intended for use with version 2.x of the VLT® Soft Starter MCD 600 Modbus TCP Card. Version 1.x of the

Modbus TCP Card does not support custom users, TCP connection, or IoT operation.

2.3 Network Connection

Table 1: Supported Protocols

Illustration 1: Overview of Network Connections

AN353424224484en-000101 / 130R09466 | Danfoss A/S © 2020.12

1 2

e77ha739.10

Modbus TCP Card

Installation Guide

3 Installation

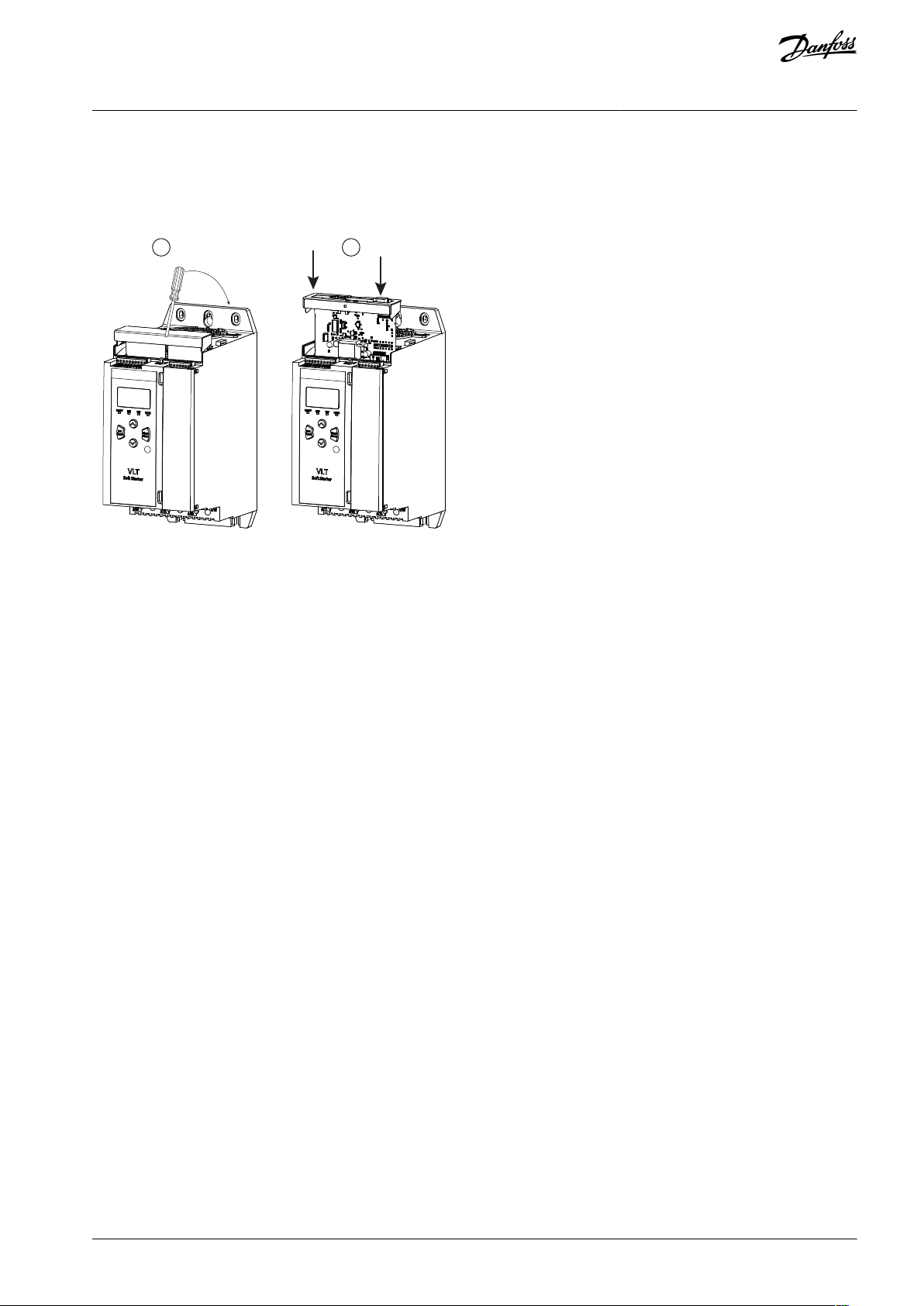

3.1 Installing the Expansion Card

Installation

Procedure

1.

Push a small flat-bladed screwdriver into the slot in the center of the expansion port cover and ease the cover away from

the soft starter.

