Fact Sheet

VLT® Common Mode Filters MCC 105

VLT® Common Mode Filters MCC

105 core kit reduce electromagnetic

interference and eliminate bearing

damage by electrical discharge.

VLT® Common Mode Filters MCC 105

(HF-CM) cores are special nanocrystalline magnetic cores which have superior fi ltering performance compared

to regular ferrite cores. They act like a

common-mode inductor (between

phases and ground).

Installed around the three motor

phases (U, V, W), they reduce high-frequency common-mode currents. As a

result, high-frequency electromagnetic

interference from the motor cable is reduced. However, the core kit should not

be used as the sole mitigation measure,

and even when the cores are used, the

EMC installation rules shall be followed.

Prevent motor

bearing currents

The most important function is to

reduce high-frequency currents

associated with electrical discharges in the motor currents.

These discharges contribute to

the premature wear-out and failure

of motor bearings. By reducing or even

eliminating discharges, the wear-out of

the bearings is reduced and the lifetime

extended. Thus, maintenance and

down-time costs are lowered.

Ideal for retro tting

Bearing current problems are most

often discovered after commissioning.

Therefore, the cores have an oval shape

which makes them ideal for retrofi tting

and for installation in restricted places.

Only 5 variants cover the entire VLT®

product range making it possible to

carry these valuable aids in a service

tool kit.

A exible solution

The cores can be combined with other

output fi lters, and especially in combination with dU/dt fi lters they off er a

low cost solution for protection of both

motor bearings and insulation.

