Page 1

Installation Instructions

VLT® Line Filter MCC 107 EMC Filter Series

®

VLT

Midi Drive FC 280 (K1–K3)

These instructions provide technical and installation

information for the MCC 107 EMC lter series.

Only Danfoss qualied personnel is allowed to install this

equipment. The personnel must be familiar with the

instructions and safety measures described in the

®

Midi Drive FC 280 Operating Guide.

VLT

Ordering Numbers

Description Ordering number

®

MCC 107 for VLT

MCC 107 for VLT

MCC 107 for VLT

MCC 107 for VLT

MCC 107 for VLT

Tab le 1.1 Ordering Num be rs

1) K1–K3 is 3 enclosure sizes of VLT

S2 represents 1x200–240 V. T4 represents 3x380–480 V.

®

Midi Drive FC 280 T4, only H1 version is optimized to operate

For VLT

with the EMC lters installed.

Midi Drive FC 280 K1S2

®

Midi Drive FC 280 K2S2

®

Midi Drive FC 280 K1T4

®

Midi Drive FC 280 K2T4

®

Midi Drive FC 280 K3T4

®

1)

1)

1)

1)

1)

Midi Drive FC 280.

134B5466

134B5467

134B5463

134B5464

134B5465

Tool s R equi red

Safety Instructions

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors which

can remain charged even when the frequency converter is

not powered. High voltage can be present even when the

warning LED indicator lights are

specied time after power has been removed before

performing service or repair work can result in death or

serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link supplies,

•

including battery back-ups, UPS, and DC-link

connections to other frequency converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum waiting time is specied in Ta bl e 1 .2.

Before performing any service or repair work, use

•

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

Failure to wait the

o.

SZS 0.6x3.5 mm slot screwdriver for EMC lter

•

terminals.

Voltage [V]

200–240 0.37–2.2 (0.5–3) 4

380–480 0.37–7.5 (0.5–10) 4

Tab le 1.2 Discharg e Time

Power range

[kW (hp)]

Minimum waiting time

(minutes)

Danfoss A/S © 05/2017, Rev. 02, All rights reserved. MI07L102

Page 2

Installation Instructions

®

VLT

Line Filter MCC 107 EMC Filter Series

®

Midi Drive FC 280 (K1–K3)