2.

Align the card with the expansion port. Gently push the card along the guide rails until it clicks into the soft starter.

3.2 Network Connections

3.2.1 Ethernet Ports

The device has 2 Ethernet ports. If only 1 connection is required, either port can be used.

3.2.2 Cables

When connecting to the device, make sure that the cables are of 1 of the following categories:

•

Category 5

•

Category 5e

•

Category 6

•

Category 6e

3.2.3 EMC Precautions

To minimize electromagnetic interference, Ethernet cables should be separated from motor and mains cables by 200 mm (7.9 in).

If the Ethernet cable must cross motor or mains cables, the crossing should be at an angle of 90°.

3.3 Network Establishment

The controller must establish communications directly with each device before the device can participate in the network.

3.4 Addressing

Each device in a network is addressed using a MAC address and an IP address.

•

The device can be assigned a static IP address during configuration or can be configured to accept a dynamic IP address (via

DHCP).

•

The MAC address is fixed within the device and is printed on a label on the front of the device.

AN353424224484en-000101 / 130R0946 | 7Danfoss A/S © 2020.12

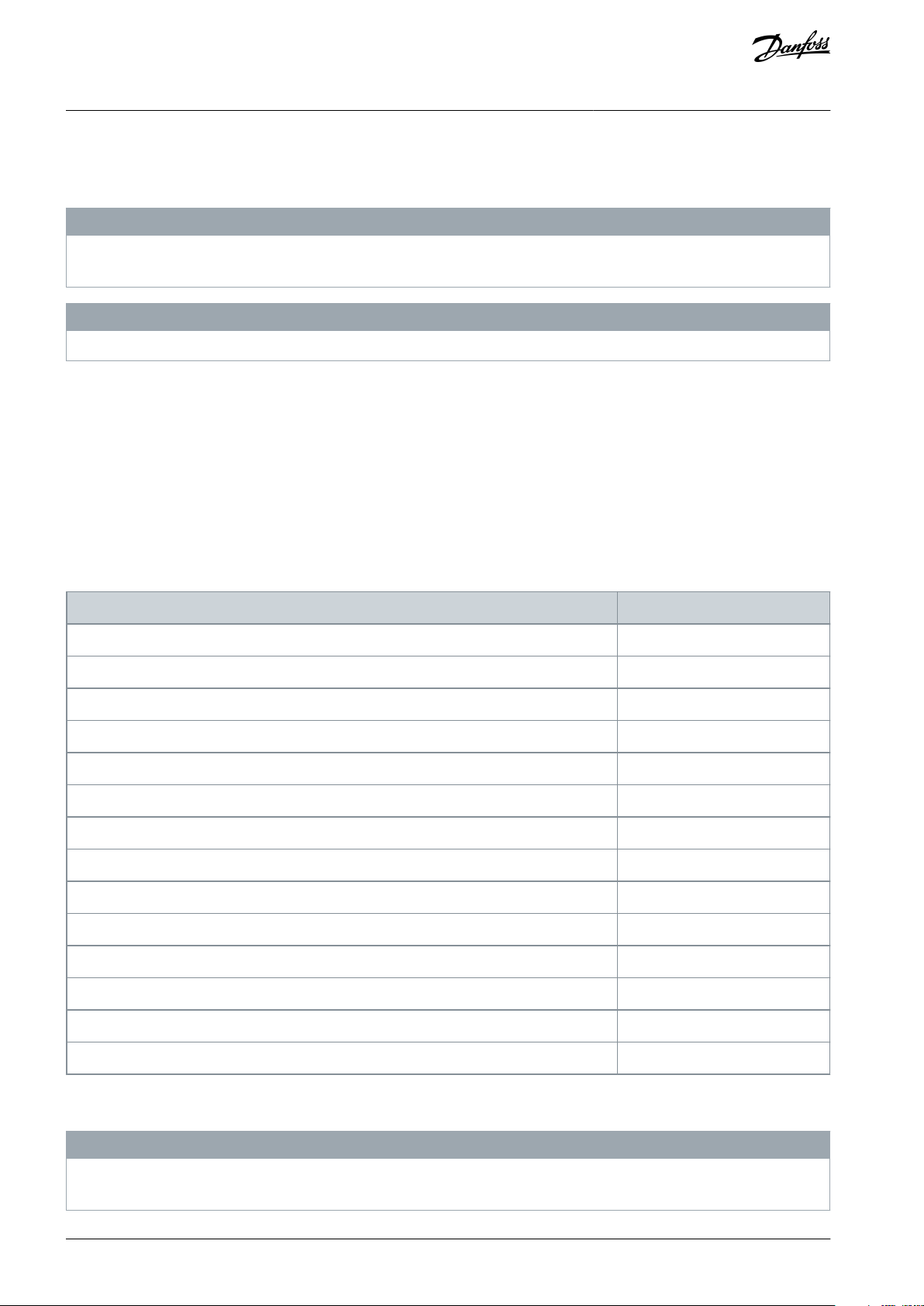

Parameter

Default

12-8 Gateway Address

192

12-9 Gateway Address 2

168

12-10 Gateway Address 3

0

12-11 Gateway Address 4

100

12-12 IP Address

192

12-13 IP Address 2

168

12-14 IP Address 3

0

12-15 IP Address 4

2

12-16 Subnet Mask

255

12-17 Subnet Mask 2

255

12-18 Subnet Mask 3

255

12-19 Subnet Mask 4

0

12-20 DHCP

Disable

12-21 Location ID

0

Modbus TCP Card

Installation Guide