Product range

Available for all power sizes

from 0.18 kW to 1.4 MW

5 core sizes cover the entire

VLT® power range

E ective

kit to reduce electromagnetic interference

Feature Benefit

– Eff ective reduction of electrical discharges

– High-performance nanocrystalline

magnetic material

– Oval shape

– Scalable solution: longer cables

handled by stacking more cores

– Only 5 core sizes cover the entire

VLT® power range

– Low investment

in the motor bearings

– Reduces bearing wear-out, maintenance

costs and down-time

– Reduces high-frequency electromagnetic

interference from the motor cable

– Easy to install in restricted places such as the

VLT® enclosure or the motor terminal box

– Easy logistics, fast delivery and

comprehensible product program

– Allows the addition to a service tool-kit

– Cost-eff ective alternative to, for example,

sine-wave fi lters if the only phenomena to

be mitigated is bearing wear-out through

electrical discharge

www.vlt-drives.danfoss.com

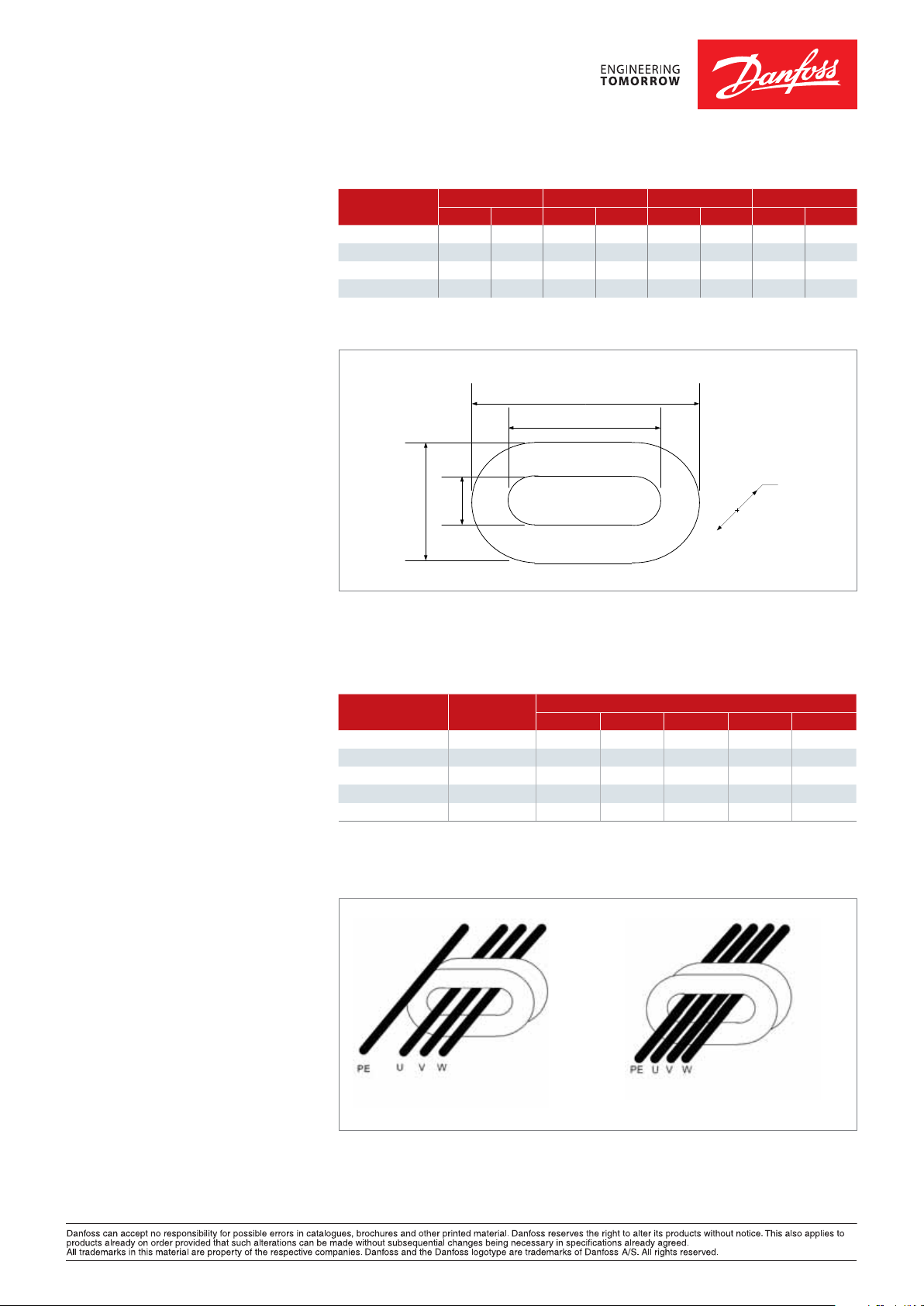

HF-CM selector

The cores can be installed at the

frequency converter’s output terminals

(U, V, W) or in the motor terminal box.

When installed at the frequency

converter’s terminals, the HF-CM kit

reduces bearing stress and high-frequency electromagnetic interference

from the motor cable. The number of

cores depends on motor cable length

and frequency converter voltage. A

selection table is shown to the right.

Cable length

Cable length

[m]

50 24222422

100 44244424

150 46444444

300* 46444644

* Longer cable lengths are easily handled by stacking more HF-CM cores.

A and B frame

T5 T7

C frame

T5 T7

D frame E and F frame

T5 T7 T5 T7

W

w

h

H

Ordering numbers and dimensions

Ordering numbers for the core kits (2 cores per package)

are given in the table below.

VLT® frame size Danfoss P/N

A and B 130B3257 60 43 40 25 22.3

C1 130B7679 82.8 57.5 45.5 20.6 33

C2, C3, C4 130B3258 102 69 61 28 37

D 130B3259 189 143 126 80 37

E and F 130B3260

WwH h d

305 249 147 95 37

Mechanical dimension [mm]

Installation

d

The HF-CM cores are easy to install:

Simply pass the three motor phase leads (U, V, W) through the cores.

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFP.651.A3.02 © Copyright Danfoss Power Electronics | Danfoss VLT Drives PE-MSMBM | November 2014

Loading...

Loading...