VLT

Product Overview

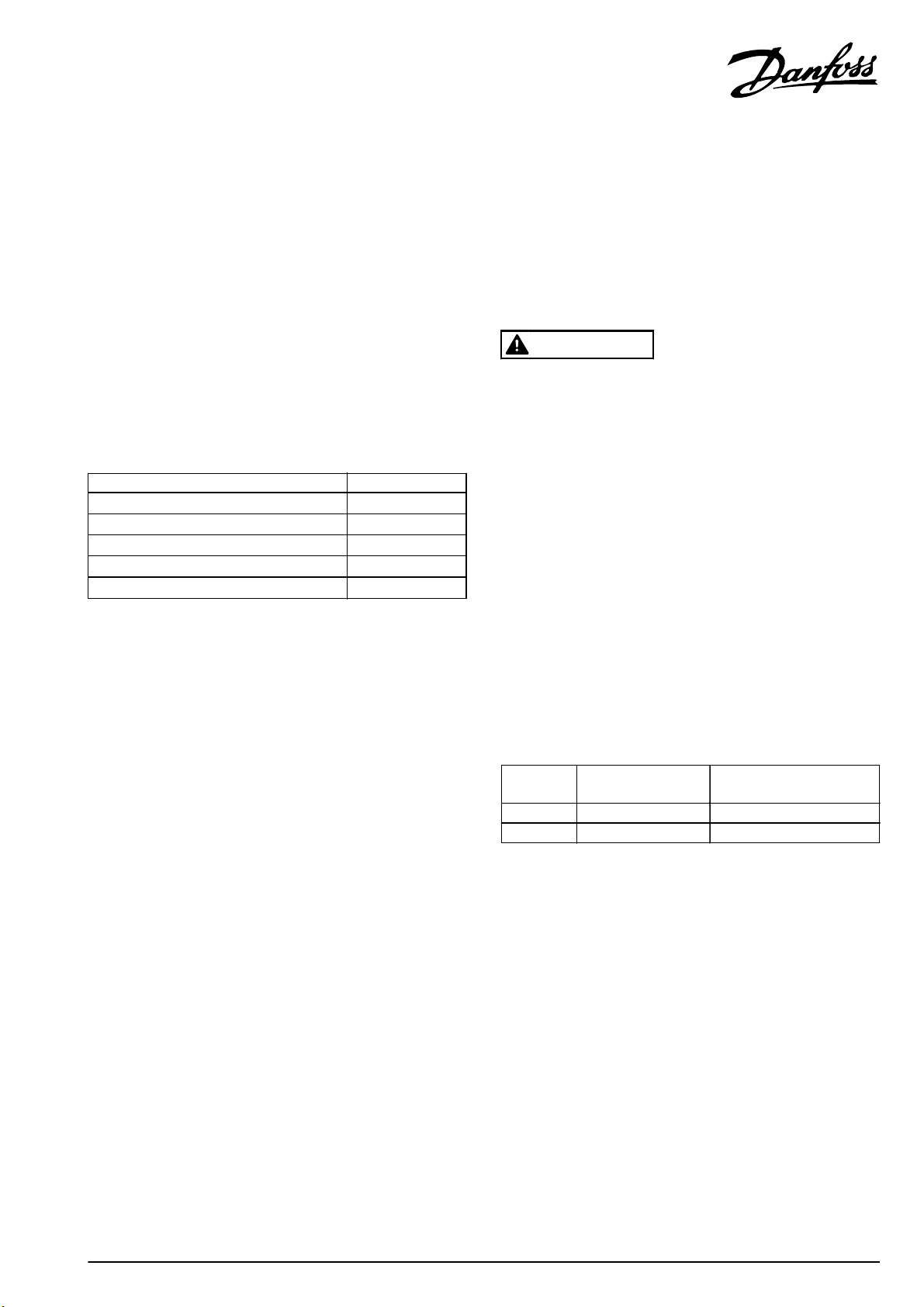

Illustration 1.1 and Illustration 1.2 show the typical circuit

diagram of the EMC

Illustration 1.1 Circuit Diagram for 1-phase EMC Filter

lters.

Number of phases 1 3

Rated voltage [V ] 1x200–240 ±10% 3x380–480 ±10%

Rated frequency

[Hz]

50–60

EMC lter

ordering number

466 467 463 464 465

134B5xxx

Frequ ency

converter

K1S2 K2S2 K1T4 K2T4 K3T4

enclosure size

Rated current in [A] 11 15 5 11.6 16

Power loss [W] 6.0 9.1 3.8 9.4 12.4

Maximum leakage

current [mA]

1)

Maximum leakage

current [mA]

2)

High-voltage test

[V-]

0 0 187 124.8 124.8

0 0 19.5 13 13

2100 Line-neutral 2780 Line-line

2700 Line-case 2780 Line-case

Table 1. 4 Tech nical Dat a

1) Calculated for maximum line voltage tolerance, by loss of 2 phases

(typical @ 50 Hz).

2) Maximum allowed voltage uctuation in accordance with IEC 38

±10%.

Illustration 1.2 Circuit Diagram for 3-phase EMC Filter

Tabl e 1.3 and Ta ble 1.4 show the operating conditions and

technical data of the EMC lters.

Enclosure protection rating IP20

°

Ambient temperature 50

Climatic category

25/085/21 [in accordance with EN

60068-1]

Type of cooling Ambient natural air

Operating conditions Continuous

°

Derating > 50

C (122 °F) -3% / K

Derating > 1000 m (3281 ft) 5% / 1000 m (3281 ft)

Table 1.3 Operating Conditions

C (122 °F)

2

Danfoss A/S © 05/2017, Rev. 02, All rights reserved. MI07L102

Page 3

Installation Instructions

®

VLT

Line Filter MCC 107 EMC Filter Series

®

Midi Drive FC 280 (K1–K3)