Device Configuration

4 Device Configuration

4.1 Before Configuring the Device

N O T I C E

The error LED flashes whenever the device is receiving power but is not connected to a network. The error LED will flash occa-

sionally during the configuration process.

N O T I C E

At power-up, the communication card loads the IP address stored in the soft starter.

4.2 Configuration Methods

Network communication parameters for the communication card can be set via the soft starter or via the on-board web server.

•

The card uses a static IP address by default. To enable DHCP addressing, set parameter 12–20 DHCP to enable or change the

setting via the on-board web server.

•

The IP address can be set via the programmable parameters of the soft starter.

•

The web server can configure the IP address and messaging settings for MQTT/OPC UA operation.

4.3 Parameters for Configuring Network Settings

Use parameters 12-8 to 12-21 to configure the network address. The parameters can be set via the Main Menu, via the Setup Tools,

or by uploading a configuration file via USB Save & Load.

4.4 Enabling Network Control

If the reset input is active, the soft starter does not operate. If a reset switch is not required, use parameter 7-9 to set the reset

input to normally open or fit a link across terminals RESET, COM+ on the soft starter.

N O T I C E

AN353424224484en-000101 / 130R09468 | Danfoss A/S © 2020.12

e77ha807.10

Modbus TCP

Modbus TCP

MCD 600

e77ha814.10

Modbus TCP Card

Installation Guide

Device Configuration

Procedure

1.

Set parameter 1-1 Command Source to Network for the soft starter to accept commands from the Modbus TCP Card.

