Page 1

Fact Sheet

VLT® dU/dt Filter MCC 102

Perfect

match for

for applications with

short motor cables,

older motors,

frequent braking,

or aggressive

environments

dU/dt filters reduce the dU/dt

values on the motor terminal

phase-to-phase voltage – an issue

that is important for short motor

cables.

dU/dt filters are differential-mode filters

which reduce motor terminal phase-tophase peak voltage spikes and reduce

the rise time to a level that lowers

the stress on the insulation of motor

windings.

Compared to sine-wave filters, the

dU/dt filters have a cut-off frequency

above the switching frequency. The

voltage at the motor terminals is still

PWM pulse shaped, but the rise time

and Upeak are reduced. They are

smaller, weigh less and have a lower

price compared to sine-wave filters.

Furthermore, because of the smaller

inductance and capacitance, the

dU/dt filters introduce a negligible

reactance between inverter and

motor and are therefore suitable for

high dynamic applications.

Superior compared to

output chokes

Output chokes cause undamped

oscillations at the motor terminals

which increase the risk of double

pulsing and over-voltages higher

than twice the DC link voltage.

The dU/dt filters are low-pass

L-C filters with a well defined

cut-off frequency. Therefore the ringing

oscillations at the motor terminals are

damped and there is a reduced risk of

double pulsing and voltage peaks.

Quality and Design

All dU/dt filters are designed and

tested for operation with the

VLT® AutomationDrive FC 302,

VLT® AQUA Drive FC 202, and the

VLT® HVAC Drive FC 102. They are

designed to match the look and quality

of the VLT® FC series drives.

Advantages

n

Compatible with all control

principles, including flux and WC+

n

Parallel filter installation is possible for

applications in the high power range

Range

3 x 200 – 690 V (up to 880 A)

Enclosures

n

IP00 and IP20/23 enclosure in the

entire power range

n

IP54 enclosure available up to 180 A

Mounting

n

Side-by-side book-style mounting

alongside the drive, for wall-mounted

filters only.

n

Footprint mounting behind the drive,

for limited size range only

n

Wall mounting up to and including

filter rating 590 A (380 V)

n

Floor mounting above filter rating

303 A (380 V)

Feature Benefit

Reduces dU/dt stresses Increases motor service interval

Lowers the magnetic interference

propagation on surrounding cables

and equipment)

Low voltage drop makes dU/dt filters

the ideal solution for highly dynamic

applications with flux vector regulation

Trouble-free operation

Small size and cost compared to sine-wave filters

www.vlt-drives.danfoss.com

Page 2

Accessories

n

NEMA 1/IP21 upgrade kit for wall-

mounted IP20 filters.