VLT

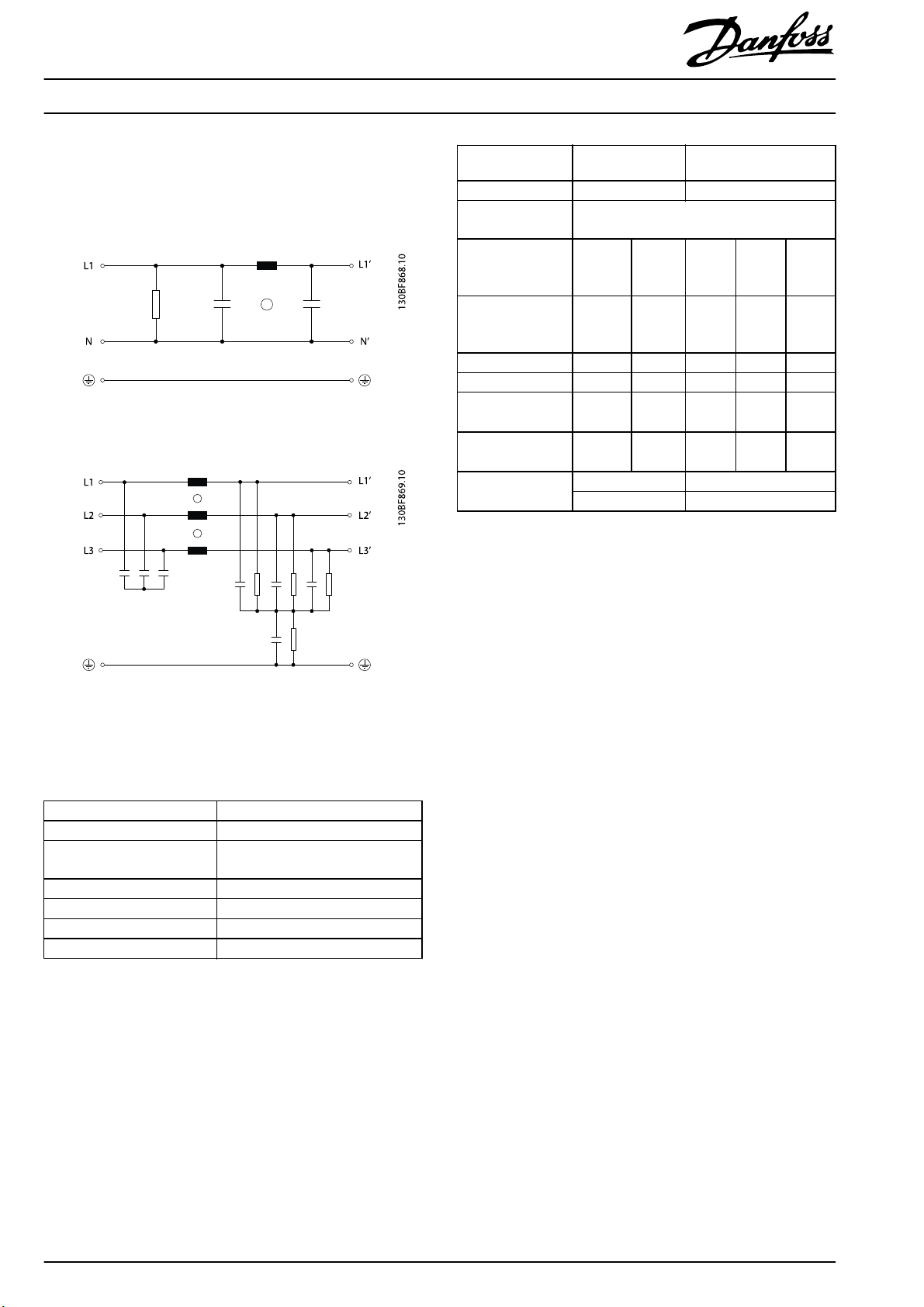

Mechanical Installation

The EMC lters support 2 mounting styles.

Footprint installation

•

Side-by-side installation

•

Footprint installation

1. Mount the EMC lter on the wall, and mount the

frequency converter on the EMC

recommended screws. Refer to Illustration 1.3.

lter.

Fasten with

Side-by-side installation

1. Mount the frequency converter and the EMC lter on

the wall side by side, and fasten with recommended

screws. Refer to Illustration 1.4.

1Frequency converter

2EMC lter

3 Recommended screws: 4 pieces M5 screws

(Not supplied by Danfoss)

4 Recommended screws (length: 10–20 mm/0.39–0.79 in):

4 pieces M4 screws for K1T4/K1S2, or

4 pieces M5 screws for K2T4/K2S2/K3T4

(Not supplied by Danfoss)

Illustration 1.3 Footprint Installation

1Frequency converter

2EMC lter

3 Recommended screws:

4 pieces M4 screws for K1T4/K1S2, or

4 pieces M5 screws for K2T4/K2S2/K3T4

(Not supplied by Danfoss)

4 Recommended screws: 2 pieces M5 screws

(Not supplied by Danfoss)

Illustration 1.4 Side-by-side Installation

MI07L102 Danfoss A/S © 05/2017, Rev. 02, All rights reserved.