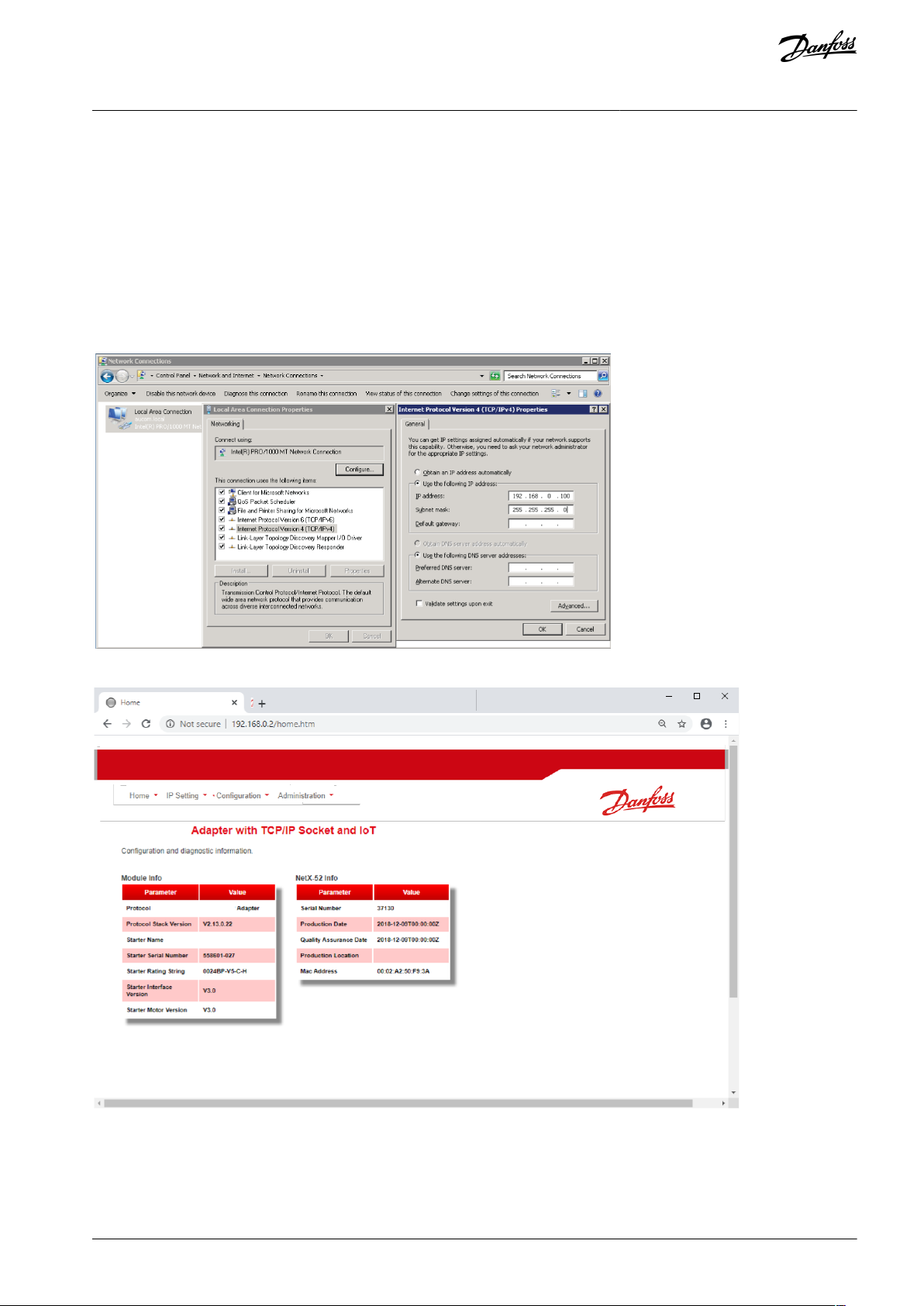

4.5 On-board Web Server

4.5.1 Connect to the Device

To configure settings using the on-board web server, the Modbus TCP Card must be installed in a soft starter, control power must

be available, and the card and computer must both be connected to the Ethernet network.

The computer must use a fixed IP address (not DHCP) and the same subnet mask as the card. The default IP address for the card is

192.168.0.2. The default subnet mask is 255.255.255.0.

Once connected, the web server reports basic information about the card and the soft starter.

AN353424224484en-000101 / 130R0946 | 9Danfoss A/S © 2020.12

1

2

3

5

6

e77ha808.10

4

Modbus TCP Card

Installation Guide

4.5.2 Manage Users and Passwords

N O T I C E

For security reasons, define a custom administrator ID and password. The default username and password are:

Username: danfoss_admin

-

Password: danfoss_admin

-

N O T I C E

Version 1.x of the Modbus TCP Card does not support custom users.

The Modbus TCP Card supports multiple users and levels of privilege.

•

Users can view the home screen and IP settings.

•

Supervisors can view the home screen and IP settings, and they can change configuration settings.

•

Administrators can view the home screen, change configuration settings, and add or delete users.

4.5.2.1 Adding a User

Device Configuration

Procedure

1.

Connect to the web server and click Administration.

2.

Click Create new user.

Enter the new username and password.

3.

4.

Click Create an account.

Set privileges (user, supervisor, administrator) as appropriate.

5.

6.

Click Save changes.

4.5.2.2 Deleting a User

Procedure

1.

Connect to the web server and click Administration.

2.

3.

Select the required entry in the user list and click Delete.

Click Delete again to confirm the action.

AN353424224484en-000101 / 130R094610 | Danfoss A/S © 2020.12

1

2

3

e77ha806.10

Modbus TCP Card

Installation Guide

Device Configuration

4.5.3 Configuring the IP Address

N O T I C E

For version 1.x of the Modbus TCP Card, changes made via the web server are not stored in the soft starter and will be lost when

control power is cycled.

Procedure

1.

Connect to the web server and click IP Setting.

2.

Edit settings as required. To enable DHCP addressing, tick the DHCP checkbox.

3.

Click Submit to send the new settings to the device.

4.5.4 Configure IoT Settings

The Modbus TCP Card supports soft starter status monitoring via IoT. The card cannot control or program the soft starter.

N O T I C E

Version 1.x of the Modbus TCP Card does not support IoT operation.

AN353424224484en-000101 / 130R0946 | 11Danfoss A/S © 2020.12

e77ha810.10

Modbus TCP Card

Installation Guide

4.5.4.1 Configuring MQTT Settings

Device Configuration

Procedure

1.