n

L-shaped terminal kits for filters

with bus-bar connection

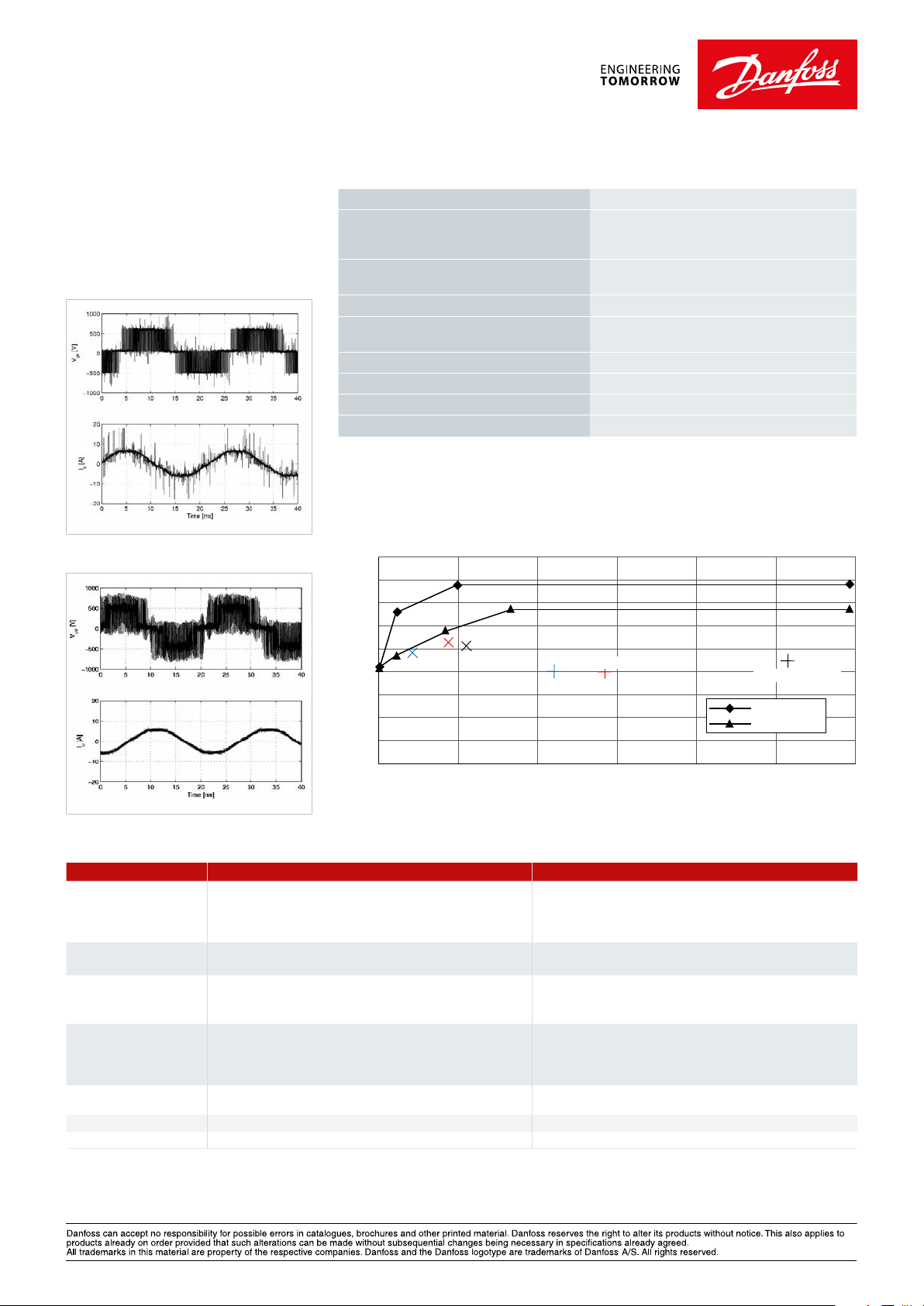

Voltage and current without filter

Specifications

Voltage rating 3 x 200 – 690 V

17 – 880 A @ 200 – 380 V, 15 – 780 A @ 460 V

Nominal current I

@ 50 Hz

N

12 – 630 A @ 600 V and 11 – 630 A @ 690 V

for higher power modules can be paralleled

Motor frequency

0 – 60 Hz without derating

Max. 100 Hz (with derating)

Ambient temperature -25° to 45°C without derating

sw

1,5 kHz – 4 kHz

Max. switching frequency

f

depending on filter type

Mounting Side-by-side

Overload capacity 160% for 60 sec every 10 min.

Enclosure degree IP00, IP20/23 and IP54

Approvals CE, UL508

dU/dt limit curves

1.8

1.6

1.4

1.2

1.0

15 m

0.8

Upeak [V]

0.6

0.4

0.2

50 m

150 m

50 m dU/dt lter

15 m dU/dt lter

150 m dU/dt lter

IEC60034-25 A

IEC60034-17

0

0.50 1.51 2.0 32.5

tr [us]

The dU/dt value decreases with the motor cable length whereas the peak voltage increases.

Voltage and current with filter

The curves show typical values.

Performance Criteria dU/dt lter Sine-wave lter

Motor insulation

stress

Motor bearing

stress

EMC performance

Max. motor

cable length

Acoustic motor

switching noise

Up to 100 m cable (shielded/unshielded) complies with

the requirements of IEC60034-17* (general purpose motors).

Above this cable length the risk of “double pulsing” increases.

Slightly reduced, mainly in high power motors

Eliminates motor cable ringing. Does not change the emission

class. Does not allow longer motor cables as specified for the

frequency converter’s built-in RFI filter.

100 m ... 150 m

With guaranteed EMC performance: 150 m screened

Without guaranteed EMC performance: 150 m unscreened

Does not eliminate acoustic switching noise from the motor

Provides a sinusoidal phase-to-phase motor terminal voltage.

Complies with IEC-60034-17* and NEMA-MG1 requirements for

general purpose motors with cables up to 500 m (1 km for

frame size D and above).

Reduces bearing currents caused by circulating currents.

Does not reduce common-mode currents (shaft currents).

Eliminates motor cable ringing. Does not change the emission

class. Does not allow longer motor cables as specified for the

frequency converter’s built-in RFI filter.

With guaranteed EMC performance: 150 m shielded and

300 m unshielded (only conducted emissions).

Without guaranteed EMC performance: up to 500 m

(1 km for frame size D and above).

Eliminates acoustic switching noise from the motor caused by

magnetostriction

Relative size 15 – 50% (depending on power size) 100%

Relative price 50% 100%

* Not 690 V

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFO.615.A2.02 © Copyright Danfoss Power Electronics | Danfoss VLT Drives PE-MSMBM | 2015.06

Loading...

Loading...