3

Page 4

®

VLT

Installation Instructions

Line Filter MCC 107 EMC Filter Series

®

Midi Drive FC 280 (K1–K3)

VLT

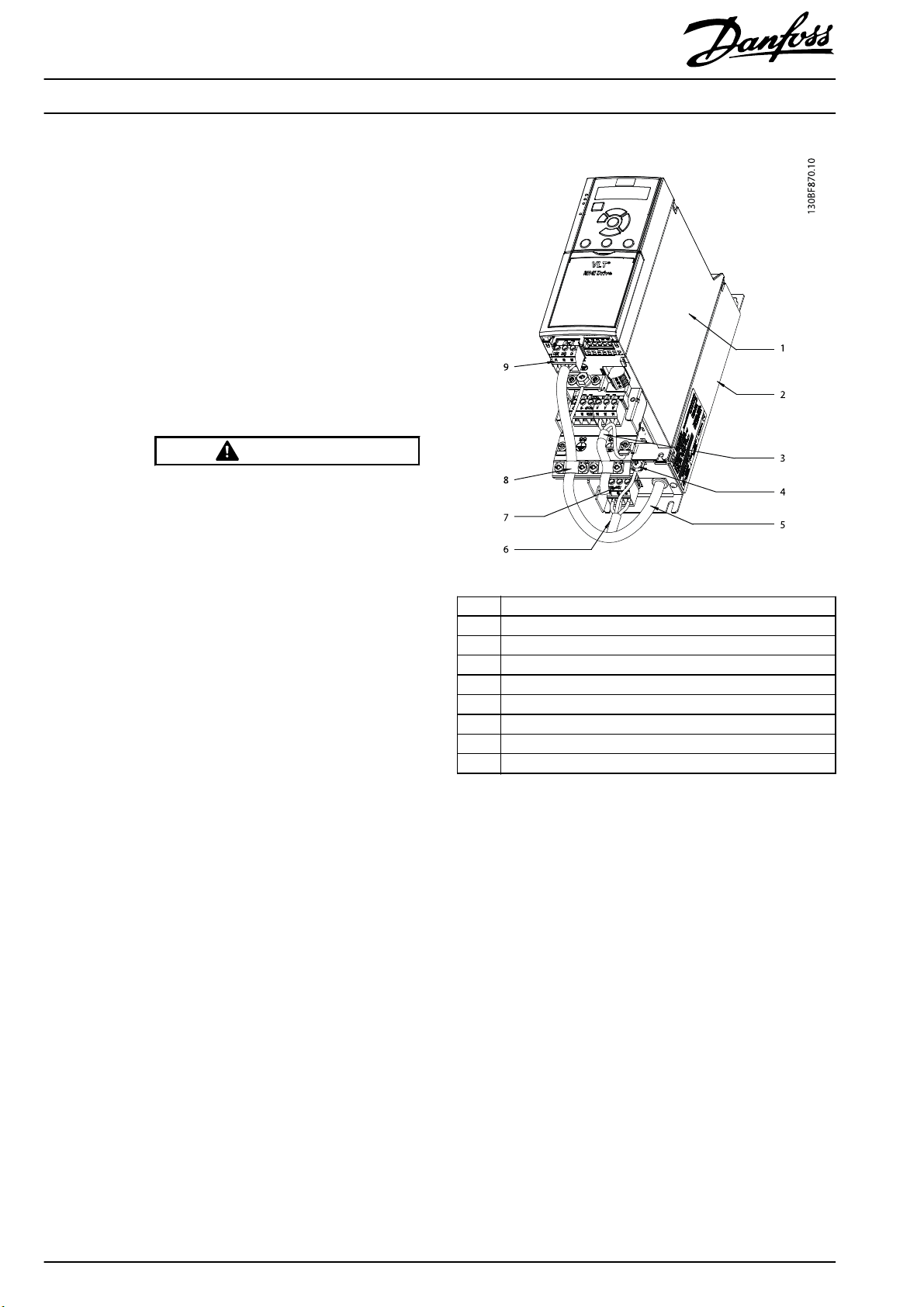

Electrical Installation

1. Connect the cables and fasten the screws as shown

in Illustration 1.5 and Illustration 1.6. Refer to Ta ble 1.5

for the tightening torque of EMC lter terminals.

1a Connect the EMC lter mains output cable

to the frequency converter mains input

terminal block (terminals N (91) and L (92)

for single-phase, or terminals L1 (91), L2

(92), and L3 (93) for 3-phase).

1b Connect the frequency converter mains

input terminal block to the frequency

converter mains input.

1c Secure the cable with the cable clamp.

WARNING

ELECTRICAL HAZARD

Touching the wires of the mains input

while they are not switched o can result

in death or serious injury.

Before continuing, use an

•

appropriate voltage measuring

device to make sure that the

mains input is switched

Ensure that the mains input

•

cannot be switched on by a third

party, while you are working.