Connect to the web server and click Configuration.

2.

Select MQTT Client.

3.

Tick the Enable checkbox to enable MQTT client operation.

4.

Click Connection and configure the settings as required.

5.

Click Connections⇒Actions to select which information the card should publish.

6.

Click Submit to save all settings in the card.

The MQTT client is enabled by default.

AN353424224484en-000101 / 130R094612 | Danfoss A/S © 2020.12

e77ha813.10

Modbus TCP Card

Installation Guide

4.5.4.2 Configuring OPC UA Settings

Device Configuration

Procedure

1.

Connect to the web server and click Configuration.

2.

Select OPC UA Server.

3.

Tick the Enable checkbox to enable OPC UA client operation.

The OPC UA client is enabled by default.

4.

Click Server Configuration and configure the settings as required.

5.

Select Actions to select the actions for different object instances.

6.

Click Submit to save all settings in the card.

4.6 Scanning the Network

If there is no connection to the web server and the soft starter cannot be accessed physically, use the Ethernet Device Configuration

Tool to scan the network and identify the device. Changes made via the Ethernet Device Configuration Tool cannot be stored permanently in the device and will be lost when the control power is cycled.

Download the Ethernet Device Configuration Tool from

www.danfoss.com under the sections Services/PC-tools.

N O T I C E

If the PC has a firewall enabled, add the tool to the list of authorized programs.

4.6.1 Identifying the Device with Ethernet Device Configuration Tool

Procedure

1.

Start the Ethernet Device Configuration Tool.

2.

Click Search Devices.

AN353424224484en-000101 / 130R0946 | 13Danfoss A/S © 2020.12

e77ha641.10

Modbus TCP Card

Installation Guide

Device Configuration

The software searches for connected devices.

3.

Use the IP address to connect to the device via the web server.

AN353424224484en-000101 / 130R094614 | Danfoss A/S © 2020.12

e77ha632.10

Modbus TCP Card

Installation Guide

5 PLC Configuration

5.1 Configuration Requirements for PLC

The PLC must be configured to map registers within the communication card to addresses within the PLC.

The device must be configured directly in the PLC. No extra files are required.

PLC Configuration

AN353424224484en-000101 / 130R0946 | 15Danfoss A/S © 2020.12

Port 1 Port 2

Keypad

LINK 2

TX/RX2

LINK 1

TX/RX1

ERROR

STATUS

e77ha742.10

LED name

LED state

Description

Error

Off

No error.

Flashing

System error.

On

Communication error.

Status

Off

The device is not powered up.

Slow flash

The device is ready but not configured.

Fast flash

Communication has been established.

Link x

Off

No network connection.

On

Connected to a network.

TX/RX x

Flashing

Transmitting or receiving data.

Off

No network connection.

Modbus TCP Card

Installation Guide

Operation

6 Operation

6.1 Requirements for Successful Operation

The Modbus TCP Card must be controlled by a Modbus client (such as a PLC), which complies with the Modbus Protocol Specification. For successful operation, the client must also support all functions and interfaces described in this manual.

N O T I C E

The available features and parameter details may vary according to the model and software version of the soft starter. Refer to

the VLT® Soft Starter MCD 600 Operating Guide for details of parameters and supported features.

6.2 Device Classification

The Modbus TCP Card is a Modbus server and must be managed by a Modbus client over Ethernet.

6.3 Ensuring Safe and Successful Control

Data written to the device remains in its registers until the data is overwritten or the device is reinitialized. If the soft starter is controlled via parameter 7-1 Command Override or is disabled via the reset input (terminals RESET, COM+), fieldbus commands should

be cleared from the registers. If a command is not cleared, it is re-sent to the soft starter once fieldbus control resumes.

6.4 Feedback LEDs

Table 2: LED Descriptions

AN353424224484en-000101 / 130R094616 | Danfoss A/S © 2020.12

Register

Description

Bits

Details

40001

Command (single write)

0–7

To send a command to the soft starter, write the required value:

00000000 = Stop

00000001 = Start

00000010 = Reset

00000100 = Quick stop (coast to stop)

00001000 = Forced communication trip

00010000 = Start using Parameter Set 1

00100000 = Start using Parameter Set 2

01000000 = Reserved

10000000 = Reserved

8–14

Reserved

15

Must = 1

40002

Reserved

40003

Reserved

40004

Reserved

40005

Reserved

40006

Reserved

40007

Reserved

40008

Reserved

40009–40xxx

Parameter management (single/multiple read or multiple write)

0–15

Manage soft starter programmable parameters.

Modbus TCP Card

Installation Guide

Modbus Registers

7 Modbus Registers

7.1 Important Information

N O T I C E

The available features and parameter details may vary according to the model and software version of the soft starter. Refer to

the VLT® Soft Starter MCD 600 Operating Guide for details of parameters and supported features.

N O T I C E

All references to registers mean the registers within the communication card unless otherwise stated.

7.2 Command and Configuration Registers (Read/Write)

Table 3: Details of Command and Configuration Registers

7.3 Parameter Management

Parameters can be read from and written to the soft starter. When writing parameters to the soft starter, every parameter is updated

to match the values in the PLC.

While parameters are being written, the soft starter cannot start/stop the motor.

The Modbus TCP protocol limits read/write operations to a maximum of 123 registers at one time. The registers must be consecutive.

N O T I C E

AN353424224484en-000101 / 130R0946 | 17Danfoss A/S © 2020.12

Register

Description

Bits

Details

30003

Reserved

30004

Reserved

30005

Reserved

30006

Reserved

30007

Reserved

30008

Reserved

30600

Product information

0–5

Binary protocol version

6–8

Parameter list major version

9–15

Product type code: 15 = MCD 600

30601

Model number

0–7

Reserved

8–15

Soft starter model ID

30602

Reserved

30603

Reserved

30604

Starter state

0–4

0 = Reserved

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart temperature check, run simulation,

reset input is open)

6 = Tripped

7 = Programming mode

Modbus TCP Card

Installation Guide

To avoid loss of communications due to an unintentional change of network configuration, write the network address parameter

settings before writing start/stop parameter settings.

Modbus Registers

7.3.1 Writing Parameters to the Soft Starter

N O T I C E

For reliable operation, the parameter block containing network configuration settings must be written first.

Procedure

1.

Configure all soft starter parameter values in the PLC as required, including IP address, gateway address, subnet mask, and

DHCP configuration.

2.

Write the parameter block that includes the network parameter settings from the PLC to the soft starter.

3.

Write the other parameter blocks from the PLC to the soft starter until all parameter values have been written.

7.4 Status Reporting Registers (Read Only)

N O T I C E

For models MCD6-0063B and smaller (soft starter model ID 1~4), the current reported via communications registers is 10 times

greater than the actual value.

Table 4: Description of Read Registers

AN353424224484en-000101 / 130R094618 | Danfoss A/S © 2020.12

Register

Description

Bits

Details

8 = Jog forward

9 = Jog reverse

5

1 = Warning

6

0 = Uninitialized

1 = Initialized

7

Command source

0 = Remote LCP, Digital Input, Clock

1 = Network

8

Reserved

9

0 = Negative phase sequence

1 = Positive phase sequence

10–15

Reserved

30605

Current

0–13

Average rms current across all 3 phases

14–15

Reserved

30606

Current

0–9

Current (% motor FLC)

10–15

Reserved

30607

Motor temperature

0–7

Motor thermal model (%)

8–15

Reserved

30608

Power

0–11

Power

12–13

Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

14–15

Reserved

30609

% Power factor

0–7

100% = power factor of 1

8–15

Reserved

30610

Voltage

0–13

Average rms voltage across all 3 phases

14–15

Reserved

30611

Current

0–13

Phase 1 current (rms)

14–15

Reserved

30612

Current

0–13

Phase 2 current (rms)

14–15

Reserved

30613

Current

0–13

Phase 3 current (rms)

14–15

Reserved

Modbus TCP Card

Installation Guide

Modbus Registers

AN353424224484en-000101 / 130R0946 | 19Danfoss A/S © 2020.12

Register

Description

Bits

Details

30614

Voltage

0–13

Phase 1 voltage

14–15

Reserved

30615

Voltage

0–13

Phase 2 voltage

14–15

Reserved

30616

Voltage

0–13

Phase 3 voltage

14–15

Reserved

30617

Parameter list version number

0–7

Parameter list minor revision

8–15

Parameter list major version

30618

Digital input state

0–15

For all inputs, 0 = open, 1 = closed (shorted)

0 = Start/Stop

1 = Reserved

2 = Reset

3 = Input A

4 = Input B

5–15 = Reserved

30619

Trip code

0–15

See the chapter Trip Codes.

8–15

Reserved

30620–30631

Reserved

Modbus TCP Card

Installation Guide

Modbus Registers

The reset input is normally closed by default. If parameter 7-9 Reset/Enable Logic is set to normally open, the reported state is

inverted (0 = closed, 1 = open).