1d Connect the wires of the EMC

input cable to the EMC lter mains input

terminal block (terminals N (91) and L (92)

for single-phase, or terminals L1 (91), L2

(92), and L3 (93) for 3-phase).

1e Connect the EMC lter mains input terminal

block to the EMC lter mains input.

1f Connect the ground wire of the EMC

mains input cable to the EMC

terminal.

lter

lter

o.

mains

lter

PE

1 Frequency converter

2EMC lter

3 Cable connecting the frequency converter with the motor

4 EMC lter PE terminal

5 EMC lter mains output cable

6 EMC lter mains input cable

7 EMC lter mains input terminal block

8 Cable clamp

9 Frequency converter mains input terminal block

Illustration 1.5 Cable Connections for Footprint Installation

4

Danfoss A/S © 05/2017, Rev. 02, All rights reserved. MI07L102

Page 5

Installation Instructions

®

VLT

Line Filter MCC 107 EMC Filter Series

®

Midi Drive FC 280 (K1–K3)

VLT

1 Frequency converter mains input terminal block

2 Cable connecting the frequency converter with the motor

3 Cable clamp

4 EMC lter mains output cable

5 EMC lter mains input cable

6 EMC lter mains input terminal block

7EMC lter PE terminal

8EMC lter

9Frequency converter

Illustration 1.6 Cable Connections for Side-by-side Installation

Mains input terminal 0.5–0.8 Nm (4.4–7.1 in-lb)

PE terminal 2.0–2.5 Nm (17.7–22.1 in-lb)

Table 1.5 Tightening Torque for EMC Filter Terminals

EMC lter

ordering number

466 467 463 464 465

134B5xxx

Frequency converter

enclosure size

2

Input [mm

Output [mm

(AWG)]

2

(AWG)]

K1S2 K2S2 K1T4 K2T4 K3T4

3x4 (12)

1.5

(16)

4 (12)

0.75

(18)

1.5 (16) 4 (12)

Cable length for L1‘/L2‘/L3‘(L1’/N’): 280±5

mm (11.0±0.2 in).

Cable length for PE terminal: 220±5 mm

(8.7±0.2 in).

Mains input terminal M3

PE terminal M4

Tab le 1.6

MI07L102 Danfoss A/S © 05/2017, Rev. 02, All rights reserved.

Specications

for EMC Filter Terminals

5

Page 6

Mechanical Data

EMC lter ordering number 134B5466 134B5467 134B5463 134B5464 134B5465

Frequency converter enclosure size K1S2 K2S2 K1T4 K2T4 K3T4

Dimensions A [mm (in)] 250 (9.8) 312.5 (12.3) 250 (9.8) 312.5 (12.3)

Dimensions a1 [mm (in)] 234 (9.2) 303 (11.9) 234 (9.2) 303 (11.9)

Dimensions a2 [mm (in)] 19.5 (0.77) 21.3 (0.84) 19.5 (0.77) 21.3 (0.84)

Dimensions am [mm (in)] 198 (7.8) 260 (10.2) 198 (7.8) 260 (10.2)

Dimensions B [mm (in)] 75 (2.95) 90 (3.54) 75 (2.95) 90 (3.54) 115 (4.53)

Dimensions b1 [mm (in)] 55 (2.17) 70 (2.76) 55 (2.17) 70 (2.76) 90 (3.54)

Dimensions bm [mm (in)] 60 (2.36) 70 (2.76) 60 (2.36) 70 (2.76) 90 (3.54)

Dimensions C [mm (in)] 50 (1.97)

Dimensions c1 [mm (in)] 22.7 (0.89)

Dimensions D1 [mm (in)] Ø5.3 (Ø0.21)

Dimensions Dm [mm (in)] M4 M5 M4 M5

Dimensions e1 [mm (in)] 6.5 (0.26) 5 (0.20) 6.5 (0.26) 5 (0.20)

Dimensions f1 [mm (in)] 10 (0.39) 12.5 (0.49)

Dimensions fm [mm (in)] 7.5 (0.30)

Mounting screws for EMC lter M5

Mounting screws for frequency converter M4 M5 M4 M5

Weight [kg (lb)] 1.10 (2.43)

Illustration 1.7 Mechanical Data

10 (0.39) 7.5 (0.30) 10 (0.39)

1.50 (3.31) 1.20 (2.65) 1.90 (4.19) 2.10 (4.63)

12.5 (0.49)

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this mate rial are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI07L102130R0801 05/2017, Rev. 02,

*MI07L102*

Loading...

Loading...