7.5 Legacy Mode

The Modbus TCP Card can also operate in Legacy Mode, which uses the same registers as the clip-on Modbus RTU Module supplied

by Danfoss for use with older soft starters. Some registers differ from those specified in the Modbus protocol specification.

7.5.1 Initializing Legacy Mode

If the card has been operating in Standard Mode, it must be reset before communicating in Legacy Mode. To initialize the card for

Legacy Mode, either:

•

cycle control power, or

•

reset register 40001 to 0 (write 0 to bits 0–15).

7.5.2 Registers

For models MCD6-0063B and smaller, the current reported via communications registers is 10 times greater than the actual value.

Legacy Mode reports read-only status information in registers 40003 onwards to match the register definitions of the clip-on

Modbus Module. Identical data is also available via registers 30003 onwards.

N O T I C E

N O T I C E

N O T I C E

AN353424224484en-000101 / 130R094620 | Danfoss A/S © 2020.12

Register

Description

Bits

Details

40001

Reserved

40002

Command (single write)

0–2

To send a command to the starter, write the required value:

1 = Start

2 = Stop

3 = Reset

4 = Quick stop (coast to stop)

5 = Forced communication trip

6 = Start using Parameter Set 1

7 = Start using Parameter Set 2

3–15

Reserved

40003

Soft starter state

0–3

1 = Ready

2 = Starting

3 = Running

4 = Stopping (including braking)

5 = Restart delay (including temperature check)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

4

1 = Positive phase sequence (only valid if bit 6 = 1)

5

1 = Current exceeds FLC

6

0 = Uninitialized

1 = Initialized

7–15

Reserved

40004

Reserved

40005

Motor current

0–7

Average 3-phase motor current (A)

8–15

Reserved

40006

Motor temperature

0–7

Motor thermal model (%)

8–15

Reserved

40007

Reserved

40008

Reserved

40009–40xxx

Parameter management (single or multiple read/ write)

0–7

Manage soft starter programmable parameters. See the VLT® Soft

Starter MCD 600 Operating Guide for a complete parameter list.

8–15

Reserved

40600

Version

0–5

Binary protocol version

6–8

Parameter list version number

9–15

Product type code:

Modbus TCP Card

Installation Guide

Table 5: Description of Registers in Legacy Mode

Modbus Registers

AN353424224484en-000101 / 130R0946 | 21Danfoss A/S © 2020.12

Register

Description

Bits

Details

15 = MCD 600

40601

Model number

0–7

Reserved

8–15

Soft starter model ID

40602

Reserved

40603

Reserved

40604

Starter state

0–4

0 = Reserved

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart temperature check, run simulation,

reset input is open)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

5

1 = Warning

6

0 = Uninitialized

1 = Initialized

7

Command source

0 = Remote LCP, Digital Input, Clock

1 = Network

8

Reserved

9

0 = Negative phase sequence

1 = Positive phase sequence

10–15

Reserved

40605

Current

0–13

Average rms current across all 3 phases

14–15

Reserved

40606

Current

0–9

Current (% motor FLC)

10–15

Reserved

40607

Motor temperature

0–7

Motor thermal model (%)

8–15

Reserved

40608

Power

0–11

Power

12–13

Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

Modbus TCP Card

Installation Guide

Modbus Registers

AN353424224484en-000101 / 130R094622 | Danfoss A/S © 2020.12

Register

Description

Bits

Details

14–15

Reserved

40609

% Power factor

0–7

100% = power factor of 1

8–15

Reserved

40610

Voltage

0–13

Average rms voltage across all 3 phases

14–15

Reserved

40611

Current

0–13

Phase 1 current (rms)

14–15

Reserved

40612

Current

0–13

Phase 2 current (rms)

14–15

Reserved

40613

Current

0–13

Phase 3 current (rms)

14–15

Reserved

40614

Voltage

0–13

Phase 1 voltage

14–15

Reserved

40615

Voltage

0–13

Phase 2 voltage

14–15

Reserved

40616

Voltage

0–13

Phase 3 voltage

14–15

Reserved

40617

Parameter list version number

0–7

Parameter list minor revision

8–15

Parameter list major version

40618

Digital input state

0–15

For all inputs, 0 = open, 1 = closed (shorted)

0 = Start/Stop

1 = Reserved

2 = Reset

3 = Input A

4 = Input B

5–15 = Reserved

40619

Trip code

0–7

See the chapter Trip Codes

8–15

Reserved

40620–40631

Reserved

Modbus TCP Card

Installation Guide

Modbus Registers

The reset input is normally closed by default. If parameter 7-9 Reset/Enable Logic is set to normally open, the reported state is

inverted (0 = closed, 1 = open).

N O T I C E

AN353424224484en-000101 / 130R0946 | 23Danfoss A/S © 2020.12

Code

Description

255

No trip

1

Excess start time

2

Motor overload

3

Motor thermistor

4

Current imbalance

5

Frequency

6

Phase sequence

7

Overcurrent

8

Power loss

9

Undercurrent

10

Heat sink overtemperature

11

Motor connection

12

Input A trip

13

FLC too high

14

Unsupported option (function not available in inside delta)

15

Communications card fault

16

Network communication

18

Overvoltage

19

Undervoltage

23

Parameter out of range

20

Motor overload

24

Input B trip

26

L1 phase loss

27

L2 phase loss

28

L3 phase loss

29

L1-T1 shorted

30

L2-T2 shorted

31

L3-T3 shorted

33

Time-overcurrent (bypass overload)

34

SCR overtemperature

35

Battery/clock

36

Thermistor circuit

Modbus TCP Card

Installation Guide

7.6 Trip Codes

Modbus Registers

AN353424224484en-000101 / 130R094624 | Danfoss A/S © 2020.12

Code

Description

47

Overpower

48

Underpower

56

LCP disconnected

57

Zero speed detect

58

SCR Itsm

59

Instantaneous overcurrent

60

Rating capacity

70

Current Read Err L1

71

Current Read Err L2

72

Current Read Err L3

74

Motor connection T1

75

Motor connection T2

76

Motor connection T3

77

Firing fail P1

78

Firing fail P2

79

Firing fail P3

80

VZC fail P1

81

VZC fail P2

82

VZC fail P3

83

Low control volts

84–96

Internal fault x. Contact the local supplier with the fault code (x).

Modbus TCP Card

Installation Guide

Modbus Registers

AN353424224484en-000101 / 130R0946 | 25Danfoss A/S © 2020.12

e77ha628.10

e77ha629.10

Modbus TCP Card

Installation Guide

8 Network Design

8.1 Star Topology

In a star network, all controllers and devices connect to a central network switch.

Network Design

Illustration 2: Example of Star Topology

8.2 Line Topology

In a line network, the controller connects directly to 1 port of the 1st card. The 2nd Ethernet port connects to another card, which in

turn connects to another device until all devices are connected.

Illustration 3: Example of Line Topology

N O T I C E

The device has an integrated switch to allow data to pass through in line topology. The device must be receiving control power

from the soft starter for the switch to operate.

N O T I C E

If the connection between 2 devices is interrupted, the controller cannot communicate with devices after the interruption point.

AN353424224484en-000101 / 130R094626 | Danfoss A/S © 2020.12

e77ha630.10

Modbus TCP Card

Installation Guide

Network Design

N O T I C E

Each connection adds a delay to the communication with the next device. The maximum number of devices in a line network is

32. Exceeding this number may reduce the reliability of the network.

8.3 Ring Topology

In a ring topology network, the controller connects to the 1st card via a network switch. The 2nd Ethernet port of the card connects

to another device, which in turn connects to another device until all devices are connected. The final device connects back to the

switch.

The device supports beacon-based ring node configuration.

Illustration 4: Example of Ring Topology

N O T I C E

The network switch must support loss of line detection.

8.4 Combined Topologies

A single network can include both star and line components.

AN353424224484en-000101 / 130R0946 | 27Danfoss A/S © 2020.12

e77ha631.10

Modbus TCP Card

Installation Guide

Network Design

Illustration 5: Example of Combined Topologies

AN353424224484en-000101 / 130R094628 | Danfoss A/S © 2020.12

Soft starter

6-way pin assembly

Contacts

Gold flash

Network

RJ45

IP address

Automatically assigned, configurable

Device name

Automatically assigned, configurable

Link speed

10 Mbps, 100 Mbps (auto-detect)

Full duplex

Auto crossover

Consumption (steady state, maximum)

35 mA@24 V DC

Reverse polarity protected

Galvanically isolated

RCM

IEC 60947-4-2

CE

EN 60947-4-2

Modbus TCP Card

Installation Guide

9 Specifications

9.1 Connections

9.2 Settings

9.3 Network

9.4 Power

Specifications

9.5 Certification

AN353424224484en-000101 / 130R0946 | 29Danfoss A/S © 2020.12

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogs, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All

trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

*130R0946*

Danfoss A/S © 2020.12

AN353424224484en-000101 / 130R0946

*M0025601*

Loading...

Loading...